Page 1

Frequency Inverter

Convertidor de Frecuencia

Convertitore di Frequenza

Frequenzumrichter

Variateur de Vitesse

EWCFW-08

User's Manual

Manual del Usuario

Manuale dell´utente

Bedienungsanleitung

Manuel d'utilisation

Page 2

Page 3

ATTENTION!

Itisveryimportanttocheckif the inverter softwareversion is the sameas

indicatedabove.

¡

ATENCIÓN!

Es muy importante conferir si la versión de softwaredel Convertidor es igual a la

indicada arriba.

ATTENZIONE!

E 'molto importante verificare se la versione software del drive è quella sopra

indicato.

ACHTUNG!!

Bitteüberprüfen Sie,ob die SoftwareversiondesUmrichtersmit der Versionder

Betriebsan-leitungübereinstimmt.

ATTENTION!

Ilesttrès important de vérifier sila version logicielle du variateur est lamême

qu’indiquéeprécédemment.

Series:CFW-08

10000900189/02

E-S-I-G-F

FREQUENCY INVERTER MANUAL

MANUAL DEL CONVERTIDOR

DE FRECUENCIA

MANUALE DEL CONVERTITORE DI

FREQUENZA

BENIENUNGSANLEITUNG

FREQUENZUMRICHTERCFW-08

VARIATEUR DE VITESSE MANUEL

FREQUENCY INVERTER MANUAL

MANUAL DEL CONVERTIDOR

DE FRECUENCIA

MANUALE DEL CONVERTITORE DI

FREQUENZA

BENIENUNGSANLEITUNG

FREQUENZUMRICHTER CFW-08

VARIATEUR DE VITESSE MANUEL

Page 4

4

CONTENTS / ÍNDICE / SOMMARIO / INHALTSVERZEICHNIS / RÉSUMÉ

ENGLISH .......................................................................................................

Quick Parameter Reference, Fault and Status Messages

CHAPTER 1 - Safety Notices

CHAPTER 2 - General Information

CHAPTER 3 - Installation and Connection

CHAPTER 4 - Keypad (HMI) Operation

CHAPTER 5 - Start-up

CHAPTER 6 - Diagnostics and Troubleshooting

CHAPTER 7 - TechnicalSpecifications

ESPAÑOL ......................................................................................................

CAPÍTULO 1 -Instrucciones de Seguridad

CAPÍTULO 2 - Informaciones Generales

CAPÍTULO 3 - Instalación y Conexión

CAPÍTULO 4 - Uso de la HMI

CAPÍTULO 5 - Energización/Puesta en Marcha

CAPÍTULO 6 - Solución y Prevención de Fallas

ITALIANO ......................................................................................................

Parametridi Riferimento, Messaggi D’allarme e Stati

CAPITOLO 1 - Istruzioni per la Sicurezza

CAPITOLO 2 - Informazioni Generali

CAPITOLO 3 - Installazione

CAPITOLO 4 - Start

CAPITOLO 5 - Interfaccia HMI

CAPITOLO 6 - Diagnostica e guasti

CAPITOLO7-Specifichetecniche

GERMANY.....................................................................................................

KAPITEL 1 - Sicherheitshinweise

KAPITEL 2 - Allgemeine Informationen

KAPITEL 3 - Installation

KAPITEL 4 - Funktionen der Bedieneinheit (HMI)

KAPITEL 5 - Inbetriebnahme

FRANÇAIS.....................................................................................................

CHAPITRE 1 - Instructions de sécurité

CHAPITRE 2 - Informations generales

CHAPITRE 3 - Installation

CHAPITRE 4 - Demarrage

CHAPITRE 5 - Fonctionnement de l'interface HMI

Page 5

FREQUENCY INVERTER MANUAL

Quick Parameter Reference, Fault and Status Messages

CHAPTER 1

Safety Notices

1.1SafetyNoticesintheManual................................................. 16

1.2SafetyNoticesonThe Product.............................................. 16

1.3PreliminaryRecommendations............................................. 16

CHAPTER 2

General Information

2.1About this Manual .................................................................. 18

2.2Software Version................................................................... 18

2.3AbouttheCFW-08 ................................................................ 19

2.4CFW-08 Identification ........................................................... 23

2.5ReceivingandStoring ........................................................... 26

CHAPTER 3

Installation and Connection

3.1MechanicalInstallation .......................................................... 27

3.2Electrical Installation.............................................................. 32

3.3 European EMCDirective - Requirements

forConformingInstallations.................................................. 50

CHAPTER 4

Keypad (HMI) Operation

4.1Keypad(HMI)Description..................................................... 66

4.2Use of theKeypadHMI ......................................................... 67

CHAPTER 5

Start-up

5.1 Pre-Power Checks................................................................ 73

5.2Initial Power-up...................................................................... 73

5.3Start-up... ............................................................................. 74

CHAPTER 6

Diagnosticsand Troubleshooting

6.1Faults and Possible Causes ................................................. 76

6.2Troubleshooting..................................................................... 79

CHAPTER 7

TechnicalSpecifications

7.1 Power Data ........................................................................... 81

7.2Electronics/GeneralData ...................................................... 85

English

Page 6

Page 7

7

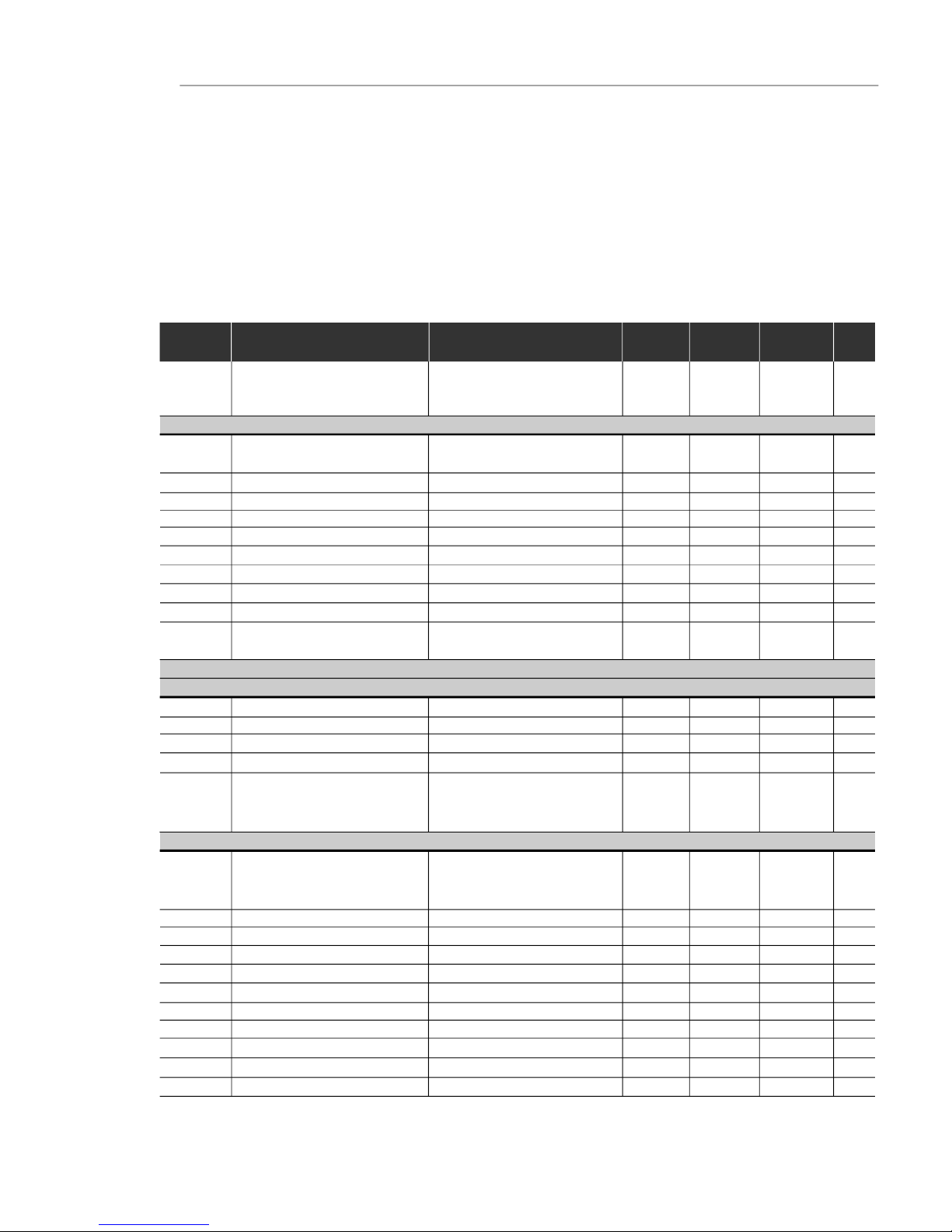

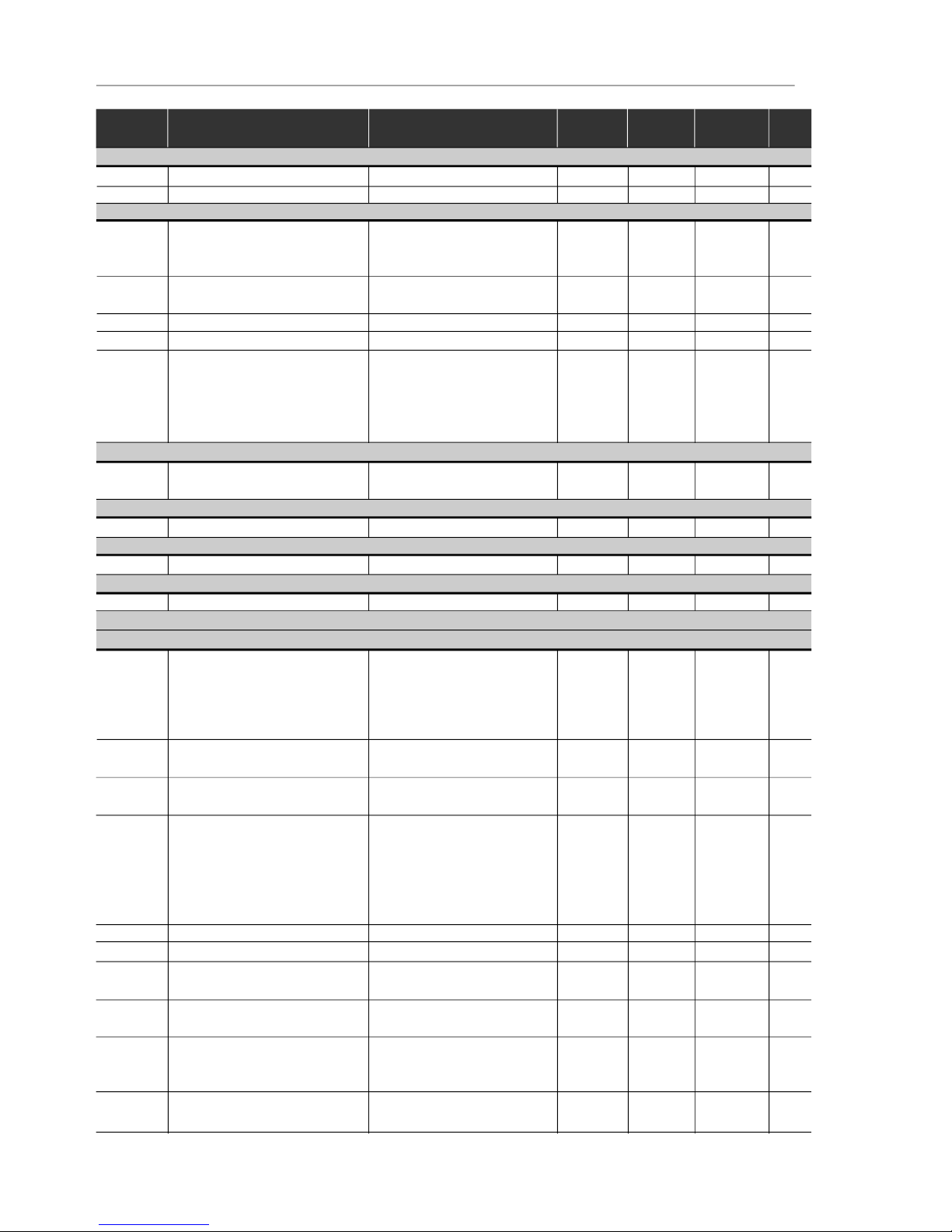

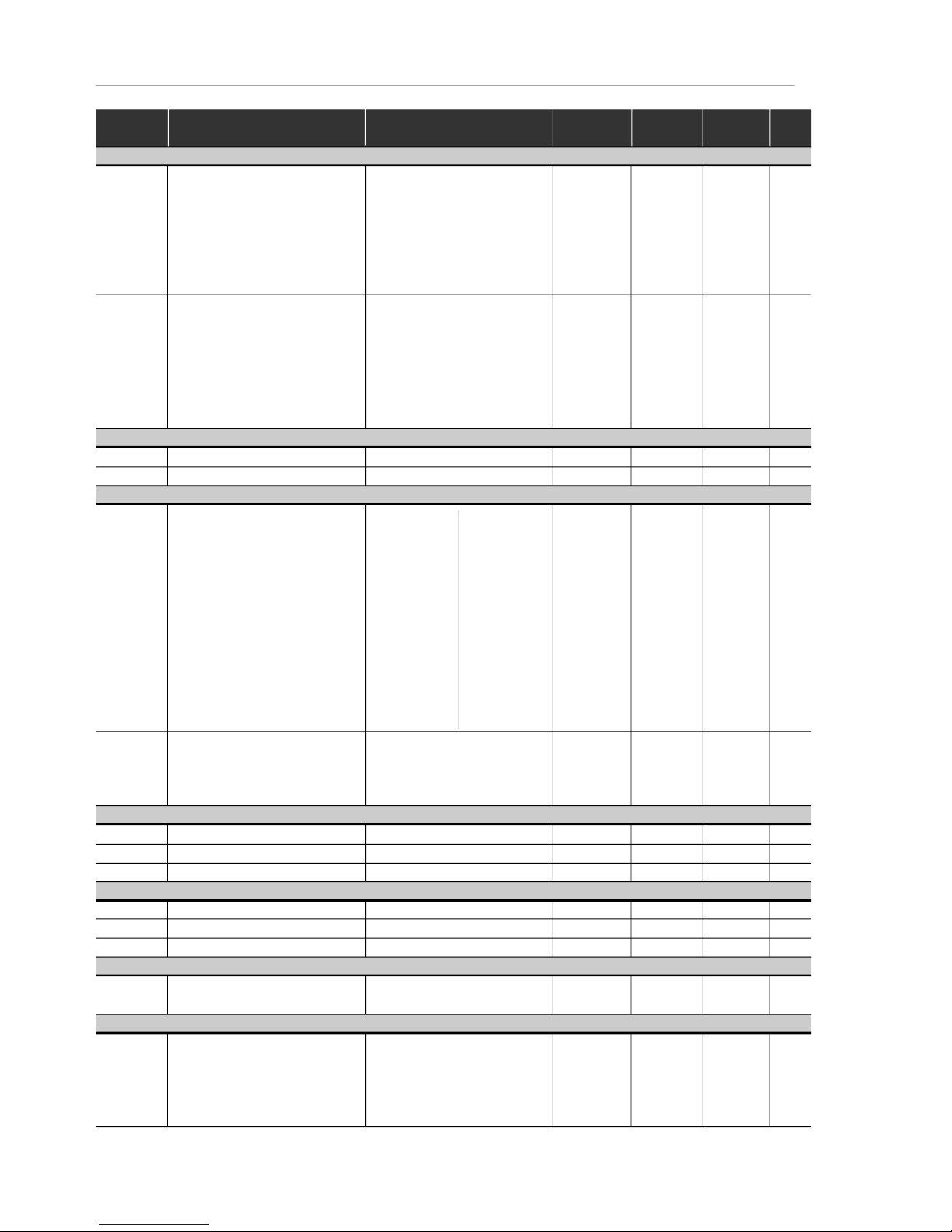

CFW-08 - QUICK PARAMETER REFERENCE

Software: V5.2X

Application:

Model:

SerialNumber:

Responsible:

Date: / / .

I.Parameters

QUICK PARAMETER REFERENCE, FAULT AND STATUS MESSAGES

Parameter Function Adjustable Range

Factory

Unit

User

Page

Setting Setting

P000 ParameterAccess 0 to 4 = Read 0 -

5 = Alteration

6 to 999 = Read

READONLY PARAMETERS-P002 to P099

P002 FrequencyProportionalValue 0 to 6553 - -

(P208xP005)

P003 MotorOutput Current 0to 1.5xI

nom

- A

P004 DCLink Voltage 0 to 862 - V

P005 Motor Output Frequency 0.00 to 300.0 - Hz

P007 MotorOutputVoltage 0 to 600 - V

P008 HeatsinkTemperature 25 to 110 - °C

P009

(1)

MotorTorque 0.0 to 150.0 - %

P014 Last Fault 00 to 41 - -

P023 SoftwareVersion x . y z - -

P040 PID ProcessVariable 0 to 6553 - -

(Value % x P528)

REGULATION PARAMETERS-P100 to P199

Ramps

P100 AccelerationTime 0.1 to 999 5.0 s

P101 DecelerationTime 0.1 to 999 10.0 s

P102 Ramp 2AccelerationTime 0.1 to 999 5.0 s

P103 Ramp2DecelerationTime 0.1 to 999 10.0 s

P104 S Ramp 0= Inactive 0 -

1 = 50 %

2 = 100 %

Frequency Reference

P120 DigitalReferenceBackup 0= Inactive 1 -

1 = Active

2 = Backup by P121

P121 KeypadReference P133 to P134 3.00 Hz

P122 JOGSpeedReference 0.00 to P134 5.00 Hz

P124 MultispeedReference1 P133 to P134 3.00 Hz

P125 MultispeedReference2 P133 to P134 10.00 Hz

P126 MultispeedReference3 P133 to P134 20.00 Hz

P127 MultispeedReference4 P133 to P134 30.00 Hz

P128 MultispeedReference5 P133 to P134 40.00 Hz

P129 MultispeedReference6 P133 to P134 50.00 Hz

P130 MultispeedReference7 P133 to P134 60.00 Hz

P131 MultispeedReference8 P133 to P134 66.00 Hz

Page 8

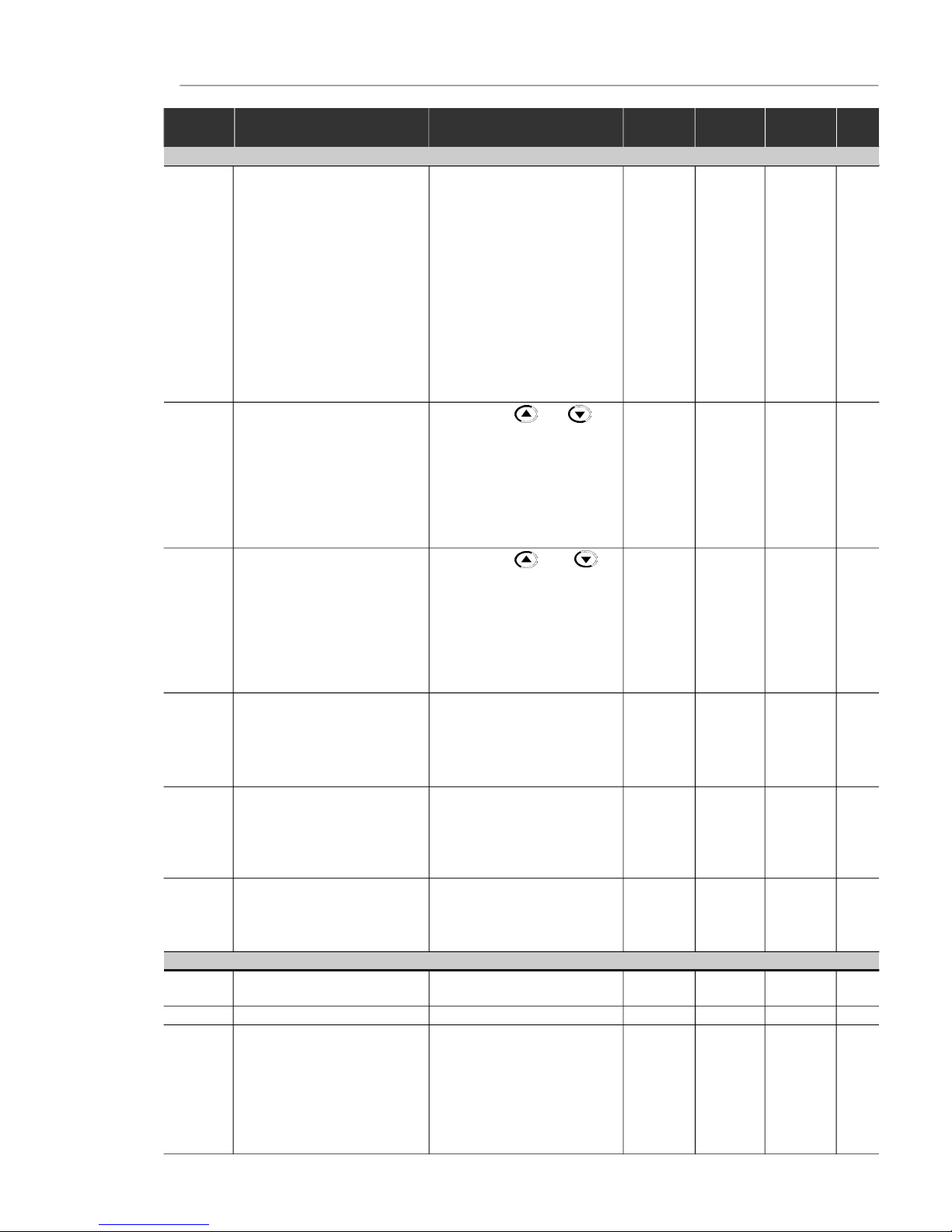

8

CFW-08 - QUICK PARAMETER REFERENCE

Parameter Function

Adjustable Range

Factory

Unit

User

Page

Setting Setting

(*) The factory default of parameter P136 depends on the inverter model as follows:

- models 1.6-2.6-4.0-7.0 A/200-240 V and 1.0-1.6-2.6-4.0 A/380-480 V: P136 = 5.0 %;

- models 7.3-10-16 A/200-240 V and 2.7-4.3-6.5-10 A/380-480 V: P136 = 2.0 %;

- models 22-28-33 A/200-240 V and 13-16-24-30 A/380-480 V: P136 = 1.0 %.

Speed Limits

P133 Minimum Frequency (F

min

) 0.00 to P134 3.00 Hz

P134 MaximumFrequency(F

max

) P133 to 300.0 66.00 Hz

V/F Control

P136

(2) (*)

ManualTorqueBoost 0.0 to 30.0 5.0 or %

(IxRCompensation) 2.0 or

1.0

(*)

P137

(2)

AutomaticTorqueBoost 0.00 to 1.00 0.00 (AutomaticIxRCompensation)

P138

(2)

SlipCompensation 0.0 to 10.0 0.0 %

P142

(2) (3)

Maximum Output Voltage 0 to 100 100 %

P145

(2) (3)

FieldWeakening P133 to P134 50.00Hzor Hz

Frequency(F

nom

) 60.00 Hz

depending

on the

market

DC Link Voltage Regulation

P151 DCLink VoltageRegulation 200 V models: 325 to 410 380 V

Level 400 V models: 564 to 820 780

Overload Current

P156 MotorOverloadCurrent 0.2xI

nom

to 1.3xI

nom

1.2xP401 A

Current Limitation

P169 MaximumOutput Current 0.2xI

nom

to 2.0xI

nom

1.5xP295 A

Flux Control

P178

(1)

Rated Flux 50.0 to 150 100 %

CONFIGURATION PARAMETERS - P200 to P398

Generic Parameters

P202

(3)

ControlMode 0 = Linear V/F Control 0 -

(Scalar)

1 = Quadratic V/F Control

(Scalar)

2 = SensorlessVectorControl

P203

(3)

SpecialFunction Selection 0 = No function 0 -

1 = PID Regulator

P204

(3)

Load Factory Setting 0 to 4 = No Function 0 -

5 = Loads Factory Default

P205 DisplayDefault Selection 0 = P005 2 -

1 = P003

2 = P002

3 = P007

4, 5 = Not Used

6 = P040

P206 Auto-ResetTime 0 to 255 0 s

P208 ReferenceScaleFactor 0.00 to 99.9 1.00 -

P212 Frequencyto Enable the Sleep 0.00 to P134 0.00 Hz

Mode

P213 Time Delayto Activate the 0.1 to 999 2.0 s

SleepMode

P215

(3) (4)

Keypad Copy Function 0 = Not Used 0 -

1 = Copy (inverter keypad)

2= Paste(keypad inverter)

P219

(3)

SwitchingFrequency 0.00 to 25.00 6.00 Hz

ReductionPoint

Page 9

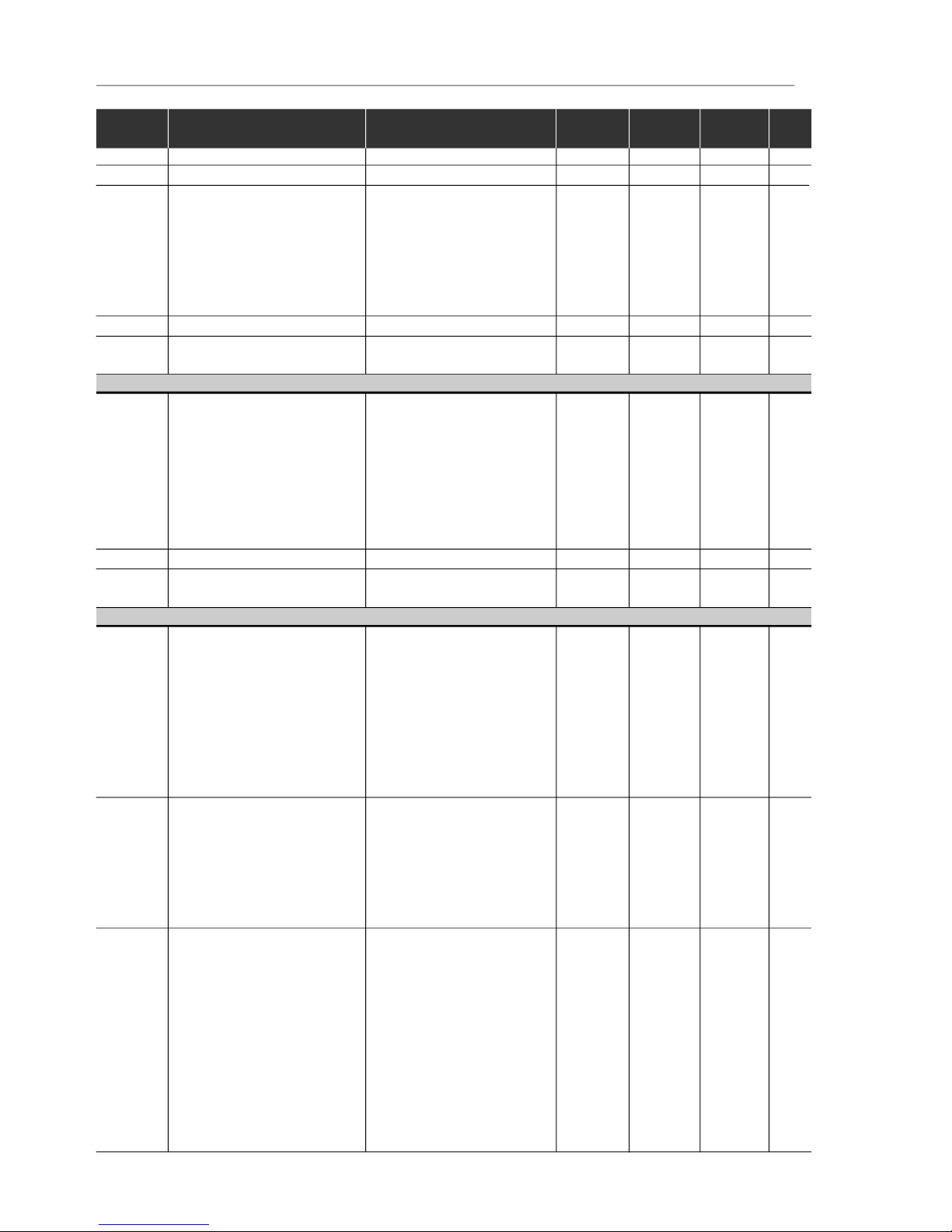

9

CFW-08 - QUICK PARAMETER REFERENCE

Parameter Function

Adjustable Range

Factory

Unit

User

Page

Setting Setting

(**) Only available on the control board A2 (refer to item 2.4). For programming instructions, please, refer to the parameter P235 detailed

description.

Local/Remote Definition

P220

(3)

Local/Remote 0 = Always Local 2 Selection Source 1 = Always Remote

2 = HMI-CFW08-P or

HMI-CFW08-RPKeypad

(default:local)

3 = HMI-CFW08-P or

HMI-CFW08-RPKeypad

(default:remote)

4 = DI2 to DI4

5= SerialorHMI-CFW08-RS

Keypad(default: local)

6= SerialorHMI-CFW08-RS

Keypad(default: remote)

P221

(3)

FrequencyLocalReference 0 = Keypad and 0 Selection 1 = AI1

2, 3 = AI2

4 = E.P.

5 = Serial

6 = Multispeed

7 = AddAI0

8 = Add AI

P222

(3)

FrequencyRemoteReference 0 = Keypad and 1 Selection 1 = AI1

2, 3 = AI2

4 = E.P.

5 = Serial

6 = Multispeed

7 = AddAI0

8 = Add AI

P229

(3)

LocalCommand Selection 0=HMI-CFW08-P or 0 -

HMI-CFW08-RPKeypad

1 = Terminals

2 = Serial or

HMI-CFW08-RSKeypad

P230

(3)

RemoteCommand Selection 0= HMI-CFW08-P or 1 -

HMI-CFW08-RPKeypad

1 = Terminals

2 = Serial or

HMI-CFW08-RSKeypad

P231

(3)

Forward/ReverseSelection 0 = Forward 2 -

- Local and Remote 1= Reverse

2 = Commands

3 = DIx

Analog Input (s)

P233 AnalogInputDeadZone 0= Inactive 1 -

1 = Active

P234 Analog InputAI1 Gain 0.00 to 9.99 1.00 -

P235

(3) (5)

Analog InputAI1 Function 0 = (0 to 10) V/(0 to 20) mA / 0 -

(-10 to +10) V

(**)

1 = (4 to 20) mA

2 = DI5 PNP

3 = DI5 NPN

4= DI5TTL

5 = PTC

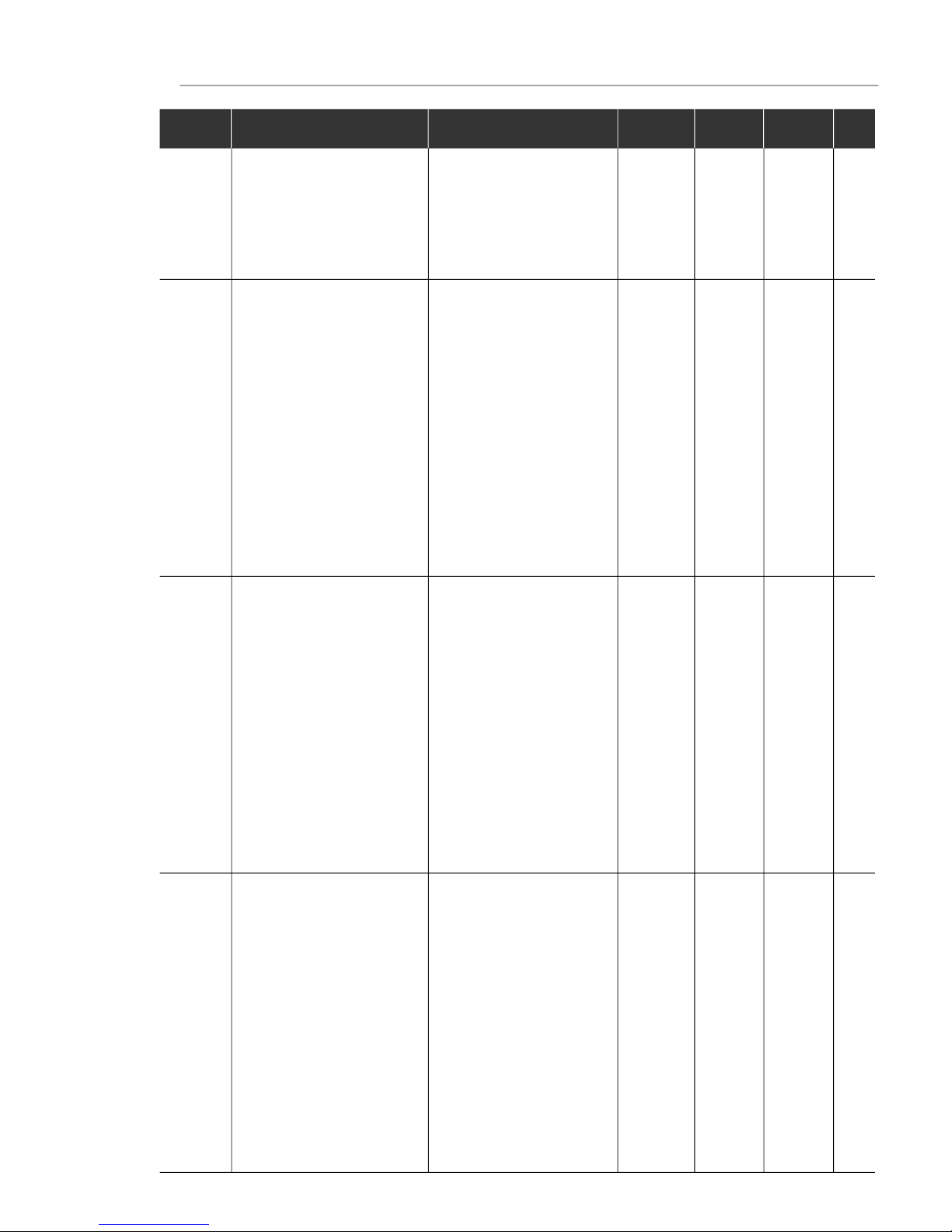

Page 10

10

CFW-08 - QUICK PARAMETER REFERENCE

Parameter Function

Adjustable Range

Factory

Unit

User

Page

Setting Setting

P236 Analog InputAI1 Offset -999 to +999 0.0 %

P238

(6)

AnalogInputAI2Gain 0.00 to 9.99 1.00 -

P239

(3)(5)(6)

Analog InputAI2 Function 0 = (0 to 10) V/(0 to 20) mA/ 0 -

(-10 to +10) V

(**)

1 = (4 to 20) mA

2 = DI6 PNP

3 = DI6 NPN

4= DI6TTL

5 = PTC

P240

(6)

AnalogInputAI2Offset -999 to +999 0.0 %

P248 Analog Inputs Filter 0 to 200 10 ms

TimeConstant

Analog Output

P251

(6)

AnalogOutput 0 = Output Frequency (Fs) 0 AO Function 1 = Input Reference(Fe)

2 = Output Current (Is)

3, 5, 8 = Not Used

4 = Motor Torque

6 = Process Variable (PID)

7 = Active Current

9 = PID Setpoint

P252

(6)

Analog Output AO Gain 0.00 to 9.99 1.00 -

P253 Analog Output AO Signal 0 = (0 to 10) V/(0 to 20) mA 0 -

1 = (4 to 20) mA

Digital Inputs

P263

(3)

Digital Input DI1 Function 0 = No Function or General 0 -

Enable

1 to 7 and 10 to 12 =

GeneralEnable

8 = Forward Run

9 = Start/Stop

13 = FWD Run Using

Ramp2

14 = On

P264

(3)

Digital Input DI2 Function 0 =Forward/Reverse 0 -

1 = Local/Remote

2 to 6 and 9 to 12 = Not Used

7 = Multispeed (MS2)

8= Reverse

13 = REV Run - Ramp 2

14 = Off

P265

(3) (7)

Digital Input DI3 Function 0 = Forward/Reverse 10 -

1 = Local/Remote

2 = GeneralEnable

3 = JOG

4 = No External Fault

5 = Increase E.P.

6 = Ramp 2

7 = Multispeed (MS1)

8 = No Function or

Start/Stop

9 = Start/Stop

10 = Reset

(**) Only available on the control board A2 (refer to item 2.4). For programming instructions, please, refer to the parameter P235 detailed

description.

Page 11

11

CFW-08 - QUICK PARAMETER REFERENCE

Parameter Function

Adjustable Range

Factory

Unit

User

Page

Setting Setting

11, 12 = Not Used

13 = Flying Start Disable

14 = Multispeed (MS1)

UsingRamp 2

15 = Manual/Automatic (PID)

16 = Increase E.P. with

Ramp2

P266

(3)

Digital Input DI4 Function 0 = Forward/Reverse 8 -

1 = Local/Remote

2 = GeneralEnable

3 = JOG

4 = No External Fault

5 = Decrease E.P.

6 = Ramp 2

7 = Multispeed (MS0)

8 = Not Used or

Start/Stop

9 = Start/Stop

10 = Reset

11, 12,14 and 15 = Not Used

13 = Flying Start Disable

16 = Decrease E.P.with

Ramp2

P267

(3) (5)

Function of the Digital 0 = FWD/REV 11 InputDI5 (only displayed 1 = Local/Remote

when P235 = 2, 3 or 4) 2 = General Enable

3 = JOG

4 = No External Fault

5 = Increase E.P.

6 = Ramp 2

7 = Multispeed (MS2)

8 = No Functionor Start/Stop

9 = Start/Stop

10 = Reset

11 and 12 = Not Used

13 = Disables Flying Start

14 and 15 = Not Used

16 = Increase E.P. with

Ramp2

P268

(3) (5) (6)

Function of the Digital 0 = FWD/REV 11 InputDI6 (only displayed 1 = Local/Remote

when P239 = 2, 3 or 4) 2 = General Enable

3 = JOG

4 = No External Fault

5 = Decrease E.P.

6 = Ramp 2

7 = Not Used

8 = No Function or Start/Stop

9 = Start/Stop

10 = Reset

11 and 12 = Not Used

13 = Disables Flying Start

14 and 15 = Not Used

16 = Decrease E.P.with

Ramp2

Page 12

12

CFW-08 - QUICK PARAMETER REFERENCE

Parameter Function

Adjustable Range

Factory

Unit

User

Page

Setting Setting

(*) It is not possible to set P297 = 7 (15 kHz) in vector control mode (P202 = 2) or when the external serial keypad (HMI-CFW08-RS) is used.

According

to the

inverter

model

DigitalOutput(s)

P277

(3)

RelayOutput RL1 Function 0 = Fs > Fx 7 -

1 = Fe > Fx

2 = Fs = Fe

3 = Is>Ix

4 and 6 = Not Used

5 = Run

7 = No Fault

P279

(3) (6)

RelayOutput RL2 Function 0 = Fs > Fx 0 -

1 = Fe > Fx

2 = Fs = Fe

3 = Is > Ix

4 and 6 = Not Used

5 = Run

7 = No Fault

Fx and Ix

P288 Fx Frequency 0.00to P134 3.00 Hz

P290 IxCurrent 0to 1.5xI

nom

1.0xI

nom

A

Inverter Data

P295

(3)

RatedInverter 300 = 1.0 A Current(I

nom

) 301 = 1.6 A

302 = 2.6 A

303 = 2.7 A

304 = 4.0 A

305 = 4.3 A

306 = 6.5 A

307 = 7.0 A

308 = 7.3 A

309 = 10A

310 = 13A

311 = 16 A

P297

(3)

SwitchingFrequency 4 = 5.0 4 kHz

5 = 2.5

6 = 10

7 = 15

(*)

DC Braking

P300 DC BrakingTime 0.0 to 15.0 0.0 s

P301 DC Braking Start Frequency 0.00 to 15.00 1.00 Hz

P302 DC BrakingCurrent 0.0 to 130 0.0 %

Skip Frequencies

P303 Skip Frequency1 P133 to P134 20.00 Hz

P304 Skip Frequency2 P133 to P134 30.00 Hz

P306 Skip Band Range 0.00 to 25.00 0.00 Hz

Serial Communication Interface I

P308

(3)

InverterAddress 1 to 30 (Serial WBus) 1 -

1to 247 (Modbus-RTU)

Flying Start and Ride-Through

P310

(3)

FlyingStartandRide-Through 0= Inactive 0 -

1 = Flying Start

2 = Flying Start and

Ride-Through

3= Ride-Through

312 = 22A

313 = 24A

314 = 28A

315 = 30A

316 = 33A

Page 13

13

CFW-08 - QUICK PARAMETER REFERENCE

Parameter Function

Adjustable Range

Factory

Unit

User

Page

Setting Setting

P311 VoltageRamp 0.1 to 10.0 5.0 s

Serial Communication Interface II

P312

(3)

SerialInterfaceProtocol 0 = Serial Wbus 0 -

1 = Modbus-RTU 9600 bps

without parity

2 = Modbus-RTU 9600 bps

with odd parity

3 = Modbus-RTU 9600 bps

witheven parity

4 = Modbus-RTU 19200 bps

without parity

5 = Modbus-RTU 19200 bps

with odd parity

6 = Modbus-RTU 19200 bps

witheven parity

7 = Modbus-RTU 38400 bps

without parity

8 = Modbus-RTU 38400 bps

with odd parity

9 = Modbus-RTU 38400 bps

witheven parity

P313 SerialInterfaceWatchdog 0 = Disabling by ramp 2 -

Action 1= General disable

2 = Shows only E28

3 = Goes to local mode

P314 SerialInterfaceWatchdog 0.0 = Disables the function 0.0 s

Timeout 0.1to 99.9 = Setvalue

MOTORPARAMETERS- P399 toP499

Rated Parameters

P399

(1) (3)

Rated MotorEfficiency 50.0 to 99.9 %

P400

(1) (3)

RatedMotor Voltage 0 to 600 V

P401 RatedMotorCurrent 0.3xP295 to 1.3xP295 A

P402

(1)

RatedMotorSpeed 0 to 9999 rpm

P403

(1) (3)

Rated Motor Frequency 0.00 to P134 Hz

P404

(1) (3)

RatedMotorPower 0 = 0.16 HP / 0.12 kW -

1 = 0.25 HP / 0.18 kW

2 = 0.33 HP / 0.25 kW

3 = 0.50 HP / 0.37 kW

4 = 0.75 HP / 0.55 kW

5 = 1 HP / 0.75 kW

6 = 1.5 HP / 1.1 kW

7 = 2 HP / 1.5 kW

8 = 3 HP / 2.2 kW

9 = 4 HP / 3.0 kW

10 = 5 HP / 3.7 kW

11 = 5.5 HP / 4.0 kW

12 = 6 HP / 4.5 kW

13 = 7.5 HP / 5.5 kW

14 = 10 HP / 7.5 kW

15 = 12.5 HP / 9.2 kW

16 = 15 HP / 11.2 kW

17 = 20 HP / 15.0 kW

According

to the

inverter

model

(motor

matched

to the

inverter)

Page 14

14

CFW-08 - QUICK PARAMETER REFERENCE

According to

theinverter

model

According to

theinverter

Parameter Function

Adjustable Range

Factory

Unit

User

Page

Setting Setting

Notesfound on the Quick ParameterReference:

(1) This parameter is onlydisplayedin vector mode (P202 = 2).

(2) This parameter is only displayedin scalar mode P202 = 0 or 1.

(3) This parameter can bechangedonlywhen the inverter is disabled (stoppedmotor).

(4) This parameterisonlyavailablewithHMI-CFW08-RS.

(5) Theanaloginputvalueis representedbyzerowhenitisnotconnectedtoan externalsignal.

In order to use an analog input as a digital input with NPN logic (P235 or P239 = 3), it is

necessary to connect a 10 k resistor from terminal 7 to 6 (AI1) or 8 (AI2) of the control

terminalstrip.

(6) This parameteris onlyavailableinthe CFW-08Plus version.

(7) The parametervalue changes automaticallywhenP203 = 1.

P407

(3)

RatedMotorPower 0.50 to 0.99 Factor

Measured Parameters

P408

(1) (3)

RunSelf-Tuning 0 = No 0 -

1 = Yes

P409

(3)

Motor Stator Resistance 0.00 to 99.99

model

SPECIAL FUNCTION - P500 to P599

PID Regulator

P520 PIDProportionalGain 0.000 to 7.999 1.000 -

P521 PIDIntegralGain 0.000 to 9.999 1.000 -

P522 PIDDifferentialGain 0.000 to 9.999 0.000 -

P525 Setpoint (Via Keypad) of the 0.00 to 100.0 0.00 %

PIDRegulator

P526 Process Variable Filter 0.01 to 10.00 0.10 s

P527 PIDAction 0 = Direct 0 -

1= Reverse

P528 Process Variable 0.00 to 99.9 1.00 -

Scale Factor

P535 Wake up Band 0.00 to 100.00 1.00 %

P536 Automatic Setting of P525 0= Active 0 -

1= Inactive

Page 15

15

CFW-08 - QUICK PARAMETER REFERENCE

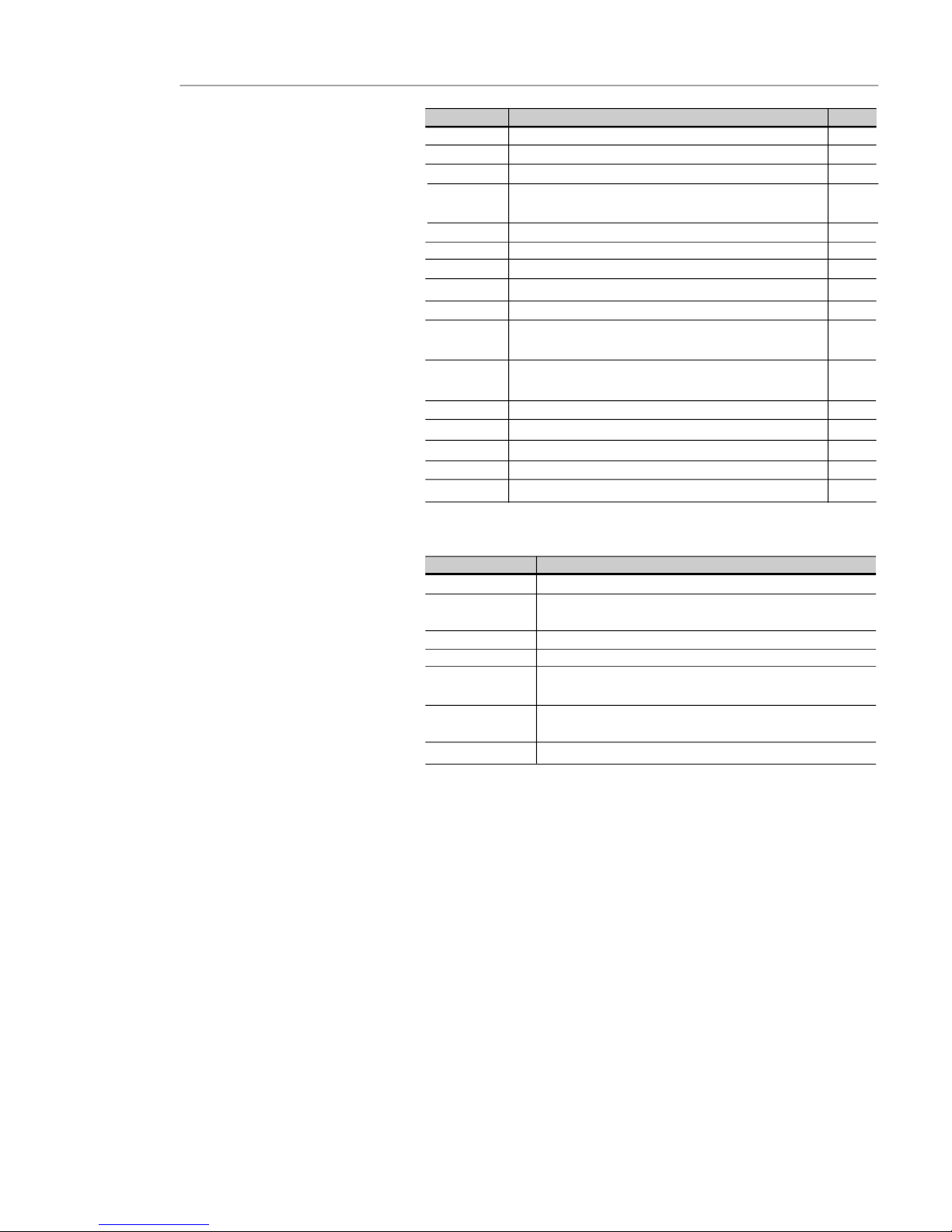

Display Description Page

E00 Outputovercurrent/short-circuit/outputgroundfault

E01 DC link overvoltage

E02 DC linkundervoltage

E04

Overtemperatureat the powerheatsink or in the

inverterinternalair

E05 Output overload(Ixt function)

E06 External fault

E08 CPU error(Watchdog)

E09 Program memoryerror(Checksum)

E10 Keypad copy function error

E14 Self-tuning routine (estimationof the motor

parameters)error

E22,E25,

Serialcommunicationerror

E26 and E27

E24 Programmingerror

E28 Serial interface Watchdog timeouterror

E31 Keypadconnectionfault(HMI-CFW08-RS)

E32 Motorovertemperature(external PTC)

E41 Self-diagnosisfault

II.FaultMessages

III.OtherMessages

Display Description

rdy Inverteris readyto be enabled

Sub

Powersupply voltage is too low for the inverter

operation(undervoltage)

dcbr Inverterin DC brakingmode

auto Inverterisrunningself-tuningroutine

copy

Keypadcopy function in progress (only available in

theHMI-CFW08-RS)- inverterto keypad

past

Keypadcopy function in progress (only available in

theHMI-CFW08-RS)- keypadto inverter

Srdy Inverter in the sleep rdy mode

Page 16

16

CHAPTER1

SAFETYNOTICES

This Manual contains necessaryinformation for the correct

useof the CFW-08frequencyinverter.

This Manual was developed for qualified personnel with

suitabletrainingandtechnicalqualificationtooperatethistype

ofequipment.

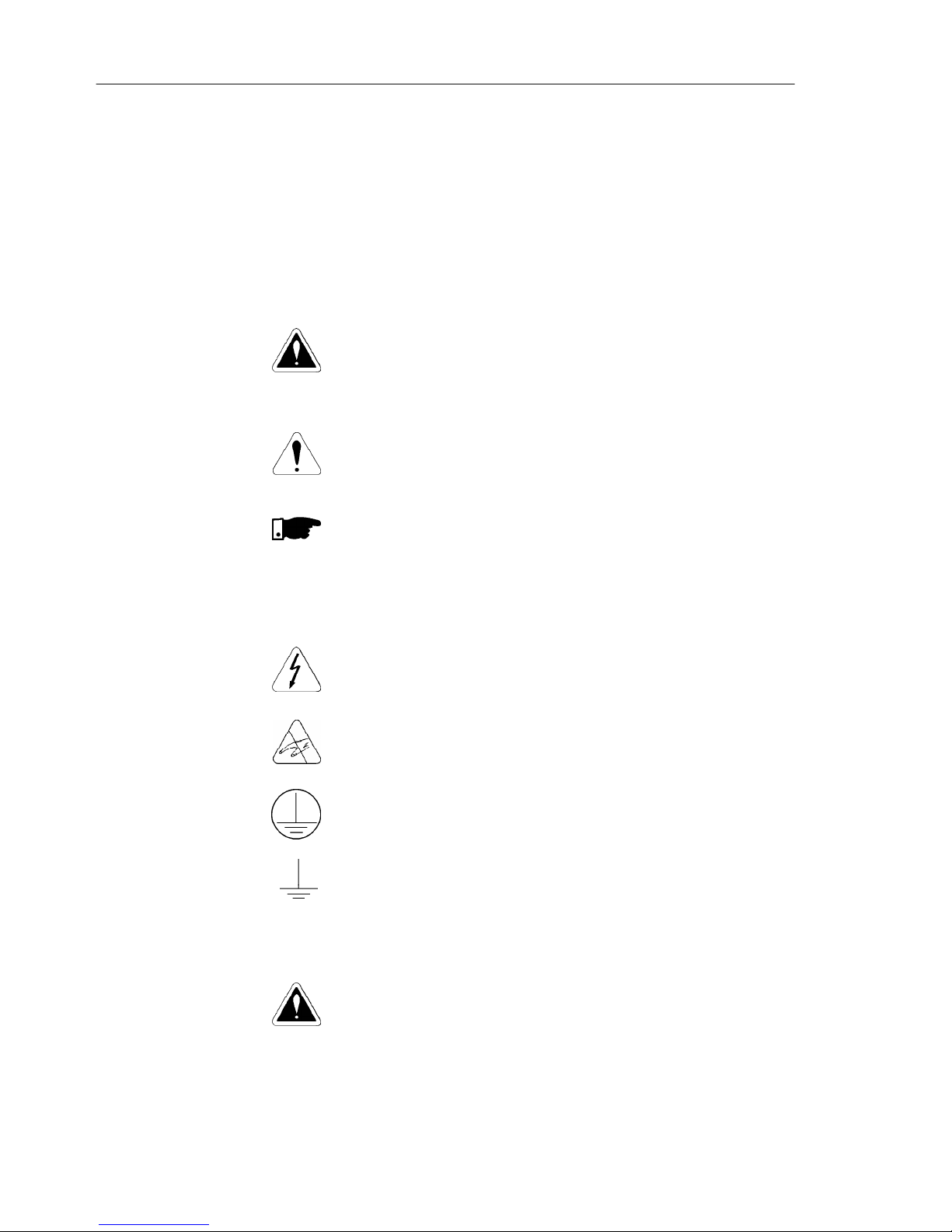

Thefollowingsafetynoticesareusedin thismanual:

DANGER!

Iftherecommended safetynoticesarenot strictlyobserved,it

canleadtoseriousorfatalinjuriesofpersonneland/ormaterial

damage.

ATTENTION!

Failureto observe the recommendedsafetyprocedurescan

lead to material damage.

NOTE!

This notice provides important information for the proper

understandingandoperationof theequipment.

Thefollowingsymbolsmaybeattachedtotheproduct,serving

assafetynotice:

High Voltages.

Componentssensitiveto electrostaticdischarge. Do not

touch them without proper grounding procedures.

Mandatory connection to ground protection (PE).

Shield connection to ground.

DANGER!

Only qualified personnel should plan or implement the

installation, start- up, operation and maintenance of this

equipment. Personnel must review entire Manual before

attemptingto install,operateortroubleshoottheCFW-08.

Thesepersonnel must followall safetyinstructionsincluded

inthismanualand/ordefinedbylocal regulations.

Failure to comply with these instructions may result in

personnelinjuryand/orequipmentdamage.

1.3 PRELIMINARY

RECOMMENDATIONS

1.2 SAFETYNOTICES

ONTHE PRODUCT

1.1 SAFETYNOTICESIN

THEMANUAL

Page 17

17

CHAPTER 1 - SAFETY NOTICES

NOTE!

Inthis manual,qualifiedpersonnelare definedas peoplethatare

trainedto:

1. Install,ground,powerup and operatetheCFW-08according

tothis manual andthe localrequiredsafetyprocedures;

2. Useofsafetyequipment accordingtothelocal regulations;

3. Administer FirstAid.

DANGER!

Theinvertercontrol circuit (ECC3, DSP) and theHMI-CFW08-P

arehighvoltagecircuitsandare notgrounded.

DANGER!

Always disconnect the supply voltage before touching any

electricalcomponentinside theinverter.

Many components are charged with high voltage and/or in

movement (fans), even aftertheincomingAC power supply has

beendisconnectedorswitchedOFF. Waitatleast10 minutesfor

thetotal discharge of the powercapacitors.

Alwaysconnecttheframeoftheequipmenttotheground(PE)at

thesuitableconnectionpoint.

ATTENTION!

All electronic boards have components that are sensitive to

electrostatic discharges. Never touch any of the electrical

components or connectors without following proper grounding

procedures. If necessary to do so, touch the properlygrounded

metallicframe or use a suitablegroundstrap.

NOTE!

Inverterscaninterferewithotherelectronicequipment.Inorderto

reduce this interference, adopt the measures recommended in

chapter3 - Installationand Connection.

NOTE!

ReadthisentiremanualbeforeinstallingoroperatingtheCFW-08.

Do not apply high voltage (high pot) test on the inverter!

If this test is necessary, contact Eliwell.

Page 18

18

Thischapterdefinesthecontentsandpurposesof thismanual and describes the main characteristics of the CFW-08

frequency inverter. Identification, receiving inspections and

storagerequirementsarealso provided.

Thismanual is divided into 7 chapters,providing information

to the user on how receive, install, start-up and operate the

CFW-08.

Chapter 1 - Safetynotices.

Chapter 2 - Generalinformationand receivingtheCFW-08.

Chapter 3 - RFIfilters, mechanical and electricalinstallation

(powerandcontrolcircuit).

Chapter 4 - Using the keypad (Human Machine Interface -

HMI).

Chapter 5 - Start-upandstepstofollow.

Chapter 6 - Solving problems, cleaning instructions and

preventivemaintenance.

Chapter 7 - CFW-08ratings,tablesandtechnicalinformation.

This manual provides information for the correct use of the

CFW-08. This frequency inverter is very flexible and allows

the operation in many different modes as described in this

manual.

AstheCFW-08canbeappliedinseveralways,itisimpossible

todescribeherealloftheapplicationpossibilities.Eliwelldoes

not accept any responsibility when the CFW-08 is not used

accordingto thismanual.

Nopartofthismanualmaybereproducedinanyform,without

thewrittenpermission of Eliwell.

It is important to note the software version installed in the

CFW-08, since it defines the functionsandtheprogramming

parameters of the inverter.

This manual refers to the software version indicated on the

insidecover.Forexample,theversion3.0Xappliestoversions

3.00 to 3.09, where “X” is a variable that will change due to

minor software revisions.The operation of the CFW-08 with

these software revisions are still covered by this version of

themanual.

Thesoftwareversion can be readin the parameterP023.

GENERALINFORMATION

2.1 ABOUTTHIS

MANUAL

2.2 SOFTWARE

VERSION

CHAPTER2

Page 19

19

CHAPTER 2 - GENERAL INFORMATION

2.3 ABOUTTHE CFW-08

TheCFW-08frequencyinverterprovidestwocontroloptions:

vector control (VVC: voltage vector control) or V/F (scalar);

bothtypes of controlcan be setaccordingtothe application.

Inthevectorcontrolmode,themotorperformanceisoptimized

relatingto torqueand speed regulation.

The"Self-Tuning"function,availableinvectorcontrol,permits

the automatic setting of the inverter parameter from the

identification(alsoautomatic)oftheparametersof themotor

connectedat the inverteroutput.

The V/F (scalar) mode is recommended for simpler

applicationssuchaspumpandfandrives.Inthesecasesone

can reduce the motor and inverter losses by using the

"QuadraticV/F" option, thatresultsin energysaving.

TheV/Fmodeisalsousedwhenmorethanonemotorshould

be driven simultaneously by one inverter (multimotor

application).

For power ratings and further technical information, refer to

Chapter7.

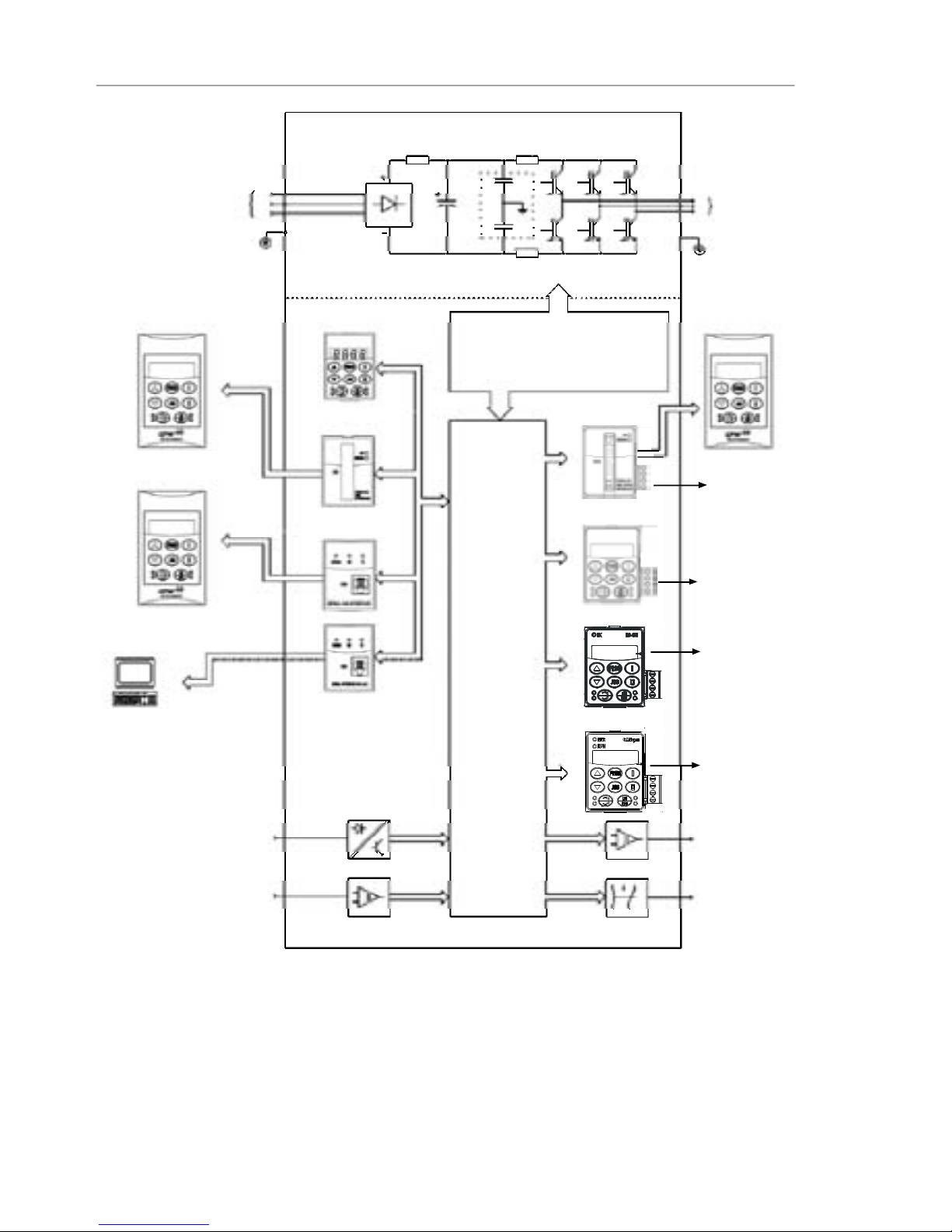

The block diagram below gives a general overview of the

CFW-08.

Page 20

20

CHAPTER 2 - GENERAL INFORMATION

Figure 2.1 - Block diagram for the models:

1.6-2.6-4.0-7.0A/200-240 V and1.0-1.6-2.6-4.0A/380-480V

Power

Supply

R

S

T

PE

HMI-CFW08-RS

PC-Software

SuperDrive

Analog

Inputs

(AI1andAI2)

Digital

Inputs

(DI1toDI4)

Interface

RS-232KCS-CFW08

Interface

MIS-CFW08-RS

or

HMI-CFW08-P

POWER

CONTROL

POWER SUPPLIESAND

CONTROL/ POWER

INTERFACES

"ECC3"

CONTROL

BOARD

WITHDSP

Motor

U

V

W

Rsh2

Rsh1

NTC

PE

RFIFilter

HMI-CFW08-RP

Interface

MIP-CFW08-RP

or

or

Analog

Output

(AO)

Relay

Output

(RL1and RL2)

CANopen

or

DeviceNet

KRS-485

KFB-COor KFB-DN

RS-485

24 V Power

Supply

24 V Power

Supply

HMI-CFW08-RP

KDC-24VR-CFW08

KDC-24V-CFW08

Page 21

21

CHAPTER 2 - GENERAL INFORMATION

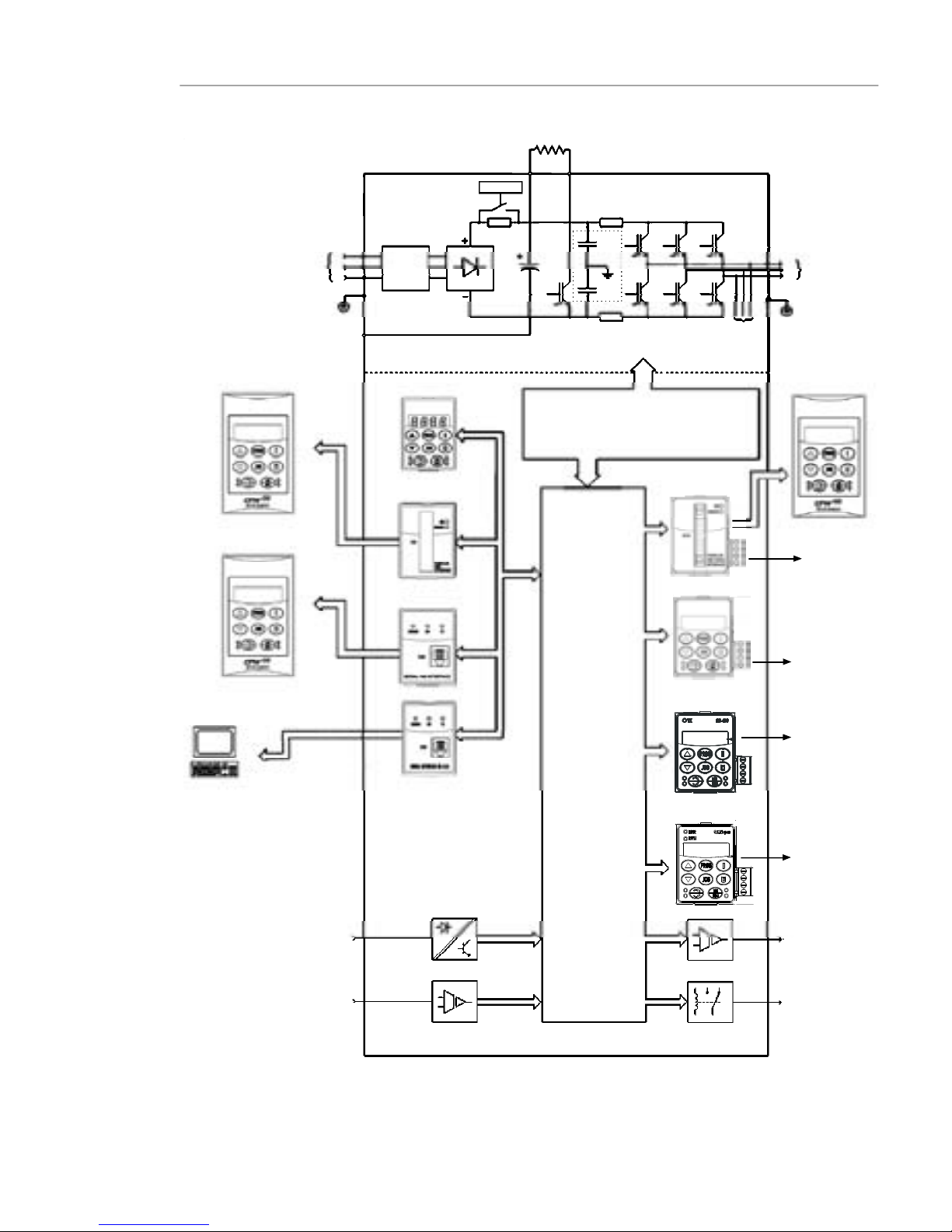

Figure 2.2 - Block diagram for the models:

7.3-10-16-22A/200-240V and 2.7-4.3-6.5-10-13-16A/380-480V

Note: models 16 A and 22 A/200-240 V are not fitted with optional RFI filter.

Redede

Alimentação

R

S

T

RFI

Suppressor

Filter

(optional)

HMI-CFW08-RS

PC-Software

SuperDrive

Analog

Inputs

(AI1andAI2)

Digital

Inputs

(DI1toDI4)

Interface

RS-232KCS-CFW08

Interface

MIS-CFW08-RS

HMI-CFW08-P

POWER

CONTROL

POWER SUPPLIESANDCONTROL

/POWER INTERFACES

"ECC3"

CONTROL

BOARD

WITHDSP

Motor

U

V

W

Rsh2

Rsh1

RPC

Pré-Carga

Braking Resistor

(ExternalandOptional)

BR

+UD

PE

-UD

Voltage

Feedback

PE

or

or

RFIFilter

or

Interface

MIP-CFW08-RP

HMI-CFW08-RP

Analog

Output

(AO)

Relay

Output

(RL1and RL2)

CANopen

or

DeviceNet

KRS-485

KFB-COor KFB-DN

RS-485

24 V Power

Supply

24 V Power

Supply

HMI-CFW08-RP

KDC-24VR-CFW08

KDC-24V-CFW08

Page 22

22

CHAPTER 2 - GENERAL INFORMATION

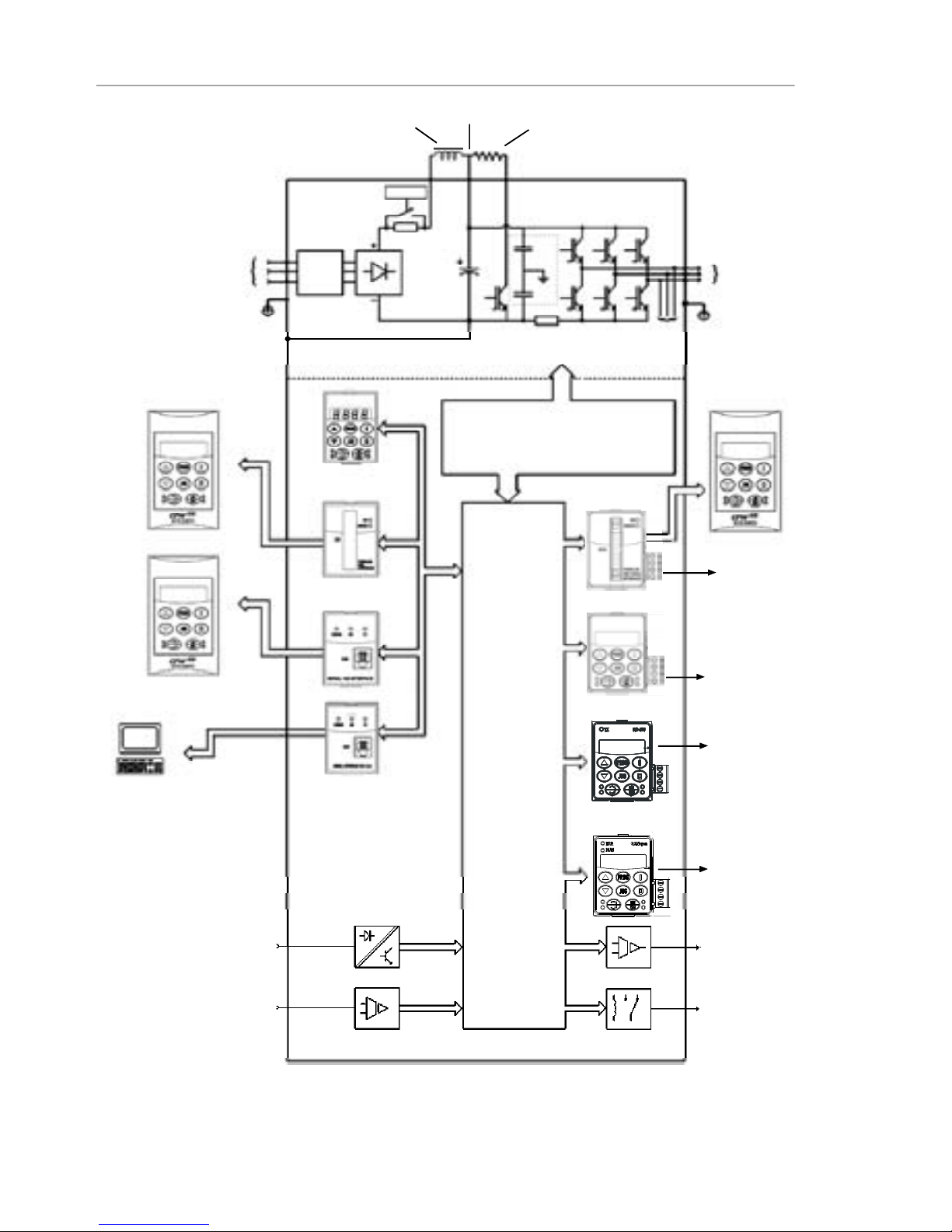

Figure 2.3 - Block diagram for the models:

28-33A/200-240 V and 24-30 A/380-480V

Note: models 28 A and 33 A/200-240 V are not fitted with optional RFI filter.

Power

Supply

R

S

T

RFI

Suppressor

Filter

(optional)

HMI-CFW08-RS

PC-Software

SuperDrive

Analog

Inputs

(AI1andAI2)

Digital

Inputs

(DI1toDI4)

Interface

RS-232KCS-CFW08

Interface

MIS-CFW08-RS

HMI-CFW08-P

POWER

CONTROL

POWER SUPPLIESAND

CONTROL/ POWER

INTERFACES

"ECC3"

CONTROL

BOARD

WITHDSP

Motor

U

V

W

Rsh1

RPC

Pré-Carga

Braking Resistor

(optional)

BR

DCR

PE

-UD

Voltage

Feedback

PE

or

or

RFIFilter

or

Interface

MIP-CFW08-RP

HMI-CFW08-RP

DCLink Inductor

(optional)

+UD

Analog

Output

(AO)

Relay

Output

(RL1and RL2)

CANopen

or

DeviceNet

KRS-485

KFB-COor KFB-DN

RS-485

24 V Power

Supply

24 V Power

Supply

HMI-CFW08-RP

KDC-24VR-CFW08

KDC-24V-CFW08

Page 23

23

CHAPTER 2 - GENERAL INFORMATION

Figure 2.4 - Description and location of the nameplates on the CFW-08

2.4 CFW-08IDENTIFICATION

Lateral Label of the CFW-08

Frontal Nameplate of the CFW-08 (under the keypad)

EliwellPart Number

SerialNumber

CFW-08Model (IntelligentCode)

SoftwareVersion

ManufacturingDate

CertificationStiker

EWCFW080130S0

12345678 V1.234

1234567890 20/02/2008

CFW-08Model

(IntelligentCode)

RatedOutput Data

(Voltage,Frequency)

SoftwareVersion

ManufacturingDate

EliwellPart Number

SerialNumber

RatedInputData

(Voltage, Current,etc)

Page 24

24

CHAPTER 2 - GENERAL INFORMATION

Note: All models include internal Class A RFI filter, Breake Chopper and have

thefollowing standard Inputs & Outputs:

- 2 Analog Inputs

- 1 Analog Output

- 4 Digital Inputs

- 2 Relay Outputs

EWCFW-08 0043 S 0

Rated Output

Current for:

0043 = 4.3A

0065 = 6.5A

0100 = 10A

0130 = 13A

0160 = 16A

0240 = 24A

0300 = 30A

380Vac to

480Vac

3-phase

Supply

Communication

Option

0 = No

communication

S = RS485

(Modbus RTU)

communication

EndCode

Eliwell

Series 08

Frequency

Inverter

HOW TO SPECIFY THE CFW-08 MODEL:

Page 25

25

CHAPTER 2 - GENERAL INFORMATION

Forthe effectofthiscode, the standardproductis conceived

asfollows:

-CFW-08withstandardcontrol board.

- Degree of protection: Nema 1 for the models 22 A,

28 A and 33 A/ 200-400 V and also 13 A,16 A, 24 A

and 30 A/380-480 V, IP20 for the other models.

CFW-08 Plus - A1 is composed of the inverter and the

controlboard 1. Example: CFW080040S2024POA1Z.

CFW-08 Plus - A2 is composed of the inverter and the

control board 2. Example: CFW080040S2024POA2Z.

Thesemodelsarefactorysetforbipolaranaloginputs(-10V

to +10 V).

Thisconfigurationislostwhenthefactorydefaultparameters

areloaded (P204 = 5). Referto the detailed descriptionof

parametersP204 andP235for furtherinformation.

CFW-08 Plus -A3 is composed of the inverter, the KFBCO-CFW08kitandtheCANopencommunicationprotocol.

Example:CFW-080040S2024POA3Z.

CFW-08 Plus -A4 is composed of the inverter, the KFBDN-CFW08kitandtheDeviceNetcommunicationprotocol.

Example:CFW080040S2024POA4Z.

CFW-08 Multipump - A5 is composed of the inverter and

thecontrolboard5,usedformultipumpsystemapplications.

7.0A, 16.0 A, 22 A, 28A and 33A /200-240 V and for all

380-480 V models are just available with three-phase

powersupply.

A Category C2 RFI filter (optional) can be installed inside

the inverter in models 7.3 A and 10 A/200-240 V (singlephase) and 2.7 A, 4.3A, 6.5 A, 10 A, 13A, 16 A, 24 A and

30A/380-480 V. Models 1.6A, 2.6A and 4.0A/200-240 V

(single-phase)and1.0A,1.6A, 2.6Aand4.0A/380-480V

can be provided mounted on a footprint Category C2 RFI

filter(optional).

Thelistingoftheexistingmodels(voltage/current)isshown

initem 7.1.

Page 26

26

CHAPTER 2 - GENERAL INFORMATION

The CFW-08 issupplied in cardboard boxes.

Theoutsideofthepackingboxhasanameplatethatisidentical

tothat on the CFW-08.

Please check if the CFW-08is the one you ordered.

Checkif the:

CFW-08nameplatedatamatcheswithyourpurchaseorder.

Theequipmenthas not beendamaged duringtransport.

Ifanyproblem isdetected,contactthe carrier immediately.

If the CFW-08 is not installed immediately,store it in a clean

anddryroom (storage temperatures between-25 °C [-13 °F]

and 60 °C [140 ºF]). Cover it to protect against dust, dirt or

othercontamination.

ATTENTION!

When theinverterisstoredforalongtime,itisrecommended

to power the inverter up for 1 hour every year.Make sure to

use a power supply with the following characteristics for all

models (200-240 V or 380-480 V): 220 V, single-phase or

three-phase,50 Hz or 60 Hz, withoutconnectingthemotorto

thedriveoutput.Afterpoweringup thedrive,keepit off for24

hoursbeforeusingitagain.

2.5 RECEIVINGAND

STORING

Page 27

27

CHAPTER3

INSTALLATION ANDCONNECTION

Thischapterdescribesthe proceduresfor the electrical and

mechanicalinstallationof the CFW-08.Theseguidelines

andsuggestionsmust be followedforproperCFW-08

operation.

The location of the inverter installation is an important factor

to assure good performance and long useful life for its

components. For proper installation, we make the following

recommendations:

Avoid direct exposureto sunlight, rain, high moisture and

sea air;

Avoidexposuretoexplosiveorcorrosivegasesandliquids;

Avoid exposure to excessive vibration, dust, oil or any

conductiveparticlesin the air.

Environment conditions:

Temperature: 0 ºC to 40 ºC (32 ºF to 104 ºF ) - nominal

conditions.From40 ºC to50 ºC (32ºFto122 ºF)- with2 %

currentderatingfor each 1 ºC (1.8 ºF) degreeabove40 ºC

(104ºF).

Relativeairhumidity:5 %to90 % - non-condensing.

Maximumaltitude: 1000m(3,300ft) - nominalconditions.

From 1000 m to 4000 m (3,300 to 13123.3 ft) - with 1 %

currentreduction for each 100 m (328 ft) above 1000 m

(3,300ft).

From2000 m (6561.6ft) to 4000 m (13123.3ft)- a voltage

reduction of 1.1 % every 100 m (328 ft) above 2000 m

(6561.6ft).

Pollution degree: 2 (according toEN50178 and UL508C)

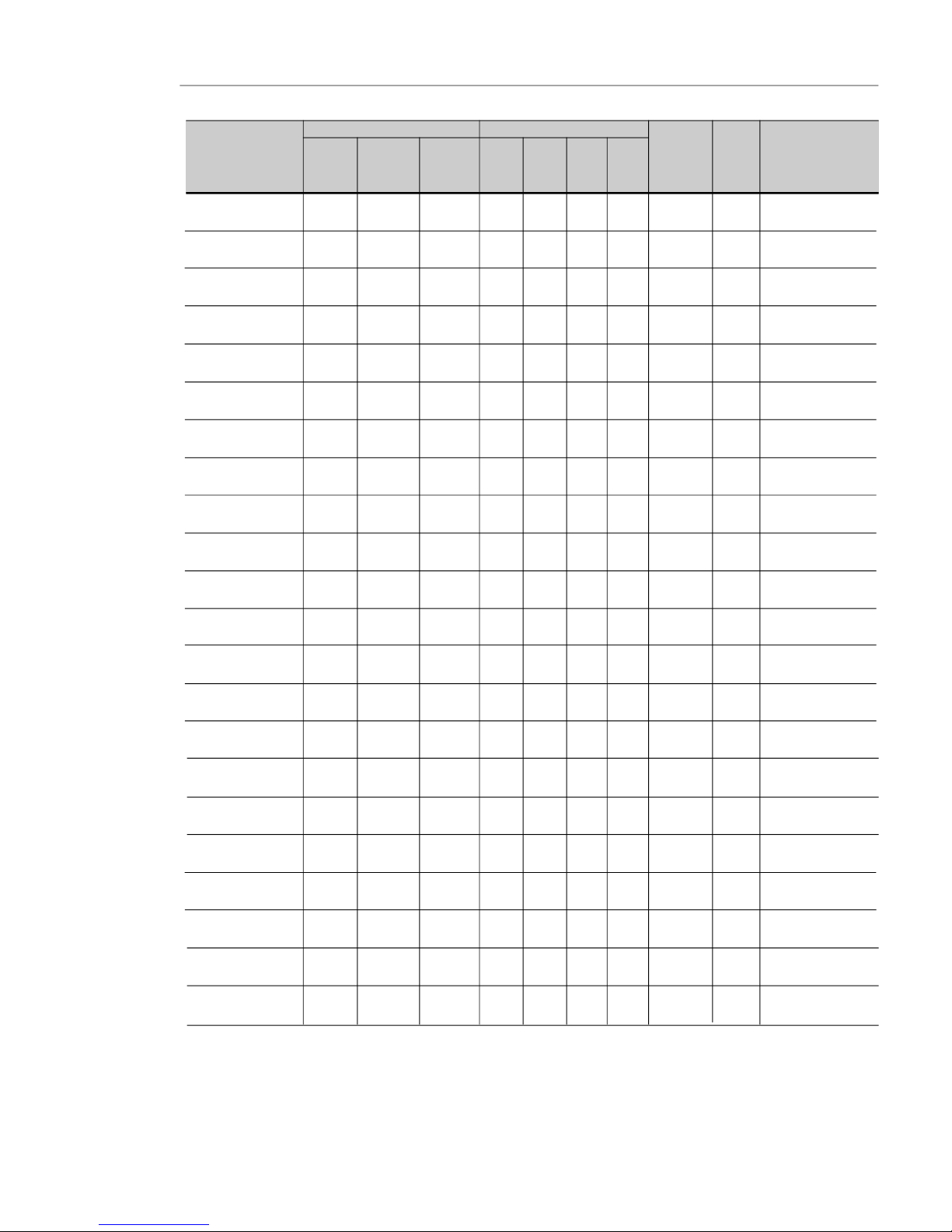

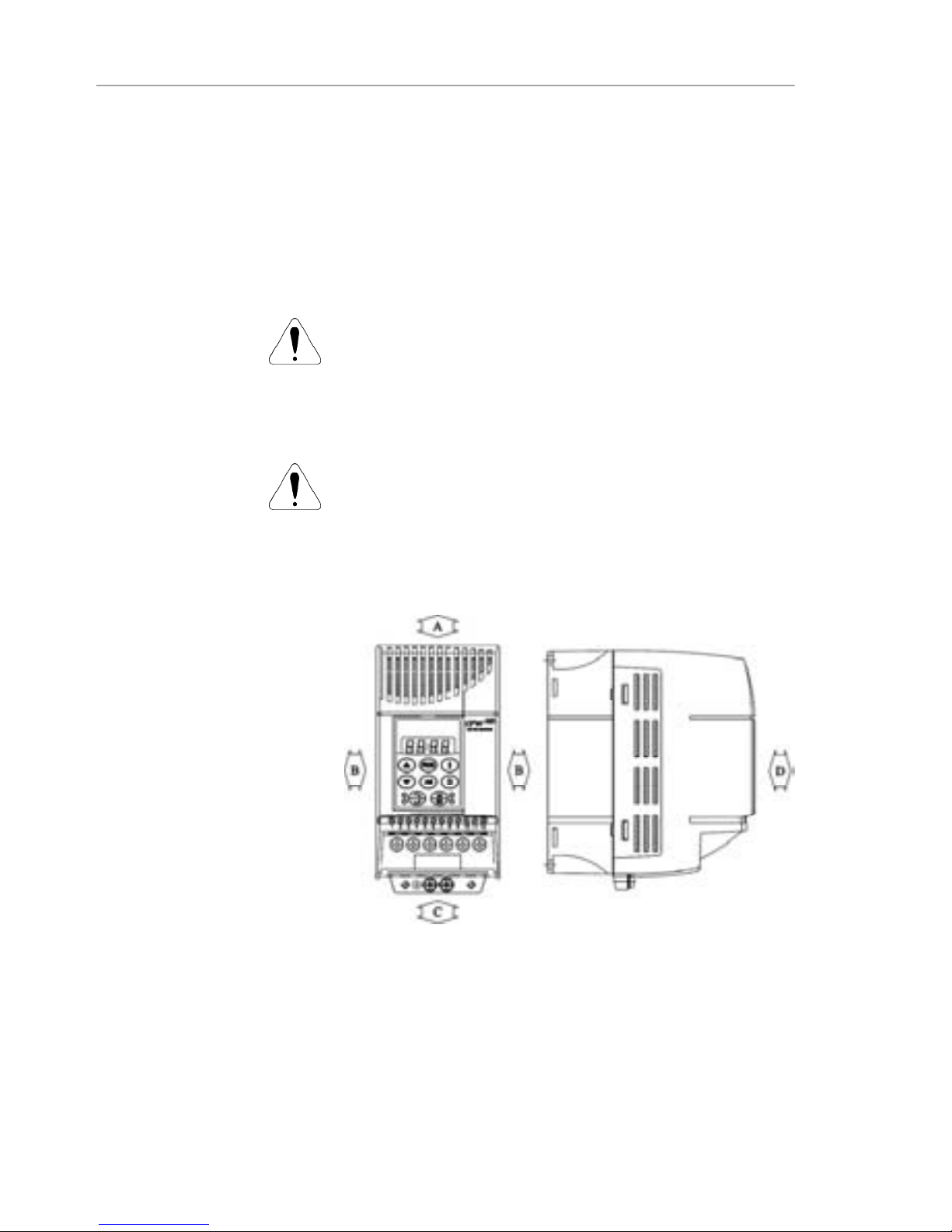

The figure 3.1 and thetable 3.1, provides external mounting

specifications,and externalfixingholes of theCFW-08.

3.1 MECHANICAL

INSTALLATION

3.1.1 Environment

3.1.2 CFW-08Mounting

Specifications

Figure 3.1 - CFW-08 mounting specifications

Page 28

28

CHAPTER 3 - INSTALLATION AND CONNECTION

Figure 3.1 (cont.) - CFW-08 mounting specifications

VIEW OF THE

MOUNTINGBASE

FRONTAL

VIEW

LATERALVIEW

1MIN. APÓSA DESENERGIZAÇÃO.

-SOMENTE REMOVAATAMPA

-LEIA OMANUAL DEINSTRUÇÕES.

ATENÇÃO

-READ THE INSTRUCTIONSMANUAL.

AFTER1 MIN. POWERHAS BEEN

-ONLY REMOVETERMINAL COVER

WARNING

DISCONNECTED.

Page 29

29

CHAPTER 3 - INSTALLATION AND CONNECTION

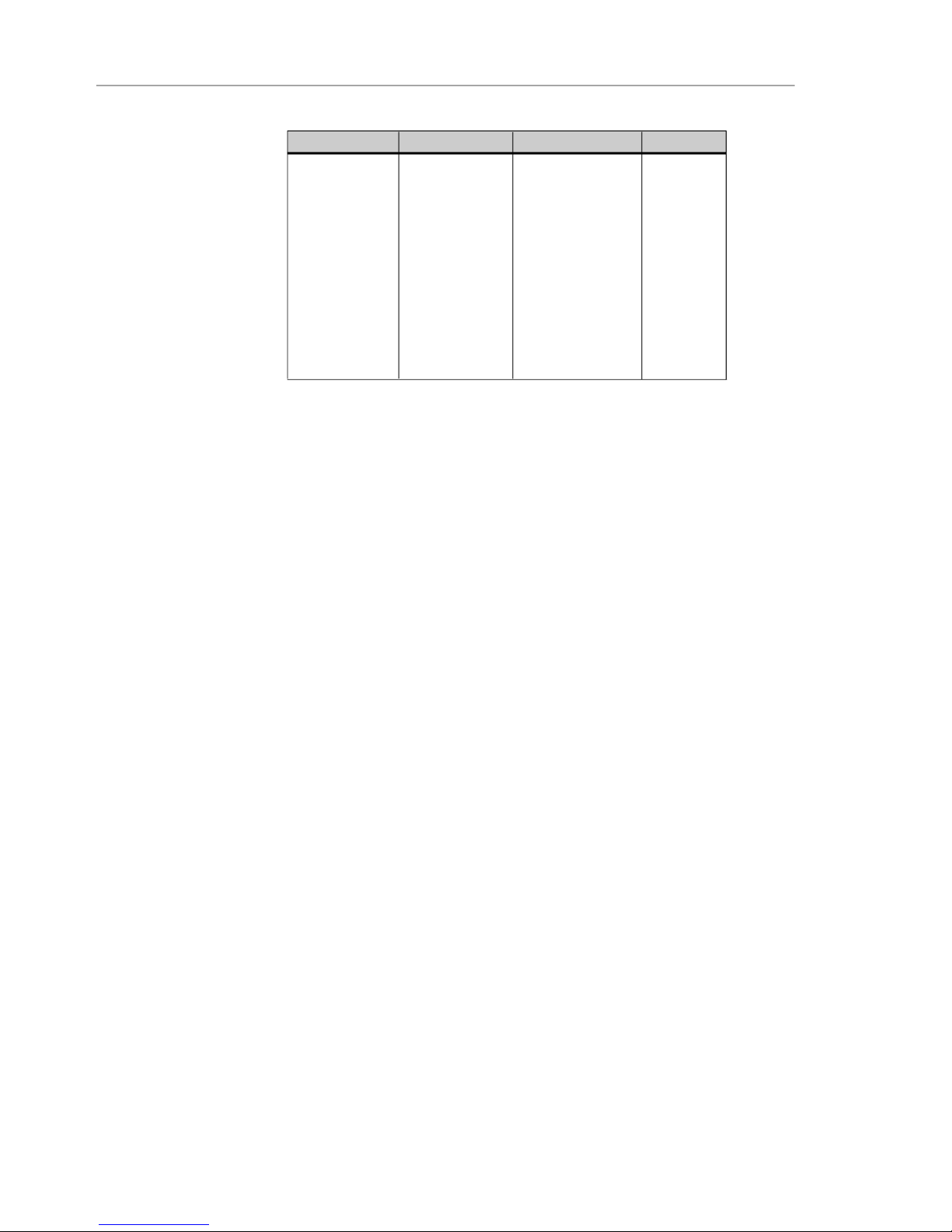

Inverter

Model

1.6A / 200-240 V

2.6A / 200-240 V

4.0A / 200-240 V

7.0A / 200-240 V

7.3A / 200-240 V

10A / 200-240 V

16A / 200-240 V

22A/200-240V

28A/200-240V

33A/200-240V

1.0A / 380-480 V

1.6A / 380-480 V

2.6A / 380-480 V

2.7A / 380-480 V

4.0A / 380-480 V

4.3A / 380-480 V

6.5A / 380-480 V

10A / 380-480 V

13A / 380-480 V

16A / 380-480 V

24A/380-480V

30A/380-480V

Width L

mm

(in)

75

(2.95)

75

(2.95)

75

(2.95)

75

(2.95)

115

(4.53)

115

(4.53)

115

(4.53)

143

(5.63)

182

(7.16)

182

(7.16)

75

(2.95)

75

(2.95)

75

(2.95)

115

(4.53)

75

(2.95)

115

(4.53)

115

(4.53)

115

(4.53)

143

(5.63)

143

(5.63)

182

(7.16)

182

(7.16)

HeightH

mm

(in)

151

(5.95)

151

(5.95)

151

(5.95)

151

(5.95)

200

(7.87)

200

(7.87)

200

(7.87)

203

(7.99)

290

(11.41)

290

(11.41)

151

(5.95)

151

(5.95)

151

(5.95)

200

(7.87)

151

(5.95)

200

(7.87)

200

(7.87)

200

(7.87)

203

(7.99)

203

(7.99)

290

(11.41)

290

(11.41)

Depth P

mm

(in)

131

(5.16)

131

(5.16)

131

(5.16)

131

(5.16)

150

(5.91)

150

(5.91)

150

(5.91)

165

(6.50)

196

(7.71)

196

(7.71)

131

(5.16)

131

(5.16)

131

(5.16)

150

(5.91)

131

(5.16)

150

(5.91)

150

(5.91)

150

(5.91)

165

(6.50)

165

(6.50)

196

(7.71)

196

(7.71)

A

mm

(in)

64

(2.52)

64

(2.52)

64

(2.52)

64

(2.52)

101

(3.98)

101

(3.98)

101

(3.98)

121

(4.76)

161

(6.33)

161

(6.33)

64

(2.52)

64

(2.52)

64

(2.52)

101

(3.98)

64

(2.52)

101

(3.98)

101

(3.98)

101

(3.98)

121

(4.76)

121

(4.76)

161

(6.33)

161

(6.33)

B

mm

(in)

129

(5.08)

129

(5.08)

129

(5.08)

129

(5.08)

177

(6.97)

177

(6.97)

177

(6.97)

180

(7.08)

260

(10.23)

260

(10.23)

129

(5.08)

129

(5.08)

129

(5.08)

177

(6.97)

129

(5.08)

177

(6.97)

177

(6.97)

177

(6.97)

180

(7.09)

180

(7.09)

260

(10.23)

260

(10.23)

C

mm

(in)

5

(0.20)

5

(0.20)

5

(0.20)

5

(0.20)

7

(0.28)

7

(0.28)

7

(0.28)

11

(0.43)

11

(0.43)

11

(0.43)

5

(0.20)

5

(0.20)

5

(0.20)

7

(0.28)

5

(0.20)

7

(0.28)

7

(0.28)

7

(0.28)

11

(0.43)

11

(0.43)

11

(0.43)

11

(0.43)

D

mm

(in)

6

(0.24)

6

(0.24)

6

(0.24)

6

(0.24)

5

(0.20)

5

(0.20)

5

(0.20)

10

(0.39)

10

(0.39)

10

(0.39)

6

(0.24)

6

(0.24)

6

(0.24)

5

(0.20)

6

(0.24)

5

(0.20)

5

(0.20)

5

(0.20)

10

(0.39)

10

(0.39)

10

(0.39)

10

(0.39)

Mounting

Screw

M4

(5/32)

M4

(5/32)

M4

(5/32)

M4

(5/32)

M4

(5/32)

M4

(5/32)

M4

(5/32)

M5

(3/16)

M5

(3/16)

M5

(3/16)

M4

(5/32)

M4

(5/32)

M4

(5/32)

M4

(5/32)

M4

(5/32)

M4

(5/32)

M4

(5/32)

M4

(5/32)

M5

(3/16)

M5

(3/16)

M5

(3/16)

M5

(3/16)

Weigth

kg

(lb)

1.0

(2.2)

1.0

(2.2)

1.0

(2.2)

1.0

(2.2)

2.0

(4.4)

2.0

(4.4)

2.0

(4.4)

2.5

(9.8)

6

(2.36)

6

(2.36)

1.0

(2.2)

1.0

(2.2)

1.0

(2.2)

2.0

(4.4)

1.0

(2.2)

2.0

(4.4)

2.0

(4.4)

2.0

(4.4)

2.5

(5.5)

2.5

(5.5)

6

(2.36)

6

(2.36)

Degreeof

Protection

IP20 / Nema 1

(*)

IP20 / Nema 1

(*)

IP20 / Nema 1

(*)

IP20 / Nema 1

(*)

IP20 / Nema 1

(*)

IP20 / Nema 1

(*)

IP20 / Nema 1

(*)

IP20/Nema 1

IP20/Nema 1

IP20/Nema 1

IP20 / Nema 1

(*)

IP20 / Nema 1

(*)

IP20 / Nema 1

(*)

IP20 / Nema 1

(*)

IP20 / Nema 1

(*)

IP20 / Nema 1

(*)

IP20 / Nema 1

(*)

IP20 / Nema 1

(*)

IP20 / Nema 1

IP20 / Nema 1

IP20 / Nema 1

IP20 / Nema 1

Dimensions Fixing base

Table 3.1 - CFW-08 dimensions for mechanical installation of the several models

(*) These modelsare Nema 1 onlywith the KN1-CFW08-MX optional.

Note: Please check availability of model with our sales office.

Page 30

30

CHAPTER 3 - INSTALLATION AND CONNECTION

When installing the CFW-08,free space around theinverter

must be left as indicated in figure 3.2. Table 3.2 shows the

required free spaces.

Installtheinverterinverticalpositionaccordingtothefollowing

recommendations:

1)Installtheinverterona flatsurface.

2)Donotinstallheatsensitivecomponentsimmediatelyabove

theinverter.

ATTENTION!

When inverters are installed side by side, maintain the

minimumrecommendeddistanceB.

When inverters are installed top and bottom, maintain the

minimum recommended distance A+ C and deflect the hot

aircomingfrom the inverterbelow.

ATTENTION!

Provide independent conduits for signal, control and power

conductorsseparation(refertoitem3.2-ElectricalInstallation).

Useseparateconduitsortrunkingforcontrolandpowerwiring

(seeitem 3.2 - Electrical Installation).

Figure 3.2 - Free spaces for cooling

3.1.3 Positioningand Fixing

Page 31

31

CHAPTER 3 - INSTALLATION AND CONNECTION

CFW-08Model

1.6A / 200-240 V

2.6A / 200-240 V

4.0A / 200-240 V

7.0A / 200-240 V

1.0A / 380-480 V

1.6A / 380-480 V

2.6A / 380-480 V

4.0A / 380-480 V

7.3A / 200-240 V

10A / 200-240 V

16A / 200-240 V

2.7A / 380-480 V

4.3A / 380-480 V

6.5A / 380-480 V

10A / 380-480 V

22A / 200-240 V

13A / 380-480 V

16A / 380-480 V

28A/200-240V

33A/200-240V

24A/380-480V

30A/380-480V

A B C D

30 mm 1.18 in 5mm 0.20 in 50 mm 2 in 50mm 2 in

35 mm 1.38 in 15 mm 0.59 in 50 mm 2 in 50 mm 2 in

40 mm 1.57 in 30 mm 1.18 in 50 mm 2 in 50 mm 2 in

50 mm 2 in 40mm 1.57 in 60 mm 2.36 in 50 mm 2 in

Table 3.2 - Recommended free spaces

When invertersare installed inside closed metallic panelsor

boxes provide suitable air exhaustion by ensuring that the

ambient temperature remains within the allowed range. For

wattlosses refer toitem9.1of this manual.

For reference, table 3.3 shows the cooling airflow for each

invertermodel.

Inverter Cooling Method: internal fan, flow direction from

thebottom to thetop.

3.1.3.1 PanelMounting

Table 3.3 - Cooling air flow requirements

CFW

-

08 Inverter Model

CFM

I/s

m3/min

4.0 A, 7.0 A/200 V

2.6 A, 4.0 A/400 V

6.0 2.8 0.17

7.3 A, 10 A, 16 A/200 V

6.5 A, 10 A/400 V

18.0 8.5 0.51

13 A, 16 A/400 V 18.0 8.5 0.51

22 A/200 V 22.0 10.4 0.62

28 A/200 V

24 A/400 V

36.0 17.0 1.02

33 A/200 V

30 A/400 V

44.0 20.8 1.25

Page 32

32

CHAPTER 3 - INSTALLATION AND CONNECTION

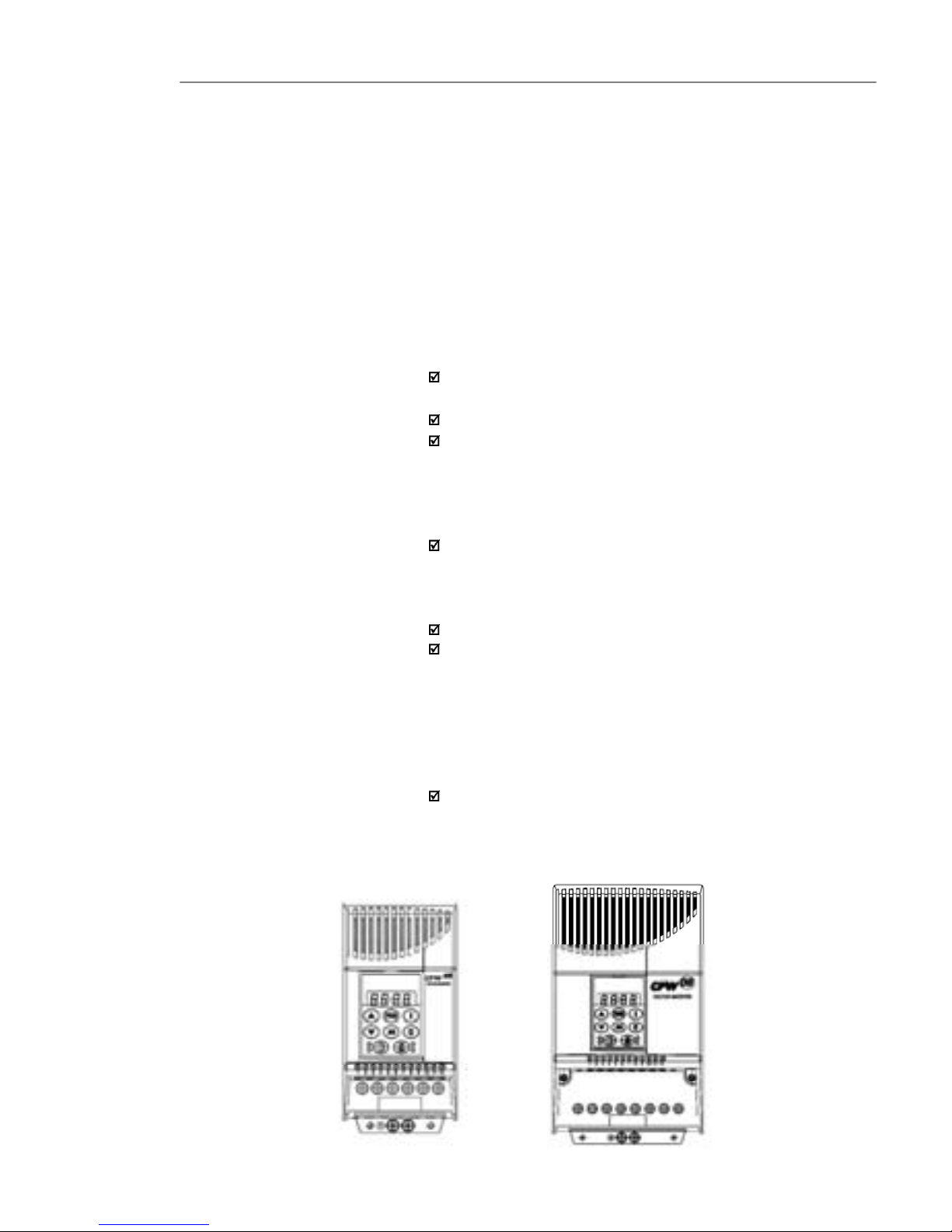

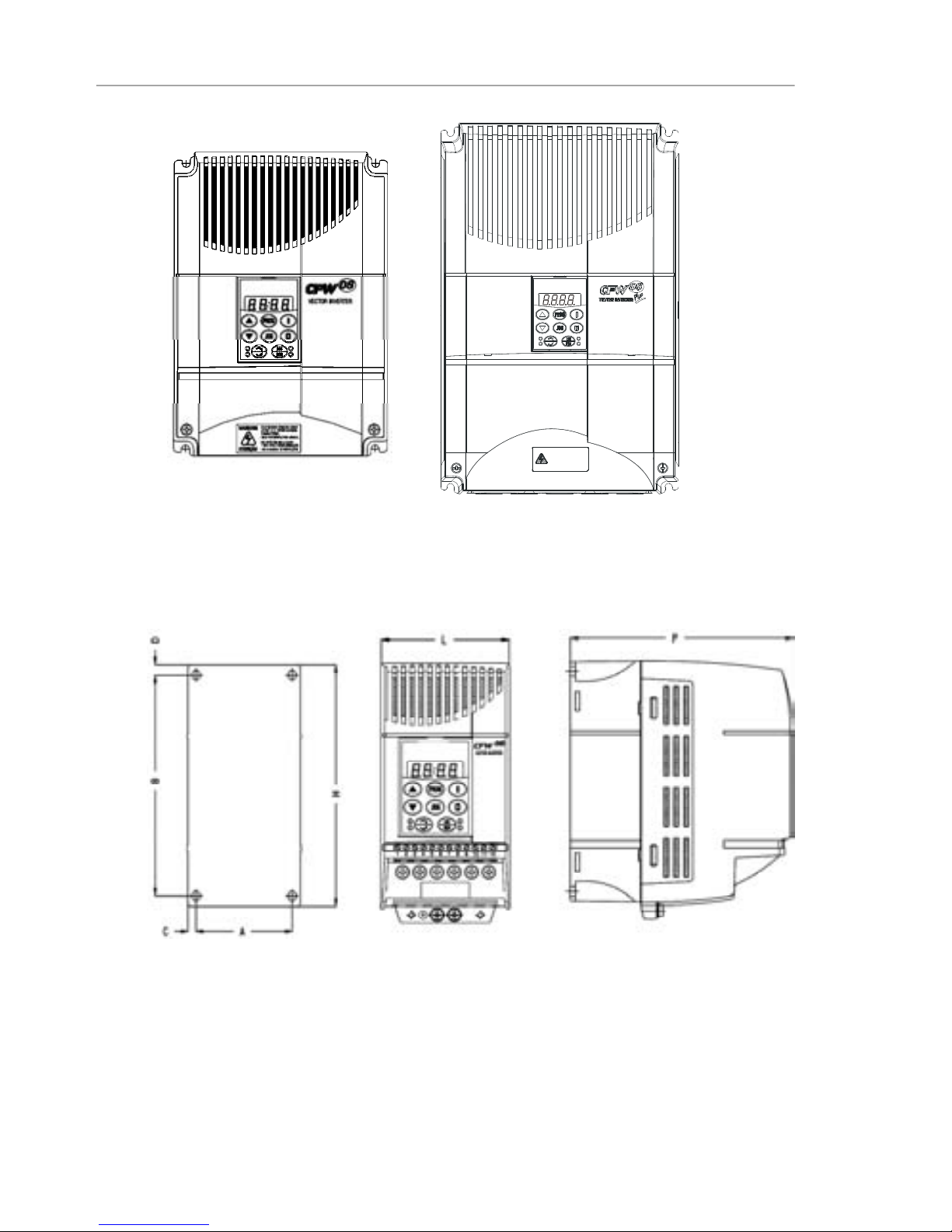

3.1.3.2 SurfaceMounting Figure 3.3 shows the surface installation procedures of the

CFW-08.

Figure 3.3 - Mounting procedures for CFW-08

3.2 ELECTRICAL

INSTALLATION

DANGER!

The information below will be a guide to achieve a proper

installation. Also follow all applicable local standards for

electricalinstallations.

DANGER!

Be sure the AC input power has been disconnected before

makinganyterminalconnection.

DANGER!

Do not use the CFW-08 as an emergency stop device. For

thispurposeprovideother additional mechanical means.

Thepowerconnectionterminalscan beofdifferentsizesand

configurations,dependingon theinvertermodel,as shownin

figure3.4.

Descriptionofthe powerterminals:

L/L1,N/L2 and L3 (R, S ,T):AC power supply.

Themodels oftheline voltage200-240V (excepting7.0A,

16A, 22A, 28A, and33A) canbeoperatedon twophases

(single-phaseoperation)withoutratedcurrentreduction.In

this case theAC powersupply can be connected to any 2

terminalsof the3inputsterminals.

U,V,W: connectiontothemotor.

3.2.1 Power/ Grounding

Terminals

AIR FLUX

Page 33

33

CHAPTER 3 - INSTALLATION AND CONNECTION

-UD:negativepoleof theDClinkcircuitisnotavailable on

themodels 1.6A-2.6A-4.0A-7.0A/200-240Vandmodels

1.0 A-1.6 A-2.6 A-4.0 A/380-480 V. It is used when the

invertersuppliedbyDC voltage(withtheterminal+UD).In

order to avoid an incorrect braking resistor connection

(mountedoutsidetheinverter),thereisaprotectiverubber

plug on this terminal, which must be removed if the –UD

terminalhastobe used.

BR:Connectionforthebrakingresistor.

Notavailableonthemodels1.6A-2.6A-4.0A-7.0A/200-240V

andonthemodels1.0A-1.6A-2.6A-4.0A/380-480V.

+UD: positive pole of the DC link circuit, notavailable on

the models 1.6A-2.6A-4.0A-7.0A/200-240 V and on the

models 1.0 A-1.6 A-2.6 A-4.0 A/380-480 V. It is used to

connectthebrakingresistor(withtheBR terminal)orwhen

the inverter shall be supplied by with DC voltage (jointly

withthe–UDterminal.

DCR: Connection for the external DC link circuit inductor

(optional).Itis onlyavailableonthemodels28Aand 33A/

200-240 V and on the models 24A and 30 A/380-480 V.

c) 22 A/200-240 V and 13-16 A/380-480 V models

b)7.3-10-16A/200-240V and 2.7-4.3-6.5-10A/380-480V models

a)1.6-2.6-4.0-7.0A/200-240V and 1.0-1.6-2.6-4.0A/380-480V models

Figure 3.4 a) to c) - Power terminals

L3 U V WL/L1

N/L2

-Ud BR +Ud

L3L/L1 N/L2

U V W

1R2S3T4U5V6W7

-UD8BR9+UD

LINE

MOTOR

Page 34

34

CHAPTER 3 - INSTALLATION AND CONNECTION

3.2.2 Location of the Power

Terminals,Grounding

TerminalsandControl

TerminalConnections

ControlXC1

Power

Grounding

a)1.6-2.6-4.0-7.0-7.3-10-16A/200-240V and

1.0-1.6-2.6-2.7-4.0-4.3-6.5-10A/380-480V models

Figure 3.5 a) and b) - Location of the power,grounding and

control connections

b)22-28-33A/200-240 V and 13-16-24-30A/380-480V models

ControlXC1

Power

Grounding

Figure 3.4 (cont.) d) - Power terminals

d) 28-33A/200-240 V and 24-30 A/380-480 V models

1R2S3T4U5V6W7

-UD8BR9+UD

LINE

MOTOR

10

DCR

Page 35

35

CHAPTER 3 - INSTALLATION AND CONNECTION

3.2.3 Power/Grounding

Wiringand

Circuit Breakers

ATTENTION!

Install the inverter and power cables distant from sensitive

equipmentandwiringsby0.25m (0.82ft),forinstancePLCs,

temperaturecontrollers,thermocouplecables,etc.

Usetherecommendedwirecrosssectionandcircuitbreakers

as shownin table 3.4. Use onlycopperwire (70 ºC [158 ºF]).

NOTE!

Thewire sizing in table3.4shallbeusedas referencevalues

only. The exact wire sizing depends on the installation

conditionsand themaximumacceptable line voltage drop.

Therecommendedtightening torqueisshownin table3.5.

ATTENTION!

The use of mini circuit breakers(MBU) is notrecommended

duetothelevelofthemagneticprotection.

Table 3.4 - Recommended wiring and circuit breakers – use only copper wire (70 ºC [158 ºF])

Page 36

36

CHAPTER 3 - INSTALLATION AND CONNECTION

Model

1.6A / 200-240 V

2.6A / 200-240 V

4.0A / 200-240 V

7.0A / 200-240 V

7.3A / 200-240 V

10.0A / 200-240 V

16.0A / 200-240 V

22.0A / 200-240 V

28.0A / 200-240 V

33.0A / 200-240 V

1.0A / 380-480 V

1.6A / 380-480 V

2.6A / 380-480 V

2.7A / 380-480 V

4.0A / 380-480 V

4.3A / 380-480 V

6.5A / 380-480 V

10.0A / 380-480 V

13.0A / 380-480 V

16.0A / 380-480 V

24.0A / 380-480 V

30.0A / 380-480 V

GroundingWiring

N.m Lbf.in

0.5 4.34

0.5 4.34

0.5 4.34

0.5 4.34

0.5 4.34

0.5 4.34

0.5 4.34

0.5 4.34

0.5 4.34

0.5 4.34

0.5 4.34

0.5 4.34

0.5 4.34

0.5 4.34

0.5 4.34

0.5 4.34

0.5 4.34

0.5 4.34

0.5 4.34

0.5 4.34

0.5 4.34

0.5 4.34

Power Cables

N.m Lbf.in

1.0 8.68

1.0 8.68

1.0 8.68

1.0 8.68

1.76 15.62

1.76 15.62

1.76 15.62

1.76 15.62

1.76 15.62

1.76 15.62

1.2 10.0

1.2 10.0

1.2 10.0

1.76 15.62

1.2 10.0

1.76 15.62

1.76 15.62

1.76 15.62

1.76 15.62

1.76 15.62

1.76 15.62

1.76 15.62

Table 3.5 - Recommendedtighteningtorque for powerand grounding connections

3.2.4 PowerConnections

a) 1.6-2.6-4.0-7.0A/200-240V and 1.0-1.6-2.6-4.0A/380-480V models - Threephase powersupply

TypeofScrewdriverfor

thePowerTerminal

Philips Number PH2

Philips Number PH2

Philips Number PH2

Philips Number PH2

Philips Number PH2

Philips Number PH2

Philips Number PH2

PhilipsNumber PH2

PozidrivNumberPZ2

PozidrivNumber PZ2

PhilipsNumber PH2

Philips Number PH2

Philips Number PH2

Philips Number PH2

Philips Number PH2

Philips Number PH2

Philips Number PH2

Philips Number PH2

Philips Number PH2

Philips Number PH2

PozidrivNumber PZ2

PozidrivNumber PZ2

Figure 3.6 a) - Power and groundingconnections

PE

R

S

T

PowerSupply CircuitBreaker

PE

T

Q1

R S

T

U V W

PE

Shielding

PE W

V

U

Page 37

37

CHAPTER 3 - INSTALLATION AND CONNECTION

c) 1.6-2.6-4.0-7.3-10A / 200-240 V models - Single phase power supply

Figure 3.6 b) and c) - Powerand grounding connections

(*) Incase of single-phase power supplywith phase and neutral cable, connect onlythe phase cable to the

circuit breaker.

(**) In the 1.6 A -2.6A and 4.0 A models, the terminals to connect the braking resistor are not available.

PE

PE

T

Q1

R S

T U V W

PE

Shielding

PE

-Ud BR

+Ud

Braking

Resistor

(**)

W V U

Phase

Neutral

PowerSupply

Circuit Breaker

(*)

b) 7.3-10-16-22A/200-240V and 2.7-4.3-6.5-10-13-16A/380-480V models - Three phasepower supply

PE

R

S

T

PowerSupply

PE

T

Q1

R S

T U V W

PE

Shielding

PE

-Ud BR

+Ud

Braking

Resistor

W V U

CircuitBreaker

Page 38

38

CHAPTER 3 - INSTALLATION AND CONNECTION

Figure 3.6 d) - Power and groundingconnections

d) 28-33A / 200-240V and 24-30 A/ 380-480 V models - Three phase power supply

DANGER!

Provide an AC disconnecting switch to switch OFF the input

powertotheinverter.Thisdeviceshalldisconnecttheinverter

from the AC input supply when required (e. g. during

maintenanceservices).

ATTENTION!

Acontactororanotherdevicethatfrequentlydisconnectsand

reapplies the AC supply to the inverter in order to start and

stop the motor may cause damage to the inverter power

section.The driveis designedto usecontrolinput signals for

startingandstoppingthemotor.If used,the inputdevicemust

not exceed one operation every 6 minutes otherwise the

invertermay be damaged.

ATTENTION!

TheAC input for the inverter must have a grounded neutral

conductor.

NOTE!

TheACinputmustbecompatiblewiththeinverterratedvoltage

Power supply line capacity:

30kArms symmetrical amperes, 200-480 Vacmaximum,

whenprotected by fusesratedmaximum of 200 % device

inputcurrent.Voltageisthesameasthedevice maximum

inputvoltage. Inorderto comply withtheULstandard,UL

recognizedfuses must be used.

3.2.4.1 ACInputConnection

PE

T

Q1

R S

T

U

V

W

PE

Shielding

PE

-Ud BR

+Ud

Braking Resistor

W V U

Phase

PowerSupply

DCR

DCLink

Inductor

(Optional)

PE

R

S

T

CircuitBreaker

Page 39

39

CHAPTER 3 - INSTALLATION AND CONNECTION

3.2.4.3 Grounding

Connections

IftheCFW-08isinstalledinnetworkswhichcansupplymore

than 30.000 Arms, you must provide suitable protection

circuitssuchas fuses and circuitbreakers.

DC link inductor / line reactors

Therequirementsforuseof line reactorsor DC linkinductor

dependonseveral applicationfactors.Refer to item 8.21.

NOTE!

Capacitorsfor power factor correctionarenotrequiredatthe

input(L/L1,N/L2,L3orR,S,T)andtheymustnotbeconnected

atthe output(U,V,W).

The inverter is provided with electronic protection against

motoroverload.This protection must be setaccording to the

specificmotor.Whenthesameinverterdrivesseveralmotors,

use individual overload relays for each motor. Maintain the

electricalcontinuityof the motor cableshield.

ATTENTION!

If a disconnect switch or a contactor is inserted in the motor

supplyline, do not operate them with motor running or when

inverter is enabled. Maintain the electrical continuity of the

motorcable shield.

Dynamic braking (DB)

When inverters with dynamic braking(DB) are used, the DB

resistor shall be mounted externally. Size it according to the

application,notexceedingthemaximumcurrentofthebraking

circuit. For the connection between inverter and the braking

resistor, use twisted cable. Provide physical separation

betweenthis cable and thesignal and control cables. When

the DB resistor is mounted inside the panel, consider watt

lossgeneratedwhendefiningthe panel ventilation.

DANGER!

Theinverter must be grounded to aprotectiveearth (PE)for

safetypurposes.

The earth or ground connection must comply with the local

regulations.Forgrounding,usecableswithcrosssectionsas

indicated in table 3.4. Make the ground connection to a

grounding bar or to the general grounding point (resistance

10 ohms).

DANGER!

Do not share the ground wiring with other equipment that

operateswithhighcurrents(forinstance:highvoltagemotors,

weldingmachines,etc).If severalinvertersareusedtogether,

refertofigure 3.7.

3.2.4.2 Output

Connections

Page 40

40

CHAPTER 3 - INSTALLATION AND CONNECTION

ATTENTION!

TheAC input for the inverter must have a grounded neutral

conductor.

EMI – Electromagnetic interference

When electromagnetic interference (EMI) generated by the

inverterinterferesin theperformanceofotherequipment,use

shieldedwires,orinstallthemotorwiresin metallicconduits.

Connect one end of the shielding to the inverter grounding

pointandtheotherendtothemotorframe.

Motor frame

Alwaysgroundthemotorframe.Groundthemotorinthepanel

wherethe inverterisinstalledorgroundittotheinverter.The

inverter output wiring must be laid separatelyfrom the input

wiringas wellasfrom the control and signalcables.

NOTE!

Donotuseneutralconductorfor groundingpurposes.

Figure 3.7 - Grounding connections for more than one inverter

GROUNDING BAR

INTERNAL TO THE PANEL

Page 41

41

CHAPTER 3 - INSTALLATION AND CONNECTION

3.2.5 Signaland Control

Connections

The signal connections(analog inputs/outputs) and control

connections (digital inputs and relay outputs) are made on

the XC1 connector of control board (referto the location in

figure 3.5, item3.2.2).

There are two configurations for the control board: standard

version (CFW-08 line)andPlusversion(CFW-08Plusline),

asshownbelow:

Figure 3.8 - XC1 control terminal description (standard control board - CFW-08)

Note: NC = NormallyClosed Contact, NO = NormallyOpen Contact.

XC1Terminal

1 DI1

2 DI2

3 DI3

4 DI4

5 GND

6

AI1or

DI5or

PTC1

7 +10 V

8 GND

9

10 N.C.

11 Commom

12 N.O.

Description

FactoryDefault Function

Digital Input 1

GeneralEnable

Digital Input 2

FWD / REV

Digital Input 3

Reset

Digital Input 4

Start/Stop

0V Reference

Analog Input 1 or Digital Input 5

orPTC Input

Frequency/ SpeedReference

(remotemode)

PotentiometerReference

0V Reference

NotUsed

Relay Output 1 - N.C. Contact

No Fault (P277 = 7)

Relay1 Common Point

Relay 1 - N.O. Contact

No Fault (P277 = 7)

Specifications

4 isolates digital inputs

- Logic NPN

Minimum high level: 10 Vdc

Maximum high level: 30 Vdc

Maximum low level: 3 Vdc

- Logic PNP

Maximum low level: 10 Vdc

Minimum high level: 21.5 Vdc

Maximum high level: 30 Vdc

Inputcurrent: -11mA

Maximum input current: -20 mA

Not connected to PE

( 0 to10) Vdc (0 to 20) mA (4 to 20)

mA(figure3.10)

Impedance:100 k (voltage input)

and 500 (current input).

- Linearity error < 0,25 %

- Maximum voltage input: 30 Vdc

ForfurtherinformationrefertoP235

detailedparameterdescription

+10 Vdc, ± 5 %, capacity: 2 mA

Contact capacity:

0.5 A / 250 Vac

Relay 1

10 12

11

CCW

CW

5k

FactoryDefault

Settings

Page 42

42

CHAPTER 3 - INSTALLATION AND CONNECTION

Figure 3.9 - Description of the XC1 connector for the control board A1 (CFW-08 Plus), control board A2

(CFW-08 Plus with AIs -10 V to +10 V), control board A3 (CFW-08 Plus with CANopen protocol) and control

boardA4 (CFW-08 Plus with DeviceNet protocol)

Connector

XC1

1 DI1

2 DI2

3 DI3

4 DI4

5 GND

6 AI1or

DI5or

PTC1

7 +10 V

8 AI2or

DI6or

PTC2

9 AO

10 N.C

11 Commom

12 N.O.

Description

FactoryDefault Function

Digital Input 1

NoFunctionorGeneralEnable

Digital Input 2

FWD / REV

Digital Input 3

Reset

Digital Input 4

No Function or Start/Stop

0V Reference

AnalogInput1orDigitalInput5

orPTC1 Input

Frequency/SpeedReference

(remotemode)

PotentiometerReference

Analog Input 2 or Digital Input

Digital 6 or PTC2 Input

NotUsed

AnalogOutput

Output Frequency (Fs)

Relay 2 - N.C. Contact

Fs>Fx (P279 = 0)

RelaysCommon Points

Relay 1 - N.O. Contact

No Fault (P277 = 7)

Specifications

4 isolates digital inputs

- Logic NPN

Minimum high level: 10 Vdc

Maximum high level: 30 Vdc

Maximum low level: 3 Vdc

- Logic PNP

Maximum low level: 10 Vdc

Minimum high level: 21.5 Vdc

Maximum high level: 30 Vdc

Inputcurrent: -11mA

Maximum input current: -20 mA

Not connected to PE

(0to10)Vdcor(0to20)mAor(4to20)mA

and (-10 to +10) Vdc

(*)

(figure 3.10)

Impedance:100k (voltage input) and

500(currentinput)

- Linearity error < 0,25 %

- Maximum voltage input: 30 Vdc

For further information refer to P235

detailedparameterdescription

+10 Vdc, ± 5 %, capacity: 2 mA

(0to10)Vdc or (0 to 20) mA or(4 to

20)mA and (-10 to +10) Vdc

(*)

(figure

3.10) Impedance:100 k (voltage

input) and 500 (currentinput)

- Linearity error< 0.25%

- Maximumvoltage input: 30 Vdc

Forfurtherinformationrefer toP239

detailedparameterdescription

(0to10)Vdcor(0to20)mAor(4to20)mA,

RL 10k Resolution: 8 bits

Linearity Error < 0.25 %

Contact capacity:

0.5 A / 250 Vac

Relay 1

11

Relay 2

12 10

RPM

-

+

CCW

CW

CCW

CW

10k

Note: NC = NormallyClosed Contact, NO = NormallyOpen Contact.

(*)

Thisoption is availableonly for versionA2of thecontrol board (refertoitem 2.4).

In version A2 the linearity error is smaller than 0.50 %.

10k

FactoryDefault

Settings

Refer to item 2.4for additional information onthecontrol boards.

Page 43

43

CHAPTER 3 - INSTALLATION AND CONNECTION

AI1AODI AI2

Figure3.10 - Jumperspositionfor selectingthe analoginputs andoutputs operation mode(voltage- 0 to 10 Vdc

or current - 0 to 20 mA / 4 to 20 mA) as well as the digitalinputs operation mode(highlogic level - PNP or low

logic level - NPN). Refer to the digital inputs definition on items 3.2.5.1 and 3.2.5.2

I/O

DI1to DI4

AO

AI1

AI2

FactoryDefault Setting

Refer to the parameters P263,

P264, P265 andP266

OutputFrequency

Frequency/ SpeedReference

(remotemode)

NoFunction

DIP

Switch

S1:1

S1:2

S1:3

S1:4

Selection

OFF: digital inputs as low active (NPN)

ON: digital inputs as high active (PNP)

ON: (0 to 10) Vdc

OFF: (4 to 20) mA or (0 to 20) mA

OFF: (0 to 10) Vdc or DI5

ON: (4 to 20) mA or (0 to 20) mA or PTC

OFF: (0 to 10) Vdc or DI6

ON: (4 to 20) mA or (0 to 20) mA or PTC

Table 3.6 - Dip switch configuration (inputs and outputs)

Asadefault,theanalog inputs and outputsaresettovoltage

mode (0 to 10) Vdc and the digital inputs are set to active

(NPNlogic).Changeitbyusing DIP switchS1 (refer to figure

3.10) on the control board and by setting parameters P235,

P239 and P253 (refer to table 3.6).

NOTE!

If it'suseda(4to20)mA signal,setparameterP235,P239

and P253 that defines the signal type atAI1,AI2 and AO

respectively.

The parameters related to the analog inputs are: P221,

P222,P234,P235,P236,P238,P239,P240,P251,P252,

P253.

Page 44

44

CHAPTER 3 - INSTALLATION AND CONNECTION

Inverter side

Insulatewith tape

Figure 3.11- Shield connection

Connect to earth: bolts are

located on the heatsink

Donot ground

During the signal and control wire installation note the

following:

1) Cable cross section: (0.5to 1.5) mm²/(20 to 14)AWG

2)MaximumTorque:0.50N.m(4.50lbf.in).

3) XC1 wiring must be connected with shielded cables and

installedat least 10 cm (3.9in) minimum separatelyfrom

otherwiring (power,control at 110/220V, etc) for lengths

up to 100 m (330 ft) and 25 cm (9.8 in) minimum for total

lengthsover100 m(330ft). Ifthecrossingof thesecables

isunavoidable, installthemperpendicular,maintaininga

mimimumseparationdistanceof 5cm(2in)atthecrossing

point.

Connectthe shield as shownbelow:

4) Forwiringdistances longerthan50m(150ft),itisnecessary

touse galvanic isolators for the XC1:5 to 9 signals.

5) Relays, contactors, solenoids or eletromagnetic braking

coilsinstalledneartheinverterscangenerateinterferences

inthecontrolcircuit.Toeliminatethisinterference,connect

RC suppressor in parallel with the coils of AC relays.

Connectfree-wheeling diode incase of DC relays.

6) When external keypad (HMI) is used, separete the cable

thatconnectsthekeypad to the inverter fromothercables,

maintaining aminimumdistanceof10cm(3.9 in)between

them.

7) When analog reference (AI1 or AI2) is used and the

frequency oscillates (problem caused by eletromagnetic

interference)connectXC1:5totheinverterheatsink.

Page 45

45

CHAPTER 3 - INSTALLATION AND CONNECTION

3.2.5.1 DigitalInputsas

LowLevelActive

(S1:1 to OFF)

Connector XC1

1 DI1

2 DI2

3 DI3

4 DI4

5 GND

b) Example using a PLC - NPN transistor output

Connector XC1

1 DI1

2 DI2

3 DI3

4 DI4

5 GND

Figure 3.12 a) and b) - Digital inputs

as low logic level configuration

PLC output relay

COM

PLCoutput NPN

GND(PLC)

In these options, the equivalent circuit at inverter side is

presentedin thefigure3.13.

Thisoptioncan be selected whena PLC is used with relay or

transistoroutputis used(lowlogiclevel toactivatetheDI).

a) Example using a PLC - relay output

Figure 3.13 - Equivalent circuit – Digital inputs as low logic level

XC1:1

XC1:2

DI2

DI1

1

2

2k

2k

10 V

10 V

SMD

Optocoupler

SMD

Optocoupler

+12 V

S1:1 in OFF

GND

Page 46

46

CHAPTER 3 - INSTALLATION AND CONNECTION

This option can be selected when a PLC is used with PNP

transistor output (high logic level to activate the DI) or PLC

with relay output is used. For this last alternative you must

applyan externalpowersupply24V +/- 10 %.

3.2.5.2 DigitalInputas

HighLevelActive

(S1:1to ON)

Figure 3.14 a) and b) - Configuration of the active digital inputs as

high logic level

In this option, the equivalent circuit at the inverter side is

presentedin thefigure3.15.

b) Example using a PLC - PNP transistor output

a) Example using a PLC - relay output

Connector XC1

1 DI1

2 DI2

3 DI3

4 DI4

5 GND

24 V (internal PLC)

PLCoutput

PNP

GND(PLC)

PLC output relay

GND(source

external24 V)

24 V (external)

Connector XC1

1 DI1

2 DI2

3 DI3

4 DI4

5 GND

Figure 3.15 - Equivalent circuit - Digital inputs as high logic level

XC1:1

XC1:2

DI2

DI1

1

2

2k

10 V

10 V

SMD

Optocoupler

SMD

Optocoupler

+12 V

S1:1 in ON

2k

GND

Page 47

47

CHAPTER 3 - INSTALLATION AND CONNECTION

DI1 - No Function or

GeneralEnabling

DI2 - FWD / REV

DI3- Reset

COM

AI1

+10 V

AI2

AO1

NC

Common

NO

DI4- No Function

or Start/Stop

S1: FWD/REV

S2: Reset

S3: Start/Stop

R1:Potentiometerfor

speed setting

1 2 3 4 5 6 7 8 9 10 11 12

NOTES!

Theinverteris factorydefaultprogrammed withthe digital

inputs as lowlevel active (S1:1 in OFF). When the digital

inputsareusedashighlevelactive,youmustsetthejumper

S1:1to ON.

The jumper S1:1 selects the high level or low level active

forall 4 digital inputs.Youcan not select them separately.

3.2.6 TypicalTerminal

Connections

Connection 1 - Keypad Start/Stop (local mode)

With the factory default programming, you can operate the

inverterinlocalmodewiththeminimumconnectionsshownin

figure 3.6 (Power) and without control connections. This

operationmodeis recommendedforuserswhoareoperating

the inverter for the first time. Note that there is no need of

connectionofcontrolterminals.

Forstart-up accordingtothisoperationmode,refertochapter5.

Connection 2 - Wire Start/Stop (remote mode)

Valid forfactorydefault programming and inverter operating

in remote mode. For the factory default programming, the

selection of the operation mode (local/remote) is made via

thekey (defaultis local).

Thefigure3.16showstheinverterterminal connectionforthis

typeof driving.

Figure 3.16 - XC1 wiring for connection 2

R1

S3

S2

S1

5k

Page 48

48

CHAPTER 3 - INSTALLATION AND CONNECTION

NOTES!

Fortheproperoperationofconfiguration2,terminal5shall

beconnectedtoterminal 1 (generalenable).

Thefrequency reference canbe sent viaAI1 analog input

(as shown in figure 3.16), via keypad HMI-CFW08-P, or

viaanyothersource(asdescribedintheparametersP221

and P222).

When a line fault occurs by using this type of connection

withswitchS3atposition"RUN", themotorwillbeenabled

automaticallyas soon as the line isre-established.

Connection 3 - Wire ON/OFF

Functionenabling(threewirecontrol):

Set DI1 to ON: P263 = 14

Set DI2 to OFF: P264 = 14

SetP229 = 1 (command via terminals)if youwantthe3-wire

controlin local mode.

SetP230 = 1 (command via terminals)if youwantthe3-wire

controlinremote mode.

Thefigure3.17belowshows theconnectionsatVFDterminals

forthis typeofconfiguration.

S1: Start

S2: Stop

S3: Changes the

speeddirection

Figure 3.17 - XC1 wiring for connection 3

DI1-ON (3-wire)

DI2- OFF(3-wire)

DI3

COM

AI1

+10 V

AI2

AO1

NC

Common

NO

DI4 - FWD / REV

S2

S1

1 2 3 4 5 6 7 8 9 10 11 12

S3

Page 49

49

CHAPTER 3 - INSTALLATION AND CONNECTION

NOTES!

S1and S2are push buttons, start (NO contact) and stop

(NCcontact),respectively.

The speed reference can be via analog input AI1 (as in

Connection2),viakeypad(HMI-CFW08-P),orviaanyother

source (as described in the parameters P221 and P222).

When a line fault occursbyusing this connection with the

motor running and the S1 and S2 switches are in original

position (S1 openned and S2 closed), at the moment the

voltagereturnstheinverterwillnotbeenabledautomatically,

itwillonlybeenabledif the S1 switchwereclosedagain (a

pulseattheStartdigitalinput).

Connection 4 - FWD/REV Function

Parameter to be programmed:

Set DI1 to Forward Run : P263 = 8

SetDI2 to Reverse Run: P264 =8

Make sure the inverter commands are via terminals, i.e.,

P229 = 1 to local mode or P230 = 1 to remote mode.

Thefigure3.18belowshowstheinverterterminalconnection

forthistypeof driving.

Figure 3.18 - XC1 wiring for connection 4

S1 open: Stop

S1 closed:Forward Run

S2 open: Stop

S2closed: ReverseRun

DI1-ForwardRun

DI2-ReverseRun

DI3- Reset

COM

AI1

+10 V

AI2

AO1

NC

Common

NO

DI4- No Function

S2

S1

1 2 3 4 5 6 7 8 9 10 11 12

NOTE!

For the correct operation of the connection 4, P266 must

be programmed as“Not Used”.

The speed reference can be via analog input AI1 (as in

connection2),viakeypad(HMI-CFW08-P),orviaanyother

source (refer to the description of parameters P221 and

P222).

When a line fault occurs,thisconnectionwithswitchS1 or

switchS2isclosed, themotorwillbeenabledautomatically

as soon as the line is re-established.

Page 50

50

CHAPTER 3 - INSTALLATION AND CONNECTION

3.3 EUROPEAN EMC

DIRECTIVEREQUIREMENTS

FORCONFORMING

INSTALLATIONS

TheCFW-08inverterserieswasdesignedconsideringsafety

andEMC(Electromagnetic Compatibility)aspects.

The CFW-08 units do not have an intrinsic function until

connectedwithother components(e.g.a motor).Therefore,

the basic product is not CE marked for compliance with the

EMC Directive. The end user takes personal responsibility

for the EMC compliance of the whole installation. However,