Page 1

EW 4800

UNIVERSAL CONTROLLERS

Temperature regulators and process controllers

code. 9IS44040

rel. 11/06 -GB-

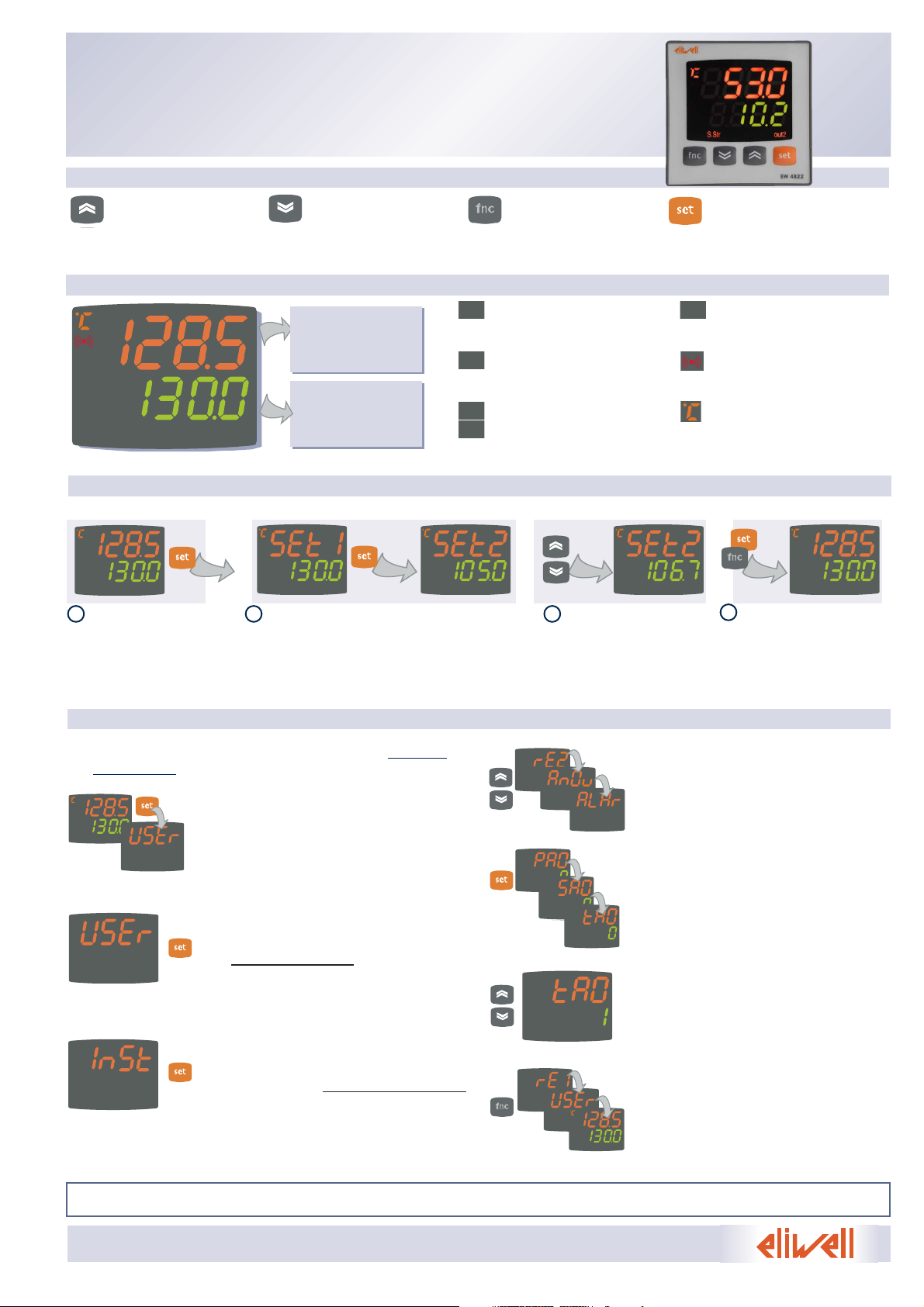

Keys

UP

Scrolls through menu items

Increases values

Programmable by parameter

(see par. H31)

DOWN

Scrolls through menu items

Decreases values

Programmable by parameter

(see par. H32)

fnc

Opens QuickStart menu

ESC (exit) function

set

Accesses the Setpoint

Opens the Programming Menu

Activates functions

Confirms commands

Display and Leds

out2out1Tun .

Tun

Flashes when Autotuning is active;

otherwise OFF;

S.Str

ON if the Soft Start function is active;

OFF in all other cases;

out1 - out2

ON when output active; otherwise OFF;

Flashes if there is a delay, a protec-

tion, or activation is blocked

aux

ON for output active;otherwise OFF

Alarm

ON if there is an alarm; otherwise

OFF; flashes if an alarm is switched off;

°C/°F

Indicates whether the temperature

display is in °C or °F;

Off for other units of measure

Set value (SV):

Used to display the

setpoints, parameter

values, function statuses,

other statuses.

Setting the Setpoint

out2out1Tun.

aux

S.Str

out2out1Tun.

aux

S.Str

out2out1Tun.

aux

S.Str

out2out1Tun.

aux

S.Str

out2out1Tun.

aux

S.Str

The following procedure is to be followed in order to set the 2 setpoint values in the device: SEt1 and SEt2

When the initial display

is present, press and release

the Set key.

The PV display shows label SEt1, and the SV

display shows the current Setpoint value. Press

the Set key again to display the Setpoint 2 in

the same way.

The UP and

DOWN keys can be used

to change the Setpoint

value shown on the SV

display.

When the Set or “fnc” key

is pressed, or the timeout has

elapsed (15 sec), the new

value appears and the initial

display returns

1

2 3

4

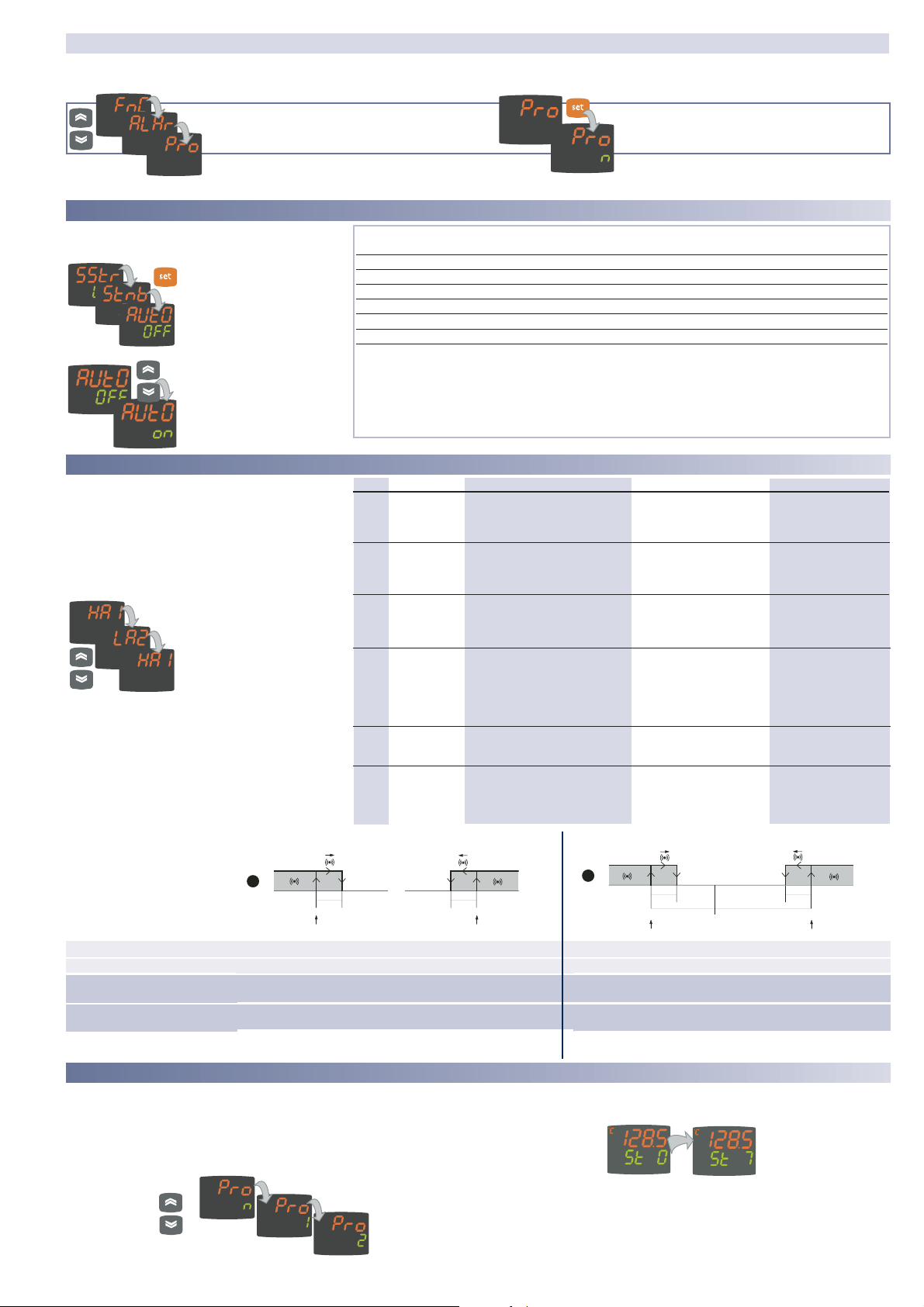

Programming menu

The programming menu contains all the parameters needed for setting the device functions, and is divided into two levels user level

and installer level:

• When the Set is pressed on the main

display for 3 seconds, the user can access the

Parameter Programming menu;

the USEr label appears, to indicate user

level of the menu.

User level access:

• Indicated by label USEr press and release

the Set key to open the folders containing

the user level parameters

Installer level access (InSt):

• Indicated by label UsEr the UP and DOWN

keys can be used to display the InSt label,

which indicates the access point of the folders containing the installer level parameters.

When InStis displayed, press and release the

Set key

How to change the parameter values (in both levels):

• Press the UP and DOWN keys to scroll

through all the user level folders and, on the

desired folder, press the Set key to access

the parameters in the folder (for example,

the ALAr folder).

• When the Set key is pressed on the ALAr

folder, the first parameter in the folder is

displayed, as follows:

- PV display: parameter label (PAO)

- SV display: current parameter value (0)

The Set key can be used to scroll through all

the parameters in the folder.

• To change the value of a displayed parameter, use the UP and DOWN keys. When

the parameter has been set to the desired

value, press “fnc”, or allow the 15 second

timeout to elapse, to save the new parameter setting.

• Now press and release the “fnc” key to return

to the previous display levels.

out2out1Tun.

aux

S.Str

out2out1Tun.

aux

S.Str

out2out1Tun.

aux

S.Str

out2out1Tun.

aux

S.Str

out2out1Tun.

aux

S.Str

out2out1Tun.

aux

S.Str

out2out1Tu

n.

aux

S.Str

out2out1Tu

n.

aux

S.Str

out2out1Tu

n.

aux

S.Str

out2out1Tun.

aux

S.Str

out2out1Tun.

aux

S.Str

out2out1Tun.

aux

S.Str

out2out1Tun.

aux

S.Str

out2out1Tun.

aux

S.Str

At any level of any of the menus, press the “fnc” key, or allow the 15 second timeout to elapse, in order to return to

the previous menu level. The last value shown on the display will then be stored in memory.

Process value (PV):

Used to display the

process value, and the

labels of parameters,

alarms and functions.

Tun.

S.Str

out1

out2

Aux

Page 2

EW4800

Label Alarm

E1 Probe 1

(regulation)

faulty

HA1 High

temperature

alarm

LA1 Low

temperature

alarm

EAL External

alarm

tOA Autotuning

timeout

nOC Autotuning

failure

Problem solving

• check the probe

wiring

• replace probe

• Wait for the temperature value read by the

probe to come back

below HA1/2-AFd

• Wait for the temperature value read by the

probe to come back

above LA1/2-AFd

• Stop the alarm manually

by pressing a key

• if H11=10, the regulators are activated

again only after the

digital input is disabled

• Press 'set' button to

restore the normal display

• Press 'set' button to

restore the normal display

EFFECTS

Label E1 shown on main display but not in the ALAr

folder;

Alarm created in the ALAr

folder through label

HA1/HA2

Alarm created in the ALAr

folder through label

LA1/LA2

Alarm Led lit continuously;

Alarm indicated in the

ALAr folder through label

EAL;

If H11=10, the regulators

are blocked.

Autotuning is blocked

Label tOA shown on SV display

Autotuning is blocked

Label nOC shown on SV

display

Cause

• measured values are outside the

nominal range

• regulating probe faulty/short-circuited/open

• value read by probe > HA1/2 after

time “tAO”. (see “ALARMS MIN MAX”

diagram and description of parameters

“HA1/2” and “Att” and “tAO”)

• value read by probe < LA1/2 after

time “tAO”. (see “ALARMS MIN MAX”

diagram and parameters “LA1/2” and

“Att” e “tAO”)

• alarm regulating with delay set

by parameter H14 from D.I. active

if H11=9 or 10 (see H11 and H14)

• Autotuning cycle aborted within

AtO time out

• Autotuning cycle failure before

time out

2/9

QuickStart Menu

In the main menu, the “fnc” key can be pressed to open the QuickStart menu and access the special functions, which are useful for setting

and managing the device, for example the Functions Folder and the Alarms Folder (if at least one alarm is present).

The following is a description of the menu structure and the functions in the individual folders:

After pressing the “fnc” key, the UP and

DOWN keys can be used to scroll through

the folders in the menu

When a label is selected, the Set key can be

pressed to access the corresponding folder.

out2out1Tun .

aux

S.Str

out2out1Tun .

aux

S.Str

out2out1Tun .

aux

S.Str

out2out1Tun .

aux

S.Str

out2out1Tun .

aux

S.Str

Alarms Folder*

On the ALAr label, press Set to access the alarms

folder.

This folder contains all the alarms managed by the

device.

If no alarms are present, the folder does not

appear in the menu.

If there are alarms present,

the UP and DOWN keys can

be used to scroll through and

display them

* Appears only if at least one alarm is present.

out2out1Tun .

aux

S.Str

out2out1Tun .

aux

S.Str

out2out1Tun .

aux

S.Str

Programs Folder

The unit can be used to program 2 different sequences, each with 8

steps; the individual steps can be set in the StEP folder in the parameter

setting menu. (see “STEP Folder” on page 3)

The Pro folder can be opened and the desired steps in the 2 possible

sequences (programs) can be set by pressing the Set key.

When the desired program has been set, it can be activated by selecting

the special StEP function in the Functions folder.

To indicate that a program is running, the display on the device shows SV

and the current step, from first (Step 0) to last (Step 7).

out2out1Tun .

aux

S.Str

out2out1Tun .

aux

S.Str

out2out1Tun .

aux

S.Str

out2out1Tun.

aux

S.Str

out2out1Tun.

aux

S.Str

Minimum temperature alarm

Maximum temperature alarm

Temperature less than or equal to LA1/2 (LA1/2 with sign)

Temperature less than or equal to set+LA1/2 (LA1/2 positive only)

Temperature greater than or equal to set+HA1/2 (HA1/2 positive only)

Temperature greater than or equal to HA1/2 (HA1/2 with sign)

Returning from maximum

temperature alarm

Returning from minimum

temperature alarm

Temperature greater than or equal to LA1/2+AFd Temperature greater than or equal to set + LA1/2 + AFd

set -|LA1/2|+AFd

Temperature less than or equal to set+HA1/2-AFd

Temperature less than or equal to HA1/2-AFd

Absolute temperature value (par “Att”=0) Abs(olute)

Temperature relative to Setpoint value (par “Att”=1) rEL(ative)

if Att=reL(ative) LA1/2 must be negative: therefore,

set+LA1/2<set since set+(-|LA1/2|)=set-|LA1/2|

MAX-MIN

ALARMS

On the FnC label, the Set key can be pressed to

access the functions.

The label will be displayed,

with the current status of the

function.

To scroll through the available

functions, use the Set key.

To change the status of a

function, use the UP and

DOWN keys.

Function Label Status of D.I. Key Indication

function default function active

Soft Start SStr ON 1 1 LED S.Str ON

Stand-by Stnb OFF 5 5 /

Autotuning* Auto OFF 7 7 LED Tun flashing

Start work cycles/sequences** StEP OFF 8 8 /

Reset work cycles/sequences*** rStS OFF - - /

Reset PID* rStP OFF - - /

Notes

* function visible if H01=2-3-7-8-9-10-11

** If pressed during a work cycle, the device goes into STOP status. In this status, the cycle time

must stop and be re-started by a START command.

*** Visible only if work cycles have been enabled. When pressed, the cycle is reset and the device

is brought into the STOP position.

Functions Folder

out2out1Tun .

aux

S.Str

out2out1Tun .

aux

S.Str

out2out1Tun .

aux

S.Str

out2out1Tun .

aux

S.Str

out2out1Tun .

aux

S.Str

1

AFd

LA1/HA2

AFd

HA1/HA2

2

AFd

SP1+ LA1/SP2 + LA2

Off

AFd

set

SP1+ HA1/SP2 + HA2

Page 3

EW 4800 3/9

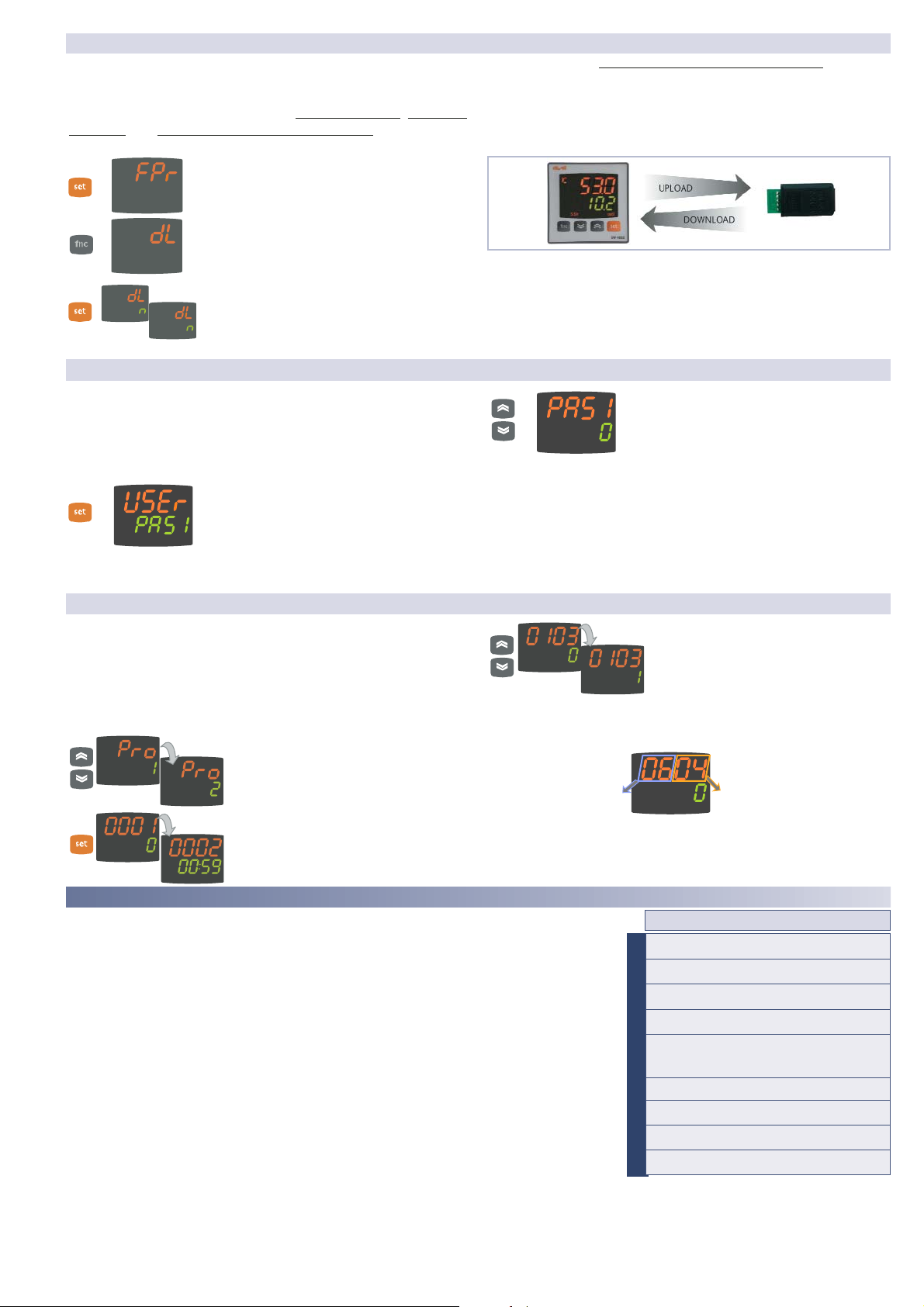

The Copy Card is an accessory which, when connected to the TTL

serial port, allows quick programming of the device parameters

(upload and download of a parameter map to or from one or

more devices of the same type). The upload (label UL), download

(label dL) and key formatting (label Fr) operations are performed

as follows:

• The FPr folder, located in the USEr level of the

programming menu, contains the commands

necessary for using the Copy Card. Press Set to

access the functions.

• Scroll with the UP and DOWN keys to find the

desired function. Press the Set key and the

desired function (upload, download or

formatting) will be carried out.

• If the operation is successful, the display

shows y; otherwise, it shows n.

Download reset: Connect the key with the device OFF. When

the device is switched on, the programming parameters are loaded into the device; After the lamp test, the display shows the

following for about 5 seconds:

• label dLY, if the operation is successful

• label DLn otherwise.

NOTES:

• after the reset download operation, the device will operate

with the settings in the map that has been newly loaded.

• see folder FPr, “Parameters” on page 4-5

• Connect Copy Card with "MEMORY MODULE" label upside”

Copy Card

Passwords can be set to limit the accesses to each parameter

management level. The two different passwords can be activated

by setting parameters PA1 and PA2 in folders “diSP” (PA1 at USEr

level and PA2 at InSt level). The password is enabled if the value

of parameter PA1/PA2 is different from 0.

• To access the “Programming” menu, hold

down the “set” key for more than 5 seconds”.

If it has been set, the PASSWORD will be

requested; press Set again.

• If activated (value different from 0), password PA1 must be entered. Carry out

this operation by selecting the correct value

using the UP and DOWN keys, then confirm by

pressing the Set key.

If the password entered is incorrect, the device displays label

PAS1 again and the operation must be repeated.

Password PAS2, for the InSt level, works in the same way as password PAS1.

Passwords

out2out1Tun.

aux

S.Str

out2out1Tun.

aux

S.Str

out2out1Tun.

aux

S.Str

out2out1Tun.

aux

S.Str

STEP Folder

Only Installer level (InSt) shows the StEP folder, which can be

used to store two working programs, each consisting of up to 8

steps; 9 parameters must be set for each step. The operations

for setting these parameters correctly are described below.

Press and release the Set key on the StEP folder label to access

the folder:

• Use the UP and DOWN keys to select

one of the two programs available, and

press Set on either 1 or 2.

• The first parameter (01), corresponding

to the first step (00) is then displayed;

use the Set key to scroll through the

parameters.

• To change the value of a parameter,

use the UP and DOWN keys.

Each label is made up of 4 digits, which indicate the step and the

number of the parameter it contains:

To exit from any level of the StEP folder, simply press the “fnc”

key, or allow the 15 second timeout to elapse.

out2out1Tun.

aux

S.Str

out2out1Tun.

aux

S.Str

out2out1Tun.

aux

S.Str

out2out1Tun.

aux

S.Str

Indicates the number of

the step (from 00 to 07)

Indicates the number of the

parameter (from 01 to 09)

out2out1Tun.

aux

S.Str

out2out1Tun.

aux

S.Str

StEP Folder Parameters - Prog 1/2

0x01

0...99:59

0

hours/mins

0x02

0...99:59

00:59

hours/mins

0x03

0...1

0

Flag

0x04

-328...2910 0

°C/°F

0x05

On1/On2/Ne/

Cyc/PH/PC/

PHC

On1

num

0x06

0...1 0

Flag

0x07

0...1

0

Flag

0x08

1...7

2

num

0x09

0...7

0

num

InSt

InSt

InSt

InSt

InSt

InSt

InSt

InSt

InSt

Parameter Description - Parameters Table

0x01 Step activation delay. Defines the delay at which the step is activated after starting.

If it is the first step in the program, it is activated by the “Start process” key

During the delay time, the working set is the one defined by Fine Step mode.

0x02 Step duration. Defines the length of time of the step: expressed in hours/minutes;

if set a - - - indicates that the step ends when a temperature is reached.

0x03 Length of time from start, or from when Setpoint is reached. Defines whether step duration is

to be calculated from when the step started (value 0), or from when the Setpoint (value 1) is

reached within the step.

0x04 Setpoint step. Defines the regulation set for the step.

0x05 Regulator active. Indicates which regulator is active in the step:

On1=on/off1; On2=on/off2; Ne=neutral zone; Cyc=cyclic;

PH=Pid heating; PC=Pid cooling; PHC=Pid heating/cooling;

0x06 Enable/disable Soft Start. Indicates whether the Soft Start function is enabled during the step.

0x07 AUX relay mode. Indicates a mode for the AUX relay, if configured, during the the step between

ON, OFF and Duty Cycle

0x08 Fine step mode. Indicates the way in which the step ends; any of the following can be selected:

1= end program; 2*=go to next step, maintaining the current setpoint;

3*=go to next step waiting for the new set point (unregulated);

4=go back to start of sequence; 5=go back to sequence No. xx; 6=infinite duration,

maintaining the setpoint

0x09 Go back to sequence No.xx. indicates the sequence number to go back to. This parameter has a

value only if parameter 0x08 is set to 5.

* NOTE: The values 2 and 3 are disabled only for parameter 0708, therefore the setting of values 2

and 3 is not possible for this parameter.

Par.

Range Default* U.M.

Level

aux

S.Str

out2out1Tun.

S.Str

aux

out2out1Tun.

S.Str

out2out1Tun.

aux

Page 4

EW 4800 4/9

PARAMETERS TABLE

Par.

Range Default* U.M. Level

Dynamic Parameter Folders

The two folders Pid and Aut are visible only if the device has been set

for PID regulation, i.e. if parameter H01 is equal to 2-3-7-8-9-10-11. These

folders can be navigated along with their subfolders, and there is a procedure for saving values when exiting from these subfolders. How to navigate inside the two Pid and Aut dynamic parameter folders is described

below:

Press the Set key on the Pid label the label

of the first subfolder PrH is displayed. Scroll

through the subfolders using the UP and

DOWN keys.

Press the Set key on the desired subfolder to

access the parameters. To scroll through the

parameters, use the Set key, and to change a

value, use the UP and DOWN keys.

When exiting the subfolders using the “fnc”

key, or after the 15 second timeout has

elapsed, the user will be asked whether to

save any changes that have been made.

Use the UP and DOWN keys to select y (save

changes) or n (not to save changes), then

press Set to exit the folder.

out2out1Tun .

aux

S.Str

out2out1Tun .

aux

S.Str

out2out1Tun .

aux

S.Str

out2out1Tun .

aux

S.Str

out2out1Tun .

aux

S.Str

out2out1Tun .

aux

S.Str

out2out1Tun .

aux

S.Str

out2out1Tun .

aux

S.Str

out2out1Tun .

aux

S.Str

label Alar

label AUtO(1)

Pid

Reg. PID - Pid (1)

Regulator 2 - label rE2

Regulator 1 - label rE1

OS1

-30.0...30.0

0

°C/°F

OS2

-30.0...30.0

0

°C/°F

label SFt

dSi

0...25

0

°C/°F

Std

0...255

0

ore/min/sec

unt

0...2

1

num

SEn

0...3

1

num

Sdi

0...30

0

°C/°F

cLc

Con

0...255

0

min

CoF

0...255

0

min

Att

AbS/rEL

AbS

flag

AFd

1...50

2

°C/°F

tun(2)

0...1

0

flag

AtO

1...100

10

ore

Adt

0...1

1

Flag

PrE

0...1

1

Flag

ASA

0...1

1

Flag

Autotuning - PA**

label diSP

SP1

LS1...HS1 0.0

°C/°F

db1

0.0...30.0

1.0

°C/°F

dF1

-30.0...30.0

-1.0

°C/°F

HS1

LS1...HdL 999.9

°C/°F

LS1

LdL...HS1

0.0

°C/°F

HA1

LA1...2910.0

LA1...9999(*)

999.9

300(*)

°C/°F

LA1

-328.0...HA1

-1999...HA1(*)

0.0

-50.0(*)

°C/°F

dn1

0...255

0

sec

do1

0...255

0

min

di1

0...255 0

min

dE1

0...255 0

sec

On1

0...255 0

min

OF1

0...255

1

min

db2

0.0...30.0

1.0

°C/°F

dF2

-30.0...30.0

-1.0

°C/°F

HS2

°C/°F

LS2

°C/°F

HA2

°C/°F

LA2

°C/°F

dn2

0...255

0

sec

do2

0...255

0

min

di2

0...255 0

min

dE2

0...255 0

sec

On2

0...255 0

min

OF2

0...255

1

min

SP2

LS2...HS2 0.0

°C/°F

bP

0.1...999.9

50.0

°C/°F

ti

0...9999

600

sec

td

0...9999

150

sec

Pid Heating - PrH**

bP

0.1...999.9

50.0

°C/°F

ti

0...9999

600

sec

td

0...9999 150

sec

Pid Cooling - PrC***

Fun

P/Pi/Pd/Pid Pid

num

APL

0...100

1

°C/°F

Autotuning Heating - PAH**

label Add

PAO

0...10

0

ore

SAO

0...24

0

ore

tAO

0...255

0

min

PSt

t/d

t

flag

dEA

0...14

0

num

FAA

0...14

0

num

PtY

n/E/o

E

num

StP

1b/2b

1b

flag

label CnF

LOC

n/y

n

Flag

PA1

0...999

0

num

H00

ntc/Ptc/pt10/

tcJ/tcH/tcS/

tcr/tct/Pt1

420/020/t01/

t05/t10/Pt1(*)

Pt1

Pt1(*)

flag

run

dut

Regolatore PID - Pr

0...1

1

Flag

-100...100 0

%

Autotuning Cooling - PAC***

Fun

P/Pi/Pd/Pid Pid

num

APL

0...100

1

°C/°F

label AnOu(2) ****

AOL

020/420/001/

005/010

020

num

AOF

rO/Er/cPH/

cPc/diS

rO

num

AOS

Aon/AoF

AoF

Flag

LAO

LdL...HdL

0

num

HAO

LdL..HdL 100.0

num

STEP(3)

Pro 1 parametri programma 1

Pro 2 parametri programma 2

PA2

0...999

0

num

ndt

n/y

0...3(*)

y

1(*)

Flag

num(*)

CA1

-30...30

0

°C/°F

CAi

0...2

2

num

LdL

-328...HdL

-1999...HdL(*)

0.0

°C/°F

HdL

LdL...2910.0

LdL...9999(*)

999.9

8000(*)

°C/°F

dro

0...1

0...16(*)

0

Flag

H01

0...11

4

num

H02

0...15

5

sec

InSt

USEr/InSt

USEr/InSt

USEr/InSt

USEr/InSt

USEr/InSt

USEr/InSt

InSt

InSt

InSt

InSt

InSt

InSt

USEr/InSt

USEr/InSt

USEr/InSt

InSt

InSt

InSt

USEr/InSt

USEr/InSt

USEr/InSt

USEr/InSt

USEr/InSt

USEr/InSt

InSt

InSt

InSt

InSt

InSt

InSt

USEr/InSt

USEr/InSt

USEr/InSt

USEr/InSt

USEr/InSt

InSt

InSt

InSt

InSt

InSt

InSt

InSt

biAt

0...100 50

num

APr

0...100

50

num

AHr

0.0...100.0

0.3

°C/°F

InSt

InSt

InSt

biAt

0...100 50

num

APr

0...100

50

num

AHr

0.0...100.0

0.3

°C/°F

InSt

InSt

InSt

USEr/InSt

USEr/InSt

USEr/InSt

USEr/InSt

USEr/InSt

InSt

InSt

InSt

InSt

InSt

InSt

InSt

InSt

InSt

InSt

InSt

USEr/InSt

USEr/InSt

USEr/InSt

AOP

nC/nO

nC

Flag

InSt

InSt

InSt

InSt

InSt

InSt

InSt

InSt

InSt

InSt

InSt

USEr/InSt

USEr/InSt

USEr/InSt

USEr/InSt

USEr/InSt

USEr/InSt

InSt

NOTES:

(1) Folder visible if H01= 2-3-7-8-9-10-11.

(2) Folder present only in models equipped with an analog output

(3) see paragraph ”STEP Folder” on page 3

(4) These parameters are visible only in models equipped with a digi-

tal input

** These subfolders are visible only if H01=2-7-8-10

*** These subfolders are visible only if H01=3-7-9-11

**** Folder AnOu is visible in models equipped with an analog output

biA

-100...100 0

num

tt

0...9999

300

sec

c

0...100

0

num

SLO

0...100

0

num

SHI

0...100

100

num

PEd

20...1310

20

sec

InSt

USEr/InSt

InSt

InSt

InSt

USEr/InSt

biA

-100...100 0

num

tt

0...9999

300

sec

c

0...100

0

num

SLO

0...100

0

num

SHI

InSt

USEr/InSt

InSt

InSt

LS2...HdL 999.9

LdL...HS2

0.0

LA2...2910.0

LA2...9999(*)

999.9

300(*)

-328.0...HA2

-1999...HA2(*)

0.0

-50.0(*)

H03(*)

-1999...9999

20

num

USEr/InSt

H04(*)

USEr/InSt

label FPr

UL

/

/

/

dL

/

/

/

Fr

/

/

/

H06

n/y

y

flag

H08

0...2

2

num

H10

0...255

0

num

H11(4)

0...10

0

num

H13(4)

0...3

0

num

H14(4)

0...255

0

min

H21

no/nc/noP/ncP noP

num

H22

0...4

0

num

H25

0...1

0

num

H31

0...8

0

num

H32

0...8

0

num

InSt

InSt

USEr/InSt

InSt

InSt

InSt

InSt

InSt

InSt

InSt

InSt

USEr/InSt

USEr/InSt

USEr/InSt

rEL

/

/

num

tAb

/

/

num

USEr/InSt

USEr/InSt

0...100

num InSt

PEd

20...1310

20

sec USEr/InSt

100

-1999...9999

100

num

(*) Range and default values for versions with V/I/Pt100 analogue input

Page 5

EW 4800

5/9

SP1/SP2 Setpoint 1/2 Control Setpoint

REGULATOR 1/2 (folder with label “rE1”/”rE2”)

OS1/OS2 Offset Setpoint 1/2. Temperature value to be added arithmetically to

the Setpoint if a reduced set is enabled; it cannot have a 0 value.

db1/db2 Response band above Setpoint 1/2

dF1/dF2 Setpoint 1/2 differential band. With negative sign

Hot operation; with positive sign, Cold operation.

If dF1=0 goes back above SP1/2, dF1=db1

HS1/HS2 Maximum value that can be assigned to setpoint 1/2.

LS1/LS2 Minimum value that can be assigned to setpoint 1/2.

HA1/HA2 Maximum temperature alarm. Temperature limit (the relative or

absolute status of this value is controlled by “Att”, present in the

installer menu, folder ALAr), beyond which the alarm is activated.

LA1/LA2 Minimum temperature alarm. Temperature limit (the relative or abso

lute status of this value is controlled by “Att”, present in the installer

menu, folder ALAr) below which the alarm is activated.

dn1/dn2 Delay after which regulator 1/2 is started. The delay time indicated must

elapse between the request for activation of the regulator relay and switch-on.

do1/do2 Delay time after switching off. The delay time indicated must elapse

between deactivation of the regulator relay and the next switch-on.

di1/di2 Delay between switch-ons. The delay time indicated must elapse

between two consecutive switch-ons of the regulator.

dE1/dE2 Switch-off delay. The delay time indicated must elapse between the

request for deactivation of the regulator relay and switch-off.

NOTE: for parameters dn1/2, do1/2, di1/2, dE1/2, 0= not active

On1/On2 Switch-on time for regulator if probe faulty. If set to “1”

with Of1/2 at “0”, the regulator remains on continuously, and with

Of1/2 >0, it operates in Duty Cycle mode. See the Duty Cycle diagram.

OF1/OF2 Regulator switch-off time if probe faulty. If set to “1” with On1/2 at

“0”, the regulator remains off continuously, and with On1/2 >0 it

operates in Duty Cycle mode. See the Duty Cycle diagram.

PID REGULATOR (folder with label “Pid”)

(folder visible only if H01=2-3-7-8-9-10-11)

PID regulator, common parameters

heating/cooling (subfolder with label Pr)

run Manual or automatic mode selection:

0=manual; 1=automatic;

dut PID Duty Cycle in manual mode.

PID heating regulator (subfolder with label PrH)/

PID cooling regulator (subfolder with label PrC)

bp PID proportional band

ti Total PID time; OFF if =0

td derivative time

biA Static PID polarization

tt total time for antireset windup (OFF if =0)

n derivative component limiting

b proportional setpoint weighting

c derivative setpoint weighting

SLO minimum output saturation

SHi maximum output saturation

PEd period divided with Duty Cycle

AUTOTUNING (folder with label “AutO”)

(folder visible only if H01=2-3-7-8-9-10-11)

Autotuning, common parameters

heating/cooling (subfolder with label PA)

tun Hot/cold Autotuning selection; 0=hot, 1=cold;

IMPORTANT:parameter visible only if H01=7;

AtO Timeout for Autotuning

Adt Enable Autotuning of parameters

PrE Restore parameter default settings (pretuning)

0=no; 1=yes;

ASA Automatic saving of parameters after Autotuning

0=no; 1=yes;

Heating Autotuning (subfolder with label PAH)/

Cooling Autotuning (subfolder with label PAC)

Fun PID regulator selection:

P=Proportional; 1=Proportional/supplementary;

2=Proportional/derivative; 3=Prop./supplementary/derivative;

APL amplitude of oscillation in Autotuning

biAt relay polarization in Autotuning

APr relay amplitude in Autotuning

AHr relay hysteresis in Autotuning

CONFIGURATION OF ANALOG OUTPUT (folder with label “AnOu”)

AOL Analog output mode:

020=0...mA; 420=4...20mA; 001=0...10V;

005=0...5V; 010=0...10V;

AOF Analog output mode:

dis=output disabled;

ro=read out, output proportional to probe reading, within the

range set by parameters LAO and HAO

Er=error, output proportional to error between setpoint 1 and

the value read on the probe, within the error range specified by

the parameters LAO and HAO

cPH= PID Hot control variable, output proportional to the

percentage power output, if PID Hot is selected.

cPC= PID control variable, output proportional to the percentage

power output, if PID Cold is selected.

AOS Analog output mode if probe faulty:

Aon

=analog output ON; AoF=analog output OFF;

LAO Analog output minimum limit

HAO Analog output maximum limit

PROGRAM 1/2 PARAMETERS FOLDER

(folder with label “StEP”)

Program 1/2 parameters subfolder

Inside folder StEP there are 2 subfolders that contain the parameters

that make up the steps in each program. It is possible to set 2

different programs, each with 8 steps and each step made up of 9

parameters. see “STEP Folder” on page 3

SOFT START REGULATOR (folder with label “SFt”)

see “Soft Start”, page 7

dSi Soft Start regulator step value

Std Duration of step for Soft Start regulator (unit of measurement

defined by unt)

unt Unit of measurement for step duration (defines the unit of

measurement for Std): 0=hours; 1=minutes; 2=seconds;

SEn Regulator selection for Soft Start function. Determines the

regulator on which the Soft Start function is to be enabled.

0=disabled; 1=enabled on regulator 1;

2=enabled on regulator 2 3=enabled on regulators 1 and 2;

Sdi Automatic return band for Soft Start function

CYCLIC REGULATOR (folder with label “cLc”)

see “Cyclic Regulator”, page 7

Con ON time for cyclic regulator output

CoF Off time for cyclic regulator output

ALARM REGULATOR (folder with label “ALAr”)

Att Modes of parameters HA1/HA2 and LA1/LA2:

Abs=absolute; rEL=relative;

Afd Alarm differential

PAO Alarm exclusion time after the device is switched on, following a

power failure.

SAO Timeout for “set point not reached” alarm indication

tAO Time delay for temperature alarm indication.

AOP Alarm output polarity:

nc=normally closed; no=normally open;

COMMUNICATION (folder with label “Add”)

Pts Protocol selection: t=Televis; d=Modbus

dEA index of the device within the family (valid values from 0 to 14)

FAA device family (valid values from 0 to 14)

The pair of values FAA and dEA represents the network address of

the device and is indicated in the format “FF.DD”

(where FF=FAA and DD=dEA).

PtY Modbus parity bit: n=none; E=Even; o=odd;

StP Modbus stop bit: 1b=1 bit; 2b=2 bit;

DISPLAY (folder with label “diSP”)

LOC Keyboard lock (set and keys). It is still possible to go into

parameter programming and modify the parameters, including this

one, in order to allow keyboard unlocking. y = yes; n = no.

PA1 Password 1. When enabled (value other than 0), this is the access

key to the user level parameters (USEr).

PA2 Password 2. When enabled (value other than 0), this is the access

key to the installer level parameters (inSt).

ndt Format with decimal point. y = yes; n = no.

CA1 Calibration 1. Positive or negative temperature value added to the

value read from probe 1, according to the setting of parameter “CA”

CAi Calibration operation:

0=sum with displayed temperature only;

1=sum with only the temperature used by the regulators;

not for the display, which remains unchanged;

2=sum with the displayed temperature, which is also used by the

regulators;

LdL Minimum value that can be displayed by the device.

HdL Maximum value that can be displayed by the device.

dro Selection of °C or °F for displaying the temperature read from

the probe. 0 = °C, 1 = °F.

PLEASE NOTE: if °C is changed to °F or vice versa, the values

for setpoint, differential, etc., are not changed. (for example,

set=10°C becomes 10°F)

NOTE 2: Other engineering units can be set in the models with

V/I/Pt100 analogue input (0 =°C; 1 =°F; 2 =Bar; 3 =%RH; 4 =Pa;

5=Psi; 6=void) by means of management with TelevisCompact

DESCRIPTION OF PARAMETERS

Page 6

EW 4800 6/9

PID Regulator / Autotuning

The PID regulator is available as an alternative to the on/off regulator, if

greater control precision is required.

Enabling:

The PID regulator is enabled if:

• H01 = 2-3-7-8-9-10-11 (see Parameters, folder CnF)

This setting of parameter H01 enables display of the PId and Aut folders

in the parameter Programming Menu.

Parameter settings:

It is also necessary to set the run parameter. This parameter is used to

select the regulating mode: manual* (Duty Cycle) or automatic (PID). The

run parameter is therefore set to=1.

The device is now enabled for PID regulation; the PId folder is visible in

the Programming Menu, and the parameters in it can be modified in

order to improve regulating performance: these parameters can also be

modified in automatic mode using the Autotuning function.

* if manual regulation is selected (run=0), the activation percentage must be set dut

(see ‘Parameters’ on page 4). Then set the period divided with the Duty Cycle, using

the PEd parameter (see ‘Parameters on ages 4-5)

Autotuning

The setting of the PID regulation parameters can be simplified using the

Autotuning function, which can calculate the PID parameters automatically. Autotuning is activated through a dedicated function in the Functions

Folder (see QuickStart Menu on page 2), or by using a key if appropriately configured (see par. H31, H32 in ‘Parameters’ on page 5).

The Tun Led on the device flashes to indicate when Autotuning is in

progress.

Mode setting

If parameter H07 is set to 7 (PID hot-cold regulation), Autotuning must

be carried out twice: once for cold and once for hot.

In this mode, the tun parameter is also visible in the PA subfolder

contained in the Aut folder; this parameter is used to select the

Autotuning mode: hot (tun=0)/cold (tun=1).

To carry out autotuning in PID hot-cold mode (H01=7), therefore, proceed as follows:

- set H01=7

- set tun=0

- activate the Autotuning function in the Functions Folder

- wait for the Autotuning function to be performed

- set tun=1

- activate the Autotuning function in the Functions Folder

independent ON-OFF regulation plan. The two outputs

regulate as though they

were completely independent of each other

1

relative ON-OFF regulation

plan.

Setpoint SP2 regulates relative to SP1

2

ON-OFF regulation plan with

Neutral Zone (or window).

NOTE: if both dF1 and dF2 are

set to 0, the outputs are deactivated when SP1 is reached

3

dF1<0

hot

hot

-

NOTE: examples with dF1<0 ((hot) and dF2>0 (cold)

dF2>0

cold

cold

-

H01

4

5

6

regulation type

independent setpoints

relative setpoints

Neutral Zone (or window)

Regulator On/Off

The device has two ON/OFF type regulators that can be configured by the user through the H01 parameter:

• H01=4, 5 threshold regulator

• H01=5 regulator with window

CONFIGURATION PARAMETERS (folder with label “CnF”)

H00 Selection of probe type for models NTC/PTC/Pt100/Pt1000/TC:

ntC=Ntc; PtC=Ptc; Pt10=Pt1000; tcJ=tcJ; tcH=tCK;

tcS=tcS; tcr=tcr; tct=tct; Pt1=Pt100;

Selection of probe type for models V/I/Pt100:

420=4...20mA; 020=0...20mA; t01=0...1Vc;

t05=0...5Vc; t10=0...10Vc; Pt1=Pt100;

H01 Configuration of regulators:

H02 Activation time for keyboard functions. For the ESC, UP and DOWN

keys, which are configured with a second function, a time is set for

activation of the second function. One exception is the AUX

function, which has a fixed delay of 0.5 sec.

H03 Current/voltage input lower limit

(only for models V-I-Pt100, see parameter H00)

H04 Current/voltage input upper limit

(only for models V-I-Pt100, see parameter H00)

H06 Key or aux/light digital input active with the device OFF:

0=n=not active; 1=y=active;

H08 Stand By mode:

0= Only display switches off.

1= Display on, control devices and alarms off.

2= Display off, control devices and alarms off.

3= PV display with label OFF and control devices off.

H10 Delay for output activation after Power On; Minimum delay time for

connection of utilities in the event of restart after a power failure;

H11 Configurability and polarity of digital input:

0=disabled; 1=activate/deactivate Soft Start;

2=activate/deactivate OSP; 3=activate/deactivate cyclic regulator;

4=activate/deactivate Aux output; 5=activate/deactivate Stand-by;

6=call for maintenance; 7=activate/deactivate Autotuning;

8=activate/deactivate step control; 9=external alarm;

10=external alarm to lock controllers;

H13 Polarity and priority of digital inputs:

no=normally open; nc=normally closed;

noP=normally open with priority;

ncP=normally closed with priority;

H14 Activation delay for digital inputs;

H21* Configurability of digital output 1:

0=disabled; 1=alarm; 2=cyclic; 3=aux/light;

4=stand-by; 5=buzzer;

H22* Configurability of digital output 2: Same as H21

* see table of H01 parameter

H25 Buzzer enabling (only if buzzer present):

n=not enabled; y=enabled;

H31 Configurability of UP key:

0=disabled; 1=activates/deactivates soft start;

2=activates/deactivates OSP; 3=activates/deactivates cyclic regulator;

4=activates/deactivates aux output; 5=activates/deactivates stand-by;

6=request maintenance; 7=activates/deactivates autotuning;

8=activates/deactivates step control;

H32 Configurability of DOWN key: Same as H31

rEL Device version. read-only parameter.

tAb Reserved. Read-only parameter.

COPY CARD (folder with label “Fpr”)

see “Copy Card”, page 3

UL UpLoad: transfer parameters from device to CopyCard.

dL downLoad: transfer parameters from Copy Card to device.

Fr Format. Erase all data entered in the key.

H01 Description OUT1 OUT2

0 free H21 H22

1 ON/OFF H/C H22

2 PID Heating H H22

3 PID Cooling C H22

4 two independent ON/OFFs H/C H/C

5 two related ON/OFFs H/C H/C

6 neutral zone H/C H/C

7 PID Heating-Cooling H C

8 PID Heating-O/OFF H H/C

9 PID Cooling-ON/OFF C H/C

10 PID Heating-Alarm H Alarm

11 PID Cooling-Alarm C Alarm

Description of Regulators

dF1<0

On

SP1-dF1

dF1<0

On

OUTPUT 2

On

SP1-db2

SP1-dF1

dF1

dF1

dF2

SP1-db2+dF2

Off

H01=4

SP1

Off

H01=5

SP1

Off

SP1

Off

Off

SP2

SP1+SP2

SP1+db1-dF1

dF2

dF2

dF1

dF2>0

SP2+dF2

dF2>0

SP1+SP2+dF2

OUTPUT 1

SP1+db1

On

On

On

Page 7

The technical specifications in the document that relate to measurement (range, accura-

cy, resolution, etc.,) refer to the device in the strict sense, not to any of the accessories

supplied, for example probes. Consequently, any errors introduced by the probe must be

added to the characteristic error of the device

Front protection

Container

Dimensions

Mounting

Usage temperature

Storage temperature

Ambient humidity in use

and in storage

Display range

Analog input

Digital input

Serial

Analog outputs

Digital outputs (configurable)

- OUT1 output

- OUT2 output

- SSR control output*

Buzzer output

Accuracy

Resolution

Consumption

Power supply

IP65

PC+ABS plastic resin body PC+ABS UL94 V-0

front 48x48 mm, depth 113mm

and panel with 45x45mm drilling template

-5°C...55°C

-20°C...85°C

10...90% RH (non-condensing)

See Probes Table

1 input - set by parameter H00

1 digital input free of voltage

TTL for connection to Copy Card or TelevisSystem

Analog output V-I: 0-1V,0-5V,0-10V,0...20mA,4...20mA

(Configuration A only)

1 SPDT 3A 250 Va

1 SPST 2A 250 Va

Vout = 0...12Vc / Imax = 0...15mA / Vmin = 7,5V

only on models where provided

See probes Table

See probes Table

2,80W (12-24Va/12-36Vc model)

2,60W (95-240 Va model)

12-24Va ±10% / 12-36Vc ±10% / 95-240 Va ±10%

EW 4800 7/9

NOTE: The SOFT START function can be selected by key, by D.I. or

by a function.

The Soft Start regulator can be used to set the temperature gradient over

which a given setpoint is reached within a predefined time.

With this function, the regulation Setpoint is raised progressively and

automatically from value Ta (ambient temperature when switched on) to

the value actually set on the display; this allows the initial temperature

rise to be slowed down and thus reduce the risk of “overshoot”.

NOTE: The PERIODIC CYCLE function can be selected by key or by digital

input

This function can be associated with both the outputs by relay (by setting

parameters H21, H22 to 2), and can be used to actuate “Duty Cycle” regulation

with the intervals set by parameters Con and CoF.

Soft Start

Cyclic Regulator

The auxiliary regulator can be activated through the digital input if this is

set to auxiliary (parameter H11=4), or by a key (parameter H31 or H32=4):

in this case, the regulator control must be configured as Aux by setting

parameters H21(22) to 4.

This function is used to energize the relay if it was de-energized, or vice

versa. The relay state is stored in order to maintain correct operation in

the event of a power failure, unless parameter H11 is set to 4 (aux); in this

case, the relay reflects the state of the digital input.

Parameter H13 can also be used to set the priorities/polarities for activation by key or digital input.

NOTE: The significance of the Digital Input (D.I.) must remain the

same: for example, when activating the relay by D.I. and switching

off with a key, if the D.I. is repositioned, the relay does not change

state when de-energized by key

Auxiliary Regulator

TECHNICAL DATA EW4821 WIRING DIAGRAM

An error condition in the probe causes one of the

following actions:

• code E1 is shown on the display

• the regulator is activated as indicated by parameters On1/On2 and OF1/OF2 if set for Duty

Cycle

On1/On2

0

0

>0

>0

OF1/OF2

0

>0

0

>0

Compressor output

OFF

OFF

ON

dc

Outputs protection

Duty Cycle Diagram

parameters On1/On2, OF1/OF2 set for Duty Cycle

TECHNICAL DATA EW4820 WIRING DIAGRAM

Front protection

Container

Dimensions

Mounting

Usage temperature

Storage temperature

Ambient humidity in use

and in storage

Display range

Analog input

Serial

Digital outputs (configurable)

- output OUT1

- output OUT2

- SSR control output*

Buzzer output

Accuracy

Resolution

Consumption

Power supply

IP65

PC+ABS plastic resin body PC+ABS UL94 V-0

front 48x48 mm, depth 113mm

and panel with 45x45mm drilling template

-5°C...55°C

-20°C...85°C

10...90% RH (non-condensing)

See Probes Table

1 input selectable by parameter H00

TTL for connection to Copy Card or TelevisSystem

1 SPDT 3A 250 Va

1 SPST 2A 250 Va

Vout = 0...12Vc / Imax = 0...15mA / Vmin = 7,5V

only on models where this is provided

See Probes Table

See Probes Table

2,45W (12-24Va/12-36Vc model)

2,40W (95-240 Va model)

12-24Va ±10% / 12-36Vc ±10% / 95-240 Va ±10%

*optional output alternative to out1

*optional output alternative to out1

I

V

I

V

TERMINALS

1 - 3 -N.C. out1 relay output, see H21

-SSR control output 0/12Vc 15mA*

2 - 3 N.O. out1 relay output, see H21

6 - 7 N.O. out2 relay output, see H22

8-9-10 Probe input

4 - 5 Power supply

A TTL input for Copy Card and

Televis system

TERMINALS

1 - 3 -N.O. relay output out1,see H21

-SSR control output

0/12Vc 15mA*

2 - 3 N.O. relay output out1, see H21

6 - 7 N.O. relay output out2, see H22

8-9-10 Probe input

11-12 Digital Input D.I.

13-14-15 Analog Output V-I

4 - 5 Power supply

A TTL input for Copy Card and Televis System

SSR optional control

output 0/12Vc

SSR optional control

output 0/12Vc

OUT

On

Off

OFt

Ont Ont

EW4820

out2

SSR

6

7

8

9

10

+

1

Uscita 12Vc opzionale

2

per pilotaggio SSR

3

-

1

2

out1

3

4

Power

Supply

5

A

V (0...1/0...5/0...10V)

8

9

10

PTC/NTC/Pt1000

8

9

+

10

TC

8

9

10

Pt100

-

8

9

+

+12V

10

I (0...20/4...20mA)

-

8

+

9

10

EW4821

out2

SSR

6

7

8

9

10

1

2

3

11

D.I.

12

+

13

V

-

14

I

+

15

A

+

Uscita 12Vc opzionale

per pilotaggio SSR

-

1

2

out1

3

4

Power

Supply

5

V (0...1/0...5/0...10V)

8

9

10

PTC/NTC/Pt1000

8

9

+

10

TC

8

9

10

Pt100

-

8

9

+

+12V

10

I (0...20/4...20mA)

-

8

+

9

10

Page 8

EW 4800 8/9

TECHNICAL DATA EW4822 WIRING DIAGRAM

Front protection

Container

Dimensions

Mounting

Usage temperature

Storage temperature

Ambient humidity in use

and in storage

Display range

Analog input

Digital Input

Serial

Analog output*

Digital outputs (configurable)

- output OUT1

- output OUT2

- SSR control output**

Buzzer output

Accuracy

Resolution

Consumption

Power supply

* maximum loads controlled by the analog output:

output type maximum load

0-1 V 20mA with minimum load resistance 50 Ohm

0-5 V 20mA with minimum load resistance 250 Ohm

0-10 V 20mA with minimum load resistance 500 Ohm

0-20mA 350 Ohm

4-20mA 350 Ohm

IP65

PC+ABS plastic resin body PC+ABS UL94 V-0

front 48x48 mm, depth 113mm

and panel with drilling template 45x45mm

-5°C...55°C

-20°C...85°C

10...90% RH (non-condensing)

See Probes Table

1 input selectable by parameter H00

Configuration C: 1 digital input free of voltage

TTL for connection to Copy Card or TelevisSystem

and RS-485 serial port

Configuration A: Analog output I: 0-1V, 0-5V, 0-10V

Configuration B: Analog output V: 0...20mA, 4...20mA

1 SPDT 3A 250 Va

1 SPST 2A 250 Va

Vout = 0...12Vc / Imax = 0...15mA / Vmin = 7,5V

only on models where provided

See Probes Table

See Probes Table

2,80W (12-24Va/12-36Vc model)

2,60W (95-240 Va model)

12-24Va ±10% / 12-36Vc ±10% / 95-240 Va ±10%

IMPORTANT! CHECK THE AVAILABILITY OF THE MODELS AND RELATED ACCESSORIES DESCRIBED IN THIS DOCUMENT

Probe* Range Probe error limits Resolution Accuracy**

Ptc -55...150°C -60...155°C 0,1°C (0,1°F) 0.5% end of scale + 1 digit

Ntc -50...110°C -55...115°C 0,1°C (0,1°F) 0.5% at end of scale + 1 digit

Pt1000 -200...800°C -210...810°C 0,2°C 0.5% end of scale + 1 digit

TCj -40...760°C -50...770°C 0,6°C (0,6°F) 0.4% end of scale + 1 digit

TCk -40...1350°C -50...1360°C 0,6°C (0,7°F)

0.5% end of scale + 1 digit (over entire scale)

0.3% end of scale + 1 digit (-40...800°C)

TCS 0...1600°C -10...1610°C 0,6°C (0,8°F)

0.5% end of scale + 1 digit (over entire scale)

0.3% end of scale + 1 digit (-40...800°C)

TCR 0...1600°C -10...1610°C 0,6°C (0,7°F)

0.5% end of scale + 1 digit (over entire scale)

0.3% end of scale + 1 digit (-40...800°C)

TCT -40...350°C -50...360°C 0,6°C (0,7°F)

0.5% end of scale + 1 digit (over entire scale)

0.3% end of scale + 1 digit (-40...800°C)

Pt100 -200...800°C -210...810°C 0,1°C (0,2°F)

0.5% end of scale + 1 digit (over entire scale)

0.2% end of scale + 1 digit (-150...300°C)

V-I

(1)

0...1 V

0...5 V

0...10 V

0...20 mA

4...20 mA

-1...10 %

-0,20...10 %

-0,10...3 %

0,05...5 %

-6,25...6,25 %

1 digit if ndt=0

0,1 digit if ndt=1

0,01 digit if ndt=2

0,001 digit if ndt=3

0.5% end of scale + 1 digit

Probes Table

* Important! Check the probes and models available.

** NOTE: The accuracy values shown are valid for an ambient temperature of 25°C

(1) The maximum load present on the +12V feed of the sensor is 60mA

I

V

TERMINALS

1 - 3 N.O. relay output out1,see H21

-SSR control output 0/12Vc 15mA*

2 - 3 N.O. relay output out1, see H21

6 - 7 N.O. relay output out2, see H22

8-9-10 Probe input

4 - 5 Power supply

A TTL input for Copy Card and Televis System

Configuration A:

11-12-13 RS-485 serial port

14-15 Analogic output I

Configuration B:

11-12-13 RS-485 serial port

14-15 Analog output V

Configuration C:

11-12-13 RS-485 serial port

14-15 Digital Input D.I.

**optional output alternative to out1

SSR optional

control

output 0/12Vc

EW4822

A

-

out2

B

out2

C

out2

6

7

8

9

10

EW4822

6

7

8

9

10

EW4822

6

7

8

9

10

RS-485

11

12

13

14

15

11

12

13

14

15

11

12

13

14

15

+

GND

+

A

-

+

GND

+

A

+

GND

D.I.

A

-

-

-

I

RS-485

V

RS-485

1

2

out1

3

4

Power

Supply

5

1

2

out1

3

4

Power

Supply

5

1

2

out1

3

4

5

V (0...1/0...5/0...10V)

Power

Supply

8

9

10

PTC/NTC/Pt1000

8

9

+

10

TC

8

9

10

Pt100

-

8

9

+

+12V

10

I (0...20/4...20mA)

-

8

+

9

10

+

1

Uscita 12Vc

opzionale per

2

pilotaggio SSR

3

SSR

Page 9

EW 4800 9/9

DISCLAIMER

This document is the property of Eliwell alone and may not be reproduced or circulated unless expressly authorized by Eliwell Controls. All possible

care has been taken to ensure the accuracy of this document; Eliwell Controls cannot accept liability for any damage resulting from its use. The same

applies to any person or company involved in preparing and editing this document. Eliwell Controls reserves the right to make changes , whether stylistic or functional, at any time and without prior notice.

The device can be connected to Televis remote control systems

through a TTL serial port (use TTL- RS interface module 485 BUS

ADAPTER 130 or 150) or, in models where provided for (EW4822), by

means of direct RS485 connection. To configure the device for this

purpose, open the folder identified by the “Add” label and use parameters “dEA” and “FAA”.

TELEVIS SYSTEM

11/2006 GB

code. 9IS44040

CONDITIONS OF USE

PERMITTED USE

For safety reasons, the device must be installed and used according to the instructions provided. In particular, parts carrying dangerous voltages must not be accessible in normal conditions.

The device must be adequately protected from water and dust according to the application, and must also

only be accessible using tools (with the exception of the front panel).

The device is suitable for use in household refrigeration appliances and/or similar equipment and has been

tested for safety aspects in accordance with the harmonised European reference standards. It is classified as

follows:

• depending on construction, as a built-in automatic electronic control device;

• according to its automatic operating characteristics, as a type 1B control type device;

• according to its software class and structure, as a Class A device.

USES NOT PERMITTED

The device must not be used for applications other than those described.

Note that the relay contacts provided are of a functional type and therefore subject to malfunction: Any

protection devices required by product standards, or suggested by common sense, must be installed externally to the instrument for obvious safety reasons.

RESPONSIBILITY AND RESIDUAL RISKS

Eliwell Controls will not be liable for damage resulting from:

- installation/uses other than those specified and, in particular, which do not comply with the safety requirements set out in the regulations and/or stated herein;

- use on panels that do not provide adequate protection against electric shock, water or dust when assembled;

- use on panels that allow access to dangerous parts without having to use tools;

- tampering and/or modification of the product;

- installation/use on panels that do not comply with the current standards and regulations.

MECHANICAL ASSEMBLY

The device is designed for panel mounting. Make a 45x45 mm drill hole and insert the device; fix it with the special brackets provided. Do not mount

the device in damp and/or dirt-laden areas. It is suitable for use in places with ordinary or normal levels of pollution. Keep the area around the device

cooling slots adequately ventilated

ELECTRICAL CONNECTIONS

Warning! Switch off the device before working on the electrical connection. The device is equipped with screw terminals for connecting electric

cables of 2.5 mm2 maximum cross-section(one wire per terminal in the case of power connections): for the capacity of the terminals, see the label on

the device. The relay outputs are free of voltage. Do not exceed the maximum permitted current; for higher loads, use a contactor with sufficient

power capacity. Make sure that power supply is the correct voltage for the device. The probe has no specific connection polarity and can be extended

using a normal two-pole cable (note that extending the probe has a negative effect on the device’s EMC characteristics: take great care with the

wiring). The probe cables, power supply cables and the TTL serial cable should be kept separate from the power cables.

ELIWELL CONTROLS s.r.l.

Via dell'Industria, 15 Zona Industriale Paludi

32010 Pieve d'Alpago (BL) ITALY

Telephone +39 0437 986111

Facsimile +39 0437 989066

Internet http://www.eliwell.it

Technical Customer Support:

Telephone +39 0437 986300

Email: techsuppeliwell@invensyscontrols.com

Invensys Controls Europe

An Invensys Company

Loading...

Loading...