Page 1

Lunette Series

Home Theater Curved Fixed Frame Projection Screen

User’s Guide

Important Safety and Warning Precautions

Please follow these instructions carefully to ensure proper maintenance and safety with your Lunette

Series Fixed Frame Curved Screen

1. When hanging the screen up, please make sure that no other objects – such as power switches, outlets,

furniture, ladders, windows, etc., occupy the space designated for your Fixed-Frame screen.

2. Regardless if the screen is hung on or installed into the wall, make sure that the proper mounting anchors

are used and that the weight is supported appropriately by a strong and structurally sound surface just as

any large and heavy picture frame should.

(Please consult a home improvement specialist for the best advice on installation.)

3. Frame parts are made of high quality velour-surfaced aluminum and should be handled with care.

4. When not in use, cover over the screen with a furniture sheet to protect it from dirt, grime, paint, or any

other impurities.

5. When cleaning, use a soft cloth moistened with warm water to remove any marks on the frame or

screen surface.

6. Never attempt to use any solutions, chemicals, or abrasive cleaners on the screen surface.

7. In order to avoid damaging the screen, avoid touching it directly with your fingers, writing

stationary, tools, or any other sharp or abrasive objects.

8. Spare parts should be placed out of reach of small children in accordance with household safety guidelines.

CAUTION:

The projection screen frame is made of high-quality aluminum alloy and should be handled with

care.

Use a soft cloth with warm water to remove any spots on the screen material surface.

To avoid damaging the screen material, never attempt to use any solutions, chemicals, or

abrasive cleaners on the screen itself, and never attempt to touch screen with your fingers or

sharps/abrasive objects.

Rev042314 EA www.elitescreens.com 1

Page 2

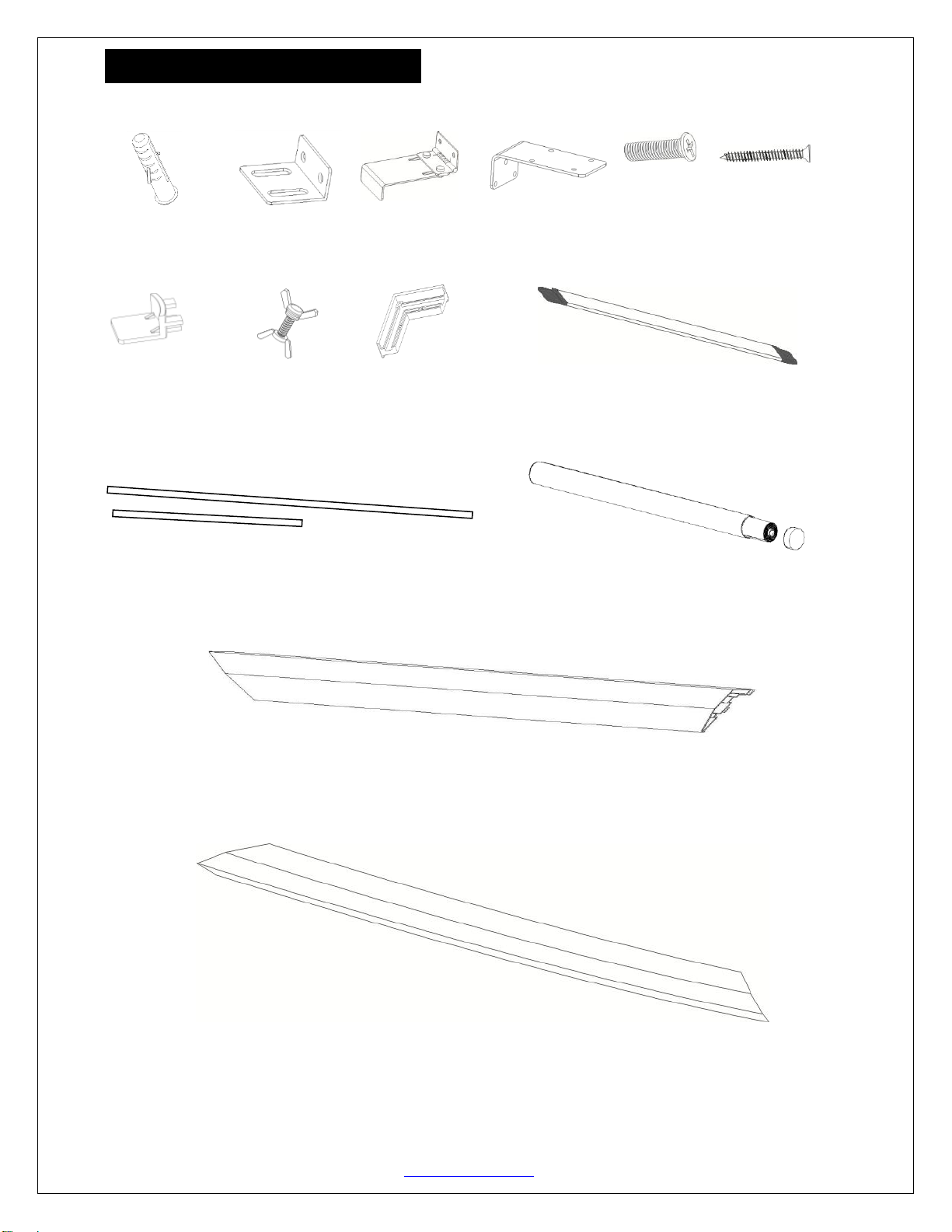

Hardware and Parts List

L. Tension Rods

M. Screen Material

N. Vertical Upright Frame

O. Horizontal Curved Frame

A. Dry-wall anchor

B. 1.77” L-Bracket

C. 3.54” L-Bracket

D. Lower bracket

E. M5 Screw

F. Wood screw

G. Fix Plate

K. Butterfly Screw

J. Elbow Joint

H. Center Support Bar

Note: Center support bar may be packed in a plastic

tube with the screen material.

Rev042314 EA www.elitescreens.com 2

Page 3

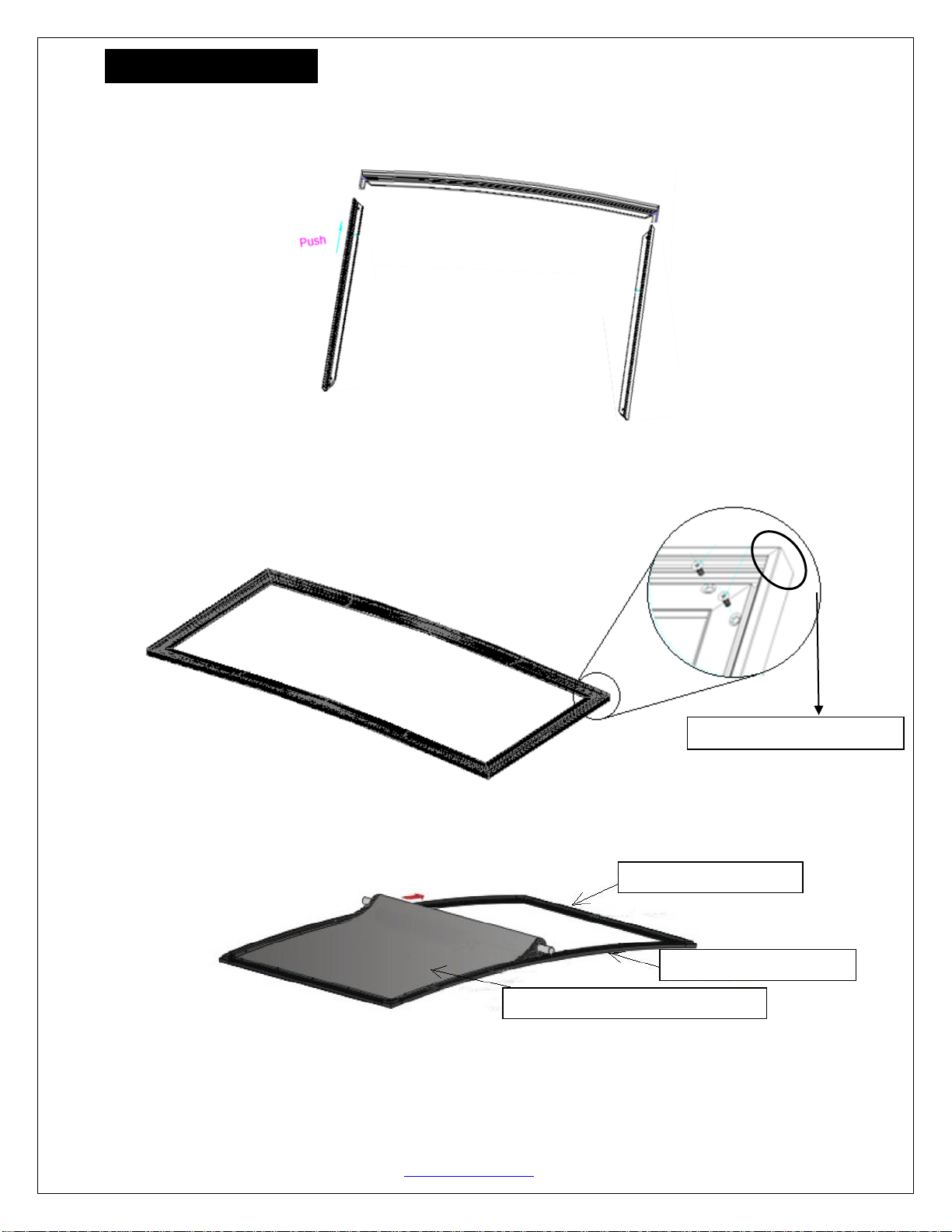

Frame Assembly

Vertical Upright Fame

Horizontal Curved Frame

Black Backing of the screen material

Minimal gap is normal here

1. Insert both Elbow Joints (J) into each Horizontal Curved Frame (N) and join all four frame

parts together as shown below.

2. After making sure that all four corners join at right angles (forming a perfect rectangle),

fasten the four angles together by using x8 M5 screws (E).

3. Layout the Screen Material and Tension Rods on a clean and dry surface. Then, gently

roll out the screen material over the back of the fixed frame.

Rev042314 EA www.elitescreens.com 3

Page 4

4. Insert Tension Rods through the sleeves. The longer rods are used on the horizontal edges of the

Tension Rod

Viewing Surface

Fix Plate

screen material, and the shorter rods are used on the vertical edges, as seen below.

5. Slip the screen tension rods into the grooves running along the back of the frame. Clip on the

Fix Plates to the back of the frame to secure the rods into place forming a tight and flat surface.

See Attaching the Fix Plates section below for details.

Rev042314 EA www.elitescreens.com 4

Page 5

Black backing for AcousticPro models

Fix plates secure Acoustic material and the black

backing behind it.

Fix Plate

Tension Rod (stretches the Acoustic material)

Black backing for

Acoustic material

Interval markings reveal the best points for inserting the fix plates (Fig. 1). The prongs on the fix plates insert to the lip on

the back of the frame creating a friction hold that will firmly keep the material and black backing in place (Fig. 2-3). After

the material has been installed, the backing will lie over the back of the white (Acoustic) material and then be held in place

by the Velcro on the fix plates (Fig 4).

The black backing is held in place by the Velcro that is on the fix plates.

Fig. 1

Fig. 2

Black backing

Fig. 3

Fig. 4

This procedure only applies to AcousticPro models. Disregard this section if your Fixed Frame

does not include an acoustic transparent screen material. The purpose of the black backing

material is to block out any light penetration that may reflect off of anything mounted behind

the screen, which can cause distortion to the projected image.

Rev042314 EA www.elitescreens.com 5

Page 6

Attaching the Fix Plates

Fix Plate Push

Fig. 6

Fig. 5

1. Make sure that the material and frame are both lying face down on a clean, dry, and non-

abrasive surface.

2. Center the material inside the frame.

Please note the material will be noticeably smaller than the frame, as the material must be

stretched to create a sufficient amount of tension for perfect material flatness.

3. Start attaching the Fix Plates in the corner of the frame’s horizontal edge, and then alternate

with the corners of the frame’s vertical edge as shown in diagram.

4. Attach the fix plates starting from the ends and moving towards the center as shown in the

diagram below to create an evenly tensioned surface.

Example 1 Example 2

Rev042314 EA www.elitescreens.com 6

Page 7

Center Support Bar

For 165” and above models

1. Center Support Bar may be packed in a plastic tube with the screen material.

Center support bar

2. Insert the Center Support Bar into the upper top groove on the back of the frame (note: this not

the same groove where the fix plate inserts) with the bottom end near the center point of the

frame, and place it in at an angle so that both ends of the bar are aligned with the groove.

3. Slide the top end of the bar into the top center point location (as shown below) to complete the

center support bar installation. This will provide added stability to the frame and added

tension to the material.

Rev042314 EA www.elitescreens.com 7

Page 8

Installation

Upper base line

Upper bracket

Wood screw

Hollow wall anchor

Wall

Wall

Upper bracket

Lower bracket

Hollow wall anchor Wood screw

1. Use butterfly screws to install the upper bracket as shown in diagram:

Use butterfly screws to assemble a 1.77” L-Bracket and a 3.54”L-Bracket into an upper bracket

2. Locate the height where you want to set up, and draw an upper base line. Confirm the distance

between the two brackets on the level direction following E on the diagram below. Mark the hole

location on the wall by following the base line and the upper bracket’s screw hole site, and then

drill the hole. Insert the wall anchor and tighten the upper bracket using the provided screw.

(The base line must be on the level.)

3. Draw a lower base line according to F and the upper base line, and then make a hole on the wall

according to the screw hole location for the lower bracket, then insert the anchor and tighten the

lower bracket with the provided screw.

Rev042314 EA www.elitescreens.com 8

Page 9

4. Place the upper frame on the upper brackets, and gently pull the frame down onto the bracket.

Upper base line

Lower base line

Installation diagram

of frame and

bracket

Base line

Swing the bottom

bracket to the left or

right to fit it in the

groove of the lower

frame.

The lower bracket will also slide into the groove of the lower frame.

5. Mounting the frame to the brackets will finish your installation.

Note: Two (2) or more people must install the frame for added safety.

Rev042314 EA www.elitescreens.com 9

Loading...

Loading...