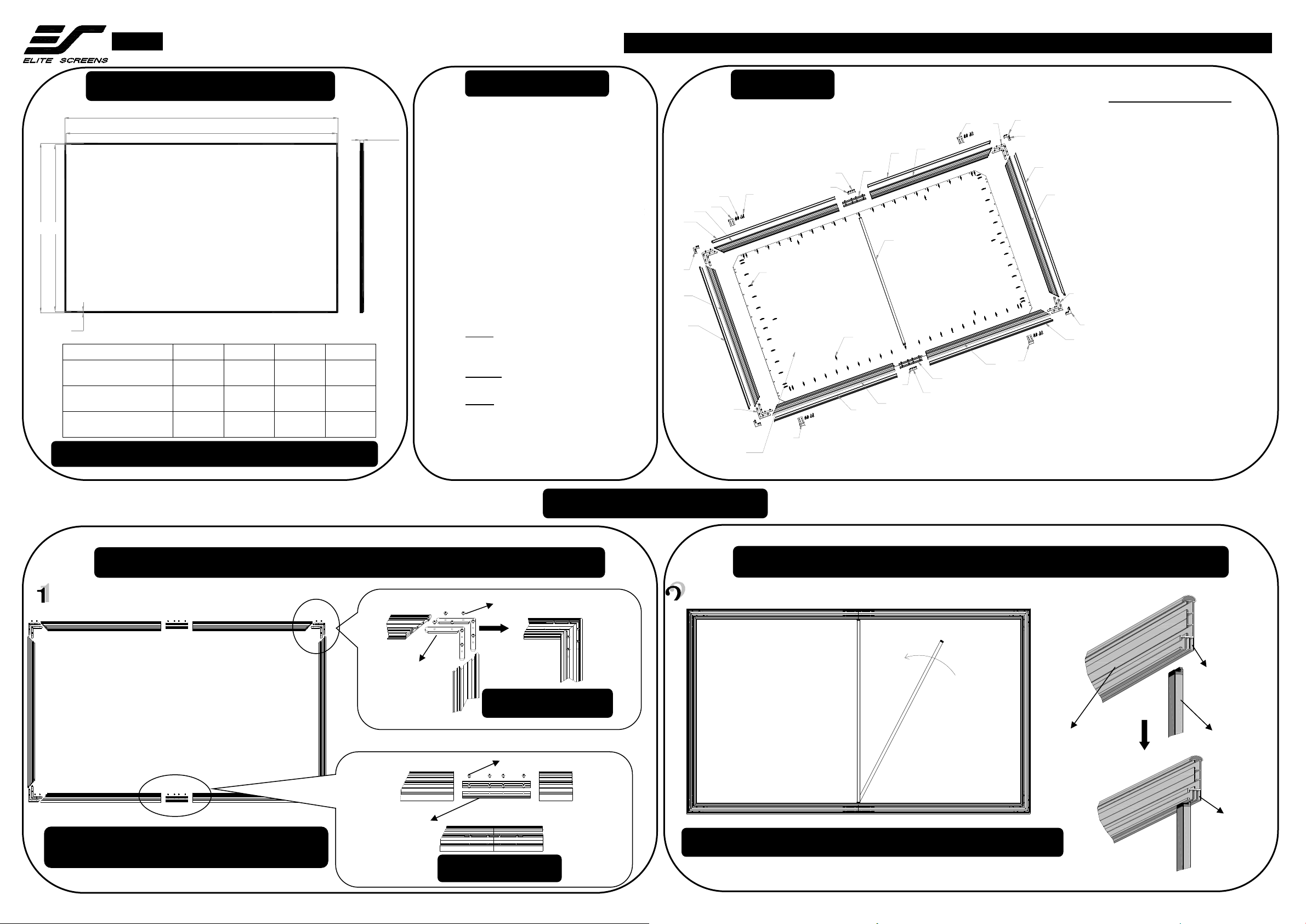

Elite Screens Aeon CLR Series, Aeon AR90H-CLR, Aeon AR100H-CLR, Aeon AR120H-CLR User Manual

Page 1

1

2

3

4

5

6

7

8

9

10

3

11

12

7

13

14

15

12

1

3

2

8

6

11

10

9

3

15

13

14

12

18

17

16

19

Aeon CLR® Series (spring type) | User’s Guide -03252019MZ

Unit: mm (inch)

A B C

D

AR90H-CLR

2013

(79.3”)

1993

(78.5”)

1142

(45.0”)

1122

(44.2”)

AR100H-CLR

2234

(88.0”)

2214

(87.2”)

1265

(49.8”)

1245

(49.0”)

AR120H-CLR

2677

(105.4”)

2657

(104.6”)

1514

(59.6”)

1494

(58.8”)

Dust, dirt and scratches on the projection screen

surface will affect the quality and performance

of the projection image. Follow the instructions

below to properly maintain the screen.

1) The screen surface has a horizontal structure.

DO NOT wipe the screen up and down or in a

circular motion. Wipe from left to right only.

2) Clean the dust on the screen surface with a

soft brush or microfiber cloth. A rough towel or

cloth may damage the screen’s surface.

3) Gently wipe the screen with a moistened

microfiber cloth with mild soap diluted in

water.

Notes: The following precautions should

always be followed to avoid damaging the

material, which is not covered under

warranty.

• Don’t touch the screen material to avoid

leaving fingerprints. Use gloves when

handling the material.

• Don’t scratch the material, as it will leave

permanent markings on the screen’s surface.

• Don’t point to the screen material with a

fingertip or other sharp objects to prevent

damage to the material.

• Don’t use acetone, benzene, alcohol and any

other organic solvents to clean the screen

A

B

DC

Dimensions Table

Screen Maintenance

Exploded view

Hardware and Parts List

(1) Edge Trim A x2

(2) Frame A x2

(3) Wall Bracket x4

(4) Anchor x8

(5) Wood crews x8

(6) Short Center joints x2

(7) M4x4 Screws x24

(8) Long Center joints x4

(9) Edge Trim B x2

(10) Frame B x2

(11) M5x6 Screws x48

(12) Elbow Joints b x4

(13) Edge Trim C x2

(14) Frame C x2

(15) Elbow Joints a x8

(16) Support Bar x1

(17) Springs a x74-84

(18) StarBright CLR® material x1

(19) Springs b x8

Screen Installation

Frame Assembly

Center support bar Installation

Insert the support bar’s

tip into the frame’s

groove in the middle,

then rotate it and insert

the other end on the

other side of frame.

(16) Support

Bar

See illustration on the right side on how to properly install the Support bar.

Frame

(back side)

Note:Make sure all holes are in alignment and the

frame pieces are flush (no gaps), then fasten the screws.

(8) Long Center

joints

(11) M5x6 Screws

Center Connection

Note: The listed measurements are for general reference only.

(15) Elbow Joint a

(11) M5x6 Screws

Corner Connection

(2) Frame A

(10) Frame B

(14) Frame C

(2) Frame A

(10) Frame B

(14) Frame C

Frame Width =

28.2 mm (1.1”)

Insert groove

Support Bar

properly inserted

into groove

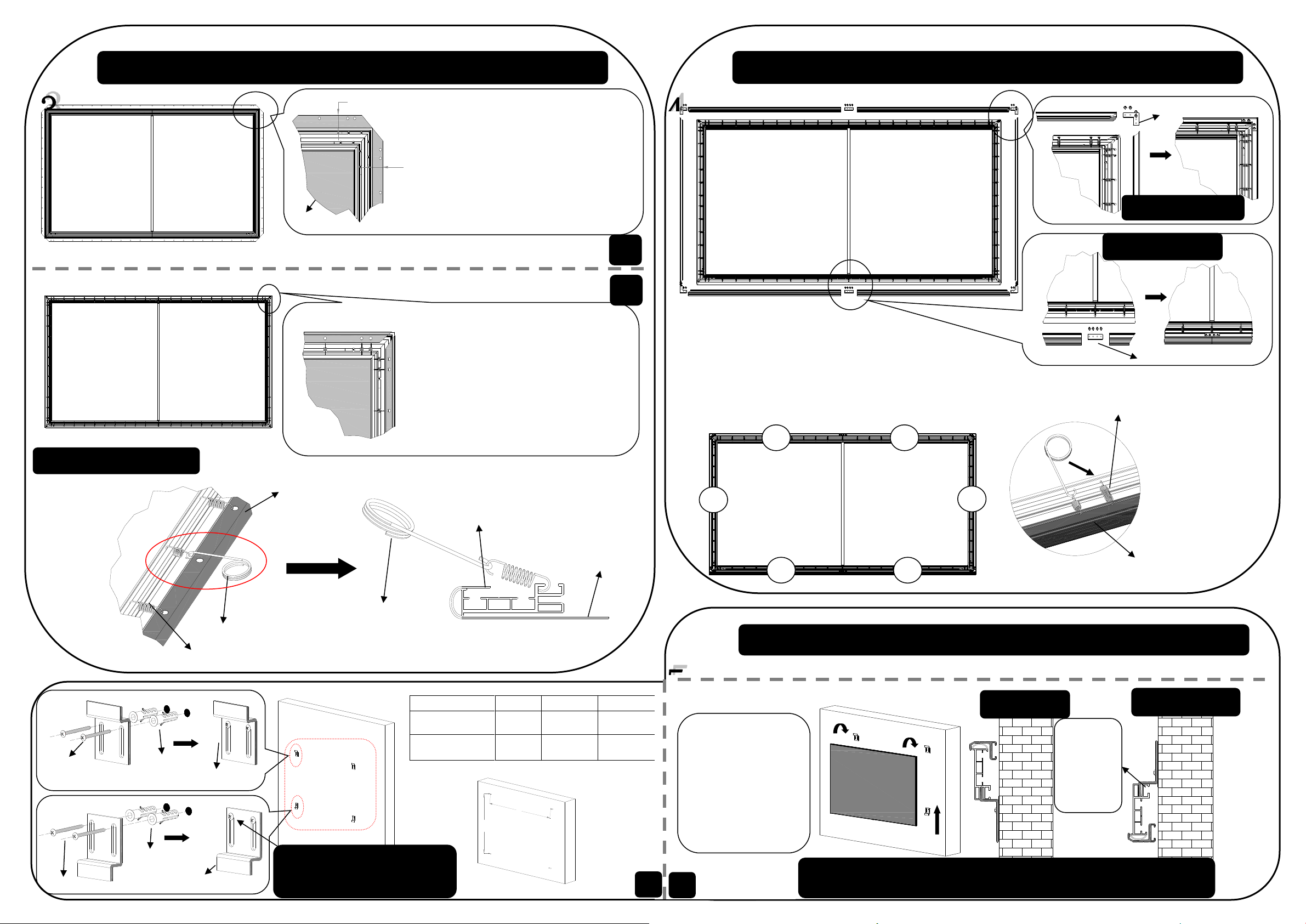

Page 2

L

H

Unit:mm(inch)

90

100

120

L(Length of left

to right)

1500

(59.1”)

1500

(59.1”)

2000

(78.7”)

H(Length of top

to bottom)

960

(37.8”)

1083

(42.6”)

1332

(52.4”)

Wall Installation

Screen Material Installation

Edge Trim Installation

1. Put on the supplied pair of white gloves,

two people carefully unroll the material on

the supplied cloth (keep the front of the

material face down)

2.Carefully and gently place the assembled

frame on top of the screen material.

3. Adjust the distance between the edge of

the frame and the material (a1 = a2) to 35

mm/1.4”

Backside

Spring Attachment Method

Two people required

1. Begin by simultaneously attaching three

springs in the center of the side frames (A→B)

and repeat for top/bottom frames (C→D).

2. Then, simultaneously attach the springs from

the center to all corners.

3. Finally, attach the springs at the four corners

(E→F→G→H).

4. Inspect the assembled screen for flatness.

C D A B F E G

H

①

Corner Connection

Center Connection

(12) Elbow Joints b

(6) Short Center joints

Top Bracket

Bottom Bracket

Note: The

bottom

bracket

can be

adjust

from top

to bottom.

Tolerance:±3mm(.12”)

Spring hook

(18) Material

Note: Do not fasten up the screws

on the bottom bracket, so the

bracket can be easily adjusted.

1. Connect edge trims A&B to form the top/bottom

trims with the Short Center joints, and then insert

them on the top/bottom frames.

2. Connect the side edge trims C with the

top/bottom edge trim with elbow joints b.

3. Adjust the trim so that the top and bottom trim

pieces are touching and show no gaps on the

corners. Then fasten them with the M4 x4 screws.

②

(1) Two people hold

the screen. First align

and place it on the

bottom bracket.

(2) Then pull up the

screen on the top

bracket and adjust the

screen left to right as

needed.

Note: Make sure the direction of the CLR material is correct before you hang the

screen to the wall. The material is labeled top or bottom.

4.Attach a spring b

on the middle of

each edge trim (1-6)

to the frame as show

on the left

illustration.

Edge Trim

(19) Spring b

(17) Spring a

(1)

(2)

a1

a2

a1=a2

(18) Material

Spring hook

Hole on the material

①

②

Hook springs on frame

then use spring hook to

attach to material

(5) Wood Screws

(4) Anchor

(3) Top Wall Bracket

(5) Wood Screws

(4) Anchor

(3) Bottom Wall Bracket

Loading...

Loading...