Elington ANT54AV5WCR Installation Manual

Installation Guide

F.P.O.

For Placement Only

For Model:

READ THESE INSTRUCTIONS AND

SAVE THEM FOR FUTURE USE

F. P.O.

For Placement Only

ANT54AV5WCR

Table of Contents:

Safety Tips. pg. 1

Unpacking Your Fan. pg. 2

Parts Inventory. pg. 2

Installation Preparation. pg. 3

Hanging Bracket Installation. pg. 3

Fan Assembly. pgs. 4 - 5

Wiring. pgs. 5 - 6

Canopy Assembly. pg. 7

Scroll Arm Assembly. pg. 7

Blade Assembly. pg. 8

Switch Housing Assembly. pg. 8

Wall Control Operation. pg. 9

Testing Your Fan. pg. 9

Troubleshooting. pg. 10

net weight of fan: 37 lb. (16.78 kg)

Parts Replacement. pg. 10

Warranty. pg. 10

PRINTED IN CHINA

SAFETY TIPS.

WARNING: To reduce the risk of electrical shock, turn off the electricity to the fan at the main fuse box or circuit

panel before you begin the fan installation or before servicing the fan or installing accessories.

1. READ ALL INSTRUCTIONS AND SAFETY INFORMATION CAREFULLY BEFORE INSTALLING YOUR FAN

AND SAVE THESE INSTRUCTIONS.

CAUTION: To avoid personal injury, the use of gloves may be necessary while handling fan parts with sharp

edges.

2. Make sure all electrical connections comply with Local Codes or Ordinances, the National Electrical Code,

and ANSI/NFPA 70-1999. If you are unfamiliar with electrical wiring or if the house/building wires are

different colors than those referred to in the instructions, please use a qualified electrician.

3. Make sure you have a location selected for your fan that allows clear space for the blades to rotate, and at

least seven (7) feet (2.13 meters) of clearance between the floor and the fan blade tips. The fan should

be mounted so that the tips of the blades are at least thirty (30) inches (76 centimeters) from walls or

other upright structures.

4. The outlet box and ceiling support joist used must be securely mounted, and capable of supporting at

least 50 pounds (22,68 kilograms). The outlet box must be supported directly by the building structure.

Use only UL listed outlet boxes marked "FOR FAN SUPPORT."

WARNING: To reduce the risk of fire, electrical shock, or personal injury, mount to the outlet box marked

"Acceptable for Fan Support of 22.68 kg (50 lbs) or less," and use the mounting screws provided with the outlet

box. Most outlet boxes commonly used for the support of lighting fixtures are not acceptable for fan support

and may need to be replaced. Consult a qualified electrician if in doubt.

WARNING: To reduce the risk of fire, electrical shock, or personal injury, wire connectors provided with this fan

are designed to accept only one12 gauge house wire and two lead wires from the fan. If your house wire is larger

than 12 gauge or there is more than one house wire to connect to the corresponding fan lead wires, consult an

electrician for the proper size wire connectors to use.

5. Electrical diagrams are for reference only. Light kits that are not packed with the fan must be UL listed and

marked suitable for use with the model fan you are installing. Switches must be UL general use

switches. Refer to the instructions packaged with the light kits and switches for proper assembly.

6. After installation is complete, check that all connections are absolutely secure.

7. After making electrical connections, spliced conductors should be turned upward and pushed carefully up

into the outlet box. The wires should be spread apart with the grounded conductor and the

equipment-grounding conductor on opposite sides of the outlet box.

WARNING: To reduce the risk of electrical shock or fire, do not use this fan with any solid state speed control

device or control fan speed with a full range dimmer switch. [Using a full range dimmer switch to control fan

speed will cause a loud humming noise from fan.]

8. Do not operate the reverse switch until fan has come to a complete stop. [Note: If using remote control

with reverse capability, reverse fan blade direction only when on LOW speed.]

9. Do not insert anything between the fan blades while they are rotating.

WARNING: To reduce the risk of personal injury, do not bend the blade arms during assembly or after

installation. Do not insert objects into the path of the blades.

WARNING: To avoid personal injury or damage to the fan and other items, be cautious when working around or

cleaning the fan.

10. Do not use water or detergents when cleaning the fan or fan blades. A dry dust cloth or lightly dampened

cloth will be suitable for most cleaning.

WARNING: To reduce the risk of personal injury, use only parts provided with this fan. The use of parts OTHER

than those provided with this fan will void the warranty.

NOTE: The important safety precautions and instructions appearing in the manual are not meant to cover all

possible conditions and situations that may occur. It must be understood that common sense and caution are

necessary factors in the installation and operation of this fan.

page 1

1. Unpacking Your Fan.

Carefully open the packaging. Remove items

from Styrofoam inserts. Remove motor housing

and place on carpet or Styrofoam to avoid

damage to finish. Do not discard fan carton or

Styrofoam inserts should this fan need to be

returned for repairs.

Check against parts inventory that all parts have

been included.

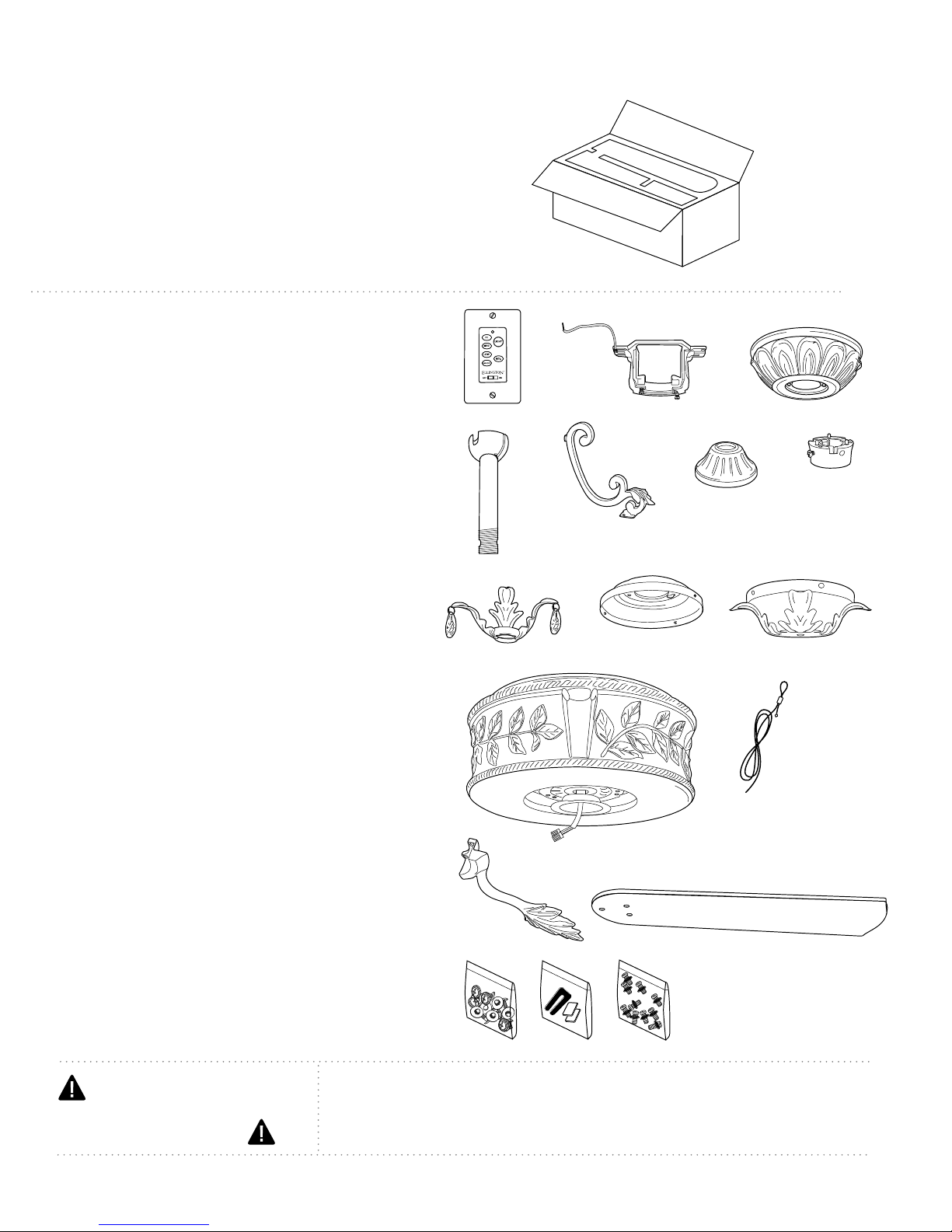

2. Parts Inventory.

a. wall control and plate. 2 separate pieces

b. hanging bracket. 1 piece

c. canopy. 1 piece

d. 12in. downrod and hanging ball. 1 piece

e. scroll arm. 3 pieces

f. yoke cover. 1 piece

g. scroll arm support. 1 piece

h. decorative downrod collar. 1 piece

i. switch housing plate. 1 piece

j. switch housing. 1 piece

a

d

h

k

b

e

i

f

c

g

j

l

k. motor housing. 1 piece

l. safety cable (already attached to motor).

m. blade arm. 5 pieces

n. blade. 5 pieces

o. hardware packs

IMPORTANT REMINDER: You must

use the parts provided with this fan for

proper installation and safety.

1 piece

mn

o

page 2

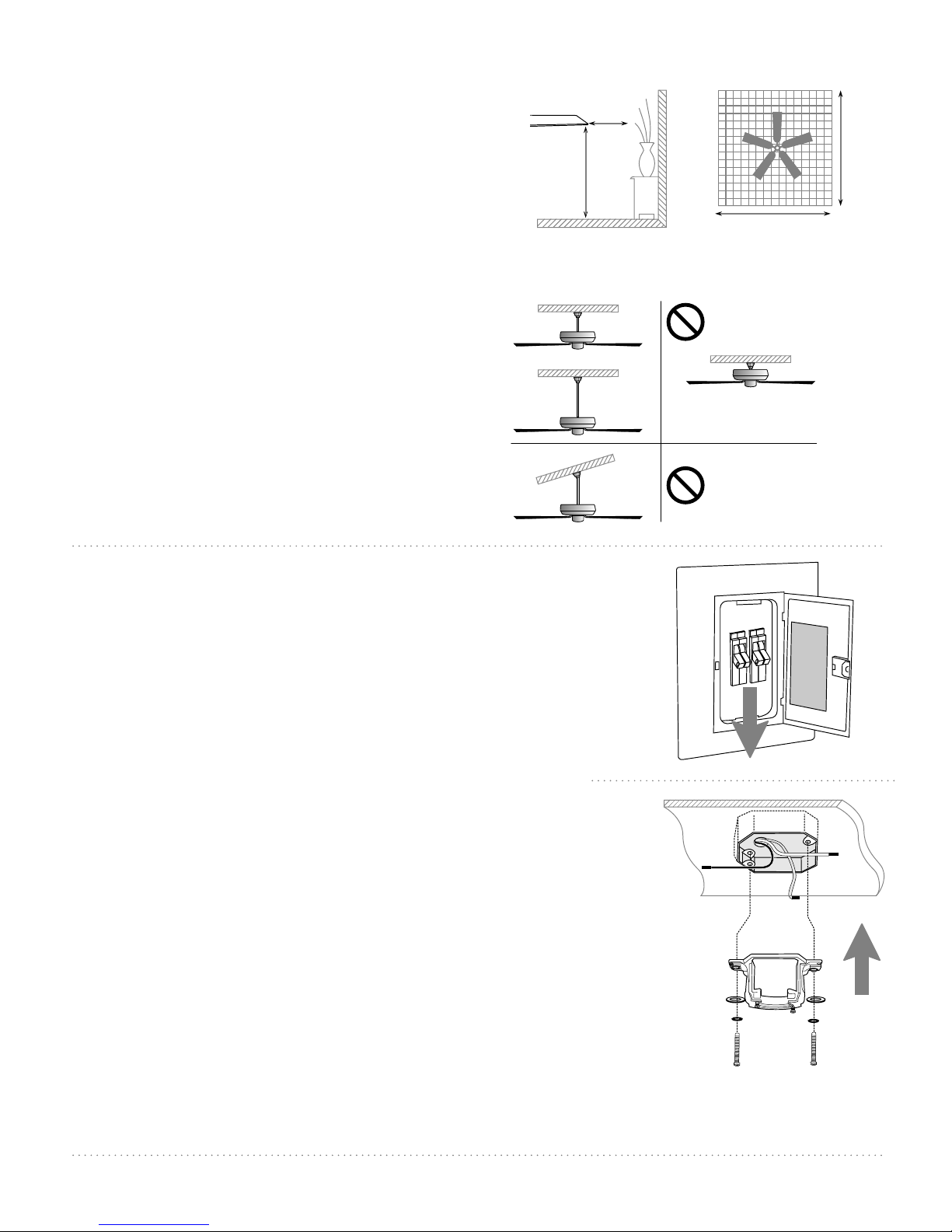

3. Installation Preparation.

blade edge

To prevent personal injury and damage,

ensure that the hanging location allows the

blades a clearance of 7ft. (2.13m) from the

floor and 30in. (76cm) from any wall or

obstruction.

This fan is suitable for room sizes up to 400

square feet (37.2 square meters).

This fan can be mounted with a downrod

on a regular (no-slope) or vaulted ceiling. The

hanging length can be extended by

purchasing a longer downrod (0.5in./1.27cm

diameter). Other installation, such as

flushmount, is not available for this fan.

Installation requires these tools:

Phillips screwdriver, flathead screwdriver,

adjustable pliers or wrench, stepladder, wire

cutters, and rated electrical tape.

4. Hanging Bracket Installation.

4. Hanging Bracket Installation

30

inches

7 feet

(2.13m)

(76cm)

downrod

installation

12ft. - 20ft.

(3.66m - 6.1m)

flushmount

installation

Vaulted ceiling

angle is not to

exceed 25 degrees.

12ft. - 20ft.

(3.66m - 6.1m)

Turn off circuit breakers to current fixture from breaker panel

and be sure operating light switch is turned to the OFF

position.

WARNING: Failure to disconnect power supply prior to

installation may result in serious injury.

Remove existing fixture.

WARNING: To reduce the risk of fire, electric shock, or personal

injury, mount to outlet box marked "Acceptable for Fan Support

of 22.68 kg (50lbs) or Less" and use mounting screws provided

with the outlet box. Most outlet boxes commonly used for the

support of lighting fixtures are not acceptable for fan support

and may need to be replaced. Consult a qualified electrician if in

doubt. When using an existing outlet box, be sure the outlet box

is securely attached to the building structure and can support

the full weight of the fan. Ensure outlet box is clearly marked

"Suitable for Fan Support." If not, it must be replaced with an

approved outlet box. Failure to do so can result in serious injury.

Install hanging bracket to outlet box, using original screws,

spring washers and flat washers provided with new or

original outlet box.* If installing on a vaulted ceiling, face

opening of hanging bracket towards high point of ceiling.

Arrange electrical wiring around the back of the hanging

bracket and away from the bracket opening.

hanging bracket

flat washers

spring washers

outlet box screws

ON

ON

OFF

OFF

*Note: It is very important that you use the proper hardware

when installing the hanging bracket as this will support the

fan.

page 3

5. Fan Assembly.

If you wish to extend the hanging length of your fan,

you must remove the hanging ball from the 12in.

downrod provided to use with an extended downrod

(sold separately). [If you wish to use the 12in. downrod,

please proceed to instructions following the short dotted

line below.]

To remove the hanging ball, loosen set screw on

hanging ball, lower hanging ball and remove stop pin.

Slide hanging ball off of original downrod, A, and slide it

down the longer downrod, B (the top of the downrod

should be noted as having a set screw hole; use this hole

when setting the set screw). Insert stop pin into top of

extended downrod and raise hanging ball. Be sure stop

pin aligns with slots on the inside of the hanging ball.

Tighten set screw securely.

Remove vice from safety cable by loosening the screw

and nut on the vice.

Tip: To prepare for threading electrical wires through

downrod, apply a small piece of electrical tape to the

ends of the electrical wires--this will keep the wires

together when threading them through the downrod.

set screw

A

electrical wiring

downrod

set screw hole

stop pin

hanging ball

B

safety cable

vice

Loosen yoke set screws and nuts at top of motor and

remove pin and clip from yoke at top of motor. Be sure set

screw in scroll arm support is loosened and that notches in

scroll arm support face upward. Slide downrod through

canopy, decorative downrod collar, scroll arm support

and yoke cover.

Thread safety cable and electrical wires through

downrod and pull extra wire slack from the upper end of

the downrod.

Thread downrod into the motor housing yoke until holes

for pin and clip in downrod align with holes in

yoke--make sure wires do not get twisted. Re-insert pin and

clip that were previously removed. Securely tighten yoke

set screws and nuts. Lower yoke cover to motor housing.

Remove blade arm screws and lock washers from

underside of motor and then remove stabilization plate.

Important: Stabilization plate may be discarded once

removed but save blade arm screws and lock washers for

later use.

["Fan Assembly" continued on next page.]

NOTE: The important safety precautions and instructions

appearing in the manual are not meant to cover all possible

conditions and situations that may occur. It must be

understood that common sense and caution are necessary

factors in the installation and operation of this fan.

pin

canopy

scroll arm

support

blade arm

screws and

lock washers

decorative

downrod

collar

yoke cover

clip

yoke set screw

motor housing

stabilization plate

page 4

5. Fan Assembly. (cont.)

Tip: Code switches in the first part of Section 6

can be set on the top of the motor housing prior

to hanging the fan.

With the hanging bracket secured to the outlet

box and able to support the fan, you are now

ready to hang your fan. Grab the fan firmly with

two hands. Slide downrod through opening in

hanging bracket and let hanging ball rest on the

hanging bracket. Turn the hanging ball slot until it

lines up with the hanging bracket tab.

WARNING: Failure to align slot in hanging ball

with tab in hanging bracket may result in serious

injury or death.

Suggestion: Seek the help of another person to

hold the stepladder in place and to lift the fan up

to you once you are set on the ladder.

Find a secure attachment point (wood ceiling joist

highly recommended) and secure the safety

cable. It will be necessary to use a heavy duty

wood screw, washer and lock washer (not

supplied) with the safety cable loop. Extra cable

slack can be left in ceiling area.

wood

ceiling

joist

safety cable loop

wood screw

and washer

screw

nut

safety cable

hanging bracket tab

hanging ball slot

motor housing

Replace vice on safety cable and adjust safety

cable length by pulling on the cable. Adjust slack

in cable to a hands length and secure vice by

tightening screw and nut securely. [Refer to

drawing at right.] The loop at the end of the safety

cable should just fit over the threads on the wood

screw. Test safety cable by pulling on loose end with

pliers. If the safety cable slips, the vice and nut must

be set tighter.

6. Wiring.

Use a ballpoint pen or a small screwdriver to set

the code switches for the wall control, and

built-in receiver so that they match. Factory

setting is pre-set and not recommended for use. If

your wall control interferes with other appliances,

change to another matching code on the wall

control and built-in receiver.

wall control

code switches

motor housing

1

2

4

3

["Wiring" continued on next page.]

page 5

green/

bare

ground

6. Wiring. (cont.)

CAUTION: Be sure outlet box is properly grounded

and that a ground (GREEN or Bare) wire is present.

Make sure all electrical connections comply with

Local Codes or Ordinances and the National

Electrical Code. If you are unfamiliar with electrical

wiring or if the house/building wires are different

colors than those referred to in the instructions,

please use a qualified electrician.

Note: Excess lead wire length from the fan can be

cut to the desired length and then stripped.

When downrod is secured in place on the

hanging bracket, electrical wiring can be

made as follows:

Connect BLACK wire from fan to BLACK wire

from ceiling with wire connector provided.

Connect WHITE wire from fan to WHITE wire

from ceiling with wire connector provided.

Connect all GROUND (GREEN) wires together

from fan to BARE/GREEN wire from ceiling with

wire connector provided.

from ceiling

from fan

white supply wire

black supply wire

black

white

white

black

ground

(green or bare)

ground

(green

or bare)

*

* Wrap each wire connector separately with

electrical tape as an extra safety measure.

IN ORDER TO WIRE WALL CONTROL, remove

existing wall switch.

After codes have been properly set according to

"Wiring" instructions on previous page, wire the

WALL CONTROL with wire connectors provided

as shown in diagram at right.

* Wrap each wire connector separately with

electrical tape as an extra safety measure. Gently

push wires and taped wire connectors into outlet

box.

Attach wall control to outlet box and secure with

screws from original wall switch. Attach front

plate to wall control using 2 screws provided in

the wall control.

outlet box

breaker box)

green/

ground

ground

black

(AC IN from

green/

bare

bare

black

wall

control

1

2

3

green

black (OUT to fan)

black

(TO POWER supply)

4

plate

code

switches

page 6

Loading...

Loading...