Elimko E-PR-110 Series, E-PR-110-1-1-1-1-0-0, E-PR-110-1-1-3-3-0-0, E-PR-110-1-1-1-5-1-0, E-PR-110-4-4-4-5-1-0 User Manual

...

Manufacturer / Technical Support

Elimko Electronic Production and Control Co. Ltd.

8. Avenue 68. Street No:16 06510 Emek- Ankara / TURKEY

Phone: + 90 312 212 64 50 Fax: + 90 312 212 41 43

www.elimko.com.tr / e-mail:elimko@elimko.com.tr

E-PR-110

Paperless Recorder

User Manual

Manufacturer / Technical Support

Elimko Electronic Production and Control Co. Ltd.

8. Avenue 68. Street No:16 06510 Emek- Ankara / TURKEY

Phone: + 90 312 212 64 50 Fax: + 90 312 212 41 43

www.elimko.com.tr / e-mail:elimko@elimko.com.tr

K - Q

TSE-ISO-EN

9000

TS EN ISO 9001

Quality Management System Certificate

KY-PR110-0417-1

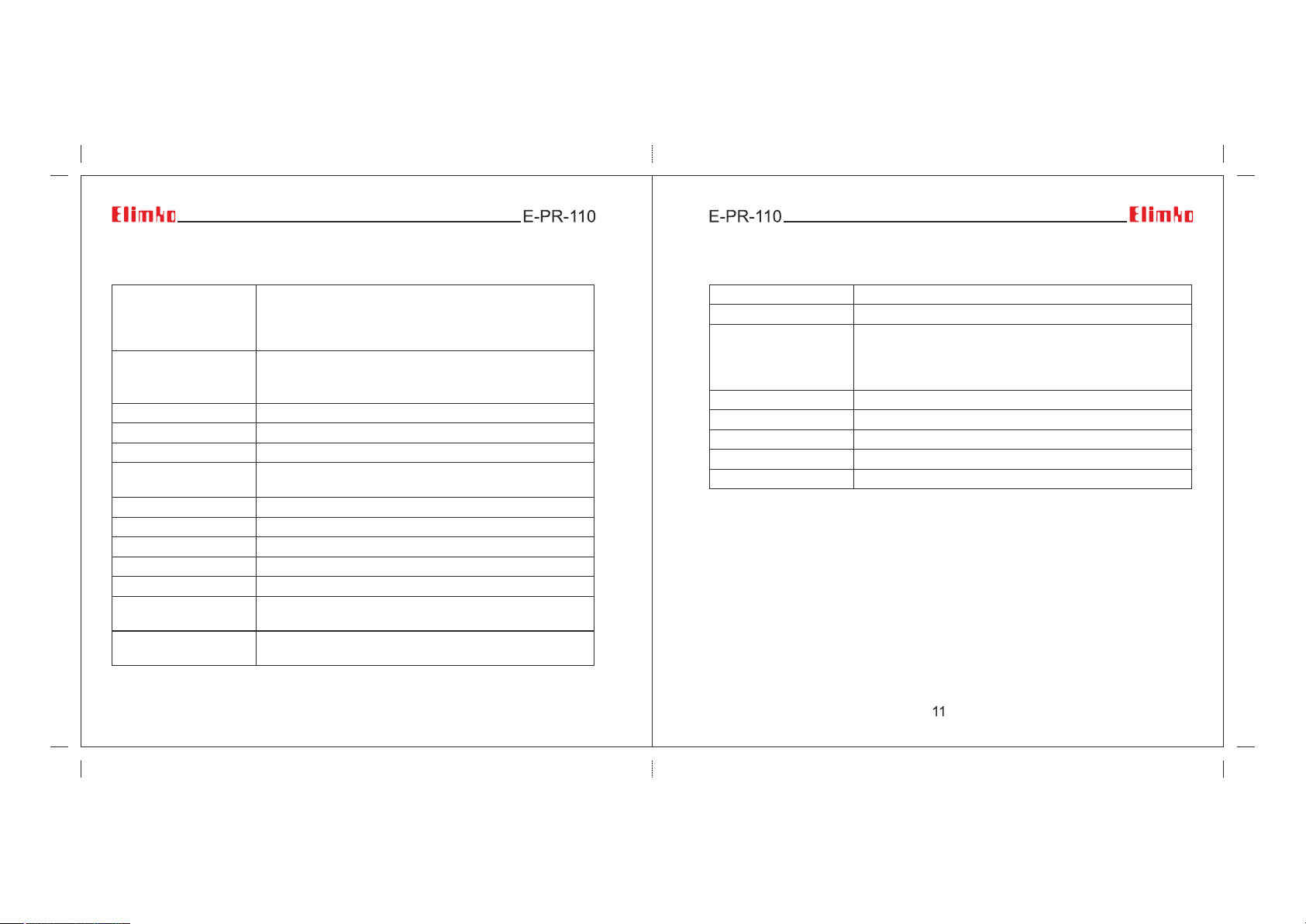

1 - INDEX

1. INDEX

2. FIGURES

3. WARNINGS

4. DESCRIPTION

4.1. Type Coding

4.2. Technical Specification

4.3. Dimensions

4.4. Panel Mounting

5. USAGE

5.1. Front Panel

5.2. Trend Page

5.3. Bar Graphic Page

5.4. Digital View Page

5.5. Overview Page

5.6. Alarm Log

5.7. Totalizer Log

5.8. Instrument Log

5.9. Operator Log

5.10. Digital Log

5.11. Digital 2

6. MENU PAGES

6.1. Adjusting Parameters

6.2. Main Menu

6.3. Device Page

6.4. Security Page

6.5. Hardware Page

6.5.1. Slot Adjustments

...............................................................................................................

.........................................................................................................

......................................................................................................

................................................................................................

..................................................................................................

....................................................................................................

.............................................................................................

............................................................................................................

....................................................................................................

....................................................................................................

..........................................................................................

...........................................................................................

..............................................................................................

......................................................................................................

.................................................................................................

..............................................................................................

.................................................................................................

...................................................................................................

........................................................................................................

..................................................................................................

.....................................................................................................

..................................................................................................

................................................................................................

.............................................................................................

.........................................................................................

..................................................................................

....................................................................................

1

1 - 2

3 - 6

7

8

9

10 - 11

12

13

14

14 - 16

17 - 20

21

22 - 23

24

25

26

27

28

29

30

31

32

33

34

35

36

36 - 41

1 - INDEX

6.5.2. Ethernet Ayarları

6.5.3. Seri Port Ayarları

6.5.4. Ekran Ayarları

6.6. Kanallar

6.6.1. Röle Kartı Ayarları

6.6.2. Sayısal Çıkış Kartı Ayarları

6.6.3. Analog Giriş Kartı Giriş Ayarları

6.6.4. Analog Çıkış Kartı Ayarları

6.6.5. Alarm Ayarları

6.6.6. Toplayıcı Ayarları

6.6.7. Kayıt Ayarları

6.6.8. Sayısal Giriş Kartı Ayarları

6.6.9. Modbus Kanalları Sayfası

6.6.10. Matematik Kanal Ayarları

6.7. Gerçek Zaman Kanalları

6.8. Gruplar

6.9. Kullanıcı Tanımlı Tablolar

6.10. Arşiv

6.11. E-mail

6.12. PID

7. BAĞLANTI ŞEMALARI

8. VERİ TRANSFERİ VE İLETİŞİM PROTOKOLLERİ

9. EKLER

EK 1 Ethernet Bağlantısı

EK 2 Math Editor ile Eşitlik Girilmesi

EK 3 Modbus RTU İletişim Adresleri

EK 4 Barkod Okuyucu

.........................................................................................................

...........................................................................................................

.............................................................................................................

..........................................................................................................

.............................................................................................................

..............................................................................................................

.........................................................................................

.........................................................................................

..............................................................................................

.......................................................................................

..........................................................................

...................................................................

...........................................................................

..............................................................................................

.........................................................................................

...............................................................................................

...........................................................................

............................................................................

...........................................................................

................................................................................

...............................................................................

.....................................................................................

......................................................................................

....................................................................

....................................................................

..........................................................................................

2 3

.........................................

42

43

44

45

46

47

48 - 52

53 - 54

55 - 57

58

59 - 60

61

62 - 64

65

66 - 67

68

69

70 - 72

73 - 76

77 - 84

85 - 91

92 - 93

94

94 - 95

96 - 98

99

100

2 - FIGURES

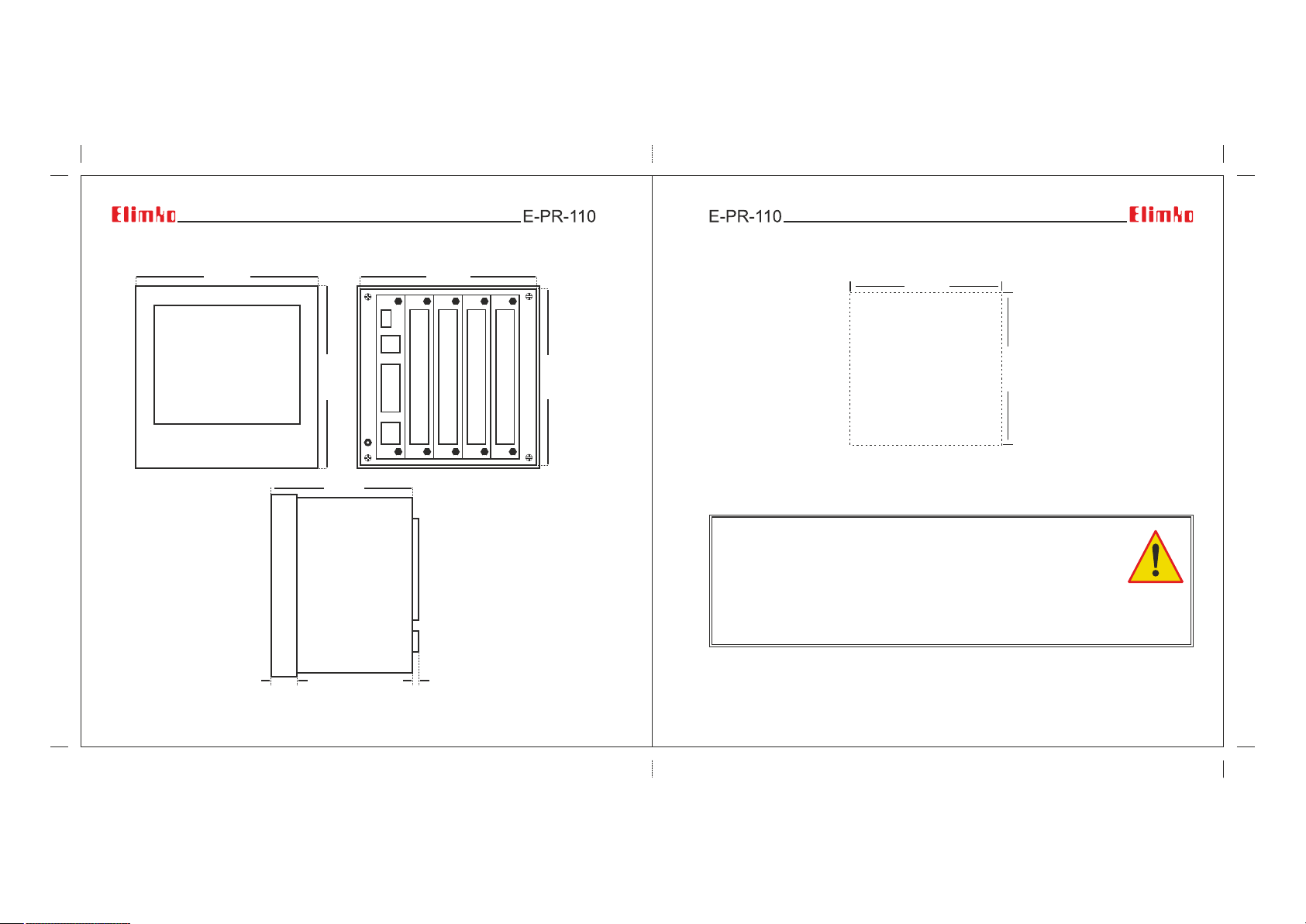

Şekil 4.1 E-PR-110 boyutları ve pano montaj aparatı

Şekil 4.2 E-PR-110 Panel Kesiti

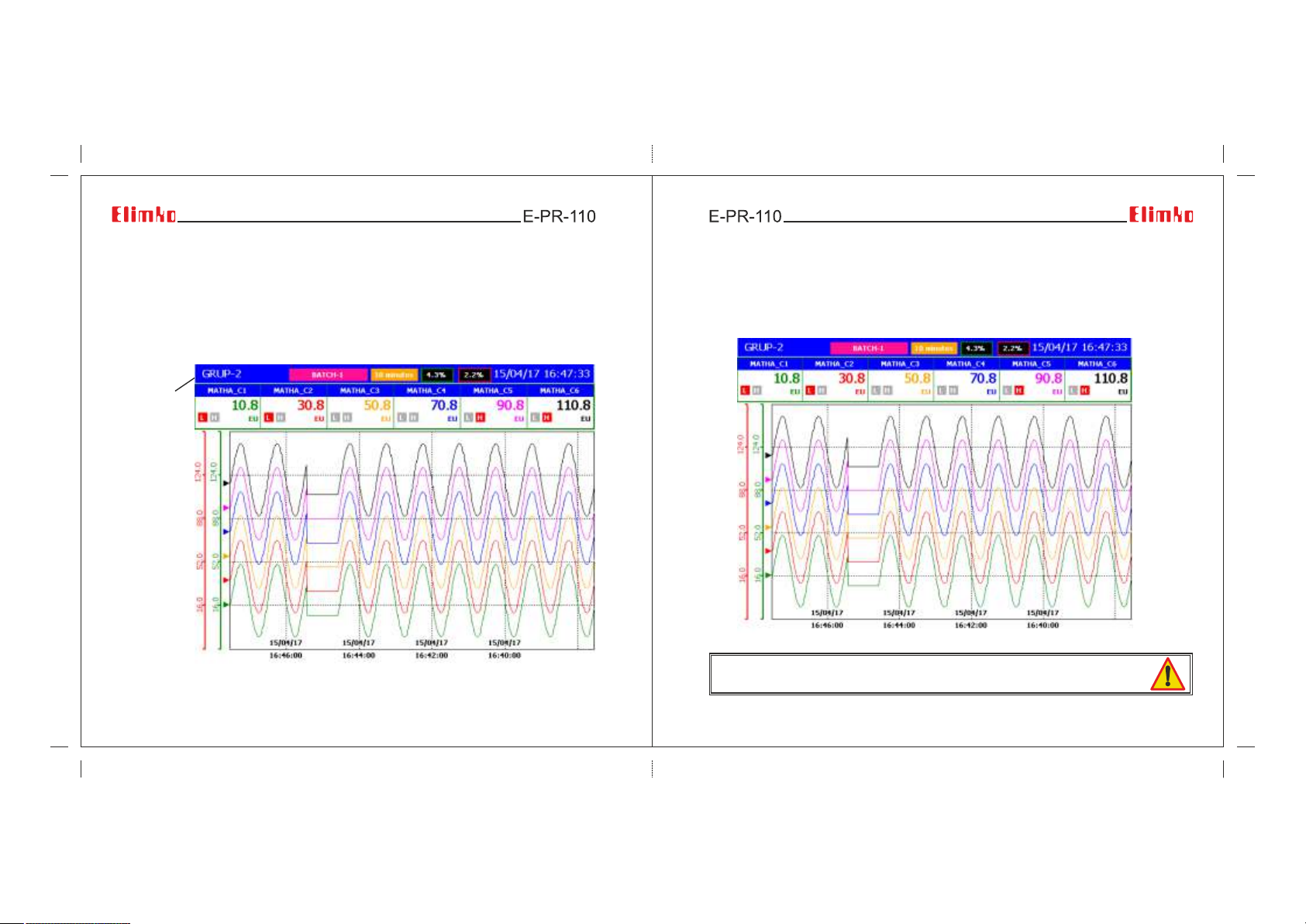

Şekil 5.1 Trend Görünümü

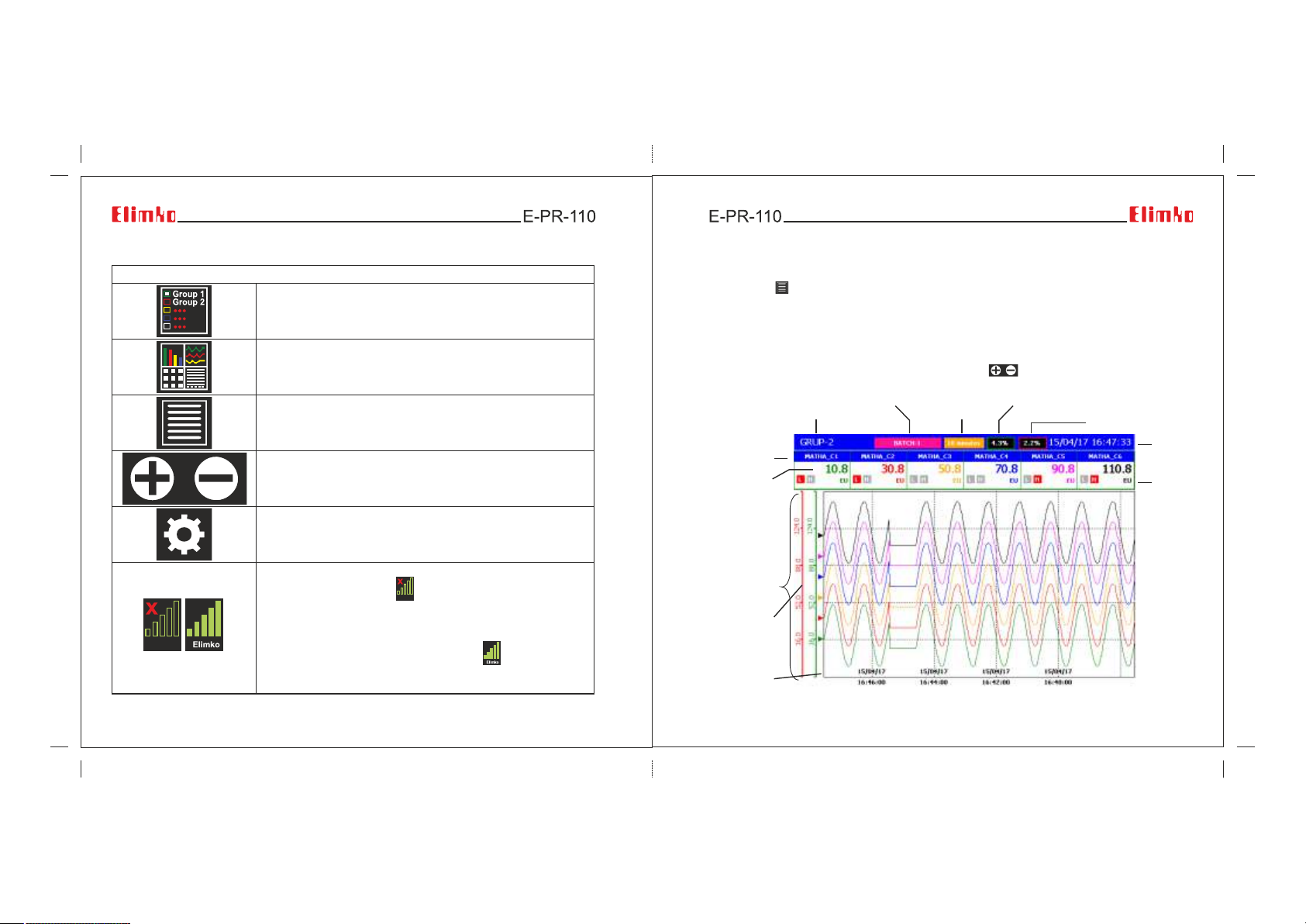

Şekil 5.2 Operasyon tuşları

Şekil 5.3 Trend Görünüm Ekranı

Şekil 5.4 Trend görünüm ekranında aktif butonlar ve anlamları

Şekil 5.5 Trend görünüm ekranındaki aktif butonlar ve seçenekleri

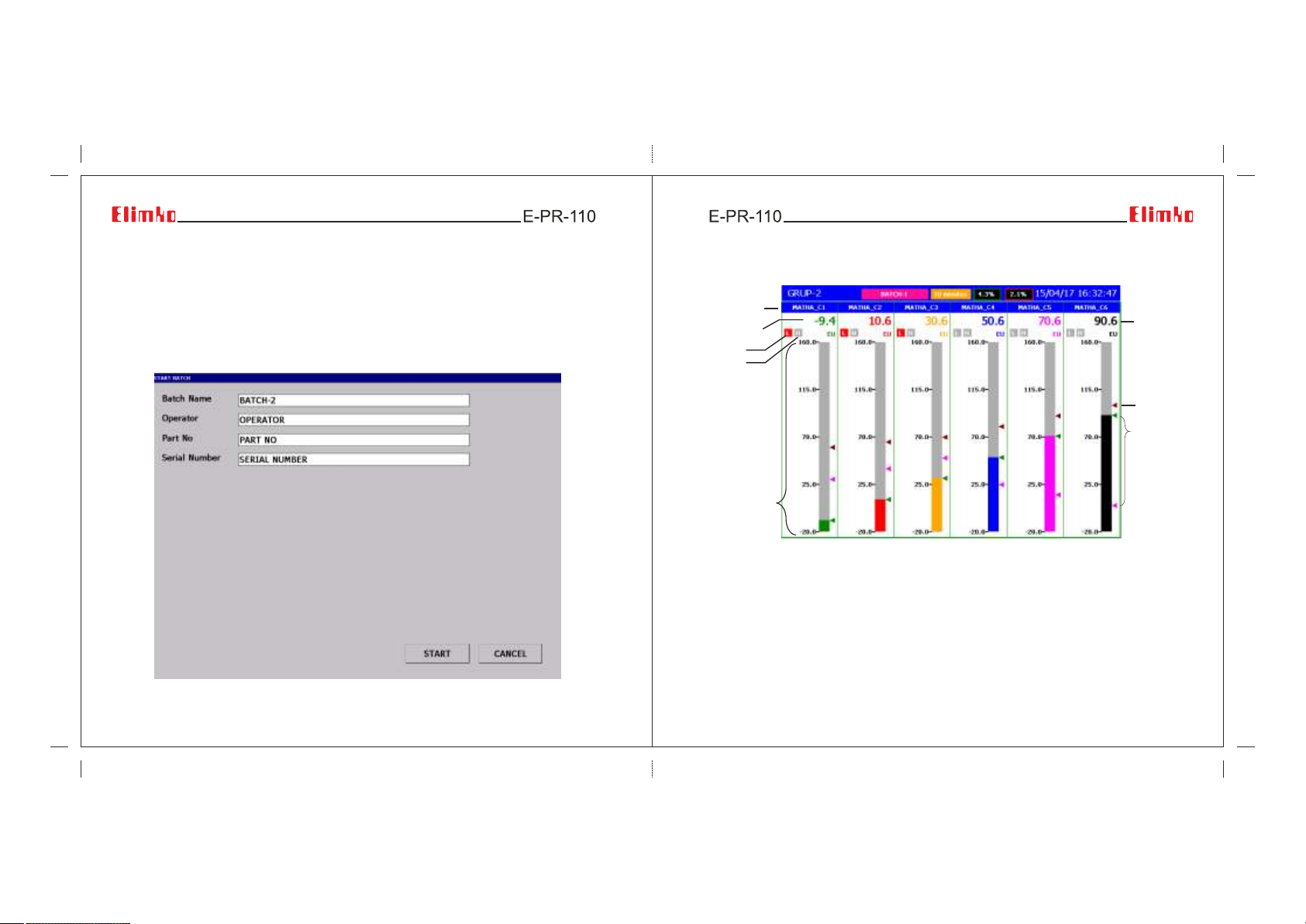

Şekil 5.6 İşlem başlat ekranı

Şekil 5.7 Bar görünüm ekranı

Şekil 5.8 Sayısal görünüm ekranı

Şekil 5.9 Sayısal görünüm ekranında toplayıcı resetleme

ve operatör mesajı ekleme

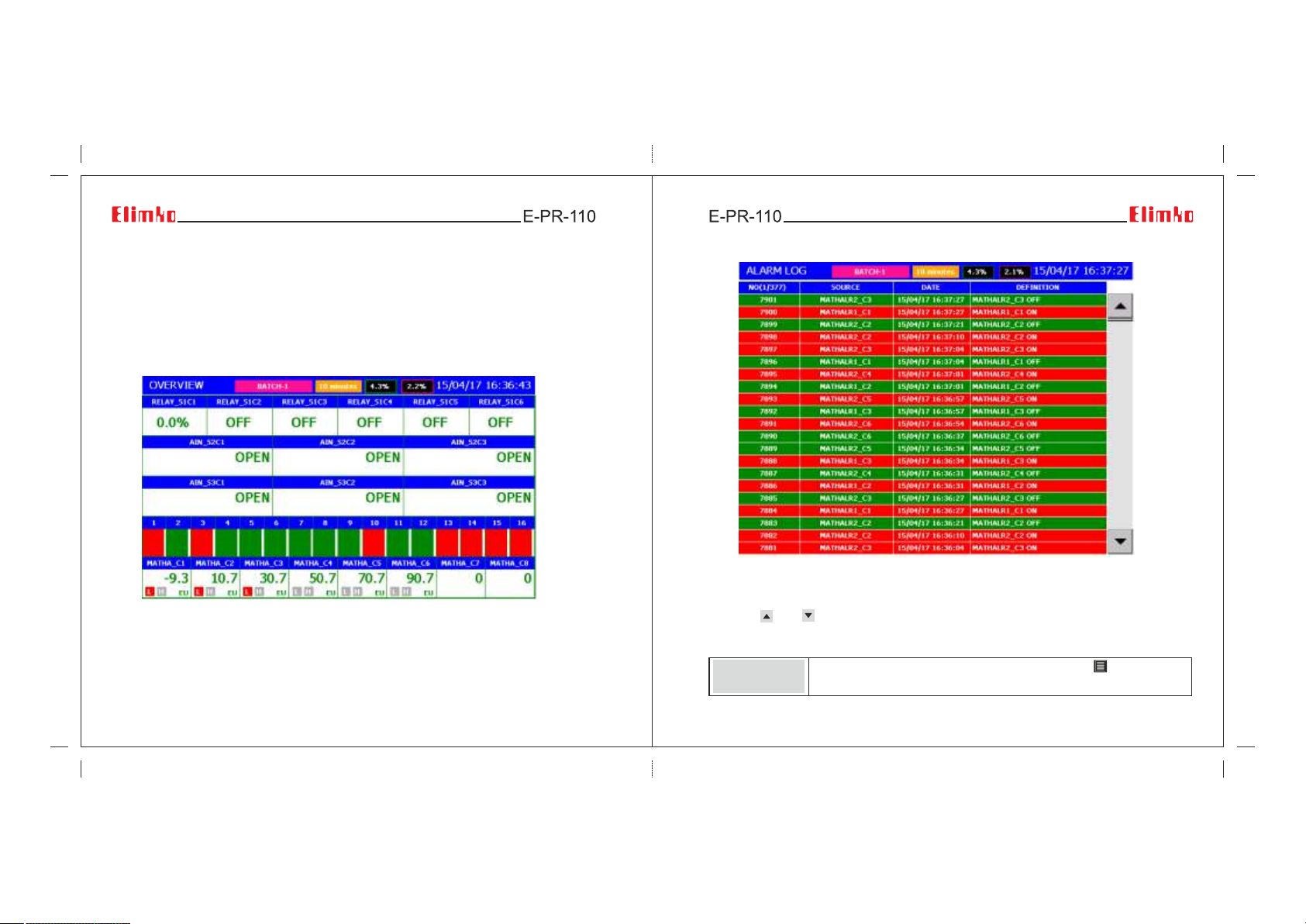

Şekil 5.10 Toplu görünüm ekranı

Şekil 5.11 Alarm Log ekranı alarm durumu

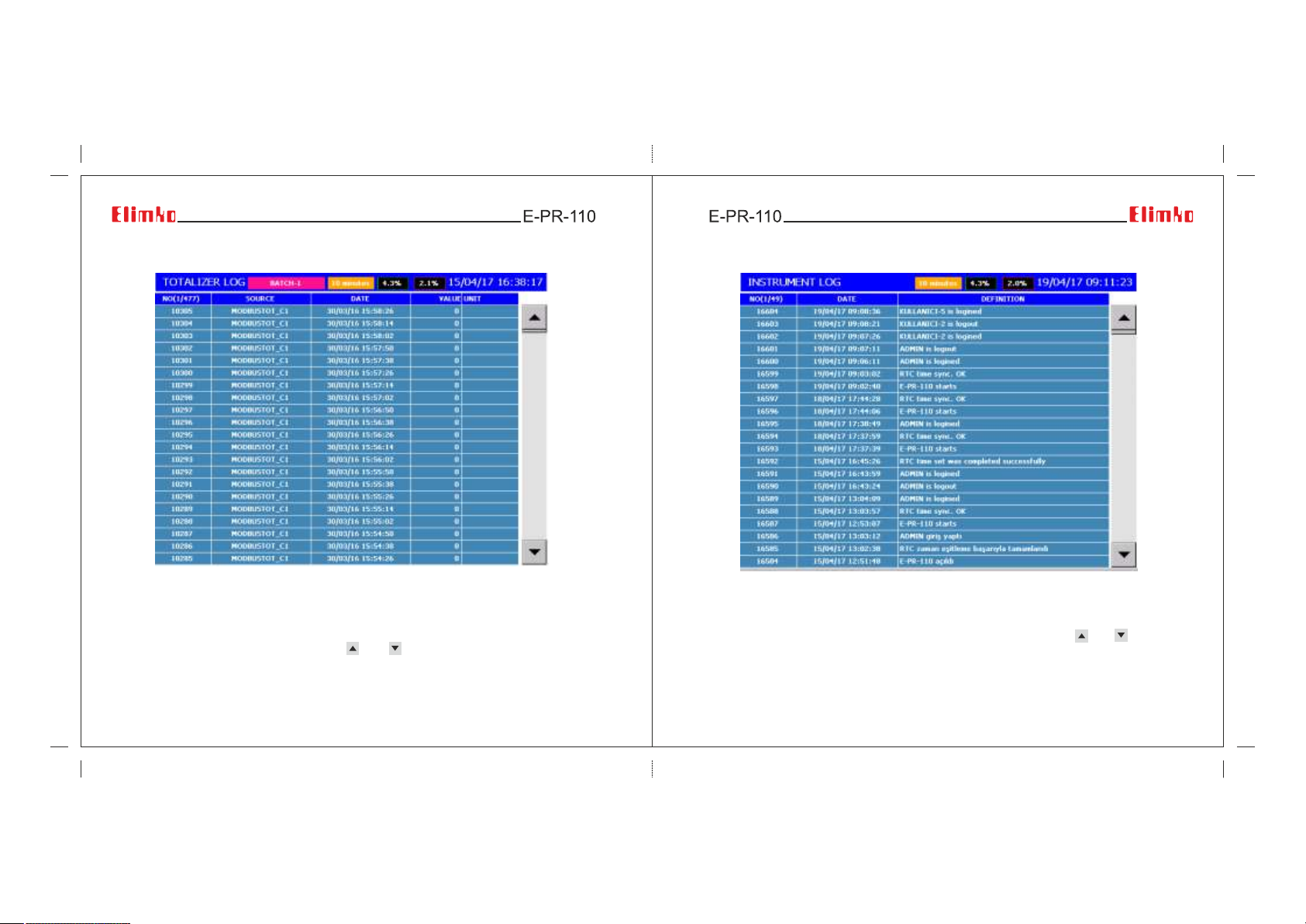

Şekil 5.12 Toplayıcı Log ekranı

Şekil 5.13 Cihaz Log ekranı

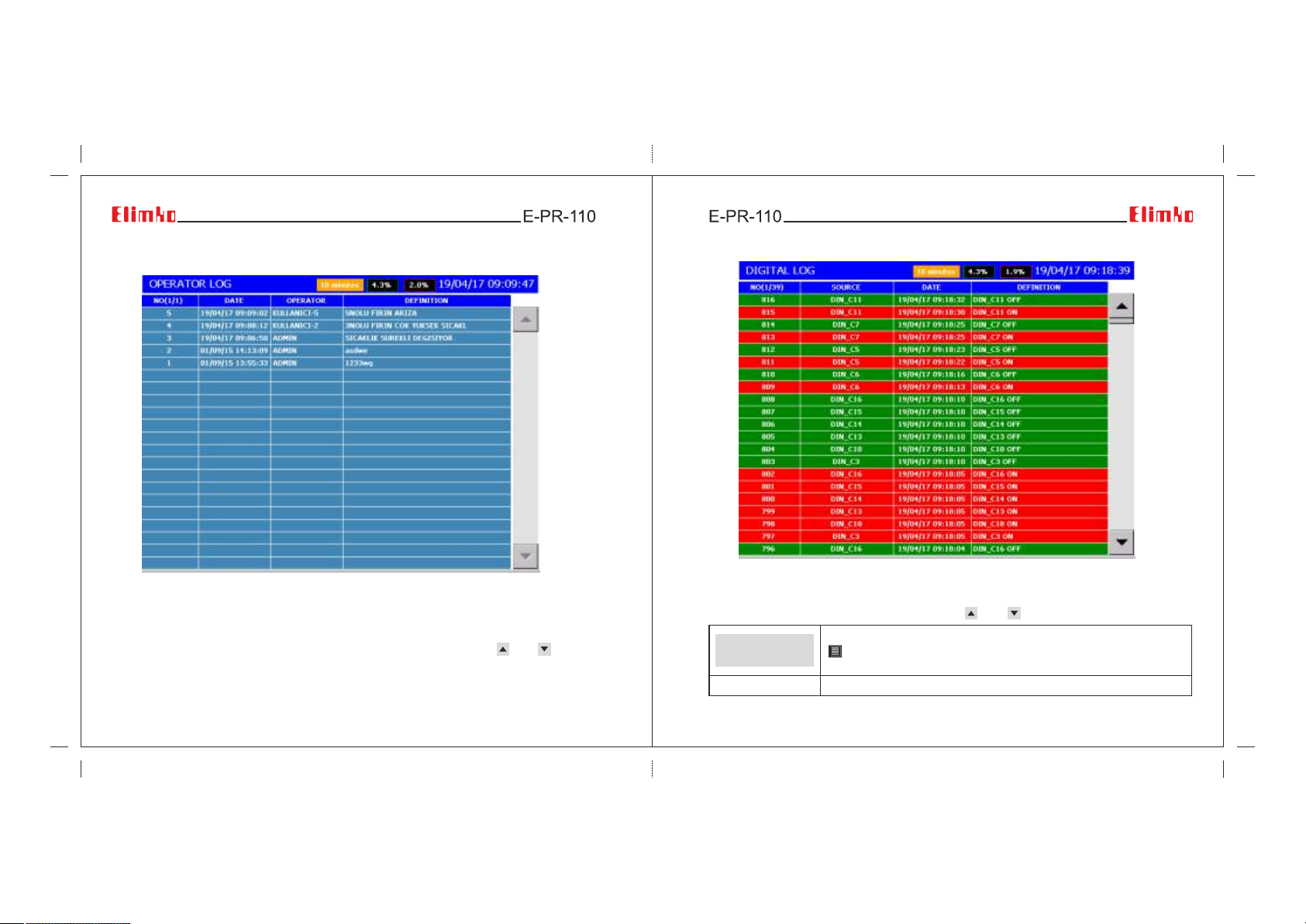

Şekil 5.14 Operatör Log ekranı

Şekil 5.15 Sayısal Log ekranı

Şekil 5.16 Sayısal 2 ekranı

Şekil 6.1 Ana Menüye giriş şifre penceresi

Şekil 6.2 Ana Menü

Şekil 6.3 Cihaz Bilgileri Sayfası

Şekil 6.4 Tarih – Saat Ayarlama Sayfası

Şekil 6.5 Güvenlik Ayarları Sayfası Admin Ayarı

..............................................................................................

............................................................................

....................................................................................

...................................................................................

...........................................................................

..................................................................................

................................................................................

..........................................................................

.....................................................................

...........................................................................

...........................................................

.............................................................................

..................................................................................

.............................................................................

................................................................................

....................................................................................

...........................................................

............................................................................

...............................................................

...........................................

............................

.................................................

......................

12

13

14

15 - 16

17

18

19

20

21

22

22

23

24

25

26

27

28

29

30

31

33

34

34

35

2 - FIGURES2 - FIGURES

Şekil 6.6 Güvenlik Ayarları Sayfası Kullanıcı Ayarı

Şekil 6.7 Donanım Slot Ayarları Sayfası

Şekil 6.8 Donanım Röle Çıkış Test Sayfası

Şekil 6.9 Donanım Analog Giriş Kartı Kalibrasyon Sayfası

Şekil 6.10 Donanım Analog Çıkış Kartı Kalibrasyon Sayfası

Şekil 6.11 Donanım Ethernet Sayfası

Şekil 6.12 Donanım Ethernet Sayfası

Şekil 6.13 Donanım Seri Port penceresi

Şekil 6.14 Donanım Ekran Ayarları penceresi

Şekil 6.15 Çizim Opsiyonları penceresi

Şekil 6.16 Renk Seçim penceresi

Şekil 6.17 Slot Kanalları sayfası

Şekil 6.18 Röle Kartı Ayarları

Şekil 6.19 Sayısal Çıkış Kartı Ayarları

Şekil 6.20 Analog Giriş Kartı Giriş Ayarları

Şekil 6.21 Giriş Tipi Seçimi

Şekil 6.22 Termokupl seçimi

Şekil 6.23 Rezistans Termometre seçimi

Şekil 6.24 Giriş tipi Ohm, Milivolt, Miliamper ya da

Volt seçilmiş ise Lineerleyici seçimi

Şekil 6.25 Giriş tipinin Termokupl seçili olmaması durumunda

CJ Tipi, CJ Sıcaklık ve CJ Kaynak parametreleri

Şekil 6.26 CJ Tip seçim durumlarına göre CJ Sıcaklık ve

CJ Kaynak parametlerinin durumu

................................................................................

...................................................................................

..................................................................................

................................................................

...........................................................

....................................................................

....................................................................

...............................................................

.................................................................

.........................................................................

............................................................................

...................................................................

...........................................................

...............................................................

...........................................

....................................

.......................................................

......................................................

.......................................................

4 5

................................

.................................

35

36

37

38

40

42

42

43

44

44

44

45

46

47

49

50

50

50

50

50

51

27

52

28

Şekil 6.27 Analog Çıkış Kartı Kaynak Proses Değeri

ile Çıkış Değeri Değişimi

Şekil 6.28 Analog Çıkış Kartı Ayarları

Şekil 6.29 Alarm 1 Seçimleri

Şekil 6.30 Alarm 2 Seçimleri

Şekil 6.31 Alarm Tip Seçimleri

Şekil 6.32 Low ve High Alarm Formları

Şekil 6.33 Slow Rate ve Fast Rate Alarm Formları

Şekil 6.34 Analog Giriş Toplayıcı ayarları

Şekil 6.35 Analog Giriş Kayıt ayarları

Şekil 6.36 Sayısal Giriş Kartı Giriş ayarları

Şekil 6.37 Sayısal Giriş Kartı Kayıt ayarları

Şekil 6.38 MODBUS Kanalları Sayfası

Şekil 6.39 Reg. Tipi seçenekleri

Şekil 6.40 Matematik Analog Sayfası

Şekil 6.41 Matematik Sayısal Sayfası

Şekil 6.42 Gerçek Zaman Kanalları (RTC) Sayfası

Şekil 6.43 Gerçek Zaman Kanalları (RTC) kaynak seçimi

Şekil 6.44 Gerçek Zaman Kanalları (RTC) periyod seçimi

Şekil 6.45 Gruplar Sayfası

2

Şekil 6.46 Gruplar Sayfası Grup seçimi

Şekil 6.47 Kullanıcı Tanımlı Tablolar Sayfası

Şekil 6.48 Analog Giriş sayfasında tablo seçimi

Şekil 6.49 Arşiv Senkronizasyon Sayfası

....................................................................................

....................................................................

.................................................................................

.................................................................................

..............................................................................

.................................................................

..............................................................

....................................................................

...........................................................

..........................................................

.................................................................

............................................................................

....................................................................

...................................................................

................................................................

..............................................................

...........................................

...............................................

..............................................

....................................

....................................

........................................................

...................................................

53

29

54

56

56

56

57

57

58

59

61

61

64

64

65

65

67

67

67

68

68

69

69

72

3 - WARNINGS2 - FIGURES

Şekil 6.50 Arşiv Yedek Sayfası

Şekil 6.51 E-MAIL Sunucu Sayfası

Şekil 6.52 E-MAIL Alıcılar Sayfası

Şekil 6.53 E-MAIL Kaynaklar Sayfası

Şekil 6.54 E-MAIL Olaylar Sayfası

Şekil 6.55 PID Kontrol Kanalları Sayfası

Şekil 6.56 PID Kaynağın Analog Çıkışa Tanımlanması

Şekil 6.57 PID Kaynağın Röle Çıkışa Tanımlanması

Şekil 6.58 PID Kontrol Trend Görünüm

Şekil 6.59 PID Kontrol Set Noktasının Değiştirilmesi

Şekil 6.60 Toplu Görünüm Sayfası

Şekil 7.1 E-PR-110 Arka Panel

Şekil 7.2 Güç, Transmitter Besleme, RS-485 ve Ethernet Bağlantıları

Şekil 7.3 3 Kanallı Analog Giriş Kartı Bağlantı Şemaları

Şekil 7.4 6 Kanallı Analog Giriş Kartı Bağlantı Şemaları

Şekil 7.5 Sayısal Giriş ve Çıkış Kartı Bağlantı Şemaları

Şekil 7.6 Röle Çıkış Kartı Bağlantı Şeması

Şekil 7.7 Analog Çıkış Kartı Bağlantı Şeması

Şekil 9.1 Röle Çıkışı Kartı Bağlantı Şeması

Şekil 9.2 RJ 45 pin numaraları ve Crossover kablo bağlantısı

Şekil 9.3 MATH EDITOR Sayfası

Şekil 9.4 Script tuş seçimleri

Şekil 9.5 Operatör ve Fonksiyon Açıklamaları

Şekil 9.6 MODBUS Tablosu

Şekil 9.7 Sayısal Veri Bit Yerleşimi

..............................................................................

........................................................................

.........................................................................

....................................................................

........................................................................

...............................................................

.........................................

.............................................

.................................................................

............................................

........................................................................

..............................................................................

.....................................

.....................................

.......................................

...........................................................

.......................................................

..........................................................

..............................

...........................................................................

..................................................................................

.......................................................

...................................................................................

........................................................................

6 7

.................

72

73

74

75

76

77

80

81

82

83

84

85

86

87

88

89

90

91

94

95

97

97

98

99

99

E-PR-110 recorder is designed for panel mounting and should be used in

industrial environment.

The package of E-PR-110 recorder contains;

Recorder

2 pieces of mounting clamps

1 piece M3 bolt nut

User Manual

Guarantee Certificate

Elimko Data Explorer Pro Cd.

• After opening the package, please check the contents with the above list. If the

delivered product is wrong type, any item is missing or there are visible defects,

contact the vendor from which you purchased the product.

• Before installing and operating the controller, please read the user manual thoroughly.

• The installation and configuration of the recorder must only be performed by a person

qualified in instrumentation.

• Keep the unit away from flammable gases that could cause explosion.

• Do not use alcohol or other solvents to clean the recorder. Use a clean cloth soaked in

water tightly squeezed to gently wipe the outer surface of the recorder.

• Do not use any sharp objects or abrasives to avoid damaging the device.

• The product life of this instrument is 10 years.

This recorder complies with the European Low Voltage Directive 2006/95/EC,

by the application of safety standard TS EN 61010-1. (Pollution Degree 2)

This recorder complies with the EMC Directive 2004/108/EC by the application of

EMC standard TS EN 61326.

4 - DESCRIPTION

4.1 - Type Coding

E-PR-110 series industrial recording and control devices complies with IEC/TR 60668

standard with its 144x144 mm front panel. These series has a high brightness and high

resolution, 640x480 pixel TFT touch panel and features several analog and digital

interfaces.

• 5.7 '', 640x480 , touch panel TFT screen

• Up to 24 universal Analog Input Channels

• Up to 18 Relay Outputs

• TCP/IP Modbus Master and Slave Protocol

• RS-485 Modbus Master and Slave Protocol

• Data connection with internal HTTP and FTP Server

• Up to 64 Digital Input Channels

• Up to 64 Digital Output Channel

• Analog çıkış?

• Standard RS-485 communication port

• 10/100 Mbit Ethernet Port

• Wi-Fi® (Optional)

• USB Host Port

8

E-PR-110 - S1 - S2 - S3 - S4 - Y - Z

Operating Voltage

0 : 85 - 265 VAC,

0 : Empty

1 : 03 Analog Input

2 : 06 Analog Input

3 : 06 Relay Output

4 : 16 Digital Input

5 : 16 Digital Output

6 : 04 Analog Output

50-60 Hz / 85 - 375 V DC

Wi-Fi

0 : Without Wi Fi

1 : With Wi Fi

Example

E-PR-110-1-1-1-1-0-0

E-PR-110-1-1-3-3-0-0

E-PR-110-1-4-4-3-0-0

E-PR-110-1-1-1-5-1-0

E-PR-110-4-4-4-5-1-0

NOTE: The total number of relay and analog output should not exceed 18.

Digital Output number is limited to 64.

12 (3+3+3+3) analog input

6 (3+3) analog input, 12 (6+6) relay output

3 analog input, 32 (16+16) digital input, 6 relay output

9 (3+3+3) analog input, 16 digital output, with Wi-Fi

48 (16+16+16) digital input, 16 digital output, with Wi-Fi

9

4.2 - Technical Specification

4.2 - Technical Specification

Input Types

Accuracy

Operating Voltage

Power Consumption

Data Storage Memory

Communication

Sampling Rate

Configuration Ports

Screen Type

Operating Tempreature

Storage Temperature

Analog Input

Analog Output

TC (B, E, J, K, L, N, R, S, T, U)

RT (Pt-50, Pt-100, Pt-500, Pt-1000, Ni-100, Ni-200, Ni-500,

Ni-1000)

0 ... 20 mA, 4 ... 20 mA, -2000 mV ... 2000 mV, 0 ... 10 V

TC : ±%0.5 of the reading value or ±1°C

RT : ±%0.5 of the reading value or ±1°C

Voltage / Current : ±%0.5 FS

85 - 265 V AC; 50 - 60 Hz / 85-375 V DC

30 W maximum

8 GB Micro SD Flash

10 - 100 Mbit Ethernet, RS-485, USB Host,

802.11bgn 2.4GHz Wi-Fi®

100 ms (For all channels)

Touch Panel, USB Mouse and Keyboard connections

5.7" TFT LCD, 640×480 resolution, 18 bit color, Touch panel

0°C ... 50°C

-10°C ... 85°C

Max. 24 Analog Inputs 16 bit

(1)

(isolation of channels 1000 V AC )

0 – 20 mA / 0 – 10 V can be configured.

Number of analog outputs is limited to 18

(1)

10

Digital Input

Digital Output

Max. 64 Digital Inputs

Max. 64 Digital Outputs, 24 V DC, 40 mA

(1)

(1)

Max. 18 Relay Outputs, SPST-NO; 250 V AC, 5 A

Relay Output

Mechanical Life > 10.000.000 operation

(The relay life depends on the usage configuration)

Electrical Life > 1.000.000 operation (1/10 load)

Language

Transmitter Supply

Password Protection

Protection Class

Weight

(1)

Configuration dependent. Number of analog outputs, relay outputs and transmitter

supply capacity are interdependently limited (See Section 4.1 Type Coding).

(2)

The total number of 4-20 mA transmitters to be supplied, relay outputs and analog

Turkish, English

(2)

Adjustable different authority (Max. for 5 user)

Front Panel: IP65, Rear Panel: IP20

Approx. 1.6 kg

outputs should not exceed 16 (A+B+C<=18) due to internal 24 V DC power limitation.

This limitation is valid only with the assumption of all the output will be active at the same

time.

For certain situations such as backup purposes, different output usage scenarios etc,

the number of outputs could be increased. Please contact your sales provider for advise!!!

A= Number of 4-20 mA transmitters to be supplied

B= Number of Relay Outputs (number of individual outputs, not

the number of cards, each relay output card has 6 relay outputs)

C= Number of Analog Outputs (number of individual outputs, not

the number of cards, each analog output card has 4 analog outputs)

4.3 - Dimensions

144 mm

137 mm

4.4 - Panel Mounting

138 mm

Elimko

E-PR-110 Dimensions

and Panel Mounting

Figure 4.1

20 mm

144 mm

110 mm

10 mm

137 mm

Figure 4.2 E-PR-110 Panel Cut Hole

• E-PR-110 device should be installed inside a suitable grounded metal enclosure (panel).

This must prevent the live parts being accessible to human hands and metal tools.

(See Section 7. CONNECTION DIAGRAMS).

• E-PR-110 does not include a power switch. Therefore, the power supply of the

device and power outputs must be wired through the proper fuse or circuit breaker.

• To minimize the pick-up of electrical noise, the wiring of low voltage lines,

particularly the sensor input should be routed away from the high-current power cables. Where

it is not possible, use shielded cables which are grounded at both ends.

• The cables used for powering the controller and the power outputs must conform to the

standards IEC 60245 and IEC 60227.

12 13

138 mm

Panel Cut Hole

5 - USAGE

5.1 - Front Panel

5.1 - Front Panel

In the event of a new alarm, the background color of the title area flashes between red

and blue. After the alarms were acknowledged, the flashing ceases and the title area

appears in blue (see Figure 5.1).

Title area

Figure 5.1 Trend View

14 15

During normal operation, the operation buttons are hidden to increase

the display area. Hidden operation buttons can be made visible by touching

the bottom of the screen (see Figure 5.2). Explanations are given below

regarding the operation buttons.

Figure 5.2 Operation Keys

The capacitive touch sensor device only works with the human hand and

capacitive pens.

5.1 - Front Panel

OPERATION BUTTONS

This button is used to select one of the 6 groups and

is active only TREND, BAR, DIGITAL and DIGITAL 2 views.

This button is used to select any of the TREND, BAR,

DIGITAL, OVERVIEW, ALARM LOG, TOTALIZER LOG,

INSTRUMENT LOG, OPERATOR LOG, DIGITAL LOG,

DIGITAL 2 and SCAN VIEWS options.

This button allows the operator access to the menu of

selected view. Each view has a different menu and detailed

explanations of the menus are given in the related

description of the views.

This button is active only in the trend view.

Used to increase or decrease the width of the screen.

This button allows access to the configuration pages.

5.2 - Trend Page

Traces, process values, and alarm states of the channels in selected group are viewed.

By pressing button the menu given Figure 5.5 is opened.

In Trend Page while not in History mode, newest recorded data is drawn on the screen

continuously. To view historical data, History mode should be selected in Operator Menu.

While in history mode, process values, date and time seen on the screen are the values

at the time of cursor location. By touching the screen, the location of the cursor can be

changed. While in history mode, date and time on the screen are written in red.

By Go To Date, One Grid Forward, One Grid Back, buttons, desired date and time

can be chosen.

Channel

Name

Process

Value

Group Name

Batch Name

Screen Width

Disc Storage Rate

Memory Usage

Rate

Date and

Time

Process

Unit

Figurel 5.2 Operation Buttons

Used to set up a Wi-Fi connection. If the Wi-Fi connection is

not installed, the button appears. This button is pressed

to establish a Wi-Fi connection. In the window that opens,

enter the network SSID and Password. The network

connection is established by pressing the Connect button.

If the network connection is established, the symbol

appears. Under the Wi-Fi icon, it writes the SSID of the

connected network.

16 17

Graphic

Scale

Graphic

Pen

Last Data

Figure 5.3 Trend View Screen

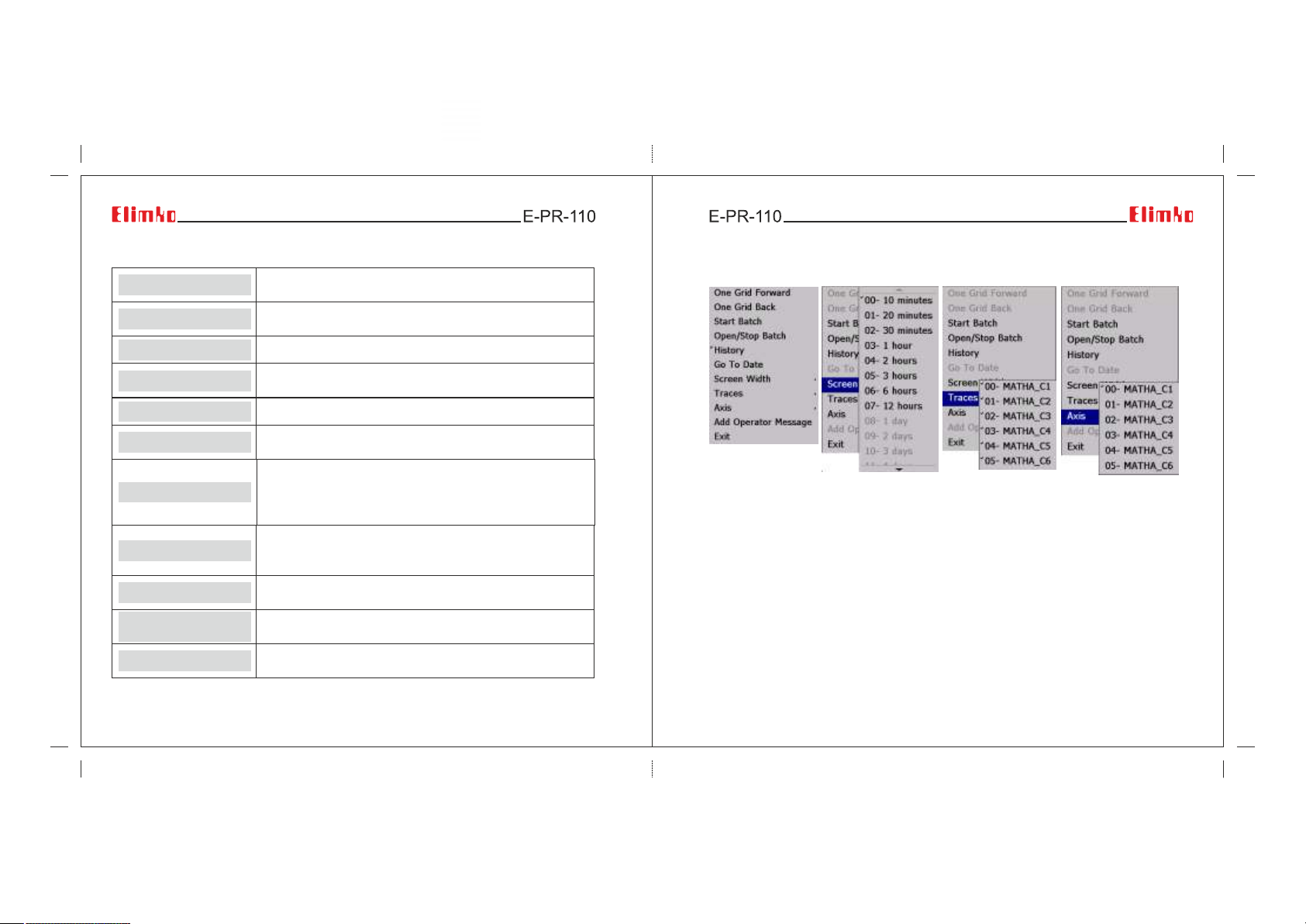

5.2 - Trend Page

5.2 - Trend Page

One Grid Forward

One Grid Back

Start Batch

Open/Stop Batch

History

Go To Date

Screen Width

Traces

Axis

Add Operator

Message

Exit

Figure 5.4 Active buttons and meaning in the Trend view screen

Historical mode must be selected for this key to be active.

This button scrolls the graph forward by a grid interval.

Historicaly mode must be selected for this key to be active.

This button scrolls the graph backwards by a grid interval.

Starts a new batch.

Opens batch management window in which user can stop

running batches and open completed batches for review.

Selects Historical mode.

While History is selected, any past date can be chosen to

review. The desired time can be entered by the keyboard.

Determines time interval that will be shown on the screen.

According to selected sampling rate, some time intervals

can appear disabled in a purpose to limit number of data

points to be displayed.

The traces that desired to be seen can be chosen with this

parameter. Desired traces can be opened or closed in

Traces Menu.

The axis of the channel to be seen on the trend can be

chosen with this parameter.

Adds operator messages. User must login in order to

reach this menu. (see Section 6. MENU PAGES)

Used to exit the screen. The same operation can be

performed by touching an empty area on the screen.

18 19

Figure 5.5 Active buttons and options on the Trend view screen

5.2 - Trend Page

Recording can be made continuously or batch base. To start a batch in any time,

Start Batch is selected in Operator Menu. Start Batch screen will be opened as

shown below. In this screen Batch Name, Operator, Part No and Serial No can be

filled to any values depending on batch process and Start is selected. When the batch

starts, Batch Name is written on the top of Trend Page. Stop Batch command in

Operator Menu provide access to manage running and recorded batches. Start/Stop

batch operations can also be performed with a barcode reader. (see Appendix 4)

Figure 5.6 Start Batch Screen

20 21

5.3 - Bar Graphic Page

Channel

Name

Process

Value

Alarm 1

Alarm 2

If the alarms are

defined, H or L

is written

according to

alarm types.

Active alarms

are shown with

red color.

Scale

Figure 5.7 Bar View Screen

In Bar Graphic Page, bar graphics, process values, and alarm states of

6 channels in selected group are viewed.

Process

Unit

Process

Value

Alarm Set

Points

The set points

of Alarm1 and

Alarm2.

The set points

of Alarm1 and

Alarm2 are

shown with

purple and

claret red

respectively.

5.4 - Digital View Page

Channel

Name

Process

Value

Alarm

States

Figure 5.8 Digital View Screen

In Digital View Page, totalizer values, process values, and alarm states of

6 channels in selected group are viewed.

22 23

Process

Unit

Totalizer

and Unit

5.4 - Digital View Page

Figure 5.9 Totalizer reset and add operator messages (Digital View Page)

Reset Totalizer

Add Operator Message

Exit

Operator Menu for Digital View Page is opened by pressing

button. To reset the totalizer of an individual source,

select the corresponing source name in sub menus of

Reset Totalizer menu. To reset the totalizers of all sources

in selected group, All can be selected.

Add Operator Message: Adds a operator message. It is

only active when the user is logged in.

(See Section 6. MENU PAGES).

5.5 - Overview Page

All channels can be viewed in this page together. Process values of all available sources

can be viewed in a single page. Each row in the page corresponds to a process group

from one of the available slots, Modbus Channels or Math Analog Channels. Empty slots

and undefined MATH and MODBUS channels are not shown. Analog process groups

having more than 8 channels occupy two rows and due to overall row limitation, some

of the process groups appears intermittently.

Figure 5.10 Batch Screen View

5.6 - Alarm Log

Figure 5.11 Alarm Log screen

The last occurred and released 10000 alarms with date and definitions are listed in

Alarm Page. The latest alarm is on the top of the list. The list can be scrolled by

pressing and buttons. Active alarms are shown in red color and released

alarms are shown in green color. Active alarms which appear in red turn green after

the alarms were acknowledged by selecting Acknowledge Alarms parameter.

Acknowledge

Exit

Operator Menu for Alarm Page can be opened with button. Alarms

are acknowledged with selecting Acknowledge Alarms parameter.

24 25

5.7 - Totalizer Log

5.8 - Instrument Log

Figure 5.12 Totalizer Log screen

Source Name, record date, totalizer value and unit of the last recorded 10000 totalizer

values are listed in Totalizer Page. The last recorded totalizer is displayed at the top of

the list. Totalizer values can be scrolled by and buttons. The time intervals of

totalizers are defined with the Logging Source parameter of related Totalizer.

26 27

Figure 5.13 Instrument Log screen

The date and definition of last recorded 1000 events of the device are listed in

Instrument Log Page. The last recorded event appears on the top. and buttons

are used to scroll the list up or down.

5.9 - Operator Log

Figure 5.14 Operator Log screen

Operators can add messages anytime while operating the device in order to assert

certain events and information. In order to add messages, the operator must login first

and should press Add Operator Message menu in the Operator Menu. Operator

message with descending date order are listed in Operator Log Page. and keys

scrolls the page up and down direction (see Section 5.2 TREND PAGE and

5.4 DIGITAL VIEW PAGE).

28 29

5.10 - Digital Log

Figure 5.15 Digital Log screen

Source Name, record date and definition of the last recorded 65536 digital log values

are listed in Digital Log Page. The last recorded digital log value is displayed at the top

of the list. Digital log values can be scrolled by and buttons.

Acknowledge

Exit

Operator Menu for Digital Log Page can be opened by pressing

button. Alarms are acknowledged by selecting

Acknowledge digital logs menu.

Note: In "NO(X/Y) column, X is page number and Y is number of pages.

5.11 - Digital 2

6 - MENU PAGES

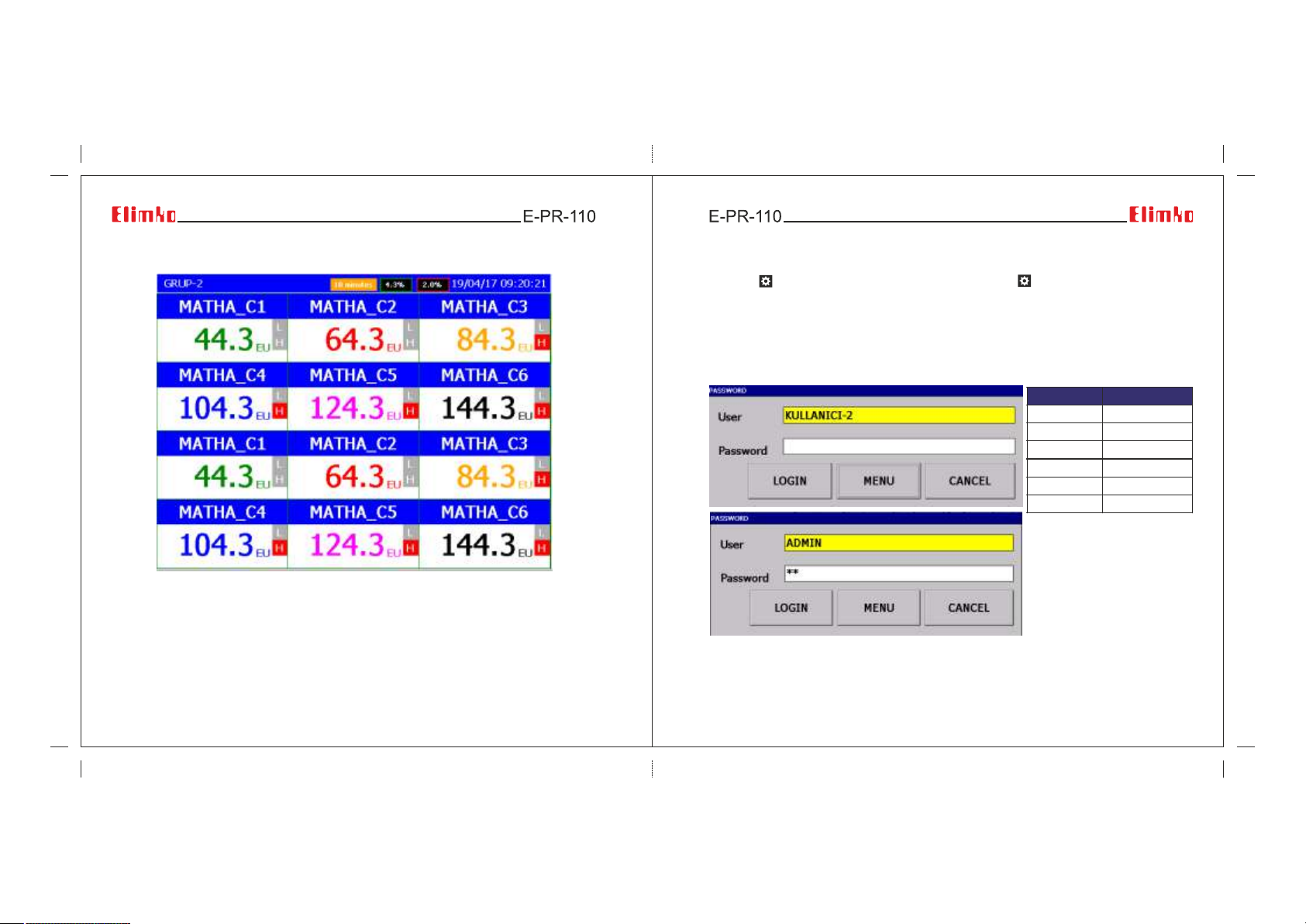

Pressing key accesses to Menu page. Upon pressing key authentication window

opens and user name/ password are asked. After selecting UserName and Password,

main menu is reached by either pressing MENU or LOGIN button. LOGIN access does

not require authentication on subsequent entries until LOGOUT is pressed from Main

Menu. Depending on previously defined authorization rights, some of the sub menus

may appear disabled (see Section 6.4. Security). Default values for the user password

are given:

Figure 5.16 Digital 2 screen

Two consecutive groups (selected group and the following group which may wrap to first

or last group depending on selected group) can be viewed digitally on the same page.

30 31

Figure 6.1 Password input window to the main menu

USERS

ADMIN

USER 2

USER 3

USER 4

USER 5

USER 6

PASSWORD

10

02

03

04

05

06

Loading...

Loading...