Elimko E-70-O User Manual

E-70-Ö DIGITAL CONTROLLER USER MANUAL

Elimko

m

The package of E-70-Ö controller contains; Controller, 2 pieces of mounting clamps, User manual and Guarantee certificate

m

After opening the package, please check the contents with the above list. If the delivered product is wrong type, any item is

missing or there are visible defects, contact the vendor from which you purchased the product.

E-70-Ö controller is designed for panel mounting and should be used in an industrial environment.

m

Before installing and operating the controller, please read the user manual thoroughly.

m

The installation and configuration of the controller must only be performed by a person qualified in instrumentation.

m

Keep the unit away from flamable gases, that could cause explotions.

m

Do not use alcohol or other solvents to clean the controller. Use a clean cloth soaked in water tightly squeezed to gently wipe the outer

surface of the controller.

m

The product life of this instrument is 10 years.

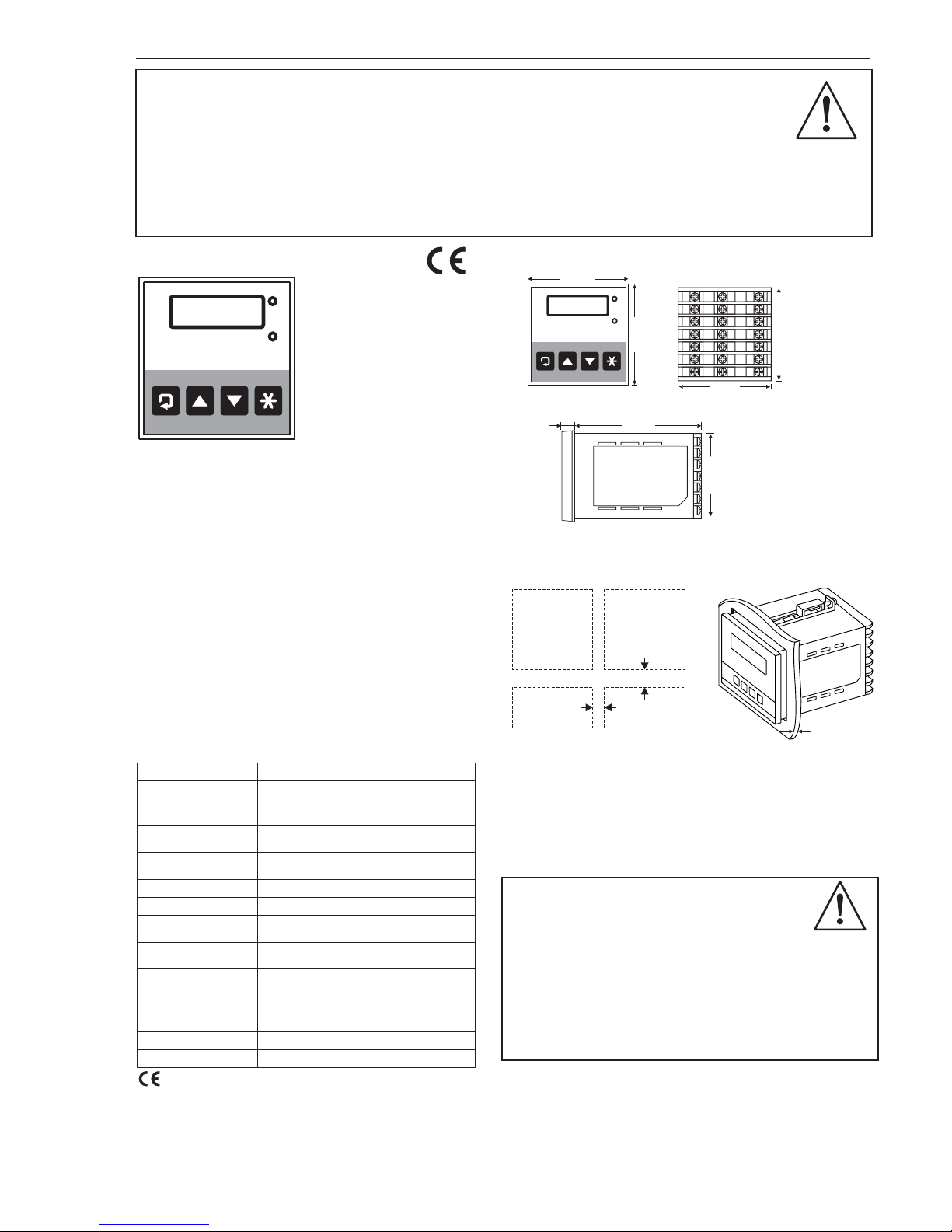

1. DESCRIPTION

ALM

ECO

22 C°

3. DIMENSIONS

67 mm

67 mm

72 mm

72 mm

10 mm

100 mm

67 mm

ALM

ECO

q

This controller complies with the European Low Voltage

Directive 73/23/EEC, by the application of safety standard

TS 2418 EN 61010-1. (Pollution degree 2)

q

This controller complies with the EMC Directive 89/336/EEC,

by the application of EMC standard TS EN 61326.

2. TECHNICAL SPECIFICATIONS

Resistance Thermometer (Pt-100)

4 digit 10 mm 7 segment led display

24 V AC ± %10; 50-60 Hz

2.5 W (4 VA)

±0.5% of the reading value or ±2 C)

±1 digit max.

o

16 bit

>1 000 000 operations (under 1/10 of load)

EEPROM (100.000 max. write-erase)

0 C, +55 C

(with no condensation or icing)

oo

-25 C, +65 C

(with no condensation or icing)

oo

Front Panel : IP 66 (

Rear Case : IP 20

NEMA 4X)

380 g

Input Type

Alarm Outputs

Display Type

Accuracy

Analog Digital

Converter

Operating Voltage

Power Consumption

Protection Class

Operating

Temperature

Storage Temperature

Relay Mechanical Life

Memory

Weight

Relay Electrical Life

10 000 000 operations

Relay 2: SPDT-NO-C-NC 250 V AC, 5A

Relay 1: SPST-NO 250 V AC, 5A

q

q

q

q

Cut a hole in the panel. (See the figure for overall dimensions.)

Slide the controller into the cutout from the front of the panel.

Fit the mounting clamps to the controller, ensuring the lugs are

located in their slots.

Fasten the mounting clamps using the retaining screws.

The cables used for powering the controller and the power outputs

must conform to the standarts IEC 60245 and IEC 60227.

m

To minimize the pick-up of electrical noise, the wiring of low voltage

lines, particularly the sensor input should be routed away from the

high-current power cables. Where it is not possible, use shielded

cables with the shield grounded at both ends.

m

E-70-Ö controller does not include a power switch. Therefore, the

power supply to the controller and power outputs must be wired

through the proper fuse or circuit breaker.

m

E-70-Ö controller should be installed inside a suitable

grounded metal enclosure (panel). This must prevent

the live parts being accessible to human hands and

metal tools.

m

4. PANEL MOUNTING

min.35 mm

min.10 mm

+0.7

-0.0

68x68mm

max. 15 mm

Panel Cutout and

Minimum Spacing

E-70-Ö digital controller

measures its input temperature

by means of a Pt-100 resistance

thermometer and controls two

output relays as a function of the

input temperature and the state

of internal timers. The control of

RL1 and RL2 output relays are

as follows;

RL1: When the device is energized, the output relay RL1 is

activated. When the measured temperature decreases and

becomes equal to SETL (2°C), 10 minutes timing will be started.

During the timing period, RL1 will be active and measured

temperature has no effect on the state of RL1. When the time is

out, RL1 becomes inactive, provided that the measured temperature

is less than SETH (10°C). When the temperature increases and

reaches SETH, RL1 becomes active again and the same steps will

be repeated. The state of RL1 is indicated by the green led ECO,

this led is illuminated while RL1 is inactive.

RL2: Applying the operating voltage to the controller starts 20

minute timer. Initially the output relay RL2 is de-energized. During

the timing period, RL2 will be inactive and measured temperature

has no effect on the state of RL2. When timing expires, the state of

RL2 is controlled by the input temperature. When the temperature

is between ASTL (0°C) and ASTH (15°C), RL2 will be inactive. If

the measured temperature is greater than ASTH or less than ASTL,

RL2 will be energized. ALM led (red) on the front panel will be

flashed while RL2 is energized.

E-70-Ö is housed in a 72 x 72 mm plastic case conforming IEC

668 standard. The operating voltage of the device is 24 V AC

±%10, 50-60 Hz.

E-70-Ö DIGITAL CONTROLLER USER MANUAL

5. CONNECTION DIAGRAM

Before operating the controller, ensure that the controller

is correctly configured. Incorrect configuration could

result in damage to the process being controlled.

m

The terminals 01 to 07 are electrically live. While the

instrument is powered, never touch to these terminals.

m

The labels on the sides of the controller identify the ordering

code (Type), serial number and wiring connections.

Connection diagram is given below.

Manufacturer / Technical Support:

Elimko Co. Ltd. 8. cadde 68. Sokak No:16 06510 Emek - ANKARA / TURKEY

Phone:+ 90 312 212 64 50 Fax:+ 90 312 212 41 43 www.elimko.com.tr e-mail:elimko@elimko.com.tr

KY-70-1209-0-Ö

The front panel view of the E-70-Ö controller is given in

section. In normal operation, the four digit display displays the process

value and unit. The display of the controller displays between -19 and 99.

Out of this range or while the connection of the sensor is broken the

display will be shown as ( )

1. DESCRIPTION

--

6. OPERATION

The other parameters are configured in configuration mode.

q

In order to access the configuration mode, and buttons must be

pressed simultaneously.

CD

q

Just after this operation, message is displayed for one second

duration, is displayed in the display. The security code must be

entered with and buttons in order to access the parameters.

COD

0

AF

q

The entered security code must be correct, otherwise pressing

button will revert to normal operation.

D

q

The factory setting value of security code is “10”. The security code is

defined by parameter; user can edit this parameter to define a new

security code. If the value of security code is forgotten, pressing and

buttons simultaneously at least 10 seconds, makes possible to access

the parameters.

PAS

C

D

q

If the entered security code is correct, pressing key will select the

first parameter.

C

q

While a parameter is selected, the parameter value is edited by and

buttons.

Pressing button will select the next parameter.

Pressing button exist the configuration mode.

F

A

C

D

16

15

18

19

20

PT-100

02

21

17

04

03

01

06

07

3A

250

VAC

3A

250

VAC

05

24 V AC; 50-60Hz24 V AC; 50-60Hz

RL1

3A

250

VAC

3A

250

VAC

RL2

7. EXPLANATION OF PARAMETERS

21 C*

ASTL

0C*

SETL

2*C

Code ok. Code wrong

COD

0

SETH

SFT

0*C

10*C

UNT

PAS

10

0

ASTH

10*C

COD:Security code is asked with this parameter. It can be

adjusted between -1999 and 9999.

SFT

:

Defines the shift value of the input. It can be adjusted

between -10°C and 10°C. The value of input that seen

on the display is the sum of measured value and

parameter.

SFT

UNT : Indicates the measuring unit of the input. It can be

adjusted as 0 (°C) or 1 (°F). If parameter is changed,

, , , , and parameters should be

revised. Also the adjustment limits of set points are depend

on this parameter.

UNT

ASTL ASTH SETL SETH SFT

PAS:Define the security code. Parameter can be adjusted

between -1999 and 9999.

ASTL:The low value of alarm set point. This parameter is

used for controlling Relay 2.

ASTH

:

The high value of alarm set point. This parameter is

used for controlling Relay 2.

SETL

:

The low value of control set point. This parameter is

used for controlling Relay 1.

SETH

:

The high value of control set point. This parameter is

used for controlling Relay 1.

Loading...

Loading...