Page 1

Page 2

Page 3

Page 4

Page 5

Page 6

15

EN - Instruction on mounting and use

Closely follow the instructions set out in this manual. All

responsibility, for any eventual inconveniences, damages or

fires caused by not complying with the instructions in this

manual, is declined. The hood is conceived for the suction of

cooking fumes and steam and is destined only for domestic

use.

! It is important to conserve this booklet for consultation at

any moment. In the case of sale, cession or move, make

sure it is together with the product.

! Read the instructions carefully: there is important

information about installation, use and safety.

! Do not carry out electrical or mechanical variations on the

product or on the discharge conduits.

! Before proceeding with the installation of the appliance

verify that there are no damaged all components.

Otherwise contact your dealer and do not proceed with

the installation.

Note: the elements marked with the symbol “(*)” are optional

accessories supplied only with some models or elements to

purchase, not supplied.

Caution

Before any cleaning or maintenance operation, disconnect

hood from the mains by removing the plug or disconnecting

the mains electrical supply.

Always wear work gloves for all installation and maintenance

operations.

This appliance can be used by children aged from 8 years and

above and persons with reduced physical, sensory or mental

capabilities or lack of experience and knowledge if they have

been given supervision or instruction concerning use of the

appliance in a safe way and understand the hazards involved.

Children shall not be allowed to tamper with the controls or

play with the appliance.

Cleaning and user maintenance shall not be made by children

without supervision.

The premises where the appliance is installed must be

sufficiently ventilated, when the kitchen hood is used together

with other gas combustion devices or other fuels.

The hood must be regularly cleaned on both the inside and

outside (AT LEAST ONCE A MONTH).

This must be completed in accordance with the maintenance

instructions provided in this manual. Failure to follow the

instructions provided in this user guide regarding the cleaning

of the hood and filters will lead to the risk of fires.

The flaming of foods beneath the hood itself is severely

prohibited.

The use of exposed flames is detrimental to the filters and

may cause a fire risk, and must therefore be avoided in all

circumstances.

Any frying must be done with care in order to make sure that

the oil does not overheat and ignite.

CAUTION! Accessible parts of the hood may become hot

when used with cooking appliance.

For lamp replacement use only lamp type indicated in the

Maintenance/Replacing lamps section of this manual.

WARNING! Do not connect the appliance to the mains until

the installation is fully complete.

With regards to the technical and safety measures to be

adopted for fume discharging it is important to closely follow

the regulations provided by the local authorities.

The ducting system for this appliance must not be connected

to any existing ventilation system which is being used for any

other purpose such as discharging exhaust fumes from

appliances burning gas or other fuels.

Do not use or leave the hood without the lamp correctly

mounted due to the possible risk of electric shocks.

Never use the hood without effectively mounted grids.

The hood must NEVER be used as a support surface unless

specifically indicated.

Use only the fixing screws supplied with the product for

installation or, if not supplied, purchase the correct screws

type.

Use the correct length for the screws which are identified in

the Installation Guide.

In case of doubt, consult an authorised service assistance

centre or similar qualified person.

WARNING! Failure to install the screws or fixing device in

accordance with these instructions may result in electrical

hazards.

We will not accept any responsibility for any faults, damage or

fires caused to the appliance as a result of the nonobservance of the instructions included in this manual.

This appliance is marked according to the European directive

2002/96/EC on Waste Electrical and Electronic Equipment

(WEEE). By ensuring this product is disposed of correctly, you

will help prevent potential negative consequences for the

environment and human health, which could otherwise be

caused by inappropriate waste handling of this product.

The symbol

on the product, or on the documents

accompanying the product, indicates that this appliance may

not be treated as household waste. Instead it should be taken

to the appropriate collection point for the recycling of electrical

and electronic equipment. Disposal must be carried out in

accordance with local environmental regulations for waste

disposal.

For further detailed information regarding the process,

collection and recycling of this product, please contact the

appropriate department of your local authorities or the local

department for household waste or the shop where you

purchased this product.

Appliance designed, tested and manufactured according to:

• Safety: EN/IEC 60335-1; EN/IEC 60335-2-31, EN/IEC

62233.

• Performance: EN/IEC 61591; ISO 5167-1; ISO 5167-3; ISO

5168; EN/IEC 60704-1; EN/IEC 60704-2-13; ISO 3741; EN

50564; IEC 62301.

• EMC: EN 55014-1; CISPR 14-1; EN 55014-2; CISPR 14-2;

EN/IEC 61000-3-2; EN/IEC 61000-3-3. Suggestions for a

Page 7

16

correct use in order to reduce the environmental impact:

Switch ON the hood at minimum speed when you start

cooking and kept it running for few minutes after cooking is

finished. Increase the speed only in case of large amount of

smoke and vapour and use boost speed(s) only in extreme

situations. Replace the charcoal filter(s) when necessary to

maintain a good odour reduction efficiency. Clean the grease

filter(s) when necessary to maintain a good grease filter

efficiency. Use the maximum diameter of the ducting system

indicated in this manual to optimize efficiency and minimize

noise.

Additional Installation Specifications:

Use only the fixing screws supplied with the product for

installation or, if not supplied, purchase the correct screws

type.

Use the correct length for the screws which are identified in

the Installation Guide.

In case of doubt, consult an authorised service assistance

centre or similar qualified person.

WARNING! Failure to install the screws or fixing device in

accordance with these instructions may result in electrical

hazards.

Use

The hood is designed to be used either for exhausting or filter

version.

Ducting version

The hood is equipped with a top air outlet B for discharge of

fumes to the outside (exhaust pipe and pipe fixing clamps not

provided).

Attention! If the hood is supplied with carbon filter, then it

must be removed.

Filter version

Should it not be possible to discharge cooking fumes and

vapour to the outside, the hood can be used in the filter

version, fitting an activated carbon filter and the deflector F

on the support (bracket) G, fumes and vapours are recycled

through the top grille H by means of an exhaust pipe

connected to the top air outlet B and the connection ring

mounted on the deflector F (exhaust pipe and pipe fixing

clamps not provided).

Attention! If the hood is not supplied with carbon filter,

then it must be ordered and mounted.

The models with no suction motor only operate in ducting

mode, and must be connected to an external suction device

(not supplied).

The connecting instructions are supplied with the peripheral

suction unit.

Installation

The minimum distance between the supporting surface for the

cooking equipment on the hob and the lowest part of the

range hood must be not less than 50cm from electric cookers

and 50cm from gas or mixed cookers.

If the instructions for installation for the gas hob specify a

greater distance, this must be adhered to.

Electrical connection

The mains power supply must correspond to the rating

indicated on the plate situated inside the hood. If provided with

a plug connect the hood to a socket in compliance with current

regulations and positioned in an accessible area, after

installation. If it not fitted with a plug (direct mains connection)

or if the plug is not located in an accessible area, after

installation, apply a double pole switch in accordance with

standards which assures the complete disconnection of the

mains under conditions relating to over-current category III, in

accordance with installation instructions.

Warning! Before re-connecting the hood circuit to the mains

supply and checking the efficient function, always check that

the mains cable is correctly assembled.

The hood is provided with a special power cable ; if the cable

is damaged, request a new one from Technical Service.

Mounting

Before beginning installation:

• Check that the product purchased is of a suitable size for

the chosen installation area.

• To facilitate installation, remove the fat filters and the

other parts allowed and described here, dismantle and

mount it.

To remove see also the relative paragraphs.

• Remove the active carbon (*) filter/s if supplied (see also

relative paragraph). This/these is/are to be mounted only

if you want lo use the hood in the filtering version.

• Check (for transport reasons) that there is no other

supplied material inside the hood (e.g. packets with

screws (*), guarantees (*), etc.), eventually removing

them and keeping them.

• If possible, disconnect and move freestanding or slide-in

range from cabinet opening to provide easier access to

rear wall/ceiling. Otherwise put a thick, protective

covering over countertop, cooktop or range to protect

from damage and debris. Select a flat surface for

assembling the unit. Cover that surface with a protective

covering and place all canopy hood parts and hardware

in it.

• Disconnect the hood during electrical connection, by

turning the home mains switch off.

• In addition check whether near the installation area of the

hood (in the area accessible also with the hood mounted)

an electric socket is available and it is possible to

connect a fumes discharge device to the outside (only

suction version).

• Carry out all the masonry work necessary (e.g.

installation of an electric socket and/or a hole for the

passage of the discharge tube).

Expansion wall plugs are provided to secure the hood to most

types of walls/ceilings. However, a qualified technician must

verify suitability of the materials in accordance with the type of

wall/ceiling. The wall/ceiling must be strong enough to take

the weight of the hood. Do not tile, grout or silicone this

appliance to the wall. Surface mounting only.

Page 8

17

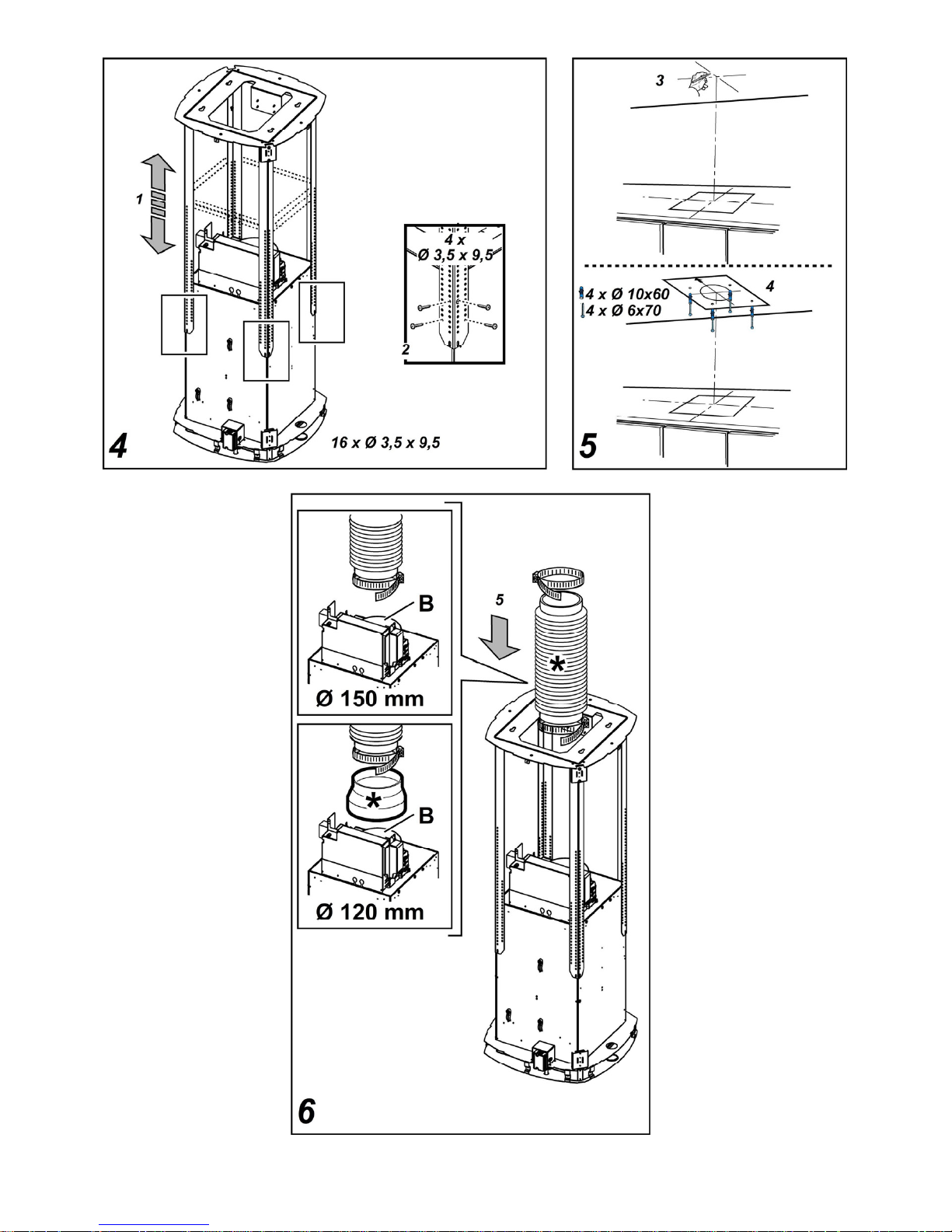

Fig. 4

1. Adjust extension of the hood support structure, as the

final height of the hood depends on this.

Note: In some cases the upper section of the lattice is

fixed to the lower section with one or more screws,

eventually check and remove them temporarily to allow

the adjustment of the support structure.

2. Fix the two sections of the structure with a total of 16

screws (four per corner).

Note: If supplied, temporarily remove the screws fixing

the reinforcement bracket to the perforated frame (keep

these screws in a safe place) and position it over the

motor assembly.

The bracket should be fixed in place again only after the

perforated frame has been fitted to the ceiling.

Fig. 5

3. Apply the drilling template to the ceiling so that it is

vertically in line with the hob (the centre of the template

should be aligned with the centre of the hob and the

sides should run parallel to the sides of the hob; the side

of the template displaying the text FRONT (or the arrows)

should correspond to the connection box side). Make the

electrical connection.

4. Make holes as indicated (4 holes for 4 wall dowels), Screw

in 4 screws into the holes indicated in the drawing leaving

a space between the head of the screw and the ceiling of

about 1 cm.

Fig. 6

5. Fit an exhaust pipe inside the truss and connect it to the

motor compartment connection ring (exhaust pipe and

fixing brackets are not supplied).

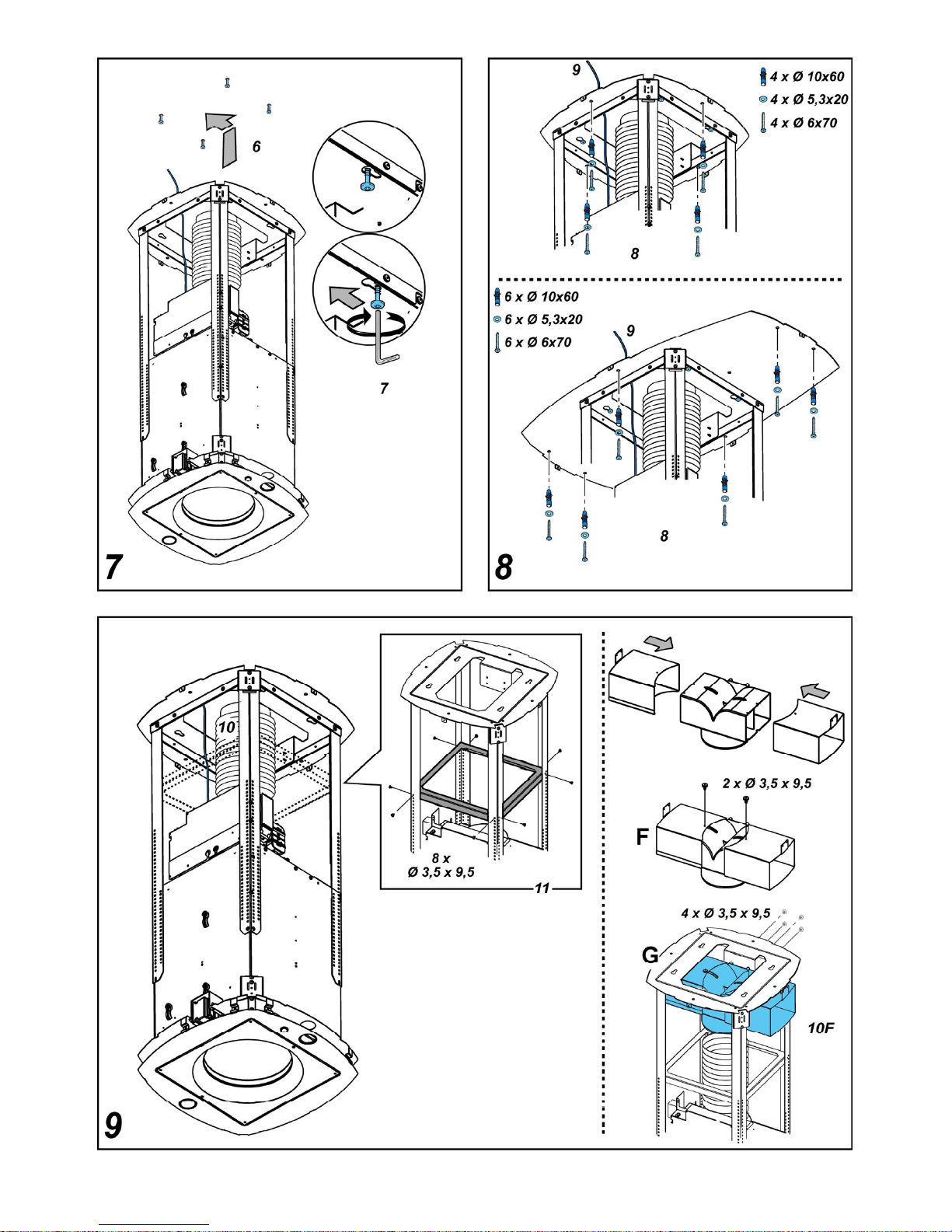

Fig. 7

6. Hook the frame onto the 4 screws (see step 4).

7. Tighten the 4 screws.

Fig. 8

8. Drill around the holes (4 or 6 holes) on the flange, fit the

rawl plugs into the wall and fix the screws and washers in

place.

9. Carry out the electrical connection to the mains power

supply, only turn on the power supply upon completion of

assembly.

Fig. 9

10. For extractor versions, connect the other end of the

exhaust pipe to the flue.

For filter versions (10F), fit deflector F to the truss and

secure it to the bracket supplied using 4 screws, then

connect the exhaust pipe to the connection ring located on

the deflector.

11. Fix the reinforcement bracket (see step 2) to the

perforated frame in a position which is as near to the

middle as possible.

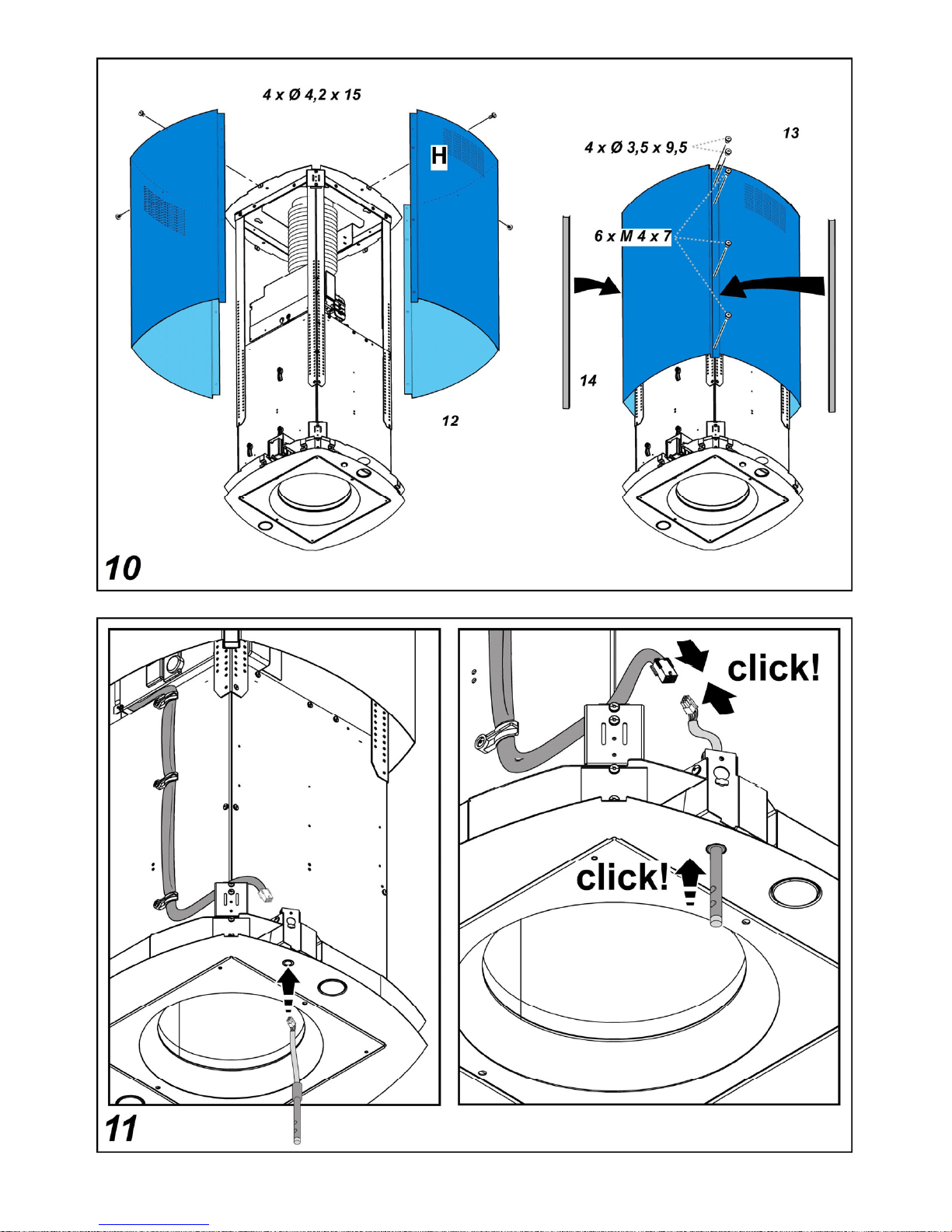

Fig. 10

12. Join the two upper sections of the duct covering the

perforated frame.

Fix each individual section in place using 2 screws (1 per

side) near the ceiling.

13. Fix the upper duct to the perforated frame using 10

screws (5 per side).

14. Apply 2 casings (supplied) to cover the fixing points on

the upper duct sections (CAUTION: THE UPPER DUCT

CASINGS ARE EASY TO RECOGNISE BECAUSE

THEY ARE WIDER, DEEPER AND ARE FITTED BY

PRESSING THEM INTO PLACE).

Fig. 11

15. Fit the control shaft in the correct position by

pushing it upwards.

16. Connect the electricity.

Fig. 12

17. First insert the lower section of the duct, on which the

threaded inserts can be found.

Fix it to the frame, tightening the first and fourth screws

on both sides (counting from the bottom).

18. Join the second lower section by tightening the second

and third screws on each side (counting from the

bottom).

Fix the 2 sections in place using 4 screws (2 per side).

Fig. 13

19. Apply 2 casings (supplied) to cover the fixing points on

the lower duct sections (CAUTION: THE LOWER DUCT

CASINGS ARE EASY TO RECOGNISE BECAUSE

THEY ARE NARROWER AND LESS DEEP).

Turn the mains power on again at the central electrical panel

and check for correct hood operation.

Page 9

18

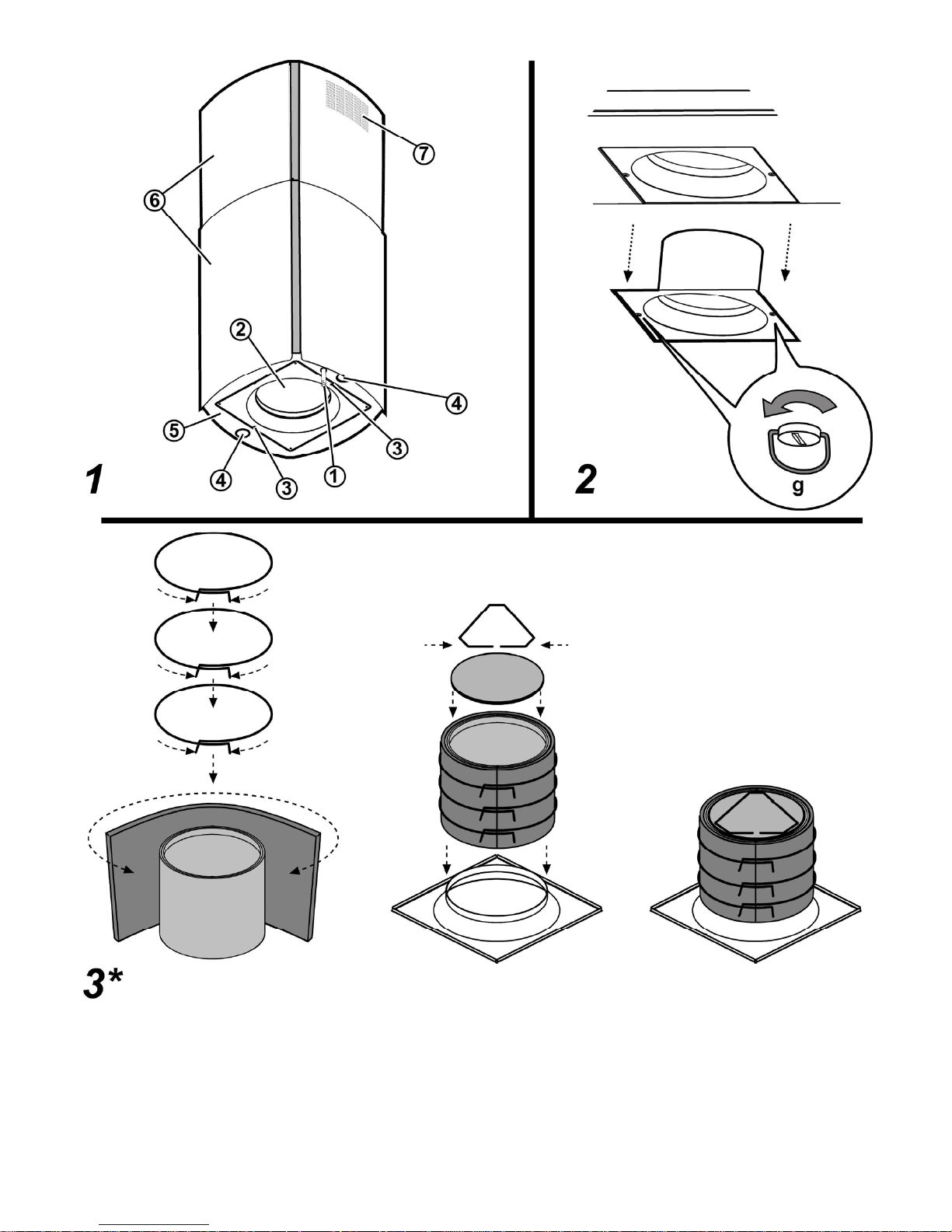

Description of the hood

Fig. 1

1. Control panel

2. Grease filter

3. Grease filter release handle

4. Halogen lamp

5. Vapour catcher

6. Telescopic chimney

7. Air outlet (used for filter version only)

Operation

Use the high suction speed in cases of concentrated kitchen

vapours. It is recommended that the cooker hood suction is

switched on for 5 minutes prior to cooking and to leave in

operation during cooking and for another 15 minutes

approximately after terminating cooking.

The hood is equipped with a “TOUCH” device to control the

lights and speed.

For the correct use please carefully read the intructions below.

The cooker hood can be controlled through a remote control

available as accessory kit (see the paragraph relating to the

functioning of the remote control).

Automatic start-up function

The hood is equipped with a temperature sensor which

activates the motor to the first suction speed (power) in the

event that the temperature in the surrounding area is higher

than 70°C.

The user may switch off or modify the suction speed (power)

(see paragraph “suction speed (power) control”).

Suction speed (power) control

The suction speed (power) is cyclical depending on the speed

sequence “stand-by – 1-2-3-4- Stand by -1-2-...” therefore

every time the T1 button is pressed on the control panel, the

suction speed (power) is increased by one level, in order to

switch off (stand-by) if the button is pressed again when the

hood is in suction speed (power) 4.

The hood may be switched off (stand-by) while the hood is set

on any speed by holding down the T1 button on the control

panel for a bit longer (more than 3 seconds).

The hood's suction speed (power) may be determined as the

control panel is equipped with a LED light that changes colors

as follows, depending on the suction speed (power):

Hood in stand-by: LED LIGHT SWITCHED OFF

1st suction speed (power) -GREEN LED LIGHT

2nd suction speed (power) – ORANGE LED LIGHT (amber)

3rd suction speed (power) - RED LED LIGHT

4th suction speed (power) - RED LED LIGHT (FLASHING)

Note: The 4th suction speed (power) stays on for 5 minutes,

after which the suction motor will position itself on the 2nd

speed.

If pressed again, the suction motor will switch off (stand-by).

Grease filters need cleaning: FLASHING GREEN LED light

(read instructions found under “Reset and configuration for

filter saturation signal”)

Coal filters must be cleaned or replaced: FLASHING

ORANGE (amber) LED light (read instructions found under

“Reset and configuration for filter saturation signal”)

Note: The reset procedure may be activated by both the

control panel and the remote control.

Center light check

The center light may be switched on and off by pressing the

T2 button on the control panel.

Side light check (when scheduled)

The side lights may be switched on and off by pressing AND

HOLDING DOWN the T2 button on the control panel.

HOLDING DOWN the button, besides permitting to switch the

hood on and off, it also regulates the light intensity given from

the lights.

Note: The switching on and off functions (and regulating

function) alternate.

The regulation of the light intensity is not available for hoods

with neon lights.

Reset and configuration for filter saturation signal

Switch on hood to any speed (see above paragraph “Suction

speed (power) selection”)

Reset grease filter saturation signal (FLASHING GREEN

LIGHT on control panel)

First proceed with filter maintenance as described in

corresponding paragraph.

Press and hold down (for more than 3 seconds) the T1 button

on the control panel, the LED light will stop flashing indicating

that the signal reset has been carried out, the hood will switch

off.

Reset coal filter saturation signal (FLASHING ORANGE

(amber) LED light)

First proceed with filter maintenance as described in

corresponding paragraph.

Press and hold down (for more than 3 seconds) the T1 button

on the control panel, the LED light will stop flashing indicating

that the signal reset has been carried out, the hood will switch

off.

Page 10

19

Coal filter saturation signal disactivaction (for particular

applications)

Switch off hood (see above paragraph “suction speed (power)

selection”).

Press and hold down (for more than 5 seconds) the T1 button

on the control panel, the LED light will start flashing GREEN

indicating that the coal filter saturation signal has been

disactivated.

In order to reactivate the coal filter saturation signal, repeat

operation, the LED light will flash ORANGE (amber)

Page 11

20

Remote control

Warning! Some functions of this remote control may only be activated with certain hood models.

Remote control affiliation:

Keep T2 +T5 pressed within the first minute the hood is powered.

Once pairing is complete it is displayed on the hood.

Description of the remote control functions

T1. OFF key

T2. ON/OFF key and dim light intensity adjustment

T3. Suction speed (power) control key:

T4. Hob light ON/OFF key

T5. Delayed hood ON/OFF key

T6. Sensor ON/OFF key.

T7. Filter saturation warning reset key.

L3. Remote control operation LED

Note: touch the keys lightly to select the available functions.

T1. OFF key

Press to switch the hood off

T2. ON/OFF key and dim light intensity adjustment

Press briefly to switch the dim light on or off

Press longer to adjust intensity.

Note: The dim light is only available on some models.

T3. Suction speed (power) control key

Touch the key starting from any position, turning it clockwise or

anticlockwise to increase or decrease suction speed.

The key is divided into several sectors. You can select the

desired speed directly in the corresponding sector as follows:

T3a: Speed 1 (low suction)

T3b: Speed 2 (medium suction)

T3c: Speed 3 (high suction)

T3d: Speed 4 (intensive suction)

T4. Hob light ON/OFF key

Press to switch the hob light on or off.

T5. Delayed hood ON/OFF key.

Press to program the delayed switch-off of the hood based on

the suction speed (power) active at that moment:

Speed 1 (low suction): 20 minutes

Speed 2 (medium suction): 15 minutes

Speed 3 (high suction): 10 minutes

T6. Sensor ON/OFF key

Keep it pressed to activate/deactivate the mode with sensor

which manages fume extraction in automatic mode.

Note: The sensor is only available in some models.

T7. Filter saturation warning reset key.

With the hood off, press T7, the LED L1 quits signalling the

saturation warning.

Page 12

21

Maintenance of the remote control

Cleaning the remote control:

Clean the remote control with a damp cloth and a neutral

solution of detergent without abrasive substances.

Changing the battery:

• Open the battery casing.

• Replace the flat batteries with 3 new 1.5 V type AAA

batteries.

Respect the polarity indicated in the battery casing when

inserting the new battery!

• Close the battery casing up again.

Disposal of the batteries

Ultimate disposal of the batteries should be handled according

to all national laws and regulations. Do not place used

batteries in your regular waste.

Ultimate disposal of the batteries must be done safely.

Contact your local waste management officials for other

information regarding the environmentally sound collection,

recycling, and disposal of the batteries.

Maintenance

ATTENTION! Before performing any maintenance operation,

isolate the hood from the electrical supply by switching off at

the connector and removing the connector fuse.

Or if the appliance has been connected through a plug and

socket, then the plug must be removed from the socket.

Cleaning

The cooker hood should be cleaned regularly (at least with the

same frequency with which you carry out maintenance of the

fat filters) internally and externally. Clean using the cloth

dampened with neutral liquid detergent. Do not use abrasive

products. DO NOT USE ALCOHOL!

WARNING: Failure to carry out the basic cleaning

recommendations of the cooker hood and replacement of the

filters may cause fire risks.

Therefore, we recommend observing these instructions.

The manufacturer declines all responsibility for any damage to

the motor or any fire damage linked to inappropriate

maintenance or failure to observe the above safety

recommendations.

Grease filter

Fig. 2

This must be cleaned once a month (or when the filter

saturation indication system – if envisaged on the model in

possession – indicates this necessity) using non aggressive

detergents, either by hand or in the dishwasher, which must

be set to a low temperature and a short cycle.

When washed in a dishwasher, the grease filter may discolour

slightly, but this does not affect its filtering capacity.

Remove the filter holder frame by turning the knobs (g) 90°

that affix the chimney to the cooker hood.

Charcoal filter (filter version only)

Fig. 3

It absorbs unpleasant odours caused by cooking.

The charcoal filter can be washed once every two months (or

when the filter saturation indication system – if envisaged on

the model in possession – indicates this necessity) using hot

water and a suitable detergent, or in a dishwasher at 65°C (if

the dishwasher is used, select the full cycle function and leave

dishes out).

Eliminate excess water without damaging the filter, then put it

in the oven for 10 minutes at 100° C to dry completely.

Replace the mattress every 3 years and when the cloth is

damaged.

Assembly

Place the mat around the grease filter and fix it in place using

the devices provided.

Position the upper cap and fix it in place using the fixing pin.

To disassemble, perform the steps in the reverse order.

Replacing lamps

The hood is equipped with a lighting system based on LED

technology.

The LEDs guarantee an optimum lighting, a duration up to 10

times as long as the traditional lamps and allow to save 90%

electrical energy.

For replacement, contact the technical service.

Loading...

Loading...