ELGO Electronic P40-SN002 Series Operation Manual

Operation Manual

Series P40-SN002

Application metal shears

Programmable controller

LCD Display

Simple handling

Manual inching function

Single set operation

Program memory

Digital outputs

Analog Output

Contents

- 2 -

Content

1. General Information ....................................................................................................... 4

1.1. Information Operation Manual ............................................................................. 4

1.2. Explanation of Symbols ......................................................................................... 4

1.3. Statement of Warranties ....................................................................................... 5

1.4. Demounting and Disposal ..................................................................................... 6

2. Safety .............................................................................................................................. 7

2.1. General Cause of Risks ......................................................................................... 7

2.2. Personal Protective Equipment .............................................................................. 7

2.3. Conventional Use ................................................................................................. 8

3. Transport and Storage ................................................................................................... 8

3.1. Safety Instructions for Transport/Unpacking and Loading ...................................... 8

3.2. Handling of Packaging Material ............................................................................ 8

3.3. Check of Transport ............................................................................................... 9

3.4. Storage ................................................................................................................ 9

4. Product Features ........................................................................................................... 10

5. Technical Data .............................................................................................................. 11

5.1. Dimensions ......................................................................................................... 12

6. Configuration and Functions ........................................................................................ 13

6.1. Elements ............................................................................................................. 13

6.1.1. Control Elements ....................................................................................................... 13

6.1.2. Display Elements ....................................................................................................... 13

6.1.3. Function of Keys ........................................................................................................ 14

6.2. Menu, sections and parameters .......................................................................... 15

6.2.1. Axis Menu / Distances ............................................................................................... 16

6.2.1.1. Distance / Longitudes Parameters ............................................................................... 17

6.2.2. Axis menu / times ...................................................................................................... 21

6.2.3. Axis menu / analog ................................................................................................... 23

6.2.3.1. Analog parameters ................................................................................................... 24

6.2.4. Axis menu / General ................................................................................................. 26

6.2.4.1. System parameters .................................................................................................... 27

6.2.5 Material Table .................................................................................................................... 31

6.2.5.1 Explanation of the Interpolation .................................................................................... 31

6.2.6 Menu / System .......................................................................................................... 32

6.3. Machine setting .................................................................................................. 34

6.3.1. Gap Setup (Cut gap) ................................................................................................. 34

6.3.2. Angle Setup (cut angle) .............................................................................................. 34

6.4 Configuration of inputs and outputs .................................................................... 35

6.4.1. Link-up the inputs with functions .......................................................................................... 35

6.4.2. Allocation to the logic input functions .................................................................................. 35

6.4.3. Linking the outputs of functions ........................................................................................... 35

6.4.4. Logic Allocation to Outputs ................................................................................................ 35

Contents

- 3 -

7. Operation ....................................................................................................................... 36

7.1 Operation Modes .............................................................................................................. 36

7.1.1 Manual mode .................................................................................................................... 36

7.1.2 Single mode ....................................................................................................................... 36

7.1.3 Program mode ................................................................................................................... 36

7.1.3.1 Input of a program .......................................................................................................... 36

7.1.3.2. Handle of a program .................................................................................................. 37

7.1.4 Reference....................................................................................................................... 37

7.1.4.1 Function of reference drive ........................................................................................... 37

7.2 Connector pin assignment .................................................................................. 38

7.2.1 Overview Terminal Assignment ...................................................................................... 39

7.3 Diagnostics ....................................................................................................................... 40

8. Interferences .................................................................................................................. 41

8.1 Security .............................................................................................................. 41

8.2 Electrical interference suppression ....................................................................... 42

8.3 Restart after fault clearance ................................................................................ 42

8.4 EMC information ................................................................................................ 43

9 Maintenance ................................................................................................................. 44

10 Type Designation ......................................................................................................... 45

11 Accessories .................................................................................................................... 46

- 4 -

1. General Information

1.1. Information Operation Manual

The manual contains important information regarding the handling of the controller.

Precondition for safe operation is the compliance with the specified safety and handling instructions.

Moreover, observe the existing local accident prevention regulation and general safety rules.

Please read the operation manual carefully before starting to work. The manual should be kept accessible at

anytime. The illustrations in the manual are for better representation of the facts they are not necessarily to

scale and can be slightly different to the actual construction.

1.2. Explanation of Symbols

Warning notices

Warning notices are characterized by symbols in the operation manual.

The notes will be introduced by signal words to express the magnitude of the danger.

Follow these advices in order to avoid accidents and injuries to persons and property.

DANGER!

... adverts to direct dangerous situations that can lead to death or severe injuries.

CAUTION!

... advices to potentially dangerous situations that can lead to death or severe

injuries.

ATTANTION!

... advices to potentially dangerous situations that can lead to damages on

property.

General Information

- 5 -

Hints and commendations

ADVERT!

...highlights helpful hints and recommendations for efficient and failure-free

operation.

Specific safety instructions

The following symbols in conjunction with safety instructions are used in order to point out possible hazards:

DANGER!

...marks perilous situations by electricity. By non-observance of the safety

instructions the possibility of death or severe injuries exist. The operations have to be

carried out only by an electrician.

General Information

1.3. Statement of Warranties

The warranty conditions are in a separate document.

Guarantee

The producer guarantees the functional capability of the process engineering and the selected parameter.

The period of warranty is one year and begins with the date of delivery.

General Information

- 6 -

1.4. Demounting and Disposal

Unless otherwise authorized, dispose the item considering the safety instructions.

Before demounting

Disconnect the power supply

Secure against re-start

Disconnect supply lines physically and discharge remaining energy

Dispose operating supplies with respect to the environment

Disposal

Recycle the decomposed elements:

Scrap metal elements

Recycle plastic parts

Dispose the rest of the components according to their material consistence

ATTENTION!

Wrong disposal Î damage caused to the environment!

Electronic waste, electronic components, lubricants and operating supplies are

liable to treatment of hazardous waste.

Only approved specialized companies should perform disposal.

Local authorities and waste management facilities provide information about environmentally suitable

disposal.

- 7 -

2. Safety

2.1. General Cause of Risks

This chapter gives an overview about all important safety aspects to guarantee an optimal protection of

employees.

Non-observance of the instructions mentioned in this operation manual can result in hazardous situations.

2.2. Personal Protective Equipment

Employees should wear protective clothing during installation of the device to minimize the risk of accidents.

Therefore:

Change into protective clothing before beginning the work process. Also observe any labels in the operating

area regarding protective clothing.

Protective clothing

Safety working clothing

... is close-fitting

... is tear proof

... has tight sleeves without distant parts

Also wear no rings, necklaces or other jeweler.

Protective gloves

... for protecting the hands against abrasion and cuts

Safety

Conventional use, Transport, Storage

- 8 -

2.3. Conventional Use

The controller P40 is for the limited purpose as described in this manual:

The controller P40 is constructed for positioning uses only.

CAUTION!

Danger through non-conventional use!

Non-intended use and non-observance of this operation manual can lead to dangerous

situations.

Therefore:

Use P40 only as described

Strictly follow this manual

Avoid in particular:

Remodeling, refitting or changing of the device or parts of it with the intention to alter

functionality or scope of the position controller.

ELGO is not liable for any damages resulting from improper use of the product.

3. Transport and Storage

3.1. Safety Instructions for Transport/Unpacking and Loading

ATTENTION!

Professional transport only.

Do not throw, hit or fold the package.

3.2. Handling of Packaging Material

Adverts for proper disposal refer to 1.4.

Conventional use, Transport, Storage

- 9 -

3.3. Check of Transport

Examine delivery immediately after receiving for completeness and transport damages.

In case of externally recognizable transport damages:

Do not accept the delivery or do accept under reserve

Note extent of damages on the transportation documents or on the delivery note

File complaint immediately

ADVERT!

Claim any damages you recognize as soon as possible. The claims for damage must be

filed in the lawful reclaim periods.

3.4. Storage

Store device only under following conditions:

Do not store outside

Keep dry and dust-free

Do not expose to aggressive media

Protect from direct sun light

Avoid mechanical shocks

Storage temperature: 20 to + 50 °C

Relative humidity: 60% non-condensing

Inspect packages regularly if stored for an extensive period of time (> 3 months)

Product Features

- 10 -

4. Product Features

Essential features:

Analog or digital outputs for 1 - 3 speed operation

16 free programmable digital in-/outputs

Program memory (1000 sets)

Angle control / gap control / backgauge

Limitation of the cutting length

Material List for angle and gap control

The single axis controller of P40 series is applicable

to easy positioning tasks. An important feature is the

easy structured function menu. It allows a quick and

comfortable setting of the target value, if necessary

a specific quantity of desired pieces, an angle or the

gap. Target and actual value of the axes plus

quantity will be displayed on the front panel. The

keyboard is simple and user-friendly. With the inputs

the cutting angle or gap can be displayed and

controlled. These encoder inputs work in an analog

mode. A back stop can be programmed. The P40

series has an internal program memory with up to

1000 lines. For the positioning two different kinds of

output signals are available: Switch mode

positioning and PID-analog output. The P40 series

can alternatively be supplied with 24VDC or 24VAC.

An optional serial interface allows data transmission

for communication with a superior system.

Basic modes of operation:

The P40 consists of three general operation modes:

1. Manual: Inching operation moves the axes through operating the keypad or external switches.

2. Single: A whole set can be worked off.

3. Program: In this operation mode a programmed set can be worked off.

Technical Data

- 11 -

5. Technical Data

P40 – ELGO-position controller

Input supply voltage 24 VDC

Power input 24 VDC; max. 150 mA (no-load condition)

Rotary encoder supply unit 24 VDC or 5VDC ; max. 130 mA

Analog input (option) 12 Bit resolution ; 3,3 V Supply measuring system

Input signals The Pin assignment of the inputs and the input logic are programmable

Minimum pulse duration: 300 ms

Input current /Pin: max. 10 mA

Output signals The Pin assignment of the outputs and the output logic are programmable

Open Emitter (PNP)

Complete short-circuit-proof

Output current: max. 80 mA

Recovery diode is integrated

Actual value memory E² Prom

Durability: 105 On-Off-Switch-Cycle or 10 years

Connection technology Phoenix Connectors

Displays LCD Dot-Matrix 128 x 80 mm with white backlight

Hardware 32-Bit-Microprocessor with 1 MByte Flash 56 Kbyte RAM

System accuracy +/ -1 Increment

Input frequency

15 KHz (upgrade on enquiry possible) equals by 0,1 mm resolution: 120

m/min. (2 m/s)

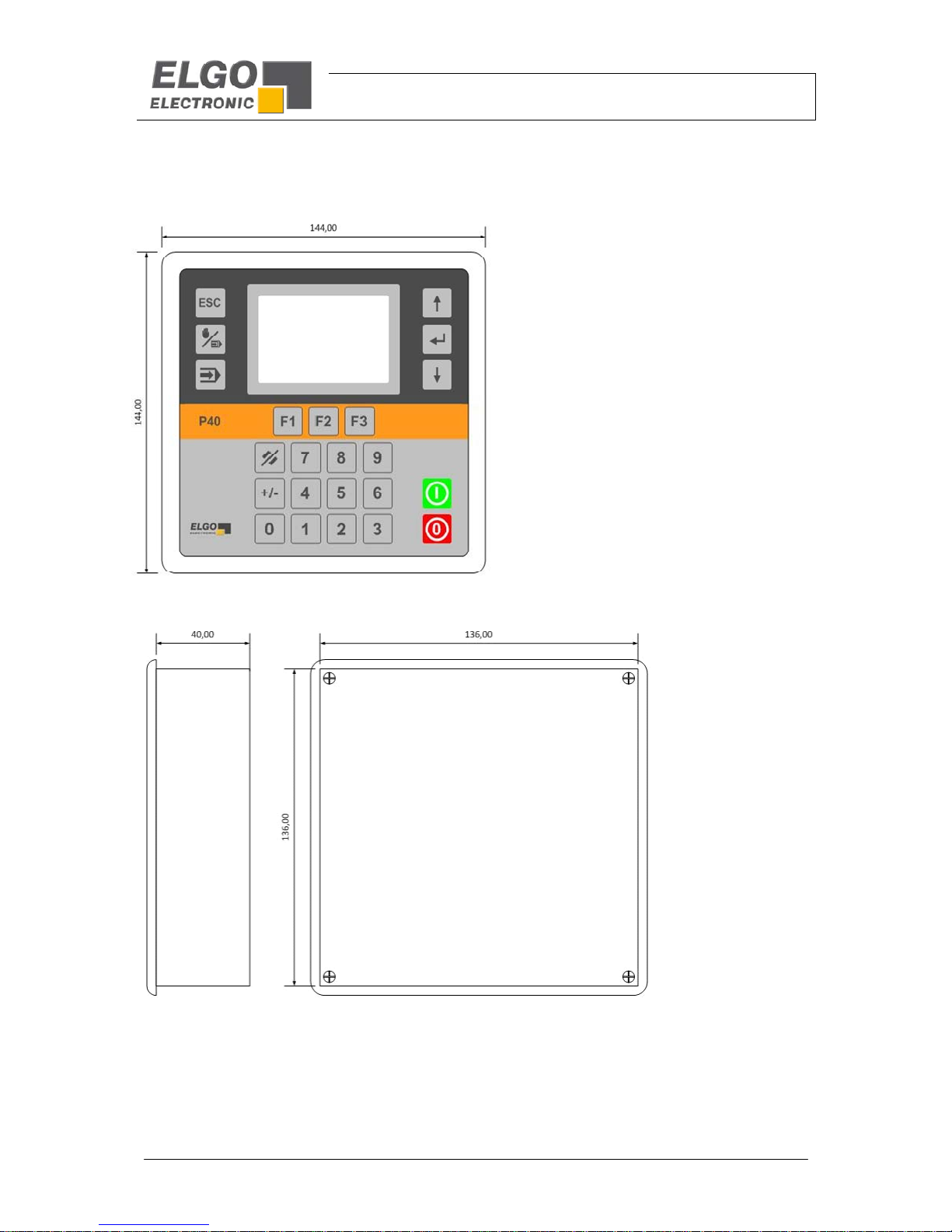

Housing dimensions W x H x D = 144 mm x 144 mm x 40 mm (without connector)

Disruption degree W x H = 136 mm x 136 mm

Installation depth without

connector

40 mm

Installation depth with

connector

75 mm

Ambient temperature 0 to +45 °C

Technical Data

- 12 -

5.1. Dimensions

Configuration and Functions

- 13 -

6. Configuration and Functions

6.1. Elements

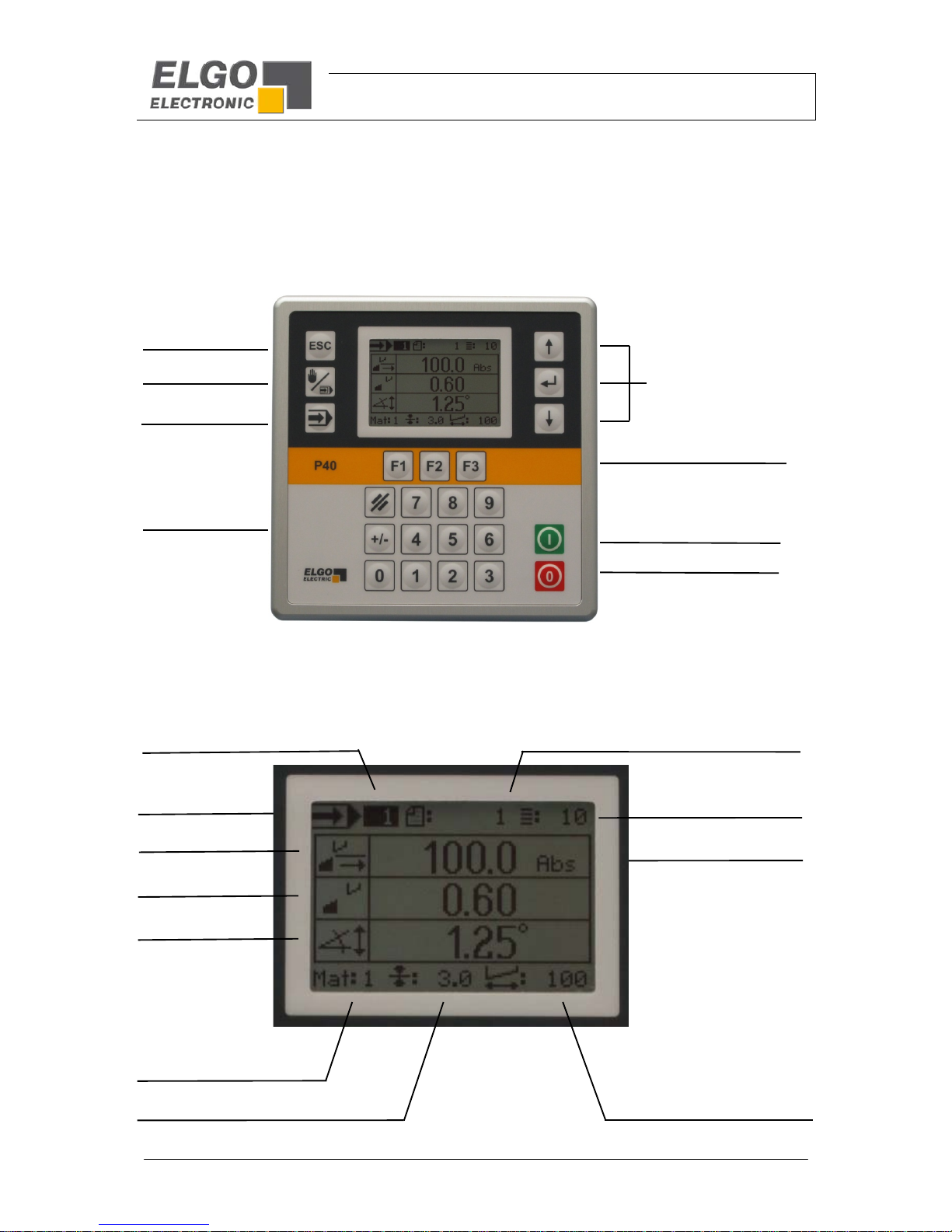

6.1.1. Control Elements

6.1.2. Display Elements

Menu navigation

Forward/backward/Enter

Start

Sto

p

Escape

Manual/Single

Function keys

Input

Program-Mode

Cutting Length

Position Mode

Material Thickness

Symbol Operation

mode

Material

Quantity

Set Number

Backgauge

Gap

Angle

Program Number

Configuration and Functions

- 14 -

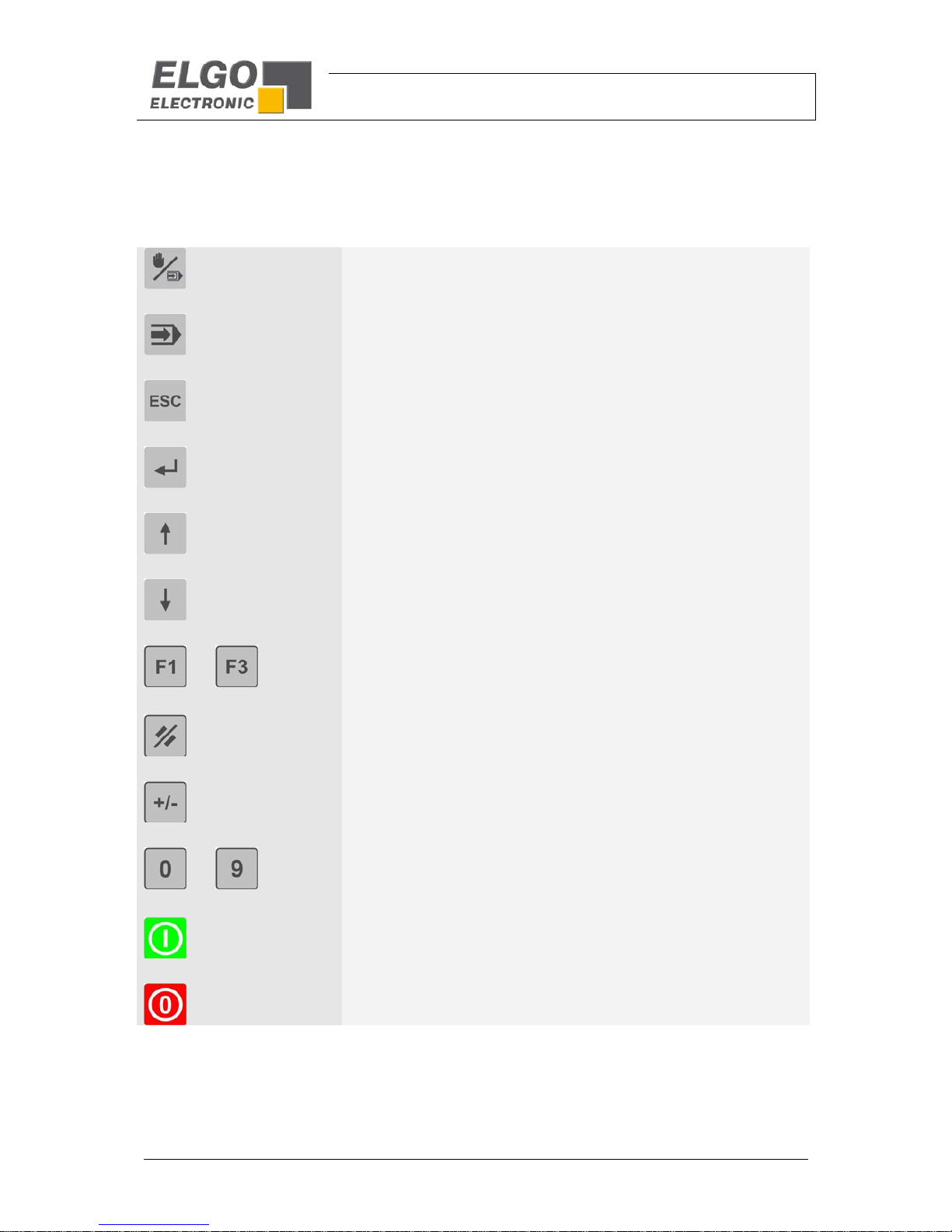

6.1.3. Function of Keys

Change Operation mode between „Manual“ and „Single“

Operation Mode “Program”

Leaving an Operation Mode or a Sub menu

Select or Confirm

Cursor navigation „up“

Cursor navigation „down“

...

Function keys (addicted to Menu or Operation mode)

Clear or reset an input

Change of Sign

...

Enter Target Value or Parameter value

Start Positioning

Stop Positioning

Loading...

Loading...