Operating Manual

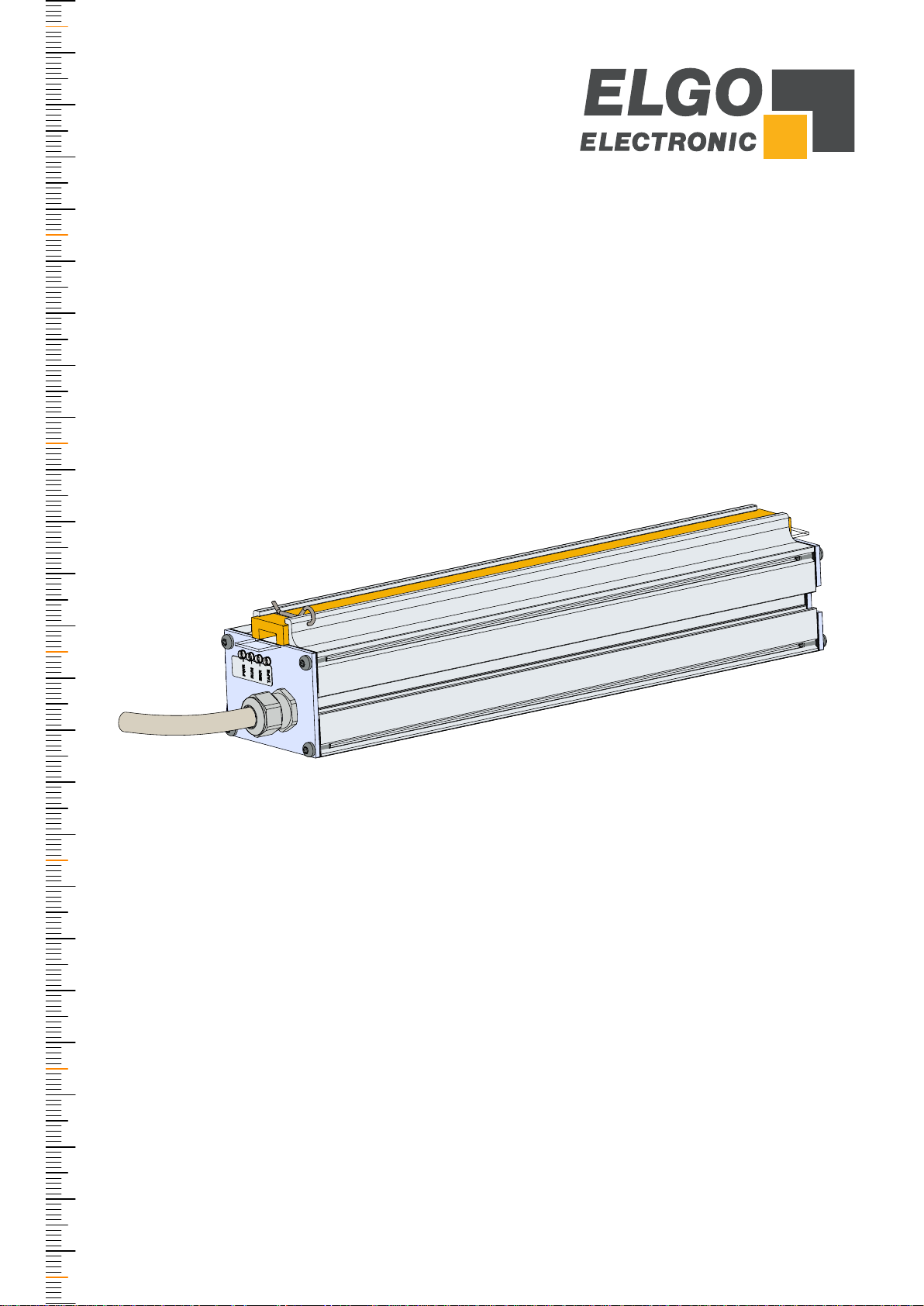

SERIE LIMAX02

Magnetic Absolute Shaft Information System for Elevators

Robust measuring principle for usage in rough environments

Insensitive against dirt, smoke and humidity

Simple and flexible installation

High accuracy and reproducibility

Absolute position measurement with a length up to 260 m

Resolution up to 1 mm, higher resolution on request

Absolute position is always directly available

no referencing even after long power failure

Compatible with many established controls with absolute encoder interface

Available interfaces:

SSI, CAN, CANopen (DS406, DS417), RS422, RS232, PROFIBUS

799000350 / Rev. 9 / 2019-04-02

Translation of the original operating manual

- 2 -

Publisher

ELGO Electronic GmbH & Co. KG

Carl-Benz-Str. 1

D-78239 Rielasingen-Worblingen

Technical Support

+49 (0) 7731 9339 - 0

+49 (0) 7731 2 88 03

info@elgo.de

Document- No.

799000350

Document - Name

LIMAX02-00-MA-E_14-19

Document- Revision

Rev. 9

Issue Date

2019-04-02

Copyright

© 2019, ELGO Electronic GmbH & Co. KG

Contents

- 3 -

1 Contents

1 Contents ..................................................................................................... 3

2 General, Safety, Transport and Storage .................................................... 4

2.1 Information Operating Manual ........................................................................................... 4

2.2 Explanation of Symbols ...................................................................................................... 4

2.3 Statement of Warranties ..................................................................................................... 5

2.4 Demounting and Disposal .................................................................................................. 5

2.5 General Causes of Risk ..................................................................................................... 5

3 Product Features ........................................................................................ 7

3.1 Functional principle ........................................................................................................... 7

4 Technical Data ........................................................................................... 8

4.1 Identification .................................................................................................................... 8

4.2 Dimensions Sensor Standard .............................................................................................. 8

4.3 Dimensions Sensor Option unguided ................................................................................... 9

4.4 Dimensions Sensor Option PNO ......................................................................................... 9

4.5 Dimensions Magnetic Tape .............................................................................................. 10

4.6 Technical Data Sensor ..................................................................................................... 10

4.7 Technical Data Magnetic Tape ......................................................................................... 11

5 Installation and First Start-Up ................................................................. 12

5.1 Operating Area .............................................................................................................. 12

5.2 Description installation of the Sensor ................................................................................. 13

5.3 Description installation / Mounting of the Magnetic Tape ..................................................... 14

6 Connections and Interfaces ...................................................................... 19

6.1 LED’s (Operating status and notices).................................................................................. 19

6.2 CAN Interface ................................................................................................................ 19

6.3 SSI Interface ................................................................................................................... 26

6.4 RS232 / RS422 / RS485*................................................................................................. 27

6.5 Option Unguided ........................................................................................................... 30

6.6 Option PROFIBUS Interface .............................................................................................. 31

7 Disturbances, Maintenance, Cleaning ..................................................... 34

7.1 Fault Clearance .............................................................................................................. 34

7.2 Re-start after Fault Clearance ........................................................................................... 34

7.3 Maintenance .................................................................................................................. 35

7.4 Cleaning ....................................................................................................................... 35

8 Type Designation ..................................................................................... 36

8.1 Type Designation ............................................................................................................ 36

8.2 Control specific Sensors ................................................................................................... 37

8.1 Accessories .................................................................................................................... 38

9 Index ........................................................................................................ 39

General, Safety, Transport and Storage

- 4 -

DANGER!

This symbol in connection with the signal word “Danger” indicates an immediate danger for the life and health of

persons. Failure to heed these instructions can result in serious damage to health and even fatal injury.

WARNING!

This symbol in connection with the word „Warning” means a possibly impending danger for the life and health of

persons. Failure to heed these instructions can result in serious damage to health and even fatal injury.

CAUTION!

This symbol in connection with the signal word “Caution” indicates a possibly dangerous situation. Failure to heed

these instructions can lead to minor injuries or damage of property.

DANGER!

This symbol in connection with the signal word “Danger” indicates an immediate danger for the life and health of

persons due to voltage.

Failure to heed these instructions can result in serious damage to health and even fatal injury. The operations may

only be carried out by a professional electrician.

NOTE!

… points out useful tips and recommendations as well as information for an efficient and trouble-free operation.

2 General, Safety, Transport and Storage

2.1 Information Operating Manual

This manual contains important information regarding the handling of the device. For your own safety and operational safety, please observe all safety warnings and instructions.

Precondition for safe operation is the compliance with the specified safety and handling instructions. Moreover, the existing local accident

prevention regulations and the general safety rules at the site of operation have to be observed.

Please read the operating manual carefully before starting to work with the device! It is part of the product and should be kept close to the

device and accessible for the staff at any time. The illustrations in the manual are for better demonstration of the facts. They are not necessarily to scale and can slightly differ from the actual design.

2.2 Explanation of Symbols

Special notes in this manual are characterized by symbols. The notes are introduced by signal words which express the magnitude of danger.

Please follow this advice and act carefully in order to avoid accidents, damage, and injuries.

Warning notes:

Special safety instructions:

Tips and recommendations:

Reference marks:

Marks a reference to another chapter of this manual.

Marks a reference to another chapter of another document.

General, Safety, Transport and Storage

- 5 -

CAUTION!

Wrong disposal causes environmental damages!

Electronic scrap, electronic components, lubricants and other auxiliary materials are subject to special refuse and can

only be disposed by authorized specialists!

CAUTION!

Please read the operating manual carefully, before using the device! Observe the installation instructions! Only start

up the device if you have understood the operating manual. The operating company is obliged to take appropriate

safety measure.

The initial operation may only be performed by qualified and trained staff.

Selection and installation of the devices as well as their embedding into the controlling system require qualified

knowledge of the applicable laws and normative requirements on the part of the machine manufacturer.

PROTECTIVE CLOTHING

… is close-fitting working clothing with light tear strength, tight sleeves and without distant parts. It serves preliminarily for protection against being gripped by flexible machine parts.

Do not wear rings, necklaces or other jewellery.

PROTECTIVE GLOVES

… for protecting the hands against abrasion, wear and other injury of the skin.

PROTECTIVE HELMET

… for protection against injuries of the head.

2.3 Statement of Warranties

The producer guarantees the functional capability of the process engineering and the selected parameters.

2.4 Demounting and Disposal

Unless acceptance and disposal of returned goods are agreed upon, demount the device considering the safety instructions of this manual

and dispose it with respect to the environment.

Before demounting, disconnect the power supply and secure against re-start. Then disconnect the supply lines physically and discharge

remaining energy. Remove operational supplies and other material.

Disposal:

Recycle the decomposed elements: Metal components in scrap metal, Electronic components in electronic scrap, Recycle plastic components, dispose the remaining components according to their material consistence

Local authorities and waste management facilities provide information about environmentally sound disposal.

Safety

2.5 General Causes of Risk

This chapter gives an overview of all important safety aspects to guarantee an optimal protection of employees and a safe and trouble-free

operation. Non-observance of the instructions mentioned in this operating manual can result in hazardous situations.

2.5.1 Personal Protective Equipment

Employees have to wear protective clothing during the installation of the device to minimize danger of health.

Therefore: Change into protective clothing before performing the works and wear them throughout the process.

Additionally observe the labels regarding protective clothing in the operating area.

Protective clothing:

General, Safety, Transport and Storage

- 6 -

CAUTION!

Danger through non-conventional use!

Non-intended use and non-observance of this operating manual can lead to dangerous situations.

Therefore:

Only use the device as described

Strictly follow the instructions of this manual

Avoid in particular:

Remodelling, refitting or changing of the construction or single components with the intention to alter the

functionality or scope of the device.

CAUTION!

Transport the package (box, palette etc.) professionally. Do not throw, hit or fold it.

NOTE!

Claim any damage immediately after recognizing it. The claims for damage must be filed in the lawful reclaim periods.

2.5.2 Conventional Use

The ELGO-device is only conceived for the conventional use described in this manual.

The LIMAX02 - ELGO- length measuring system only serves to measure lengths.

Claims resulting from damages due to non-conventional use are not possible.

Only the operator is liable for damages caused by non-conventional use.

2.5.3 Safety Instructions for Transport, Unpacking and Loading

2.5.4 Handling of Packaging Material

Notes for proper disposal: 2.4

2.5.5 Inspection of Transport

Check the delivery immediately after the receipt for completeness and transport damage.

In case of externally recognizable transport damages:

Do not accept the delivery or only accept under reserve.

Note the extent of damages on the transportation documents or delivery note.

File complaint immediately.

2.5.6 Storage

Store the device only under the following conditions:

Do not store outside

Keep dry and dust-free

Do not expose to aggressive media

Protect from direct sun light

Avoid mechanical shocks

Storage temperature ( 4) needs to be observed

Relative humidity ( 4) must not be exceeded

Inspect packages regularly if stored for an extensive period of time (>3 months)

Product Features

- 7 -

3 Product Features

LIMAX02 is an absolute measuring shaft information system that is used for positioning of elevator cars. It consists of only two components: sensor and magnetic band.

A big advantage of the system is the simple and flexible installation. The assembly of the system components

is very simple and can be performed by specialists in less than an hour. The system can be placed anywhere in

the shaft, depending of the space conditions. With the small space requirement, LIMAX02 is perfect for retrofitting and modernization.

LIMAX02 detects the absolute car position up to a hoisting height of 260 meters and is designed for speeds of

up to 10 m/s. In the standard configuration LIMAX02 evaluates the position with a resolution of 1 mm. Resolutions up to 0.0625 mm are possible.

LIMAX02 is equipped with various interfaces and thus can be directly connected to the most established elevator

controls.

The features at a glance:

Robust measuring principle for usage in rough environments

Simple and flexible installation

High accuracy and reproducibility

No slip

Absolute position is always directly available - no referencing even after long power outages

3.1 Functional principle

The concept is simple: A sensor mounted on the elevator car detects the current absolute car position using Hall

sensors, which read the magnetic tape mounted in the shaft without any contact. Through this method, the car´s

position can be determined at any time with high accuracy. The guide is only used to keep the tape within a

defined distance from the sensor.

Due to its robustness, the magnetic tape technology is ideal for use in elevator systems - dust, dirt, and even

dense black smoke won't affect measurement quality. The system even withstands humidity and high temperatures without any problems - making LIMAX02 ideally suited for firefighters´ elevators. And that with a long

maintenance-free service life.

Technical Data

- 8 -

4 Technical Data

4.1 Identification

The type label serves for the identification of the unit. It is located on the housing of the sensor and gives the

exact type designation (=order reference, see type designation) with the corresponding part number.

Furthermore, the type label contains a unique, traceable device number.

When corresponding with ELGO always indicate this data.

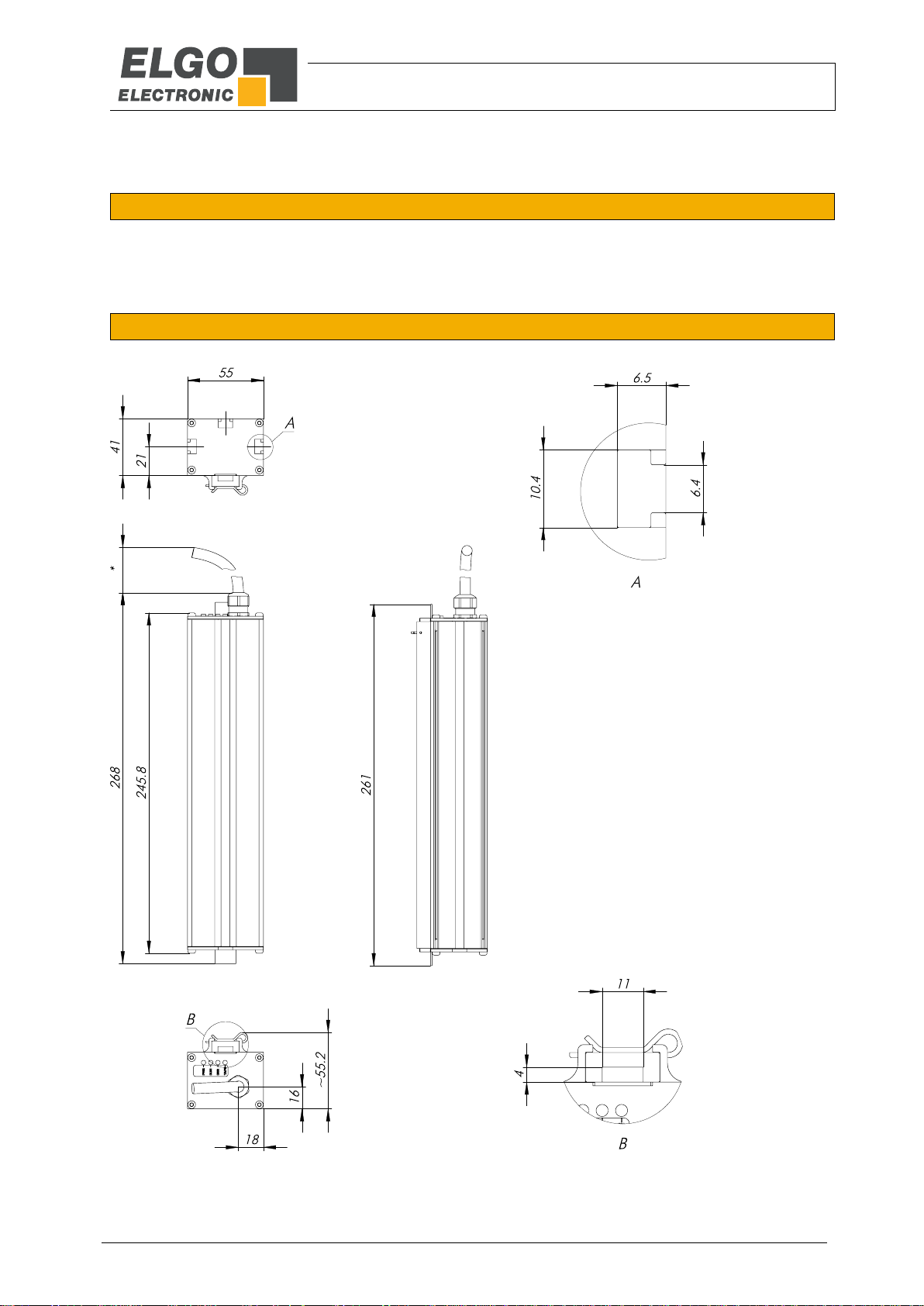

4.2 Dimensions Sensor Standard

Figure 1: Dimensions Sensor Standard

Technical Data

- 9 -

244

236

40

55

55

51

271

55

51

32,5

41,5

13,5

38

19,5

4.3 Dimensions Sensor Option unguided

Figure 2: Dimensions Sensor Option unguided

4.4 Dimensions Sensor Option PNO

Figure 3: Dimensions Sensor Option PNO

Technical Data

- 10 -

LIMAX02 (Standard version)

Mechanical Data

Measuring principle

absolute

Repeat accuracy

+/- 1 Increment

System accuracy in µm at 20°C

+/- (1000 + 50 x L[m])

L = measuring length in meter

Distance from sensor to magnetic

tape

4 mm

Basic pole pitch

8 mm

Sensor housing material

aluminium

Sensor housing dimensions

L x W x H = 246 x 55 x 55 mm

Necessary type

AB20-80-10-1-R-D-15-BK80

Maximum measuring length

260 m

Connection

Open cable ends (more options 8)

Sensor cable

3 m standard cable length (other on request)

Weight

approx. 460 g without cable (cable approx. 60 g/m)

Electrical Data

Supply voltage

10 … 30 VDC

Residual ripple

10 … 30 VDC < 10%

Power input

max. 200 mA

Interfaces

SSI, CAN, CANopen (DS406, DS417), RS422, RS232, RS485, PROFIBUS

Resolution

According to the Type Designation ( 8)

Speed

max. 10 m/s (higher speeds on request)

Conditions

Storage temperature

-20 … +85° C

Operation temperature

-10 … +70° C

(-25 … +85° C on request)

Humidity

max. 95 %, not condensing

Protection class

IP50

Scale 5:1

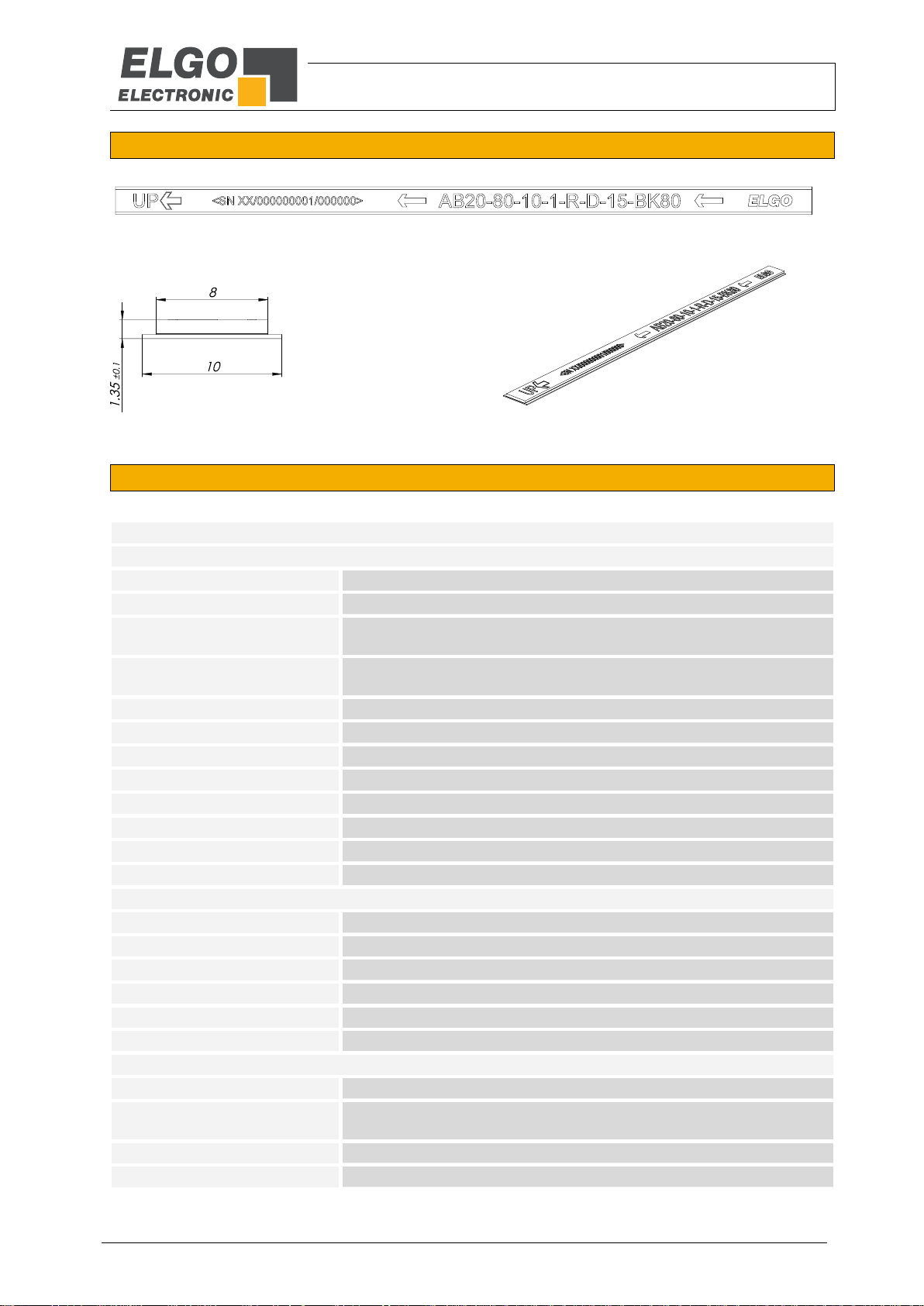

4.5 Dimensions Magnetic Tape

Figure 4: Dimensions Magnetic Tape

4.6 Technical Data Sensor

Technical Data

- 11 -

TEMPLATE Magnetic Tape AB20-80-10-1-R-D-15-BK80

Coding

absolute, single track system

Pole pitch

8 mm

Operation temperature installed

-20 … +65° C

(-20 … +80° C when using without adhesive tape, options „B“ or „D“)

Storage temperature uninstalled

Short-term: -10 … +60° C

Medium-term: 0 … +40° C

Long-term: +18° C

(-20 … +80° C when using without adhesive tape, options „B“ or „D“)

Gluing temperature:

+18 … +30° C

Relative humidity

max. 95 %, non-condensing

Accurateness 20°C in µm

+/- (1000 + 50 x L[m])

(L = measuring length in meters)

Material carrier tape

Precision strip 1.4310 / X10CrNi 18-8 (EN 10088-3)

Double-faced adhesive tape

3M-9088 (observe instructions), others on request

Dimensions

without adhesive tape:

10 mm (+/- 0.1) x 1,35 mm (+/- 0.11)

with adhesive tape (excl. carrier):

10 mm (+/- 0.1) x 1,56 mm (+/- 0.13)

with adhesive tape (incl. carrier):

10 mm (+/- 0.1) x 1,63 mm (+/- 0.14)

Length expansion coefficient

16 x 10-6 1/K

Thermal length expansion

∆L[m] = L[m] x [1/K] x ∆[K]

(L = tape length in meters, ∆ = relative temperature change)

Available lengths

up to 260 m

Weight magnetic tape

ca. 62 g/m (incl. magnetic tape and cover tape)

Tape imprint

ELGO standard, printing color black, digit height >= 5 mm

Influence of external magnets

External magnetic fields must not exceed 64 mT (640 Oe; 52 kA/m) on

the surface of the magnetic tape as this could damage or destroy the

code on the tape.

Protection class

IP65

4.7 Technical Data Magnetic Tape

The magnetic tape consists of two components:

The actual magnetic tape which carries the position information

A mechanical stainless steel back iron

Installation and First Start-Up

- 12 -

CAUTION

Please read the operating manual carefully before using the device! Strictly observe the Installation instructions!

In case of damage caused by failure to observe this operating manual, the warranty expires.

ELGO is not liable for any secondary damage and for damage to persons, property or assets.

Der Betreiber ist dazu verpflichtet, geeignete sicherheitsrelevante Maßnahmen zu ergreifen

und durchzuführen.

The operator is obliged to take appropriate safety measures. The first start-up may only be

performed by staff that has been trained and authorized by the operator.

WARNING!

Do not use the device in explosive or corrosive environments!

The device must not be installed close to sources of strong inductive or capacitive interference

or strong electrostatic fields!

CAUTION!

The electrical connections must be made by suitably qualified personnel in accordance with

local regulations.

The device may be designed for switchboard mounting. During work on the switchboard, all

components must be de-energized if there is a danger of touching the energized parts!

(protection against contacts)

Wiring works may only be performed in the de-energized state!

Thin cable strands have to be equipped with end sleeves!

Before switching on the device, connections and plug connectors have to be checked!

The device must be mounted in a way that it is protected against harmful environmental influences such as splashing water, solvents, vibration, shock and severe pollution and the operating temperature must not be exceeded.

5 Installation and First Start-Up

5.1 Operating Area

Installation and First Start-Up

- 13 -

Figure 5: Installation with tension weight

Figure 6: Installation with dowel and spring

Sensor

Magnetic tape

Guide rail

Upper tape fixation

Tension weight

Sway guard

Upper tape fixation

Sensor

Magnetic tape

Spring

Guide rail

5.2 Description installation of the Sensor

5.2.1 Installation Principe

LIMAX02 can be installed at any position in the shaft, depending on spatial conditions and layout of the particular elevator installation.

The magnetic tape is installed freely suspended in the shaft. It can be fixed with the RMS mounting kit (available

as option) on the guide rail. Alternatively fixation in the shaft head is either on beams or directly bolted into the

ceiling. The necessary tension in the tape is provided by a tension weight of about 5 kg. A sway guard at the

bottom will keep the tape from swaying in an uncontrolled position. Alternatively the magnetic tape can be tensioned by a spring.

The sensor head can be mounted onto the cabin or cabin frame, depending on the spatial conditions of the

elevator.

Installation and First Start-Up

- 14 -

The integrated mounting notches on the housing of

the sensor head allow for a very simple and selfexplanatory installation from three sides. You can

either use M6 hexagon head screws (DIN 933) or M6

square nuts (DIN 562), to mount the system at the

desired position.

Figure 7: Mounting grooves on the sensor

NOTE

During installation of the magnetic tape in the sensor, pay attention to the marks on the magnetic tape and on the sensor head.

Wrong orientation of tape vs. Sensor head will yield incorrect position readings!

The arrows printed on the magnetic tape and sensor head point in positive counting direction

(in the direction of the shaft head)!

NOTE External Magnetic Fields

The magnetic tape must not be influenced by external magnetic fields!

The magnetic tape must not come into direct contact with other magnetic fields (e.g. permanent magnets, magnetic clamps, electromagnets, magnetic stands)! This may cause

irreparable damage, which will compromise the measuring accuracy or even the functioning.

5.2.2 Installation of the Sensor

The sensor is fixated on the cabin or on the car frame. The mounting position is basically determined by the

condition.

5.3 Description installation / Mounting of the Magnetic Tape

5.3.1 General Information

The technology has proven to be highly robust.LIMAX02 will work under the most adverse environmental conditions. Extreme temperatures, high moisture and excessive soiling will not alter the information coded onto the

tape nor will these conditions affect reading precision of the sensor. Even weak magnetic fields such as they are

generated by door magnets can be tolerated.

If some basic rules and guidelines are followed LIMAX02 systems require a minimum amount of installation and

maintenance effort while offering maximum lifetime.

One important issue to consider is the protection of the magnet tape against mechanical wear. The LIMAX02

tape consists of two components:

- The magnetic tape which actually carries the position information

- A protective steel tape which gives the mechanical properties

Installation and First Start-Up

- 15 -

NOTE!

The magnetic tape itself is not designed to withstand excessive mechanical wear. It is therefore important to ensure that the system is installed such that the mechanical contact between

tape and sensor head is mainly between the steel tape and the polymer sensor guide. These

two materials have been specifically paired for this application.

Wrong Tolerable

Recommended

Constant contact

between magnetized side

and sensor housing lead

to abrasion

Vertical alignment

minimal contact between

band and sensor

Enforced contact

between steel band

and polymer housing

Tape touches

the guide with

the magnetized

side

Tape touches

the guide with

the steel side

5.3.2 Installation Concept

5.3.2.1 Basic Principle for the Mounting

Avoiding contact between the magnetic side and the sensor could be achieved with a perfectly perpendicular

installation of the band. Yet, in reality this is not practicable. It is therefore preferable to install the tape with a

horizontal offset from the sensor. During operation this method will result in a forced contact between the steel

side of the band and the polymer guide of the sensor which guarantees an optimal operation of the system.

Figure 8: Assessment of the pretention of the magnetic tape

Installation and First Start-Up

- 16 -

Shaft head Shaft pit

Magnetic Tape

Sensor

Mounting Angle

Car

5.3.3 Installation Procedure

1. Attach the top end of the tape in the shaft head. Ideally use an ELGO Mounting Kit. Check for correct

orientation of the tape. The arrows on the magnetic side must point in upward direction.

Figure 9: Correct orientation of the magnetic tape

2. The magnetic side of the tape must face the sensor body. In most situations this means that the steel side

points to the shaft wall.

3. Drive down the shaft with inspection speed and unroll the tape. The ELGO tape packaging system has

been specifically designed for this purpose. The tape can be unwound directly from the box without opening.

4. Attach the tension weight (about 7.5 kg) at the bottom end of the tape in the shaft. Secure the tape with a

sway guard. Pay attention to a proper vertical mounting of the tape.

If you use dowels to fix the tape in the shaft, tighten the spring such, that the according tractions results to

minimum 7.5 kg. When using the ELGO Mounting Kit RMS/RMS90 this is equivalent to a spring elongation of about 90 mm.

Note that slightly higher tensile forces are never a problem, but avoid under-tensioning. In higher buildings it may even be preferable to slightly increase the tension in order to prevent flapping of the tape during operation. However, if correctly installed tensile forces of more than 10 kg should never be necessary.

5. Drive the car to the middle of the shaft.

6. Attach the sensor to the car. The side with the cable outlet and the LED’s must face upward.

7. Adjust the sensor using the tape as a reference. First, align sensor and magnet band on their centerline.

Figure 10: Distance and orientation of the magnetic tape in relation to the sensor

Installation and First Start-Up

- 17 -

Tape is flat in

the guide

Tape is

skewed in the

guide

Tape is

skewed in the

guide

Tape is flat in

the guide

Tape is

skewed in the

guide

Tape is

skewed in the

guide

8. Adjust now the distance between sensor and tape. Up to a travel height of 50 m we recommend an offset

of at least 15 mm. This will ensure steady contact between steel side of the band and the polymer guide

of the sensor. This level can be increased later, if it turns out that the band still rubbing with the magnetic

side on the sensor.

In higher installations this distance may be increased by the initial assembly up to 5 cm.

Pay attention to a perpendicular alignment of the sensor. Misalignment will lead to increased wear.

9. Pass the tape through the sensor. Loosen the splint-pin and release the polymer guide. Insert the tape and

re-attach the guide with the tape in its position.

10. Pay attention that the pad does not slip after removal of the polymer guide from the aluminum guide out

and drops down in the shaft.

11. Check for proper alignment of band vs. sensor. Any angular offset should be corrected.

Figure 11: Assessment of the guiding rail of the tape in the sensor - twisted magnetic tape

Figure 12: Assessment of the guiding rail of the tape in the sensor - skewed mounting of the magnetic tape

Installation and First Start-Up

- 18 -

Recommended

Falsche vertikale

Ausrichtung

12. IMPORTANT: Installation check!

Values for tape tension and offset between tape and sensor are guidelines based on experience. But in

any case, a proper check after installation is mandatory. It must absolutely be avoided that the magnetic

side constantly grinds on the sensor body during operation. Run an inspection trip along the complete

shaft. Observe the system and pay attention to the respective positions of band and sensor. You have

achieved an optimal installation if the steel side of the tape is constantly pressed slightly against the polymer guide of the sensor. At some points in the shaft also double-check on the bottom side of the sensor.

If the sensor is tilted it may look good on top but the tape can still grind along the bottom edge of the

sensor.

Figure 13: Assessment of the vertical alignment of the sensor

13. If the installation check reveals that the tape slides on magnetic side, start to increase the offset between

sensor and tape. Values of up to 5 cm are acceptable. If this measure does not solve the problem it is

very likely that the tape is not plumb in the shaft. This is easy to check for, provided your elevator control

allows for inspection trips without the absolute position signal: Just take the tape out of the sensor and

run an inspection trip along the shaft. Observe the distance between sensor and tape along the travel.

Misalignments will become obvious.

Also ensure that the tension on the tape is sufficient. A loosely tensioned tape will hinder proper guiding.

14. After completion of the installation clean the tape. Beginning at the top of the shaft drive down the com-

plete travel distance pulling the magnet tape through a dry cloth.

Be specifically alert if steel construction work is taking place in the shaft. Steel particles released by grinding, welding, or such work will adhere to the magnetic tape. Clean this debris off instantly.

Repeat the cleaning process before putting the elevator into service after complete installation.

Connections and Interfaces

- 19 -

CAN Standard

Bitrate

250 kbit/s

Resolution

1.0 mm

Identifier

184 (hex)

First 4 Bytes

Position in mm

Next 2 Bytes

Speed in mm/s

6 Connections and Interfaces

6.1 LED’s (Operating status and notices)

The LED’s located on the front serve for monitoring of operating conditions.

With startup it has to be ensured that the yellow LED illuminates as this monitors the internal supply voltage.

Figure 14: LED signals on the upper side of the sensor

PWR YELLOW Supply voltage

ON = Supply voltage OK

OFF = Supply voltage not provided

RUN GREEN

for CANopen device: RUN-LED according to DR 303-3

other device: Interface state, flashes during active communication

ERR RED

for CANopen device: ERR-LED according to DR303-3

other device: Error message

ON = State error, system not operational

OFF = State OK, system ready for operation

TAPE YELLOW Indicator for magnet tape

ON = Magnet tape missing

OFF = Magnet tape available

6.2 CAN Interface

6.2.1 CAN Standard

Table 1: Configuration of CAN Standard

Connections and Interfaces

- 20 -

CANopen DS406

Bit rate

250 kbit/s

Identifier

184 (hex)

Event timer

10 ms

Producer heartbeat

500 ms

Resolution

1.0 mm

First 4 Bytes

Position in mm

Next 2 Bytes

Speed in mm/s

CANopen DS417

Bit rate

250 kbit/s

Identifier

18 C (hex) [Node ID 0x04]

Event timer

0 (switched off)

Producer heartbeat

500 ms

Resolution

0.5 mm

ABS-Position

Speed

xxh

MSB

yyh

LSB

yyh

MSB

xxh

xxh

LSB

xxh

ABS-Position

Speed

xxh

MSB

yyh

LSB

yyh

MSB

xxh xxh

LSB

xxh

ABS-Position

xxh

MSB

xxh xxh

LSB

xxh

Figure 15: Protocol CAN standard

6.2.2 CANopen DS 406 and DS417

For LIMAX02 the CANopen Interfaces DS406 (encoder profile) und DS417 (lift profile) are available. These

interfaces are configured by default as follows:

Table 2: Configuration of CANopen DS406

Figure 16: Protocol DS406

Table 3: Configuration of CANopen DS417

Figure 17: Protocol DS417

Connections and Interfaces

- 21 -

9-pin D-SUB connector

Open cable exit

PIN-No.

Function

Color

Function

Pin 6

0 V / GND

White

0 V / GND

Pin 9

+ 24 VDC

Brown

+ 24 VDC

Pin 2

CAN L

Green

CAN L

Pin 7

CAN H

Yellow

CAN H

Pin 3

CAN GND

Blue

CAN GND

Housing*

PE

Shield*

PE

Note!

The commands which are described in section 6.2.4.2 Normal Mode are only processed by

the CANopen device in the Operational and Pre-Operational mode.

2B 17 10 00 YY ZZ 00 00

DLC:ID: XXX 8

Set Heartbeat cycle time

Master

CANopen

device

XXX = 600h + node-ID

Example: 604h for the device node-ID 4

YY = LSB of cycle time in milliseconds

ZZ = MSB of cycle time in milliseconds

Example: for a cycle time of 500ms (1F4h) is

YY = F4h and ZZ = 01h

ID: DLC:XXX 8

60 17 10 00 00 00 00 00

XXX = 580h + node-ID

Example: 584h for the device node-ID 4

Acknowledgment of the CANopen device

6.2.3 Pin Assignment CAN

Table 4: Pin Assignment CAN

6.2.4 Command Descriptions

6.2.4.1 Initial Operation

*) please connect shield only at control unit side!

After starting the CANopen device is in the Pre-operational Mode ( 6.2.6.2) and therefore doesn’t send any

position data. In order to achieve this, the device needs to be set into Operational Mode ( 6.2.6.1) and if

necessary the sending cycle of the position data has to be adjusted ( 6.2.4.4).

6.2.4.2 Normal Mode

6.2.4.3 Setting the Heartbeat Cycle Duration

A CANopen device sends the heartbeat cyclically. This message communicates the current Operating Mode to

the other bus sharing units.

1. Change into the Operational or Pre-operational Mode, if necessary

2. The following illustration shows the CAN-message, which should be transmitted to the CANopen device

and the following answer.

Figure 18: Setting the Heartbeat Cycle Duration

Connections and Interfaces

- 22 -

2B UU VV 05 YY ZZ 00 00

DLC:ID: XXX 8

Set cycle time for position data

Master

CANopen

device

XXX = 600h + node-ID

Example.: 604h for the device with node-ID 4

UU = 00h (DS406), 06h(DS417)

VV = 18h (DS406), 19h(DS417)

YY = LSB of cycle time in milliseconds

ZZ = MSB of cycle time in milliseconds

Example: for a cycle time of 10ms (Ah) is

YY = 0Ah and ZZ = 00h

05

ID: DLC:XXX 8

60 UU VV 00 00 00 00

XXX = 580h + node-ID

Example: 584h for the device node-ID 4

Acknowledgment of the CANopen device

3. If the setting should be maintained in the case of a power failure, the changes have to be saved, as

described in section ( 6.2.5).

6.2.4.4 Setting the Sending Cycle for the Position Data

The position data are sent cyclically by the device, therefore the device has to be in the Operational Mode (

6.2.6.1).

The settings of the cycle duration takes place in the device profile DS406 in the object 1800h, Sub-index 5 and

for devices with DS417 profile in object 1906h, Sub-index 5.

1. Change into the Operational or Pre-operational Mode, if necessary.

2. The following figure shows the CAN-message, which should be transmitted to the CANopen device and

the following answer.

Figure 19: Setting the Sending Cycle for the position data

3. If the settings should be maintained in case of a power failure, the changes have to be saved, as de-

scribed in section ( 6.2.5).

6.2.5 Saving the Parameters

In the normal case the settings are lost at power failure. In order to avoid this, they need to be saved according

to the following procedure.

1. Change into the Operational or Pre-operational Mode, if necessary.

2. The following figure shows the CAN-message, which should be transmitted to the CANopen device and

the following answer:

Connections and Interfaces

- 23 -

23 10 10 01 73 61 76 65

DLC:ID: XXX 8

Saving all parameters

Master

CANopen

device

XXX = 600h + node-ID

Example: 604h for the device node-ID 4

ID: DLC:XXX 8

60 10 10 01 00 00 00 00

XXX = 580h + node-ID

Example: 584h for the device with node-ID 4

Acknowledgment of the CANopen device

01 00

DLC:ID: 000 2

Changing all participants into the Operational Mode

Master

CANopen

device

80 00

DLC:ID: 000 2

Changing all participants into Pre-Operational Mode

Master

CANopen

device

Figure 20: Saving the parameters

6.2.6 Changing the Operating Modes

6.2.6.1 Changing the device into the Operational Mode

In the Operational Mode the communication of the device is fully functional.

The following CAN-message causes the change of all CANopen participants into the Operational Mode.

Figure 21: Changing the device into the Operational Mode

6.2.6.2 Changing the device into the Pre-operational Mode

In the Pre-operational Mode the communicating settings of the device are adjusted.

The following CAN-message causes the change of all CANopen participants into the Pre-Operational mode.

Figure 22: Changing the device into the Pre-operational Mode

Connections and Interfaces

- 24 -

02 00

DLC:ID: 000 2

Changing all participants into Stopped Mode

Master

CANopen

device

ATTENTION!

With the following command all the bus sharing units which are in the Stopped Mode are

changed into the LSS Configuration Mode. Use this command, if only one device is connected

to the bus, because other devices could be affected in their function.

04 01 00 00 00 00 00 00

DLC:ID: 7E5 8

Changing all participants into LSS Configuration Mode

Master

CANopen

device

Saving the parameters

17 00 00 00 00 00 00 00

DLC:ID: 7E5 8

ID: DLC:7E4 8

17 00 00 00 00 00 00 00

Master

CANopen

device

6.2.6.3 Changing the device into the Stopped Mode

Bus sharing units in the Stopped Mode are passive participants. In this mode all the communication is turned off,

except the monitoring activity (e.g. heartbeat).

The following CAN-message causes the change of all CANopen participants into the Stopped Mode:

Figure 23: Changing the device into the Stopped Mode

6.2.7 LSS Configuration

Basic settings like node-ID and baud rate have to be adjusted with the Layer Setting Services (LSS).

6.2.7.1 Changing into the LSS Configuration Mode

In order to be able to change the Parameter (node-ID, bit rate), the device has to be changed into the LSS Configuration Mode.

The following CAN-message causes the change into the LSS Configuration Mode.

Figure 24: Changing into the LSS Configuration

6.2.7.2 Saving the Parameters in the LSS Mode

In order not to lose the changes in case of a power failure, they have to be saved in the non-volatile memory of

the CANopen device.

The following figure shows the necessary message for this procedure.

Figure 25: Saving the parameters in the LSS Mode

Connections and Interfaces

- 25 -

ATTENTION!

During the saving procedure the device is not accessible over a period of a few milliseconds.

13 00 XX 00 00 00 00 00

DLC:ID: 7E5 8

ID: DLC:7E4 8

13 00 00 00 00 00 00 00

Master

CANopen

device

Adjusting the baud rate

Values for XX:

0 = 1 MBit/s

1 = 800 kBit/s

2 = 500 kBit/s

3 = 250 kBit/s

4 = 125 kBit/s

5 = reserved

6 = 50 kBit/s

7 = 20 kBit/s

8 = 10 kBit/s

Changing the node-ID

11 XX 00 00 00 00 00 00

DLC:ID: 7E5 8

ID: DLC:7E4 8

11 00 00 00 00 00 00 00

CANopen

device

Master

XX = new node-ID in the range 01h .. 7Fh

6.2.8 Setting the Baud Rate

1. Change the device into the Stopped mode ( 6.2.6.3)

2. Change the device into the LSS Configuration Mode ( 6.2.7.1)

3. Change baud rate according to the following command:

Figure 26: Setting the baud rate

4. Save parameter as described in section ( 6.2.7.2).

5. Turn the device off and restart it again.

6.2.9 Setting the node-ID

1. Change the device into the Stopped Mode ( 6.2.6.3)

2. Change the device into the LSS Configuration Mode ( 6.2.7.1)

3. Change node-ID with the following message:

Figure 27: Setting the node-ID

4. Save parameter as described in section ( 6.2.7.2).

5. Turn the device off and restart it again.

Connections and Interfaces

- 26 -

Open cable ends

Color

Function

White

0 V / GND

Brown

+ 24 VDC

Pink

Data -

Grey

Data +

Yellow

CLK -

Green

CLK +

Shield

PE

9-pin. D-SUB Connector

NEWLIFT FST1 (D9M0)

NEWLIFT FST2 (D9M1)

Pin

Function

Function

1

DATA +

0V / GND

2

CLK -

CLK +

3 - N.C.

4

24 VDC

DATA +

5

0V / GND

0V / GND

6

DATA -

+ 24 VDC

7

CLK +

CLK -

8 - DATA -

Housing

PE

N.C.

T

23

22

21

20

19

18

17

16

15

14

13

12

11

10 9 8 7 6 5 4 3 2 1 0

PFB = Power Failure Bit

Tm = monostable multivibrator time > 10µs

24 Data bits/3 Bytes

PFB

6.3 SSI Interface

6.3.1 Function Principle

If the clock is not interrupted for the time Tm-T/2 (output of further 25 periods), the shift register clocks once

again the same data value (error recognition in the evaluation). Some encoders contain a Power Failure Bit

(PFB). Attention: With the LIMAX02 the PFB is always “LOW”!

6.3.2 Data Protocol

T = length of clock signal

Figure 28: Data Protocol SSI Interface

6.3.3 Pin Assignment

Table 5: Pin Assignment SSI open cabel ends

Table 6: Pin Assignment SSI Interface

Connections and Interfaces

- 27 -

ABS position

STX

02h

MSB

xxh

00h

ETX

03h

LSB

xxh

xxh 0Dh

Open cable ends (Standard)

Color

RS232

RS422

RS485

White

0 V / GND

0 V / GND

0 V / GND

Brown

+ 24 VDC

+ 24 VDC

+ 24 VDC

Pink

TX

TX -

TX -

Grey

RX

TX +

TX +

Yellow

-

RX - Green

-

RX +

Shield

PE

PE

PE

ABS position

Speed

STX

02h

MSB

xxh

00h

ETX

03h

LSB

yyh

MSB

yyh

LSB

xxh

xxh 0Dh

STX = starts a message

ETX = ends a message

STX = starts a message

ETX = ends a message

Figure 29: Data Protocol Version 2321 / 4221 / 4851

Figure 30: Data Protocol Version 2320 / 4220 / 4850

6.4 RS232 / RS422 / RS485*

*) Attention: RS485 only unidirectional

If the measuring system is equipped with an RS232, RS485 or RS422 interface, the data communication has the

following format:

19200 baud (other baud rates on request)

1 Start bit

8 data bits

1 stop bit

no parity

6.4.1 Data Protocol

The measured absolute position will be represented in the three ABS-position data bytes.

Version 2321 / 4221 / 4851

Version 2320 / 4220 / 4850

6.4.2 Pin Assignment

Table 7: Pin Assignment

Connections and Interfaces

- 28 -

06h = characterizes a message as address allocation

i = the new LIMAX02 address. Important: At the answer you get the new address + 80h.

04h = characterises the message as position request

i = address of the LIMAX02 (0Bh – 7Fh) to request

Bit 0 has the value 10µm, position values are always smaller than FFFF00h

STX = starts a message

ETX = ends a message

Check Byte = contains the arithmetic checksum of STX, byte 1 and byte 2.

The meaning of bytes 1 to 4 can be found in the following chapters.

ABS-Position

05h = characterizes a message as address request

i = LIMAX02 address

FFh FFh does not occur immediately after STX with position inquires as answer!

In this case (0Bh <= i <= 7Fh) this is the answer of the address request.

STX

02h

Byte 1 ETX

03h

Byte

check

Byte 2 STX

02h

Byte 1 Byte 4 Byte 3 Byte 2 STX

02h 04h

ETX

03h

Byte

check i

STX

02h

MSB

xxh

Adr. i LSB

xxh xxh

STX

02h 05h

ETX

03h

Byte

check 05h

STX

02h FFh

ETX

03h i xxh FFh

STX

02h

06h

ETX

03h

Byte

check

i

STX

02h FFh

ETX

03h

i +

80h FFh

6.4.3 Command Descriptions

Important:

Before you send a new message to the LIMAX02 wait for the answer first. After allocating a new address the

LIMAX02 answers in max. 0.5 seconds. In other cases it even in a few milliseconds. After this time it is not

expected to get an answer (transmission error).

6.4.3.1 Principle Format of Message

To LIMAX02 answer

6.4.3.2 Position request of LIMAX02 with the address “i”

To LIMAX02 answer

6.4.3.3 A LIMAX02 address request

Attach in each case only one LIMAX02 e.g. over a RS422/RS232 converter to the serial interface (COM-port) of

a PC.

To LIMAX02 answer

6.4.3.4 Allocation of an LIMAX02 address

Attach in each case only one LIMAX02 e.g. over a RS422/RS232 converter to the serial interface (COM-port) of

a PC.

To LIMAX02 answer

The addresses 80 h – FFh as well as 00 h – 0 Ah are FORBUDDEN. If you try to assign an address smaller than

eight, LIMAX02 gives you a “negative answer” and keeps its former address.

Connections and Interfaces

- 29 -

Code

Meaning

04h

Wrong sequence of bytes sent to LIMAX02, for example if 4. Byte after STX is no ETX or the Byte after

STX is not 0x04, 0x05 or 0x06.

05h

Receiving Error / Interface Error (for example if a message with a wrong baud rate was sent etc.)

06h

Invalid LIMAX02 address: appears after trying to assign an address smaller 0Bh or bigger 7Fh to LIMAX02.

07h

LIMAX02 has lost its address: internal check of X redundantly stored address of LIMAX02 has failed.

This message is sent at power up immediately if an error in reading EEPROM is detected or if the internal address error cannot be fixed.

08h

Internal EEPROM storage error.

09h

Error in transmission of position (no tape, tape damaged or distance between tape and sensor head

too big).

0Ah

Check-Sum-Error: Check-sum of a message sent to LIMAX02 is wrong.

ERR = Error-Code (04h – 0Ah) error – codes are listed at the next page.

STX

02h

FFh

ETX

03h

ERR

xxh

FFh

6.4.3.5 Error Messages

If one of the described operations failed for some reason LIMAX02 gives an error message with a respective

error-code.

Answer from LIMAX02

Table 8: Error-codes of an addressable LIMAX02

Connections and Interfaces

- 30 -

6.4.3.6 Connection to a RS422 Master

Figure 31: Connection to a RS422 Master

6.5 Option Unguided

LIMAX02 "unguided" is an absolute measuring system, which is used for positioning in the most diverse areas

horizontally and vertically. It consists of only two components: magnetic tape and the sensor.

Figure 32: LIMAX02 Option unguided

Connections and Interfaces

- 31 -

Function

Setting Range

Factory Setting

Monoflop

20 ... 255 µs

[200]

Clock quantity SSI

18 ... 32

[24]

Scale SSI/x

1 ... 255

[1]

Offset

-1073741823 ... 1073741824

[0]

LED

RUN (green)

ERROR (red)

MSD LSD

6.6 Option PROFIBUS Interface

6.6.1 LED’s (Operation Status and Messages)

The LED’s located on the top side, a green LED (Bus Run) and a red LED (Bus Fail), serve for monitoring of op-

erating status. For setting the address are two rotary coding switches located on the top next to the LED’s

BUS RUN GREEN

ON = Ready

OFF = Supply voltage not provided

Flashes cyclic = Slave has no cyclic data exchange with PROFIBUS-DP-MASTER

Flashes irregular = start: Missing or faulty configuration

Runtime: Host watchdog- time error

BUS FAIL RED

ON = unrecoverable Converter – Fault

OFF = no error / bus in cycle

Flashing = Converter not addressed by the master

6.6.2 Adjustment

6.6.2.1 Address Adjustment

The address adjustment is carried out with the coding switches on top of the housing. The higher decade with

the coding switch MSD and the low decade with the coding switch LSD.

Figure 33: Address Adjustment and LED Signaling

6.6.2.2 Parameter Adjustment

The following parameters can be adjusted by GSD File.

(GSD File is on CD-ROM delivered

Table 9: Parameter Adjustment by GSD File

Connections and Interfaces

- 32 -

PROFIBUS Interfac

Transmission

RS485 two-wire line

Wire lenght

1200 m at 9,6 kBaud

200 m at 1,5 Mbaud

100 m at 12 MBaud

Baud rate

9,6 kBaud to 12 Mbaud (auto detect)

Clock rate max.

250 kHz

Participants

max. 32 per Segment (with repeater until 126 expandable)

Mono- and Multi-master systems are possible

In delivery status is participant 05 set

Table 11: Pin Assignment PROFIBUS IN

Table 12: Pin Assignment PROFIBUS OUT

PROFIBUS IN (Flanged Plug M12)

Pin

Function

1

N.C.

2

Data A

3

N.C.

4

Data B

5

Shield

PROFIBUS OUT (Flanged Socket M12)

Pin

Function

1

N.C.

2

Data A

3

N.C.

4

Data B

5

Shield

Power supply (Fanged Plug M8)

Pin

Color

Function

1

Brown

+ 10 to 30 VDC

2

White

N.C.

3

Blue

0 V / GND

4

Black

N.C.

6.6.2.3 PROFIBUS Interface

The sensor option profibus is fitted as standard with a profibus interface according to IEC61158 / IEC61784.

The following parameters are specified.

Table 10: Parameter PROFIBUS Interface

6.6.2.4 Pin Assignment

Table 13: Power Supply

Connections and Interfaces

- 33 -

Profibus INProfibus OUT

Power Supply

Figure 34: Pin Assignment PROFIBUS

Disturbances, Maintenance, Cleaning

- 34 -

CAUTION!

The device, the connection line and the signal cable must not be installed next to sources of interference that emit

strong inductive or capacitive interference or strong electrostatic fields.

External perturbations can be avoided thorough suitable cable routing.

The screen of the signal output cable should only be connected to the following circuit on one side. The screens

should not be grounded on both sides. Signal cables always have to be routed separately from the load power line.

A safety distance of at least 0,5 m has to be kept from inductive and capacitive sources of interference such as contactors, relays, motors, switching power supplies, clocked controllers etc!

If interferences occur in spite of all the items stated above being observed, please proceed as follows:

1. Installation of RC-circuits via contactor coils of AC-contactors (e.g. 0,1 µF / 100 Ω)

2. Installation of recovery diodes via DC-inductors

3. Installation of RC-circuits via the different motor phases (in the terminal box of the motor)

4. Do not connect protective earth and ground

5. Connect a mains filter ahead of the external power pack

WARNING!

Danger of injury through non-conventional fault clearance!

Non-conventional fault clearance can lead to severe injuries and damage of property.

Therefore:

Any work to clear the faults may only be performed by sufficiently qualified staff

Arrange enough space before starting the works

Make sure that the mounting area is clean and tidy. Loose components and tools are sources of accidents.

If components need to be replaced:

Pay attention to a correct installation of the spare parts.

Reinstall all the fixing elements properly

Before turning on the device, ensure that all covers and safety equipment is installed correctly and functions

properly

7 Disturbances, Maintenance, Cleaning

This chapter describes possible causes for disturbances and measures for their removal. In case of increased disturbances, please follow the

measures for fault clearance in chapter 7.1.

In case of disturbances that cannot be eliminated by following the advice and the fault clearance measures given here, please contact the

manufacturer (see second page).

7.1 Fault Clearance

7.2 Re-start after Fault Clearance

After the fault clearance:

1. Reset the emergency stop mechanism if necessary

2. Reset the error report at the super-ordinate system if necessary.

3. Ensure that there are no persons in the danger area.

4. Follow the instructions from chapter 5.

Disturbances, Maintenance, Cleaning

- 35 -

WARNING!

Danger through non-conventional maintenance!

Non-conventional maintenance can lead to severe injuries and damage of property.

Therefore:

Maintenance works may only be completed by staff that has been authorized and trained by the operator.

WARNING!

The device can only be cleaned with a damp cloth, do not use aggressive cleanser!

7.3 Maintenance

The LIMAX02 shaft information system requires little maintenance. On the occasion of regular elevator inspection and maintenance do the

following:

Optical inspection of proper alignment between sensor and band. Worn off material indicates possible alignment flaws. Check

for proper guiding of the band along the complete travel distance. Correct if necessary as described in the installation procedure

above.

Optical inspection of the band. Check for abrasions or other mechanical damages. Small mechanical damages (scratches, dents,

or even small chips) do not interfere with the measuring performance at all.

However, a pre-damaged band is more exposed to mechanical stress and is prone to further wear.

Check for proper tension of the band. If the mounting was via a flute, the tension can decrease over time. Readjust if necessary.

Inspect the polymer guide for wear. Clean if dust and dirt have accumulated between polymer guide and sensor case. The poly-

mer guide is a wear part. Replace if necessary.

Clean the band. Use a dry and clean cloth. Begin at the head of the hoistway drive down the complete travel distance pulling the

magnet band through a dry cloth.

7.4 Cleaning

Type Designation

- 36 -

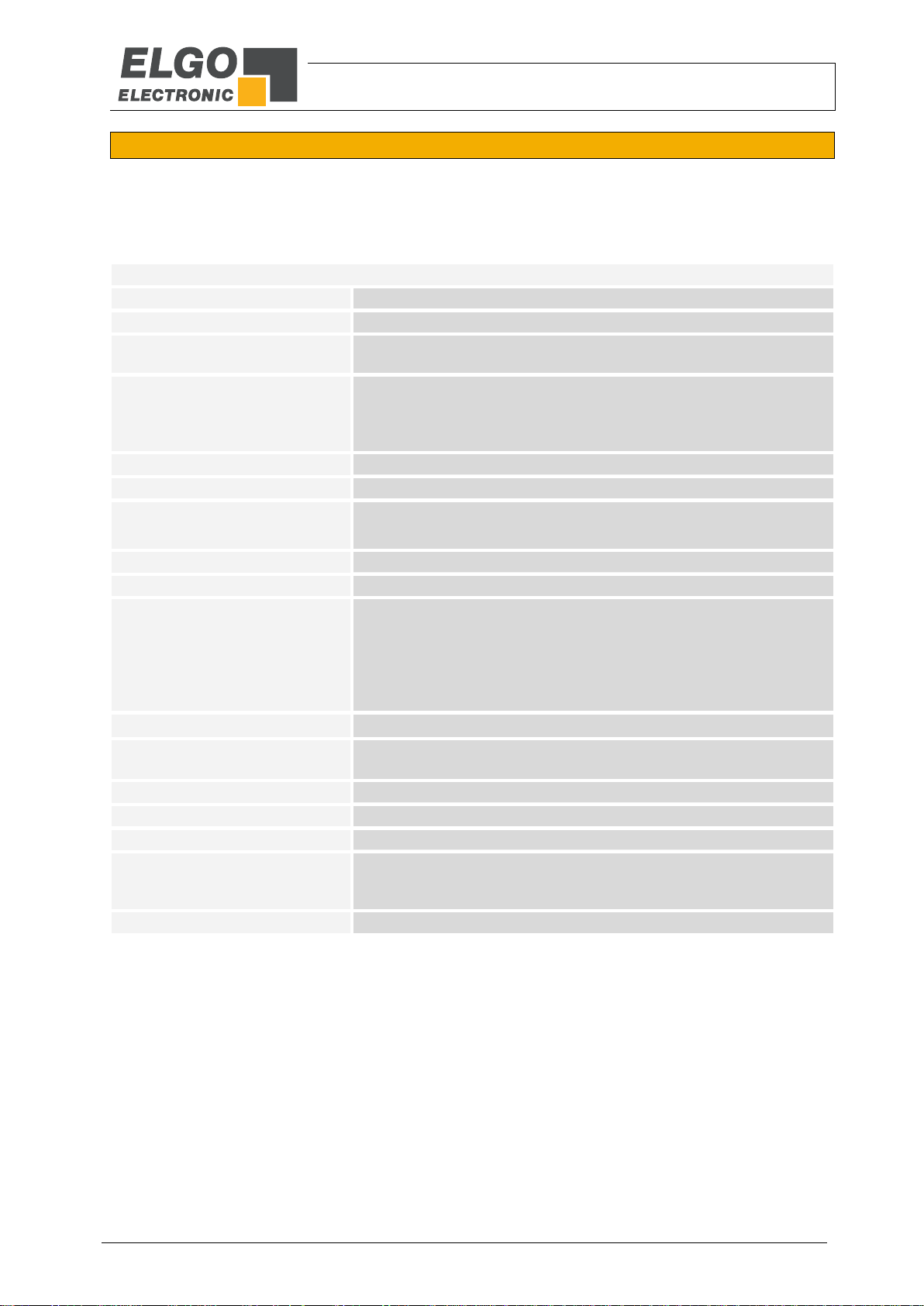

LIMAX2

Series / Type:

LIMAX2 = LIMAX02 (1-Kanal)

Signal cable length:

030 = 3,0 m (Standard)

050 = 5,0 m

Other on request

Resolution:

62N5 = 62,5 µm = 0,0625 mm

0125 = 125 µm = 0,125 mm

0250 = 250 µm = 0,25 mm

0500 = 500 µm = 0,50 mm

1000 = 1000 µm = 1,00 mm

---

SN-number:

00 = standard version

01 = special version

- 1000 CO0T -

Interface:

2320 = RS232 [sta ndard pr otocol, RS232 / positio n]

2321 = RS232 [extended protocol RS232 / po sition & speed]

4220 = RS422 [sta ndard protocol, RS422 / po sition]

4221 = RS422 [extended protocol RS422 / positio n & speed]

4850 = RS485 on request

CN0 = CAN [standard pr otocol, basic-CAN]

CO0 = CANopen [Encoder Profil DS406]

CO1 = CANopen [Elevator Profil DS417]

PNO = Profibus [according to IEC61158/IEC61784, standard ID 5, other on request]

SSB0 = SSI-Interface [25-bit binary code / position]

SSG0 = SSI-Interface [25-bit gray code / Position]

CAUTION:

-> CAN Interface is optional available with galvanic isolation / assem bly CAN-load resistor selectable

-> RS232- Interface is never terminated!

-> RS422- & RS485- & SSI- Interface is basically terminated!

Options:

(Multiple choice possible)

U = option unguided

PNO = 1 pc. Flange plug M8, 1 pc. Flange plug M12 und 1 pc. Flange socket M12

D9M = 9-pol. D-Sub-connector [CAN & CANopen]

D9M1 = 9-pol. D-Sub-connector [SSI / option NEWLIFT FST2]

D9M3 = 9-pol. D-Sub-connector [SSI / option LödigeSEW]

D9F0 = 9-pol. D-Sub-socket [RS232 / to connect to DEE/DTE ]

(open cable end if no option is selected!)

Terminat ed 120R (T)

Not terminated

CN0T (Standard)

CN0

Terminat ed 120R (T)

Not terminated

CO0T (Standard)

CO0

Terminat ed 120R (T)

Not terminated

CO1T

CO1 (Standard)

CN0TG

CN0G

CO0TG

CO0G

CO1TG

CO1G

SSG0 (Standard) SSG0G

SSB0 (Standard) SSB0G

Without galvanic

isolation

With galvanic

isolation (G)

CAN Interface

Without optocoupler at

clock input (terminated

120R)

With optocoupler at clock

input (G) (terminated

120R)

SSI Interface

D9M03000

8 Type Designation

8.1 Type Designation

Figure 35: Type designation

Type Designation

- 37 -

Product key

Control type

LIMAX2-00-030-0500-CO1TG-D9M

Böhnke bp306/bp308 (CANopen CiA 417) - terminated

LIMAX2-00-030-0500-CO1G-D9M

Böhnke bp306/bp308 (CANopen CiA 417) - not terminated

LIMAX2-00-030-62N5-SSG0-D9M1

NEWLift FST2

LIMAX2-00-030-1000-SSB0

KW Aufzugstechnik David 606

LIMAX2-00-030-1000-CO0

LIMAX02 with CANopen encoder profile DS406

LIMAX2-14-030-1000-SSBX

Kollmorgen MRL4 / MFE4 (MPK400)

LIMAX2-04-015-1000-CO1-D9M

Sodimas Quickinstall

LIMAX2-52-030-1000-CO0G

Securelift

8.2 Control specific Sensors

Table 14: Control specific Sensors

Type Designation

- 38 -

Order Designation

Description

Image

AB20-80-10-1-R-D-15-BK80

Magnetic Tape

Installation kit LIMAX MKF

Mounting set for suspended installation with dowel.

Installation kit LIMAX MKB

Mounting set for suspended installation with guiding rails and rail holder.

Installation kit LIMAX RMS

Mounting set for suspended installation with crossbeam for standard layout.

Installation kit LIMAX RMS 90

Mounting set for suspended installation with crossbeam for “Rucksack” layout.

Installation kit LIMAX S-RMS

Mounting set for suspended installation with crossbeam and tape detection.

LIMAX2 MW

Mounting flange for LIMAX02

CD-ROM with GSD File

Supplied with option profibus

Connection cable power supply

PNO

M8 coupling, 4-pin 5 m length

PROFIBUS – signal line

M12 connector, 5-pin, b-coded (assembled at one

end) 5 m length

PROFIBUS – signal line

M12 coupling, 5-pin, b-coded (assembled at one

end) 5 m length

PROFIBUS – signal line

M12 plug / socket (assembled at both ends) 5 m

length

PROFIBUS - Terminator

M12 4-pin, b-coded

8.1 Accessories

Table 15: Accessories

Index

- 39 -

9 Index

Accessories ..................................................... 38

Accident prevention regulations........................... 4

CAN Interface and Protocols ............................. 19

Causes of risk .................................................... 5

Cleaning ................................................... 34, 35

Connections .................................................... 19

Conventional use ............................................... 6

Demounting ...................................................... 5

Device number .................................................. 8

Dimensions Magnetic Tape ............................... 10

Dimensions Sensor ............................................. 8

Dimensions Sensor Option unguided ................... 9

Disposal............................................................ 5

Disturbances ................................................... 34

Explanation of symbols ....................................... 4

Fault clearance ................................................ 34

First start-up .................................................... 12

Identification ..................................................... 8

Installation ...................................................... 12

Installation of the Sensor .................................. 14

Interfaces ........................................................ 19

LED status notice ............................................. 19

Magnetic tape

Structure ..................................................... 11

Maintenance ............................................. 34, 35

Operating area ............................................... 12

Operational safety ............................................. 4

Option Profibus Interface ................................. 31

Order reference ................................................ 8

Packaging material ............................................ 6

Product Features ............................................... 7

Protection against contact ................................ 12

Protective equipment ......................................... 5

RS232 / RS422 / RS485 .................................. 27

Safety ........................................................... 4, 5

Safety instructions .............................................. 4

Safety rules ....................................................... 4

Sensor Technical Data ..................................... 10

SSI Interface .................................................... 26

Start-up .......................................................... 12

Storage ............................................................ 6

Technical Data Magnetic Tape ......................... 11

Transport .......................................................... 6

Transport damage ............................................. 6

Type designation ............................................... 8

- 40 -

Document- No.:

799000350 / Rev. 9

Document- Name :

LIMAX02-00-MA-E_14-19

Subject to change - © 2019

ELGO Electronic GmbH & Co. KG

EL G O E l e c t r o n i c GmbH & Co . K G

Me as u rin g | P os i tio nin g | C o nt r ol

Carl - B enz - S tr. 1 , D-782 39 Ri elasi n gen

Fon:+49 (0) 7731 9339-0, Fax:+49 (0) 7731 28803

Internet: www.elgo.de, Mail: info@elgo.de

Loading...

Loading...