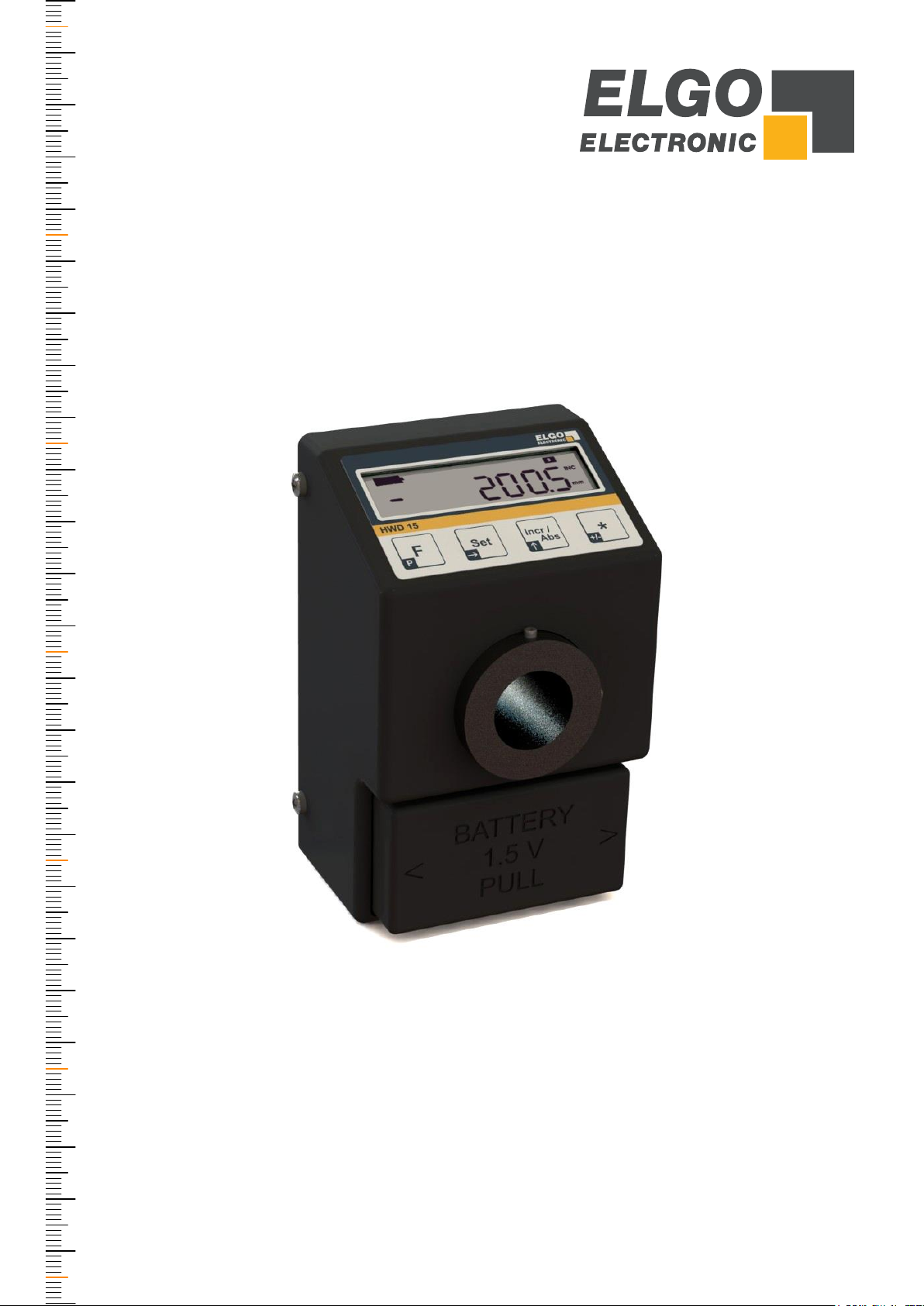

ELGO Electronic HWD15 Series, HWD15-000-001, HWD15-001-001 Operating Manual

Operating Manual

SERIES HWD15

Battery powered Display Unit with Rotative Encoder (1250 ppr)

Easy mounting and operation

Battery operation (no wirings required)

Wear-free measuring principle

LCD display with signs, special characters

and battery status indicator

„° “-Symbol for angular measurement assignable

Fraction display in inch mode possible

Resolution 0.1 mm or 0.01 mm via parameters

Display inch mode „0.001 Inch“ is possible

Tool offset and incremental measurement function

799000169 / Rev. 0 / 2019-06-07

Translation of the original operating manual

- 2 -

Publisher

ELGO Electronic GmbH & Co. KG

Carl-Benz-Str. 1

D-78239 Rielasingen-Worblingen

Technical Support

+49 (0) 7731 9339 - 0

+49 (0) 7731 2 88 03

info@elgo.de

Document- No.

799000169

Document- Name

HWD15-000-MA-E_23-19

Document- Revision

Rev. 0

Issue Date

2019-06-07

Copyright

© 2019, ELGO Electronic GmbH & Co. KG

Contents

- 3 -

1 Contents

1 Contents ............................................................................................. 3

2 General, Safety, Transport and Storage ........................................... 4

2.1 Information Operating Manual ........................................................................................... 4

2.2 Explanation of Symbols ...................................................................................................... 4

2.3 Terms and abbreviations .................................................................................................... 4

2.4 Statement of Warranties ..................................................................................................... 4

2.5 Demounting and Disposal .................................................................................................. 5

2.6 General Causes of Risk ..................................................................................................... 5

2.7 Personal Protective Equipment ............................................................................................ 5

2.8 Conventional Use ............................................................................................................. 6

2.9 Safety Instructions for Transport, Unpacking and Loading ....................................................... 6

2.10 Handling of Packaging Material .......................................................................................... 6

2.11 Inspection of Transport ...................................................................................................... 6

2.12 Storage ........................................................................................................................... 6

3 Product Features ................................................................................ 7

3.1 Application Examples ........................................................................................................ 7

4 Technical Data ................................................................................... 8

4.1 Identification .................................................................................................................... 8

4.2 Dimensions ...................................................................................................................... 8

4.3 Technical Data ................................................................................................................. 8

5 Power Supply / Battery Change ......................................................... 9

6 Installation and First Start-Up ......................................................... 10

6.1 Operating Area .............................................................................................................. 10

6.2 Mounting on the Shaft ..................................................................................................... 11

6.3 Adaptation to the Spindle Pitch ......................................................................................... 11

6.4 Display Overview ............................................................................................................ 12

6.5 Key Overview ................................................................................................................. 13

6.6 Parameter Level .............................................................................................................. 14

6.7 Parameter List ................................................................................................................. 15

6.8 Initialization Level ............................................................................................................ 16

6.9 Operator Level Functions ................................................................................................. 16

7 Disturbances, Maintenance, Cleaning ............................................. 18

7.1 Fault Clearance .............................................................................................................. 18

7.2 Re-start after Fault Clearance ........................................................................................... 18

7.3 Maintenance .................................................................................................................. 18

7.4 Cleaning ....................................................................................................................... 18

8 Type Designation ............................................................................. 19

9 Index ................................................................................................ 23

General, Safety, Transport and Storage

- 4 -

DANGER!

This symbol in connection with the signal word “Danger” indicates an immediate danger for the life and health of

persons. Failure to heed these instructions can result in serious damage to health and even fatal injury.

WARNING!

This symbol in connection with the word „Warning” means a possibly impending danger for the life and health of

persons. Failure to heed these instructions can result in serious damage to health and even fatal injury.

CAUTION!

This symbol in connection with the signal word “Caution” indicates a possibly dangerous situation. Failure to heed

these instructions can lead to minor injuries or damage of property.

DANGER!

This symbol in connection with the signal word “Danger” indicates an immediate danger for the life and health of

persons due to voltage. Failure to heed these instructions can result in serious damage to health and even fatal

injury. The operations may only be carried out by a professional electrician.

NOTE!

…points out useful tips and recommendations as well as information for an efficient and trouble-free operation.

Abbreviation/ Term

Connection option acc. to type designation

2 General, Safety, Transport and Storage

2.1 Information Operating Manual

This manual contains important information regarding the handling of the device. For your own safety and operational safety, please observe all safety warnings and instructions. Precondition for safe operation is the compliance with the specified safety and handling instructions. Moreover, the existing local accident prevention regulations and the general safety rules at the site of operation have to be observed.

Please read the operating manual carefully before starting to work with the device! It is part of the product and should be kept close to the

device and accessible for the staff at any time. The illustrations in the manual are for better demonstration of the facts. They are not necessarily to scale and can slightly differ from the actual design.

2.2 Explanation of Symbols

Special notes in this manual are characterized by symbols. The notes are introduced by signal words which express the magnitude of danger.

Please follow this advice and act carefully in order to avoid accidents, damage, and injuries.

Warning notes:

Special safety instructions:

Tips and recommendations:

Reference marks:

Marks a reference to another chapter of this manual.

Marks a reference to another chapter of another document.

2.3 Terms and abbreviations

2.4 Statement of Warranties

The producer guarantees the functional capability of the process engineering and the selected parameters.

General, Safety, Transport and Storage

- 5 -

CAUTION!

Wrong disposal causes environmental damages! Electronic scrap, electronic components, lubricants and other

auxiliary materials are subject to special refuse and can only be disposed by authorized specialists!

CAUTION!

Please read the operating manual carefully, before using the device! Observe the installation instructions!

Only start up the device if you have understood the operating manual. The operating company is obliged to take

appropriate safety measure. The initial operation may only be performed by qualified and trained staff.

Selection and installation of the devices as well as their embedding into the controlling system require qualified

knowledge of the applicable laws and normative requirements on the part of the machine manufacturer.

PROTECTIVE CLOTHING

… is close-fitting working clothing with light tear strength, tight sleeves and without distant parts. It serves preliminarily for protection against being gripped by flexible machine parts.

Do not wear rings, necklaces or other jewelry.

PROTECTIVE GLOVES

…for protecting the hands against abrasion, wear and other injury of the skin.

PROTECTIVE HELMET

…for protection against injuries of the head.

2.5 Demounting and Disposal

Unless acceptance and disposal of returned goods are agreed upon, demount the device considering the safety instructions of this manual

and dispose it with respect to the environment.

Before demounting, disconnect the power supply and secure against re-start. Then disconnect the supply lines physically and discharge

remaining energy. Remove operational supplies and other material.

Disposal: Recycle the decomposed elements: Metal components in scrap metal, Electronic components in electronic scrap, Recycle plastic

components, dispose the remaining components according to their material consistence.

Local authorities and waste management facilities provide information about environmentally sound disposal.

Safety

2.6 General Causes of Risk

This chapter gives an overview of all important safety aspects to guarantee an optimal protection of employees and a safe and trouble-free

operation. Non-observance of the instructions mentioned in this operating manual can result in hazardous situations.

2.7 Personal Protective Equipment

Employees have to wear protective clothing during the installation of the device to minimize danger of health.

Therefore:

Change into protective clothing before performing the works and wear them throughout the process.

Additionally observe the labels regarding protective clothing in the operating area.

Protective clothing:

General, Safety, Transport and Storage

- 6 -

CAUTION! Danger through non-conventional use!

Non-intended use and non-observance of this operating manual can lead to dangerous situations.

Therefore:

Only use the device as described

Strictly follow the instructions of this manual

Avoid in particular:

Remodeling, refitting or changing of the construction or single components with the intention to alter the

functionality or scope of the device.

CAUTION!

Transport the package (box, palette etc.) professionally.

Do not throw, hit or fold it.

NOTE!

Claim any damage immediately after recognizing it.

The claims for damage must be filed in the lawful reclaim periods.

2.8 Conventional Use

The ELGO-device is only conceived for the conventional use described in this manual.

The digital handwheel HWD15 only serves to measure distances, angles, revolutions and axis movements.

Claims resulting from damages due to non-conventional use are not possible.

Only the operator is liable for damages caused by non-conventional use.

2.9 Safety Instructions for Transport, Unpacking and Loading

2.10 Handling of Packaging Material

Notes for proper disposal: 2.5

2.11 Inspection of Transport

Check the delivery immediately after the receipt for completeness and transport damage.

In case of externally recognizable transport damages:

Do not accept the delivery or only accept under reserve.

Note the extent of damages on the transportation documents or delivery note.

File complaint immediately.

2.12 Storage

Store the device only under the following conditions:

Do not store outside

Keep dry and dust-free

Do not expose to aggressive media

Protect from direct sun light

Avoid mechanical shocks

Storage temperature (4) needs to be observed

Relative humidity (4) must not be exceeded

Inspect packages regularly if stored for an extensive period of time (>3 months)

Product Features

- 7 -

NOTE!

In the power-off mode the movements or adjustments of the magnetic sensor are not covered!

A referencing has to be performed after the start of operation (at a required mechanical position, the indicator must be set to ZERO or to a defined reference value).

NOTE!

Independent of the setting in P07 (see 6.7), the basic resolution of the HWD15 is

0.01mm). All settings of the multiplication factor refer to this resolution!

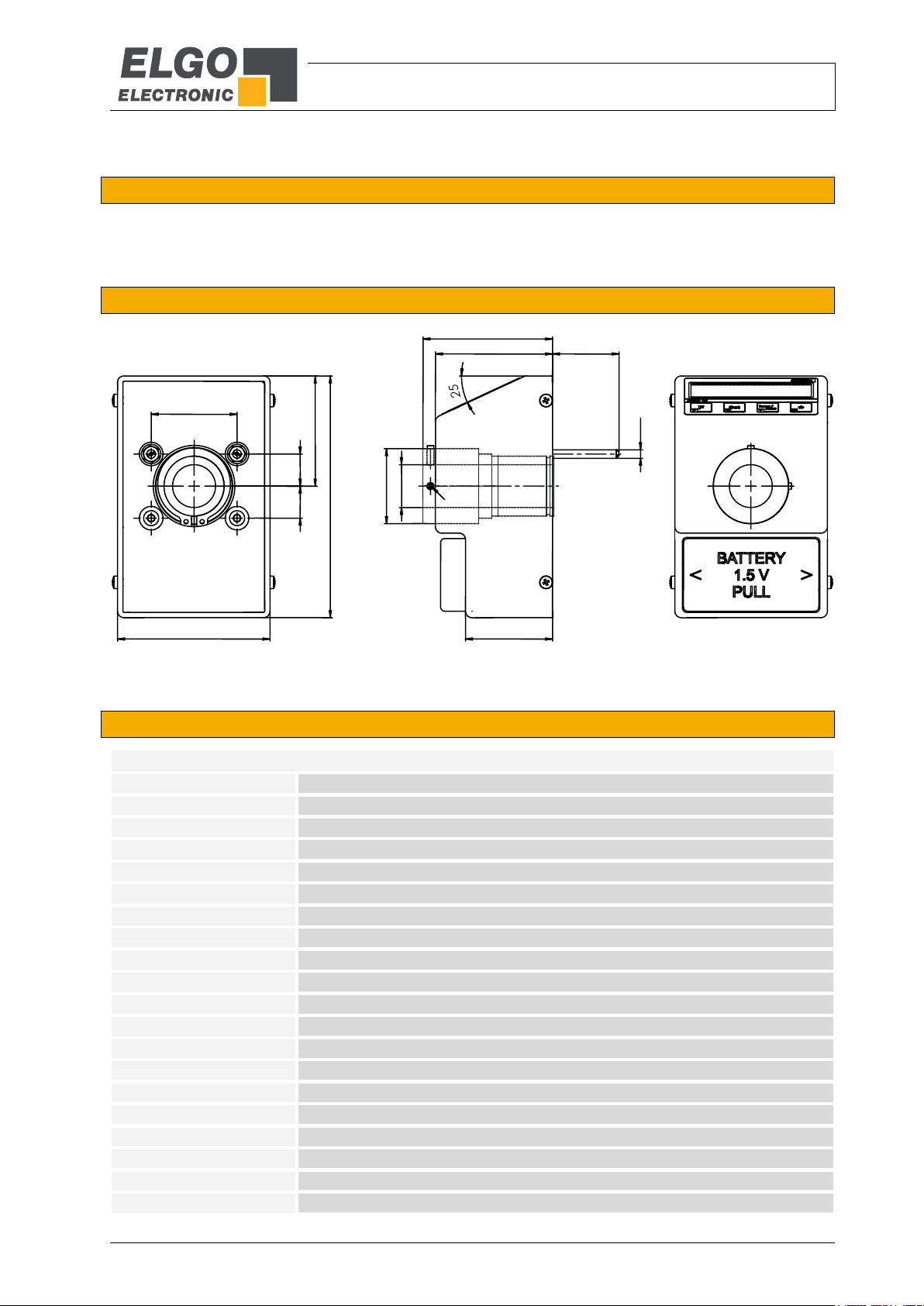

Figure 1: HWD15

3 Product Features

The battery-operated measuring and display system HWD15 provides a hollow shaft (Ø 20 mm) and is directly attached to the spindle. The position is

detected by the integrated sensor and displayed on the LCD display.

Due to its housing with a stable rear wall and flange option including torque

support, the HWD15 is a robust measuring system. However, the mechanical

loads should be absorbed by the spindle. The hollow shaft rotates in a

maintenance-free plain bearing.

The extensive basic functions and parameters allow a wide range of applications. For example, the display can easily be adapted to the respective spindle

pitch (see 6.3). The device provides a common baby cell (good quality). So

the system operates within 12 months of continuous operation.

3.1 Application Examples

Typical applications for the HWD15 are for example:

Manual and motorized adjustment units

Digital measurement of handwheels

Valve adjustments

Wrapping fixtures

Technical Data

- 8 -

Indicator HWD15

LCD

7 digits (height 9 mm) with sign, battery state and measurement units

Measurement units

mm, m, Inch or °

Perspective

12 o’clock

Keyboard

foil with short stroke keys

Measurement principle

quasi absolute

Measurement type

rotative

Battery supply

1,5 V baby cell (Type C / LR14)

Current consumption

< 1 mA at 1.5 V

Batter service life

approx. 12 months (depending on battery type)

Resolution

encoder: 1250 ppr / indicator 0.01 mm (basic resolution)

Operation speed

max. 2.5 m/s

Rotation speed

max. 1500 rpm

Housing dimensions

B x W x D = 72 x 114 x 61.5 mm

Hollow shaft diameter

20 mm

Shaft bearing

plain bearing

Maximum load

axial: 20 N / radial: 200 N

Protection class

IP43

Operating temperature

0 … +50° C

Storage temperature

0 … +70° C

Humidity

max. 80 %, non-condensing

72

114

52

15

40

61.5

30

55

41

35

20

M4

*

M4

15

*) 2 x M4 x 30 screws can be offset or removed

in the hole pattern (internal thread us able)

4 Technical Data

4.1 Identification

The type label serves for the identification of the unit. It is located on the housing of the device and indicates the

exact type designation (=order reference 8) with the corresponding part number. Furthermore, the type label

contains a unique, traceable device number. When corresponding with ELGO please always indicate this data.

4.2 Dimensions

Figure 2: Dimensions

4.3 Technical Data

Loading...

Loading...