Operating Manual

LIMAX44 RED

Safe Magnetic Absolute Shaft Information System

(Translation of the original operating manual)

Redundant sensor with integrated monitoring

TÜV certified according to SIL 3 in compliance with EN 61508

Absolute position always directly available – no reference journey even af-

ter long power failures

RS-485 Interface

Easy and flexible installation

Silent measuring principle

Immune to dirt, smoke and moisture

Door zone indication for up to 127 floors

Speeds up to 16 m/s

D-103836 / Rev. 0 / 2019-06-03

799000969

Registration No.:

968/FSP 1850.00/19

- 1 -

Publisher

ELGO Batscale AG

Föhrenweg 20

FL-9496 Balzers

Technical Support

+49 (0) 7731 9339 – 0

+49 (0) 7731 2 13 11

support@elgo.de

Document- No.

D-103836

Document - Name

LIMAX44RED-02-MA-E_23-19

Article No.

799000969

Document- Revision

Rev. 0

Issue Date

2019-06-03

Copyright

© 2019, ELGO Batscale AG

- 2 -

Contents

1 Contents

1 Contents ............................................................................................. 3

2 General .............................................................................................. 5

2.1 Information Operating Manual ............................................................................. 5

2.2 Terms and Abbreviations ...................................................................................... 5

2.3 Explanation of Symbols ........................................................................................ 6

2.4 Referenced Documents ........................................................................................ 7

2.5 Statement of Warranties ....................................................................................... 7

2.6 Demounting and Disposal .................................................................................... 7

2.7 RoHS Conformity ................................................................................................ 7

3 Safety ................................................................................................. 8

3.1 General Causes of Risk ........................................................................................ 8

3.2 Personal Protective Equipment ............................................................................... 8

3.3 Conventional Use ............................................................................................... 9

4 Transport and Storage .................................................................... 10

4.1 Safety Instructions for Transport, Unpacking and Loading ........................................ 10

4.2 Handling of Packaging Material .......................................................................... 10

4.3 Inspection of Transport ...................................................................................... 10

4.4 Storage ........................................................................................................... 10

5 Product Features .............................................................................. 11

6 Technical Data ................................................................................. 14

6.1 Identification .................................................................................................... 14

6.2 Safety Parameters ............................................................................................. 14

6.3 Technical Data Magnetic Tape and Presence Detector ............................................ 14

6.4 Dimensions Sensor ............................................................................................ 16

6.5 Technical Data Sensor ....................................................................................... 18

6.6 Technical Data Magnetic Tape ............................................................................ 19

7 Type Designation ............................................................................. 21

7.1 Available Versions ............................................................................................. 21

8 Installation and First Start-Up ......................................................... 22

8.1 Operating Area ................................................................................................ 22

8.2 General Information .......................................................................................... 23

8.3 Mounting of the Magnetic Tape .......................................................................... 23

8.4 Mounting of the Magnetic Tape Presence Detector ................................................. 26

8.5 Mounting of the Sensor ...................................................................................... 27

8.6 Installation Procedure ........................................................................................ 29

9 Design and Functions ...................................................................... 37

9.1 Sensor Design .................................................................................................. 37

- 3 -

Contents

9.2 Operating Modes ............................................................................................. 39

9.3 LED Signals ...................................................................................................... 39

9.4 Door Zone Indication ........................................................................................ 42

9.5 Connections and Interfaces ................................................................................ 42

10 Requirements for Evaluation Unit ................................................... 51

10.1 Hardware Requirements ..................................................................................... 51

10.2 Software Requirements ....................................................................................... 51

11 Accessories ....................................................................................... 52

11.1 Mounting Kit Magnetic Tape (only semi-guided variant) .......................................... 52

11.2 Mounting Aid Sensor ......................................................................................... 53

11.3 Spare Material Sensor ....................................................................................... 53

11.4 Connection Cable............................................................................................. 53

12 Disturbances .................................................................................... 54

12.1 Error in Position Determination ............................................................................ 54

12.2 Non-severe Errors ............................................................................................. 54

12.3 Severe Errors .................................................................................................... 55

12.4 Informative Errors (not Safety-Relevant) ................................................................. 55

12.5 Fault Clearance ................................................................................................ 56

12.6 Possible Errors and their Clearance ...................................................................... 57

12.7 Re-start after Fault Clearance .............................................................................. 59

13 Maintenance .................................................................................... 60

14 Cleaning ........................................................................................... 60

15 Index ................................................................................................ 63

- 4 -

General

Abbreviation/

Term

Explanation

Verified position

See safe position data

CPU

Central Processing Unit

CRC

Cyclic Redundancy Check

EEPROM

Electrically Erasable Programmable Read-Only Memory (is used as non-volatile

data memory)

FS

Functional Safety

LSB

Least Significant Bit

Motorola format

When transmitting a value, the most significant byte is transmitted first. For a 32-bit

value it is for example bit 24 … bit 31

MSB

Most Significant Bit

MW

Mounting angle

RAM

Random Access Memory (main memory)

ROM

Read-Only Memory (program memory)

S-RMS

Mounting kit for rail mounting of the magnetic tape for safe sensors

(Safe Rail Mounting Set), can be used for the semi-guided variant.

Safe evaluation unit

Device that receives the safe position data of the sensor and cuts the safety circuit

in case of a disturbance. A safe position controller can fulfil the function of a safe

evaluation unit.

Safe position data

This position information may be used for safety functions.

Unsafe position data

Position information that may not be used for safety function due to missing redundancy.

Safe state

In this mode the danger for passenger and environment is minimized. In the elevator industry, safe state means that the safety circuit of the elevator is opened and

the cabin is stopped.

Since LIMAX44 RED has no direct connection, it has to be connected to the safety

circuit via the safe evaluation unit.

2 General

2.1 Information Operating Manual

This manual contains important information regarding the handling of the device.

For your own safety and operational safety, please observe all safety warnings and instructions.

Precondition for safe operation is the compliance with the specified safety and handling instructions.

Moreover, the existing local accident prevention regulations and the general safety rules at the site of operation

have to be observed.

Please read the operating manual carefully before starting to work with the device!

It is part of the product and should be kept close to the device and accessible for the staff at any time. The illustrations in the manual are for better demonstration of the facts. They are not necessarily to scale and can slightly

differ from the actual design.

2.2 Terms and Abbreviations

- 5 -

General

DANGER!

This symbol in connection with the signal word “Danger” indicates an

immediate danger for the life and health of persons.

Failure to heed these instructions can result in serious damage to

health and even fatal injury.

WARNING!

This symbol in connection with the word „Warning” means a possibly

impending danger for the life and health of persons.

Failure to heed these instructions can result in serious damage to

health and even fatal injury.

CAUTION!

This symbol in connection with the signal word “Caution” indicates a

possibly dangerous situation. Failure to heed these instructions can

lead to minor injuries or damage of property.

DANGER!

This symbol in connection with the signal word “Danger” indicates an

immediate danger for the life and health of persons due to voltage.

Failure to heed these instructions can result in serious damage to

health and even fatal injury. The operations may only be carried out by

a professional electrician.

NOTE!

… points out useful tips and recommendations as well as information

for an efficient and trouble-free operation.

2.3 Explanation of Symbols

Special notes in this manual are characterized by symbols.

The notes are introduced by signal words which express the magnitude of danger.

Please follow this advice and act carefully in order to avoid accidents and damage and injuries.

Warning notes:

Special safety instructions:

Tips and recommendations:

References:

( 1.2) Marks a reference to chapter 1.2 of this manual.

( DOC 3.4) Marks a reference to chapter 3.4 of the document DOC.

- 6 -

General

Designation

Type

Article. No.

Description

Download URL

LIMAX S-RMS-WH

Mounting Instructions

799 000 670

Magnetic tape installation kit with tape detection and tension weight for high rise elevators

https://support.elgo.li/man/D-103858

LIMAX S-RMS-H

Mounting Instructions

799 000 971

Magnetic tape installation kit with tape detection and tension spring for high rise elevators

https://support.elgo.li/man/D-103932

LIMAX44 RED

Operating Manual

799 000 968

Original Operating Manual (German)

https://support.elgo.li/man/D-101872

CAUTION!

Wrong disposal causes environmental damages!

Electronic scrap, electronic components, lubricants and other auxiliary

materials are subject to special refuse and can only be disposed by

authorized specialists!

2.4 Referenced Documents

2.5 Statement of Warranties

The statement of warranties is enclosed separately in the sales documents.

Guarantee

The producer guarantees the functional capability of the process engineering and the selected parameters. The

period of warranty is one year and begins with the date of delivery.

2.6 Demounting and Disposal

Unless acceptance and disposal of returned goods are agreed upon, demount the device considering the safety

instructions of this manual and dispose it with respect to the environment.

Before demounting:

Disconnect the power supply and secure against re-start. Then disconnect the supply lines physically and discharge remaining energy. Remove operational supplies and other material.

Disposal:

Recycle the decomposed elements:

Metal components in scrap metal

Electronic components in electronic scrap

Recycle plastic components

Dispose the remaining components according to their material consistence

Local authorities and waste management facilities provide information about environmentally sound disposal.

2.7 RoHS Conformity

LIMAX44 RED complies to the EU Directive on the restriction of the use of certain hazardous substances in electrical and electronic equipment (RoHS) 2011/65/EU and its amendment from EU Directive 2017/2102 of 15

November 2017.

- 7 -

Safety

CAUTION!

Please read the operating manual carefully, before using the device!

Observe the installation instructions!

Only start up the device if you have understood the operating manual.

The operating company is obliged to take appropriate safety measure.

The initial operation may only be performed by qualified and trained

staff.

Selection and installation of the devices as well as their embedding into

the controlling system require qualified knowledge of the applicable

laws and normative requirements on the part of the machine manufacturer.

PROTECTIVE CLOTHING

… is close-fitting working clothing with light tear strength, tight sleeves

and without distant parts. It serves preliminarily for protection against

being gripped by flexible machine parts.

Do not wear rings, necklaces or other jewellery.

PROTECTIVE GLOVES

… for protecting the hands against abrasion, wear and other injury of

the skin.

PROTECTIVE HELMET

… for protection against injuries of the head.

3 Safety

3.1 General Causes of Risk

This chapter gives an overview of all important safety aspects to guarantee an optimal protection of employees

and a safe and trouble-free operation.

Non-observance of the instructions mentioned in this operating manual can result in hazardous situations.

3.2 Personal Protective Equipment

Employees have to wear protective clothing during the installation of the device to minimize danger of health.

Therefore:

Change into protective clothing before performing the works and wear them throughout the process.

Additionally observe the labels regarding protective clothing in the operating area.

Protective clothing:

- 8 -

Safety

CAUTION!

Danger through non-conventional use!

Non-intended use and non-observance of this operating manual can

lead to dangerous situations.

Therefore:

Only use the device as described

Strictly follow the instructions of this manual

Avoid in particular:

Remodelling, refitting or changing of the construction or single

components with the intention to alter the functionality or

scope of the device.

3.3 Conventional Use

The product described in this manual was developed to execute safety-related functions as a part of an entire

assembly or machine. It is the responsibility of the manufacturer of a machine or installation to ensure the proper functioning of the system. The ELGO-device is only conceived for the conventional use described in this manual.

The LIMAX44 RED - ELGO- length measuring system only serves to measure

lengths.

Claims resulting from damages due to non-conventional use are not possible.

Only the operator is liable for damages caused by non-conventional use.

- 9 -

Transport and Storage

CAUTION!

Transport the package (box, palette etc.) professionally.

Do not throw, hit or fold it.

NOTE!

Claim any damage immediately after recognizing it. The claims for

damage must be filed in the lawful reclaim periods.

4 Transport and Storage

4.1 Safety Instructions for Transport, Unpacking and Loading

4.2 Handling of Packaging Material

Notes for proper disposal: 2.6

4.3 Inspection of Transport

Check the delivery immediately after the receipt for completeness and transport damage.

In case of externally recognizable transport damages:

Do not accept the delivery or only accept under reserve.

Note the extent of damages on the transportation documents or delivery note.

File complaint immediately.

4.4 Storage

Store the device only under the following conditions:

Do not store outside

Keep dry and dust-free

Do not expose to aggressive media

Protect from direct sun light

Avoid mechanical shocks

Storage temperature ( 6 Technical Data) needs to be observed

Relative humidity ( 6 Technical Data) must not be exceeded

Inspect packages regularly if stored for an extensive period of time (>3 months)

- 10 -

Product Features

5 Product Features

LIMAX44 RED is an absolute shaft information system which is used for the positioning of elevator cabins. It is

available in two different versions. In the unguided version, the measuring system consists of two components:

Magnetic tape and sensor. The semi-guided version requires an additional presence detector to monitor the

correct tape position.

The tape carries the unique position information as a magnetic code. In the unguided version, it is glued directly

onto the guide rail of the elevator. In the semi-guided version, it is mounted freely suspended in the shaft and is

guided along the sensor with a plastic guiding rail. The measurement is always contact free. The guiding only

serves to keep the tape within a defined distance from the sensor.

The sensor reads the magnetic code from the tape and then provides the evaluation unit connected downstream

with the position information.

The presence detector makes sure that the magnetic tape is in the intended position and remains there – after

all, various safety functions depend on the position derived from the tape.

In the case of unguided installation, this monitoring can be omitted, as it can be assumed that the magnetic

tape does not shift in its position.

According to EN 81-20/50 and previously EN 81-1/2 the use of programmable electronic systems in safetyrelevant applications for lifts (PESSRAL) is allowed. LIMAX44 RED is designed and certified for those applications.

The sensor is designed to be used as a safe sensor together with a safe evaluation unit (like for example in

ELGO´s LIMAX44 Safe) or directly with a safe controller unit. Together, the entire system is able to fulfil the safety functions in the elevator according to EN 81-20 and EN 81-21. The product is compatible to the previous

norm EN 81-1/2 and may be used as modernization solution or as measuring range extension in existing installations. Fig. 1 shows the use in the two possible areas of operation as unguided variant, Fig. 2 as semi-guided

variant.

The magnetic measuring principle is distinguished by its extremely high robustness. Dust, dirt and moisture do

not affect the measurement in any way. Furthermore, as smoke and increased temperatures do not have any

impact on the measurement, LIMAX44 RED is especially suitable for firemen’s lifts. Thanks to its material compo-

sition, the tape itself is resistant enough to the rough conditions during the installation and operation of elevators.

Another advantage of the system is in its easy and flexible mounting. The installation itself can be carried out by

an expert in just a few minutes. Depending on the space available, the system can be installed almost anywhere

in the shaft. Since it requires little space, LIMAX44 RED is also suitable without restrictions for retrofitting and

modernizations.

The LIMAX44 RED is able to cover lifting heights of up to 786 meters and speeds up to 16 m/s.

Overview of features:

Robust measuring principle for rough conditions

Easy and flexible mounting

High accuracy and repeatability

No slip

Absolute position always directly available – no reference journey even after long power failures

Compatible with many established position controllers with absolute encoder interface.

High speeds possible

- 11 -

Product Features

communication,

power supply

Usage as stand-alone sensor Usage in the complete system LIMAX44 Safe

comm.,

PWR

system boundary electric interfaces

safe elevator

control

magnetic tape

non-safe elevator

control

safety gear trigger

communication,

power supply

safe evaluation unit

sensor head

sensor head

magnetic tape

Fig. 1: LIMAX44 RED as unguided variant in combination with a safe controller (left) or in combination with the safe evaluation unit Safe Box as the complete system LIMAX44 Safe (right)

- 12 -

Product Features

communication,

power supply

Usage in the complete system LIMAX44 Safe

safety circuit

comm.,

PWR

system boundary electric interfaces

safe elevator

control

magnetic tape

presence detector

for magnetic tape

non-safe elevator

control

safety gear trigger

safety circuit

communication,

power supply

safe evaluation unit

sensor head

Usage as stand-alone sensor

Fig. 2: LIMAX44 RED as semi-guided variant in combination with a safe controller (left) or in combination with the safe evaluation unit Safe Box as the complete system LIMAX44 Safe (right)

- 13 -

Technical Data

Designation

Value

Remark

Safety Integrity Level

SIL 3

PFH [1/h]

2.2 E-9

2.2 % of SIL 3

PFDavg

1.9 E-4

19 % of SIL 3

Proof Test Interval T1

20 years

ZS 256-11ZR-1519

Regulations:

IEC/EN 60947-5-1

BG-GS-ET-15

Operating temperature:

-30 °C … +80 °C

Dimensions (without cable):

L x B x H = 58 x 50.5 x 31 mm

Protection class:

IP67

Usage category:

AC-15; DC-13

Ie/Ue

4 A / 230 VAC; 1 A / 24 VDC

Short-circuit protection:

6 A gL/gG D-fuse

Terminal cross-section:

min. 1.5 mm²; max. 2.5 mm² (incl. cable end sleeves)

6 Technical Data

6.1 Identification

The type label serves for the identification of the unit. It is located on the housing of the sensor and gives the

exact type designation (=order reference, see type designation, chapter 7) with the corresponding part number.

Furthermore, the type label contains a unique, traceable device number, the production date as well as the

hardware and software versions.

When corresponding with ELGO always indicate this data.

Fig. 3: Type label for identification of the sensor

Also, there is an info label on the sensor that gives the following additional information on the sensor: manufacturer, supply voltage, power consumption, CRC check sum of the software and the registration number of the

certificate.

Fig. 4: Info label with additional information

6.2 Safety Parameters

6.3 Technical Data Magnetic Tape and Presence Detector

- 14 -

Technical Data

ZS 236-02ZR-1519

Regulations:

IEC/EN 60947-5-1

BG-GS-ET-15

Operating temperature:

-30 °C … +80 °C

Dimensions (without cable):

L x B x H = 30 x 58.5 x 30 mm

Protection class:

IP67

Usage category:

AC-15; DC-13

Ie/Ue

4 A / 230 VAC; 1 A / 24 VDC

Short-circuit protection:

6 A gL/gG D-fuse

Terminal cross-section:

min. 1.5 mm²; max. 2.5 mm² (incl. cable end sleeves)

- 15 -

Technical Data

6.4 Dimensions Sensor

6.4.1 Unguided variant

Fig. 5: Dimensions LIMAX44 RED variant unguided

- 16 -

Technical Data

6.4.2 Semi-guided variant

Fig. 6: Dimensions LIMAX44 RED variant semi-guided

- 17 -

Technical Data

LIMAX44 RED (Standard version)

Mechanical Data

Measuring principle:

absolute

Measurement:

linear

Maximum measuring length

786 m

Speed:

max. 16 m/s

Resolution:

7 Type Designation

Repeat accuracy:

+/- 1 Increment

System accuracy at 20°C:

+/- (1000 µm + 100 µm x L[m])

L = measuring length in meter

Distance from sensor to magnetic

tape

4.5 mm (semi-guided variant)

max. 8 mm (unguided variant)

Dimensions (without cable):

semi-guided variant:

L x W x H = 524 x 81 x 55 mm

unguided variant:

L x W x H = 482 x 78 x 36 mm

Housing material:

aluminium

Connection:

circular plug 5-pole M12

(more options as cable 11.4 Connection Cable)

Weight without cable:

approx. 1030 g (semi-guided) / 820 g (unguided)

Magnetic tape

Necessary type:

semi-guided variant:

AB20-80120-10-1-R-D-1516-BK80

unguided variant:

AB20-120-20-1-R1-C-16A-4943F (0 m … 285 m)

AB20-120-20-1-R1-C-16B-4943F (285 m … 570 m)

AB20-120-20-1-R1-C-16C-4943F (570 m … 786 m)

Conditions

Storage temperature:

-20 °C … +85 °C

Operation temperature:

-10 °C … +70 °C

Humidity:

max. 95 %, non-condensing

Protection class:

IP54 (according to EN 60529)

Operation height:

max. 2000 absolute altitude

EMC transient emission/immunity:

according to EN 12015 / EN 12016

Vibration/shock resistance:

according to EN 60068-2-6 / EN 60068-2-27

Electrical Data

Supply voltage:

+ 18 … 29 VDC (stabilized) in dual-channel operation ( 9.2.1)

+ 10 … 18 VDC (stabilized) in single-channel operation ( 9.2.2)

You must use a power supply with Safety Extra Low Voltage (SELV) or

Protective Extra Low Voltage (PELV).

Residual ripple:

< 100 mVpp

Reverse voltage protection:

integrated

Power input:

max. 200 mA @ 24 VDC without loading the output for the door zone

indication

Interfaces:

RS-485

Protection of the outputs/ interfaces:

RS-485 output: short-circuit-proof

output door zone indication: short-circuit-proof to GND, but not to

6.5 Technical Data Sensor

- 18 -

Technical Data

+24V

Cable length:

according to EIA RS-485 specifications

Maximum operating time1)

20 years

Magnetic Tape AB20-120-10-1-R-D-16-BK80 (for semi-guided variant)

Coding:

absolute, ELGO 16 Bit

Basic pole pitch:

12 mm (± 0.05 mm)

Maximum tape length:

up to 300 m per role available, other lengths up to 786 m on request

Maximum length error:

± 200 µm/m

Operation temperature:

-20 °C … +70 °C

Storage temperature:

short-run: -40 °C … +85 °C

medium-run: -20 °C … +70 °C

Relative humidity:

max. 95 %, non-condensing

Dimensions:

B / B1 x H = 10 mm (± 0.1) / 8 mm (± 0.2) x 1.35 mm (± 0.1)

Linear expansion coefficient:

16 x 10-6 1/K

Linear thermal expansion:

∆L[m] = L[m] x [1/K] x ∆[K]

(L = tape length in meter, ∆ = relative change in temperature)

Bend radius:

min. 100 mm

Weight of magnetic tape

ca. 52 g/m

Tape imprint

ELGO Standard, colour black, front size ≥ 5 mm

External magnet:

External magnetic fields shall not exceed 64 mT (640 Oe; 52 kA/m),

otherwise the magnetic coding will be damaged or destroyed.

Protection:

Back iron stainless steel (1.4310)

1)

After this time the device must be replaced.

6.6 Technical Data Magnetic Tape

The magnetic tape consists of two components:

The actual magnetic tape which carries the position information

A mechanical stainless steel back iron

- 19 -

Technical Data

Magnetic Tape AB20-120-20-1-R1-C-16x-4943F (for unguided variant)

Coding:

absolute, ELGO 16 Bit

Basic pole pitch:

12 mm (± 0.05 mm)

Maximum tape length:

300 m per role / tape section

longer tapes must be composed of several segments of 285 m each.

Maximum length error:

± 200 µm/m

Operation temperature:

-10 °C … +70 °C

Storage temperature:

short-run: -10 °C … +60 °C

medium-run: +50 °C at 50% RH

Relative humidity:

max. 95 %, non-condensing

Dimensions:

B x H = 20 mm (± 0.1) x 2.45 mm (± 0.1)

Linear expansion coefficient:

11 x 10-6 1/K

Linear thermal expansion:

∆L[m] = L[m] x [1/K] x ∆[K]

(L = tape length in meter, ∆ = relative change in temperature)

Bend radius:

min. 50 mm

Weight of magnetic tape

ca. 140 g/m (incl. adhesive tape and carrier)

Tape imprint

ELGO Standard, colour black, front size ≥ 6 mm

External magnet:

External magnetic fields shall not exceed 64 mT (640 Oe; 52 kA/m),

otherwise the magnetic coding will be damaged or destroyed.

Protection:

Back iron stainless steel (1.1248)

Adhesive tape:

3M 4943F

- 20 -

Type Designation

Order Reference

Description

LIMAX4R-02-CON-62N5-485XM12M

RS-485 Interface; Resolution 62.5 µm; 5-pin circular plug M12;

semi-guided variant

LIMAX4R-52-CON-62N5-485XM12M

RS-485 Interface; Resolution 62.5 µm; 5-pin circular plug M12;

unguided variant

LIMAX4R CON02- 62N5 485X M12M- - - -

Device designation:

Cable length:

Version:

Resolution:

LIMAX4R = LIMAX44 RED (2-channel)

CON = no cable, direct attached connector

62N5 = 62.5 µm = 0.0625 mm

Interface:

02 = semi-guided variant

52 = unguided variant

485X = RS485 [special protocol, separately defined via the special version number]

NOTE:

RS485-Interface is always terminated!

Connector-Options:

M12M = 5-pin M12-circular plug [Number of pins/pin assignment depending on the chosen

interface]

Example:

7 Type Designation

7.1 Available Versions

Cables for connecting the sensor can be found under 11.4 Connection Cable

- 21 -

Installation and First Start-Up

CAUTION!

Please read the operating manual carefully before using the device!

Strictly observe the Installation instructions!

In case of damage caused by failure to observe this operating manual,

the warranty expires.

ELGO is not liable for any secondary damage and for damage to persons, property or assets.

The operator is obliged to take appropriate safety measures.

The first start-up may only be performed by staff that has been trained

and authorized by the operator.

On the installation of the LIMAX44 RED system, the national regulations and as far as applicable the EN 81-20 (previously EN 81-1/2)

are to be considered.

WARNING!

Do not use the device in explosive or corrosive environments!

The device must not be installed close to sources of strong inductive or

capacitive interference or strong electrostatic fields!

CAUTION!

The electrical connections must be made by suitably qualified personnel in accordance with local regulations.

The device may be designed for switchboard mounting. During work

on the switchboard, all components must be de-energized if there is a

danger of touching the energized parts!

(protection against contacts)

Wiring works may only be performed in the de-energized state!

Thin cable strands have to be equipped with end sleeves!

Before switching on the device, connections and plug connectors have

to be checked!

The device must be mounted in a way that it is protected against harmful environmental influences such as splashing water, solvents, vibration, shock and severe pollution and the operating temperature must

not be exceeded.

8 Installation and First Start-Up

8.1 Operating Area

- 22 -

Installation and First Start-Up

NOTE!

When mounting the magnetic tape, the points concerning the alignment of the sensor to the magnetic tape and the bonding ( 8.6.2)

must be taken into account.

WARNING!

The magnetic tape must be mounted in such a way that it cannot move

out of its original position by more than a certain amount during normal operation under consideration of environmental conditions (e.g.

temperature fluctuations) or that the tape position at any point of the

magnetic tape does not move away from its original position by more

than this amount.

In order to guarantee this, either an appropriate mechanical construction is necessary or the position of the magnetic tape must be monitored with a presence detector (equivalent type as defined in 6.3).

As soon as the position exceeds a critical value, the safety circuit must

be opened immediately, as the positions read in by the sensor are no

longer correct in this case.

8.2 General Information

When observing some principles during the installation, LIMAX44 RED requires minimal effort during installation

and operation and has a long operating life.

One basic principle is the protection of the magnetic tape against mechanical wear. This can be achieved

through correct mounting.

Before starting with the installation in the shaft, please carefully read the chapters concerning the mounting of

the magnetic tape ( 8.3) and the sensor ( 8.5) in order to get an idea of the mounting possibilities and get

an idea of the critical points.

8.3 Mounting of the Magnetic Tape

8.3.1 Unguided variant

In the unguided version, the magnetic tape is glued in the groove of the elevator rail or on an additional carrier

tape with the supplied adhesive tape. The installation is dependent on and different parameters, which are dependent on the manufacturer of the complete lift. ELGO cannot provide exact installation instructions for this.

8.3.2 Semi-guided variant

The tape is mounted freely suspended in the shaft.

Mounting of the Tape along the Guiding Rail with Tension Weight ( 8.3.2.1)

This way of mounting prevents extreme misalignments of the tape and simplifies the installation.

In principle the tape can be mounted vertically. However, experience has shown that this kind of mounting is not

absolutely suitable for the elevator. Therefore we recommend a slight horizontal offset between the tape and the

sensor. Due to this pre-tension, the steel side of the tape will always be slightly pushed against the plastic guiding rails and optimal functioning is ensured. Fig. 10 on page 28 and Fig. 14 on page 31 show the correct installation position of the sensor in relation to the magnetic tape.

ELGO offers mounting kits for the fixation of the magnetic tape:

LIMAX S-RMS-WH: Mounting kit for the fixation on the rail with tension weight

- 23 -

Installation and First Start-Up

NOTE!

Other types of mounting for the magnetic tape used for the LIMAX

series such as mounting the tape with dowel and tension spring on the

shaft ceiling are not certified and must not be used!

LIMAX S-RMS-H: Mounting kit for the fixation on the rail with tension springs

Further information on the ELGO mounting kits can be found in the chapter Accessories on page 52.

8.3.2.1 Mounting of the Tape along the Guiding Rail with Tension Weight

The magnetic tape is attached with a mounting kit at the top and the bottom of the shaft on a guiding rail. The

lower tape fixation prevents the tape from swing back and forth in the shaft and for mounting the presence detector.

- 24 -

Installation and First Start-Up

Fig. 7: Mounting of the tape on the guiding rail with tensions weight

upper tape fixation

sensor

magnetic tape

sway guard & presence detector magnectic tape

tension weight

guiderail

ELGO offers the LIMAX S-RMS-WH mounting kit ( 11.1) for the fixation of the guiding rail.

8.3.2.2 Mounting of the Tape along the Guiding Rail with tension spring

The magnetic tape is attached to a guide rail at the top and bottom of the shaft using a mounting kit. At the

lower attachment, pre-tensioned springs provide the necessary stability for the hanging magnetic tape and ensure that it does not begin to oscillate uncontrolled in the shaft. In addition, a presence detector ensures that the

lift can only move if the magnetic tape is in the correct position.

- 25 -

Installation and First Start-Up

upper tape fixation

sensor

magnetic tape

guiderail

lower tape fixation

spring

presence detector magnectic tape

Fig. 8: Mounting of the tape on the guiding rail with tensions spring

ELGO offers the LIMAX S-RMS-H mounting kit ( 11.1) for the fixation of the guiding rail.

8.4 Mounting of the Magnetic Tape Presence Detector

This subchapter concerns only the semi-guided variant.

- 26 -

Installation and First Start-Up

NOTE!

When mounting the sensor or inserting the magnetic tape into the guiding rail, the arrows on the tape and the sensor need to be observed.

A wrong orientation does not provide the correct position!

The arrows on the magnetic tape and the sensor point towards the

positive counting direction and must point in the direction of the shaft

head!

The normally closed contact of the presence detector has to be integrated into the safety circuit at a non overbridgeable place before the main contactors. It is mechanically mounted with the fixture that is contained in the

mounting kit S-RMS-WH ( 10.1).

8.5 Mounting of the Sensor

The sensor is mounted on the cabin or the cabin frame. The mounting position is generally predetermined by the

situation on site

The integrated mounting grooves on the housing of the measuring system enable a very easy and selfexplanatory mounting on three sides. Any M6 hexagon screws (according to DIN933) or M6 square nuts (according to DIN562) can be inserted in order to attach the system at the desired position.

Fig. 9: Mounting grooves on the sensor in the unguided variant (left) and the semi-guided variant (right)

ELGO offers the LIMAX44 RED mounting angle ( 11.3) for the mounting of the sensor on the cabin roof.

- 27 -

Installation and First Start-Up

Fig. 10: Assessment of the pretention of the magnetic tape

NOTE!

The magnetic side of the tape is not designed for permanent mechanical wear in form of friction. Therefore the mounting in the lift needs to

be done in such way that the contact primarily exists between the steel

tape and the plastic guiding rail of the sensor. These two materials are

intended for such operation.

Tape touches

the guide with

the steel side

Tape touches the

guide with the

magnetized side

Constant contact

between magnetized

side and sensor housing

lead to abrasion

Tolerable

Recommended

Wrong

Vertical alignment.

Minimal conctact

between tape and

sensor.

Enforced contact

between steel band and

polymer guide

- 28 -

Installation and First Start-Up

NOTE!

Make sure that the tape is really installed vertically. Tighten the spring

as described in the manual of the magnetic tape mounting kit. A slightly higher pre-tension is also acceptable. However, do not tighten the

spring less than what is stated in the manual. Especially in higher buildings, the tension can be increased in order to prevent the tape from

moving during operation.

shaft head shaft pit

8.6 Installation Procedure

The The installation differs between unguided and semi-guided variants. The following two subchapters deal

with the installation details of the respective variant.

8.6.1 Semi-guided variant

The semi-guided LIMAX44 RED can generally be mounted in any position in the shaft. This makes for maximum

flexibility for retrofitting and modernizations.

1. Attach the top end of the tape in the shaft head using an ELGO mounting kit. Check for correct orienta-

tion. The imprinted arrows must point towards the shaft head.

Please see the details of the mounting in the manual for the mounting of the magnetic tape ( 2.4).

Fig. 11: Correct orientation of the magnetic tape

2. The printed side of the tape (magnetic side) faces towards the sensor. The steel side therefore normally

faces towards the wall of the shaft.

3. Drive down the shaft in inspection mode and unroll the tape in the process. The carton packaging of

the tape is designed so that the tape can be unrolled directly out of the package and therefore always is

ideally protected. It is therefore not necessary to open the packaging.

4. For the next step in the installation, you have to enter the shaft pit. Strictly observe the applicable safety

regulations when doing so. For the electrical installation of the magnetic tape presence detector, deenergize the safety circuit.

Fasten the bottom end of the magnetic tape in the shaft pit using the mounting kit and connect the

magnetic tape presence detector at a non-overbridgeable place in the safety circuit. To do this, the

safety circuit is cut in a suitable way at a non-overbridgeable place before the main contactors. The cut

safety circuit is closed again via the normally closed contact (contact pair 21-22) of the position switch.

The normally open contact must not be used.

Please see the details of the mounting in the manual for the mounting of the magnetic tape ( 2.4).

5. Drive the cabin to the middle of the shaft.

6. Attach the sensor on the cabin with the plug connection facing upwards.

7. Adjust the position of the sensor using the tape as a reference. First align the sensor and magnetic tape

on their centerline. (Step 7 in Fig. 12).

- 29 -

Installation and First Start-Up

Fig. 12: Distance and orientation of the magnetic tape in relation to the sensor.

Fig. 13: Assessment of the guiding rail of the tape in the sensor – twisted magnetic tape

8,21

min. 33 mm

7.

8.

magnetic tape

mounting bracket

cabin

sensor

guidance

Tape is

skewed in

the guide

Tape is flat

in the guide

8. Now adjust the distance between the tape and the sensor. For lifting heights up to 50 m we recommend

a distance of minimum 33 mm. This offset will ensure that the tape is correctly guided along the steel

side during operation. The distance can be increased later if it turns out that the tape still rubs against

the sensor with the magnetic side. In higher lifts, the distance can already be increased up to 5 cm at

the initial mounting. Make sure that the sensor is installed vertically. Misalignment will lead to an increased wear.

9. Now pass the tape through the sensor. Loosen the screws (Fig. 20 on page 38) to fix the polymer

guides and remove them. Then remount them with the tape in between.

10. Check for correct mounting. Any irregularities and angular offsets have to be corrected!

- 30 -

Installation and First Start-Up

Fig. 14: Assessment of the guiding rail of the tape in the sensor – skewed mounting of the magnetic tape

Tape is

centered in

the guide

Tape is

skewed in

the guide

Tape is

skewed in

the guide

- 31 -

Installation and First Start-Up

Fig. 15: Assessment of the vertical alignment of the sensor

Tape touches

the guide with

the steel side

Recommended

Wrong vertical

alignment

Enforced contact

between steel band and

polymer guide

11. IMPORTANT: Installation check!

The tape tension and the offset of the sensor are recommended values based on experience. What is essential, however, is that the tape does not constantly rub on the sensor with the magnetic side during operation. Occasional contact due to movement of the tape is not critical. Therefore, run an inspection

travel along the complete lifting height and control the distance between the tape and the guiding rail. If

the steel side is slightly pressed against the plastic guide the whole time, the mounting is ideal. Also check

the bottom side of the sensor at some points. If the sensor is slightly tilted, it is possible that the tape

slides perfectly into the guiding at the upper end but still touches the sensor with the magnetic side at the

lower end.

- 32 -

Installation and First Start-Up

WARNING!

Observe the applicable safety requirements for entering the shaft pit

during this step.

shaft head shaft pit

12. If the installation check shows that the magnetic side of the tape rubs against the sensor, first increase

the offset between the sensor and the tape. Up to 5 cm are acceptable without problems. If this measure is not successful, it is probable that the tape is not suspended straight in the shaft. You can easily

check that by taking the tape out of the guiding rail and performing an inspection travel along the lifting

height. While doing this, observe the distance between the tape and the sensor. Also make sure that the

tension of the tape is sufficient. If the tape is fixated too loosely, this complicates correct guiding and a

high offset between the tape and the sensor is necessary.

13. Clean the tape after the mounting. Use a clean and dry cloth. Start at the shaft head and go down the

complete height in inspection mode pulling the magnetic tape through the cloth with a slight pressure.

Especially after metal construction works in the shaft you should clean the tape. Metal particles will adhere to the magnetic tape.

14. Repeat the cleaning process before setting the elevator into operation.

15. Check the function of the magnetic tape presence detector. To do this, pull the tape about 60 mm up-

wards until the bolt of the position switch is actuated. Leave the shaft pit and make sure that all doors

are closed. Try to move the cabin electronically. This must not be possible. Go back to the shaft pit and

make sure that the tape clamp with the spring is set back into the correct vertical position in relation to

the position switch and the crossbeam and reset the bolt into the original position with a screw driver.

Leave the shaft pit and make sure that all doors are closed. Try again to move the cabin electronically.

This must now be possible.

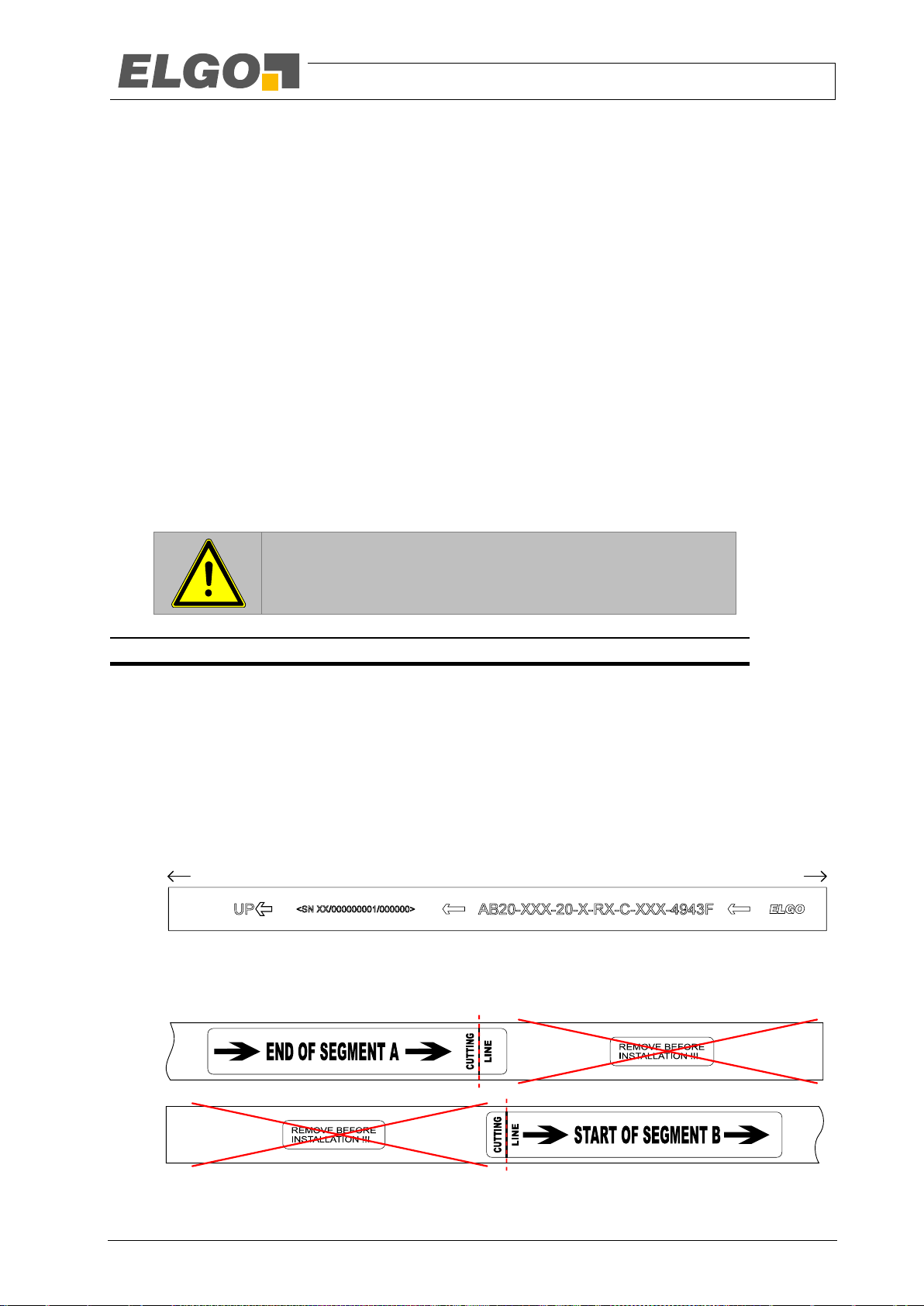

8.6.2 Unguided variant

The unguided LIMAX44 RED is mounted on a guide rail or other support. Since the mounting is strongly dependent on the environment, the details cannot be dealt with in this chapter. It is the user's responsibility to ensure that the system is properly installed in accordance with the instructions given in this chapter.

1. Fasten the tape in the shaft so that the position is continuous upwards.

Clean the surface so that it is free of dust, grease, oil or other separating agents and allow the surface

to dry if necessary.

Before mounting, check the correct order of the tape segments (A bottom, B centre, C top) and their

orientation. The printed arrows must point to the head of the shaft.

Fig 16: Correct direction of magnetic tape

At the transition points between two tape segments, disconnect the protective pole at the marked point

before sticking the magnetic tape. The optimum contact pressure is 4 - 5 kg/cm2.

In the case of longer measuring ranges consisting of more than one tape segment, care must be taken

to ensure that the segments are not laterally offset at the transition between the two segments and are

close to each other at the ends as shown in the following figure.

- 33 -

Installation and First Start-Up

NOTE!

Ensure a proper vertical tape mounting.

If the order of the tape segments is wrong, a wrong position will be

read during the transition from one segment to the next and the sensor

will go into the error state.

4 mm

General remarks:

Figure A/B: The sensor surface must be installed parallel to the magnetic tape without twisting

Figure C: The sensor must maintain a lateral offset of 4 mm over the entire measuring distance

Figure D/E: A lateral offset outside this dimension is not permitted and leads to measurement errors,

which in turn entails the request for the safe state.

A B

C

D E

2 … 8

mm

2. Mount the sensor with the plug connection pointing upwards on the cabin.

3. Align the sensor. Use the tape as a reference. First align the sensor in the middle with a lateral offset of

4 mm to the side edge of the magnetic tape (point C in Fig 17).

4. Now set the distance between the tape and the sensor. The maximum reading distance between the

sensor housing and the surface of the magnetic tape must not exceed 8 mm. Make sure that the sensor

head is mounted vertically.

5. Check the correct mounting. Deviations and angular misalignments must be corrected!

Fig 17: Evaluation of the tape alignment to the sensor - Rotation and misalignment of the magnetic tape

- 34 -

Installation and First Start-Up

General remarks:

The sensor scanning surface must be kept parallel to the tape over the entire measuring distance

A twist as shown in the left or right illustration leads to incorrect measurement results, which in

turn entails the request for the safe state.

Fig 18: Evaluation of the magnetic tape to the sensor - inclined mounting of the sensor

6. IMPORTANT: Assembly check!

To prevent damage, the sensor must not rub against the surface of the magnetic tape. However, occasional contact due to movement of the sensor is not critical. Therefore, make an inspection run over the

entire lifting height and check the distances between the belt and the sensor. Also check the underside

of the sensor at some points. If this is slightly inclined – the sensor can be perfectly aligned at the top,

but still come into contact with the magnetic tape at the bottom – the sensor may rub at the surface of

the magnetic tape.

- 35 -

Installation and First Start-Up

Correct

Wrong Wrong

General remarks:

Maximal

erlaubter

Abstand

Vorgeschriebener

Montageabstand

Minimal

erlaubter

Abstand

Minimal

erlaubter

Abstand

Maximal

erlaubter

Abstand

Abstand gleich

wie oben

Maximum

permitted

distance

Specified

mounting distance

Minimum

permitted

distance

Minimum

permitted

distance

Maximum

permitted

distance

Distance identical

to top

Over its entire length the sensor must be kept parallel and within the specified distance to the

magnetic tape

Contact between the magnetic tape and the sensor housing must be avoided, as this leads to

unwanted abrasion.

Fig 19: Evaluation of the vertical alignment of the sensor

7. If the check shows that the tape nevertheless rubs against the sensor with the magnetic side, it can be

assumed that the tape is not mounted on a vertical surface in the shaft.

8. Clean the tape after installation. Use a dry, clean cloth. Start at the head of the shaft and drive all the

way down in inspection mode. Press the cloth lightly onto the magnetic tape.

9. Cleaning should be carried out especially after metal work in the shaft. Metal chips like to stick to the

tape due to the magnetism.

10. Repeat this cleaning procedure before putting the elevator into operation.

- 36 -

Design and Functions

9 Design and Functions

9.1 Sensor Design .................................................................................................. 37

9.2 Operating Modes ............................................................................................. 39

9.2.1 Dual-Channel Operation ................................................................................................. 39

9.2.2 Single-Channel Operation ............................................................................................... 39

9.3 LED Signals ...................................................................................................... 39

9.3.1 Signalling Severe Errors ................................................................................................... 41

9.4 Door Zone Indication ........................................................................................ 42

9.5 Connections and Interfaces ................................................................................ 42

9.5.1 Power Supply ................................................................................................................. 42

9.5.2 Door Zone Indication ...................................................................................................... 42

9.5.3 Pin Assignment ............................................................................................................... 43

9.5.3.1 RS-485 Interface ................................................................................................................. 43

9.5.4 Protocol Descriptions ....................................................................................................... 43

9.5.4.1 RS-485 Interface ................................................................................................................. 43

9.5.5 Presence Detector Magnetic Tape (only semi-guided variant) ................................................ 49

9.1 Sensor Design

The sensor consists of:

Sensor housing with integrated LEDs (for signaling of various status options), fixed connector for power

supply and for communication with the safe evaluation unit.

Guide rail which holds the magnetic tape at a defined distance from the evaluation electronics (only

semi-guided version)

Ground connector to improve EMC characteristics (connection not mandatory)

- 37 -

Design and Functions

Fig. 20: Components of the sensor (semi-guided variant)

Fig. 21: Components of the sensor (unguided variant)

tape guide

connector

earth lug

LED indicator

sensor housing

screw for fixing

the tape guide

LED indicator

connector

earth lug

sensor housing

The electronic part of the sensor is basically done in a two-channel design. For safety reasons the communication interface is operated by both channels together. Each of the two channels contributes their part of the position information transmission. In case of an error, each channel is able to signal the request for transition into

safe state independently from the other channel.

Further information:

Transmission of position information 9.5.4

- 38 -

Design and Functions

Fig. 22: LED signals on the upper side of the sensor

9.2 Operating Modes

The sensor can be operated in two different modes:

Safe dual-channel operation

Non-safe single-channel operation (energy saving mode)

Switching between modes happens automatically, depending on the supply voltage.

9.2.1 Dual-Channel Operation

Usually, the sensor works in dual-channel operation. In this mode, both channels are fully functional and determine the position independently of each other. After determining the position, the position results of the two

channels are compared and then transmitted to the safe evaluation unit via a safe interface. If an internal error

is detected or if the position results of the two channels do not match, the sensor sends a request for transition

into safe state to the evaluation unit. The evaluation unit has to make sure that the safety circuit is opened.

Further information:

Overview of error status and possible errors: 12.6

Protocol description of the safe position information transmission 9.5.4

9.2.2 Single-Channel Operation

In order to keep the door zone indication functioning in case of loss of the regular power supply (24V operating

voltage), the sensor can be operated with an external 12V back-up battery or an emergency power supply. To

maximise the durability of the back-up battery, one channel is switched off. All position comparisons between

the two channels are terminated in such a case and the sensor communicates only the non-safe position result

of one channel to the evaluation unit. If the evaluation unit is still in operation at that time, it can further process

this position information for non safety related functions. The evaluation unit absolutely has to switch into safe

state.

Further information:

Possible additional circuit for automatic switch to single-channel operation 9.5.1

Protocol description of the position information transmission 9.5.4

9.3 LED Signals

The LEDs at the upper side of the sensor (shown in Fig. 22) signal the operating status or possible errors:

PWR A: Supply voltage channel A

PWR B: Supply voltage channel B

RUN: Operating status

ERR: Signalling of an error

TAPE: Magnetic tape status

The LEDs PWR A, PWR B signal the status in a static manner. They are either turned on or off. The LED RUN

flashes, with the frequency depending on the operating status. The LED ERR has three possible states: Off, regular flashing and irregular flashing. The LED TAPE also knows three possible states: off, on and irregular flashing.

- 39 -

Design and Functions

LED

Colour

Status1

Meaning

PWR A

yellow

ON

Supply voltage channel A available

OFF

Supply voltage channel A not available

PWR B

yellow

ON

Supply voltage channel B available

OFF

Supply voltage channel B not available. The sensor head is in the energy saving

mode because of low voltage supply or there is no power supply at all.

RUN

green

Flashing

5 Hz

Safe position data is transmitted via the interface

Flashing

12/3 Hz

The sensor head is operating in single-channel mode. Non-safe position information is transmitted via the interface.

Static

light on

The sensor has been blocked intentionally. Also see: LED ERR.

ERR

red

OFF

No error

Flashing

1 Hz

At least one error has been detected, but it is not classified as a severe error.

Find more information on the problem in the Error Register ( 12.2.3)

The exact cause is transmitted via the interface to the evaluation unit as long as

the sensor is in dual-channel operation ( 9.5.4) In single-channel operation;

no detailed error diagnosis is possible.

Further information on error clearance: 12.6

Flashing

irregular

frequency

The sensor had has blocked itself due to a severe error. The unit should be

replaced. The exact cause is communicated via a flashing code of the LED ERR

( 9.3.1).

TAPE

yellow

ON

Magnetic tape cannot be detected or is damaged

OFF

Magnetic tape is detected

Flashing

irregular

frequency

The sensor had has blocked itself due to a severe error. The unit should be

replaced. The exact cause is communicated via a flashing code of the LED ERR

( 9.3.1).

1

Each state has a meaning regarding whether an error occurred and how serious the error is.

The following table shows what states can be signalized by the five LEDs:

Table 1: Meaning of LED signals

The status in bold define the faultless normal operation

- 40 -

Design and Functions

Flashing

code

Meaning

01h

02h

03h

04h

RAM test failed

05h

ROM test failed

06h

CRC check sum of code memory is not the same in both channels

07h

Stack test failed

08h

Undefined case in a multiple branch

09h

Test of CRC hardware failed

0Ah

Communication test between channels failed

0Ch

CPU test failed

0Dh

0Eh

Defective program sequence

10h

Channel assignment not unambiguous

11h

Position outside the allowed range

12h

Synchronization failed

20h

21h

Timeout during memory test

22h

Error in timer for timeout detection

40h

UART error

41h

42h

Invalid parameter

43h

Undefined exception

44h

45h

46h

Faulty position determination

47h

Parameter outside the allowed range

t [s]

0 2 4 6 8 10 12 14 16 18 20 22

off

on

0 0 0 1 0 0 1 0

LED ERR

restart blink codeillustrated value 12

16

9.3.1 Signalling Severe Errors

If a severe error ( 12.3) occurs, the sensor head is intentionally blocked. All communication via the interface is

shut down. Such errors will be signalled by the LED ERR (channel A) and LED TAPE (channel B) to the user via a

sequence of 8 flashing impulses (short or long). A short flash impulse stands for a zero, a long flash impulse

stands for a one. The first impulse corresponds to the MSB, the last impulse corresponds to the LSB. The sequence is repeated after a 4 second break. You can find an example of such a sequence in Fig. 23.

If such a severe error occurs, the sensor has to be replaced. The flashing sequence codes support ELGO in

finding the exact cause for an error in case of necessary repairs.

Fig. 23: Illustrated example of an LED ERR flashing sequence, signalling a severe error

Table 2: Meaning of flashing codes due to severe errors

- 41 -

Design and Functions

NOTE!

In order to keep the indication of the door zones active for an evacuation during a loss of the regular power supply, an emergency power

supply or a back-up battery is necessary to supply the sensor with energy.

Fig. 24: Possible circuit for supply by emergency battery in case of power failure

regular power supply +24 VDC

emergency battery +12 VDC

power supply sensor

9.4 Door Zone Indication

LIMAX44 RED provides a function to indicate the door zones. This function shows whether an elevator is positioned within the door zone, even during a power failure. The location of the door zones is derived from the

flush positions of the different floors. These positions must be determined during the initial reference journey for

the evaluation unit. The positions of the floor levels are saved permanently and are available even after a power

failure.

The position of the floors must be transmitted from the evaluation unit to the sensor. Also, the evaluation unit

has to signal changes in the position of the floors to the sensor.

After the sensor is switched on, the door zone output is briefly switched to active. This enables a function check

of the downstream indicator lamp.

Further information:

Technical data of output 6.5

Protocol for alignment of floor positions 9.5.4, in the section on floor information under the respec-

tive interface

9.5 Connections and Interfaces

The following chapters will give you detailed information on the connections and interfaces

9.5.1 Power Supply

Normally, LIMAX44 RED is supplied with 24 VDC. In order to guarantee the functioning of the door zone indication for evacuation in case of a power failure, an external 12 V battery can be connected.

Switching between the two supply voltages has to take place outside the sensor and can be realized for example

with the following diode circuit:

The sensor switches automatically between the two operating modes ( 9.2) based on the applied supply voltage.

The pin assignment depends on the connection option and is documented in chapter 9.5.3.

9.5.2 Door Zone Indication

For the indication of the door zones, a PNP-output is integrated in the sensor. It can be directly connected to a

light bulb or an LED for indicating the status.

The output is short-circuit-proof against GND (but not against +24 V) and can be operated with max. 200 mA.

- 42 -

Design and Functions

WARNING!

In order not to jeopardize the safe communication between the sensor

and the evaluation unit, the RS-485 connection has to be realized as a

point-to-point connection. Apart from the sensor and the evaluation

unit, no other devices shall be connected to the bus!

Connection Type

Connection option acc.

to type designation

Drawing

Assignment

Circular plug

M12

A-Coded

M12M

1 +24 VDC

2 0 V

3 RS-485+

4 RS-4855 Output door zone indication

Segment

Length in bits

Content

A

8

Message counter

1

2

3

4

5

A B C D E F

t

bus data

9.5.3 Pin Assignment

9.5.3.1 RS-485 Interface

The internal termination resistor of the RS-485 bus is assembled in all sensors with RS-485 interface, even when

it is not explicitly stated in the interface options ( 7 Type Designation). The bus must be terminated also on the

side of the evaluation unit.

Table 3: Pin Assignment RS-485 Interface

9.5.4 Protocol Descriptions

9.5.4.1 RS-485 Interface

The communication between the sensor and the evaluation unit is bidirectional. The sensor sends the position

information and receives the floor information.

9.5.4.1.1 Interface Parameters

For a correct transmission of the data, the interface in the evaluation unit must be set to the following parameters:

115200 bps

8 data bits

No parity bit

1 stop bit

No flow control

9.5.4.1.2 Structure of a Message

A message consists of six segments and has an overall effective length of 88 bits. It is divided into 11 symbols of

8 bits each. The first three segments A to C are sent by channel A, the other three segments D to F by channel B.

Fig. 25: Structure of a RS-485 message

The different segments carry the information according to the following table. You can find a more detailed

description of the content of the segments in the following chapters. Segments A to D contain the safety-relevant

information.

Table 4: Description of the segments in an RS-485 message

- 43 -

Design and Functions

Segment

Length in bits

Content

B

4

Status bits C 20

Verified position, coarse resolution (1 LSB ≙ 1 mm)

D

32

CRC check sum for segments A to C

E

16

Additional information

F

8

Non-verified, high-resolution position offset (1 LSB ≙ 62.5 µm)

NOTE!

In single-channel operation, channel B is switched off and segments DF are not transmitted. This corresponds to a non-verified position

transmission.

Bit1

Meaning of the signalled value

4

Warning – extrapolated position:

0 = Position was determined normally in both channels

1 = Due to a reading error in one of the channels, the position was extrapolated

5

Signalling faulty tape:

0 = Tape correct

1 = Tape not present or faulty

6

Signalling unauthorized extrapolation:

0 = Extrapolation active

1 = Extrapolation was deactivated because there were too many reading errors. Further operation is

not allowed. ( 12.1)

7

Single-channel operation

0 = Sensor is in dual-channel operation

1 = Due to under voltage, the sensor is in single-channel operation. Caution: only segments A to C

are transmitted!

NOTE!

If the position is extrapolated due to reading errors unusually often, this

might point to an extremely dirty or damaged magnetic tape. In this

case, proceed as is described in chapter 13 Maintenance.

1

9.5.4.1.3 Message Counter

The message counter identifies the correct message sequence and is raised by one with every message. It is

according to this index that the additional information ( 9.5.4.1.7) is attributed.

The range of values for the message counter is from 0 to 255. When the counter has reached the maximum

value, there will be an overflow and with the following message, counting starts again from 0.

9.5.4.1.4 Status Bits

The status bits provide additional information to the position. They always refer to the position with which they

are transmitted.

Table 5: Meaning of the status bits in an RS-485 message

Since the described status bits usually never change, they are dynamised, i.e. they change their status depending

on the message counter. If the LSB of the message counter is set (odd counter value), all four status bits are

inverted bitwise before transmission; if the LSB is cleared (even counter value), the transmitted value matches the

signalled value.

9.5.4.1.5 Position

Please note that the status bits do not require an entire byte for themselves. The bit position stated here corresponds to the

actual position in the second byte of the message.

- 44 -

Design and Functions

Counter

Reading

Content

0

CRC check sum program memory, bits 16 … 31

1

CRC check sum program memory, bits 0 … 15

2

Serial number of sensor, bits 16 … 31

3

Serial number of sensor, bits 0 … 15

4

Error register channel A, bits 16 … 31 ( 12.2.3)

5

Error register channel A, bits 0 … 15 ( 12.2.3)

6

Error register channel B, bits 16 … 31 ( 12.2.3)

7

Error register channel B, bits 0 … 15 ( 12.2.3)

8

Resolution of the floor table. Specifies by how many bits the position (in mm) is shifted to the

right (this value is fixed to 4, which corresponds to a resolution of 16 mm).

9 … 127

Reserved. The transmitted value is always 0.

128 … 191

Statistical information channel A

174

Lowest detected power supply voltage channel A (1 LSB ≙ 67.7 mV)

The position is transmitted in two parts. Segment C contains the verified position, which has to be used in the

evaluation unit for safety functions. This position only counts as verified when the sensor is in dual-channel operation and transmits the correct CRC check sum ( 10.2 Software Requirements). When in single-channel

operation, the second part of the message is missing and the position cannot be sufficiently verified. This is

called a non-verified position or unsafe position data.

The position in this segment has a resolution of 1 mm. In order to reach a higher resolution, the position offset

from segment F can be used. Since this information only provides an insignificantly small contribution to the

overall position, it is not additionally verified. However, it can be used for a better quality of the safety functions,

if this cannot cause dangerous situations.

The use of the high-resolution position for position control by the controller is not restricted.

Segment C is transmitted in the Motorola format.

9.5.4.1.6 CRC Check Sum

For use in safety functions, the position, the message counter and the status bits are verified with a CRC32

check sum. The data may only be used if the CRC check sum is correct ( 10.2 Software Requirements).

The polynomial G(x)=x32+x26+x23+x22+x16+x12+x11+x10+x8+x7+x5+x4+x2+x+1 is used for calculation. This

is the same polynomial that is used in Ethernet.

The data stream D(x)=x31+…+x0 is composed from the segment data as follows:

D(x)=a7+…+a0+b3+…+b0+c19+…+c0, with the bits corresponding to the respective segments:

a7…a0: Segment A (message counter)

b3…b0: Segment B (status bits)

c19…c0: Segment C (coarse-resolution position)

The initialization value for the calculation of the CRC check sum is FFFFFFFFh.

LIMAX44 RED calculates the CRC check sum in reverse bit order, which causes the calculated CRC check sum

to be transmitted backwards. The calculated CRC check sum is inverted bitwise before the transmission. The

transmission is in the Motorola format.

9.5.4.1.7 Additional Information

The additional information in segment E only has an informative character and is meant primarily for finding

errors. The content of this segment varies depending on the value of the message counter ( 9.5.4.1.3 Message Counter). One complete transmission cycle lasts about one second (256 x 4 ms); this is sufficient for the

purely informative use. The additional information is transmitted in the Motorola format.

Table 6 describes the content of the additional information depending on the value of the message counter.

Table 6: Additional information as a function of the value of the message counter

- 45 -

Design and Functions

Counter

Reading

Content

175

Highest detected power supply voltage channel A (1 LSB ≙ 67.7 mV)

180

Errors set in error register channel A since restart, bits 16 … 31 ( 12.2.3)

181

Errors set in error register channel A since restart, bits 0 … 15 ( 12.2.3)

182

Operating time (seconds since restart) channel A bits 16 … 31

183

Operating time (seconds since restart) channel A bits 0 … 15

192 … 255

Statistical information channel B

238

Lowest detected power supply voltage channel B (1 LSB ≙ 67.7 mV)

239

Highest detected power supply voltage channel B (1 LSB ≙ 67.7 mV)

244

Errors set in error register channel B since restart, bits 16 … 31 ( 12.2.3)

245

Errors set in error register channel B since restart, bits 0 … 15 ( 12.2.3)

246

Operating time (seconds since restart) channel B Bits 16 … 31

247

Operating time (seconds since restart) channel B Bits 0 … 15

NOTE!

The operating time is transmitted in two messages, separated into highword and low-word. If the overflow in low-word (carry-over to highword) happens between the transmission from low-word to high-word,

it is possible that the combined time temporarily displays an inconsistent value.

- 46 -

Design and Functions

Counter

reading

Content

0

Number of floors

1

Size of door zone (0 … 1020 mm; 1 LSB ≙ 4 mm)

2

LSB of the flush position first floor (1 LSB ≙ 16 mm)

3

MSB of the flush position first floor (1 LSB ≙ 16 mm)

…

…

255

MSB of the flush position 127th floor (1 LSB ≙ 16 mm)

9.5.4.1.8 Floor Information

In order for LIMAX44 RED to operate the door zone indication, the evaluation unit has to transmit the floor information to the sensor. In the interval between two telegrams the evaluation unit has time for this. (

9.5.4.1.10 Bus Timing). LIMAX44 RED assigns the received information in relation to the message counter (

9.5.4.1.3) of the message that was just sent.

Table 7: Floor information as a function of the value of message counter

This data is for the transmission of the floor image, so that LIMAX44 RED can generate the door zone signal as