TS Series

TS05 to TS15

Two-Stage

Reciprocating

Air Compressor

OPERATION AND MAINTENANCE MANUAL

2

TS Series

Model Number:

Serial Number:

Date Purchased:

Purchased from:

For further technical assistance, service or replacement parts, please contact:

Elgi Compressors USA, Inc.

3201 South Boulevard

Charlotte, NC 28209

Phone: 704-943-7966

FAX: 704-944-8338

www.elgi.us

Please include the unit serial number located on the control panel with all inquiries.

Elgi reserves the right to make changes and improvements to update products sold previously

without notice or obligation.

Issue Date: August 17, 2017

3

TS Series

Table of Contents

Safety Precautions

1.0 General Information

2.0 Installation

2.1 Inspection Upon Receiving

2.2 Handling

2.3 Location

2.4 Space Requirements

2.5 Wiring

3.0 Control Panel

3.1 Wiring Schematics

4.0 Initial startup

5.0 Maintenance

5.1 Pressure Switch Adjustment

6.0 Trouble Shooting

7.0 Replacement System Parts 5 HP

7.1 Replacement Pump Parts 5 HP

8.0 Replacement System Parts 7.5 HP

8.1 Replacement Pump Parts 7.5 HP

9.0 Replacement System Parts 10 HP

9.1 Replacement Pump Parts 10 HP

10.0 Replacement System Parts 15 HP

10.1 Replacement Pump Parts 15 HP

Notes

4

TS Series

Safety Precautions

Pressurized air from the system may cause personnel injury or property damage if the unit is improperly operated or maintained. The operator should have carefully read and become familiar with the

contents of this manual before installing, wiring, starting, operating, adjusting and maintaining the

system. The operator is expected to use common sense safety precautions, good workmanship

practices and follow any related local safety precautions.

In addition:

• Before starting any installation or maintenance procedures, disconnect all power to the

package.

• All electrical procedures must be in compliance with all national, state and local codes and re-

quirements.

• A certified electrician should connect all wiring.

• Refer to the electrical wiring diagram provided with the unit before starting any installation or

maintenance work.

• Release all pressure from the package before removing, loosening, or servicing any covers,

guards, fittings, connections, or other devices.

• Notify appropriate facility personnel if repairs or maintenance will affect available compressed air

levels.

• This is a high speed, rotating piece of machinery. Do not attempt to service any part while ma-

chine is in operation.

• Do not operate unit without belt guards, shields or screens in place.

• Make sure that all loose articles, packing material, and tools are clear of the package.

• Check all safety devices periodically for proper operation.

• Never operate a compressor with its relief valve not in place. Damage to the compressor may oc-

cur.

• Electrical service must be the same as specified on the control panel nameplate or damage to

the equipment may occur.

• Vibration during shipment can loosen electrical terminals, fuse inserts, and mechanical connec-

tions. Tighten as necessary.

5

TS Series

1.0 General Information

System Configurations

The Reciprocating Air systems are tank mounted units. All consist of at least one compressor, one

motor, integral pre-wired control panel and air receiver. The complete package is pre-wired, prepiped, and assembled.

Compressor Module

The compressor is a continuous duty rated lubricated reciprocating type. The design is two stage

and air cooled with finger type stainless steel valves. An oil splasher is fitted to the connecting rod to

lubricate all moving parts. The connecting rod and crankcase assembly is precision machined and

dynamically balanced. The crankshaft is forged out of carbon steel, hardened, and precision ground.

The crankshaft is provided with steel roller bearings and phosphor bronze bushings. The crankcase

is made of high grade cast iron. It acts as sump for the lubricating oil and is provided with a breather

drain plug and dipstick. The breather maintains a partial vacuum in the crankcase to facilitate better

breathing. The cylinders and cylinder heads are made of high grade cast iron and they have close

deep fins for effective cooling. The hardness of the cylinders is closely controlled to insure high wear

resistance. The pistons are automotive type made out of low expansion aluminum alloy. They are

provide with plain compression rings, stepped compression rings and slotted oil control rings. The

rings are made of special quality close grained cast iron and designed for controlling wear and keeping oil consumption at a minimum. The wrist pins are made of chrome steel case hardened and precision ground. The intercooler is made of aluminum with fins for effective cooling.

Compressor Drive and Motor

The compressor is v-belt driven and protected by an OSHA approved totally enclosed belt guard. A

slotted mounting base allows full adjustment for belt tensioning. The motor is a NEMA rated, open

drip proof, with 1.15 service factor suitable for 208 or 230/460V electrical service.

Intake Filter

Each compressor is fitted with inlet air filters. The inlet filter removes dust from the incoming air

through an element.

Control System The mounted and wired control system is NEMA 1 and U.L. labeled. The . The

control panel also includes full voltage motor starters with overload protection, Off-On selector

switch and a pressure switch.

Air Receiver

The air receiver is ASME Coded, National Board Certified, and rated for a minimum 200 PSIG design pressure. The tank will include a safety relief valve, pressure gauge and manual drain valve.

6

TS Series

2.0 Installation

2.1 Inspection upon Receiving

The Reciprocating Air system should be carefully inspected upon delivery. Any damage by the carrier should be noted on the delivery receipt, especially if the system will not be immediately uncrated

and installed. The system may remain in its shipping container(s) until ready for installation. If the

system is to be stored prior to installation, it must be protected from the elements to prevent rust and

deterioration.

DO NOT REMOVE the protective covers from the inlet and discharge connection ports of the unit

until they are ready for connecting to the distribution system.

2.2 Handling

!!WARNING!!

USE APPROPRIATE LOAD RATED LIFTING EQUIPMENT AND OBSERVE SAFE LIFTING PRO-

CEDURES DURING ALL MOVES.

The compressor package can be moved with either a forklift or dollies. Keep all packing in place during installation to minimize damage. Examine the route the unit must travel and note dimensions of

doorways and low ceilings. Units should be placed to ensure easy access to perform maintenance

and high visibility of indicators and gauges.

2.3 Location

The Air system should be installed indoors in a clean, well-ventilated environment. Areas of excessive dust, dirt or other air-borne particulate should be avoided. Secure the package to a flat, level

surface capable of supporting the weight and forces of the unit. Make sure that the main base is not

bowed, twisted, or uneven. The tank must be securely bolted using all mounting holes provided in

the tank. If a raised concrete pad is used, the tank must not overhang the concrete pad. A method to

drain away moisture is necessary. If a gravity drain is not available, a connection to a drain is necessary. The area should have a maximum ambient temperature of 113oF (45oC). (Note: At tempera-

tures below 32oF condensate can occur which could affect operation.)

2.4 Space Requirements

The Air system should be placed to ensure easy access to perform maintenance and high visibility

of indicators and gauges. It is recommended that a minimum space of 24” be allowed on all sides of

the compressor system for ventilation and maintenance. A minimum space of 36" in front of the con-

trol panel is required by NEC code. A vertical distance of 36” is required above the unit for ventilation

and maintenance.

7

TS Series

2.0 Installation (Continued)

2.5 Wiring

WARNING!

BE SURE TO DISCONNECT ALL ELECTRICAL POWER TO THE COMPRESSOR SYSTEM BE-

FORE PERFORMING ANY ELECTRICAL PROCEDURES.

Refer to the electrical diagram provided with the unit before starting any installation or

maintenance work. Do not operate compressor on a voltage other than the voltage specified

on the compressor nameplate. All customer wiring should be in compliance with the National

Electrical Code and any other applicable state or local codes.

Check the control voltage, phase, and amp ratings before starting the electrical installation, and

make sure the voltage supplied by the customer is the same.

The wire size should be able to handle peak motor amp load of all operating units, refer to the full

load and compressor system amperes on the wiring diagram.

Check all electrical connections within the air system that may have loosened during shipment.

Only qualified electricians should make power connections to the control panel and any interconnecting wiring.

If emergency generator is used for backup make sure the electrical supply is consistent with the air

system’s requirements.

If equipped with an emergency generator the three-phase power supplied must match that of the

normal supply to allow for correct direction of the motor rotation at all times.

If equipped with an emergency generator the three-phase power supplied must match that of the

normal supply to allow for correct direction of the motor rotation at all times.

8

TS Series

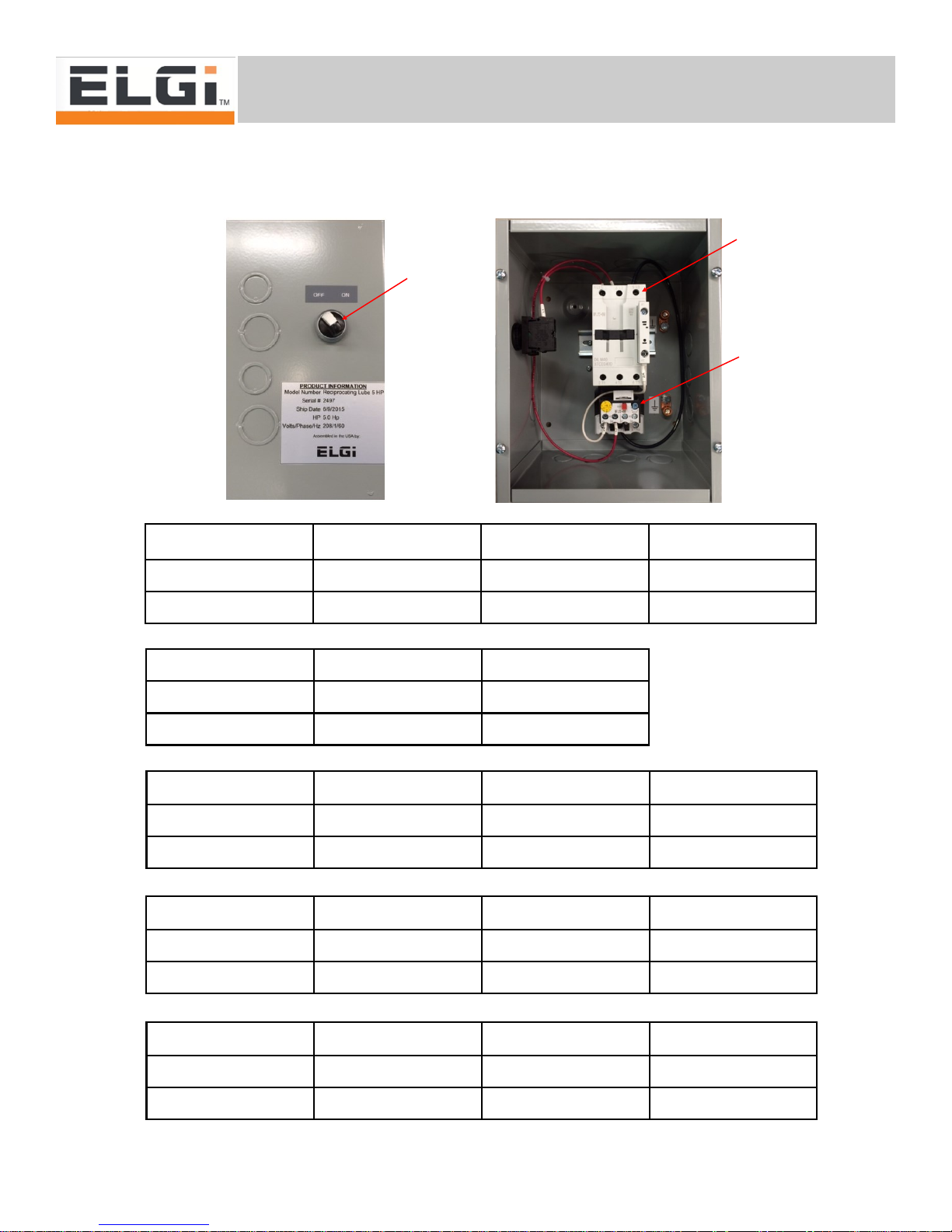

3.0 Control Panel

5 HP 208/3/60 230/3/60 460/3/60

Starter 30-03-408 30-03-417 30-03-036

Overload Relay 30-03-207 30-03-206 30-03-204

5 HP 208/1/60 230/1/60

Starter 30-03-410 30-03-420

Overload Relay 30-03-008 30-03-208

Off-On

Switch

54-17-009

Motor

Starter

(see chart)

Motor

Overload

(see chart)

10 HP 208/3/60 230/3/60 460/3/60

Starter 30-03-410 30-03-420 30-03-038

Overload Relay 30-03-208 30-03-208 30-03-206

7.5 HP 208/3/60 230/3/60 460/3/60

Starter 30-03-409 30-03-419 30-03-037

Overload Relay 30-03-208 30-03-207 30-03-205

15 HP 208/3/60 230/3/60 460/3/60

Starter 30-03-412 30-03-422 30-03-040

Overload Relay 30-03-210 30-03-209 30-03-207

9

TS Series

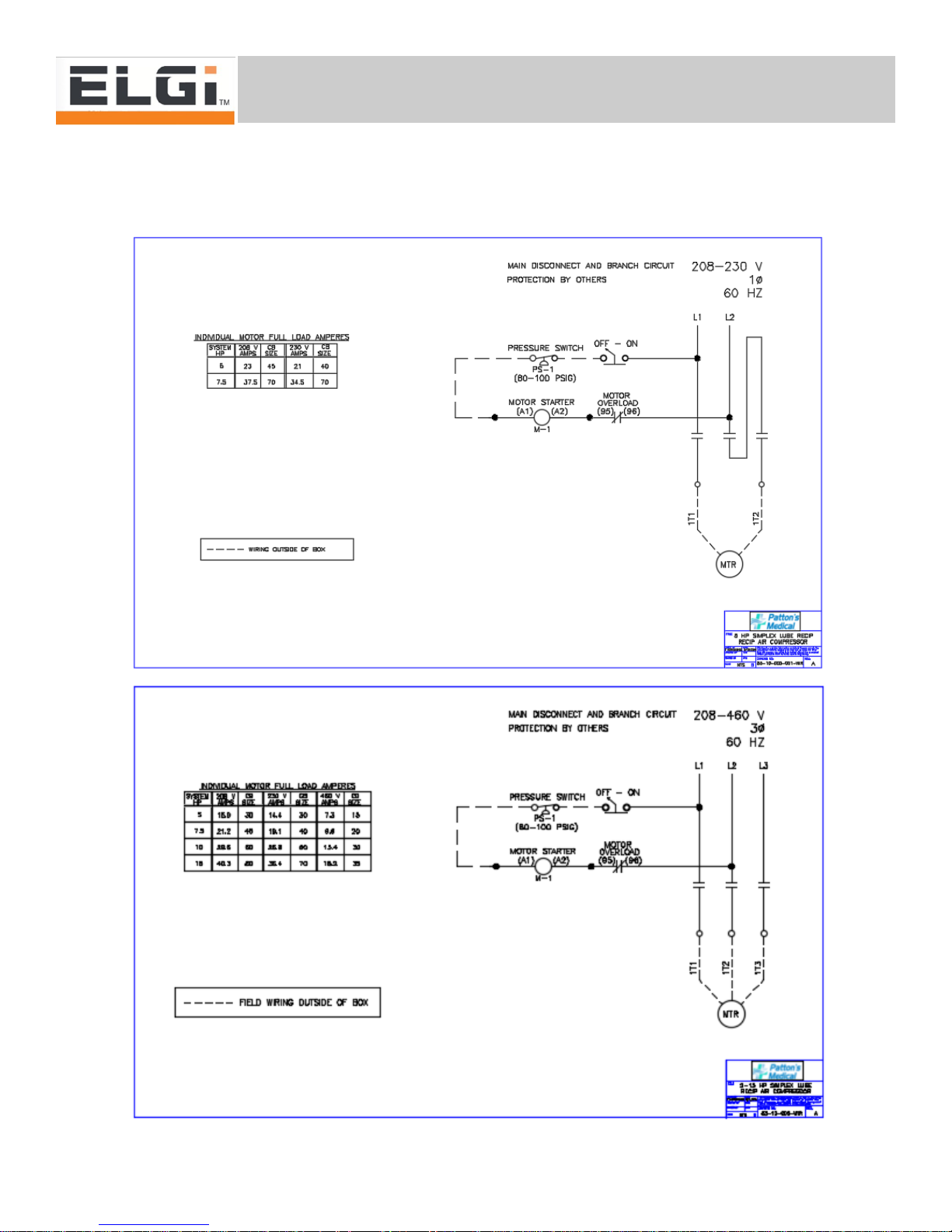

3.0 Control Panel

3.1 Wiring Schematics

Three Phase Compressors

Single Phase Compressors

10

TS Series

4.0 Initial Startup

Check for correct direction of rotation of compressor by momentarily turning the Off-On switch to the

“On” position and observing rotation.

WARNING:

DO NOT RUN THE COMPRESSOR BACKWARDS!

Rotation direction arrows are located on the belt guard (rotation is clockwise, facing the compressor

pulley). Correct the rotation, if required, by switching the motor leads at the starter.

Start compressor by turning the “Off-On” switch to the “On” position. Allow compressor to operate for

a short time (15 to 30 seconds) and check for any unusual noises or vibrations.

If everything appears normal, allow compressor to run in the “On” mode until pressure builds in the

air receiver. The compressor should stop when the pressure reading reaches 125 psig. Check for

any leaks in the piping. Repair leaks, if needed.

5.0 Maintenance

Frequency Maintenance Required

Daily or before

compressor starting

a) Check oil level

b) Drain condensate from air receiver

c) Check belt tension

150 Hours or 10 Days

a) Relieve moisture and dirt from air receiver

b) Carry out first oil change

250 Hours or 20 Days

a) Check for unusual noise or vibration

b) Check bolts for tightness

c) Check for leaks

d) Check pressure settings

e) Check inlet air filter

a) Change Oil

500 Hours or 1 Month

b) Clean breather valve

c) Tighten all wires

d) Clean air filter element

11

TS Series

5.0 Maintenance (continued)

Maintenance

Daily or before compressor starting

• Remove dirt and dust from compressor.

• Check oil level in crankcase, replenish if needed.

• Check Belt tension.

• Drain condensate from air receiver.

150 hours or 10 days

• Drain condensate from receiver.

• Drain oil from compressor after running to warm oil, add new oil to compressor.

250 hours or 20 days

• Check for unusual noise or vibration.

• Check bolts for tightness.

• Check for air leaks in piping, cooler, safety valves and drain valves.

• Check pressure switch operation and settings.

• Remove inlet air filter and clean with compressed air, reassemble on compressor.

Frequency Maintenance Required

1000 Hours or 3 Months

a) Inspect valves

b) Check piping for leaks

c) Inspect check valve

d) Change inlet filter element

e) Change breather valve

f) Check pressure setting

g) Check bolts for tightness

2500 Hours or 1 Year

a) Annual preventative maintenance kit with tune up kit

Clean coolers

a) Clean and test air receiver for leaks

2 Years

b) Change safety valves

7500 hours or 3 Years a) Overhaul Compressor

12

TS Series

5.0 Maintenance (continued)

500 hours or 1 month

• The breather valve should be dismantled, cleaned and checked for seating on the diaphragm

and reassembled.

• Tighten all control and motor wires.

• Drain crankcase oil and refill with proper quantity and oil.

• Clean air filter element.

1000 hours or 3 months

• Remove the L.P cylinder heads. Dismantled the disc valves/Finger Valves. Remove carbon from

the valve discs, springs and valve plates.

• All the pipe lines should be checked for leaks at joints and replace packing's if necessary.

• Check tank check valve for leaking, replace if required.

• Change the air filter element.

2500 hours or 1 year

• Remove Carbon from the after cooler pipe (optional) and the intercooler by any one of the follow-

ing methods.

a) Heat the cooler to appropriate temperature at which the carbon scaling may disinter

grate from the inside walls of the cooler. Then hammer the after cooler with mallet to relieve

the carbon particles off the after cooler.

b) Immerse the cooler in hydrocarbon like Benzene or Toluene solution for a substantial

period of time. Then clean the after cooler with compressed air.

• Lubricate the electric motor bearings using a special grease gun or by removing the end covers.

• The compressor should be completely stripped off by experienced personnel. All parts have to be

thoroughly cleaned, examined and repair in a clean surrounding and rebuilt. Before

dismantling the unit, disconnect the power supply and release all the air from the air

receiver by opening the shut off valve and drain valve. Pull the safety valves so that if there

is any air left inside it will escape to atmosphere. Loosen the tension adjuster and remove

the belts. Remove the pipe connection. Open the drain plug and drain oil from the

crankcase.

• The permissible tightening torque values for threaded fasteners of property class 8.8 are given in

table below.

• Carryout the annual preventive maintenance with tune up kit through Elgi authorized dealer.

Thread size M6 M8 M10 M12

Tightening Torque lb/ft 3.4 8.7 17 30

13

TS Series

5.0 Maintenance

5.1 Pressure Switch Adjustment

Turn clockwise to increase cut-out pressure

without affecting cut-in

Turn clockwise to

increase both cut-in and

cut-out pressure

Note: Max pressure

setting 175 PSI

14

TS Series

6.0 Troubleshooting

Problem Possible Causes Solution

Compressor over heats Dirty oil Change oil

Oil level low Fill correct grade of oil up to

max

level in the oil level indicator

Cylinder and cooler fins dirty Blow with compressed air or

clean manually

Breather valve not working clean and refit after checking

Rotation not correct Interchange two of the incoming

power feeds to motor

Compressor does not unload Blocked unloader tubing. Open and Clean

Defective unloader Replace pressure switch

Oil carry over in compressed air Dirty air filter Replace the air filter element

Oil level high Drain to correct level

Oil viscosity too low Change to recommended grade

Breather not working Clean and replace after check-

ing

Piston rings stuck or broken Change rings as a set

Piston to cylinder clearance ex-

cessive

Check and change as required.

Cylinder, piston and ring wear Inadequate filter maintenance Increase frequency of cleaning/

changing

Oil change frequency insufficient Increase frequency with more

periodic check of oil

Incorrect grade of oil

Change to correct grade

Water or rust formation in crankcase.

Faulty breather valve Check and replace the breather

Oil leak through breather valve

Piston rings stuck or broken Change rings as a set, Check

all related parts for wear

Breather valve is not working.

Clean and replace after checking

Piston to cylinder clearance excessive Check and change as required.

15

TS Series

6.0 Troubleshooting (continued)

Problem Possible Causes Solution

Compressor knocking Loose compressor fan pulley Remove fan pulley and exam-

ine keyway and key for wear.

Change the key/pulley as required.

Worn out piston, cylinder, crank-

shaft and connecting rod bear-

ings.

Overhaul compressor unit. Replace the related components

Check valve faulty Replace check valve

Pressure built up time excessive Leaks in pressure lines. Repair leaks

Loose belts. Tighten or replace as required

Defective seating of inlet and ex-

haust valve plates

Clean and refit after careful

inspection

Worn out piston rings. Replace and check related

components

Unloader valve leaky. Dirty or faulty pressure switch Replace as needed

Pressure switch does not work Punctured diaphragm because of

frequent operations

Replace switch

Compressor package vibration Floor not level Check for level and correct

Foundation bolts and nuts loose. Tighten bolts and nuts.

Starter chattering. Loose connection in starter mains/

coil terminals

Tighten all the wires in starter.

Pressure switch malfunctioning. Replace pressure switch

Low supply voltage. Check supply voltage and cor-

rect

Contactor tip welding Foreign particles prevent contact

from closing

Replace contactor

Low supply voltage. Check voltage and correct

Short circuit. Trace and correct fault

Defective starter Replace starter

Starter tripping. Over load setting wrong Check motor FLA and set to

proper setting

Over loading. Pressure setting too high, ad-

just

Motor winding short. Replace motor

16

TS Series

6.0 Troubleshooting (continued)

Problem Possible Causes Solution

Starter tripping. Single phasing. Check all the three phases are

available at over load terminals

and at line side of starter

High Ambient Temperature. Provide proper ventilation. En-

sure ambient temperature is

less than 105⁰F

Overload Faulty Check amp draw of motor. If

overload is tripping below set

point replace overload

Voltage fluctuation. Control the fluctuation or stop

the compressor if the voltage is

too low

Frequent start stop Check the starts and stops per

hour. Should be less than 10

times per hour. If not increase

receiver volume.

Motor does not run in normal con-

dition

Faulty pressure switch Replace pressure switch

Faulty starter coil Replace starter

Single Phasing (humming noise

and motor does not produce

enough torque)

Check to see if all phases are

available at all terminals

Loose connection on starter termi-

nals, coil terminals or pressure

switch terminals

Correct the loose connections.

Motor overload tripping Check the reasons for tripping

and correct, reset by pressing

reset button on starter

Motor winding burnt Replace motor

Motor Faulty High ambient temperature Provide proper ventilation. En-

sure ambient temperature is

less than 105⁰F

Motor fan not rotating Check for defective motor fan

Over loading Check O/L setting and pressure

switch setting

17

TS Series

6.0 Troubleshooting (continued)

Problem Possible Causes Solution

Motor Faulty Frequent start stop. Check the starts and stops per

hour. Should be less than 10

times per hour. If not increase

receiver volume.

Defective winding Replace motor

18

TS Series

7.0 Replacement Parts - TS05

Description Part Number

Compressor 5 HP (X021151) 01-01-500

Compressor 5 HP (X020758E) 01-01-502

Filter Element (Metal Canister) 022400929

Filter Element (Plastic Canister) B005705760002

Drive Belt 11-01-114

Discharge Safety Valve 16-06-044

Tank Safety Valve 13-06-022

Check Valve 13-02-025

Pressure Switch 30-06-039

Pressure Gauge 23-01-003

Motor 208/230/460/3/60 03-04-006

Motor 230/1/60 03-04-006-001

Filter Element

Motor

Drive Belt

Discharge

Safety

Valve

Compressor

Pressure

Switch

Pressure

Gauge

Check

Valve

Tank

Safety

Valve

19

TS Series

7.1 Replacement Pump Parts - TS05

20

TS Series

7.1 Replacement Pump Parts - TS05

Fig

#

Description Qty Part No.

1 Crank case 1 00 02 2560 0

2 Stud M12 x 45 4 00 05 1456 0

Stud M12 x 54 4 00 05 1455 0

3 Gasket, Free end cover 1 00 04 2550 0

4 Free end cover 1 00 03 1770 0

5 Spring washer M8 10 00 09 96 108

6 Bolt Hex. M8x25 10 00 09 06 116

7 Nipple hex. ½” BSP x ½” BSP 1 00 04 1843 A

8 Elbow ½” BSP 1 00 09 72 053

9 Pipe, breather 1 02 04 9285 0

10 Reducer ½” BSP x 1” BSP 1 02 04 9246 0

11 Breather assembly 1 A02 0201

12 Rink packing, 17x22x2 1 00 05 2186 0

13 Oil Drain plug, 3/8” BSP 1 A02 0033

14 ‘O’ Ring, OLI 1 00 05 2655 0

15 Oil Level Indicator 1 00 05 1344 0

16

Conn. rod & Combined Crank

shaft assy.

1 A02 0231

17 Bearing 6305 1 00 09 03 346

18 Bearing 6307 1 00 09 03 352

19 Gasket, Fly end cover 1 00 04 2551 0

20 Oil seal, B32x54x7 1 00 04 2034 0

21 Fly end cover 1 02 03 5039 0

22 Piston, dia 90 1 00 32 0318 0

23 Circlip, B 18 2 00 09 17 218

24 Gudgeon pin, Dia 18 1 00 34 0757 0

25

Ring, slotted oil control, Dia

90

2 00 33 0478 0

26

Ring, stepped compression,

Dia 90

1 00 33 0477 0

27

Ring, Taper plain compression, Dia 90

1 00 33 0476 0

Gasket, C/Case to Cylinder,

0.75

1 00 04 1002 A

28

Gasket, C/Case to Cylinder,

0.4

1 00 04 1002 B

Gasket, C/Case to Cylinder,

0.25

1 00 04 1002 C

Fig # Description Qty Part No.

29 Cylinder, dia 90 1 02 03 5012 0

30 Spring washer M12 8 00 09 96 112

31 Nut, Hex. M12 8 00 09 48 012

Stud, M12 x 86 3 00 04 7004 0

32

Stud, M12 x 96 1 00 05 1450 0

33 Valve finger 4 00 03 3097 0

34 Gasket, Cyl. To Valve flat 1 06 04 0013 A

35 Valve Flat 1 00 33 0479 0

36 Gasket, Valve flat to Head 1 06 04 0012 A

37 Centring Bush 4 00 04 2660 0

38 Head, dia 90 Cyl. 1 02 03 6001 0

39 Spring washer M12 8 00 09 96 112

40 Nut, Hex. M12 8 00 09 48 012

41 Nipple, Pipe 1 ¼” BSP 1 00 04 3217A

42 Piston dia 50 1 00 02 1357 0

43 Circlip B 12 2 00 09 17 212

44 Gudgeon pin, Dia 12 1 00 05 1431 0

45

Ring, slotted oil control,

Dia 50

2 00 04 1683 A

46

Ring, stepped compres-

sion, Dia 50

1 00 04 1590 A

47

Ring, Taper plain com-

pression, Dia 50

1 00 04 1589 A

48

Gasket, C/Case to Cylin-

der, 0.25

1 00 04 1004 A

Gasket, C/Case to Cylin-

der, 0.4

1 00 04 1004 B

Gasket, C/Case to Cylin-

der, 0.75

1 00 04 1004 C

49 Cylinder, dia 50 1 00 02 1004 0

50

Stud, M12 x 60 3 00 05 2013 0

Stud, M12 x 70 1 00 05 1883 0

51 Valve finger 2 00 03 3094 0

52 Gasket, Cyl. To Valve flat 1 00 04 1150 A

53 Valve Flat 1 00 03 1005 0

54 Gasket, Valve flat to Head 1 00 04 1151 A

55 Head, dia 50 Cyl. 1 00 02 1993 0

56 Nut, Connecting 2 00 05 1038 A

57 Connecting Piece, ¾” BSP 1 02 04 8483 0

58 Ring, Packing 2 00 05 2191 0

59 Inter cooler 1 00 33 0525 0

60 Connecting Piece, 1” BSP 1 00 04 1204 A

61 Safety valve assembly, 1 00 04 1318 0

62 Ring Packing 1 00 05 2184 0

63 Adapter, ¾” x 1” BSP 1 00 04 1017 B

64 Direction Indicator 1 00 05 1010 0

65 Rivet 6 00 04 6454 A

66 Name plate, RAC Unit 1 02 03 5180 F

21

TS Series

8.0 Replacement Parts - TS07

Description Part Number

Compressor 7.5 HP (X020758E) 01-01-502

Filter Element (Metal Canister) 022400929

Filter Element (Plastic Canister) B005705760002

Drive Belt 11-01-114

Discharge Safety Valve 16-06-044

Tank Safety Valve 13-06-022

Check Valve 13-02-025

Pressure Switch 30-06-039

Pressure Gauge 23-01-003

Motor 208/230/460/3/60 03-05-009

Motor 230/1/60 03-05-009-001

Filter Element

Motor

Drive Belt

Discharge

Safety

Valve

Compressor

Pressure

Switch

Pressure

Gauge

Check

Valve

Tank

Safety

Valve

22

TS Series

8.1 Replacement Pump Parts - TS07

23

TS Series

8.1 Replacement Pump Parts - TS07

Fig

#

Description Qty Part No.

1 Crank case 1 00 02 1278 0

2 Stud M12 x 45 8 00 05 1456 A

3 Gasket, Free end cover 1 00 04 2546 0

4 Free end cover 1 00 03 6546 0

5 Spring washer M8 12 00 09 96 108

6 Bolt Hex. M8x25 12 00 09 06 116

7 Pipe, breather 1 02 04 9285 0

8 Reducer ½” BSP x 1” BSP 1 02 04 9246 0

9 Breather assembly 1 A02 0030

10 Rink packing, 17x22x2 1 00 05 2186 0

11 Oil Drain plug, 3/8” BSP 1 A02 0033

12 ‘O’ Ring, OLI 1 00 05 2655 0

13 Oil Level Indicator 1 00 05 1344 0

14

Conn. rod & Combined Crank

shaft assy.

1 02 03 6253 0

14a

Conn. rod & Combined Crank

shaft assy.

1 A02 0433

15 Bearing 6307 1 00 09 03 352

16 Bearing 6309 1 00 09 03 358

17 Gasket, Fly end cover 1 00 04 5463 0

18 Oil seal, B45x60x12.5 1 00 04 2035 0

19 Fly end cover 1 02 03 5463 0

20 Piston, dia 100 1 00 32 6183 0

21 Circlip, B 20 2 00 09 17 220

22 Gudgeon pin, Dia 20 1 00 05 1419 0

23

Ring, slotted oil control, Dia

100

2 00 04 1686 0

24

Ring, stepped compression,

Dia 100

1 00 04 1757 0

25

Ring, Taper plain compression, Dia 100

1 00 04 1685 0

26

Gasket, C/Case to Cylinder,

0.25

1 00 04 1004 A

Gasket, C/Case to Cylinder,

1.00 mm

1 00 04 1004 D

Fig # Description Qty Part No.

27 Cylinder, dia 100 1 02 02 1010 0

28 Spring washer M12 8 00 09 96 112

29 Nut, Hex. M12 8 00 09 48 012

30

Stud, M12 x 86 3 00 04 7004 0

Stud, M12 x 96 1 00 05 1450 0

31 Valve finger 4 00 03 3097 0

32 Gasket, Cyl. To Valve flat 1 00 04 1156 A

33 Valve Flat 1 00 03 1007 0

34 Gasket, Valve flat to Head 1 00 04 6210 A

35 Centring Bush 4 00 04 2660 0

36 Head, dia 100 Cyl. 1 00 02 1238 0

37 Spring washer M12 8 00 09 96 112

38 Nut, Hex. M12 8 00 09 48 012

39 Nipple, Pipe 1 ¼” BSP 1 00 04 3217A

40 Piston dia 60 1 00 02 1210 0

41 Circlip B 18 2 00 09 17 218

42 Gudgeon pin, Dia 18 1 00 05 1415 0

43

Ring, slotted oil control,

Dia 60

2 00 04 1688 0

44

Ring, stepped compres-

sion, Dia 60

1 00 04 2033 0

45

Ring, Taper plain com-

pression, Dia 60

1 00 04 1687 0

46 Cylinder, dia 60 1 00 02 1011 0

47

Stud, M12 x 60 3 00 05 2013 0

Stud, M12 x 70 1 00 05 1883 0

48 Valve finger 2 00 03 3095 0

49 Gasket, Cyl. To Valve flat 1 00 04 1152 A

50 Valve Flat 1 00 03 1008 0

51 Gasket, Valve flat to Head 1 00 04 1153 A

52 Head, dia 60 Cyl. 1 00 02 1112 0

53 Connecting Piece 1 02 04 9609 0

54 Ring, Packing 2 00 05 2191 0

55 Inter cooler 1 00 03 1009 0

56 Safety valve assembly, 1 A02 0001

57 Name plate, RAC Unit 1 02 03 5180 R

24

TS Series

8.1 Replacement Pump Parts - TS 7.5

Fig # Description Qty Part No.

01 Compressor 7.5 HP 1 01-01-502

02 Pulley

1 A 02 0056

03 Cooling fan

04 Washer, spring rectangular, M8

05 Bolt, hex, M8 x 20

25

TS Series

9.0 Replacement Parts - TS 10

Description Part Number

Compressor 10 HP (X021154) 01-01-501

Filter Element (Metal Canister) 022400929

Filter Element (Plastic Canister) B005705760002

Drive Belt 11-01-113

Discharge Safety Valve 16-06-044

Tank Safety Valve 13-06-022

Check Valve 13-02-025

Pressure Switch 30-06-039

Pressure Gauge 23-01-003

Motor 208/230/460/3/60 03-06-014

Motor

Drive Belt

Discharge

Safety

Valve

Compressor

Pressure

Switch

Pressure

Gauge

Tank

Safety

Valve

Check

Valve

Inlet Filter

Elements (2)

26

TS Series

9.1 Replacement Pump Parts - TS 10

27

TS Series

9.1 Replacement Pump Parts - TS 10

Fig

#

Description Qty Part No.

39 Packing cyl head to valve flat 2 00 04 6210 A

40 Head, dia 100 cylinder 2 00 02 1238 C

41 Washer, spring, rectangular, M12 9 00 09 96 112

42 Nut, hex, M12 9 00 09 4801 2

43 Nipple, 1 1/4” BSP 2 02 04 9718 0

44 Dowety washer 3 00 09 5943 9

45 Connector, Housing 1” BSP 3 02 04 9678 0

46 Ring, packing, 30 x 38 x 2 2 00 05 2194 0

47 Elbow assy 3 02 04 9678 0

48 Piston, dia 70 1 00 02 1213 0

49 Pin, gudgeon, dia 18 1 00 05 1430 0

50 Circlip, internal,B18 2 00 09 17 218

51 Ring, slotted, oil control dia 70 2 00 04 1684 0

52 Ring stepped, compression dia 70 1 00 04 1588 0

53 Ring, plain compression, dia 70 1 00 04 1587 0

54 Gasket Crankcase, dia 70 Cyl. 0.75 1 00 04 1002 A

55 Cylinder, dia 70 1 00 02 10020

56 Washer, spring, rectangular M12 4 00 09 96 112

57 Nut, hex, M12 4 00 09 99 808

58 Stud, M12 x 60 4 00 05 2013 A

59 Valve, finger type, dia 70 cylinder 2 00 03 3096 0

60 Gasket cyl to valve flat 1 00 04 1154 A

61 Flat, valve, dia 70 cylinder 1 00 03 1004 0

62 Bush,centering 2 00 04 2660 0

63 Gasket cyl head to valve flat 1 00 04 1155 A

64 Head, cylinder dia 70 1 00 02 1393 0

65 Washer, spring rectangular, M12 4 00 09 96 112

66 Nut,hex, M12 4 00 09 99 808

67 Dowety washer 1 00 09 5943 7

68 Connector, 7/8'' BSP 1 02 04 9679 0

69 Ring, packing, 30 x 38 x 2 1 00 05 2194 0

70 Adapter assy 1 02 04 9610 0

71 Rivet 4 00 04 6454 A

72 Name Plate 1 02 03 5180 X

Fig

#

Description Qty Part No.

1 Crankcase 1 00 02 1394 0

2 Stud, M12 x 45 12 00 05 1456 A

3 Gasket, free end 1 00 04 3199 0

4 Cover, free end 1 00 03 1809 0

5 Washer 8 00 09 96 108

06 Bolt, hex M8 x 25 8 00 09 06 116

07 Pipe, breather, 1/2'' BSP 1 00 04 1361 B

08 Reducer 1" x 1/2" BSP 1 02 04 9246 0

09 Valve assembly, breather 1 A 020030

10 Ring, packing, 17 x 22 x 2 1 00 05 2186 0

11 Drain plug assembly 1 A020033

12 'O' ring, oil level indicator 1 00 05 2655 0

13 Indicator, oil level, 11/4'' BSP 1 00 05 1344 0

14 Connecting rod and crankshaft

assembly (02 02 2753 0) 1 A020427

Connecting rod with bearing 1 02 03 6255 0

15 Bush, Dia 20 Gudgeon pin 2 00 05 2311 0

16 Needle roller bearing 1 00 09 03 712

17 Bearing, ball single row, 2 00 09 03 361

18 Key, 10 x 8 x 60 1 00 05 1037 0

19 Gasket, fly end 1 00 04 3198 0

20 Seal, oil, B45 x 60 x 12.5 1 00 04 2035 0

21 Cover, fly end 1 00 03 1777 0

22 Washer, spring, rectangular 8 00 09 96 108

23. Bolt, hex, M8 x 25 8 00 09 96 116

24 Piston dia 100 2 02 03 6183 0

25 Pin, gudgeon, dia 20 2 02 03 6183 0

26 Circlip, B20 4 00 09 1722 0

27 Ring, slotted, oil control dia 100 4 00 04 1686 0

28

Ring, stepped compression, dia

100

4 00 04 1757 0

29

Ring, taper plain compression, dia

100

2 00 04 1685 0

30

Gasket Crankcase to dia 100 cyl

0.8

2 00 04 1004 C

31 Cylinder, dia 100 2 00 02 1010 D

32 Washer, spring, rectangular, M12 8 00 09 9611 2

33 Nut, hex M12 8

00 09 48 01

2

34 a) Stud, M12 x 86 6 00 04 7004 A

b) Stud, M12 x 96 2 00 05 1450 0

35 Gasket cylinder to valve flat 2 00 04 1156 A

36 Valve finger 8 00 03 3097 0

37 Flat valve dia 2 00 03 1007 0

38 Bush Centering 2 00 04 2660 0

28

TS Series

9.1 Replacement Pump Parts - TS 10

Fig # Description Qty Part No.

01 Compressor 10 HP 1 01-01-501

02 Pulley

1 A 02 0057

03 Cooling fan

04 Washer, spring rectangular, M8

05 Bolt, hex, M8 x 20

06 Disc, end 00 05 1036 A

07 Washer, spring, rectangular, M12 1 00 09 96 112

08 Bolt, hex, M12 x 35 1 00 09 99 804

09 Pipe dampening 1 02 04 9692 0

10 Valve assembly, drain, 1/4'' BSP 1 A02 0045

11 Valve assembly, safety. 3/8'' BSP 1 A02 0002

12 Pipe assembly, connecting No.3 1 02 04 9691 A

13 Pipe assembly, connecting No.2 2 02 04 9689 A

29

TS Series

10.0 Replacement Parts - TS15

Description Part Number

Compressor 15 HP (X021164) 01-01-503

Filter Element (Metal Canister) 022400929

Filter Element (Plastic Canister) B005705760002

Drive Belt 11-01-154

Discharge Safety Valve 16-06-044

Tank Safety Valve 13-06-022

Check Valve 13-02-025

Pressure Switch 30-06-039

Pressure Gauge 23-01-003

Motor 208/230/460/3/60 03-07-015

Motor

Drive Belt

Discharge

Safety

Valve

Compressor

Pressure

Switch

Pressure

Gauge

Tank

Safety

Valve

Check

Valve

Inlet Filter

Elements (2)

30

TS Series

10.1 Replacement Pump Parts - TS 15

31

TS Series

10.1 Replacement Pump Parts - TS 15

Fig

#

Description Qty Part No.

42 Bonded seal 7/8" 1 00 09 5943 7

43 Elbow assy 7/8'' 1 02 04 9679 0

44 Piston assy dia 70

45 Gudgeon pin, dia 18 1 00 04 7775 0

46 Circlip B18

47 Ring slotted, oil control

48 Ring stepped compression 1 02 24 0104 9

49 Ring taper compression

50 Gasket, crankcase to dia 70

cyl .75mm

1 00 04 1002 A

51 Cylinder dia 70 1 00 02 1002 0

52 Valve finger dia 70 2 00 03 3096 0

53 Gasket Cyl to valve flat 1 00 04 1154 A

54 Flat, valve, dia 70 cylinder 1 00 03 1004 0

55 Bush,centering 2 00 04 2660 0

56 Gasket cyl head to valve flat 1 00 04 1155 A

57 Head, cylinder dia 70 1 00 02 1393 0

58 Connector Assembly 1 02 04 9620 0

59 Ring, packing 1 00 05 2186 0

60 Pipe nipple 1 1/4” BSP 2 02 04 9718 0

Fig

#

Description Qty Part No.

1 Crankcase 1 00 02 1394 0

2 Stud, M12 x 45 12 00 05 1456 A

3 Gasket, free end 1 00 04 3199 0

4 Cover, free end 1 00 03 1809 0

5 Washer, spring, rectangular, M8 6 00 09 9610 8

06 Bolt, hex M8 x 25 6 00 09 0611 6

07 Pipe, breather, 1/2'' BSP 1 00 04 1361 B

08 Reducer 1/2'' x 1'' BSP 1 00 04 3655 0

09 Breather Assembly 1 A 020030

10 Drain plug assembly 3/8” 1 A 020033

11 Ring, packing, 3/8” drain plug 1 00 05 2186 0

12 'O' ring, oil level indicator 1 00 05 2655 0

13 Indicator, oil level, 1 1/4'' BSP 1 00 05 1344 0

14 Connecting rod and crankshaft

assembly (02 02 2753 0) 1 A020427

Connecting rod with bearing 1 02 03 6255 0

15 Bush, Dia 20 Gudgeon pin 2 00 05 2311 0

16 Needle roller bearing 1 00 09 03 712

17 Bearing, ball single row, 2 00 09 03 361

18 Key, 10 x 8 x 60 1 00 05 1037 0

19 Gasket, fly end 1 00 04 3198 0

20 Seal, oil, B45 x 60 x 12.5 1 00 04 2035 0

21 Cover, fly end 1 00 03 1777 0

22 Piston assy dia 100

23 Gudgeon pin dia 20 2 02 04 9456 0

24 Circlip B20

25 Ring slotted oil control

26 Ring stepped Compression 2 02 24 3413 9

27 Ring taper plain compression

28 Gasket Crankcase to dia 100 cyl 0.8 2 00 04 1004 C

29 Cylinder, dia 100 2 00 02 1010 A

30 Washer, spring, rectangular, M12 8 00 09 9611 2

31 Nut, hex M12 8 00 09 4801 2

32 a) Stud, M12 x 60 10 00 05 2013 A

b) Stud, M12 x 75 2 00 05 2014 0

33 Gasket, big disc valve, dia 100 cyl. 4 00 05 1921 0

34 Disc valve assembly, dia 100 2 A 02 0042

35 Gkt, small, disc valve dia 100 cyl. 2 00 05 1922 0

36 Cylinder head, dia 100 2 00 02 1239 A

37 Spring washer, M12 12 00 09 9611 2

38 Hex nut M12 12 00 09 4801 2

39 Pipe nipple 2 02 04 9718 0

40 Bonded seal 2 00 09 5943 9

41 Elbow assy 1'' BSP 2 02 04 9678 0

32

TS Series

NOTES:

_____________________________________________________

_____________________________________________________

_____________________________________________________

_____________________________________________________

_____________________________________________________

_____________________________________________________

_____________________________________________________

_____________________________________________________

_____________________________________________________

_____________________________________________________

_____________________________________________________

_____________________________________________________

_____________________________________________________

_____________________________________________________

_____________________________________________________

_____________________________________________________

_____________________________________________________

_____________________________________________________

_____________________________________________________

_____________________________________________________

_____________________________________________________

_____________________________________________________

_____________________________________________________

_____________________________________________________

_____________________________________________________

_____________________________________________________

Loading...

Loading...