ELGi TRC 1000 MN UG Owner's Manual

1

Do’s and Dont’s

Dos

3 Read the manual in detail and follow the instructions.

3 Clean the air compressor package regularly.

3 Keep the air filter clean.

3 Use only genuine spares.

3 Maintain correct oil level.

3 Use only clean, recommended lubricants.

3 Use proper tools.

3 Drain the condensate daily by opening the drain valve.

3 Attend immediately to anything unusual with the air compressor.

3 Maintain log book to monitor operation of compressor.

3 Attend Repairs / Service with qualified technicians only.

Dont’s

7 Neglect the routine attention.

7 Allow any leakage in the system.

7 Keep any tools or loose items on the compressor/other modules.

7 Meddle with any adjustments or settings.

7 Run the compressor without fan guard.

7 Use cleaning agents, when changing oil.

7 Do any repair work while the unit is running.

7 Overload the compressor for a long period eventhough it is of

continuous rating.

2

Safety instructions

Never touch moving parts

Never place your hands, fingers or other body parts near the compressor’s

moving parts.

Never operate without all guards in place

Never operate this compressor without all guards or safety features in place

and in proper working order. If maintenance or servicing requires the removal of a guard or safety features, be sure to replace the guards or safety

feature before resuming operation of the compressor.

Always wear eye protection

Always wear safety goggles or equivalent eye protection. Compressed air

must never be aimed at anyone or any part of the body.

Protect yourself against hot spot

Prevent body contact with grounded surfaces such as pipes, cylinders, cylinder heads and motor. Never operate the compressor in damp or wet locations.

Disconnect the compressor

Always disconnect the compressor from the power source and remove the

compressed air from the air tank before servicing, inspecting, maintaining,

cleaning, replacing or checking any parts.

Avoid unintentional starting

Do not carry the compressor while it is connected to its power source or

when the air tank is filled with compressed air.

Store compressor properly

When not in use, the compressor should be stored in dry place, remove

the electrical supply. Keep out of reach of children. Lock – out the storage

area.

Keep work area clean

Cluttered areas invite injures. Clear all work areas of unnecessary tools,

debris, furniture etc.

Keep children away

Do not let visitors contact compressor extension cord. All visitors should

be kept safely away from work area.

3

Operate compressor at the rated voltage

Operate the compressor at voltages specified on their nameplates. If using

the compressor at a higher voltage than the rated voltage, it will result in

abnormally fast motor revolution and may damage the unit and burn out

the motor.

Never use a compressor which is defective or

operating abnormally

If the compressor appears to be operating unusually, making strange noises,

or otherwise appears defective, stop using it immediately and arrange for

repairs by a authorized service center.

Use only genuine replacement parts

Replacement parts not original may void your warranty and can lead to

malfunction and resulting injuries. Genuine parts are available from your

dealer.

Do not modify the compressor

Do not modify the compressor. Always contact the authorized service

center for any repairs. Unauthorized modification may not only impair the

compressor performance but may also result in accident or injury to repair

personnel who do not have the required knowledge and technical expertise to perform the repair operations correctly.

Turn off the starter stop button to be latched

when the compressor is not used

When the compressor is not used, disconnect it from the power source

and open the drain cock to discharge the compressed air from the air tank.

Drain tank

Drain tank daily or after 4 hours of use. Open drain fitting and tilt

compressor to empty accumulated water.

Dress properly

Do not wear loose clothing or jewellery. They can be caught in moving

parts. Wear protective hair covering to contain long hair.

Maintain compressor with care

Follow instructions for lubricating. Inspect cords periodically and if

damaged, have repaired by authorized service facility. Inspect extension cords

periodically and replace if damaged.

Safety instructions

4

Before further use of the compressor, a guard or other part is damaged

should be carefully checked to determine that it will operate properly and

perform its intended function.

Check for alignment of moving parts, binding of moving parts breakage of

parts, mounting, air leak, and any other conditions that may affect its

operation.

A guard or other part that is damaged should be properly repaired or

replaced by an authorized service centre unless otherwise indicated

elsewhere in this Instruction Manual. Have defective pressure switches

replaced by authorized service centre. Do not use compressor if switch

does not turn it on and off.

Handle compressor correctly

Operate the compressor according to the instructions provided herein.

Never allow the compressor to be operated by children, individuals

unfamiliar with its operator or unauthorized personnel.

Keep all screws, bolts and cover tightly in place

Keep all screws, bolts and plates tightly mounted. Electrical

connections to be ensured for tightness. Check their conditions

periodically.

Keep motor air vent clean

The motor air vent must be kept clean so that air can freely flow at all

times. Check for dust build-up frequently.

Electrical installation

This compressor motor and starter should properly grounded with correct size

copper wire to avoid electrical shock and damage to the equipment.

The correct rating of fuses to be provided at the incoming side of the

Starter

The correct rating of wires to be used for incoming connection and length

of the cable to be less than 5 mtrs.

Never take any loop lines from the compressor wiring.

Safety instructions

Avoid electrical shock hazard. Never use this

compressor with a damaged or frayed electrical cord or

extension cord. Inspect all electrical cords regularly. Never

use in near water or in any environment where electric

shock is possible.

WARNING

5

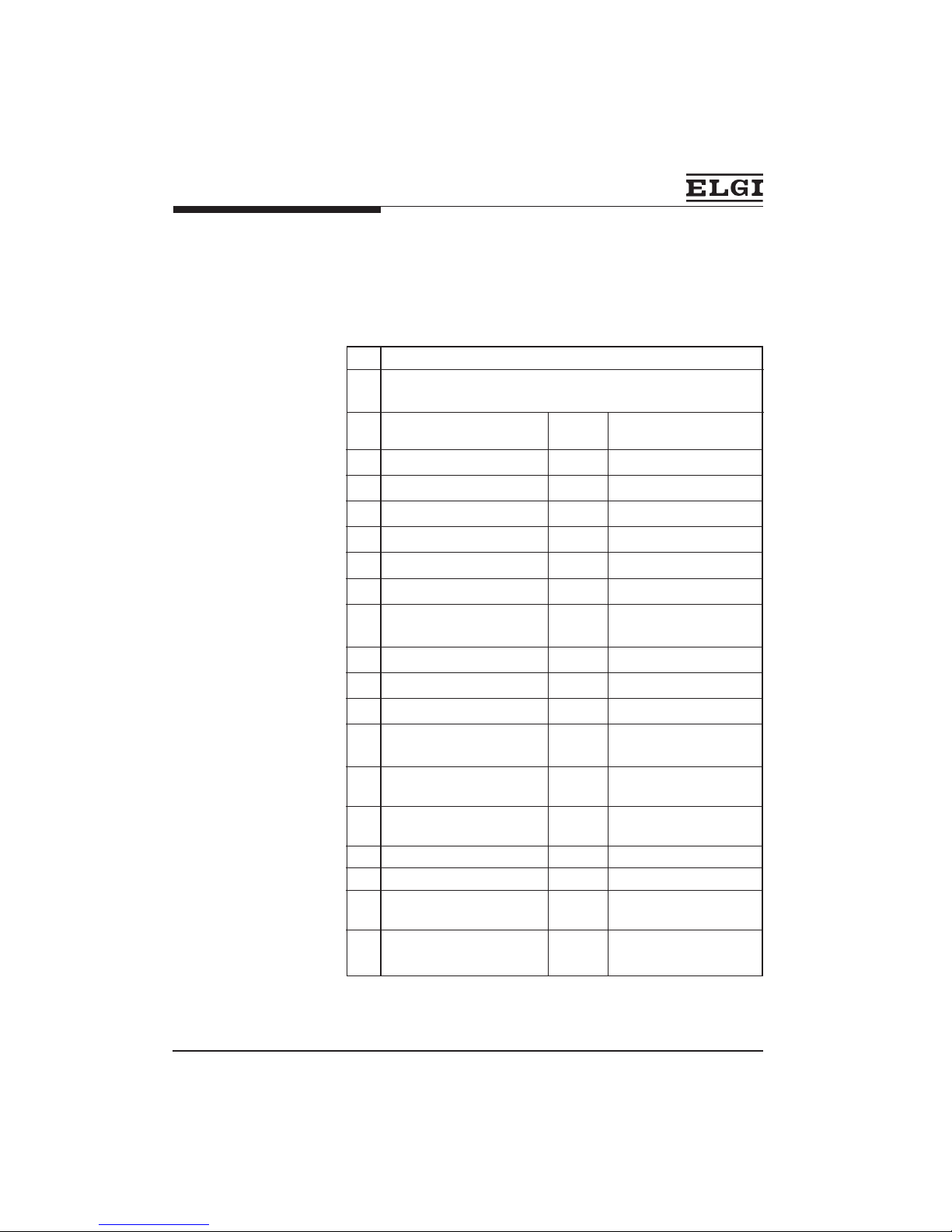

Technical Specifications

03 Working pressure kgf/cm

2

10.5

04 Displacement m3/h 78.48

cfm 46.19

lpm 1308

05 Free air delivery m3/h 60.00

cfm 35.32

lpm 1000

06 Cylinder size & stroke

length mm 100 x 60 x 100 : 85mm

07 No. of stages No. 2

08 Compressor speed rpm 980

09 Type of valve Disc valve

10 Direction of rotation Anticlockwise as viewed

from non-driving end

11 Type of drive Directly coupled with

motor by disc coupling

12 Crankcase oil capacity ml Min. 650

Max. 1880

13 Recommended oil Servo press 150

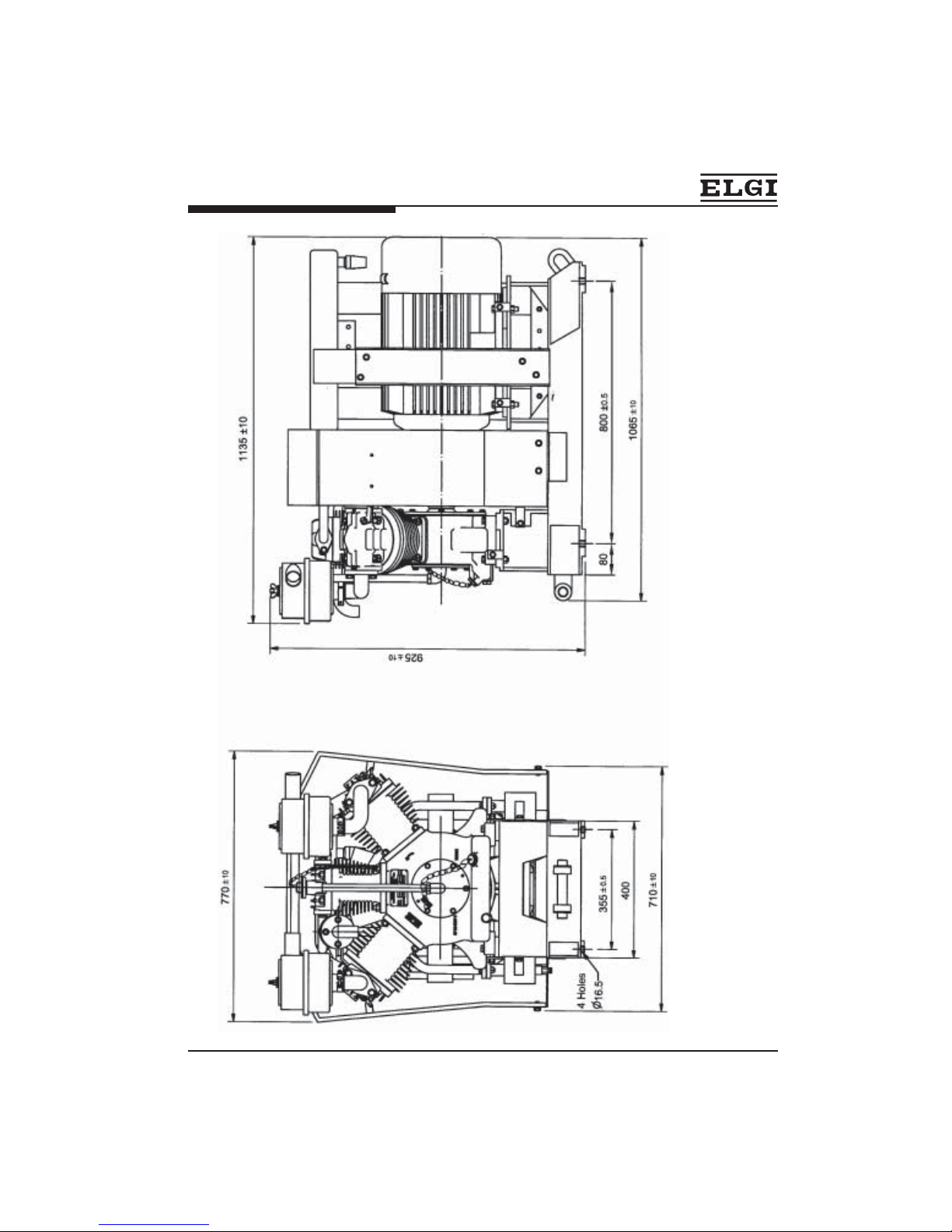

14 Nett weight kg 450±10

15 Overall dimensions mm 1135 x 770 x 925

LxBxH

16 Safety valve on intercooler

Opening pressure kg/cm

2

6

01 Model TRC 1000 MN UG

02 Type Reciprocating, Air cooled, ‘W’ type

and oil Splash lubricated

6

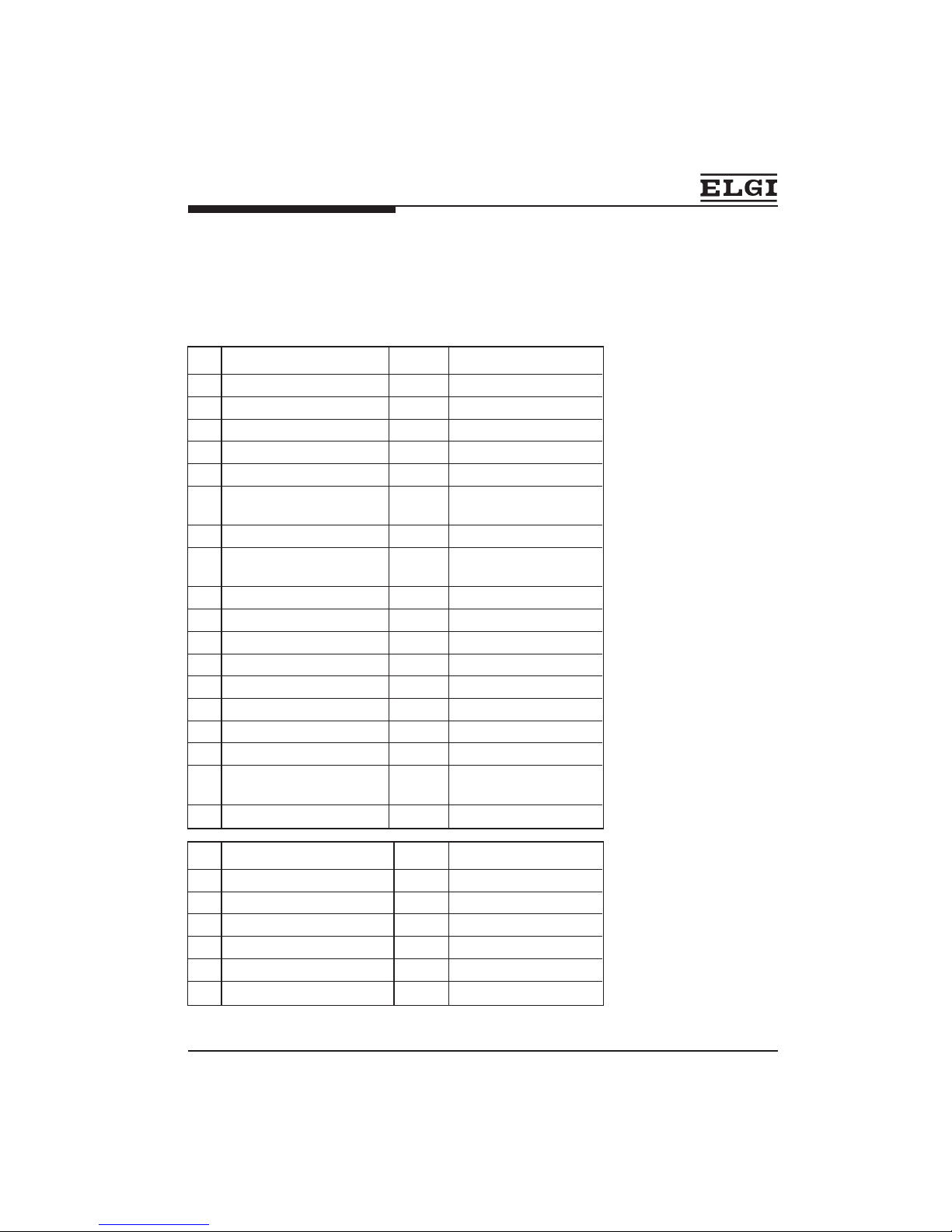

Technical Specifications

17 Coupling

Model Disc type coupling

18 Suction filter

a. Type Dry type

19 Motor Make

a. Make CROMPTON / BHARAT BIJILI

b. Type TEFC, Sqiurrel cage

induction

c. Power HP 14

d. Voltage Base voltage 415V

(290-500v)

e. Rated current Amp 24

f. No. of phases Three phase conn. in star

g. Frequency Hz 50

h. Enclosure IP 54

g. Insulation Class H

h. Speed rpm 975 / 970

i. Rating Continuous

j. Frame Size 180L / 180 L

k. Recommended grease Lithium base GR.3

SERVOGEM GR.3

L. Weight kg 200 / 205

20 Shaft & Bore size

a. Motor shaft mm Ø 48

b. Coupling bore(motor side) mm Ø 48

c. Fan flange bore mm Ø 48

d.Compressor shaft mm Ø 43

e. Coupling bore(Comp.side) mm Ø 43

f. Bore finish Ground

+0.018

+0.002

+0.021

+0.000

-0.03

-0.04

-0.030

-0.050

-0.005

-0.016

Unit

Unit

7

Technical Specifications

1 Cylinder bore mm Dia 100 Dia 60

2 Piston mm

3 Gudgeon pin size Dia 20 Dia 18

4 Clearance in cylinder Normal mm 0.15 - 0.16 0.06 - 0.09

Max mm 0.25 0.20

5 No. of plain compression rings 1 --

6 No. of stepped compression rings 2 --

7 No. of slotted oil control rings 2 --

8 No. of perma seal ring -- 2

9 No. of oil control three piece ring -- 2

10 Permissible piston rings ,

Permissible stepped rings ,

Permissible oil control rings ,

butt clearence Normal mm 0.08 to 0.25 --

Max. mm 0.40 --

11 Permisible perma seal piston ring butt

clearance 0.06 0.09

Permisible perma seal oil control ring

clearance 0.25 --

12 permissible piston rings side

play in groove Normal mm 0.04 to 0.08 0.024 to 0.074

Max. mm 0.12 0.1

13. Connecting rod small end needle

roller bearing internal diameter mm 20 18

14. Clearence between piston

Crown and disc valve mm 1.4 to 1.6 1.4 to 1.6

+0.01

0.00

Cylinder, Piston and Piston ring size

HPLPDescriptionSI.No

+0.01

0.00

0.000

-0.005

0.000

-0.005

Dia 99.835 Dia 99.855

Dia 59.941 Dia 59.915

8

General view of the compressor

9

Introduction

The Elgi air compressor model TRC 1000 MN UG is driven by an electric motor

by means of resillient flange coupling. It consists of three cylinders arranged

in a ‘W’ form on a crankcase. Dry type air filters are fitted to the suction side of

the LP cylinder heads. The discharge ports of the LP cylinder heads are

connected to the intercooler for effective cooling . Intercooler is connected to

the suction

port of HP cylinder head. The discharge port of the HP cylinder head is fitted

with a motor and mounted on a rigid, compact base. The air filters and other

pipe fittings are all clamped properly to arrest vibration. A fan with a fan guard

is provided to direct cool air on to the compressor unit. The fan draws the air

over the motor thereby cooling the motor also. An eye bolt used for lifting the

motor is provided at the terminal side of the motor. (Fix the eye bolt on top of

motor and lift the motor).

Crankcase

The crankcase is made of high grade cast iron an houses the crankshaft

assembly and cylinders. It act as the sump for lubricating oil and is provided

with a breather, drain plug and a dipstick assembly. The breather maintains a

partial vacuum in the crankcase to facilitate better lubrication.

Cylinder and cylinder head

The cylinders and cylinder heads are made of high grade cast iron and they

have close deep fins for effective cooling. The hardness of the cylinders is

closely controlled to ensure high wear resistance.

Connecting rod crankshaft assembly

The connecting rod and crankshaft assembly is precision machined and

dynamically balanced. The combined crankshaft with web is forged out of

carbon steel, hardened and precision ground. The crankshaft is provided with

single row heavy duty ball bearing at both ends. The main connecting rod big

end is provided with steel bearing rollers and small ends are provided with

needle roller bearings.

General Description

10

Piston and Piston rings

The pistons are of automotive type and made out of low expansion aluminium

alloy. They are provided with plain compression rings, stepped compression

rings and slotted oil control rings. The rings are made of special quality close

grained cast iron and designed for controlling wear and oil consumption to a

minimum. The gudgeon pins are of chrome steel case hardened and precision

ground.

Disc valves

Special type concentric disc valves have been used for suction and discharge

operations. The springs used are of high quality spring steel.

Intercooler, safety valve and aftercooler

The intercooler consists of a series of copper tubes, on which fins are wound

for effective cooling. It is mounted above the motor. It is provided with a safety

valve and a drain valve. The aftercooler is also made of copper tubes with fins

wound on them and arranged together for better cooling. A drain valve is

provided on the aftercooler.

Average Life

This type of coupling does not require any attention during running .

i. The coupling hubs will not require replacement earlier than six years of

continuous use.

ii. Misalignment if any in the coupling will reduce the life of the coupling

element.

General Description

11

The following points should be checked during commissioning.

a. Examine the unit for transit damages.

b. Position the compressor in the locomotive and check the level of the

compressor by using a spirit level.

c. Ensure that the compressor unit is properly aligned and all bed bolts

are fully tightened.

d. Rotate the compressor unit by hand and feel whether it is free, except

for compression forces.

e. Connect the motor to a three phase supply and ensure anticlockwise

rotation when viewed from the non-driving end of compressor.

f. Start up the unit and drain intercooler and aftercooler for a few minutes

and also ensure intercooler safety valve is free and functioning

properly.

g. Check if there is any abnormal noise or vibrations. If so, check up and

rectify the defect.

h. If all the above checks are satisfactory, the unit can be commissioned

for regular service.

Installation and operation

BEFORE COMMISSIONING THE COMPRESSOR

Fill up the crankcase with SERVO PRESS 150 oil upto the

maximum mark on the dipstick.

NOTE

12

General

Cleanliness and care must be observed whenever inspection and checks are

being carried out on the compressor and its accessories. For cleaning interior

parts, only rags which do not separate should be used. Cotton waste should

not be used. If any defect is noticed, it should be immediate attended to. The

unit should be properly maintained as per the undermentioned schedule.

Maintenance Schedule

The compressor should be run for a short while and

draining of the oil should be done when the oil is warm.

Do not use any cleaning agents to clean the interior, when

changing oil.

NOTE

Lubricating oil change should be carried out during

Recommended maintenance schedule

Recommended lubricating oil; Servo press 150

WARNING

During trip schedule

a. Clean the compresor thoroughly.

b. Check the oil level in the crankcase. Replenish with the correct grade of

oil if required.

c. Drain the intercooler and aftercooler in order remove the moisture

collected in them. Run the compressor for a few mintues with the drain

valve open, so that the moisture will be removed completely

During trip IA schedule

Check the compressor for satisfactory operation which include :

a. Cleanliness of the compressor.

b. Operational noise and vibration.

c. Tightness of mounting bolts and other fasteners.

13

d. Air leaks at the pipe joints and safety valve.

e. Clean the suction filter element thoroughly by using air from inside to

outside.

f. Check the suction and discharge operations and general performance of

the compressor.

g. Drain the intercooler and aftercooler.

NOTE :

RECOMMENDED GREASE

l SERVOGEM Gr.3 FOR BHARAT BIJILI MOTOR

l LITHIUM BASE Gr.3 FOR CROMPTION MOTOR

During IB schedule

a. All check points indicated under IA schedule to be carried out.

b. Breather valve should be dismantled, cleaned and checked for perfect

seating of the valve.

c. Check the safety valve setting.

d. Visually check the disc coupling for any abnormality in disc back

e. Check the oil level in the crankcase and topup the required quantity of oil

During IC, Schedule

a. All check points indicated under IA, schedule to be carried out.

b. Remove all the disc valves by removing the cylinder heads.

The valves are to be replaced with readily available spare valves since

valves that are removed should undergo thorough cleaning etc.

Maintenance Schedule

14

c. Dismantle the disc valves, check the springs, top plates and bottom plates.

There should not be any scratches or damage in the seating of valve

plates. If there is any damage, it should be lapped. If the springs are

damaged, they should be replaced. All the parts should be decarbonised

and thoroughly cleaned in kerosene. Reassemble the valve and assemble

it to the cylinder with new packings.

d. All the pipe lines should be checked for leaks at joints and packings

renewed as necessary.

During AoH Schedule

A general overhaul should be done. The compressor should be completely

stripped by experienced staff. All parts should be thoroughly cleaned,

examined and repaired in a clean surrounding.

Check the crankshaft assembly thoroughly. There should not be any shake in

the connecting rod about the crank pin. This can be checked by fixing the

crankshaft assembly between centres and shaking the connecting rod. Also

check the small end needle roller bearings. If there is any major repair, the

same may be attended to immediately.

Maintenance Schedule

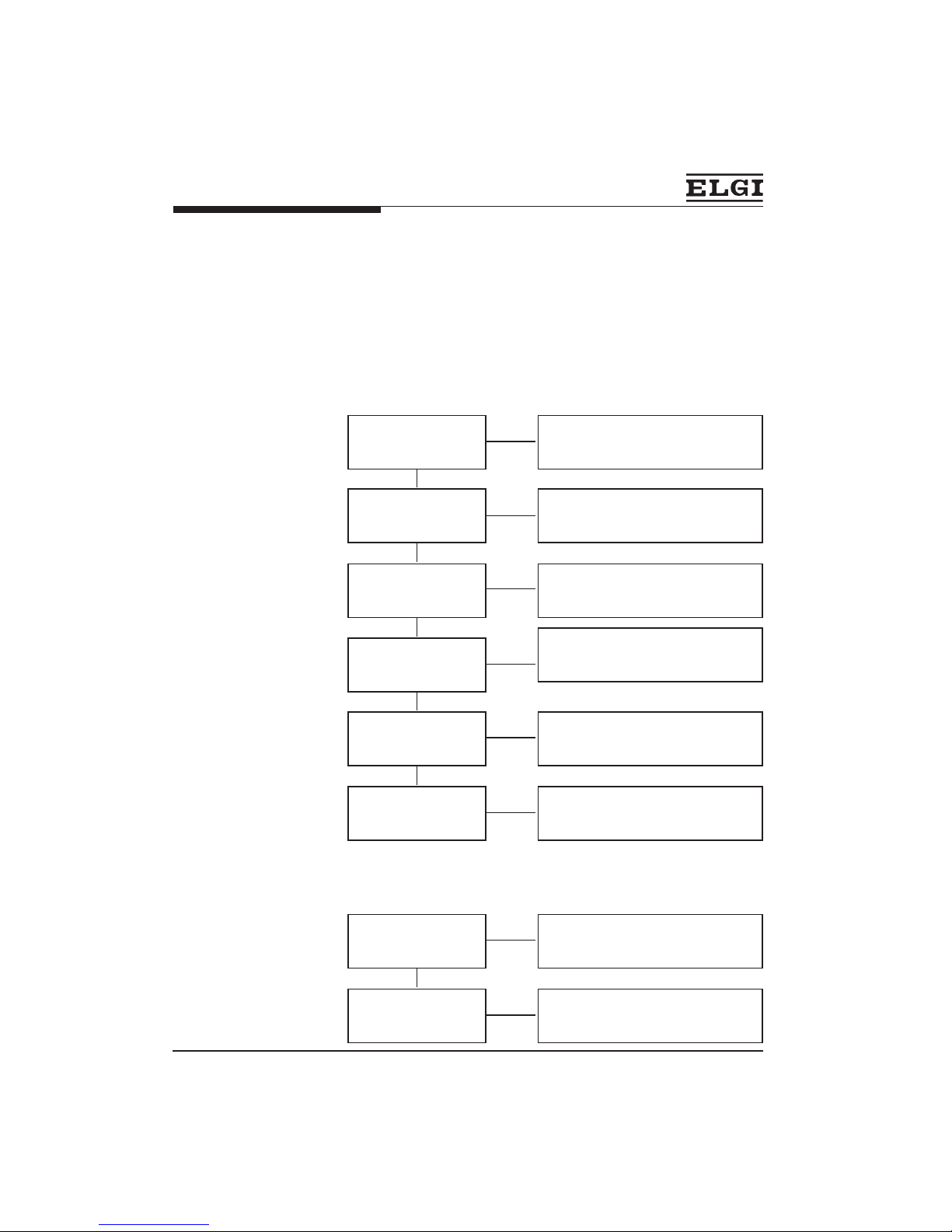

1 Check oil level and top up, if required 45 Days 90 Days

2 Greasing of coupling 45 Days Eliminated

3 Intake air filter- Inspect element, clean if dirty 90 Days 180 Days

4 Inlet & Discharge Valve cleaning & Inspection 90 Days 180 Days

5 Drain and refill oil 90 Days 180 Days

6 Replace the Piston Rings, if required 540 Days 720 Days

(AOH -M18) (AOH-M24)

7 Replace all the Pistons, if required 720 Days 1080 Days

(IOH -M24) (IOH-M36)

8 Replace all the Cylinders, if required 720 Days 1080 Days

(IOH -M24) (IOH-M36)

Maintenance Schedule -Comparison between TRC1000MN and TRC1000MNUG

Maintenance

schedule for

TRC 1000 MN UG

Maintenance

schedule for

TRC 1000 MN

Maintenance Practice

SI

No.

15

General

Only a skilled technician who knows about the compressor should dismantle

and reassemble the compressor. Before dismantling the compressor, make

sure that it is free of compressed air. Pull the safety valve and ensure this.

Ensure that the electric power is disconnected from the unit.

Accessories

Remove the intercooler after removing the respective pipe fittings and bolts.

Remove the aftercooler and suction filters. Open the drain plug and drain the

oil from the crank case.

Cylinder head, Disc valves, Cylinder

Remove the cylinder head and take out the disc valve. Take care not to damage

the disc valves.While dismantling the disc valve, the position of the springs

should be carefully noted which will help during reassembling. Refer the

exploded view of the disc valve which is self explanatory. If damaged; the

springs should be replaced with new ones. Also check the packings and if

necessary replace by new ones.

Unscrew the cylinder and remove the cylinder. If the cylinders are tightly fixed

to the crankcase rotate the fly end hub. The cylinders will automatically come

up.

Piston assembly

Remove the circlip by using a criclip plier and gently knock out the gudgeon

pin. Inspect for scratces or slackness in the piston boss. If the pin is worn out

use a new pin. Remove the piston rings using a piston ring expander.

Clean the piston rings and the ring grooves in the piston. Measure the piston

size, gudgeon pin bore size, piston ring gaps at butts and side clearances.

Replace the rings as a set when limiting clearances have been reached.

Crankshaft assembly

Disassemble the disc coupling. Then remove the free and cover. Remove the

crankshaft assembly through the fly end cover bore along with the cover.

Using puller remove the fly end cover from the crankshaft assembly. Clean the

crankshaft and connecting rod assembly thoroughly in kerosene and dry with

compressed air. Inspect the bearings, if found damaged, replace them with

new ones.

Repairs

16

Crankshaft assembly

Remove the disc coupling. Then remove the free and cover. Remove the crank-

shaft assembly through the fly end cover bore along with the cover.

Using puller remove the fly end cover from the crankshaft assembly. Clean the

crankshaft and connecting rod assembly thoroughly in kerosene and dry with

compressed air. Inspect the bearings, if round damaged, replace them with

new ones.

Repairs

Bearing

Removing ball bearings from the crankshaft

Take a small steel wedge and gently hammer it keeping in between the

crankweb and the bearing.

Then use a suitable puller and take out the bearings.

Assembling the bearings on the crankshaft

Heat them to a temperature from 100C to 120C in an oil bath or on a hot plate

which is heated by a flame or electricity insert the bearings on the shaft so that

they will slide in and fit tight when cooled.

Assembling connecting rod and crankshaft assembly in the crankcase

Take the connecting rod and crankshaft assembly, clean it and oil the bearings.

Rotate the bearings by hand and check for any tightness. They should have

free rotation. Check whether the splasher pin is secured in position. The flat

sides of the splasher pin should be perpendicular to the axis of the shaft.

Fix the fly end cover on the crankshaft assembly. Insert the crankshaft assembly

through the flyend cover bore on the crankcase. Fix the free end cover on the

other side. Then fasten the end covers bolts uniformly.

17

1. Fit the motor side hub on motor shaft, fix key way grub screw

2. Assemble the coupling spacer on motor side coupling hub.

3. Put the motor on base frame first.

4. Put the compressor on base frame ensuring that the spacer encovers the

compress side hub and lamina screws get through the compressor side

hub flange tighten the compressor side hub to spacer bolts.

5. Locate the compressor properly and tighten it to the base (this is not to be

disturbed further)

6. Maintain 101mm distance (flange to flange) by moving motor towers or

away from compressors

7. Once 101 mm is maintained. Fix the motor to the base frame firmly.

8. Mount dial gauge on compressor side hub so that one dial gauge touches

motor side hub radially and other dial touches fan blade coller (

Ø 300)

axially (ensure dial gauge pressure by 2 bar)

9. Adjust ‘0’ on both dials at the top position (i.e., 12’O’ clock position)

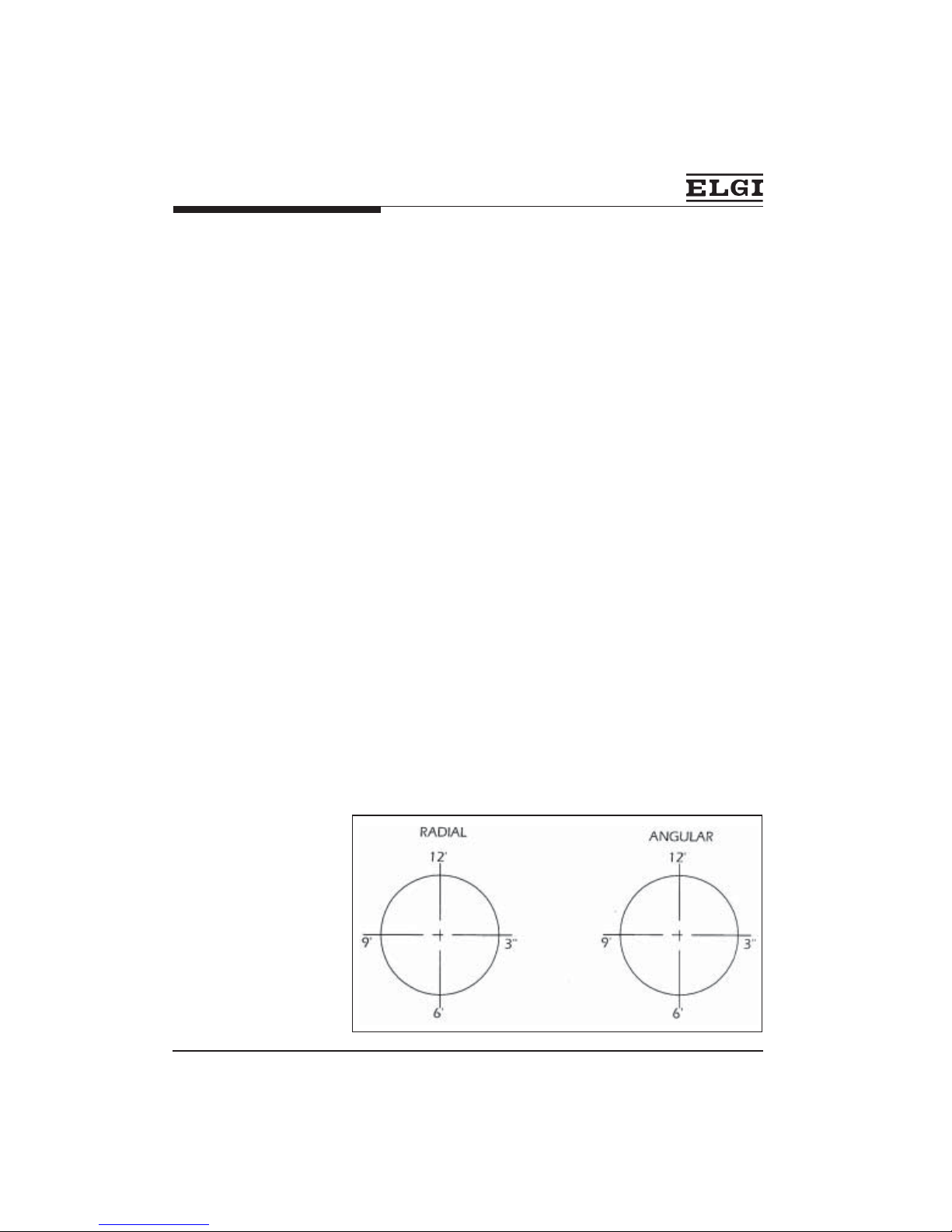

10. Take radial / angular readings at 12, 3, 6, 9 ‘O’ clock position record as

follows

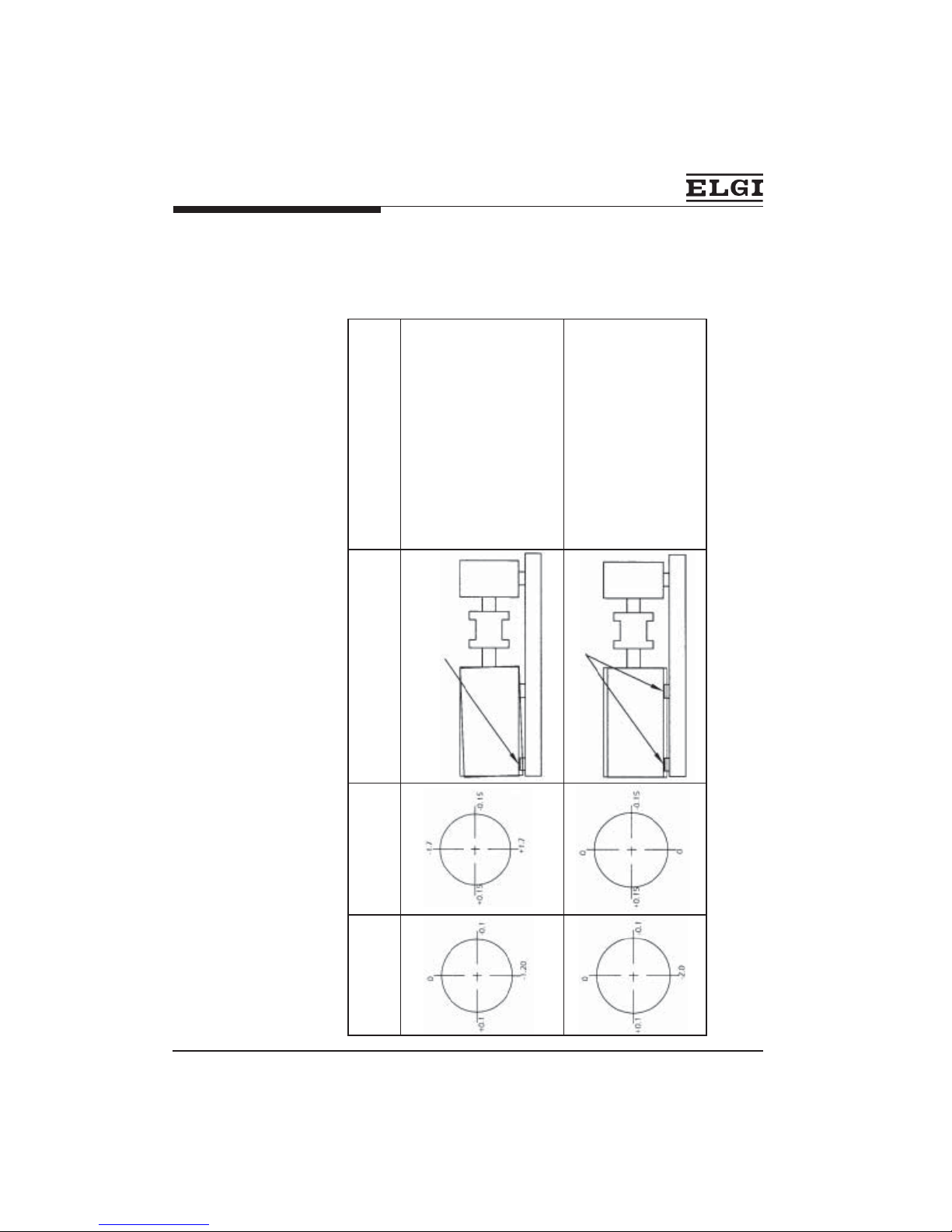

11. Sample reading for interpretation - radial allowable limit - 0.85 mm (TIR)

Disc coupling assembly procedure

18

Disc coupling assembly procedure

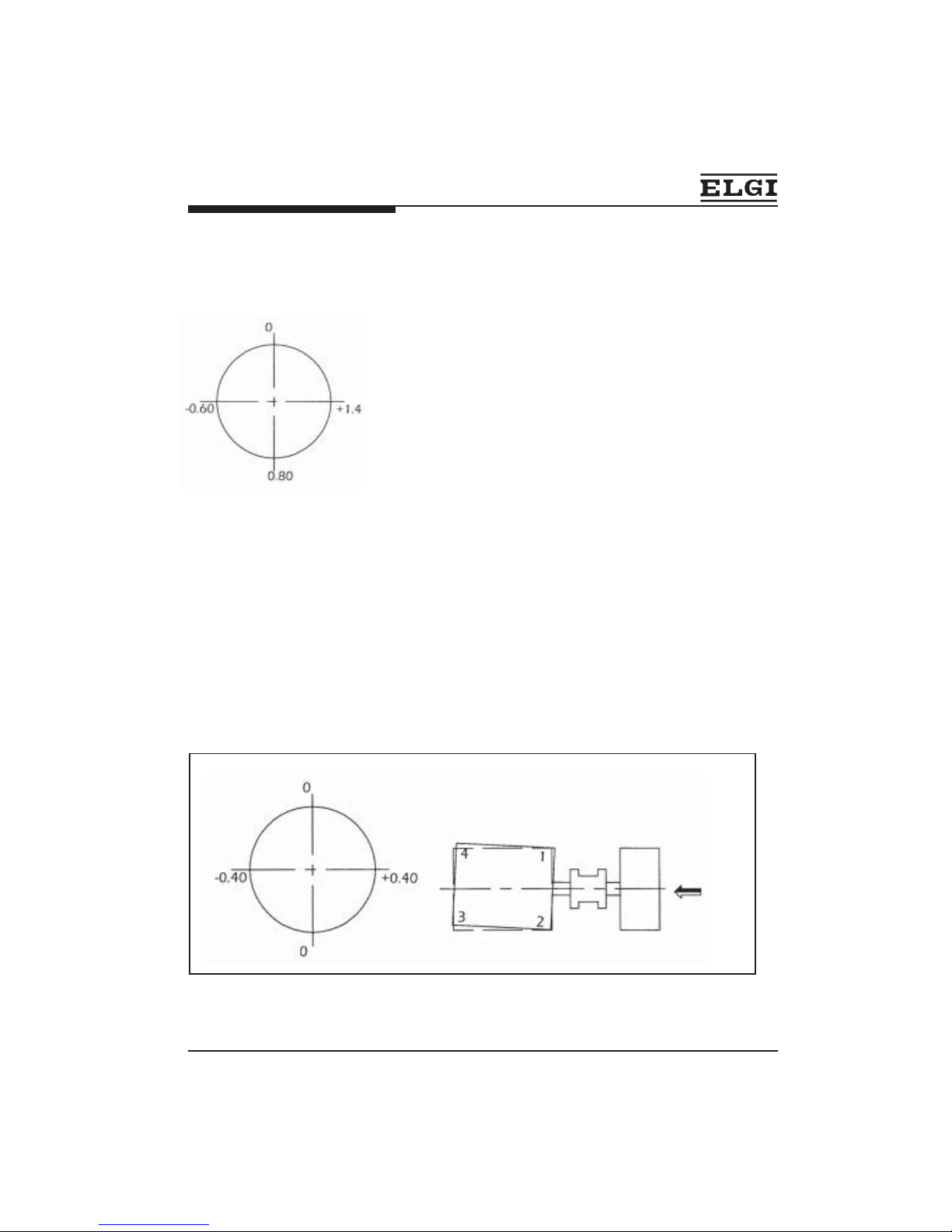

INTERPRETATION

These reading confirm the following

1. Motor axis lower than compressor

axis by 0.80 (TIR) i.e., by 0.40 radially

2. Motor is shifted radially by 1.4mm

(TIR)

CORRECTIVE ACTION

a. To adjust the vertical shift (0.8), loose motor foundation bolts add 0.4mm

shims bellow all 4 legs of motor

b. To adjust the horizontal shift [-0.6+(+1.4)=2.0mm] shift motor by side

screws towers left, by keeping a close watch on dial gauge reading till

dial gauge reading reduce to +0.4

c. After above activities, tighten the motor foundation bolts fully, and again

take dial gauge reading for radial.

d. The allowable limit for radial is 0.85 (TIR) as such plaese follow above

procedure till the reading are within limits.

13. Sample reading for interpretation - angular.

Reading taken

from this view

Allowable limit - 1.7mm (TIR) at

Ø 300

This reading confirm the following motor is

tilted as per figure bellow

19

Disc coupling model assy instructions

CORRECTIVE ACTION

a. It’s required to rotate the motor towards left by keeping the bolt no ‘1’

fixed, loosing bolt no 2,3&4 and by pushing the side screw at bolt

number 4.

b. Shift motor by side screws towers left by keeping a close watch on dial

gauge reading till dial gauge reading.

c. After above activities, tighten the motor foundation bolts fully, and agian

take dial gauge reading for angular.

d. The allowable limit for radial is 1.7mm at

Ø 300 (TIR) as such please

follow above procedure till the reading are within limits.

e. Once axial /angular/radial readings are brought within tolerances (i.e.,

25% of the tolerance mentioned on the coupling drawing) fix all the

foundation bolt and tighten all coupling bolts to the required

torque (33 N-m).

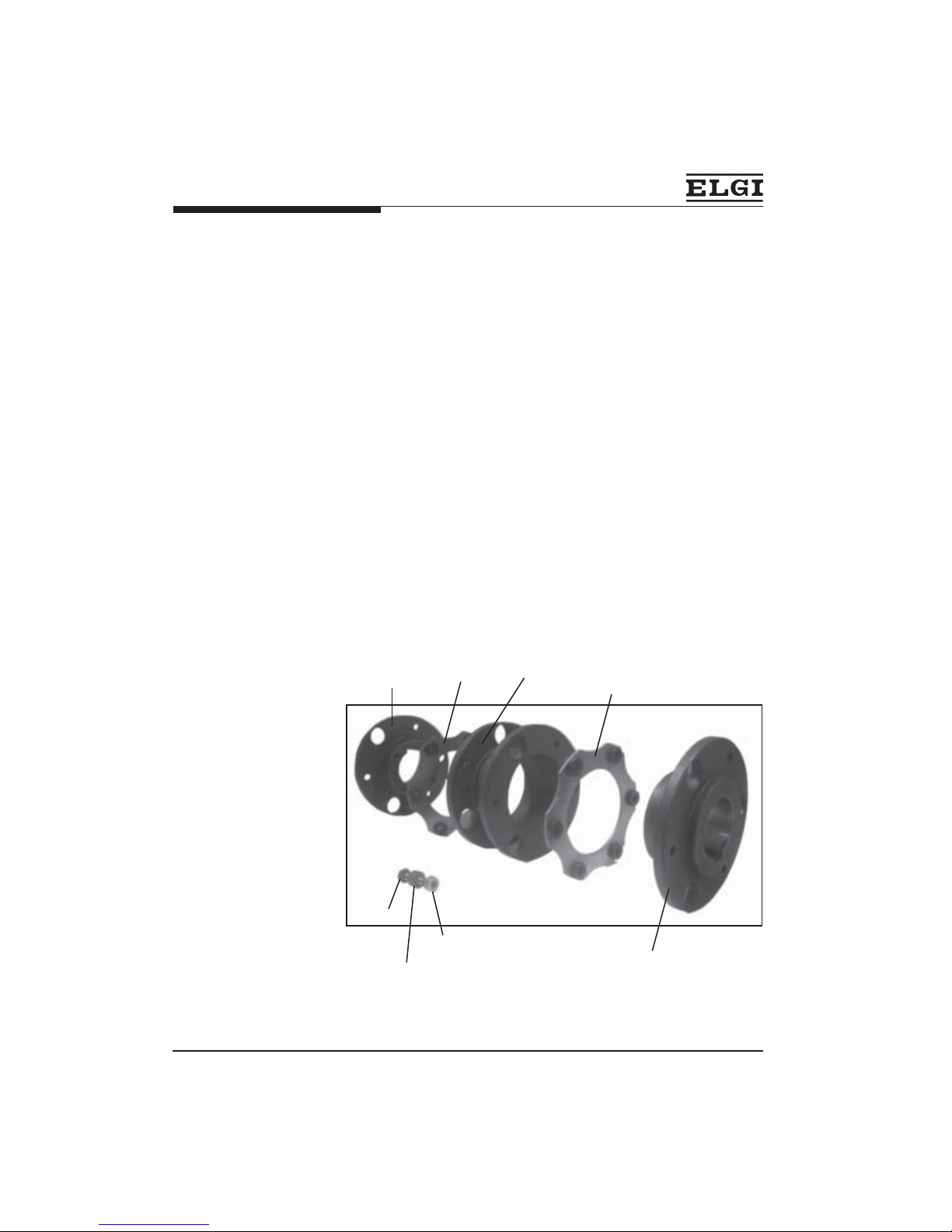

Hub motor side

Disc pack

SpacerDisc pack

Hub compressor side

Hex nut

Hex bolt

Over load washer

20

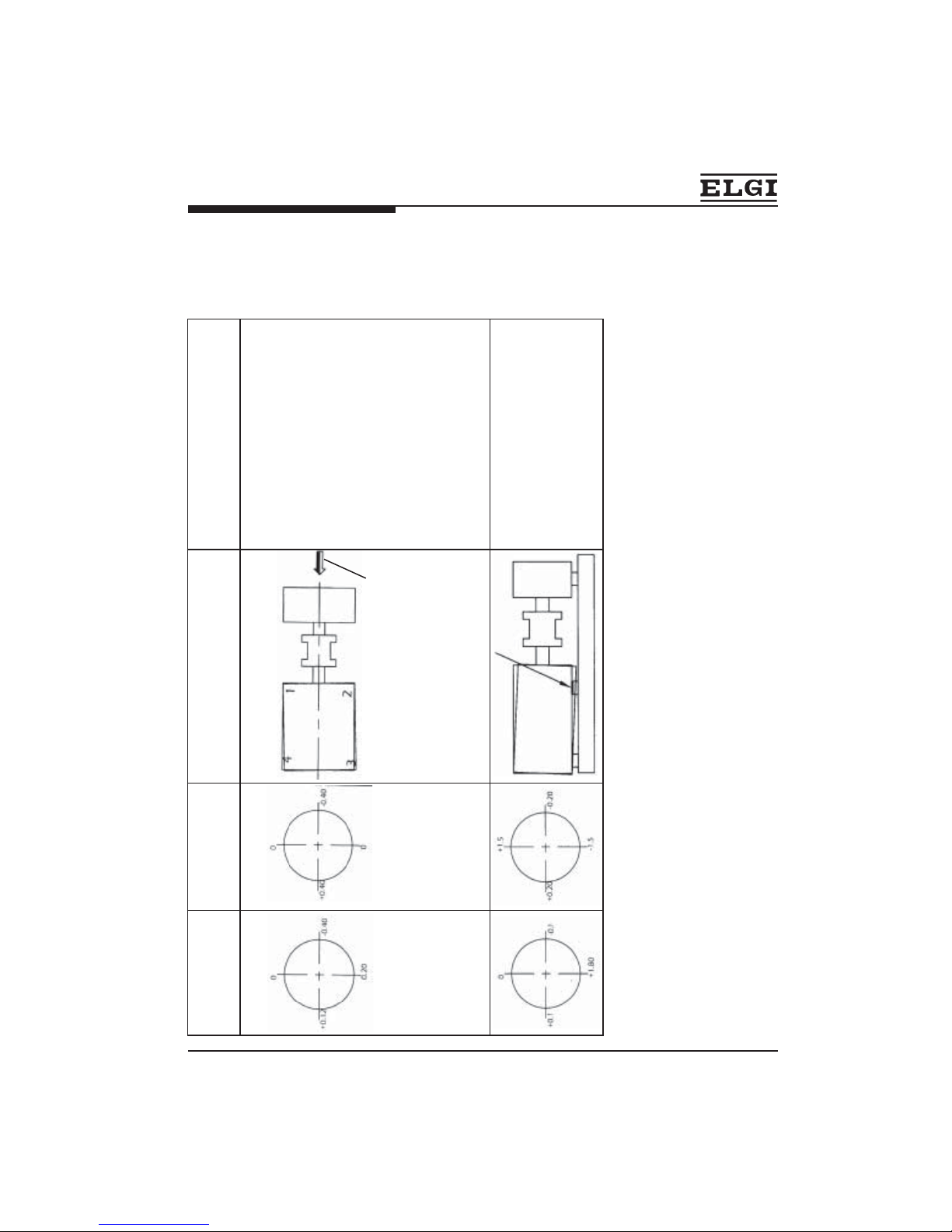

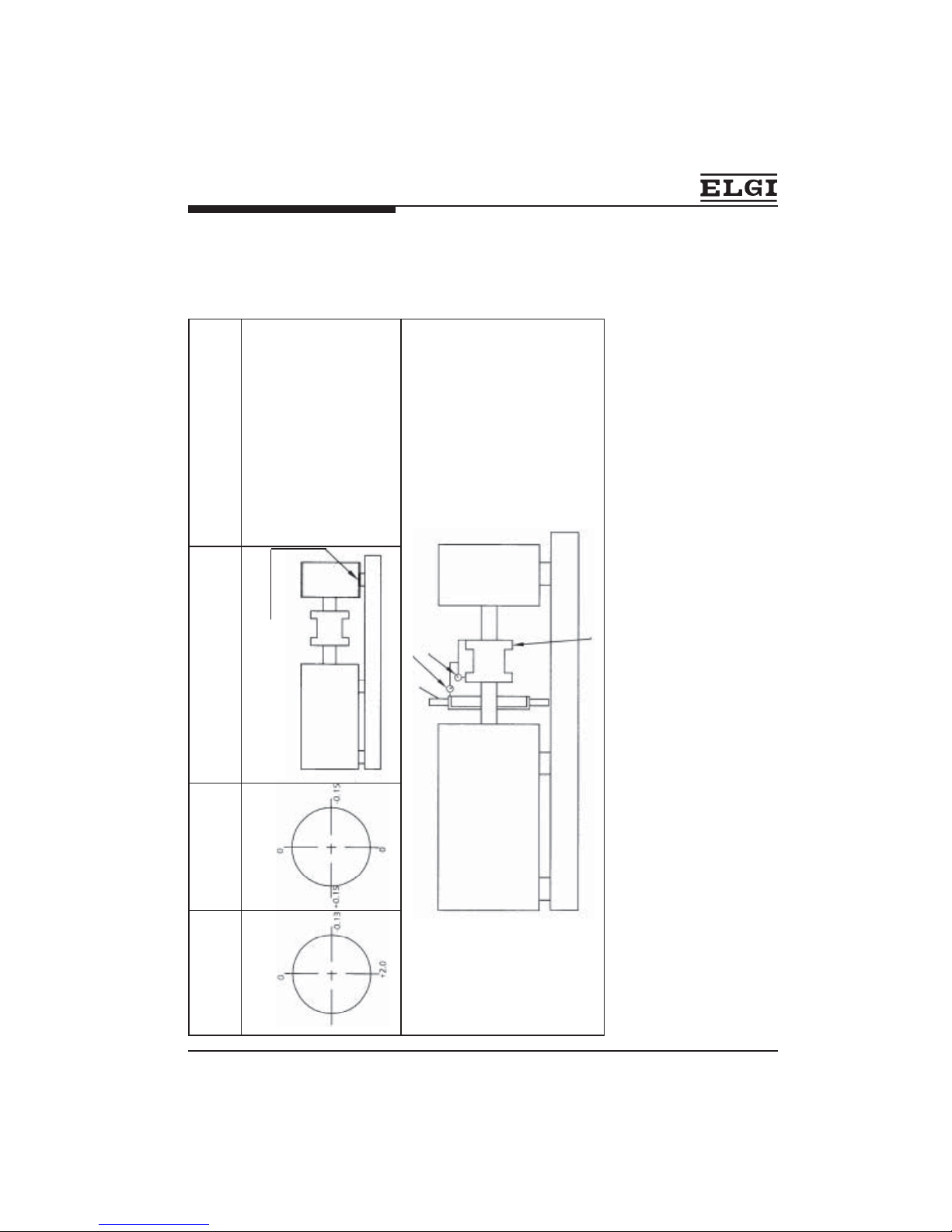

Radial sample

readings

Angular sample

readings

Motor position as per radial

reading

Remarks

Reading taken

from this view

CORRECTIVE ACTION

1. Vertical shift (0.2 TIR) is within the limit

no need to add shims.

2. Horizontal shift within the limit

[+0.12+(-0.4)=0.52mm] still you can

adjust the misalignment. To adjust shift

motor by side screws towers right, by

keeping a close watch on dial gauge

reading till dial gauge reading reduces

to +0.26

3. To adjust the angular shift it’s required

to rotate the motor towards left by

keeping the bolt no ‘2’ fixed, loosing

bolt no1,3&4 and by pushing the side

screw at bolt number 3, keeping a close

watch on dial gauge reading till dial

gauge reading reduces to ‘0’.

Add shim here

1. To adjust angular (1.5) and radial shift

(1.8 TIR), add shims at front foot.

21

1. To adjust angular (1.7) and radial

shift (1.2 TIR), add shims at rear

foot.

Radial sample

readings

Angular sample

readings

Motor position as per radial

reading

Remarks

add shim here

add shim here

1. To adjust radial shift (2.0 TIR),add

0.5 shims at front and rear foot.

22

1. To adjust radial shift (2.0 TIR),

add 0.5 shims at compressor rear

foot.

Disc coupling model assy instructions

Radial sample

readings

Angular sample

readings

Motor position as per radial

reading

Remarks

+0.1

add shim here

FAN

MOTOR

COMPRESSOR

COUPLING

DIAL GAUGE TO MEASURE ANGULAR READING

DIAL TO MEASURE RADIAL READING

Dial gauge mounting arrangement

23

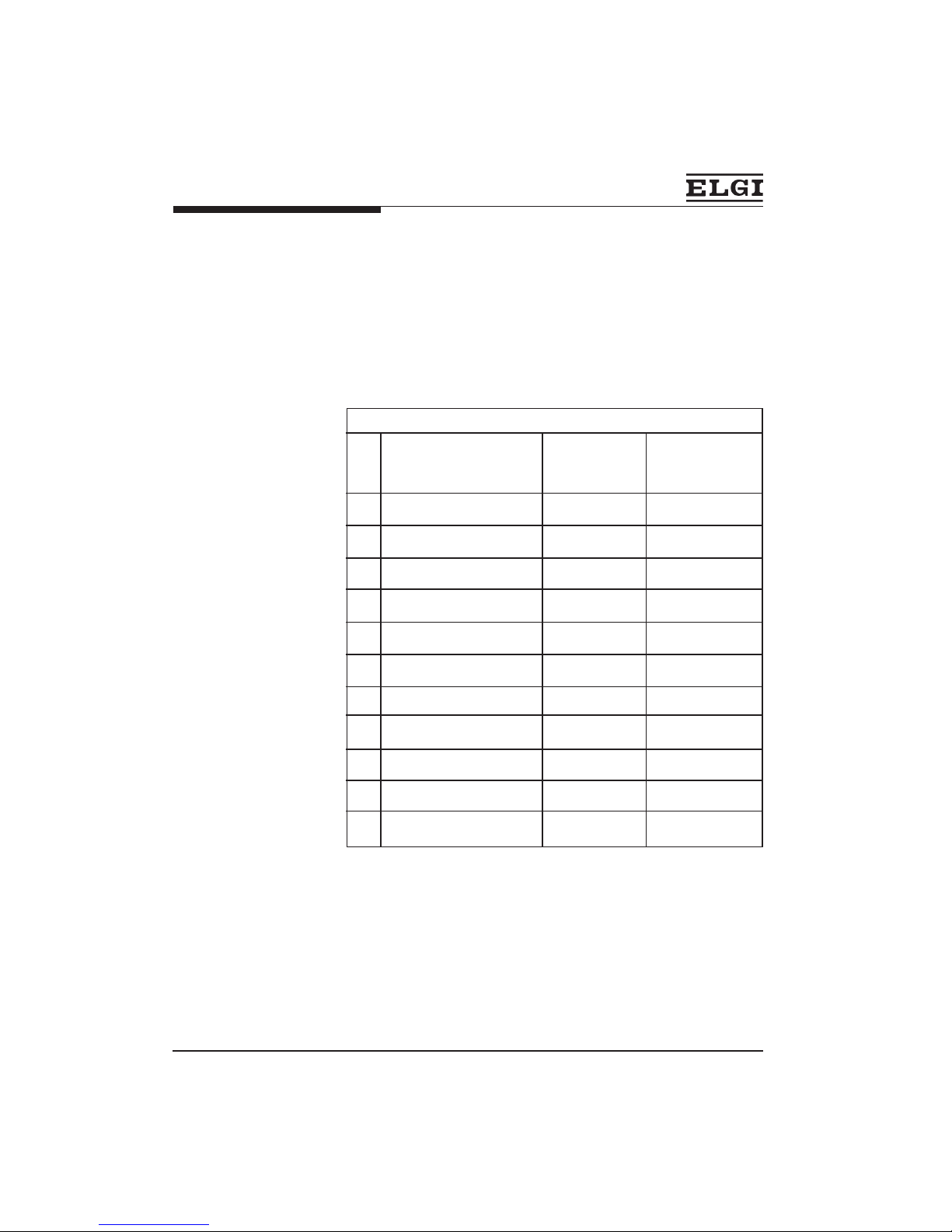

The following chart gives the tightening for various fasteners used in the

compressor.

SI.

No.

Location Thread size

Tightening

torque Values are

in N-m

1. End cover Free-end M8 30 N-m

2. End cover Fly-end M8 30 N-m

3. Crankcase to base M12 50 N-m

4. Motor to base M12 50 N-m

5. Crankcase to Cylinder M12 50 N-m

6. Cylinder to head M12 50 N-m

7. Pipe flange joints M12 50 N-m

8. Pipe flange joints M10 30 N-m

9. Disc coupling bolt M8 33 N-m

10. Drain plug 3/8" BSP 30 N-m

11. Dipstick ½" BSP 35 N-m

Torque chart

Model : TRC 1000MN - UG

24

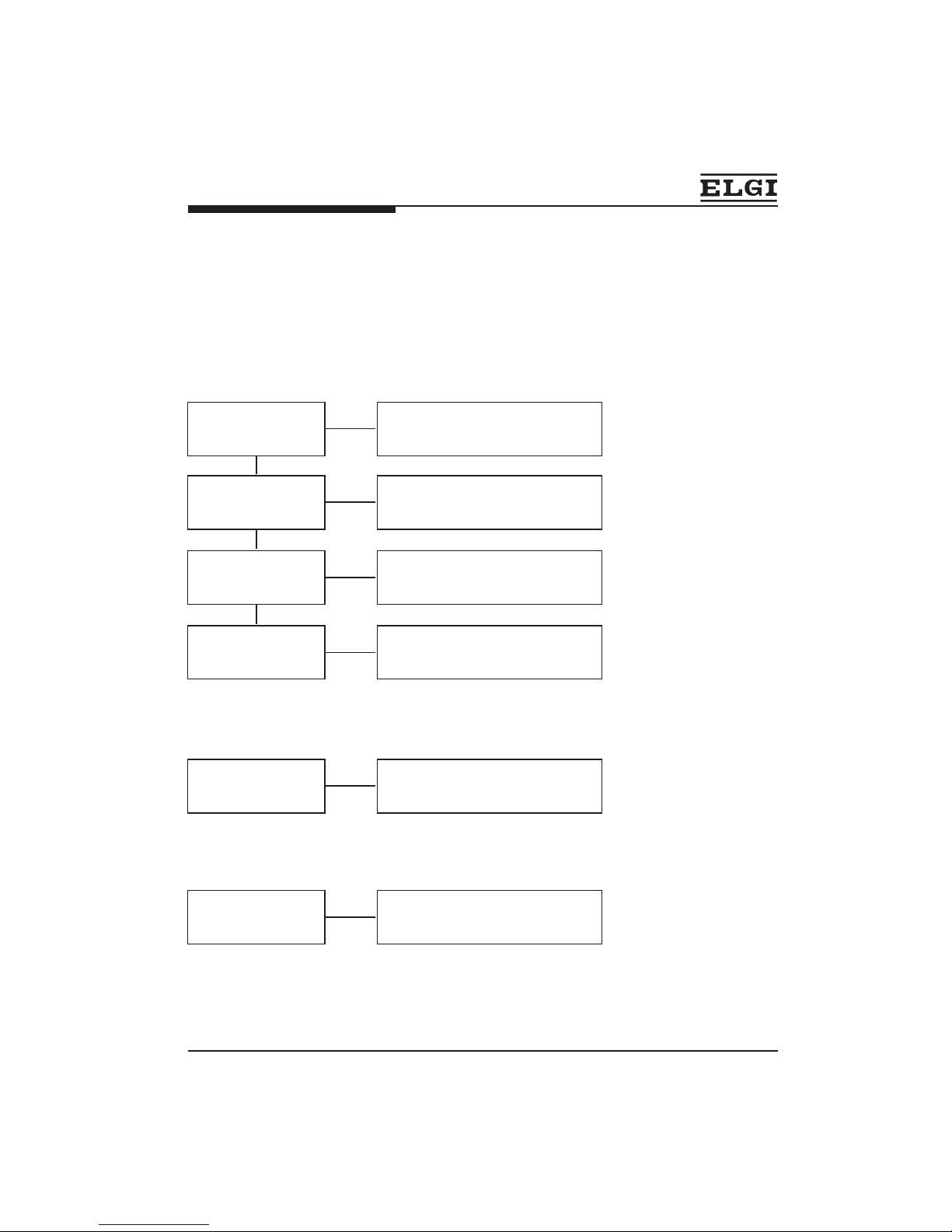

Troubleshooting

Problem : Pressure build time excessive

Check Remedy

Suction air filter is

clogged

Increase frequency of cleaning.

Pipe line leaking

Increase frequency with more level in

periodic check of oil.

Disc valves defective .

Carbon deposits too

much

Remove cylinder head and the disc

valves, decarbonisation

should be done.

Piston rings worn out

Check the ring gap, if required

change the rings.

Problem : Low pressure safety valve operates though the

specified pressure is not reached

Check Remedy

safety valve is not

functioning properly.

Check the safety valve components

for correctness & reset to

recommended rating.

Problem : LP safety valve operates during compressor

running

Check Remedy

Disc valve in the HP

cylinder not functioning

properly.

Check the disc valve components,

clean the dust if any and rectify the

defect.

ä ä ä

ä

ä

ä

ä

ä

ä

25

Troubleshooting

Problem : Abnormal noise and knocking of

compressor

Check Remedy

Connecting rod &

Crankshaft assembly

defective.

Journal bearings are

worm out.

Gudgeon pin loose in

piston

crankshaft assembly should be

reconditioned

Change the bearings.

Change piston and check for

lubrication

Disc valve is defective

Coupling is wornout

(Loose on the bore)

Key of the compressor

and motor loose.

Check and if necessary replace the

parts required.

Check the coupling hubs & change

if required.

Replace with correct size key.

Problem : Compressor overheating

Check Remedy

Dirty oil Oil, level low

Change oil, Fill correct grade of oil

upto maximum level. (SERVO 150)

Breather not working

Open, clean and refit after checking.

ä ä ä ä ä ä

ä

ä

ä

ä

ä

ä

ä

ä

Loading...

Loading...