Static electricity meter

GAMA 100

G1B.xxx

User manual

Version 2.3b

(G1BEN23b)

“ELGAMA – ELEKTRONIKA” Ltd., Lithuania 2016

“ELGAMA-ELEKTRONIKA”

Static electricity meter

GAMA 100

G1B.xxx

USER MANUAL

"ELGAMA-ELEKTRONIKA" Ltd.

2 Visorių str.

LT-08300 Vilnius

Ph.: +370 5 2375000

Fax: +370 5 2375020

E-mail: info@elgama.eu

REVISION HISTORY

Version Date Comments

1.0 2010-07-19 First release

1.1 2010-09-20 Information update

1.2 2011-09-01 Description of functional possibility added (Internal mains Relay, Shunt and

RS485 interface)

1.3 2012-01-04 Synchronization of internal clock (RTC) and control algorithm of internal

main relay was added

1.4 2012-05-14 Description of functional possibility added (current measurement in neutral

and Wired M-Bus interface was added)

1.5 2012-11-12 Control algorithm of Internal main relay by specified time and date, and by

current over limit was added. Encryption and Authentication.

2.0 2014-03-07 Description of internal PLC modem and firmware upgrade functionality was

added.

2.1 2014-04-29 Description of internal PRIME PLC modem (modification H2) and firmware

upgrade functionality was added.

2.2 2015-03-04 Tariff program update. LCD list updated and removed inaccessible

features. Bi-stable internal relay functionality updated.

2.2a 2015-04-18 New modification of optional LCD was added. Wireless M-Bus was added.

2.2b 2015-08-21 Description of internal PLC modem (modifications H3, H4), THD

measurement and Second Load Profile (Network profile) was added

2.3a 2015-08-25 DLMS/COSEM protocol Logical name (LN) referencing, non-transparent

meter case and Extended LCD was added

2.3b 2016-03-04 Information about power consumption of meter with external power supply

for modem was added. Bi-stable internal relay functionality updated.

Wireless MBus interface was added. Meter status on LCD update

S

TATIC ELECTRICITY METER

GAMA 100. U

SER MANUAL

Contents

Contents .................................................................................................................................................................. 5

About this document ................................................................................................................................................ 8

1 Safety .............................................................................................................................................................. 8

1.1

Safety requirements ............................................................................................................................... 8

1.2

Transportation and storage rules ........................................................................................................... 8

1.3

Prevention and elimination of malfunctions............................................................................................ 9

1.3.1 Exterior inspection ............................................................................................................................. 9

1.3.2 Inspection of connection and parametrization constants ................................................................... 9

1.3.3 Procedure of meter returning to manufacturer ................................................................................... 9

1.3.4 Proper disposal of product ................................................................................................................. 9

2 Designation ...................................................................................................................................................10

3 Meter modifications .......................................................................................................................................11

3.1

Modifications ........................................................................................................................................11

3.2

Technical specifications .......................................................................................................................11

4 Functional possibilities ..................................................................................................................................12

4.1

Current, voltage, frequency ..................................................................................................................12

4.2

Additional functions ..............................................................................................................................13

4.3

Sealed button functions ........................................................................................................................13

4.4

Backup power source ...........................................................................................................................14

4.5

Communication, inputs/outputs ............................................................................................................14

4.6

Voltage and current circuit separation ..................................................................................................15

4.7

Internal bi-stable mains Relay ..............................................................................................................15

4.8

LCD options ..........................................................................................................................................15

4.9

Internal PLC modem ............................................................................................................................15

5 Construction ..................................................................................................................................................16

5.1

Case .....................................................................................................................................................16

5.2

Nameplate ............................................................................................................................................16

5.3

Terminal block ......................................................................................................................................17

5.4

Operation principle ...............................................................................................................................18

5.4.1 Measurement module ......................................................................................................................18

5.4.2 Signal conversion .............................................................................................................................18

5.4.3 Micro-controller ................................................................................................................................18

5.4.4 Non-volatile memory ........................................................................................................................18

5.5

Display (LCD) .......................................................................................................................................18

5.5.1 Default LCD (Option #1) ..................................................................................................................19

5.5.2 Optional LCD (Option #2) ................................................................................................................20

5.5.3 Extended LCD (Option #3) ...............................................................................................................21

5.6

Internal clock ........................................................................................................................................22

5.6.1 Synchronization of internal clock (RTC) ..........................................................................................22

5.7

Sliding voltage link ................................................................................................................................23

6 Communication .............................................................................................................................................23

6.1

Optical communication interface ..........................................................................................................23

6.2

Electrical interface ................................................................................................................................23

6.3

Controller MCL 5.XX with internal GSM/GPRS modem ......................................................................24

6.4

PLC modem .........................................................................................................................................25

6.4.1 Internal PLC modem ........................................................................................................................26

6.5

Wired M-Bus module ............................................................................................................................26

6.6

Wireless M-Bus interface .....................................................................................................................27

6.7

Plug & Play ...........................................................................................................................................27

6.8

Outputs/Inputs ......................................................................................................................................27

6.8.1 Optical test output (red LED) ...........................................................................................................27

6.8.2 S0 outputs ........................................................................................................................................27

6.8.3 Relay output .....................................................................................................................................27

6.9

Power supply ........................................................................................................................................28

6.9.1 Power supply for external modem ...................................................................................................28

6.10 Push buttons ........................................................................................................................................28

6.10.1

Scroll push button and optical scroll key .....................................................................................28

6.10.2

Sealed push-button .....................................................................................................................29

7 Data registers ................................................................................................................................................29

7.1

Energy registers ...................................................................................................................................29

7.2

Demand registers .................................................................................................................................30

5

7.3

Maximum demand registers .................................................................................................................31

8 Data profiles ..................................................................................................................................................31

8.1

Billing profile .........................................................................................................................................31

8.2

Load profile ...........................................................................................................................................33

8.3

Second load profile ...............................................................................................................................34

8.4

Wired M-Bus load profile ......................................................................................................................34

8.5

Event log...............................................................................................................................................34

8.5.1 Power failure (outage) event log ......................................................................................................35

8.5.2 Voltage swell (over-voltage) event log .............................................................................................35

8.5.3 Voltage sag (under-voltage) event log .............................................................................................35

8.5.4 Event log of internal mains relay ......................................................................................................35

8.5.5 Power over-limit event log ................................................................................................................36

8.5.6 Reverse current flow event log ........................................................................................................36

8.5.7 Over-current event log .....................................................................................................................36

8.5.8 Neutral current balance event log ....................................................................................................37

8.5.9 Magnetic field influence event log ....................................................................................................37

8.5.10

Opening of meter cover event log ...............................................................................................37

8.5.11

Opening of terminal cover event log ............................................................................................37

8.5.12

Clock change (setting) event log .................................................................................................37

8.5.13

Parameterisation (Parameter change) event log .........................................................................38

8.5.14

Security failure (failed authentication) log ...................................................................................38

8.5.15

Meter (internal) error event log ....................................................................................................39

8.5.16

Tariffs event log ...........................................................................................................................39

8.5.17

Load profiles reset log .................................................................................................................39

8.5.18

Firmware update event log ..........................................................................................................39

9 Data monitors ................................................................................................................................................39

9.1

Demand monitor ...................................................................................................................................39

9.2

Current monitor ....................................................................................................................................40

9.3

Over-voltage monitor ............................................................................................................................41

9.4

Under-voltage monitor ..........................................................................................................................41

10 Tariff program ................................................................................................................................................42

10.1 Day tariff programs ...............................................................................................................................42

10.2 Week tariff program ..............................................................................................................................43

10.3 Tariff seasons .......................................................................................................................................43

10.4 List of special days ...............................................................................................................................43

10.5 “Emergency” tariff .................................................................................................................................44

10.6 Tariff timers ..........................................................................................................................................44

11 Data reading ..................................................................................................................................................44

11.1 Reserved-automatic (RA) display sequence ........................................................................................47

11.2 Main automatic (MA) display sequence ...............................................................................................48

11.3 Main manual (MM) display sequence ..................................................................................................48

11.4 Indication of abnormal states on LCD ..................................................................................................48

11.4.1

Internal meter errors ....................................................................................................................48

11.5 Data reading via communication interfaces .........................................................................................49

12 Parametrization .............................................................................................................................................49

13 Data protection ..............................................................................................................................................51

13.1 Physical protection ...............................................................................................................................51

13.2 Software protection ..............................................................................................................................51

13.2.1

Data access security ...................................................................................................................51

13.2.2

Passwords ...................................................................................................................................51

13.2.3

Encryption and Authentication .....................................................................................................52

13.2.4

Firmware/hardware identifiers .....................................................................................................52

13.2.5

User’s identifiers ..........................................................................................................................52

13.2.6

Blocking of optical communication interface ...............................................................................52

13.2.7

Parameterization ID .....................................................................................................................53

13.2.8

Event log, security alerts .............................................................................................................53

13.3 Firmware upgrade ................................................................................................................................53

14 Internal bi-stable main relay ..........................................................................................................................54

14.1 Action “disconnect by remote control command” .................................................................................55

14.2 Action “disconnect by contractual power exceeded” ............................................................................55

14.3 Action “disconnect by phase current limit exceeded” ...........................................................................56

14.4 Action “disconnect by swings of network voltage” ...............................................................................57

14.5 Action “allow to connect by remote control command” ........................................................................58

6

14.6 Action “allow to connect by end of billing period” .................................................................................58

14.7 Action “allow to connect by end of event” ............................................................................................59

14.8 Action “connect by Menu button” .........................................................................................................59

14.9 Action “connect by the mains switch of the internal electrical installation” ..........................................59

15 Installation .....................................................................................................................................................60

Annex A. Dimensions of the meter ........................................................................................................................61

Annex B. Screw torques used in G1B meters .......................................................................................................62

Annex C. List of data objects .................................................................................................................................63

7

About this document

This User Manual presents a description of a static electricity meter GAMA 100 (G1B.xxx)

and its instruction. Please read this instruction prior to the use of the meter. The

manufacturer does not give any guaranty in case meter is damaged during the exploitation

that contravenes with the instructions and requirements of safety stated in the manual and

meter passport.

The manufacturer is not responsible for the loss in case the meter is parameterized without

accordance with the instructions and recommendations presented in the software description

as well as with tariff order defined by the State. It does not carry the responsibility for the

unprofessional acts of responsible persons in case of full or partial loss of billing data.

User manual presents the description of all possible characteristics, functions and auxiliary

outputs of electricity meter. A concrete meter may not comply with all characteristics

introduced in this manual; however, meter passport defines a precise meter configuration,

possibilities and auxiliary outputs as well as a concrete connection scheme.

The manufacturer has a right to change the information presented in this manual without the

warning. In addition, any copying, transmission and publication of full or partial meter

documentation is forbidden without a written permission of “ELGAMA-ELEKTRONIKA” Ltd.

1 Safety

1.1 Safety requirements

1. Installing, uninstalling, parameterization and verification can be performed only by

authorized organizations that have qualified technicians. Only qualified persons should

install meters.

2. Meter’s connection or disconnection from network should be done when voltage in the

network is turned off. A protection from accidental network voltage connection must be

established.

3. No accessories can be hung on a meter, it is forbidden to hit or strike meter’s case.

4. Precautions must be taken in battery changing procedure: 1) meter has to be

disconnected from electricity network, a protection from accidental network voltage

connection must be assured; 2) use pincers or similar instruments to change battery

(connection/disconnection of a plug).

1.2 Transportation and storage rules

1. Prior to the usage meter must be kept in a closed room in a transportation packing,

where the temperature ranges from 5°C to 40°C and average area humidity is up to

80% when temperature being 25°C. The room must be without harmful gas or steam.

Meter must be kept and exploited in premises protected from dust, aggressive vapors

and gas.

2. Unpacked meters can be kept only in repair workshop. The temperature must range

from 10°C to 35°C, average area humidity must not exceed 80% when temperature

being 25°C.

3. During wintertime meters must be kept in a heated room for 6 hours or more, before

they are used.

4. Meters are to be transported only in closed vehicles (carriage, container, hold). Shake

acceleration is to be up to 30m/s², 80-120 strikes per minute. The temperature must

range from -40°C to +70°C, average area humidity must not exceed 98% when

temperature being 35°C.

8

1.3 Prevention and elimination of malfunctions

If suspected that meter works improperly, the following actions should be performed:

1.3.1 Exterior inspection

Before applying voltage to the meter makes sure its case has no mechanical damages, there

are no signs of overheating, and all wires are properly connected.

Do not plug a meter into network if it is mechanically damaged. This can cause

staff injuries and destroy meter as well as other equipment!

Before switching on network voltage, it is necessary to check if sliding voltage

link is connected (see chapter 5.7 Sliding voltage link).

1.3.2 Inspection of connection and parametrization constants

Installing, uninstalling, parametrization and verification can be performed only by authorized

organizations that have qualified technicians. After plugging a meter into electric network

technician should check whether date and time are correct, whether meter shows right

energy direction, valid tariff time zone and calendar, tariff seasons.

1. If meter shows wrong date and time, a representative from the organization in charge of

the meter installation should be informed.

2. If LCD indicator shows a warning note ‘Er’, the meter should be uninstalled and passed

for repair works.

3. If energy direction is wrong, technician should check whether inputs are connected

properly to terminal block.

4. If meter calendar season, season time name or valid tariff time zone does not correspond

to real situation, meter’s parameterization data has to be checked and errors has to be

corrected by repeated meter’s parameterization.

1.3.3 Procedure of meter returning to manufacturer

In case malfunctions cannot be eliminated on the spot, the meter should be returned to the

manufacturer for repair or replacement. Meters on their return to manufacturer must have

their Passport with notices of organization in charge of their exploitation and short description

of meter’s malfunctioning.

1.3.4 Proper disposal of product

This sign indicates, that this product cannot be thrown out with any other

waste when its validity period is over if this sign is on the product or it is

included in product’s description. In order to prohibit possible harm for

environment and human health because of uncontrolled waste

elimination, please separate this product from other forms of waste, and

if it is possible use this product or its parts repeatedly in recycling

process. Home users can contact product manufacturer or local

administration for information about product utilization and recycling

without any harm to the environment. Enterprises must contact their own

providers to revise product’s validity terms and conditions stated in

purchase agreements. This product cannot be thrown out with any other

waste of different kind.

9

2 Designation

The static meter of direct connection GAMA 100 (G1B.xxx) is designated for measurement of

active or active and reactive electrical energy in alternate current networks. G1B meters can

measure active energy in both directions (+A and –A, as well as |A|) simultaneously and measure

reactive energy in directions (+R and -R), as well as in four quadrants (R1, R2, R3, R4)

simultaneously.

G1B.xxx meters can register maximum demand on daily and monthly bases, measure

instantaneous values as well as record load profile and event log.

Meters can be either single-rate or multi-rate. The rates are controlled by internal real-time clock.

G1B.xxx meters have S0 output(s) and optionally can have optical and electrical communication

interfaces for local and remote data transmission.

Meter G1B.xxx conforms to the following requirements of directives and standards:

- Directive 2004/22/EC of the European Parliament and of the Council of 31 March 2004 on

measuring instruments;

- Directive 2004/108/EC of the European Parliament and of the Council of 15 December 2004

on the approximation of the laws of the Member States relating to electromagnetic

compatibility and repealing Directive 89/336/EEC;

- EN 50470-3:2006 “Electricity metering equipment (a.c.) – Static meters for active energy

(class indexes A, B and C)”;

- EN 50470-1:2006 “Electricity metering equipment (a.c.) – General requirements, tests and

test conditions – Metering equipment (class indexes A, B and C)”;

- IEC 62053-21:2003 “Electricity metering equipment (a.c.) – Static meters for active energy

(classes 1 and 2)”;

- IEC 62053-23:2003 “Electricity metering equipment (a.c.) – Static meters for reactive

energy (classes 2 and 3)”;

- IEC 62052-11:2003 “Electricity metering equipment (a.c.) – General requirements, tests and

test conditions. Part 11: Metering equipment”;

- IEC 62052-21:2003 “Electricity metering equipment (a.c.) – General requirements, tests and

test conditions. Part 21: Tariff and load control equipment”;

- IEC 62054-21:2004 “Electricity metering equipment (a.c.) – Tariff and load control. Part 21:

Particular requirements for time switches”;

- IEC 62056-21:2002 “Electricity metering – Data exchange for meter reading, tariff and load

control. Part 21: Direct local data exchange”;

- IEC 529 “Degrees of protection provided by enclosures”

- IEC 61334-4-41 “Distribution automation using distribution line carrier systems – Part 4:

Data communication protocols – Distribution line message specification”

- IEC 62056-46 Data link layer using HDLC protocol;

- IEC 62056-53 DLMS/COSEM Application Layer;

- IEC 62056-61 DLMS/COSEM Obis code;

- IEC 62056-62 DLMS/COSEM Interface Classes.

- EN 13757-2:2005 Communication systems for and remote reading of meters - Part 2:

Physical and link layer;

- EN 13757-3:2005 Communication systems for and remote reading of meters - Part 3:

Dedicated application layer;

- EN 50065-1 Signalling on low-voltage electrical installations in the frequency range 3 kHz to

148,5 kHz -- Part 1: General requirements, frequency bands and electromagnetic

disturbances.

Note: Tables and Figures in this User manual may present measurement values and pulse outputs

in all possible energy and power directions. Actual number of measured values and pulse outputs

of a certain meter modification are indicated in meter passport.

10

XXX.

X

1 X

5 X

Accuracy class:

Reference voltage U

, V:

Operating voltage range, % from U

:

Reference I

(maximum I

) current, A:

Starting current, % from I

:

Reference frequency, Hz:

Power consumption, VA:

Meter constant, imp/kWh, imp/kva

rh:

Internal clock (IEC 62

052-21

, IEC 62054

-21):

Tariff module functions:

S0 outputs (IEC 62053

-

31):

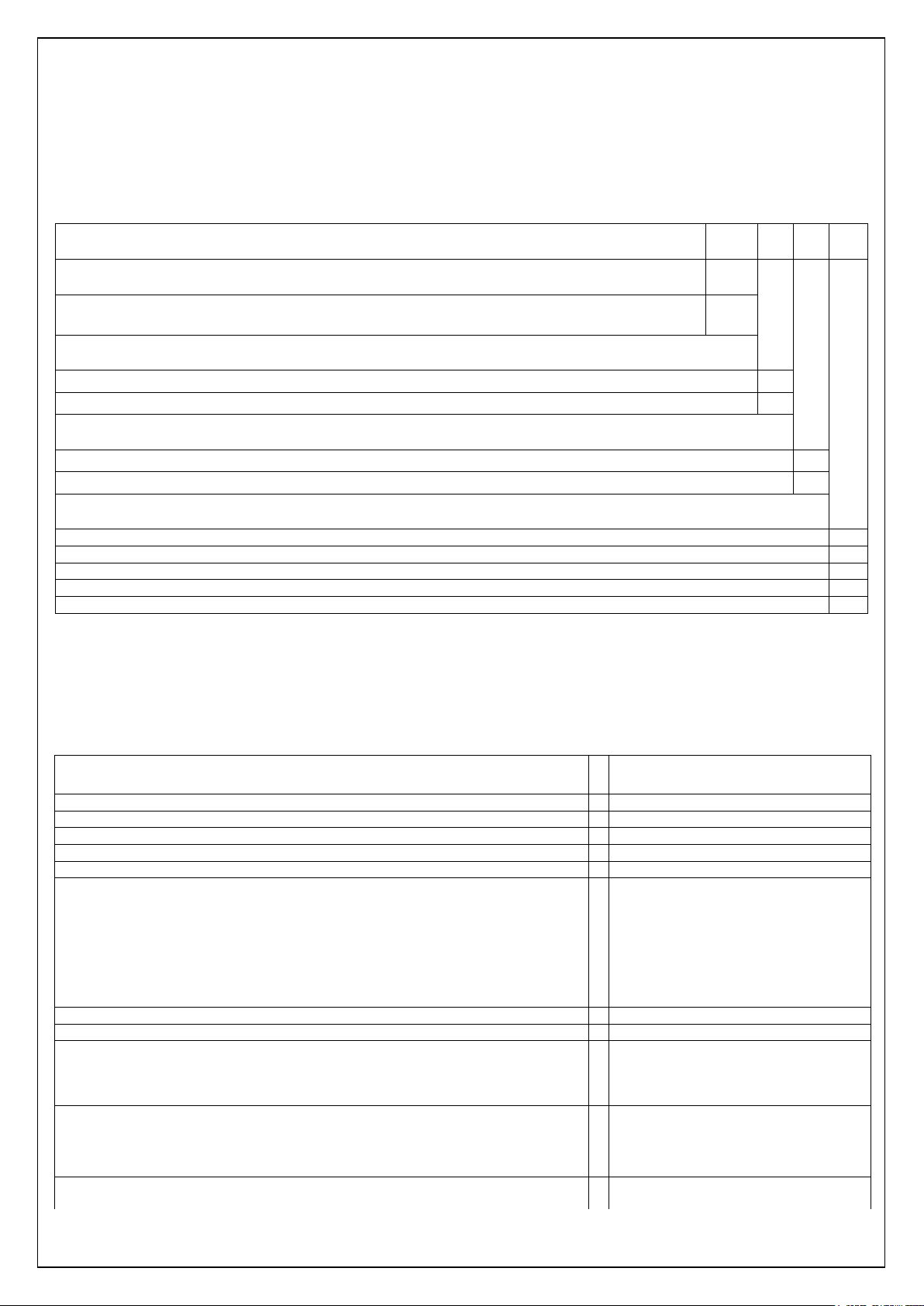

3 Meter modifications

3.1 Modifications

Meter G1B is multi-tariff meter (measures active and reactive energy).

Detailed explanation of meter modification is presented in Table 3-1.

Table 3-1 GAMA 100 meter modifications

Type explanation example:

Construction

G1B (LCD, multi-tariff, active energy or active and reactive energy, max demand, extended

functionality)

Accuracy class

A (EN 50470-3), 2.0 (IEC 62053-21) 0

B (EN 50470-3), 1.0 (IEC 62053-21) 1

Measurement circuits

1 elements, 2 wire 5

2 elements (current measurement in neutral), 2 wire 6

In/Imax, Iref/Imax

1:8 0

1:10 1

1:12 2

1:16 3

1:20 4

G1B.

G1B

2

Example: G1B.152 is G1B construction meter that conforms to the requirements of accuracy class B and 1.0. Meter is

designated for measurement of energy in 2 wire alternate current networks; it has 1 measurement element. It is directconnected meter with maximum current up to 60 A. Ratio of reference current and maximum current is 1:12.

3.2 Technical specifications

Table 3-2 Technical specifications

n

ref

Operation duration using only backup power supply (Li-ion battery) > 10 years

max

ref

Active energy measurement B (EN 50470-3), 1.0 (IEC 62053-21)

Reactive energy measurement 2.0 (IEC 62053-23)

n

In voltage circuits <1.0 VA (<0.5 W)

In current circuits < 0,05

Error < 0,5 s/24 h (T=23°C),

Backup power supply for clock Li-ion battery and/or supercapacitor

Number of energy tariffs Programmable (T1 T6)

“Emergency” tariff Programmable (T1 T6)

Number of maximum demand tariffs Programmable (M1 M6)

Data storage duration when voltage disconnected

Number 1

Output constant, imp/kWh (imp/kvarh) 50150000

See Table 4-2

-20... +15

See Table 3-1 and Table 4-2

0,4 (class B)

50

<4.0 VA (<1.3 W) with +5V power

supply for external modem

<10 VA (<1.0 W) with PLC module

<10 VA (<1.3 W) with PLC and wired

MBus modules

<10 VA (<2.2 W) with PLC and wireless

MBus modules

50150000

< 0,15 s/°C/24 h

>20 years

11

Relay output:

Internal mains relay:

Communication interfaces:

Isolation:

Magnetic field sensiti

vity

Protection against dust and water

Temperature range:

Mass, kg:

Dimensions, mm

Average service life

Code:

X X X.

FXX.

BX. PX. CXXX.

VX. RX. LX. HX

Reference current

Reference voltage

Reference frequency

F -

additional Functions

B -

sealed Button functions

P -

backup Power source

C -

Communication, I/O

V -

voltage and current circuit separation

R -

internal main relay

L -

LCD options

H –

internal PLC modem

Code:

X X X.

Reference current

Reference voltage

Reference frequency

Pulse duration, ms 30

Programmable (1 2)

Maximum commutation voltage, V 250

Maximum commutation current, mA 120

Bi-stable

Max switching current (Imax)

Max switching voltage (115% Unom)

Max switching power (1.15×Unom×Imax)

Mechanical endurance

Electrical endurance

Optical interface IEC 62056-21, DLMS/COSEM

Electrical interface – CL (20mA current loop) IEC 62056-21, DLMS/COSEM

RS485 IEC 62056-21, DLMS/COSEM

Wired M-Bus/ Wireless M-Bus EN 13757-2; EN 13757-3

Pulse voltage tests (IEC 60060-1) 6 kV (1,2/50 µs)

Alternating voltage tests 4 kV @ 50 Hz, 1 minute

Immunity against permanent magnetic fields

Immunity against electromagnetic HF fields

Operation:

For meters with battery and for meters without power backup source

For meters with supercapacitor

Storage, transportation: - 40 +70°C

with usual terminal cover

with special terminal cover for GSM/GPRS modem

Option #1 Option #2 Option #3

≤ 40A

≤265 V

≤10,6 kW

1×105

5×103

PLC EN 50065-1 (CENELEC A (3–95 kHz))

> 3.5 mT

≤ 300 mT (current sensor – shunt)

≤ 30 V/m (80 - 2000 MHz)

IP53 default

IP54 (optional)

- 40 +70°C (3K7)

- 25 +70°C

< 0,9

180 x 130 x 65 (see Figure A-0-1)

200 x 130 x 80 (see Figure A-0-2)

16 years

≤ 80A

≤265 V

≤21,2 kW

1×105

5×103

≤ 100A

≤265 V

≤26,5 kW

1×105

5×103

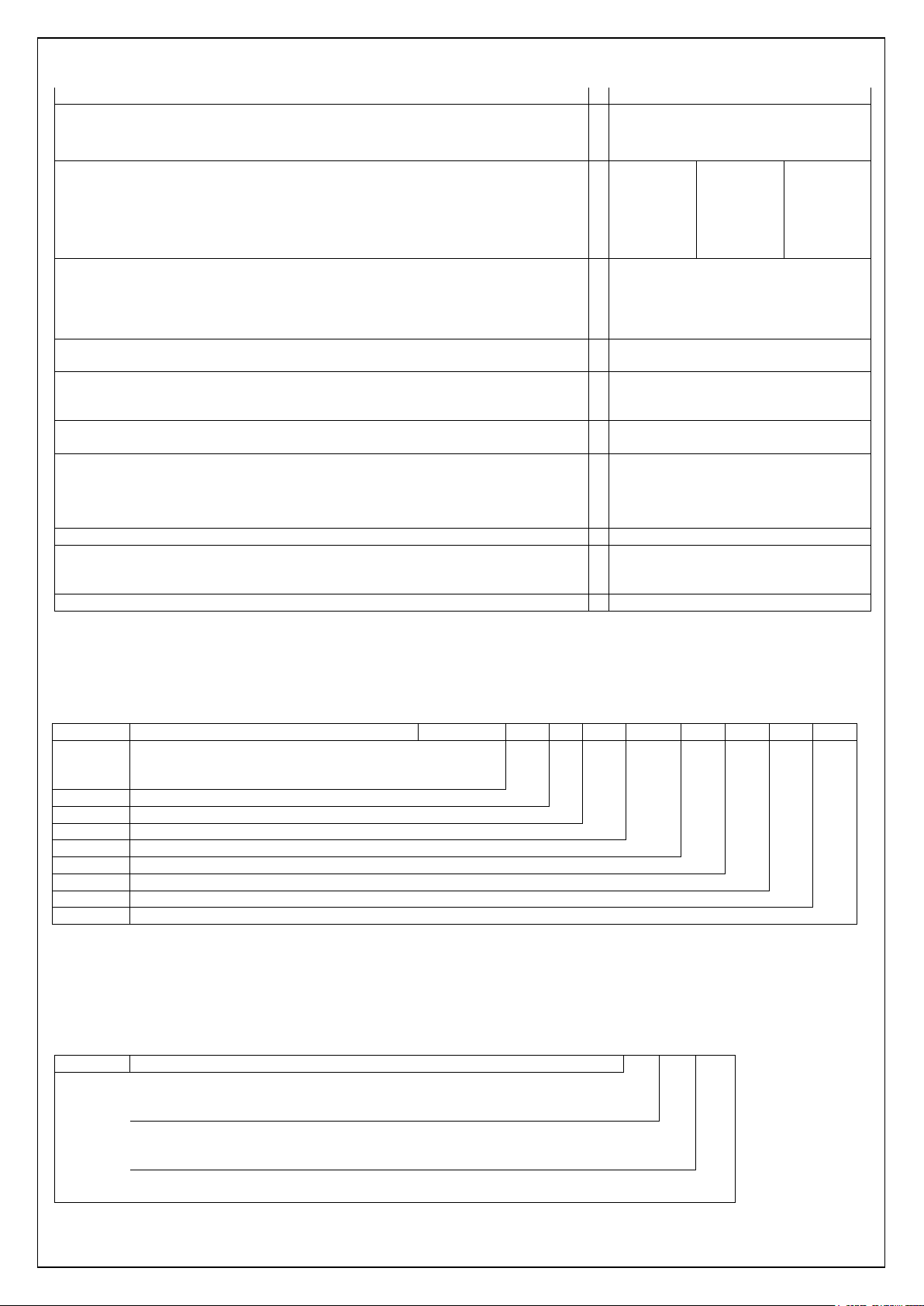

4 Functional possibilities

G1B meters can have different functional possibilities which are described below.

Table 4-1 Ordering code

Section No.

1

2

3

4

5

6

7

8

9

4.1 Current, voltage, frequency

G1B meters may differ in current, voltage and frequency. Choices are denoted with the first three

digits in ordering code and are listed in Table 4-2.

Table 4-2 Possible code choices for current, voltage and frequency

No.

Section 1

5 A 2

10 A 3

100 V, 120 V, 127 V 1

220 V, 230 V, 240 V 2

50 Hz 0

See chapter 4.1

See chapter 4.1

See chapter 4.1

See chapter 4.2

See chapter 4.3

See chapter 4.4

See chapter 4.5

See chapter 4.7

See chapter 4.8

See chapter 4.9

See chapter 4.6

12

F -

Energy measurement, instantaneous values, loa

d profiles

Code:

FX X.

Energy measurement

F3

F4

DLMS/COSEM protocol

-

8

B-sealed Button functions

Code:

BX.

4.2 Additional functions

Along with unidirectional and bidirectional active energies, G1B meters may measure reactive

energy and maximum demand, store registers of up to 16 billing periods in billing profile, measure

instantaneous values and record load profile. Choices for energy measurement and programmable

functions are denoted with letter “F” and two digits in ordering code and are listed in Table 4-3.

Table 4-3 Possible code choices for energy measurement, instantaneous values and load profiles

No.

Section 2

Billing and load profile, instantaneous values and maximum demand

Billing and load profile, instantaneous values and maximum demand, reactive energy

Short name (SN) referencing

Logical name (LN) referencing

Table 4-4 List of instantaneous values.

12.7.0 Instantaneous RMS voltage (V)

11.7.0 Instantaneous RMS current (A) in phase

15.7.0

16.7.0 Instantaneous active power ±P (kW)

3.7.0 Instantaneous reactive power +Q (kvar)

4.7.0 Instantaneous reactive power –Q (kvar)

13.7.0

14.7.0 Frequency (Hz)

91.7.0 Instantaneous RMS current (A) in neutral

12.7.124 Instantaneous THD for voltage

11.7.124 Instantaneous THD for current

Harmonics analysis is performed by using a digital band-pass filter, tuned to 50 Hz (narrow band).

Total Harmonic Distortion (THD) for current and voltage is calculated by formulas:

Wide band RMS values are measured up to 21st harmonics (21 × 50 Hz = 1050 Hz).

Maximum demand registration is explained in chapter 7.3. For more information about billing

profile refer to chapter 8.1. List of measured instantaneous values is presented in Table 4-4.

Instantaneous data can be readout via all available communication interfaces.

Please note: meters that do not contain reactive energy registers (Code F3), do not measure

instantaneous reactive power, as well as power factor cos(φ). For more information about load

profile refer to chapter 8.2.

Instantaneous active power |P| (kW)

cos ϕ

THD−=

I

22

II

NBWB

2

I

NB

THD−=

U

U

2

NB

22

UU

NBWB

IWB – RMS value of current, measured in wide frequency band;

INB – RMS value of current, measured in narrow frequency band (50 Hz);

UWB – RMS value of voltage, measured in wide frequency band;

UNB – RMS value of voltage, measured in narrow frequency band (50 Hz).

The sample rate is Fs = 2184.53 Hz (32768 Hz/15).

4.3 Sealed button functions

G1B meters may have sealed button, which may perform one of the functions described below.

Choices of sealed button functions are denoted with letter “B” and one digit in ordering code and

are listed in Table 4-5. More about button functions in chapter 6.10.2.

Table 4-5 Possible code choices for sealed button functions

No.

Section 3 Without Billing period reset B1

Communication unblock for parameterization B2

Billing period reset and communication unblock for parameterization B4

13

No. P -

backup Power source

Code:

PX.

C -

Communication, I/O

Code:

CX X X.

Optical and

electrical interfaces

Outputs/inputs

Control outputs

4.4 Backup power source

G1B meters may have different backup power sources. Backup power source choices are denoted

with letter “P” and one digit in ordering code and are listed in Table 4-6.

Table 4-6 Possible code choices for backup power source

Section 4 Without

Supercapacitor

Unchangeable battery

Changeable battery P3

Changeable battery and supercapacitor P4

Unchangeable battery and supercapacitor P5

P1

P2

Unchangeable battery is mounted on the top right corner of the PCB. Changeable battery is

mounted on the top right corner of the meter under the sealable battery cover and under silicone

protection. Battery cover with sealing option is available on the top right corner of both meters with

changeable and with unchangeable meter. Sealed button is placed under the cover. It is

accessible only when battery cover is opened.

Changing of battery:

• Ensure conditions for meter LCD to be turned-off (do not push scroll button or do not allow

to pass light to optical scroll key);

• Open changeable battery cover and remove silicone protection;

• Make ready new battery for old battery’s replacement;

• Disconnect old battery’s connector, remove the battery;

• Place new battery into old one’s location and connect plug to the corresponding meter

socket;

• Put in silicone protection and close the battery cover;

• After pushing scroll button, meter must display data. Appearance of data is a sign of correct

battery changing process.

4.5 Communication, inputs/outputs

G1B meters may have optical (see chapter 6.1) and electrical interfaces (see chapter 6.2). Meters may

have S0 outputs for transmission of information about measured energy (see chapter 6.8.2). G1B

meters may also have relay output (see chapter 6.8.3). Choices of communications, inputs/outputs are

denoted with letter “C” and three digits in ordering code and are listed in Table 4-7.

Table 4-7 Possible code choices for communications, inputs/outputs

No.

Section 5

Without interfaces C0

Optical interface C1

Optical and 20 mA “current loop” interface C2

Optical and RS485 interface C3

Optical, RS485 and M-Bus C6

Optical, M-Bus and RS485 (PLC duplication) C7

Optical and wireless M-Bus (868 MHz) C9

Optical and wireless M-Bus (169 MHz) CA

Optical and USB host CB

Without 0

S0 out (A) 1

Without

Relay output 1

Two relay outputs 2

0

14

V -

voltage and current circuit separation

Code:

VX.

R -

internal bi

-

stable mains relay

Code:

RX.

L -

LCD options

Code:

LX.

H –

Internal PLC modem

Code:

HX

4.6 Voltage and current circuit separation

G1B meters may be manufactured with or without voltage and current circuit separation. Choices

of circuit separation denoted with letter “V” and one digit in ordering code and are listed in Table

4-8.

Table 4-8 Possible code choices for circuit separation

No.

Section 6 The voltage and current circuits separated by sliding voltage link The voltage and current circuit not separated V1

4.7 Internal bi-stable mains Relay

G1B meters may be manufactured with or without internal mains relays. Choices of internal mains

relay are denoted with letter “R” and one digit in ordering code and are listed in Table 4-9. More

information about internal main relay is in chapter 14.

Table 4-9 Possible code choices for internal main relay

No.

Section 7 Without relay With relay R1

4.8 LCD options

G1B meters may be manufactured with or without function of LCD backlight. Backlight of LCD can

be switched on and turned off by locally and remotely. Choices of LCD options are denoted with

letter “L” and one digit in ordering code and are listed in Table 4-10. Optional LCD display supports

indication of up to 6 (six) tariffs. Extended LCD displays OBIS code by means of 6 symbols, while

default LCD and optional LCD possess only 4 symbols for LCD (see chapter Error! Reference

source not found.).

Table 4-10. Possible code choices for LCD options

No.

Section 8 (LCD Option #1) Default LCD (4 tariffs, 4 symbols for OBIS code) (LCD Option #1) Default LCD with backlight L1

(LCD Option #2) Optional LCD (6 tariffs, 4 symbols for OBIS code) L2

(LCD Option #2) Optional LCD with backlight L3

(LCD Option #3) Extended LCD (4 tariffs, 6 symbols for OBIS code) L4

(LCD Option #3) Extended LCD with backlight L5

4.9 Internal PLC modem

G1B meters may be manufactured with or without internal PLC modem. Choices of internal PLC

modem are denoted by letter “H” and one digit in ordering code, and are listed in Table 4-11. See

chapter 6.4 for further details.

Table 4-11. Possible code choices for internal PLC modem

No.

Section 9 Without internal PLC modem -

With internal PLC modem (DCSK modulation) H1

With internal PLC modem (PRIME) H2

With internal PLC modem (PRIME) and RS485 (PLC duplication) H3

With internal PLC modem (G3) and RS485 (PLC duplication) H4

NOTE: If an option with character “-” is chosen, that function will not be included in the ordering

code.

15

1

6

2

7

3

8

4

9

5

10

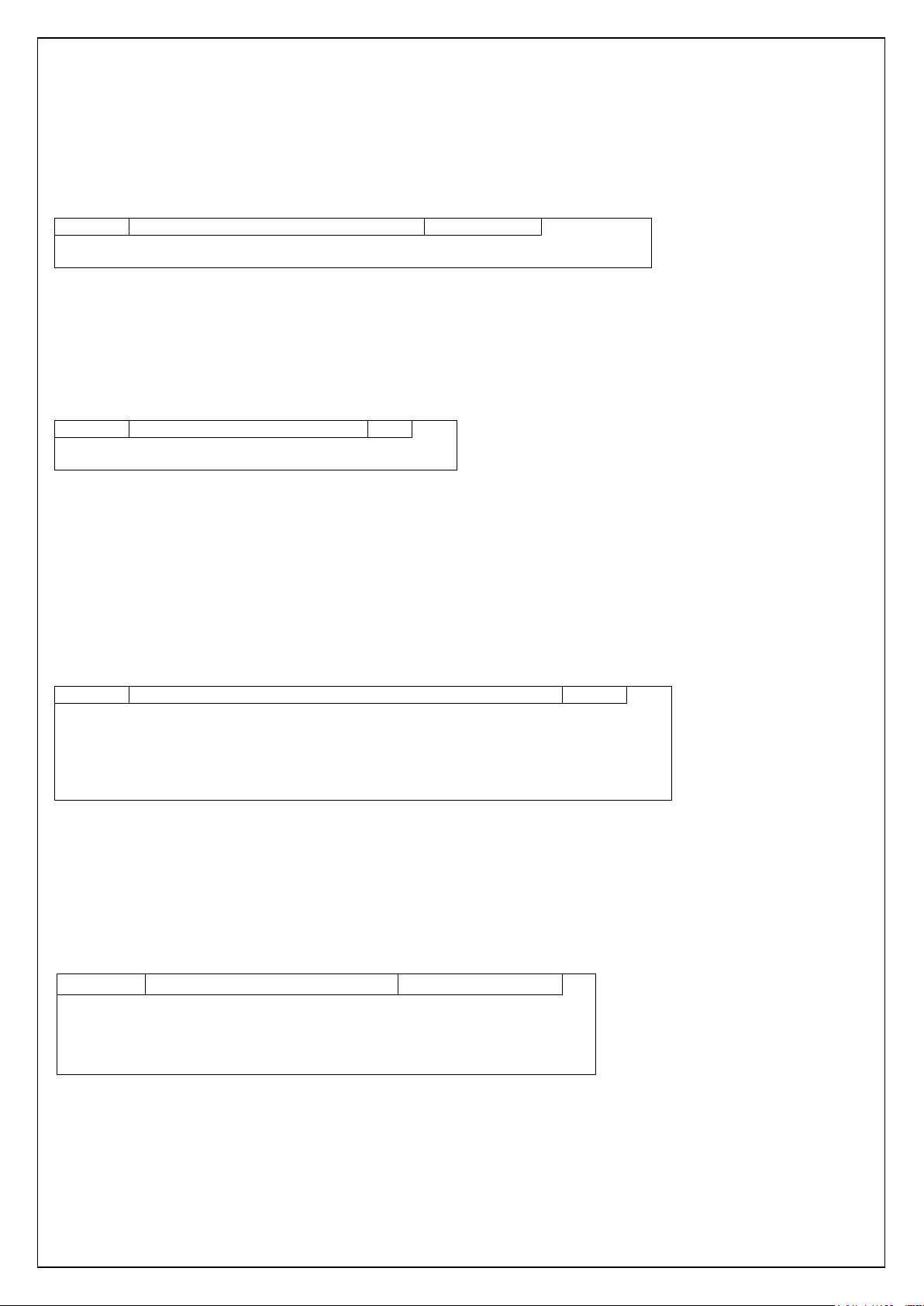

5 Construction

5.1 Case

Meter case, fixing holes and terminal block conform to the requirements of standard DIN 43857.

Meter case can be made from transparent highly mechanically resistant and fire retardant

insulation material – polycarbonate, stabilized by ultraviolet rays or molded of non-transparent

polycarbonate with transparent polycarbonate windows for LCD, optical interface and optical test

output. It protects meter interior parts and its nameplate. Main cover (transparent and nontransparent parts of main cover) is fixed to the base by two sealing screws. Removal of main cover

of mounted meter could be done only after terminal cover removal. An option of special sealing

bolts preventing disassemble of meter is available. Terminal cover is fastened with 1 sealing screw

(suspended seal). Access to the terminals without terminal cover removal is excluded. This affords

additional level of security to the customer. Terminal cover has a hole for threading sealing wire to

sealing screw. The possibility to touch the meter terminals with sealing wire while sealing the

terminal cover is prevented.

Figure (See Figure 5-1) presents meter exterior parts and allotment of control elements. For case

dimensions and allotment of fixing holes see Figure A-0-1.

There is a liquid crystal display (LCD), optical communication interface, optical scroll key for

display control, sealable and not sealable buttons on the main cover of the meter. See chapter 11

for the explanation of display control commands, and chapter 6.10 for the description of push

buttons.

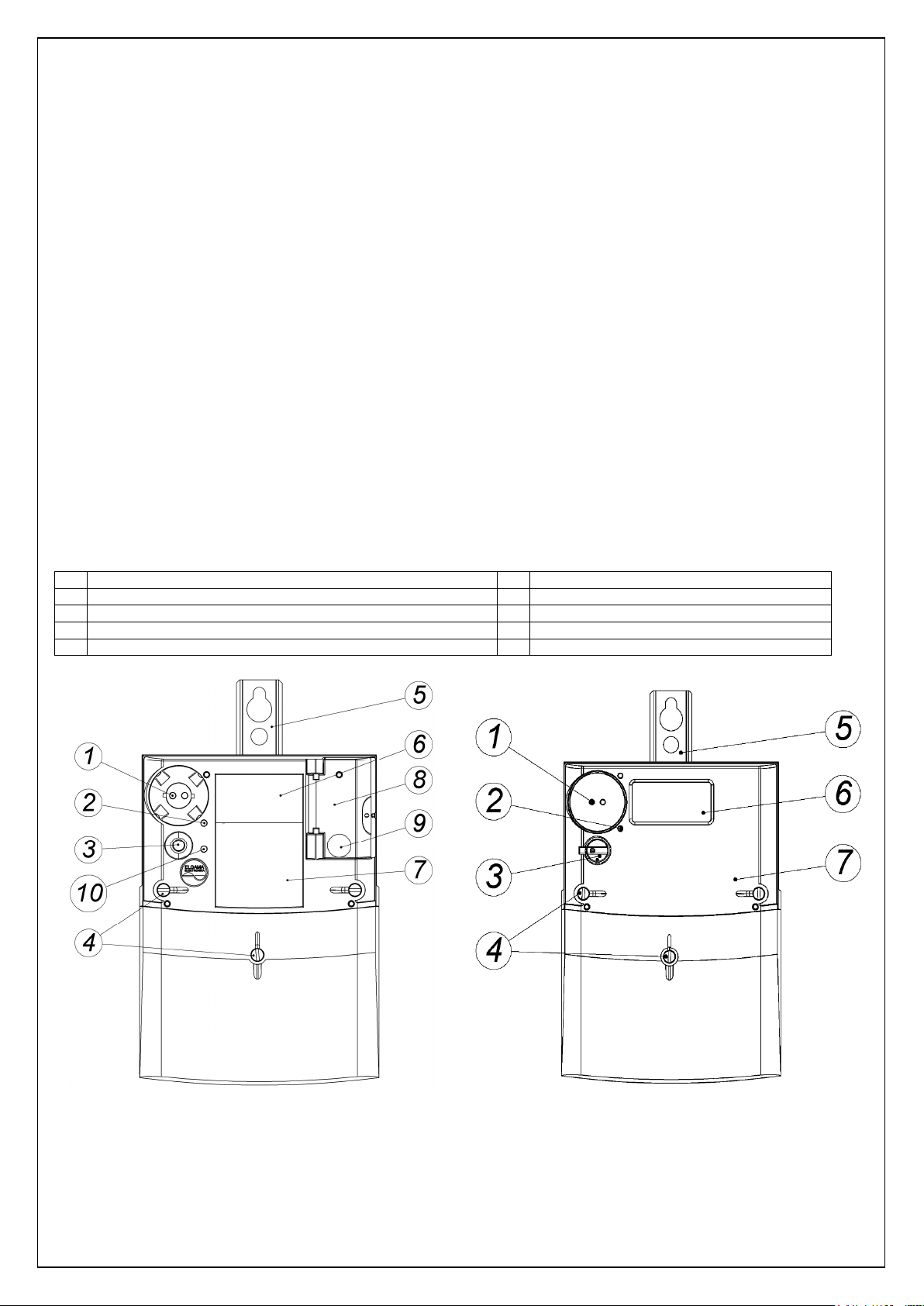

Table 5-1 Explanation of Figure

Optical Interface

Optical test output [imp/kWh]

Scroll push-button or Multifunctional (two-position) button

Sealing screws of main cover and terminal cover

Eyelet

LCD

Nameplate

Changeable battery cover

Sealed push-button

Status indicator (LED) of internal mains relay

Figure 5-1 G1B meter exterior view with transparent cover Figure 5-2 G1B meter exterior view with non-transparent cover

5.2 Nameplate

Nameplate for meter, with transparent cover, is printed on plates made of PET material during the

meter manufacturing process. This ensures that all marks and inscription are clear, non-erasable

16

Error!

and non-transferable. Nameplate for meters with non-transferable cover is marked on the nontransparent part of main cover by means of laser marking technology during the meter

manufacturing process. This ensures that all marks and inscription are clear, non-erasable and

non-transferable.

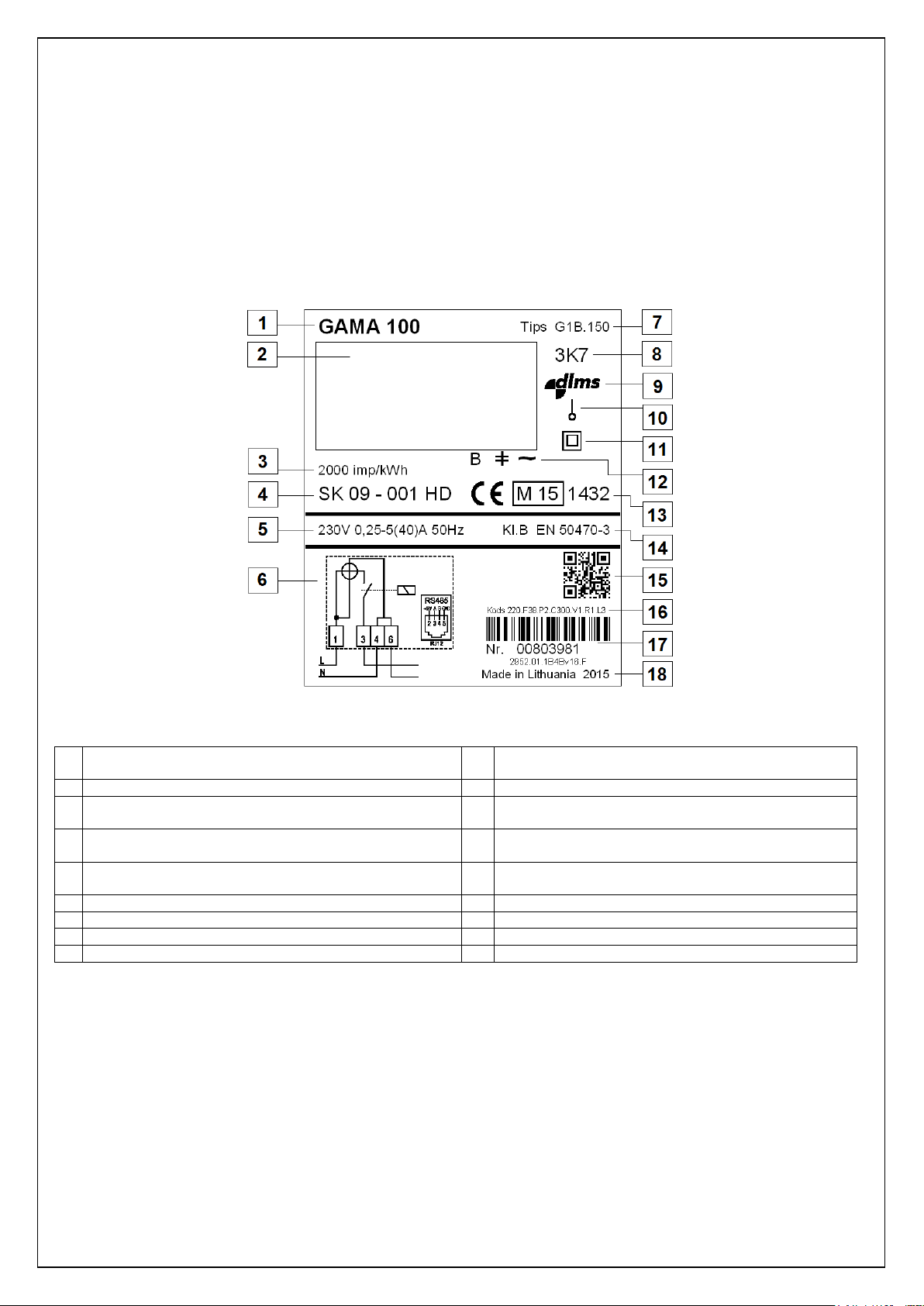

The nameplate bears all the necessary information according to EN 50470-1 and Directive

2004/22/EC, as well as identification of main data, displayed on LCD. Example of nameplate is

provided in Figure 5-3. Meter serial number is displayed as barcode (by default, barcode type

Interleaved 2/5). Additional QR (DataMatrix) code which contains the meter technical information is

printed on the nameplate.

Figure 5-3 G1B meter nameplate

Table 5-2 Explanation of Figure 5-3

1 Meter family (Gama 100) 10 The number of phases and the number of wires

(graphical symbols given in EN 62053-52)

2 Meter LCD 11 The sign of protective class II

3 The meter constant (imp/kWh) 12

4 Approval mark (number of the EC design examination

certificate)

5 Reference voltage, current measuring range, reference

frequency

6 Connection diagram or explanation of OBIS codes 15 QR code (contains the meter technical information)

7 Meter type 16 Ordering code and barcode

8 The environmental class 17 The serial number, firmware version

9 DLMS logo 18 Place and year of manufacture

Notification of LCD segments (refer to chapter

Reference source not found.)

13 The conformity marking “CE” and “M”, number of

notified body

14 The class index of the meter

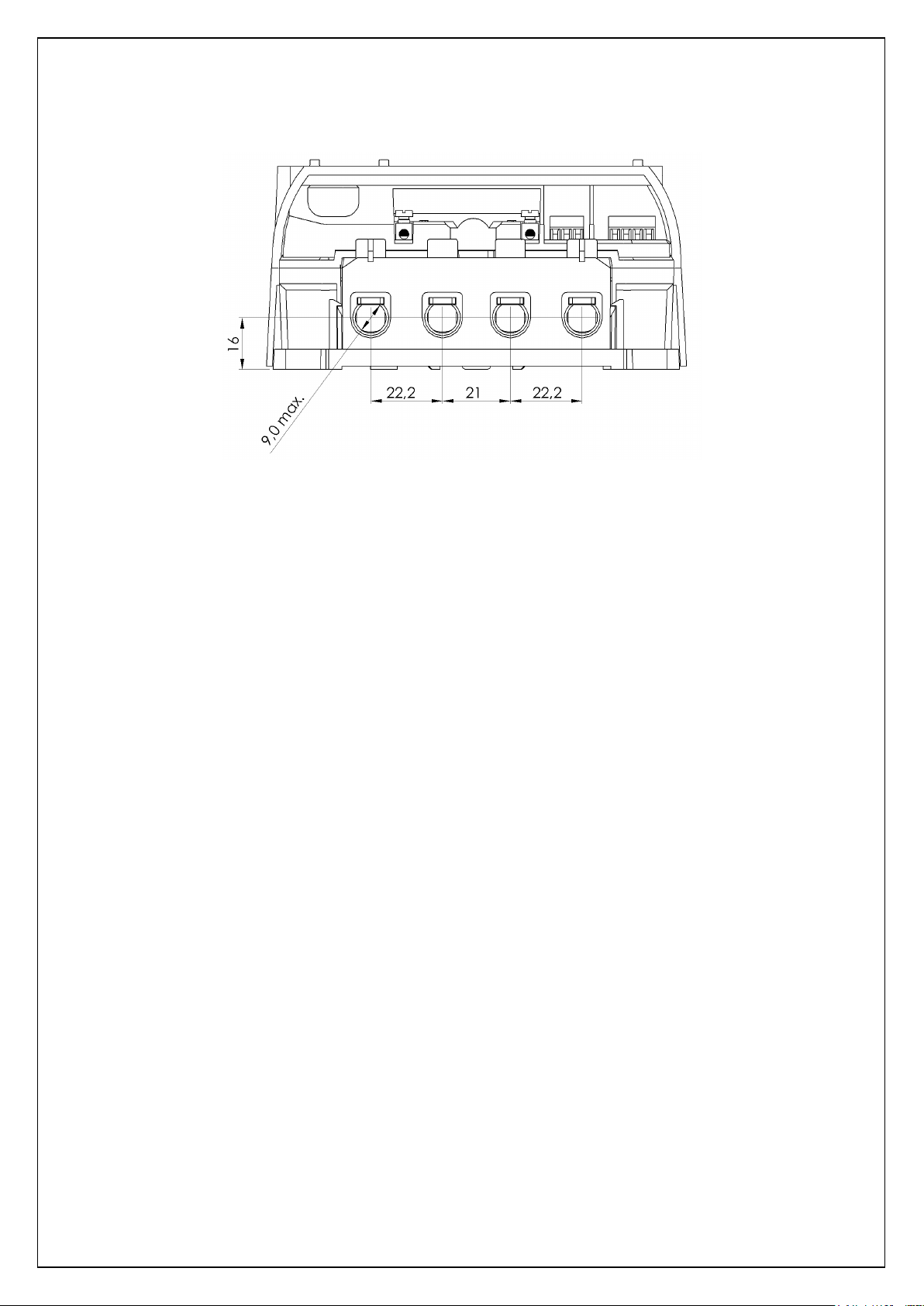

5.3 Terminal block

The terminal block with all meter connections is situated behind the terminal cover. Terminal block

made from highly mechanically resistant and fire retardant insulation material and conform to the

requirements of standard DIN 43857. One utility seal in the fixing screw of the terminal cover

prevent unauthorized access to the phase connections and therefore also prevent unrecorded

energy consumption.

Current and voltage terminals can be made of zinc-plated iron or nickel-plated brass (copper) and

it provides the ability to add copper or aluminium wires without oxidation process. Terminal

assures the same quality of the contact irrespective of the shape of the connection conductor (a

compact wire, a stranded wire, greater or smaller cross-sections).

17

Current terminals for current up to 100 A are with 9 mm hole diameter and wires cross sectional

area at 2.5 mm2 to 60 mm2.

Figure 5-4 Meter terminal block (wires cross sectional area at 2.5 mm2 to 60 mm2)

5.4 Operation principle

5.4.1 Measurement module

In measurement module, current and voltage values of each phase are transformed into

proportionally analogous signals.

Precise current transformers, shunts or di/dt current sensors are used for current measurement in

phase circuit. In case meter contains two measurement elements (i.e. type G1B.x6x carries out

current measurement in neutral as well), current measurement in neutral circuit is based on

different type of current sensor (current transformers or shunts). For voltage measurement,

resistant voltage dividers are employed.

5.4.2 Signal conversion

Analogous signals are transformed into digital codes by three-channel Sigma - Delta converter.

Digital signal processor (DSP) calculates average power values P(t) and Q(t), as well as

instantaneous RMS values of current and voltage. Furthermore, DSP outputs values of RMS

current in neutral and electricity network frequency.

5.4.3 Micro-controller

By integrating power values, micro-controller accumulates import and export energy values.

Energy values are registered to corresponding energy and demand tariff registers in accordance

with the valid tariff program.

Furthermore micro-controller controls liquid crystal display, communication interface, meter

outputs, tariff program and internal clock.

5.4.4 Non-volatile memory

G1B meters contain non-volatile flash memory of different capacity (2048 kB). Flash memory is

used for data profiles and parameter storage. Memory retains data for 20 years and more.

5.5 Display (LCD)

Gama 100 meters are provided with a liquid crystal display (LCD). The display can be provided

with backlight for easier reading (read chapter 4.8). LCD backlight may be configured (only by

manufacturer) for one of two work modes and can work permanently or can be switched on by

18

pressing one of the buttons and is extinguished automatically after a short time if no further button

is pressed. LCD backlight can be switched on and turned off locally or remotely.

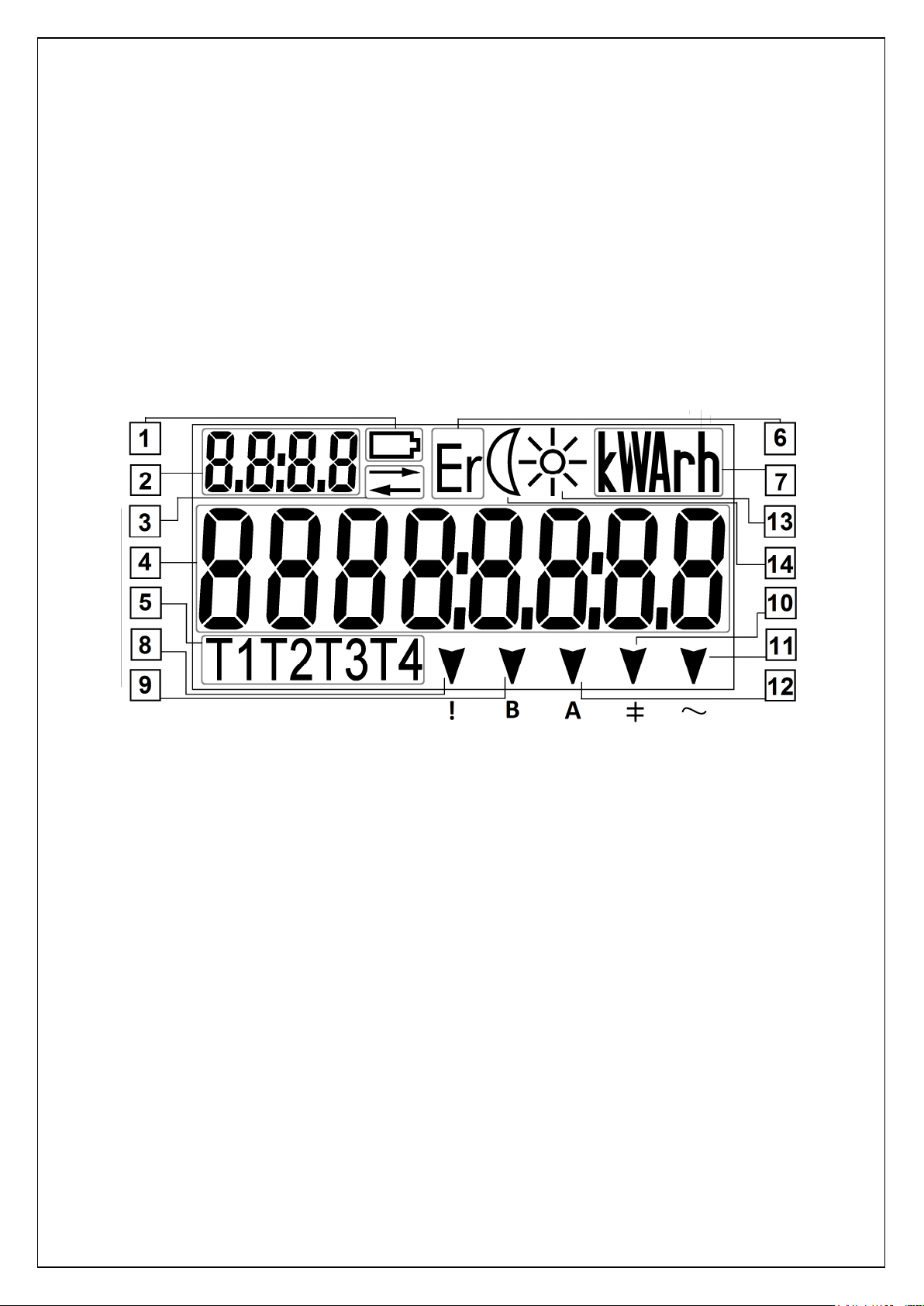

Default liquid crystal display of G1B meter contains 115 controlled segments (marked in dark

colour in Figure 5-5 - Figure 5-7). Vertical dimension of main digits is 10 mm. LCD displays

majority of data accumulated in meter and parameterization constants.

LCD divided into 7 information fields which description is not changeable and

status indication

fields (▼).

An arrow symbols

(▼)

are an additional status indication for load, billing reset block, fraud,

alarm, etc. The arrow points to a status description on the nameplate and can be allocated in

different positions for meters with default LCD (

option #1), optional LCD (option #2), and

extended LCD (option #3).

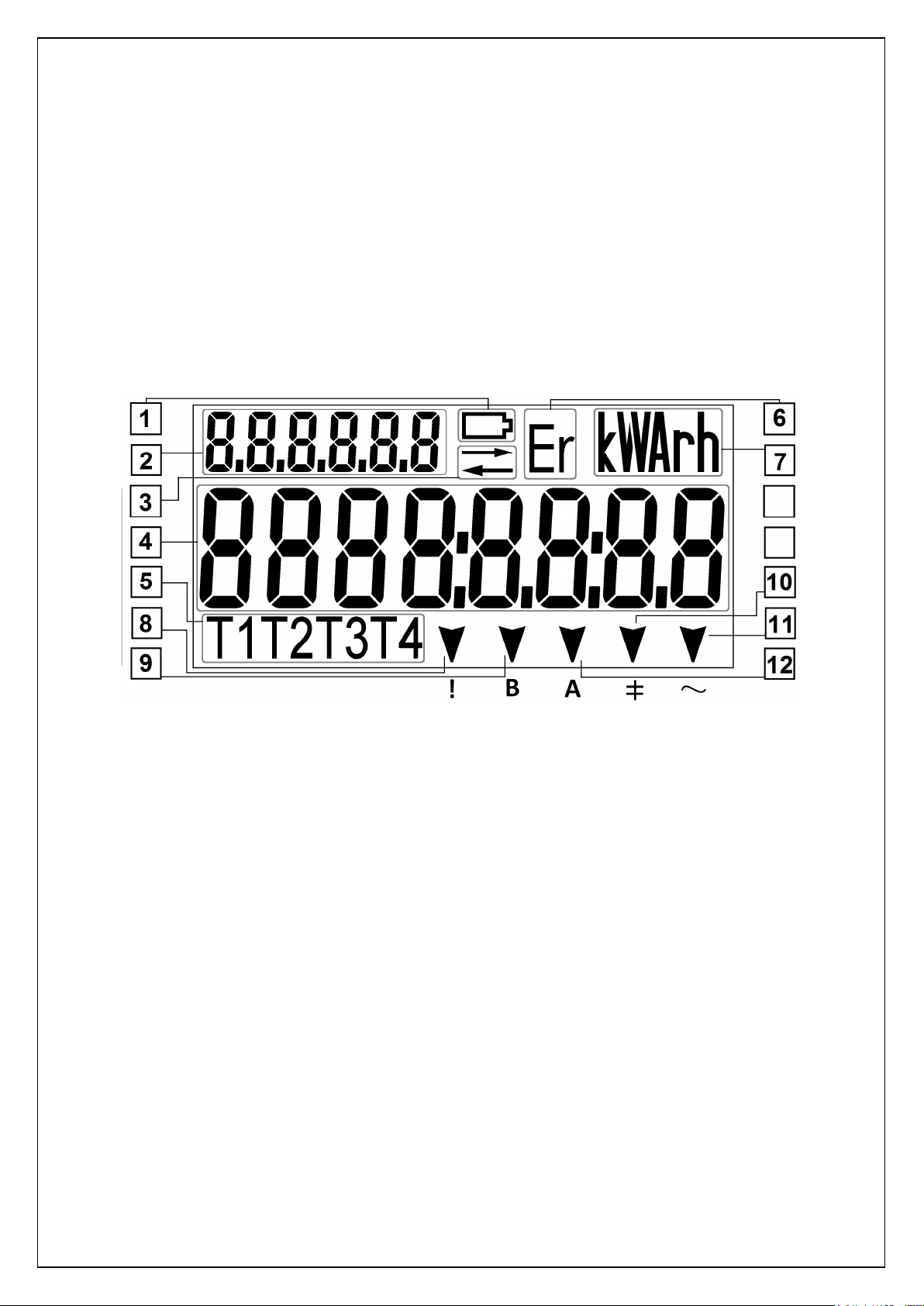

5.5.1 Default LCD (Option #1)

LCD supports indication of up to four tariffs and four symbols for OBIS code (Figure 5-5).

Figure 5-5. Segments and fields of default G1B liquid crystal display

1. Battery state indicator. The symbol appears if the voltage of battery is to low and warns

when battery has to be replaced;

2. Index field. Identifies measured data code (OBIS* code). Explanation of OBIS codes (for

basic data) can be printed on meter’s nameplate;

3. Communication indicator. Indicates when communication operates via optical or electrical

communication interface;

4. Main value field. Shows the measured value (up to 8 digit values are displayed);

5. Tariff field (T1 T2 T3 T4). Shows current energy tariff (only one segment is turned on). Lit

segment indicates active energy tariff, blinking segment indicates active emergency tariff for

energy;

6. Internal fault field (Err). Shows when internal meter error occurs;

7. Measurement unit. Shows units of measured value kW(h), kvar(h), VA, V, A, Hz;

8. Alarm (!).Warns if a contractual power limit is exceeded or neutral current imbalance

(symbol “!” is printed on the nameplate under corresponding segment);

9. Billing period reset (B). Warns about the availability to re-reset billing period. Segment is

not lit – manual billing period reset is available; segment is lit – influence by magnetic field is

registered, segment is blinking – Billing period was just reset recently and sealed pushbutton is currently blocked for some time period (symbol “B” is printed on the nameplate

under corresponding segment).

19

10. Reactive demand (╪). Segment is lit in case of reactive load (±Q). Segment is not lit in

case there is no reactive load (symbol “╪” is printed on the nameplate under corresponding

segment).

11. Active demand (~). Segment is lit in case of positive active load (+P). Segment blinks in

case of negative active load (-P). Segment is not lit in case there is no active load (symbol

“~” is printed on the nameplate under corresponding segment);

12. Fraud (A). Warns if either main cover or terminal cover was opened (symbol “A” is printed

on the nameplate under corresponding segment);

13. Reserved.

14. Reserved.

5.5.2 Optional LCD (Option #2)

LCD supports indication of up to four tariffs and six symbols for OBIS code (Figure 5-6).

Figure 5-6. Segments and fields of optional G1B liquid crystal display

1. Battery state indicator. The symbol appears if the voltage of battery is to low and warns

when battery has to be replaced;

2. Index field. Identifies measured data code (OBIS* code). Explanation of OBIS codes (for

basic data) can be printed on meter’s nameplate;

3. Communication indicator. Indicates when communication operates via optical or electrical

communication interface;

4. Main value field. Shows the measured value (up to 8 digit values are displayed);

5. Tariff field (T1 T2 T3 T4). Shows current energy tariff (only one segment is turned on). Lit

segment indicates active energy tariff, blinking segment indicates active emergency tariff for

energy;

6. Internal fault field (Err). Shows when internal meter error occurs;

7. Measurement unit. Shows units of measured value kW(h), kvar(h), VA, V, A, Hz;

8. Alarm (!).Show wen influence by magnetic field is registered (symbol “!” is printed on the

nameplate under corresponding segment);

9. Billing period reset (B). Warns about the availability to re-reset billing period. Segment is

not lit – manual billing period reset is available; segment is blinking – Billing period was just

reset recently and sealed push-button is currently blocked for some time period (symbol “B”

is printed on the nameplate under corresponding segment);

10. Reactive demand (╪). Segment is lit in case of reactive load (±Q). Segment is not lit in

case there is no reactive load (symbol “╪” is printed on the nameplate under corresponding

segment);

20

11. Active demand (~). Segment is lit in case of positive active load (+P). Segment blinks in

case of negative active load (-P). Segment is not lit in case there is no active load (symbol

“~” is printed on the nameplate under corresponding segment);

12. Fraud (A). Warns if either main cover or terminal cover was opened or a contractual power

limit is exceeded or neutral current imbalance (symbol “A” is printed on the nameplate under

corresponding segment);

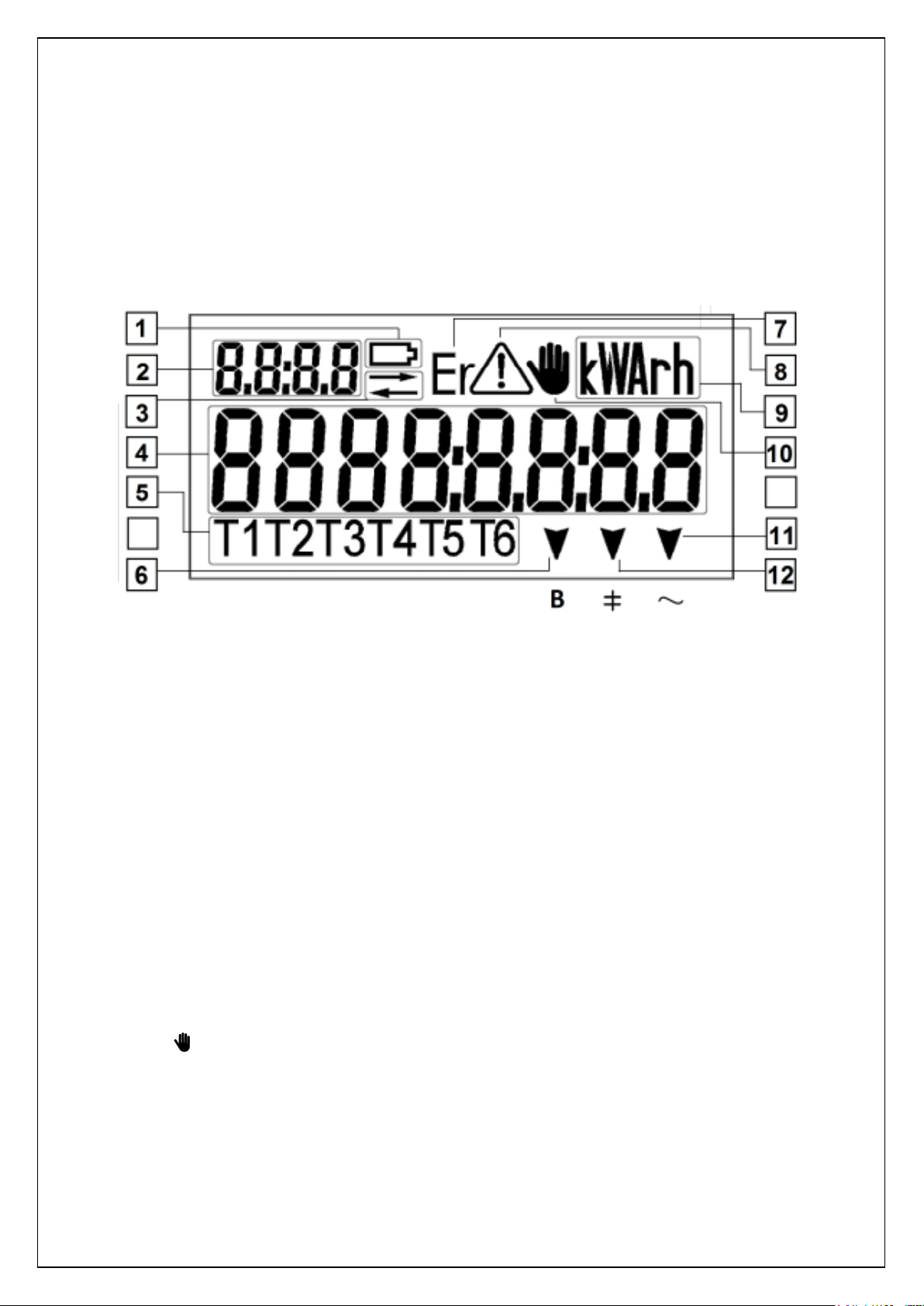

5.5.3 Extended LCD (Option #3)

LCD supports indication of up to six tariffs and four symbols for OBIS code (Figure 5-7).

Figure 5-7. Segments and fields of extended G1B liquid crystal display

1. Battery state indicator. The symbol appears if the voltage of battery is to low and warns

when battery has to be replaced;

2. Index field. Identifies measured data code (OBIS* code). Explanation of OBIS codes (for

basic data) can be printed on meter’s nameplate;

3. Communication indicator. Indicates when communication operates via optical or electrical

communication interface;

4. Main value field. Shows the measured value (up to 8 digit values are displayed);

5. Tariff field (T1 T2 T3 T4 T5 T6). Shows current energy tariff (only one segment is turned

on). Lit segment indicates active energy tariff, blinking segment indicates active emergency

tariff for energy;

6. Billing period reset (B). Warns about the availability to re-reset billing period. Segment is

not lit – manual billing period reset is available; segment is lit – influence by magnetic field is

registered, segment is blinking – Billing period was just reset recently and sealed pushbutton is currently blocked for some time period (symbol “B” is printed on the nameplate

under corresponding segment);

7. Internal fault field (Err). Shows when internal meter error occurs;

8. Alarm (!). Warns if a contractual power limit is exceeded or neutral current imbalance;

9. Measurement unit. Shows units of measured value kW(h), kvar(h), VA, V, A, Hz;

10. Fraud ( ). Warns if either main cover or terminal cover was opened;

11. Active demand (~). Segment is lit in case of positive active load (+P). Segment blinks in

case of negative active load (-P). Segment is not lit in case there is no active load (symbol

“~” is printed on the nameplate under corresponding segment);

12. Reactive demand (╪). Segment is lit in case of reactive load (±Q). Segment is not lit in

case there is no reactive load (symbol “╪” is printed on the nameplate under corresponding

segment);

21

Date format

While network voltage is disconnected, micro-controller operates in energy saving mode, thus,

indicator is not active. When G1B meter is disconnected, data still may be reviewed by affecting

optical scroll key by long light signal or by pushing a scroll push button for 2 to 5 seconds. For

more information see chapter 11.1.

*- The OBject Identification System (OBIS) defines the identification codes (ID-codes) for commonly used data items in

electricity metering equipment. OBIS provides a unique identifier for all data within the metering equipment, including

not only measurement values, but also abstract values used for configuration or obtaining information about the

behaviour of the metering equipment (IEC 62056-61 Electricity metering – Data exchange for meter reading, tariff and

load control – Part 61: Object identification system (OBIS)).

5.6 Internal clock

Meter contains internal clock of real time, which counts years, months, weekdays, hours, minutes

and seconds. Clock information is used to change energy and maximum demand tariffs to form

demand intervals and to register events with date and time stamp. Clock is stabilized by quartz

resonator. Temperature drift is compensated by software (only when network voltage supplies

meter).

Table 3-2 presents the main clock characteristics. Clock can be automatically adjusted to daylight

saving changes. There are different ways to define time and date of daylight saving changes. They

are listed in Table 5-3.

Table 5-3 Possible clock adjustments

[MMDD.hh]

0000.00 No adjustment for daylight saving changes

Clock is adjusted for summer time on the last Sunday of a month MM at 2 a.m. by winding the clock 1 hour

MM00.00

MM00.hh

MMDD.hh

forward;

Clock is adjusted for standard time on the last Sunday of a certain month MM at 3 a.m. by winding the clock 1

hour backward;

Clock is adjusted for summer time on the last Sunday of a specified month on the time specified by winding the

clock 1 hour forward;

Clock is adjusted for standard time on the last Sunday of a specified month on the time specified by winding the

clock 1 hour backward;

Clock is adjusted for summer time on the time and date specified by winding the clock 1 hour forward;

Clock is adjusted for standard time on the time and date specified by winding the clock 1 hour backward;

5.6.1 Synchronization of internal clock (RTC)

In G1B meters it is possible to synchronize internal clock of the meter. There are two concepts in

G1B meter – clock synchronization and clock setting. Clock synchronization is considered when

clock adjustment value is less than ±9 seconds. If meter receives clock synchronization command

with <±9s, then internal clock is adjusted with corresponding value and this event is not recorded

in event logs nor in load profile. Otherwise, when meter receives clock synchronization command

with >±9s value, such event is considered as clock setting and meter adjusts internal clock with

corresponding value and this event is recorded into event log and an entry is made in load profile

with corresponding status byte. Maximum value of clock synchronization command can be ±60s.

There are some security measures implemented in G1B meters in order to prevent attempts of

corrupting the measurements of the meter. There are no limitations of how many clock

synchronization commands could be send to the meter within a day, but there is a limitation, than

single clock synchronization command can be accepted within integration period and a total

correction value cannot exceed ±600s over single year. If there are several attempts of

synchronizing the meter during single integration period or total synchronization value exceeds

±600s, then meter will ignore this command and no clock adjustments will be made (return error

message). Time synchronization can be carried out via all available communication interfaces.

Date and time of clock adjustment

22

5.7 Sliding voltage link

A sliding voltage link is intended for fast and simple separation of the meter current and voltage

circuits for calibration or accuracy testing. A special slider that can be shifted side to side by

means of a screwdriver is built in a terminal block.

Meter main cover enables two options (option is selected during the moulding process by means

of changeable inserts in the mould):

1) Voltage link is secured (covered) by main cover;

2) Voltage link accessible via hole in the main cover.

Picture (see Figure 5-8) illustrates option – voltage link is accessible via hole in the main cover.

When a voltage link is disconnected (slider shifted to the left side), it means that a voltage circuit

is separated from a current circuit, while connected (slider shifted to the right) it means that it is

closed.

Remark: sliding voltage link is absent, when shunt is used as current sensor in phase circuit, and

meter current and voltage circuits are connected permanently.

Figure 5-8 Sliding voltage link (connected)

6 Communication

The meter supports two-way communication via various interfaces: data reading at the request, as

well as transfer of various commands to the meter (e.g. billing period reset) or from the meter (e.g.

alarms).

6.1 Optical communication interface

Optical communication interface meets the requirements of the standards IEC 62056-21,

DLMS/COSEM and is used to download data locally into PC or hand held terminal by means of

optical head. Interface is also used for parameterization of a meter. Data transmission speed

3009600 Baud. G1B meters maintain the interface blocking function, which prevents

unauthorized data reading and parameter changes. Read more about this function in chapter

13.2.6.

6.2 Electrical interface

G1B meters may have primary electrical communication interface - 20mA current loop, RS485 or

M-Bus (either wired, or wireless). Communication protocols for these electrical interfaces are listed

in Table 3-2. Maximum data rate is 19200 Baud. Simultaneous data transmission via optical and

electrical interfaces is possible.

23

6.3 Controller MCL 5.XX with internal GSM/GPRS modem

GAMA 100 meters may be equipped with a controller MCL 5.XX with electrical interface (CL or

RS485). Controller is manufactured by “ELGAMA SISTEMOS” Ltd. and is used in AMI (Advanced

Metering Infrastructure) systems for remote automated data reading, parameterization and

firmware update of electricity meters.

GSM radio network with CSD/GPRS/EGDE/3G technology and TRANSPARENT DATA TCP/IP

protocols is used for data transmission to dispatcher offices. Controller supports two-direction data

exchange (data reading, parameterization and firmware update) with communication protocols IEC

62056-21 or DLMS/COSEM. Controller can be assembled with internal antenna (located under

terminal cover) as well as with external one (with an extended cable).

Controller can be mounted in terminal covers of electricity meters manufactured by “ElgamaElektronika” Ltd. (see Figure A-0-2) as well as fixed to DIN rail separately. For more information

please refer to modem’s instruction.

Meter is equipped with RJ12 connector for easy controller connection. Controller (depends on his

construction) can be powered from RJ12 connector or can be powered from mains, therefore

power supply terminals of controller have to be connected to voltage terminals (terminals 2 and 5)

of electricity meter (see Figure 6-1 and Figure 6-2).

Controller can be mounted under the transparent terminal cover, therefore LED indicators of

controller (LEDs “Signal strength” and “Operation”) are visible to user (see Figure 6-3).

Controller supports Plug&Play functionality. It enables automatic registering on network, therefore

additional configuration of communication device is not needed during the installation process.

Furthermore, meter can send alarm messages in case of special events (e.g. tampering). For more

information about Plug&Play functionality see section 6.7.

Figure 6-1. Controller without internal 220V power supply is

powered from RJ12 connector

Figure 6-2. Connection of external modem with internal 220V

power supply

24

Figure 6-3. Controllers under the transparent terminal cover

6.4 PLC modem

GAMA 100 meters may be equipped with a Power Line Communication (PLC) modem. PLC

modem is supplied in the following options:

• As an external modem, connected via electrical interface (CL or RS485). Modem can be

mounted in terminal cover of electricity meter manufactured by “Elgama-Elektronika” Ltd.

(see Figure A-0-2), as well as fixed to DIN rail separately.

• As an internal modem, installed under the main cover of meter (see section 4.9 and section

6.4.1).

Modem is manufactured by “ELGAMA-Elektronika” Ltd. and is used in metering systems for

automated remote data reading, parameterization, as well as firmware update of electricity meters

by means of DLMS COSEM protocol. Open specification (Specification for PowerLine Intelligent

Metering Evolution, version 1.3.6), defined by Power Line Intelligent Metering Evolution (PRIME),

is used for PLC communication. PLC modem employs OFDM (Orthogonal Frequency-Division

Multiplexing) modulation technology for data transmission over low voltage power lines. Please

refer to official web site of the PRIME Alliance (http://www.prime-alliance.org/) for further

information.

Modem is based on chipset (processor C2000 and analog front end AFE031) reference design

and software (Prime PLC service node), provided by Texas Instruments. Texas Instruments Prime

PLC solution is certified for PRIME Compliance.

PLC modem operates in CENELEC A-band (3 – 95 kHz), which is exclusively devoted for energy

suppliers. PLC signal strength complies with standard EN 50065-1 emission requirements.

Raw data rate depends on available transmission conditions on the network, and it is automatically

selected in the range 2164 Kbps, as described in Prime specification.

Prime PLC solution supports tree topology structure of communication network. Data Concentrator

(Base Node) is at the root of the tree and acts as master node that provides connectivity to the

network. Any other node (electricity meter) of the network is a Service Node. Service Nodes are

either leafs of the tree or branch points of the tree. These nodes (electricity meters) carry out two

responsibilities: connecting themselves to the network and retransmitting the data of their

neighbours (more remote meters) in order to propagate connectivity.

25

Since complying with Prime PLC specification, electricity meter G1B with PLC modem can

communicate to any Data Concentrator, supporting Prime PLC. Manufacturer recommends Data

Concentrator DMDC, produced by Elgama Sistemos Ltd.

Prime PLC modems support Plug&Play functionality. It enables automatic registering on network,

therefore additional configuration of communication devices is not needed during the installation

process. Furthermore, meter can send alarm messages in case of special events (e.g. tampering).

For more information about Plug&Play functionality see section 6.7.

6.4.1 Internal PLC modem

GAMA 100 meters may be equipped with internal PLC modem, installed under the main cover of

meter. This feature is available in modification, marked by code “H2” or “H3” (see section 4.9).

Internal PLC modem support functionality, described in section 6.4. Maximum self-consumption of

PLC modem is presented in Table 6-1. Internal PLC modem can be disabled (switched-off) by

special configuration command. This is usually carried out, when meter is connected to AMI

system by means of another modem (e.g. GSM/GPRS modem).

Table 6-1. Maximum self-consumption of internal PLC modem

Maximum self-consumption: Value Remark

in standby mode 0.6 W

during transmission 10 W @1Ω network impedance

Status of internal PLC modem can be monitored on the LCD display of meter. Object “PLC status”

(OBIS = C.62.5) should be included in the display sequence, during parameterization of meter.

PLC status can be in one of the following states:

• “PLC ---“ – meter is not connected to PLC network (see Figure 6-4);

• “PLC On” – meter is connected to PLC network (see Figure 6-5);

• “PLC Off” – internal PLC modem is switched off (see Figure 6-6).

Figure 6-4. PLC status “PLC ---“

Figure 6-5. PLC status “PLC On

Figure 6-6. PLC status “PLC Off”

6.5 Wired M-Bus module

GAMA 100 meters may be equipped with wired M-Bus Master interface for automated remote data

reading from gas and water meters. M-Bus interface is implemented according to EN-137757-2

and EN13757-3 standards. Hourly consumption data of water and gas meters is stored in M-Bus

load profile (see chapter 8.4).

26

6.6 Wireless M-Bus interface

G1B meters may be equipped with wireless M-Bus interface for automated remote data reading

from gas and water meters, as well as for billing data transmission to In-Home-Displays. Wireless

M-Bus interface is implemented according to EN-137757-2 and EN13757-4 standards. Wireless

M-Bus interface is available in two frequency range options: 169 MHz and 868 MHz. The same

hardware platform – SPIRIT1 transceiver from STMicroelectronics – is used for both frequency

ranges.

6.7 Plug & Play

G1B meters have Plug&Play software functionality which helps to speedup installation process, as

well, indicates whenever meter was logged out (power failure, communication disorders). This

software feature is implemented in following way: after start-up of the meter, it starts sending alarm

message over electrical interface (after some random delay from start-up). An external modem

(GSM, PLC) has to be connected and corresponding communication network must be functional in

order for Plug&Play could be implemented. External modem has to be configured with server

(base station) connection settings, so that alarm message could reach dedicated destination.

Corresponding alarm message is UI frame that contains serial number to identify the caller and

login new meter into the billing system. Alarm message is send every hour, until the first request

from billing system is received. Meter changes its status to offline when there is no request from

billing system for more than 24 hours, or after every start-up.

Plug&Play function over PLC is ensured by means of PLC communication provider and data

concentrator (DMDC). New meters in PLC network are registered in DMDC, whenever there is

stable PLC communication and event is passed to MDMS system. This rapid process allows

detecting new meters in short time and allows verifying correctness of installation easily.

6.8 Outputs/Inputs

6.8.1 Optical test output (red LED)

Meters contain optical test output - red LED, which produce light impulses for meter calibration

with frequency proportional to measured energy. Only the manufacturer is permitted to program

meter’s constant (imp/kWh) and pulse duration (30 ms).

6.8.2 S0 outputs

Meters have S0 output for transmission of information about measured energy. Output is

galvanically isolated by optocouple. Constant of pulses is programmed in the interval from 50 to

150000 imp/kWh (imp/kvarh). Maximum commutation voltage is 24 V, maximum commutation