Elgama EPQS User Manual

Multifunction Meter of

active, reactive and apparent Electric Energy

EPQS

User Manual

Version 5.2a

(PQSEN52a)

“ELGAMA – ELEKTRONIKA”, Lithuania 2017

3

“ELGAMA-ELEKTRONIKA”

EPQS

Multifunction Meter of Active, Reactive and

Apparent Electric Energy

User Manual

"ELGAMA-ELEKTRONIKA" Ltd.

Visoriu str. 2,

LT-08300 Vilnius

Lithuania

Tel. 8 5 2375 000

Fax. 8 5 2375020

e-mail: info@elgama.eu

4

This user manual describes the electronic multifunction EPQS meter of electric energy and the use of

the meter. Please read this document carefully before installing and using the meter. The

manufacturer’s warranty shall not apply if the meter is damaged as a result of failure to comply with

the requirements described in this manual or registration certificate or those of work safety.

The manufacturer shall not be held liable for any kind of loss incurred by the meter parameterization

performed not following instructions described in the users program as well as recommendations and

State-defined tariffs. The manufacturer shall be not held liable for any damage related to partial or

total data loss due to unprofessional actions of authorized persons.

This user manual describes all possible features, functions, and auxiliary outputs of the electrical

energy meter. Your meter might not have some features, functions, or auxiliary outputs described in

this document. The exact configuration, features, accessories, and connection diagram of the meter is

provided in its registration certificate.

5

Table of Contents

1. PURPOSE AND FEATURES ........................................................................................................... 6

1.1. MARKING OF METER MODIFICATIONS ................................................................................................................ 7

1.2. TECHNICAL SPECIFICATIONS............................................................................................................................ 8

2. DESIGN ........................................................................................................................................... 9

2.1. CASE ............................................................................................................................................................. 9

2.2. GENERAL REQUIREMENTS AND INSTALLATION PROCEDURE ............................................................................ 10

2.3. ELECTRONIC CIRCUITRY AND PRINCIPLES OF OPERATION ................................................................................ 12

2.3.1. Measurement module ......................................................................................................................... 12

2.3.2. Analog to Digital Signal Conversion ................................................................................................... 12

2.3.3. Central Processor Unit ........................................................................................................................ 12

2.3.4. Non-volatile RAM Unit ......................................................................................................................... 13

2.3.5. Internal Clock ...................................................................................................................................... 13

2.3.6. Liquid Crystal Display (LCD) ............................................................................................................... 13

2.4. COMMUNICATION INTERFACES ....................................................................................................................... 14

2.4.1. Optical Interface (D0) .......................................................................................................................... 14

2.4.2. Electrical communication Interface ..................................................................................................... 14

2.4.3. Auxiliary Communication Interface (optional) ..................................................................................... 14

2.4.4. Interface Priorities ............................................................................................................................... 14

2.5. THE METER INPUTS AND OUTPUTS ................................................................................................................ 14

2.5.1. Optical LED Output (Red Light Emission Diodes) .............................................................................. 14

2.5.2. Pulse Output contacts ......................................................................................................................... 15

2.5.3. Relay Outputs (Optional) .................................................................................................................... 15

2.5.4. External Backup Power Supply (optional) .......................................................................................... 16

2.6. POWER SUPPLY ............................................................................................................................................ 16

2.7. PUSH BUTTON .............................................................................................................................................. 16

3. DATA REGISTRATION .................................................................................................................. 16

3.1. ENERGY REGISTRATION ................................................................................................................................ 18

3.2. DEMAND REGISTRATION ................................................................................................................................ 19

3.3. REGISTRATION OF INSTANTANEOUS VALUES .................................................................................................. 19

3.4. POWER QUALITY REGISTRATION.................................................................................................................... 21

3.5. “END OF BILLING PERIOD” .............................................................................................................................. 22

4. TARIFF MODULE .......................................................................................................................... 23

4.1. DAY PROGRAM.............................................................................................................................................. 23

4.2. WEEK PROGRAM ........................................................................................................................................... 23

4.3. TARIFF SEASONS .......................................................................................................................................... 23

4.4. SPECIAL DAYS .............................................................................................................................................. 24

4.5. TARIFF MODULE OPERATION IN CASE OF CLOCK FAILURE .............................................................................. 24

5. DATA DISPLAY MODES ............................................................................................................... 25

5.1. AUTOMATIC CYCLIC DATA INDICATION MODE ................................................................................................. 25

5.2. STATIC DATA INDICATION MODE .................................................................................................................... 25

5.3. DATA REVIEW ALGORITHMS .......................................................................................................................... 25

6. PARAMETERISATION .................................................................................................................. 27

7. METER DATA PROTECTION ........................................................................................................ 28

7.1. PHYSICAL PROTECTION OF DATA AND PARAMETERS ....................................................................................... 28

7.2. SOFTWARE PROTECTION ............................................................................................................................... 28

7.2.1. Password ............................................................................................................................................ 28

7.2.2. Lock of optical interface (optional) ...................................................................................................... 28

7.2.3. Event logbook ..................................................................................................................................... 28

7.2.4. Counters and Timers .......................................................................................................................... 29

7.2.5. Protection of Factory Constants ......................................................................................................... 29

ANNEX A. DATA AVAILABLE TO DISPLAY ON LCD........................................................................ 30

6

1. Purpose and Features

The EPQS meter is a multifunction device for measurement of electric energy. CT operated meters

comply with requirements of IEC 62053-22 standard, class 0,5 or 0,2s.

The meter data structure is compatible with DLMS standard. Each measured parameter has its OBIS

(OBject Identification System) code describing the parameter or value. OBIS codes together with

allocated parameters are transmitted through the communication interfaces and displayed on the

meter LCD display screen.

The meter measures, registers, and collects data on active energy of both directions (+A, -A), reactive

energy of both directions (+R, -R), reactive energy in four quadrants (R1, R2, R3, R4), and apparent

energy of both directions (+W, -W). The meter also registers maximums of average power, collects

load profiles and registers cumulative powers.

Besides the aforementioned values, the EPQS meter can display or transmit via its communication

interfaces the following profiles stored in any of 16 freely programmed channels: phase and line

voltages; currents; instantaneous active, reactive, and apparent power; frequency; power factor (cos

). It can also analyze power quality and generate weekly reports of power grid quality.

Up to eight of energy and the same number of power maximum tariffs can be activated for tariffication

of energy and power. The structure of tariff module lets adapt the meter for virtually any of existing

tariff program.

For remote data transmission, the meter has two independent electrical communication interfaces.

For local data readout, optical interface D0 is provided.

Several modifications of EPQS meter are manufactured. They may differ in nominal current, voltage,

connection type, and the meter hardware or software. The designation of different modifications of

EPQS meter is explained in Table 1-1.

7

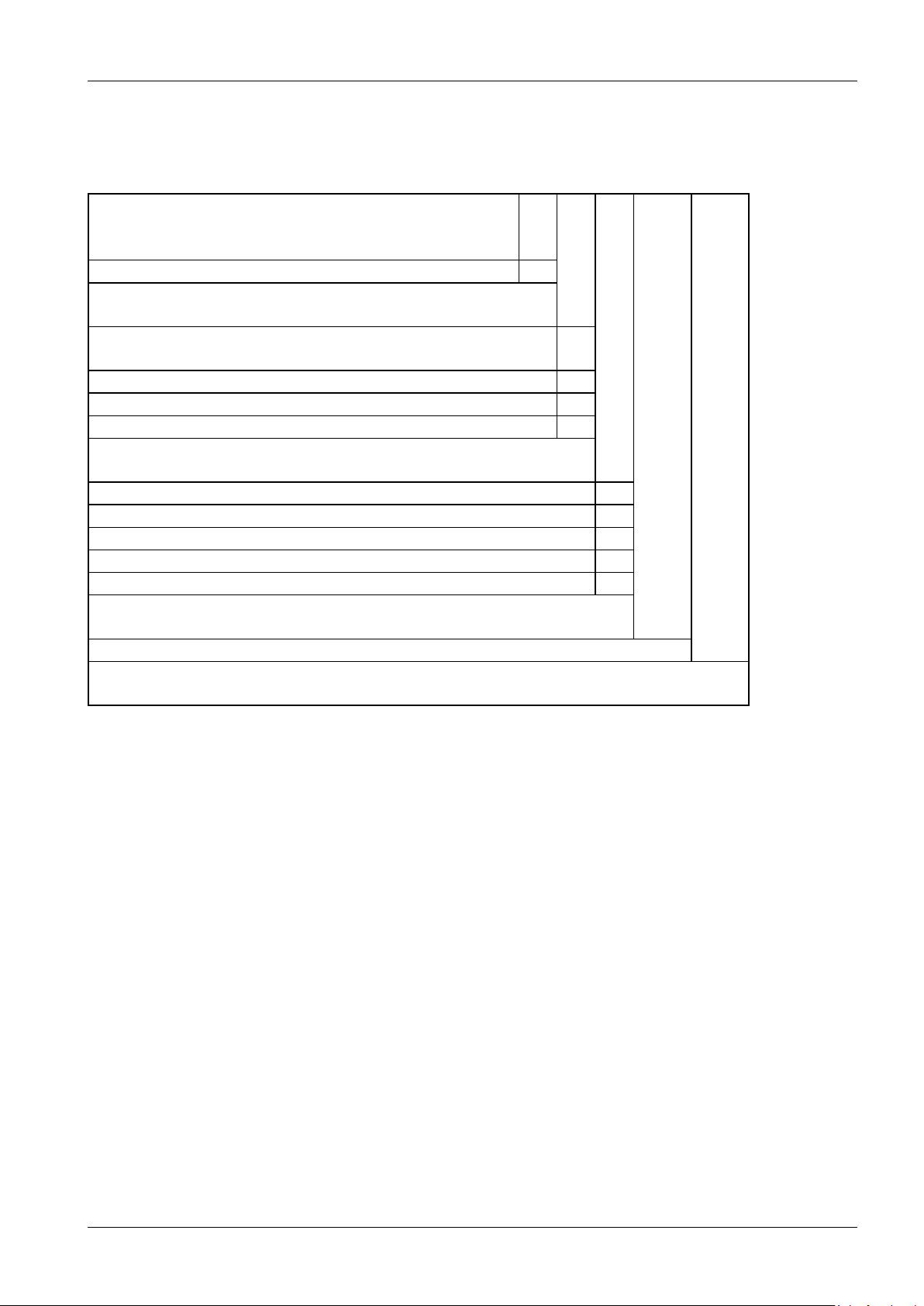

1.1. Marking of meter modifications

Table 1-1. Explanation of meter modification code

EPQS

X

X

X.

XX.

XX

Measuring elements:

3 elements, 4 – wire connection

1 Rated voltage, V:

3x57,7/100; 3x63,5/110; 3x69,2/120; 3x100; 3x110;

3x120

1

multi range (3x57,7 ...230/100 ...400)

2

3x220/380; 3x230/400; 3x380; 3x400

3

3x120/208; 3x127/220; 3x220; 3x230

4 Rated (maximal) current, A:

CT connection 5(6,25)

1

CT connection 5(10)

2

CT connection 1(2), 1(1,25)

3

CT connection 1(6)

4 5 Software code:

Hardware code:

Hardware of class 0.2s

2X

8

1.2. Technical Specifications

Accuracy class:

CT operated

0.2s or 0.5s (IEC 62053-22)

Rated voltage, V

see table 1-1

Rated (maximum) current, A

see table 1-1

Rated frequency, Hz

50 or 60

Sensitivity threshold, %I

nom

CT operated

0,1

Power consumption, VA

in voltage circuits

< 3 (0,76W)

in current circuits

< 0,5/phase (CT operated)

Meter constant, imp/kWh

130000

Communication interfaces:

optical interface D0

IEC 62056-21

electrical interface I

IEC 62056-31

electrical interface II

IEC 62056-31

pulse outputs:

number:

6 (independent)

output constant, imp/kWh (imp/kVArh):

130000

pulse duration, ms

30

External backup power supply:

= 12V

Tariff module:

number of energy tariffs:

programmable (1 … 8)

number of maximum demand tariffs:

programmable (1 … 8)

Data storage without power supply:

20 years (t=20°C);

2 years (t=60°С)

Backup supply of internal clock:

Li battery

Battery resource for not connected meter

> 5 years

Insulation:

pulse voltage test (IEC 60060-1)

6kV

alternating voltage test

4kV

Operating temperatures

-40°C … +60°C

Storage and transportation temperatures

-50°C … +70°C

Weight, Kg:

< 1,5

Dimensions, mm

325 x 177 x 55

9

2. Design

2.1. Case

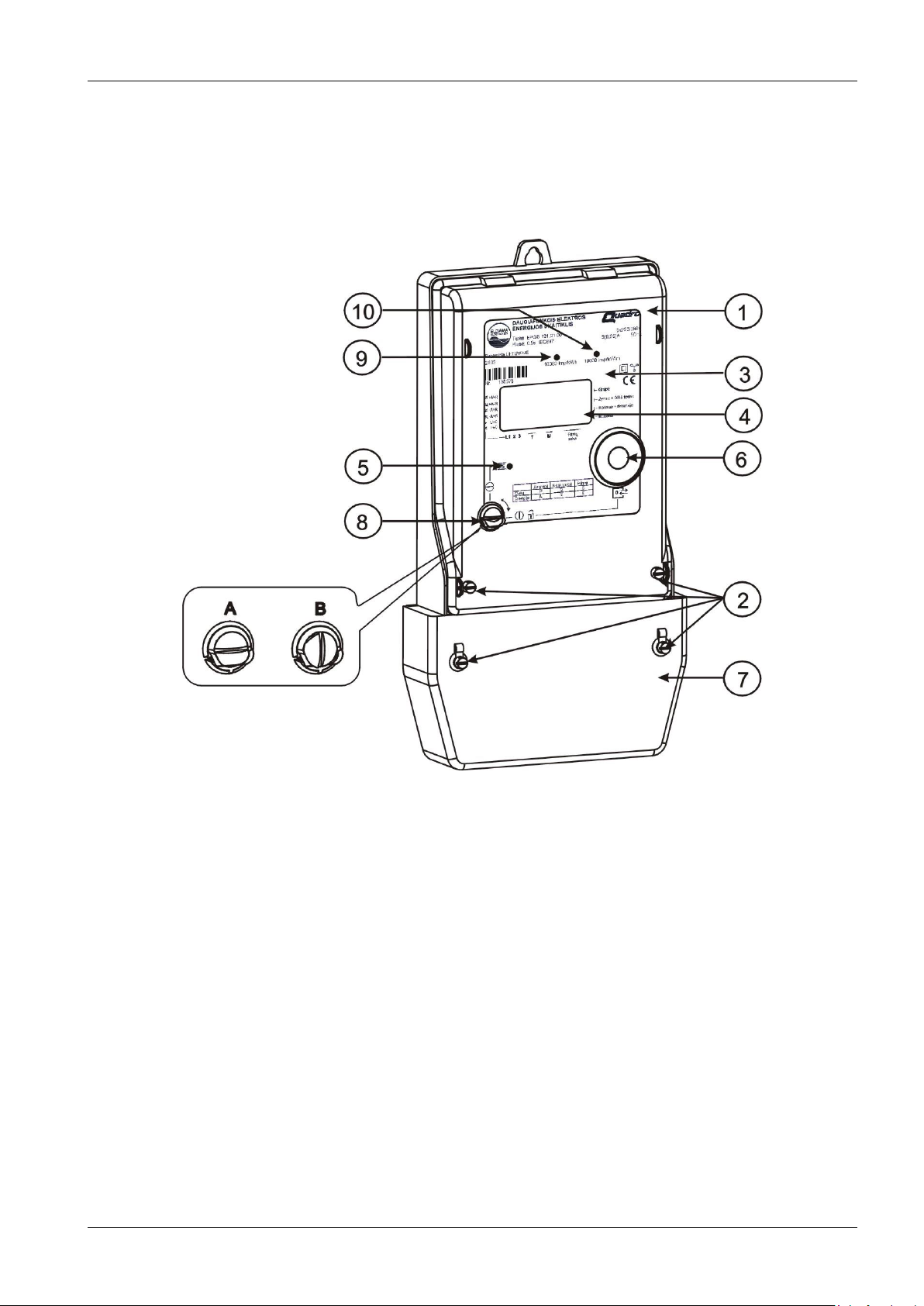

Picture 2-1 presents the external view of the device.

Picture 2-1. Meter exterior

1

Transparent cover

6

Optical communication interface;

2

Sealed screws;

7

Terminal block cover

3

Meter panel;

8

Button

4

Liquid Crystal Display;

9

Light emitting diode (LED) 1;

5

Display control photo sensor

10

Light emitting diode (LED) 2;

The meter panel is covered by transparent cover moulded from UV ray-stabilised polycarbonate cover

providing protection from external mechanical factors and moisture.

The cover is fixed to the case by two sealed screws.

The liquid crystal display (LCD) is located in the frontal part of the meter. It allows the display of all

values stored in the memory, instantaneous values and parameters.

On the lower left, a display control photo sensor is located. In order to display specific information on

the display, a corresponding light signal must be transmitted to the photo sensor.

The D0 optical interface is located on the right side of the frontal part. The purpose of this interface is

data transfer between the meter and a portable computer or terminal and the meter parameterisation.

10

The meter has its own backup power supply that provides power to the internal clock should the main

electrical network fail. The backup supply consists of a standard 3.6 V Li-Ion battery. If a –Battery lowmessage appears on the display, the battery must be replaced.

Only the manufacturer or its authorised representative may replace the battery!

The power and auxiliary terminal block is located on the bottom of the meter. All connections having

been completed and checked, the terminal block shall be covered with sealed cover.

2.2. General Requirements and Installation Procedure

1. Only personnel authorised by the Electric Utility can carry out the meter installation,

disconnection, repair, any subsequent parameterisation, and sealing; the rules of installation

of electrical devises must be observed. The manufacturer shall not be held liable for the meter

malfunction should the user fail to adhere to the relevant requirements.

2. The meter is installed in dry premises containing no chemically aggressive gases or vapour.

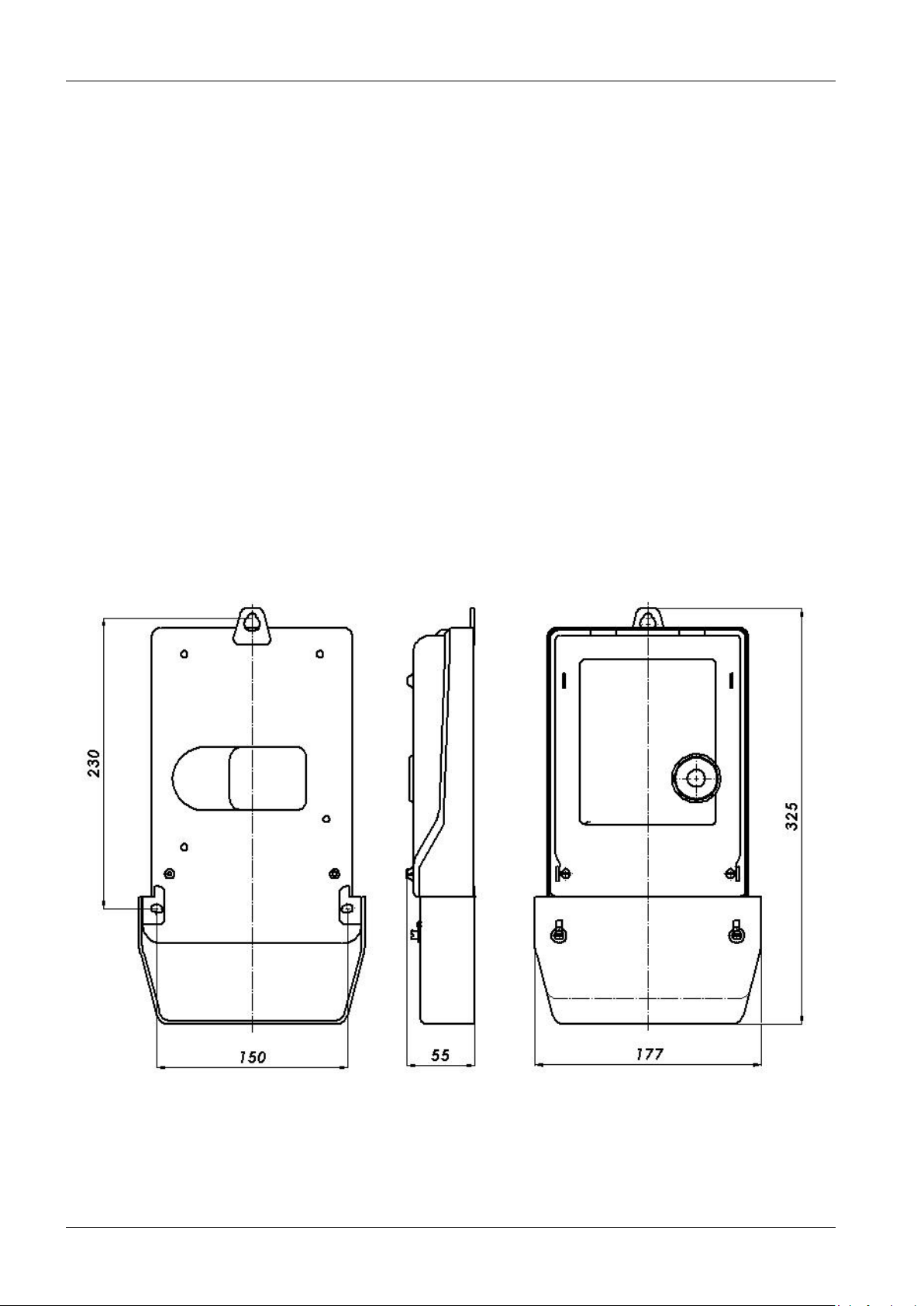

3. The meter is fixed with three screws. The meter overall dimensions and distances between the

mounting holes are shown in picture 2-2.

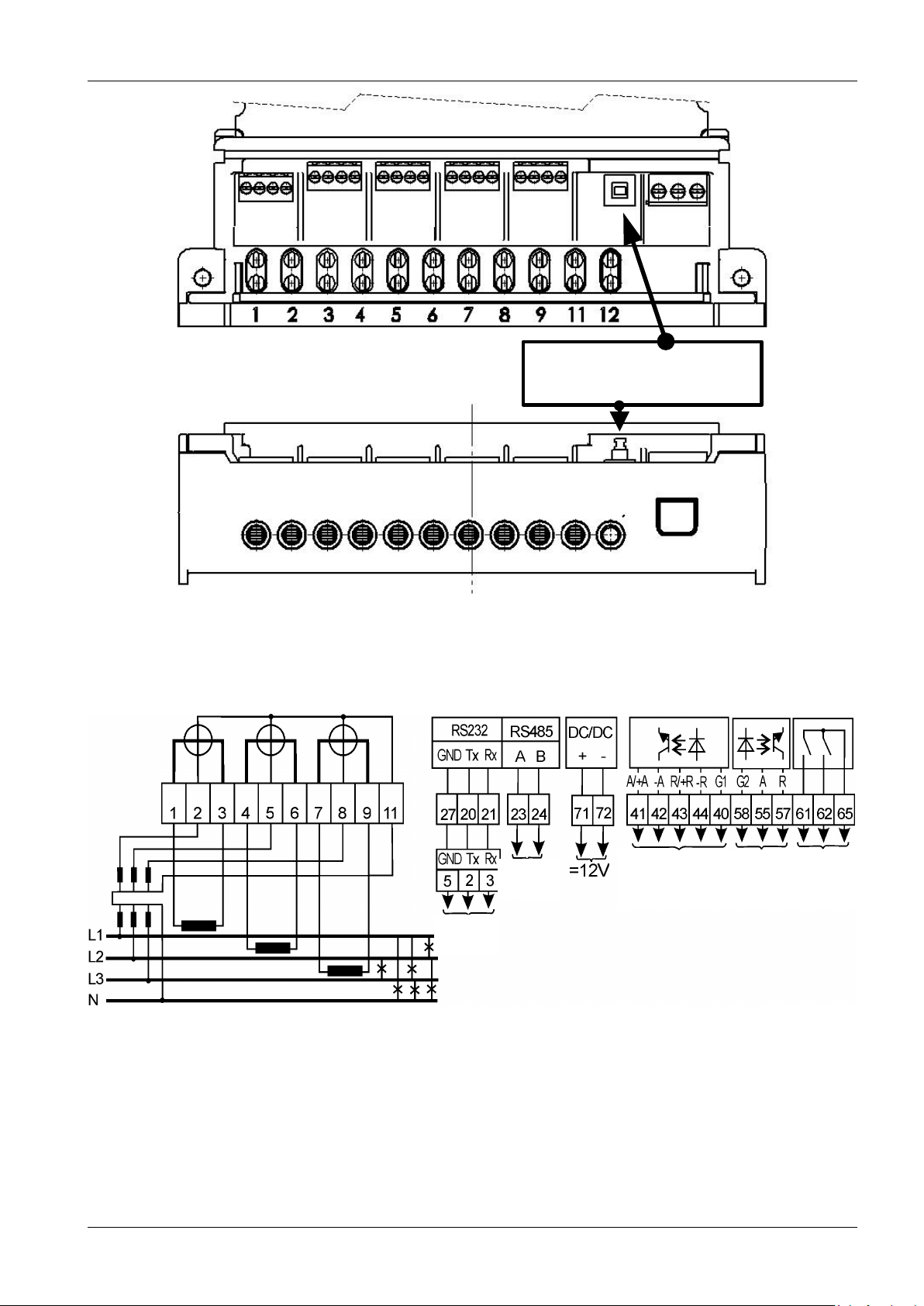

4. The meters are connected according to the scheme shown on the cover of the meter terminal

box diagrams. Picture 2-4 shows the general connection of EPQS meters through current and

voltage transformers.

5. Regular verification of the meter shall be carried once in eight years.

6. Only natural or legal persons authorised by the manufacturer can repair the meter.

Picture 2-2. The Overall Dimensions and Mounting Holes of EPQS Meter

11

20 21 27 28 23 24 41 42 43 44 40 58 16 15 31 32 55 57 71 72 61 62 65

Terminal cover opening

button

Picture 2-3. Meter terminal box

S0 outputs Test Relay

outputs

CL1

CL2

Picture 2-4. Wiring diagram

Loading...

Loading...