ELGA PURELAB Prima 7, PURELAB Prima 7 BP, PURELAB Prima 15 BP, PURELAB Prima 15, PURELAB Prima 30 Operator's Manual

...

PURELAB Prima 7/15/30

Operator Manual

ELGA PURELAB Prima 7/15/30 Operator Manual

PURELAB Prima 7/15/30 Version 01 09/08 Page i

Copyright Note

The information contained in this document is the property of VWS

(UK) Ltd. and is supplied without liability for errors or omissions.

No part of this document may be reproduced or used except as

authorized by contract or other written permission from VWS (UK) Ltd.

The copyright and all restrictions on reproduction and use apply to all

media in which this information may be placed.

VWS (UK) Ltd. pursue a policy of continual product improvement and

reserve the right to alter without notice the specification, design, price

or conditions of supply of any product or service.

© VWS (UK) Ltd. 2008

All rights reserved

Publication ref: MANU38902

Version 01 – 09/08

PURELAB Prima 7/15/30 Operator Manual ELGA

Page ii PURELAB Prima 7/15/30 Version 01 09/08

TABLE OF CONTENTS

1. INTRODUCTION ..................................................................... 1

1.1 Product Range ............................................................... 1

1.2 Use of this Manual ......................................................... 1

1.3 Customer Support .......................................................... 1

2. HEALTH AND SAFETY NOTES ............................................. 2

2.1 Electricity ........................................................................ 2

2.2 Pressure......................................................................... 2

2.3 Sanitization Chemicals .................................................. 2

2.4 Control of Substances Hazardous to Health (COSHH) . 2

3. PRODUCT AND PROCESS DESCRIPTION .......................... 3

3.1 Product Description ....................................................... 3

3.2 Process Description ....................................................... 4

3.3 Technical Specifications ................................................ 6

4. CONTROLS ........................................................................... 10

5. INSTALLATION INSTRUCTIONS ........................................ 11

5.1 Unpacking the PURELAB Prima ................................ 11

5.2 Positioning the PURELAB Prima ................................ 11

5.3 Connecting up the PURELAB Prima .......................... 13

5.4 Initial Controller Set-Up ................................................ 15

5.5 Initial Start Up .............................................................. 17

6. OPERATION .......................................................................... 18

6.1 Alarm Conditions ......................................................... 18

7. MAINTENANCE .................................................................... 19

7.1 Replacing the LC140 Pre-treatment Cartridge ............ 20

7.2 Cleaning the Inlet Strainer ........................................... 21

7.3 Replacement of LC143 Reverse Osmosis Cartridge(s)21

8. SANITIZATION PROCEDURES ........................................... 22

8.1 CT1 Sanitization Tablet - Safety Information ............... 23

9. TROUBLE SHOOTING ......................................................... 24

10. CONSUMABLES AND ACCESSORIES ............................... 25

11. KEY TO CONTROL PANEL .................................................. 26

11.1 Icons ............................................................................ 26

11.2 Alarm Conditions ......................................................... 26

11.3 Replacement Timers .................................................... 26

11.4 Quality and Standby Alarms ........................................ 27

12. WARRANTY/CONDITIONS OF SALE .................................. 28

13. USEFUL CONTACT DETAILS.............................................. 30

ELGA PURELAB Prima 7/15/30 Operator Manual

PURELAB Prima 7/15/30 Version 01 09/08 Page 1

1. INTRODUCTION

1.1 Product Range

This Operator Manual has been prepared for the PURELAB Prima

product models:

PURELAB Prima 7

PURELAB Prima 7 BP (with boost pump)

PURELAB Prima 15

PURELAB Prima 15 BP (with boost pump)

PURELAB Prima 30

PURELAB Prima 30 BP (with boost pump)

1.2 Use of this Manual

This manual contains full details on installation, commissioning and

operation of the PURELAB Prima unit. If this unit is used contrary to

the instructions in this handbook, then the safety of the user may be

compromised.

1.3 Customer Support

Service support and consumable items are available from your local

supplier or distributor. Refer to customer service contact details

shown at the end of this publication.

PURELAB Prima

PURELAB Prima 7/15/30 Operator Manual ELGA

Page 2 PURELAB Prima 7/15/30 Version 01 09/08

2. HEALTH AND SAFETY NOTES

PURELAB Prima products have been designed to be safe, however,

it is important that personnel working on these units understand any

potential dangers. All safety information detailed in this handbook is

highlighted as WARNING and CAUTION instructions. These are used

as follows:

WARNING! WARNINGS ARE GIVEN WHERE FAILING

TO OBSERVE THE INSTRUCTION COULD

RESULT IN INJURY OR DEATH TO

PERSONS.

CAUTION! Cautions are given where failure to

observe the instruction could result in

damage to the equipment, associated

equipment and processes.

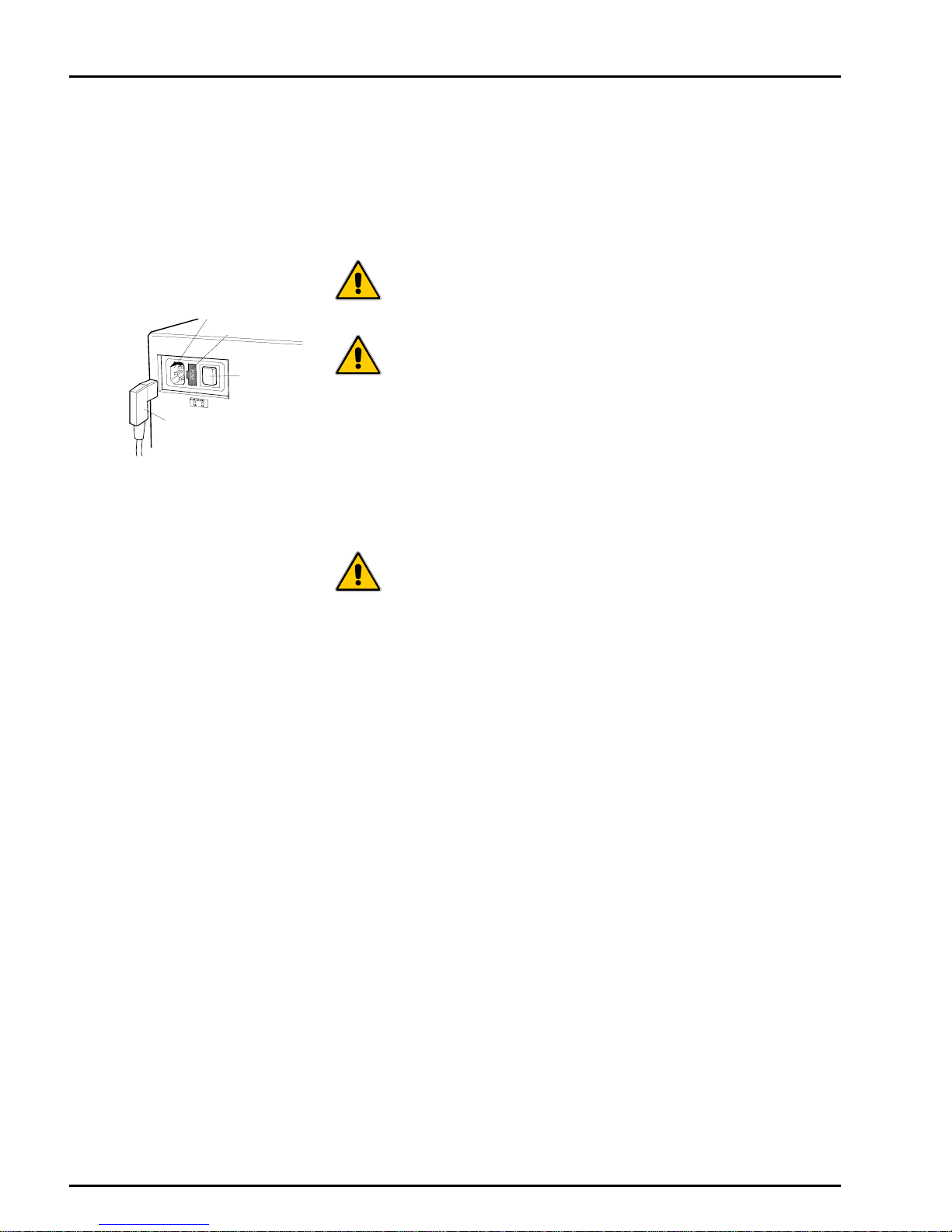

2.1 Electricity

It is essential that the electrical supply to the PURELAB Prima is

isolated before any items are changed or maintenance work

performed.

The ON/OFF switch is located at the left-hand side of the unit. The

mains power lead is located just behind the ON /OFF switch.

WARNING! THIS APPLIANCE MUST BE EARTHED.

2.2 Pressure

The main water supply pressure should be isolated and residual

pressure released prior to removal of any cartridges or carrying out

work on the unit.

Switching off the electrical supply will isolate the source of pressure,

but pressure trapped within the unit should be released.

2.3 Sanitization Chemicals

During the sanitization cycle a CT1 sanitization tablet is used and

relevant safety information is included in this handbook. A safety data

sheet conforming to COSHH regulations is also provided with the

tablets and should be read before the tablet is used.

2.4 Control of Substances Hazardous to Health (COSHH)

Material safety data sheets covering the various replaceable

cartridges are available upon request. Contact your local supplier or

distributor.

Fuse

ON/OFF

switch

Mains power lead

Mains power socket

Mains Power Supply

ELGA PURELAB Prima 7/15/30 Operator Manual

PURELAB Prima 7/15/30 Version 01 09/08 Page 3

3. PRODUCT AND PROCESS

DESCRIPTION

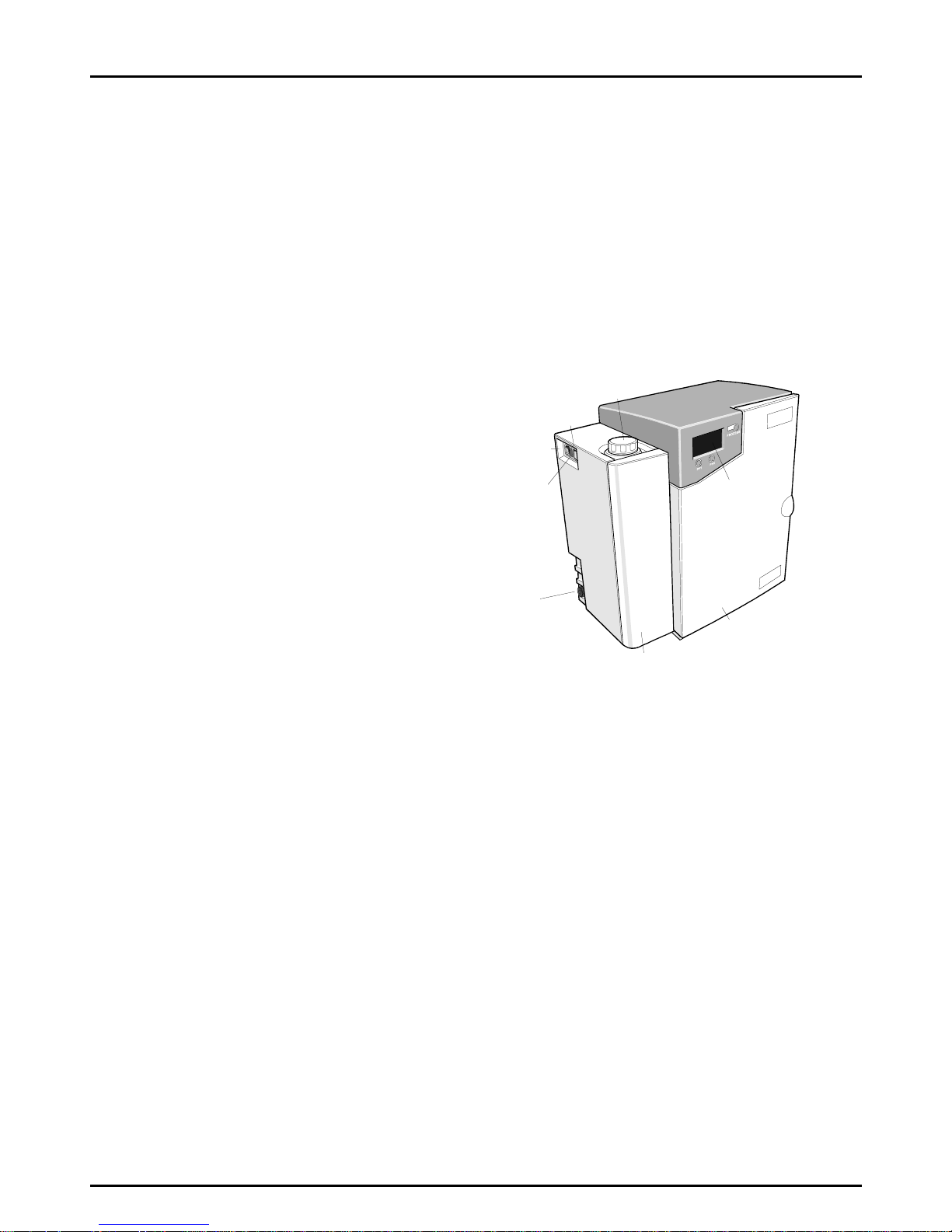

3.1 Product Description

The PURELAB Prima water purification unit has been specifically

designed to provide a supply of purified 'primary' grade water for

laboratory, medical and industrial applications.

The PURELAB Prima can be bench or wall mounted with an optional

wall mounting kit. A range of accessories are available to complement

the unit. (See Section 10 – Consumables and Accessories, for detail).

Sanitization port

Powe

r

switch ON/OFF

Mains powe

r

socket

Fuse

Feedwater inlet

connection

Removeable cover

Control panel

Door

PURELAB Prima

PURELAB Prima 7/15/30 Operator Manual ELGA

Page 4 PURELAB Prima 7/15/30 Version 01 09/08

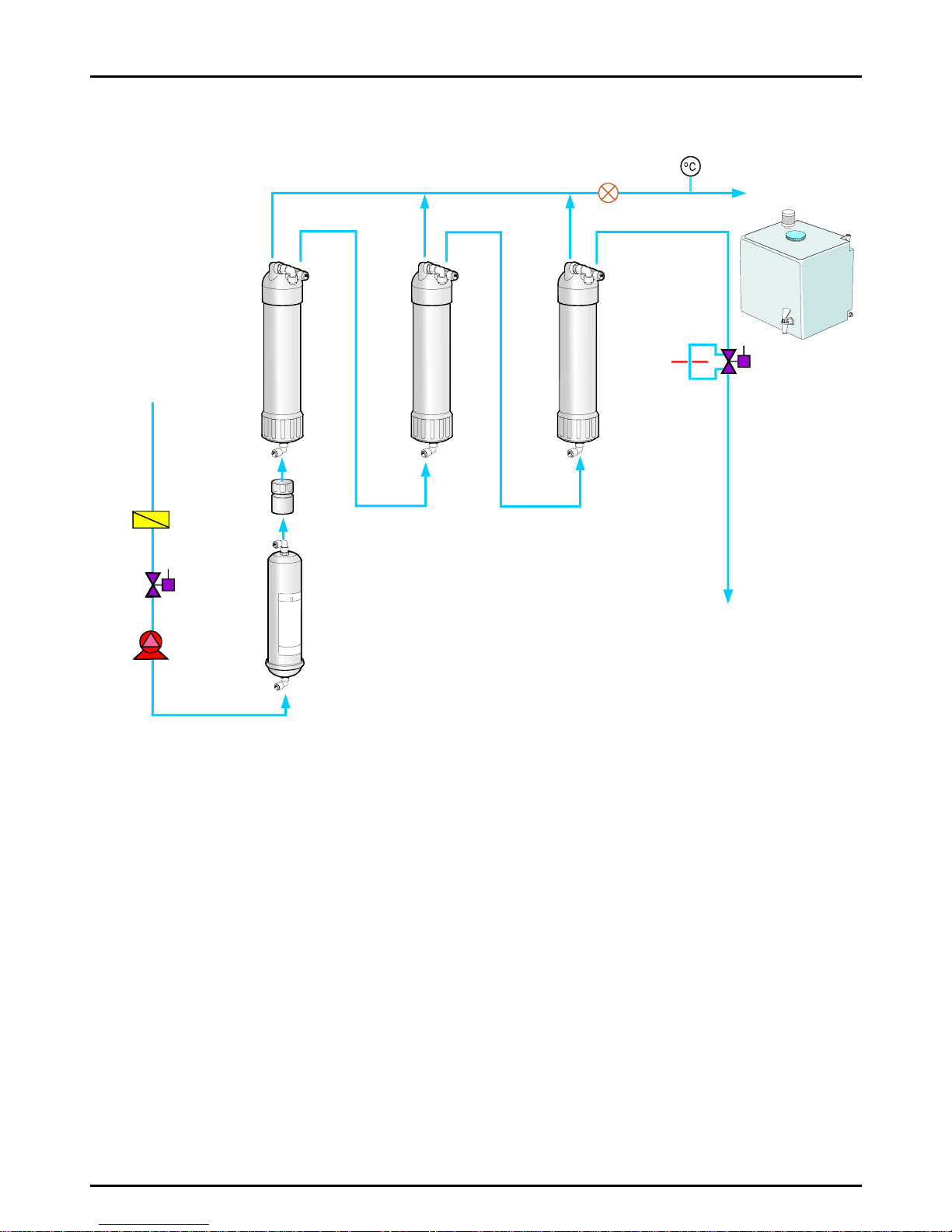

3.2 Process Description

The PURELAB Prima process links two purification technologies,

reverse osmosis, adsorption and also incorporates an optional RO

feed water boost pump.

The unit is designed to operate from a good quality potable water

supply, at 15°C and produces 7, 15 or 30 liters per hour of purified

reverse osmosis grade water which is delivered to a treated water

reservoir.

A graphics screen displays the system status and provides control by

means of three function buttons.

The water is processed and treated by the PURELAB Prima unit as

follows:

• Potable water enters through a strainer and inlet solenoid

valve at either regulated mains water pressure, or is pumped

by means of a feed water pump (optional), and passes

through the pre-treatment cartridge. The pre-treatment

cartridge has been designed to protect the reverse osmosis

cartridges from particulate/colloidal matter and excessive

free chlorine, which may be present in the incoming

feedwater.

• The water then passes the sanitization port and through

one, two or three reverse osmosis cartridges, set up in

series, which split the flow into permeate and concentrate

streams. The permeate water is further purified whilst the

waste concentrate stream is passed to drain.

• The permeate water is passed through a:

• Water quality sensor, which measures the conductivity of

the water.

• Temperature sensor which provides accurate

temperature measurement.

• Finally, the purified water is delivered to a treated water

reservoir.

• To ensure that the quality of the purified outlet water from

the unit is maintained at its highest level, the unit has an inbuilt automated auto-rinse cycle. The auto-rinse cycle is

performed every time the process is initiated and consists of

a 1 minute high flow rinse to drain across the reverse

osmosis cartridges.

ELGA PURELAB Prima 7/15/30 Operator Manual

PURELAB Prima 7/15/30 Version 01 09/08 Page 5

Temp

measurement

Water quality

sensor

Outlet

Outlet Outlet

Drain Drain Drain

Reverse

Osmosis

LC143

Reverse

Osmosis

LC143

Reverse

Osmosis

LC143

Inlet

Inlet Inlet

Feed water

inlet

Sanitization

Port

Strainer

Solenoid

Boost

pump

(optional)

Pre-treatment

LC140

Concentrate

drain

Auto rinse

solenoid

with internal

bypass

Product outlet

(permeate)

Dispense

Tap

Process Flow - PURELAB Prima

Reservoir

PURELAB Prima 7/15/30 Operator Manual ELGA

Page 6 PURELAB Prima 7/15/30 Version 01 09/08

3.3 Technical Specifications

The Technical Specifications for the PURELAB Prima are as follows:

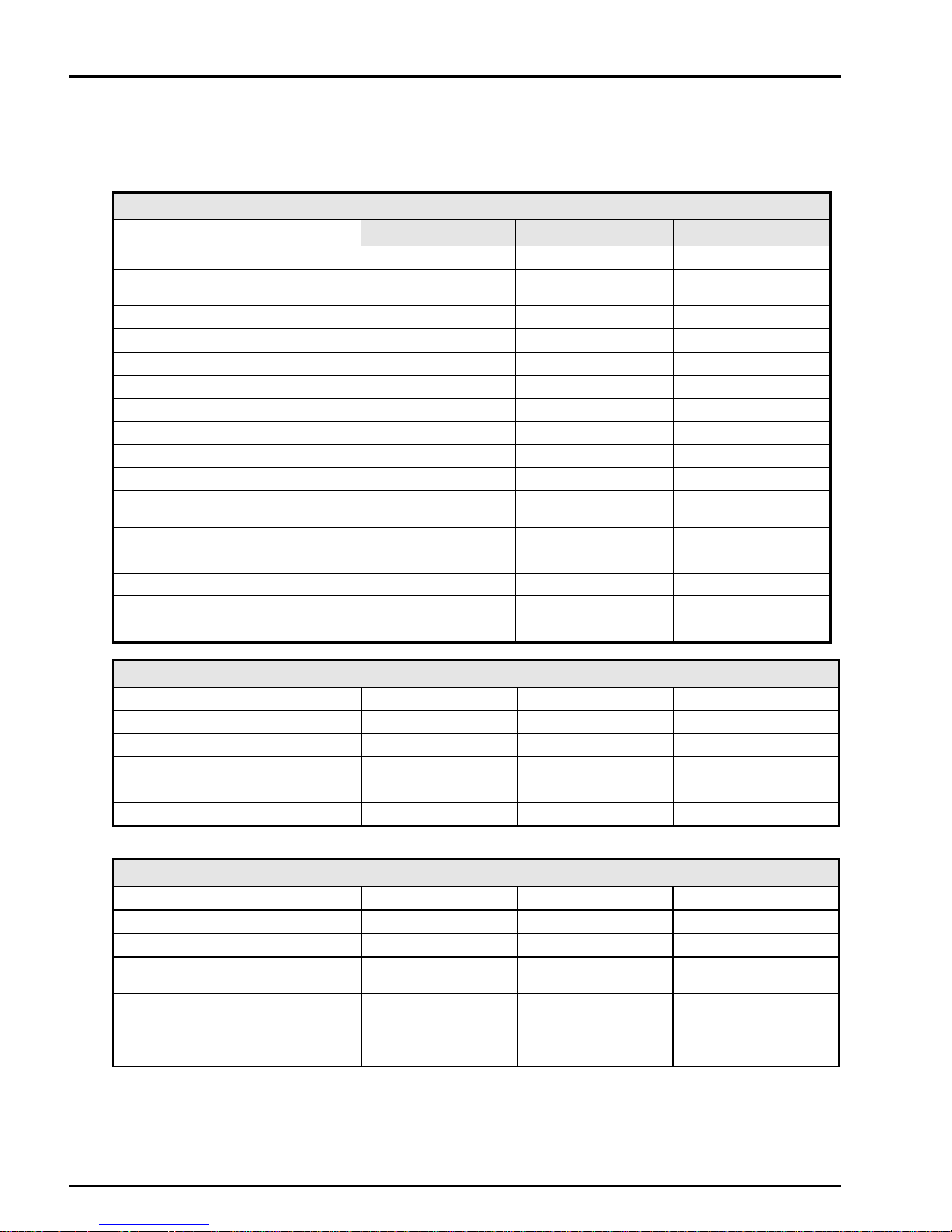

Feedwater

PURELAB Prima 7 PURELAB Prima 15 PURELAB Prima 30

Feedwater

Source Quality Potable mains water

supply

Potable mains water

supply

Potable mains water

supply

Fouling Index-maximum 10 10 10

Total Dissolved Solids-maximum

1400µS/cm 1400µS/cm 1400µS/cm

Free Chlorine-maximum 0.5ppm 0.5ppm 0.5ppm

Chloramine-maximum 0.5ppm 0.5ppm 0.5ppm

Heavy Metals - maximum 0.05ppm 0.05ppm 0.05ppm

Silica - maximum 30ppm 30ppm 30ppm

TEMPERATURE

1 - 35°C 1 - 35°C 1 - 35°C

FLOWRATE (maximum requirement)

145 l/hr 150 l/hr 155 l/hr

Drain requirements (gravity fall with air gap).

Maximum during service

70 l/hr 70 l/hr 80 l/hr

Feedwater Pressure

Maximum - without internal boost pump 6.0 bar (90 psi) 6.0 bar (90 psi) 6.0 bar (90 psi)

Minimum - without internal boost pump 4.0 bar (60 psi) 4.0 bar (60 psi) 6.0 bar (90 psi)

Maximum - with internal boost pump 2.0 bar (30 psi) 2.0 bar (30 psi) 2.0 bar (30 psi)

Minimum - with internal boost pump Flooded Suction Flooded Suction 1.0 bar (15 psi)

Dimensions

Height 460mm (18.1") 460mm (18.1") 460mm (18.1")

Width 410mm (16.2") 410mm (16.2") 410mm (16.2")

Depth 270mm (10.6") 270mm (10.6") 270mm (10.6")

Weight

With internal boost pump 13.5kg (30lb) 14.5kg (32lb) 15.0kg (33lb)

Without internal boost pump 11.5kg (25lb) 12.5kg (28lb) 13.0kg (29lb)

Connections

Inlet-quick connect 8mm (5/16") OD 8mm (5/16") OD 8mm (5/16") OD

Outlet-quick connect 8mm (5/16") OD 8mm (5/16") OD 8mm (5/16") OD

Drain RO-quick connect 8mm (5/16") OD 8mm (5/16") OD 8mm (5/16") OD

Positioning Wall, bench or under

bench mounted.

Wall, bench or under

bench mounted.

Wall, bench or under bench

mounted.

Environment Clean dry indoor.

Temp 5 - 40°C.

Humidity max 80%

non-condensing.

Clean dry indoor.

Temp 5 - 40°C.

Humidity max 80%

non-condensing.

Clean dry indoor.

Temp 5 - 40°C.

Humidity max 80%

non-condensing.

ELGA PURELAB Prima 7/15/30 Operator Manual

PURELAB Prima 7/15/30 Version 01 09/08 Page 7

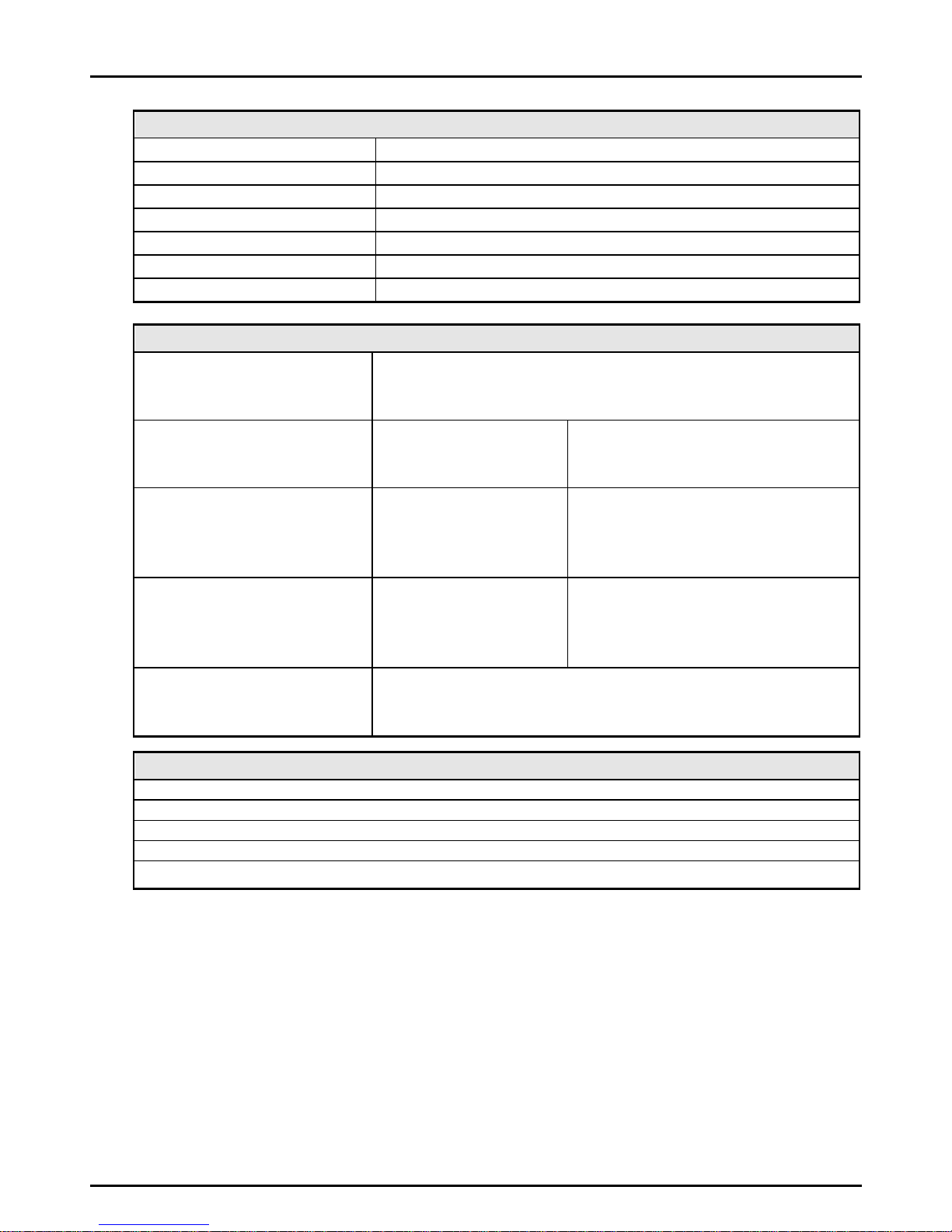

Electrical Requirements

Mains input 100-240V ac, 50-60Hz all models

System voltage 24V dc

Power consumption with boost pump 52VA

Power consumption without boost pump 28VA

Fuses 2 x T3.15 Amp

Reservoir level connection Jack Plug 3.5mm

Noise level <45 dBA

User Interface

Display Continuous graphical and numerical reservoir level display

Graphical flow schematic on screen with mimic display

Intuitive Icons

Adjustable settings Auto restart after power failure Selectable

Audible alarm Selectable

Water purity Alarm setpoints

Indicators Reverse osmosis permeate water conductivity

Temperature Degrees centigrade

Reservoir % Full

Pre-treatment cartridge Maximum remaining life indicator

Alarms-Audiovisual Purified water purity Outside set point alarm

Reservoir Low level

Reservoir Level control disconnect alarm

Pre-treatment cartridge Change reminder

Outputs RS232 Printer connection

RS232 Remote display connection

Volt free contact-internal

Safety Features

Power fail safe

Boost pump protection from particulates

Low operating voltage 24V

Audio visual alarms

Adjustable alarm settings

Loading...

Loading...