Elevated Access Sinoboom GTJZ1412, Sinoboom GTJZ1414 Maintenance Manual

GTJZ1412

& GTJZ1414

Maintenance Manual

0800 222 111 sales@elevatedaccess.co.nz

021 500 486 www.elevatedaccess.co.nz

GTJZ1412 & GTJZ1414 Maintenance Manual

Key Points

Before maintaining the machine, it is necessary to

read, understand and observe those safety rules,

operation instructions and maintenance instructions.

Only the trained and authorized personnel are allowed

to maintain the machine. It is necessary to always

keep this Manual along with the machine as a part of

it. Please contact with Hunan SINOBOOM Heavy

Industry Co., Ltd.

Table of Contents

Importance ....................................................... 2

afety Rules .................................................... 2

S

Product Performance Parameters .................... 4

Operating Procedures ...................................... 8

Regular Maintenance Procedures ................... 8

Procedure A ........................................... 13

A-1 Inspect All Manuals ............... 13

A-2 Inspect All Labels .................. 13

A-3 Inspect Damaged, Loose or

Lost Parts ....................................... 13

A-4 Inspect Hydraulic Oil Level .. 14

A-5 Inspect Hydraulic Oil Leakage14

A-6 Functional Tests ..................... 14

A-7 Carry out Maintenance after 30

Days............................................... 14

A-8 Inspect Battery

....................... 15

Procedure B ........................................... 16

B-1 Inspect Electric Wires ............ 16

B-2 Inspect Rim and Tire (Including

Mounting Nuts) ............................. 16

B-3 Test Key Switch ..................... 17

B-4 Test Emergency Stop Buttons 17

B-5 Test Horn................................ 17

B-6 Test Braking Device .............. 17

B-7 Testing Traveling Speed

(Platform in Lifted State) .............. 18

B-8 Testing Traveling Speed

(Platform in Fully Retracted State)18

B-9 Test Full Lifting and Full

Lowering Time .............................. 18

B-10 Ins

pect Hydraulic Oil ........... 19

B-11 Check the hydraulic tank

ventilation system ......................... 19

Procedure C ........................................... 20

C-1 Replace Air Filter of Hydraulic

Oil Tank ........................................ 20

C-2 Inspect Platform Weighing

System (Optional) ......................... 20

Procedure D ........................................... 20

D-1 Inspect Scissor Arm Installation

Bearing .......................................... 20

D-2 Inspect Base Frame Slider ..... 20

D-3 Replace Return Oil Filter of

Hydraulic Oil Tank........................ 20

Procedure E ........................................... 21

E-1 Inspect and Re

place Hydraulic

Oil .................................................. 21

Maintenance Procedures ............................... 22

Platform Components ........................... 23

1-1 How to Remove Electric

Control Box from Platform ........... 23

1-2 How to Remove Platform ....... 23

1-3 How to Remove Extension

Platform ......................................... 23

Scissor Arm Part.................................... 24

2-1 How to Remove Scissor Arm . 24

2-2 How to Remove Lifting

Cylinder ......................................... 24

Base Frame Components ...................... 25

3-1 How to dismantle the brake .... 25

3-2 How to dismantle

the driving

motor ............................................. 25

3-3 How to Remove Storage Battery26

3-4 How to Remove Hydraulic

Valve Block ................................... 26

3-5 How to dismantle the hydraulic

power unit ..................................... 26

3-6 How to Remove Hydraulic Oil

Tank ............................................... 26

3-7 How to Remove Steering Oil

Cylinder of Front Wheel ............... 27

3-8 How to dismantle the front

wheel bracket ................................ 27

Hydraulic System .................................. 27

4-1 Detection of Function Pump... 27

4-2 How to Remove H

ydraulic

Pump ............................................. 28

GTJZ1412 & GTJZ1414 Maintenance Manual

4-3 Control valve block on the

platform ......................................... 29

4-4 Symbols of Hydraulic System 33

4-5 Hydraulic Schematic Diagram 34

Electrical System................................... 35

5-1 Use and Maintenance of

Lead-Acid Storage Battery ........... 35

5-2 Trouble Diagnosis (Deltatech

System) .......................................... 40

5-3 Fundamental Troubleshooting 43

5-4 Electrical Symbols .................. 46

5-5 Electrical Schematic Diagram

(Deltatech system) ........................ 47

1

Importance

Hazard

Warning

Caution

Caution

Attention

GTJZ1412 & GTJZ1414 Maintenance Manual

You have understood and observed the safe

operation rules in the operation manual

Before maintaining GTJZ1412 it is necessary to read,

understand and observe corresponding safety rules

and operation instructions.

This Manual provides detailed maintenance

information for the owner and the operator, and

specifies inspection, maintenance and troubleshooting

methods and procedures for the competent

professional maintenance personnel.

The execution of maintenance procedures requires

basic knowledge on

machinery, hydraulic and

electrical aspects. Some maintenance procedures need

special skills, tools, lifting equipment and appropriate

work place. Therefore, it is strongly recommended to

maintain and repair at the designated service center of

the SINOBOOM.

Hunan SINOBOOM Heavy Industry Co., Ltd. will

provide accurate information and quality services.

However, the products will be improved continuously

and technical specification of prod

uct may be

modified without advance notice. We suggest the

users to update latest product maintenance

specifications regularly.

We will appreciate if the customers could inform us

the deficiencies of the products and propose

improvement measures. We will consider all

suggestions carefully and use them as the reference

for the preparation of maintenance specification and

other specifications. Please contact us by E-mail or

fax.

You shall have read, understood and observed

—Manufacturer’s in

structions and safety rules

—User’s safety rules and workplace regulations

—All the applicable government regulations

You must use appropriate tools, lifting

equipment and work place.

Personal safety

All working staff on or around the machine must be

aware of any possible safety hazards. The personal

safety and the continuous and safe operation are the

most important.

Read the procedures carefully. The marks used in the

labels in

this manual and on the machine are defined

as follows:

Safety warning mark- It is used to prompt

potential personal injuries. Observe all

safety prompts behind this mark for the

purpose of avoiding personal injuries or

death.

Red mark- It is used to prompt the urgent

hazardous cases; if not avoided, it would

lead to death or serious injuries.

Orange mark- It is used to prompt

potential hazardous cases

it would lead to death or serious injuries.

; if not avoided,

Saf

ety Rules

Hazard

Failure to observe the instructions in this Manual and

corresponding operation manual would cause death or

serious injury accident.

Pay attention to the unsafe operations mentioned in

the operation manual when carrying out maintenance

procedures.

Do not operate, unless:

Orange mark with safety warning- It is

used to prompt potential hazardous case;

if not avoided, it might lead to mild or

moderate personal injury.

Orange mark without safety warning- It is

used to prompt potential hazardous case;

if not avoided, it might lead to property

losses.

Green mark- It is used to prompt

operation or maintenance information.

It is necessary to wear protective goggles,

and work clothes.

With potential hazards such as movable

parts, components which could rotate

2

GTJZ1412 & GTJZ1414 Maintenance Manual

freely or have not been fixed, lifting or moving weight.

Be sure to wear work boots.

Safety in Work Place

Keep sparks, flame and lit cigarette end

away from flammable and explosive

materials such as storage battery and

engine fuel. Equip qualified fire

extinguisher nearby.

Maintain all tools and work place

properly for future use. Ensure the

working environment to be clean and

prevent the sundries or fragment dropping

into the machine compo

Ensure good ventilation and illumination

conditions in the work place and working

area.

Ensure any forklift, traveling crane or

other lifting/supporting equipment to

have sufficient bearing and lifting

capacity. Ensure to use steel wire rope or

belt with sufficient bearing capacity and in good

condition.

nents, resulting in damages.

Do not use disposable fasteners (such as

split pins and self-locking nuts)

repeatedly. The componen

become invalid if they are used again.

Dispose the used hydraulic oil and other

fluid appropriately. Use appropriate

container. Protect the environment from

being polluted.

ts might

3

Width

Height

Maximum platform height

Maximum working height

Maximum horizontal

extension

Hydraulic system

GTJZ1412 & GTJZ1414 Maintenance Manual

Product Performance Parameters

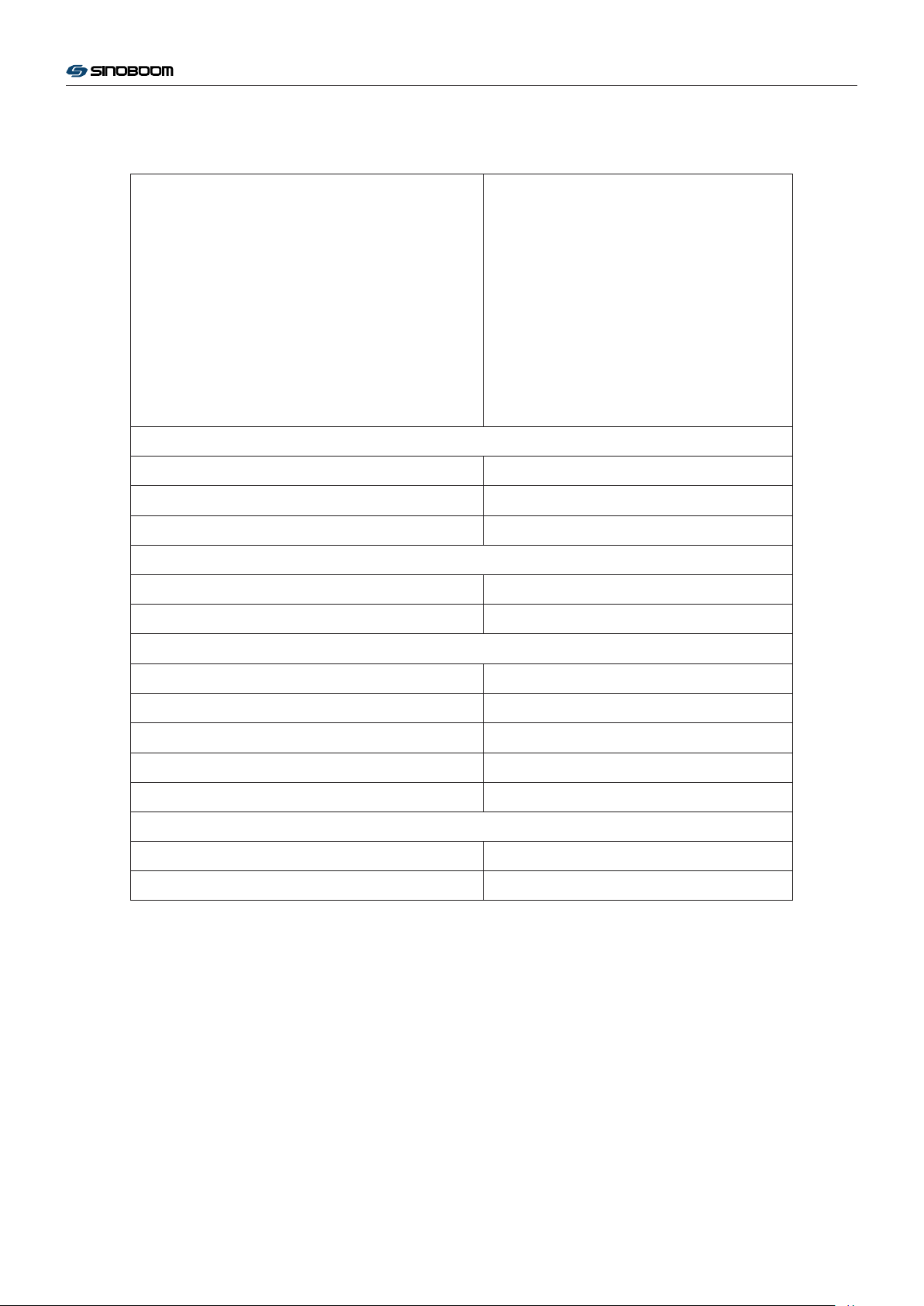

Parameter Items Unit GTJZ1412

Outline dimension

Length

Ground clearance mm 100

Ground clearance (Pithole

protective device stretches)

Total weight kg 3364

Design dimension

m 2.76

m 1.25

m 2.60

mm 22

m 13.8

m 15.8

m 0.9

Maximum bearing capacity kg 227

Extended platform bearing capacity kg 120

Allowable quantity of people

working on the platform

Wheel base m 2.22

Wheel span m 1.25

Turning radius

Internal wheel m 0

External wheel m 2.56

Maximum allowable yawing force

(indoor/outdoor)

Control voltage (DC) V 24

Platform dimensions

Length m 2.64

Height m 0.81

Tire size

Diameter mm 380

Height mm 125

Oil volume

Hydraulic oil tank L 14

Pressure of hydraulic system bar 240

System voltage (DC) V 24

Maximum noise for normal

working

Traveling speed

Person 2 (indoor)/1 (outdoor)

N 400/200

L 42 (Oil tank)

dB 72

4

GTJZ1412 & GTJZ1414 Maintenance Manual

Off-running status km/h 0~3.2

Lifting status km/h 0~0.8

Gradeability % 25

Lifting/lowering time s 83s~92s /55s~65s (No load)

Maximum allowable wind speed

(indoor/outdoor)

Maximum allowed inclined

angle

m/s 0/12.5 (Gale Level 6)

Front and rear 3°/Left and right 1.5°

5

GTJZ1412 & GTJZ1414 Maintenance Manual

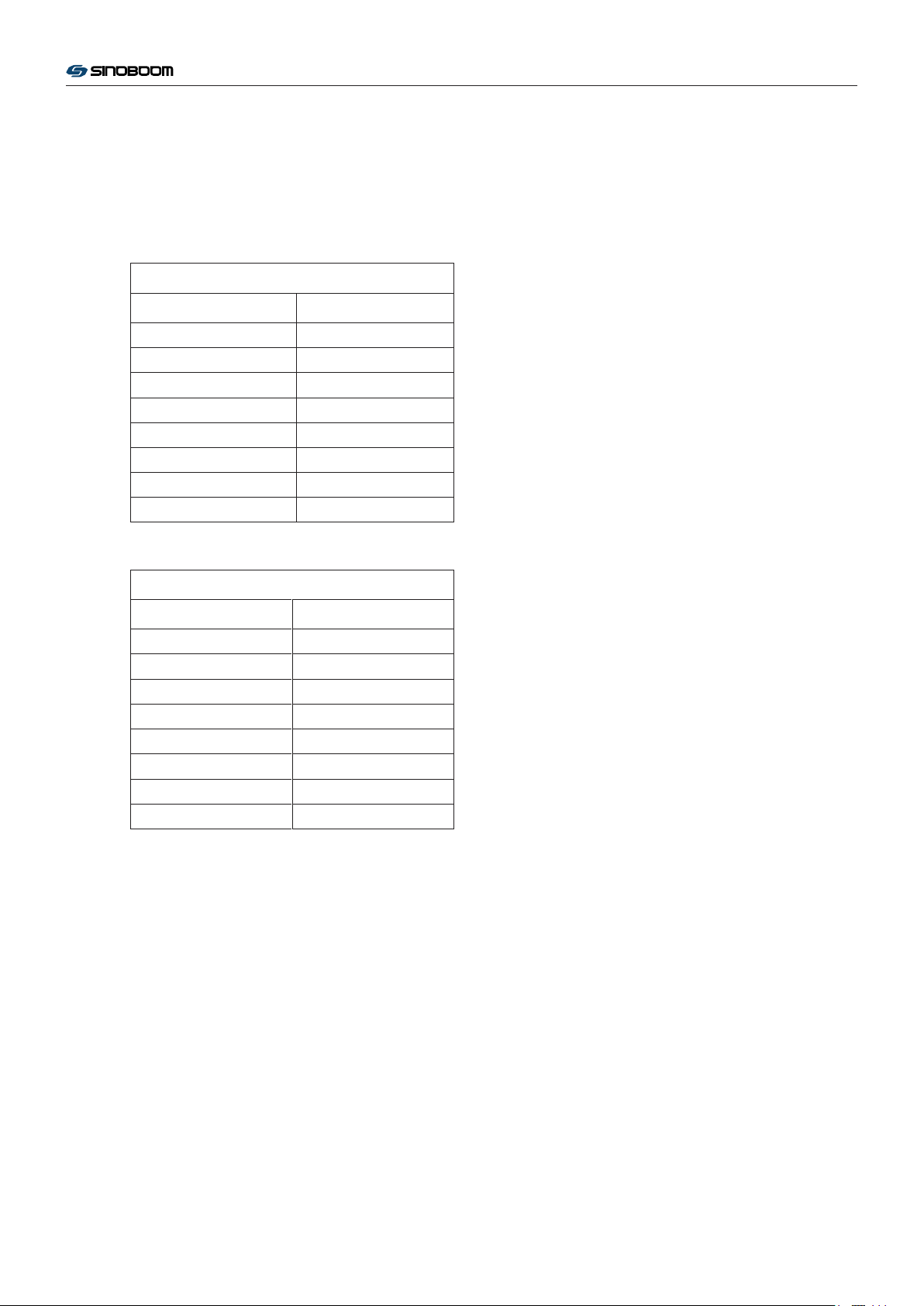

Description of Hydraulic System

Normal temperature region (0℃ to 40℃):

L-HM46;

Cold region (-25℃ to 25℃): L-HV32;

Hot region

(>40℃): L-HM68;

Extremely cold region

(<-30℃):

Special scheme to be determined;

Different hydraulic oil may be filled in

according to the requirements of the customer

upon delivery.

Hydraulic pump

Type Gear pump

Flow rate (at 3000r/min) 12L/min

Maximum driving pressure 248bar

Traveling motor

Type Orbit motor

Displacement 375cc/r

Functional valves

Pressure of function main safety valve 248bar

Pressure of lifting overflow valve 210bar

Pressure of steering overflow valve 120bar

Pressure of travelling overflow valve 248bar

Opening pressure of travelling brake 28 bar

Oil return filter

Oil return filter of hydraulic oil tank SP-06×10

Bypass pressure of oil return filter 2.5bar

6

GTJZ1412 & GTJZ1414 Maintenance Manual

Installation Instructions for Hydraulic Hoses and

Fittings

When removing or installing the hydraulic hoses and

fittings with O-ring, it is necessary to operate as per

the torque specified in the following table.

Hose fittings

Thread Torque Nm

G1/8A 20±1

G1/4A 35±2

G3/8A 50±3

G1/2A 75±5

G3/4A 120±8

G1A 180±10

G1 1/4A 240±15

7/16-20 21±2

Hoses

Thread Torque Nm

M12×1.5 19±1

M14×1.5 26±2

M16×1.5 40±3

M18×1.5 50±4

M22×1.5 70±5

M26×1.5 90±6

M30×2 120±8

M36×2 150±12

Tightening Procedures

1. Replace the O-ring. It is necessary to replace the

O-ring if the seal has been damaged. The O-ring

shall not be reused if the pipe fitting or the hose

has between tightened.

2. Lubricate the O-ring before installation.

3. Ensure to place and fix the O-ring properly.

4. Align the hose nut to the pipe fitting, and tighten

the nut.

5. Tighten the nut or the pipe fitting as per the

torque specified

6. Perform all machine functions and inspect hoses,

hose fittings and relevant components to confirm

that no leakage occurs.

in the above table.

7

Warning

GTJZ1412 & GTJZ1414 Maintenance Manual

Operating Procedures

Energy

4 sets of 6V lead-acid cell in series for driving of a

24V DC motor. The gear pump is connected to the

output shaft of the motor with the spline to provide

power for the system.

Hydraulic System

All functions of the machine are driven by a hydraulic

system which is divided into two parts: one for the

travelling and steering functions and the other for the

lifting function of the platform.

When the motor i

the pressure oil to the function valve block which is

equipped with a directional valve and a flow

regulating valve for performing different actions and

adjusting the speed. In order to protect relevant

components and avoid overload of system pressure, a

relief valve is installed on the valve block.

Electrical System

4 separate 6V batteries are used in the system to drive

the hydraulic pump and drive

the lift function of the lift arm. The storage batteries

are re-charged with external power supply.

Machine Control

s working, the hydraulic pump sends

a controller that controls

Regular Maintenance Procedures

Compliance

The maintenance and inspection should be

completed by trained and competent personnel.

The regular maintenance inspection consists of

daily, quarterly, semiannual, annual and biennial

maintenance. The maintenance and inspection

personnel must inspect and maintain according

to the maintenance and inspection reports, and

fill in

maintenance and inspection reports in

details.

Warning: Failure to carry out

maintenance procedures

specified herein timely and

regularly may lead to death, serious injury or machine

damages.

The damaged or troubled machine must be

labeled and moved away timely.

The functions of the machine are controlled with one

controller in this system. This controller is installed in

the ground control box. The controller exchanges data

through a high-speed data bus.

Safety Measures

A series of angle sensors and limit switches provides

signals to the con

the angle of vehicle body on axis X and axis Y; when

the angle on axis X exceeds 1.5° or the angle on axis

Y exceeds 3°, the alarm will be triggered, and the

machine could not lift, travel or turn.

Travel switch shall be used to confirm if the pit

protective mechanism is opened enough. If the

platform is lifted off ground by 2.5m, the pit

protective plate is not stretched, and the sens

detected the signals, the platform will stop rising.

trollers. The level sensor measures

or has not

The damaged or troubled machine must be

repaired before operation.

All records shall be stored for at least three

years.

The machine which has not bee

over three months must be subjected to quarterly

inspection.

Unless otherwise specified, the maintenance

procedures shall be carried out according to the

following precautions:

Park the vehicle on level firm ground

Engage the platform in loaded state

Turn the key switch to the position “OFF” and

take down the key

Turn the red emergency stop buttons on

platform controller and ground controller to the

position “OFF”

onnect all DC power supplies on the

Disc

machine

n maintained by

Lock the tires

8

Hazard

Warning

Caution

Caution

Attention

GTJZ1412 & GTJZ1414 Maintenance Manual

Description

This section provides detailed operation procedures

for the regular maintenance and inspection.

Symbol Definition

Safety warning mark- It is used to prompt

potential personal injuries. Observe all safety

prompts behind this mark for the purpose of

avoiding personal injuries or death.

Red mark- It is used to prompt the urgent

hazardous cases; if not avoided, it would lead to

death or serious injuries.

Orange mark- It is used to prompt potential

hazardous cases; if not avoided, it would lead to

death or serious injuries.

Orange mark with safety warning- It is used to

prompt potential hazardous case; if not avoided,

it might lead to mild or moderate personal injury.

Orange mark without safety warning- It is used

to prompt potential hazardous case; if not

avoided, it might lead to property losses.

Green mark- It is used to prompt operation or

maintenance information.

Maintenance Symbol Definition

The following symbols are

Attention

the intent of this specification. If one or several

symbols are marked in front of the maintenance

procedure, it is defined as follows:

used in this manual for

helping the reader understand

Indicate that this operation must be carried

out by the supplier

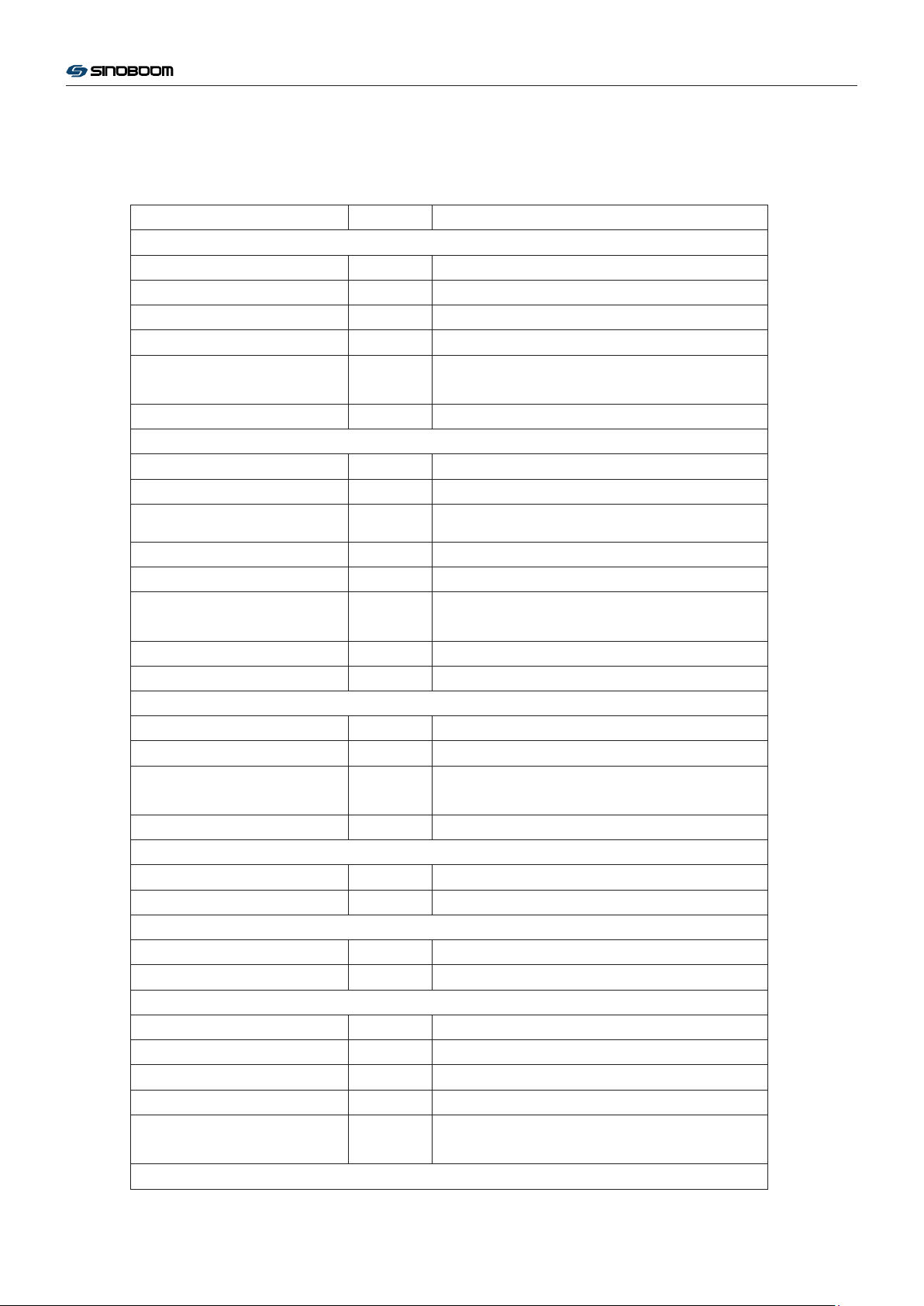

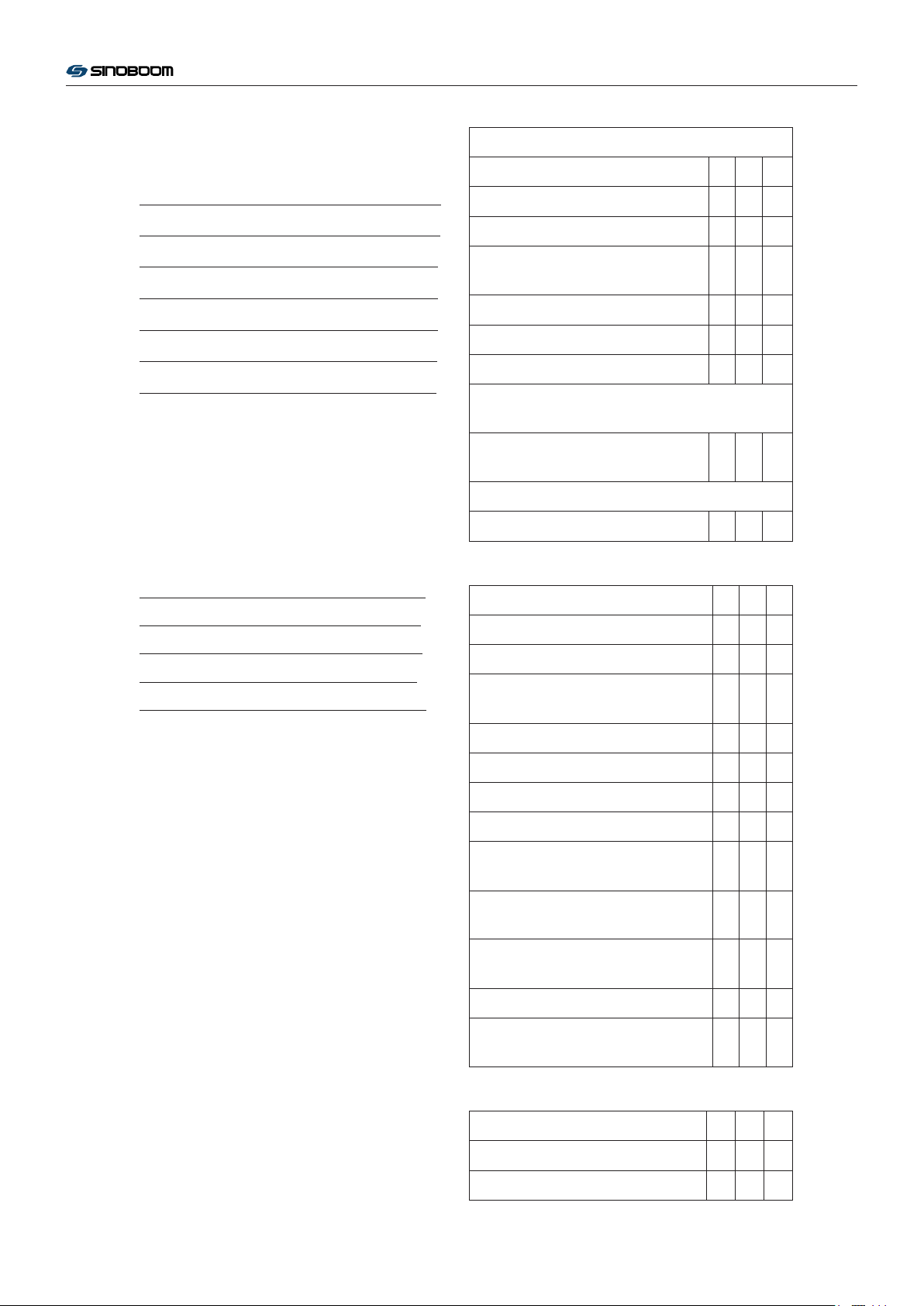

Maintenance Schedule

There are five types of repair & inspection to be

carried out according to the schedule: Every day,

every quarter, every six months, every year and every

two years. With consideration to the repeated

procedures, the

“Regular Repair Procedure Section”

and the “Repair & Inspection Report” shall be

classified into five sections- A, B, C, D and E. The

necessary procedure combination for regular

inspection shall be determined according to the

following table.

Inspection Interval Inspection Procedures

Every day or every 8 hours A

Every quarter or every 250 hours A+B

Every half a year or every 500 hours A+

Every year or every 1,000 hours A+B+C+D

Every two years or every 2,000 hours A+B+C+D+E

B+C

Repair & Inspection Report

The repair & inspection report shall include the

inspection table of each regular inspection.

Indicate the tools for carrying out this

operation

Duplicate the repair & inspection report for each

inspection. Store the completed tables by over three

Indicate new parts for carrying out this

years.

operation

Indicate that hydraulic motor must

be

stopped before carrying out this operation

Indicate that hydraulic motor must be

started before carrying out this operation

9

Attention

GTJZ1412 & GTJZ1414 Maintenance Manual

Pre-delivery Inspection:

It is quite necessary to carry out the preparation before

delivery.

Carry out this procedure each time before delivery for

the convenience of finding before putting the machine

into service whether there are any obvious errors.

Damaged or troubled machine shall not be used. It is

necessary to label and move away the machine if

finding damaged or abnormal machine.

The machine repair must be completed b

competent repair personnel strictly according to the

repair manual.

Daily maintenance must be completed by the

competent operator according to the provisions of this

Manual.

y the

Description:

Use the operation manual for this machine.

The preparation before delivery includes inspection

before delivery, maintenance procedures and

functional inspections.

Record the inspection results. If any inspection result

is N, it is necessary to stop the machine, repair the

machine and then re-inspect the machine, and mark R.

Notes:

Y—Yes, the machine is in good condition.

N—No, the machine has trouble.

R—Repaired, the machine has been repaired.

Record Form of Preparation before Delivery

Items Y N R

Inspection before

Delivery

Maintenance Procedures

Functional Inspections

Model

Serial No.

Date

User

Signature of Inspector

Position of Inspector

Organization of Inspector

10

GTJZ1412 & GTJZ1414 Maintenance Manual

Maintenance Record Form:

Model

Serial No.

Date

User

Signature of Inspector

Position of Inspector

Organization of Inspector

Description:

Record the following results after inspection on each

step.

Time Interval Inspection Procedures

Record Form A

Items Y N R

A-1 Inspect All Manuals

A-2 Inspect All Labels

A-3 Inspect Damaged, Loose or Lost

Parts

A-4 Inspect Hydraulic Oil Level

A-5 Inspect Hydraulic Oil Leakage

A-6 Functional Inspections

Carry out Inspections of New Vehicle after 40

Working Hours

A-7 Carry out Maintenance after 30

Days

Carry out Inspections Every 125 Hours

A-8 Inspect Battery

Every day or every 8 hours A

Every quarter or every 250 hours A+B

Every half a year or every 500 hours A+B+C

Every year or every 1,000 hours A+B+C+D

Every two years or every 2,000 hours A+B+C+D+E

Inspect according to the steps in this section to get

acquainted with the inspection procedures.

Record the inspection results. If any inspection result

is N, it is necessary to stop the machine, repair the

machine and then re-inspect the machine, and mark R.

Notes:

Y—Yes, the machine is in good condition.

N—No, the machine has trouble.

R—Repaired, the machine has been repaired.

Record Form B

Items Y N R

B-1 Inspect Electric Wires

B-2 Inspect Rim and Tire (Including

Mounting Nuts)

B-3 Test Key Switch

B-4 Test Emergency Stop Buttons

B-5 Test Horn

B-6 Test Braking Device

B-7 Test Traveling Speed (Platform in

Lifted State)

B-8 Test Traveling Speed (Platform in

Fully Retracted State)

B-9 Test Full Lifting and Full Lowering

Time

B-10 Inspect Hydraulic Oil

B-11 Inspect Ventilation System of

Hydraulic Oil Tank

Record Form C

Items Y N R

C-1 Replace the hydraulic oil tank air

11

filter

GTJZ1412 & GTJZ1414 Maintenance Manual

C-2 Inspect Platform Weighing

System (Optional)

Record Form D

Items Y N R

D-1 Inspect Scissor Arm Installation

Bearing

D-2 Inspect Base Frame Slider

D-3 Replace Return Oil Filter of

Hydraulic Oil Tank

Record Form E

Items Y N R

E-1 Inspect and Replace Hydraulic Oil

12

Procedure A

Attention

Attention

A-1 Inspect All Manuals

GTJZ1412 & GTJZ1414 Maintenance Manual

A-3 Inspect Damaged, Loose or Lost Parts

Storing the operation manual and the maintenance

manual in appropriate place is of great importance to

the safe operation of the machine. The manuals shall

be stored in the dedicated storage box on the platform.

The illegible or damaged manuals could not provide

necessary safety and operation information for safe

operation.

1. Inspect and confirm that the document box is

placed on appropriate po

2. Inspect and confirm that the operation manual

and the maintenance manual are stored in the

storage box on the platform properly.

3. Inspect the pages of the manuals and confirm that

they are legible and intact.

4. Return the manual into the storage box after use.

Heavy Industry Co., Ltd.

A-2 Inspect All Labels

sition of the platform.

If needing to replace the

manual, please contact

with Hunan SINOBOOM

Inspecting the condition of the machine daily is of

great importance to the safe and reliable operation of

the machine.

damaged, loose or lost parts have not been found and

repaired timely.

Observe the entire machine and check whether any

parts are damaged, installed improperly or lost,

including:

Electrical components, wirings and cables

Hydraulic power unit, oil tank, fittings, hoses,

Storage battery pack and its connection

Driving motor, brake device and fastening bolts

Tyre and fastening nut

Power unit

Limit switch and horn

It would lead to unsafe operation if the

hydraulic cylinders and valve blocks

Maintaining all safe

great importance to the safe operation of the machine.

The labels are used to prompt the operator the

potential risks in the operation process, and

meanwhile provide operation and maintenance

information to the user. The illegible labels could not

guide the operator properly, and might result in unsafe

operation.

1. Consult to the label section in the “GTJZ1412

Operation Manual” and determine the

positions of the labels according to the label list

and chart.

2. Inspect whether all labels are legible and intact;

replace the damaged and illegible labels timely.

Hunan SINOBOOM Heavy Industry Co., Ltd.

ty and prompt labels properly is of

correct

If needing to replace the

labels, please contact with

Alarms and indicator lamps (if provided)

Nuts, bolts and other fasteners

Intermediate hurdles of entrance or door for

platform

Pit-hole protector

Extended zone of platform

Pivot of scissors arm and fastener

Platform joystick

Fastening bolts on the sliding block of the

platform

13

Loading...

Loading...