Elettronika TXUP1500, TXUP500, TXUP1000 Users manual

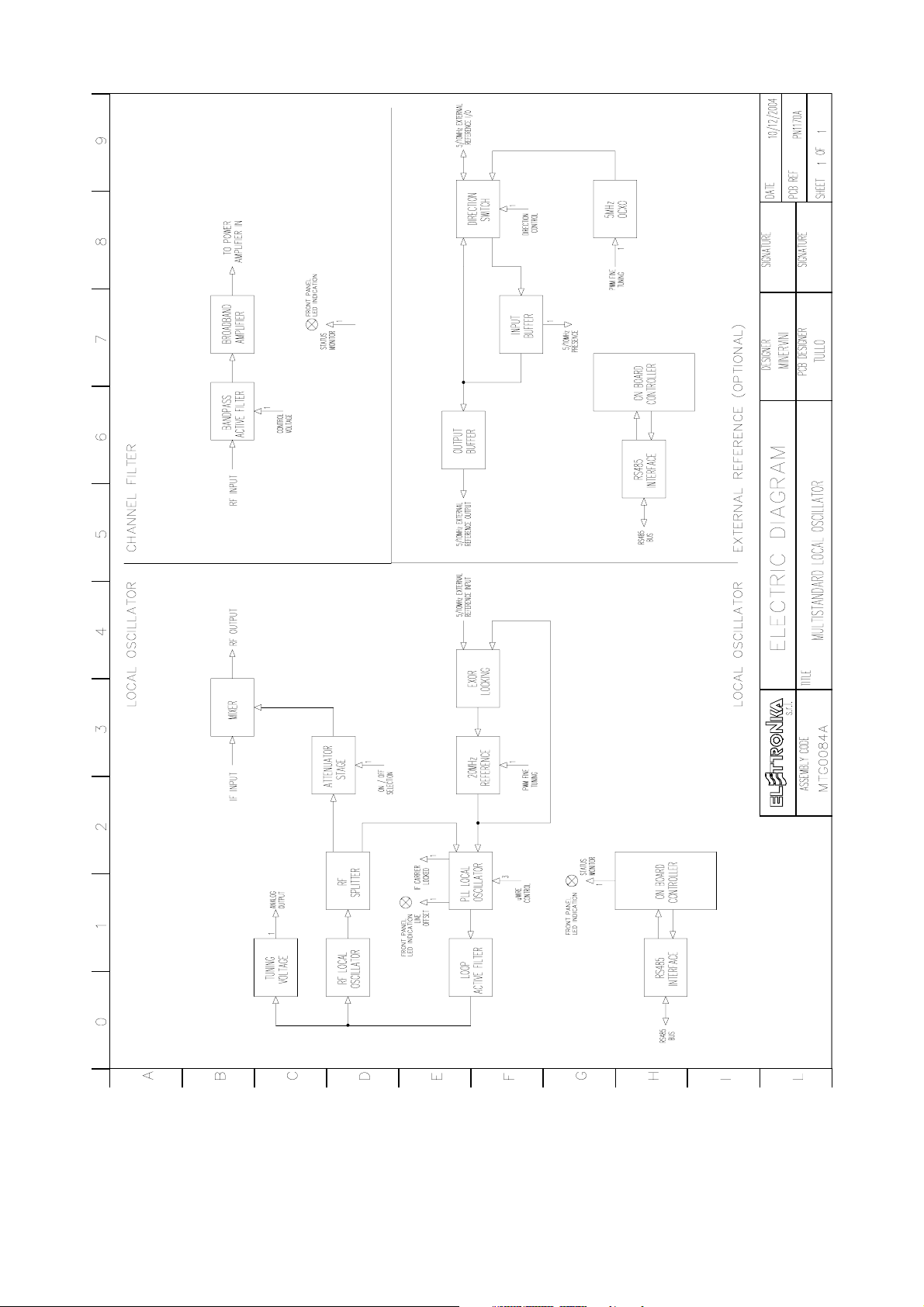

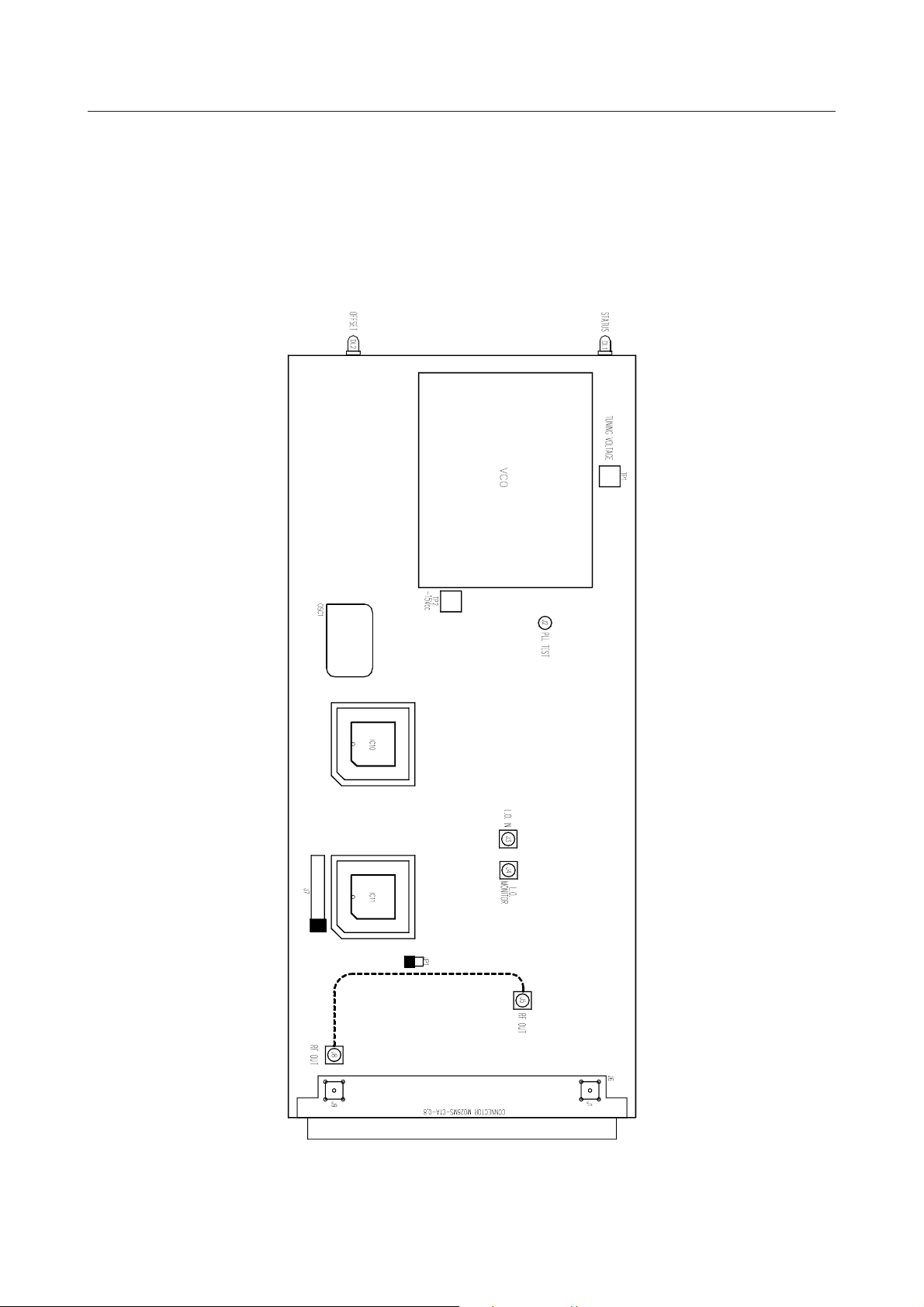

MULT. UHF LOCAL OSCILLATOR MODULE MTG0084AR0

DESCRIPTION

The synthesis system of the local oscillator for the channel conversion is based on a control

technique which allows to obtain the programming of the standard, the channel (split into

the three bands I, III, IV/V) and the line offset (as multiple of the line frequency of the

video signal) via software, with no change to be made.

The module includes an internal VCTCXO reference which can be locked to a more

precise 5/10MHz reference (trough the bus) needed if the field offset is used.

TECHNICAL CHARACTERISTICS

Nominal level +13dBm ±1dB

FM S/N ccir unweight. > 65dB

FM S/N ccir wght. > 60dB

Analog measures VCO control voltage

Carrier frequency synthesis A PLL

Offset Line offset, step ±1/12 line frequency

O.L. carrier characteristics On/Off selection and fine adjust

Frequency reference Internal TCXO externally lockable

External interface Microprocessor with RS485 protocol

Firmware Re-configurable via RS485

102

103

The module contains the following blocks:

1. Local oscillator generated the carrier to be synthesised, it is split into three windows (I-II / III / IV-V

band) to ensure the coverage of all of the TV channels to be implemented for all standards.

2. Radio-frequency splitter splits the signal coming from the local oscillator by means of splitters and

amplifiers, with 10dB attenuation and gain respectively, to ensure the complete isolation of the LO from

the other stages and to minimise the frequency pulling phenomenon.

3. PLL stage synthesises the desired channel by locking the LO to a 20MHz frequency reference by

means of a PLL which can be configured via uWire and provides the locking and line-offset indication

(LED on frontal panel); the choice is made via software.

4. Active ring filter stabilises the system in PLL retro-action and e has to be modified if the operating

band of the module changes (see table attached to the electrical diagram).

5. Conditioning stage of the correction voltage conditions the correction voltage of the PLL ring

providing a conditioned analog voltage for the A/D conversion; the voltage is processed by the

microcontroller of the display board (see MTG0079) to be displayed as VU-METER.

6. Mixer in the UPCONVERTER version of the module, converts to channel the intermediate frequency

coming from the pre-corrector (see MTG0073) using a LEVEL13 mixer (in case the module is only used

as LO, see REPEATER configuration, this stage is not present and the synthesised carrier goes directly to

the output of the module).

7. 20MHz reference the frequency reference to the PLL synthesis of the carrier is generated by an

internal TCXO which fine control of the frequency is internally generated via PWM by the microcontroller

or, alternately, can be locked to a more precise 5/10MHz external reference (see MTG0076).

8. Controller all of the described operations are managed by a microcontroller communicating to the user

interface board (see MTG0079) by RS485 protocol; the local controller stores the status of the module

and a reprogramming of the firmware (possible via RS485 from the display board) does not alter its

contents.

CALIBRATION PROCEDURE

- List of instrument

MEASURE INSTRUMENT

- Spectrum analyser

Lock of the carriers and reference

- Oscilloscope

- Tester

104

- Description of the adjustment points

COMPONENT DESCRIPTION

C1, C2, C3

J3

J5, J8

J4

JP1

J2

Tuning of the local oscillator (SCH0292 - 0309 - 0310)

LO input

RF link (absent in case of LO configuration)

LO monitor (panel)

Unused

Testpoint for the debug of the PLL

The calibration procedure of the module requires a complete structure of display board (see MTG0079)

and extension module (see MTG0095) in order to perform the software selection which will be referred

to later and power the module itself..

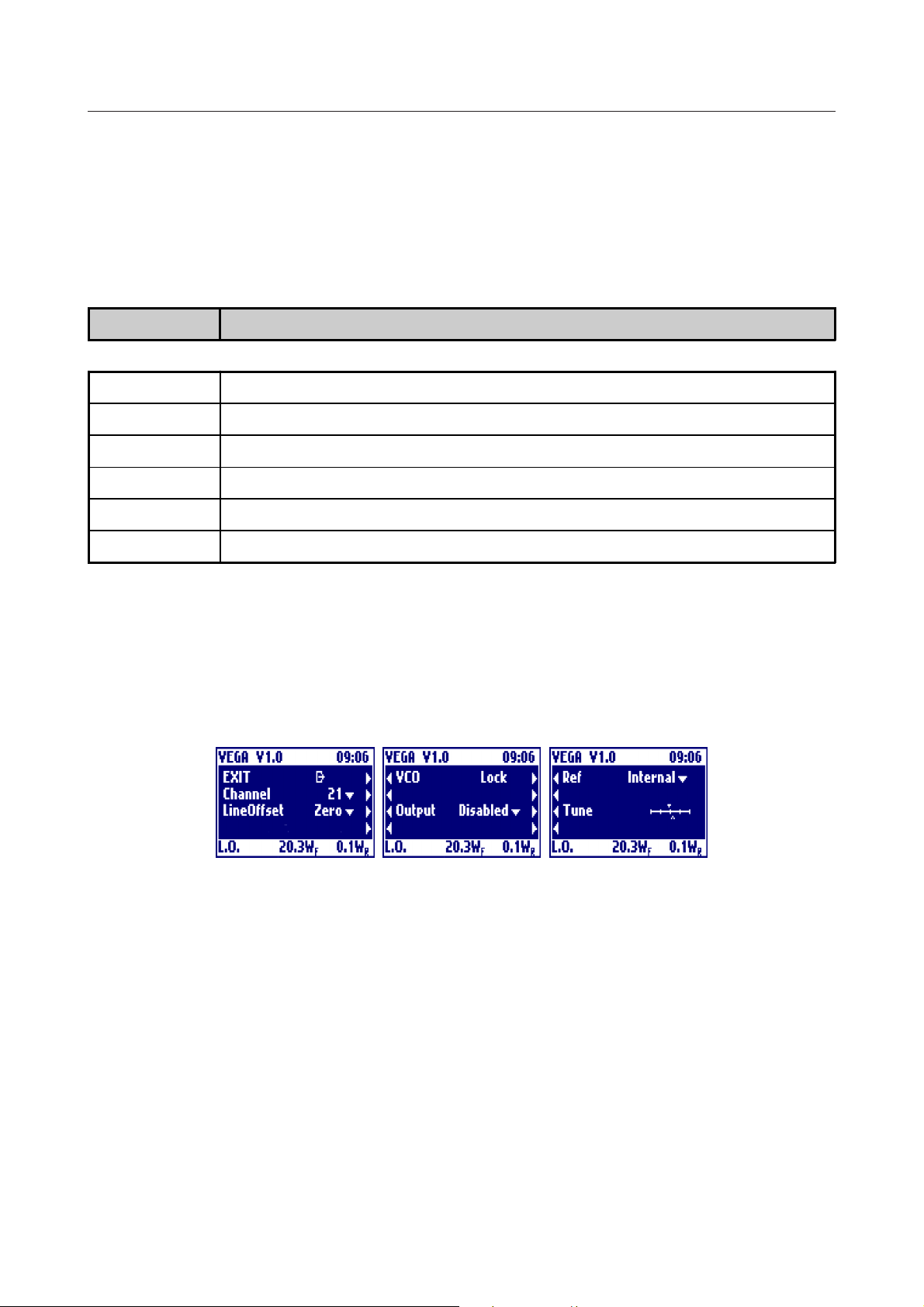

- Menu of the Multistandard UHF Local Oscillator Module

Verification of the local oscillator section connect a spectrum analyser to the monitor of the J4 module

and check the sections therein:

q Configure the module with Output Enabled, LineOffset Zero, Ref Internal and Channel on the

desired channel, and calibrate C1(C2 and C3) to lock the carrier to the LO frequency of the standard and

channel set (to change the standard refer to the standard changing procedure) and obtain a locking

voltage between 2V and 3V on TP1, checking that VCO is on Lock in the display menu.

Verification of the external reference section connect a spectrum analyser to the monitor of the J4

module and check the sections therein:

q Configure the module with Ref Internal and check that it is possible to find adjust the synthesised frequency

by acting on Tune.

105

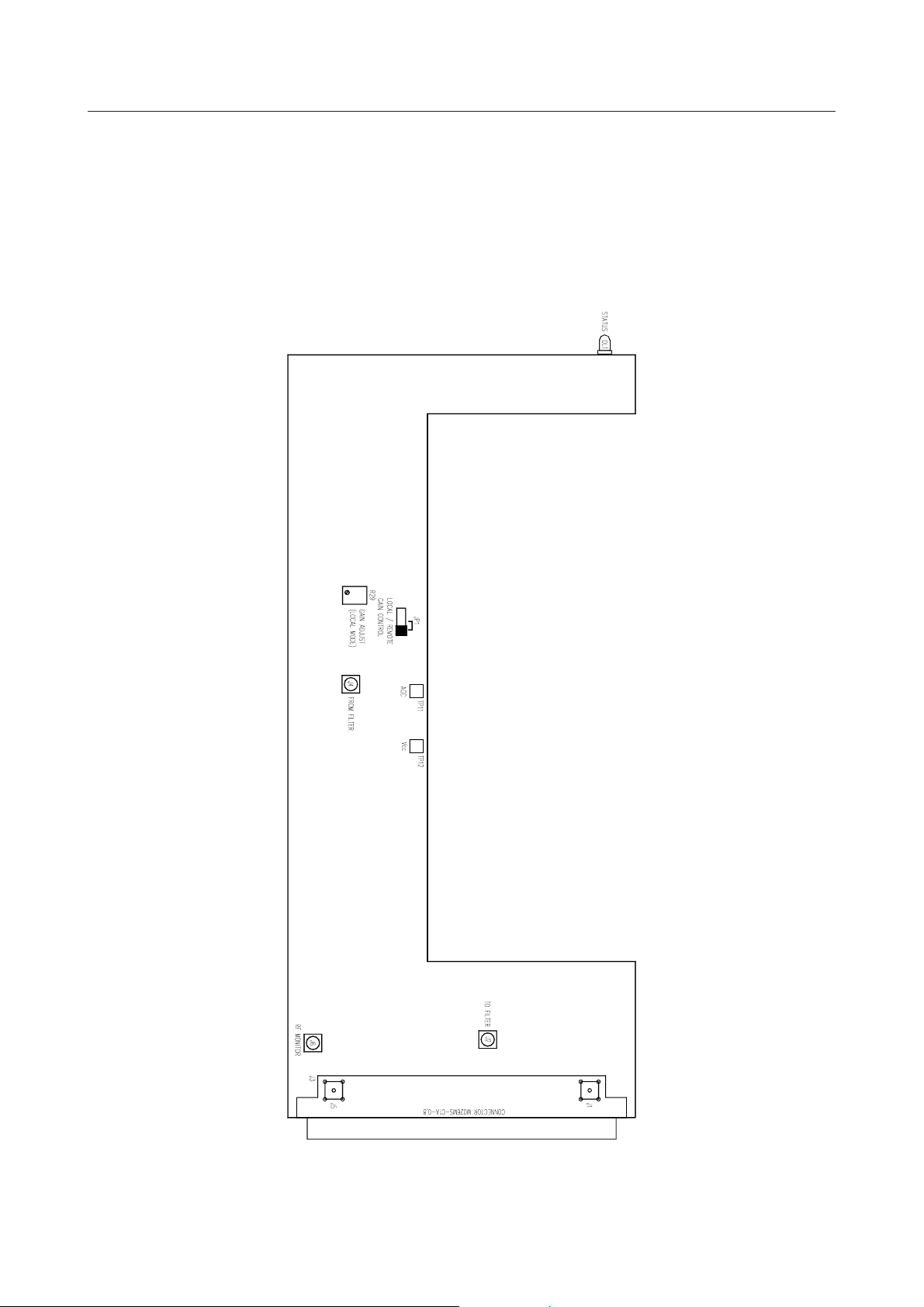

Component layout for adjustment points

106

Component layout SCH0293AR0

Component layout SCH0292AR0

107

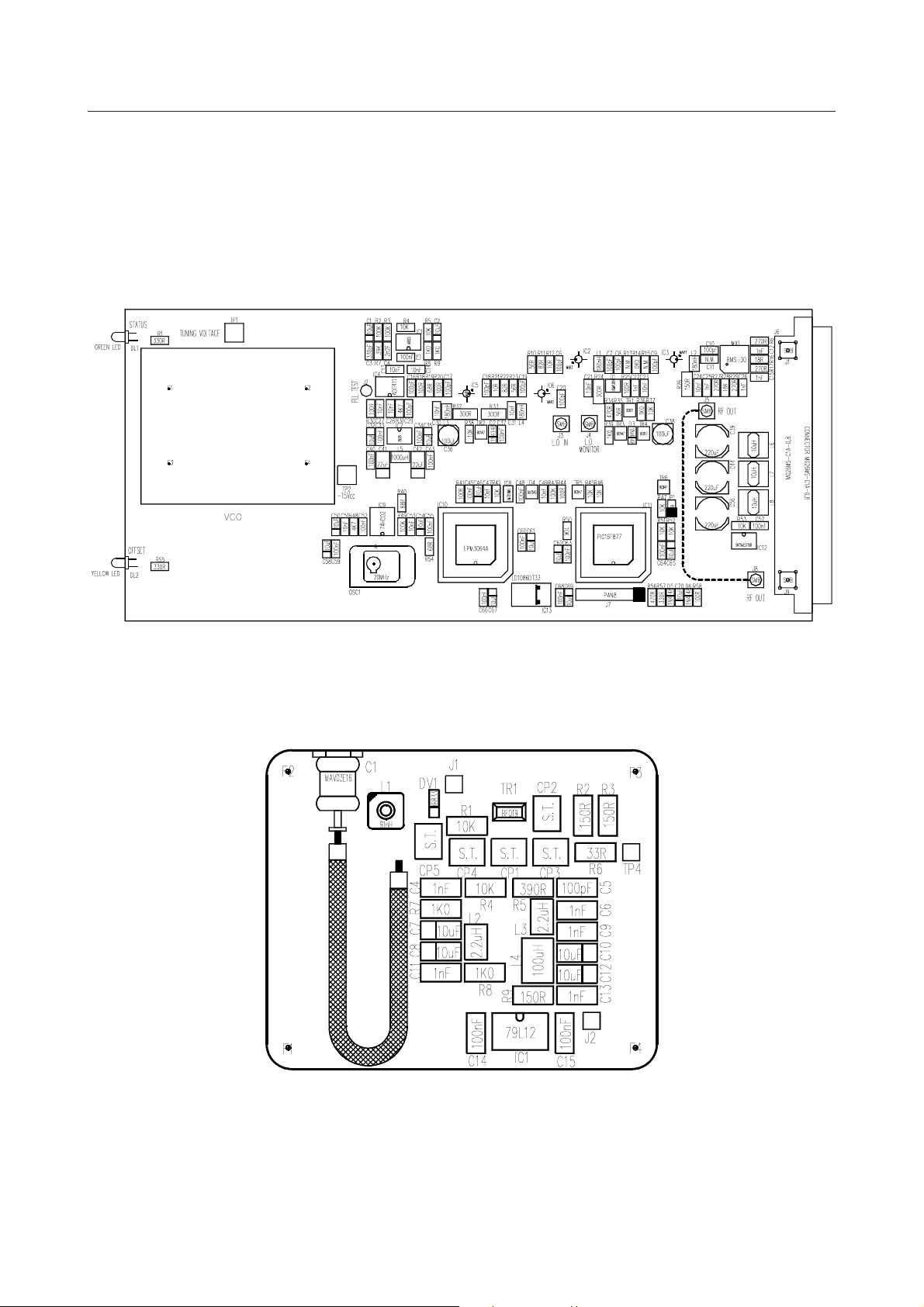

MULT. UHF CHANNEL FILTER MODULE MTG0075AR0

DESCRIPTION

The module filters the signal coming from the conversion mixer removing the local oscillator

and the upper side-band and contains the voltage-controlled gain stage composed by a

pin-diode attenuation cell followed by a wide-band amplification stage used as driver of

the final stage.

TECHNICAL CHARACTERISTICS

Input/output impedance 50W R.O.S.>20dB

Filter type Active 5-cell band-pass

RF-attenuation type 4 PIN-diodes cell

Output amplifier Wide band

Overall gain 25dB (max.)

The module contains the following blocks:

1. Active band-pass filter filters the lower side-band after conversion, it is split into three windows (I-II

/ III / IV-V band) to ensure the coverage of all of the TV channels to be implemented for all standards,

and contains the PIN-diode attenuation cell for the gain control.

2. Wide-band amplifier amplifies the filtered channel in order to obtain the correct driving level for the

RF final stages (see MTF0088-0087-0089).

CALIBRATION PROCEDURE

- List of instruments

MEASURE INSTRUMENT

Calibration of the channel filter

- Network analyser

- Spectrum analyser with tracking

108

- Description of the adjustment points

COMPONENT DESCRIPTION

C1-C8, C18-19

C17, C20-24,

C26-27, C31-32

L1-6

J6

JP1, R29

J2

J4

Channel filter calibration for bands III and IV-V

Channel filter calibration for band I-II

Channel filter calibration for band I-II

RF monitor (panel)

Local gain control of the filter

Channel filter input

Channel filter output

The calibration procedure of the module requires a complete structure of display board (see MTG0079)

and extension module (see MTG0095) in order to perform the software selection which will be referred

to later and power the module itself.

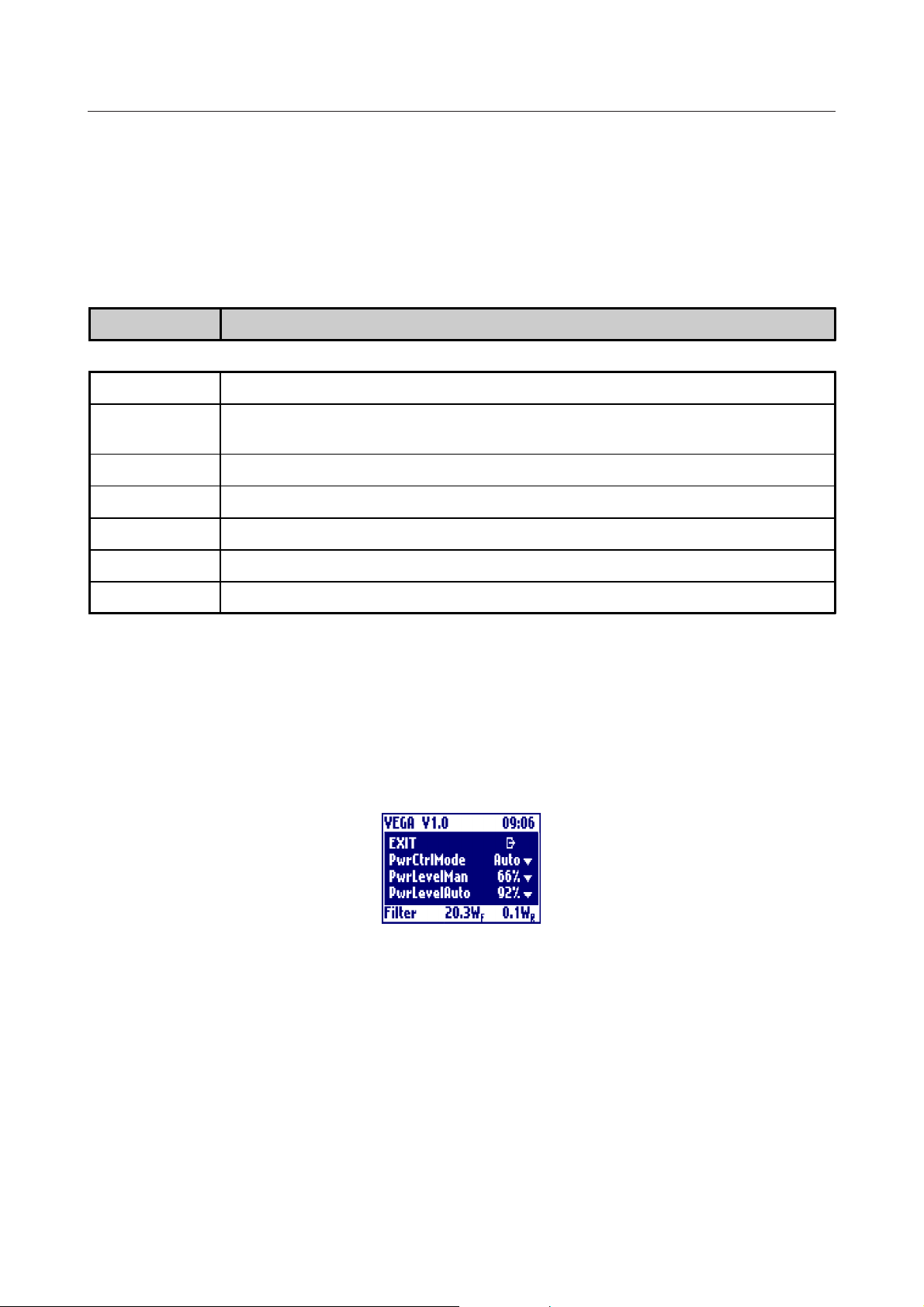

- Menu of the Multistandard UHF Channel Filter Module

Verification of the channel filter connect a network analyser to the channel filter and calibrate its

components to obtain the desired frequency response:

q Configure the module with PwrCtrlMode Man and verify that it is possible to change the gain of the filter

by acting on PwrLevelMan, setting JP1 Remote.

Verification of the wide-band amplifier section connect a spectrum analyser with tracking between J4

and J5 check that the frequency response of the amplifier is flat within 1dB from 50MHz to 900MHz.

109

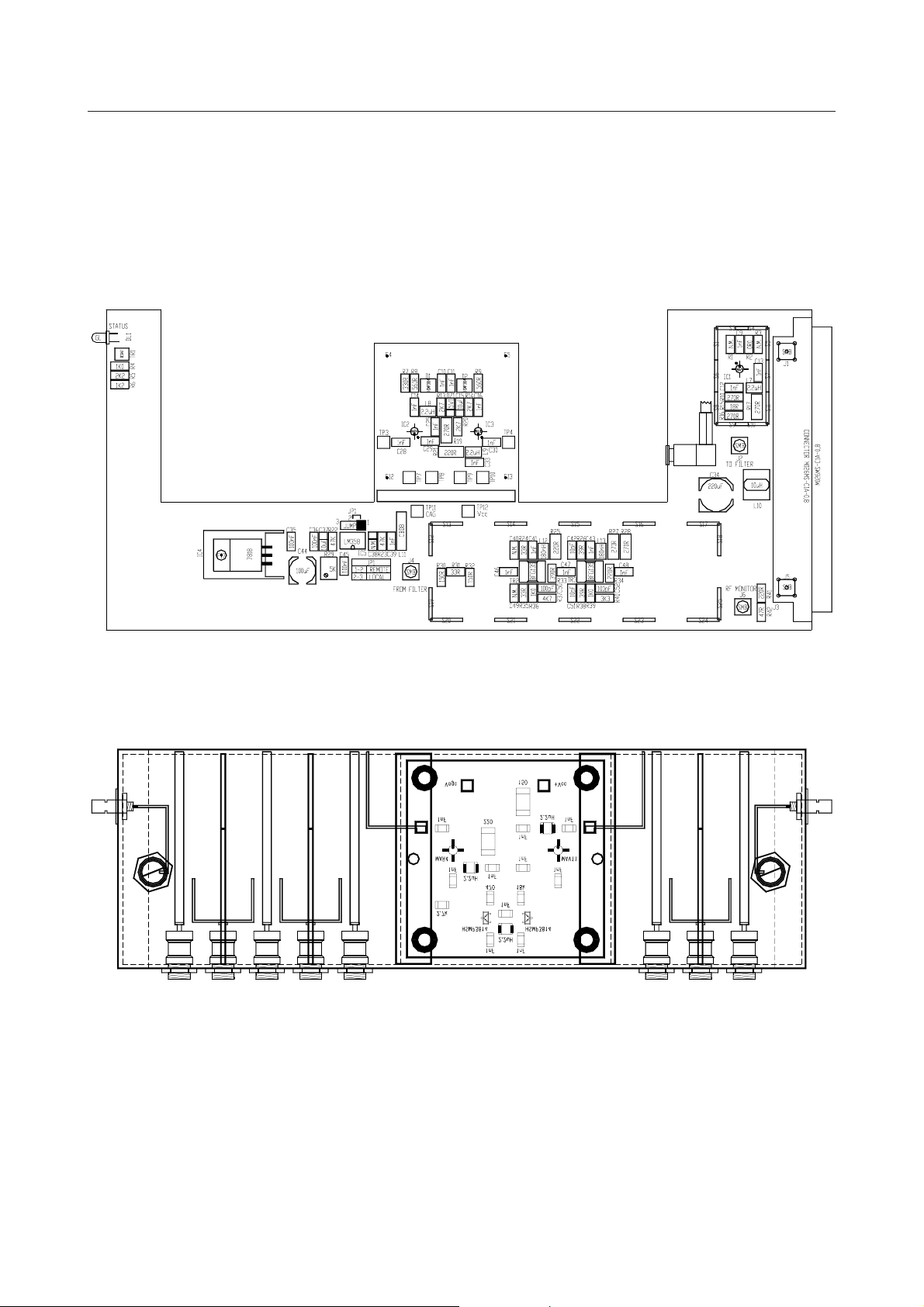

Component layout for adjustment points

110

Component layout SCH0222AR2

Component layout UHF Channel Filter

111

CONTROLLER MODULE MTG0079AR0

SCH0135AR1 DESCRIPTION

The Controller module, located on the right side of the VEGA

TV modulator, is the user interface of the whole modulator. It

gathers the data from all the sections of the modulator, processes

them by means of a 16bit flash micro-controller by Fujitsu and

makes them available to the user both through the local interface,

composed by a display and a knob, and the remote interface

made up by the serial port (either the RS232 on the front or the

RS485 on the back, as selected) or the interface of the

telemeasuring connector.

The acquisition and setting of all the concerned parameters is

made in two different ways. Analog measures reach the board

from the individual modules as voltages, are conditioned on the board and then converted by an internal A/D

converter in the micro.

The remaining parameters are gathered through a 2-wire RS485 interface, which runs on the bus. The display

board acts as master on this 485 bus. Besides it is provided with an RTC and a non-volatile memory on an

internal I2C bus.

- Dip-Switch

The display board is provided with 4 dip-switches. The dip-switches 3 and 4 are used to program the flash

memory of the flash micro-controller by Fujitsu, in detail:

DIP3: On DIP4: Off Boot Programming

DIP3: Off DIP4: On Run or Firmware Programming

The "Boot Programming" configuration is only for BIOS programming purposes.

Once the BIOS has been programmed, the firmware has to be programmed at least once in order to use the

board. The firmware programming and the normal operation of the board are obtained with the same position

of the dip switches.

For more detail on Firmware upgrade please refer to the "Firmware Upgrade" section.

DIP2: On Factory setting

DIP2 is set to ON only during the factory setup of the exciter. This allow to store in the memory all of the

settings made as 'factory defaults'.

Once the test is completed, and while the modulator is used normally, the DIP2 must be kept OFF.

112

Loading...

Loading...