Elettronika TXUP2000 User Manual

_______________________________________________________________________________________________

Section 2 - Installation

Contents:

2.1 Operating environment

2.2 Preliminary operations

2.3 Telemeasuring socket connections

2.4 RS232 and RS485 socket connections

2.5 SCH0005AR1 Calibration procedure

2.6 Preventive maintenance

- Front panel

- Rear panel

59

2.1 OPERA TING ENVIRONMENT

You can install the apparatus in a standard component rack or on a suitable surface such as a bench or

desk. In any case, the area should be as clean and well-ventilated as possible. Always allow for at least

2 cm of clearance under the unit for ventilation. If you set the apparatus on a flat surface, install spacers

on the bottom cover plate. If you install the apparatus in a rack, provide adequate clearance above and

below . Do not locate the apparatus directly above a hot piece of equipment.

2.2 PRELIMINARY OPERA TIONS

Correct installation of the equipment is important for maximum performance and reliability . Antenna

and earth connections must be installed with the greatest care. The equipment adjustment isn’t need,

because the unit is completely adjusted by our technical staff. This is the installation procedure:

1. connect the power supply cable of the transmitter to the auxiliary socket on the rear panel of the

amplifier;

2. connect the power supply cable of the amplifier to the electric network (230VAC). If there is the Isolator

Transformer , the amplifier is provided with cable and plug;

3. connect the exciter / antenna cable to the RF IN and RF OUT on the rear panel of the amplifier.

3

2

1

3

WARNING!!!

FOR ELECTRICAL SAFETY REASONS AND IN ORDER TO KEEP THE APPARATUS SAFE,

THE GROUND TERMINAL OF THE APPARATUS MUST BE CONNECTED TO THE EX-

ISTING GROUNDING SYSTEM AND NOT BY USING THE SHIELD OF THE OUTPUT

COAXIAL CABLE.

60

When the apparatus is put within a combined system it is directly connected to the input splitting and output

combining systems.

Before fully powering the apparatus, check that the output connections of the coaxial cable to the

antenna system are working.

In order to this it is possible to check the indication of the reflected power at low power levels. Only if

the SWR indication on the display is 0, the output power can be slowly increased. At maximum output

power, some watts might be shown as reflected power.

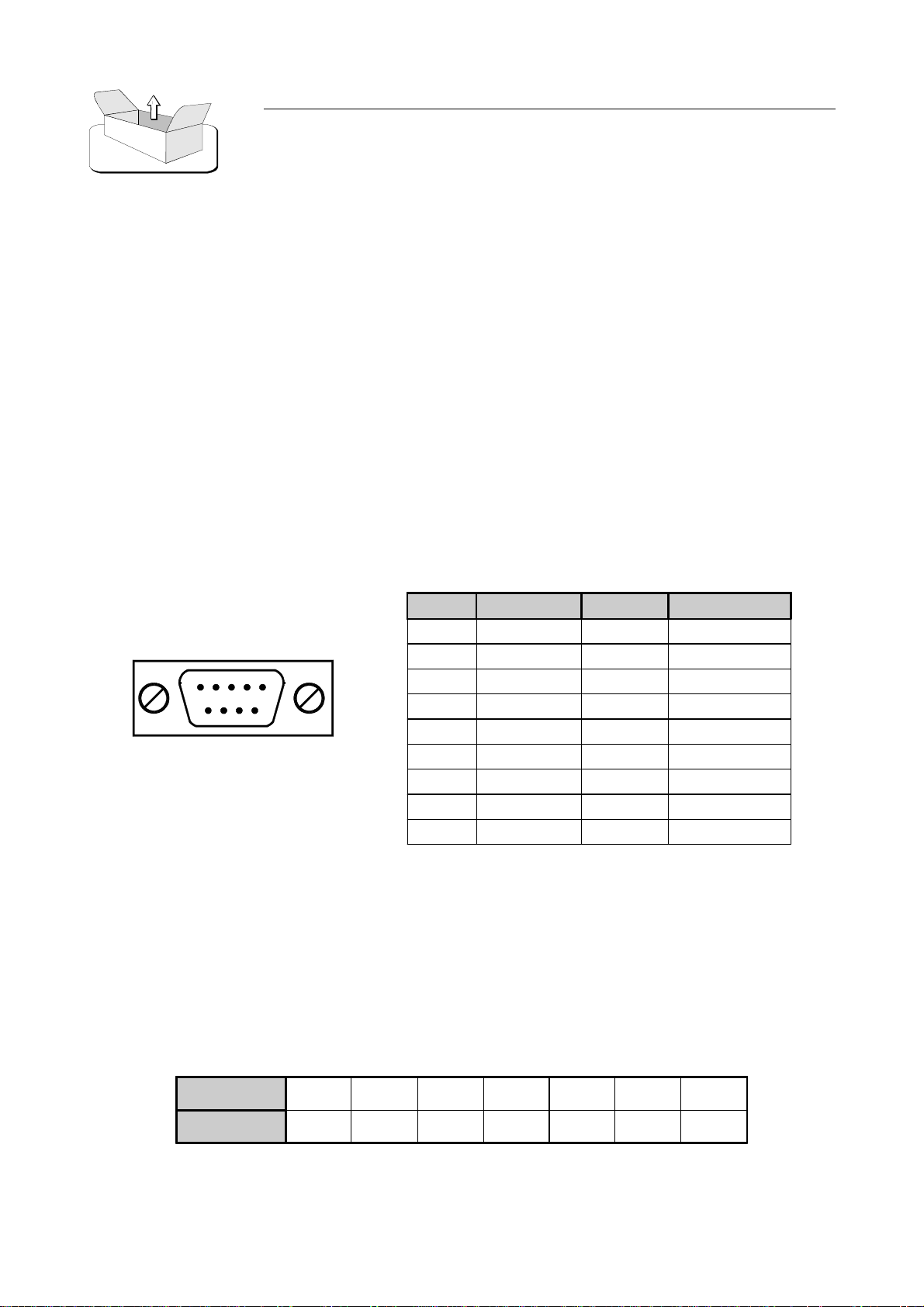

2.3 TELEMEASURING SOCKET CONNECTIONS

The following table summarizes the T elemeasuring pin connections.

N° Pin SYGNAL TYPE IN/OU T FUNCTION

1 Ground

2 Logical Input 5V= On - 0V= Off

3 Analog O utput Dir Power

4 Analog Outp ut Re f Power

5 Ana l og O utp ut Unbalanci ng

DB9 Socket

6 Analog O utput Temperature

7 Analog Output Alarm 5V= On - 0V= Off

8N.C.

9N.C.

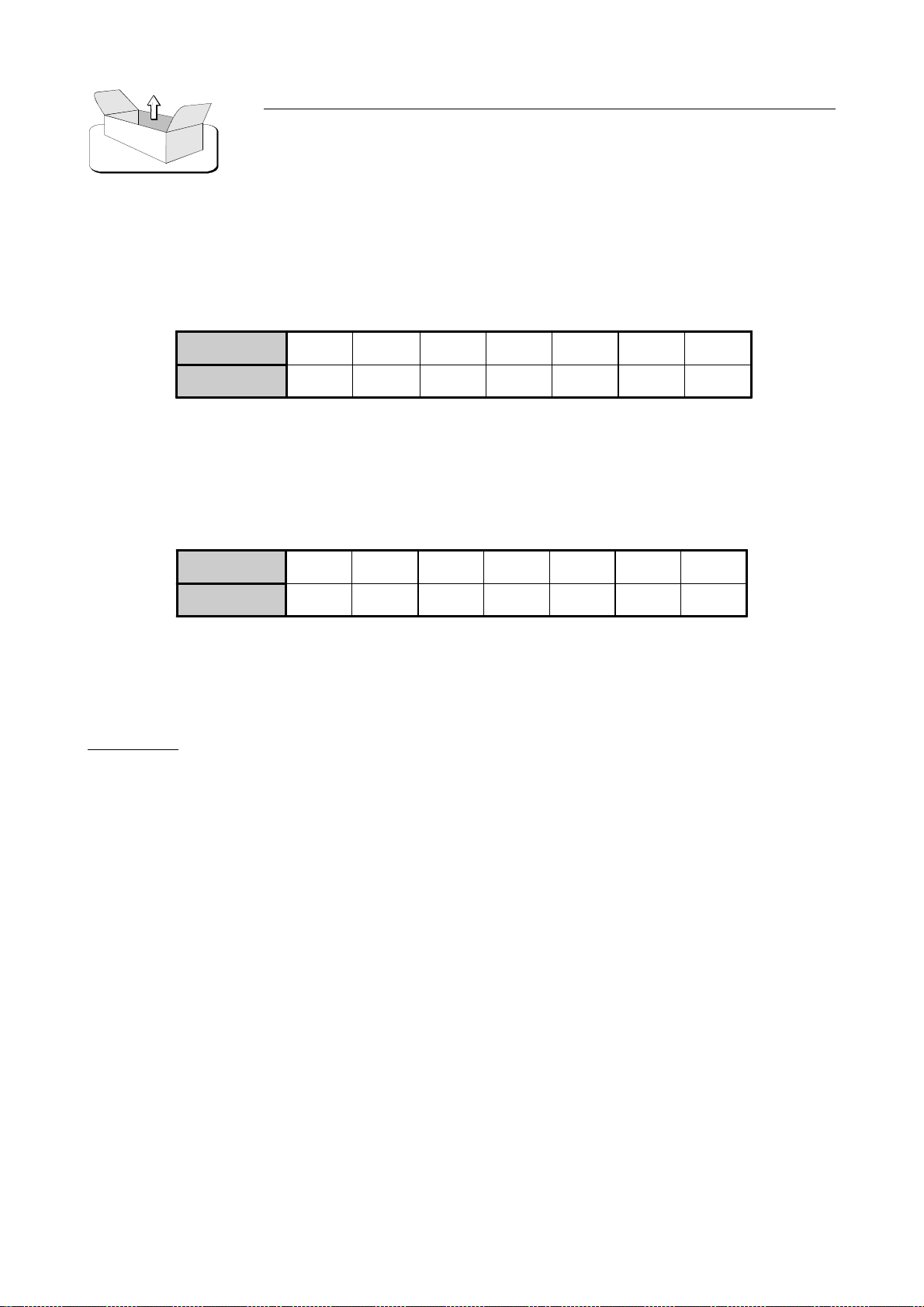

2.4 RS232 AND RS485 SOCKET CONNECTIONS

The connector DB25 may be configured as RS232 or RS485 socket, depending on the position of the

jumpers on the board. In case it is used as RS232 socket, the jumpers JP3, JP4, JP5 and JP6 have to be

positioned towards the serigraphy “RS232”. If the jumpers JP1 and JP2 are placed in “N” position, the

follwing configuration is obtained:

PIN

FUNCTIONS

23567820

RxD TxD RTS 12V GND 12V 12V

61

If the jumpers JP1 and JP2 are put in “M” position, the following configuration will be obtained:

PIN

FUNCTIONS

23456720

TxD RxD RTS CTS 12V GND 12V

In order to use the connector as RS485 socket, the jumper JP3, JP4, JP5 and JP6 have to be positioned

towards the serigraphy “RS485”. In this way , the following configuration will be obtained:

PIN

FUNCTIONS

23456720

Rx+ RX- TX- TX+ 12V GND 12V

2.5 SCH0005AR1 CALIBRA TION PROCEDURE

WARNING: this procedure is very delicate, so be VERY CAREFUL in order to avoid damaging

the equipment !!!

First of all turn on the equipment with the correct antenna connection, and then perform the following steps:

- Power supply voltages and currents calibration

Measure with a tester the voltage Vdr1 on the power supply of the first driver transistor without loading the

power supply (this can be done by disconnecting the six supply wires from the RF power modules). V erify

that it is 29V . Then take the calibration load (consisting of five 47Ω/20W resistors connected in parallel) and

connect it between the positive power supply terminal (corresponding to Vdr1) and ground. Turn the trimmer

R1 until you read on the display Vdr1 equal to the value measured before with the tester . Then turn the

trimmer R22 until you read on the display Idr1 = 3.1A.

Repeat the procedure above for the power supply of the second driver stage: measure with the tester the

voltage Vdr2 and turn the trimmer R3 and R27 until you read on the display the correct values.

Measure with a tester the voltage V1 on the power supply of the first final power transistor . V erify that it is

62

around 32V. Then take the calibration load and connect it between the positive power supply terminal

(corresponding to V1) and ground. Turn the trimmer R5 until you read on the display V1 equal to the value

measured before with the tester. Then turn the trimmer R33 until you read on the display Idr1 = 3.4A.

Repeat the procedure above for the power supplies of the remaining three power transistors: measure with

the tester the voltages V2-V3-V4 and turn the trimmers R7-R9-R11 until you read on the display the correct

values measured.

T o calibrate the remaining currents readings, you have to connect the calibration load to the other three power

supplies (not all together, but one at a time!) and then turn the trimmers R39-R45-R51 until you read on the

display I2=I3=I4= 3.4A.

- Temperature calibration

Measure with a tester the voltage of the OUT pin of the integrated temperature sensor mounted on the heat

dissipating element. Than perform the operation explained in this example:

- voltage measured (for example) = 2.93V

- fixed number = 2.73

- perform subtraction: 2.93-2.73 = 0.20

If you get a result of 0.20, it means that the temperature is 20°C, so you have to turn the trimmer R102 until

you read TEMP = 20°C.

- Forward power calibration

Disconnect the antenna and connect a wattmeter (with a suitable dummy load!) to the antenna connector. Put

the cover on the amplifier module and then give power to the equipment until you read 1000W on the

wattmeter. Then turn the trimmer R96 until you read FWD = 1000W (approximately).

- Reflected power calibration

T o perform the reflected power calibration just disconnect the REF SMB (J6) and the FWD SMB (J7)

connectors from the control board and connect the forward power reading cable to J6 (REF). Give 50W of

forward power to the equipment and turn the R97 trimmer until you read on the display REF = 50W .

Note: When you have completed this calibration be sure to restore the original connections on the

control board!

63

T o ensure the best reliability for the board operations it is advisable that you turn the unused trimmers (those

corresponding to the unused readings connectors) counterclockwise until they reach the zero position (you

will hear a click).

2.6 PREVENTIVE MAINTENANCE

T o ensure maximum performance and minimum repair trouble, we strongly recommend you to follow the

below stated headlines for preventive maintenance:

1. check antenna installation and ground connection at regular intervals;

2. keep your apparatus clean and dry externally: this will ensure continuous functioning of the front panel

controls;

3. if the apparatus has not been used for a long period of time combined with exposure to extreme environmental conditions, open the unit and make a visual inspection.

Remove salt, water or ice with a moist cloth before turning the apparatus on. Check that the cooling fans are

running freely .

4. for general maintenance and top performance, call an authorized service technician to give the apparatus

and the complete antenna/earth connection installation a general check every 12-18 months;

5. check at regular intervals that the air intake located on the front panel is free of dust. If there is visible dust,

remove it by means of a soft brush.

64

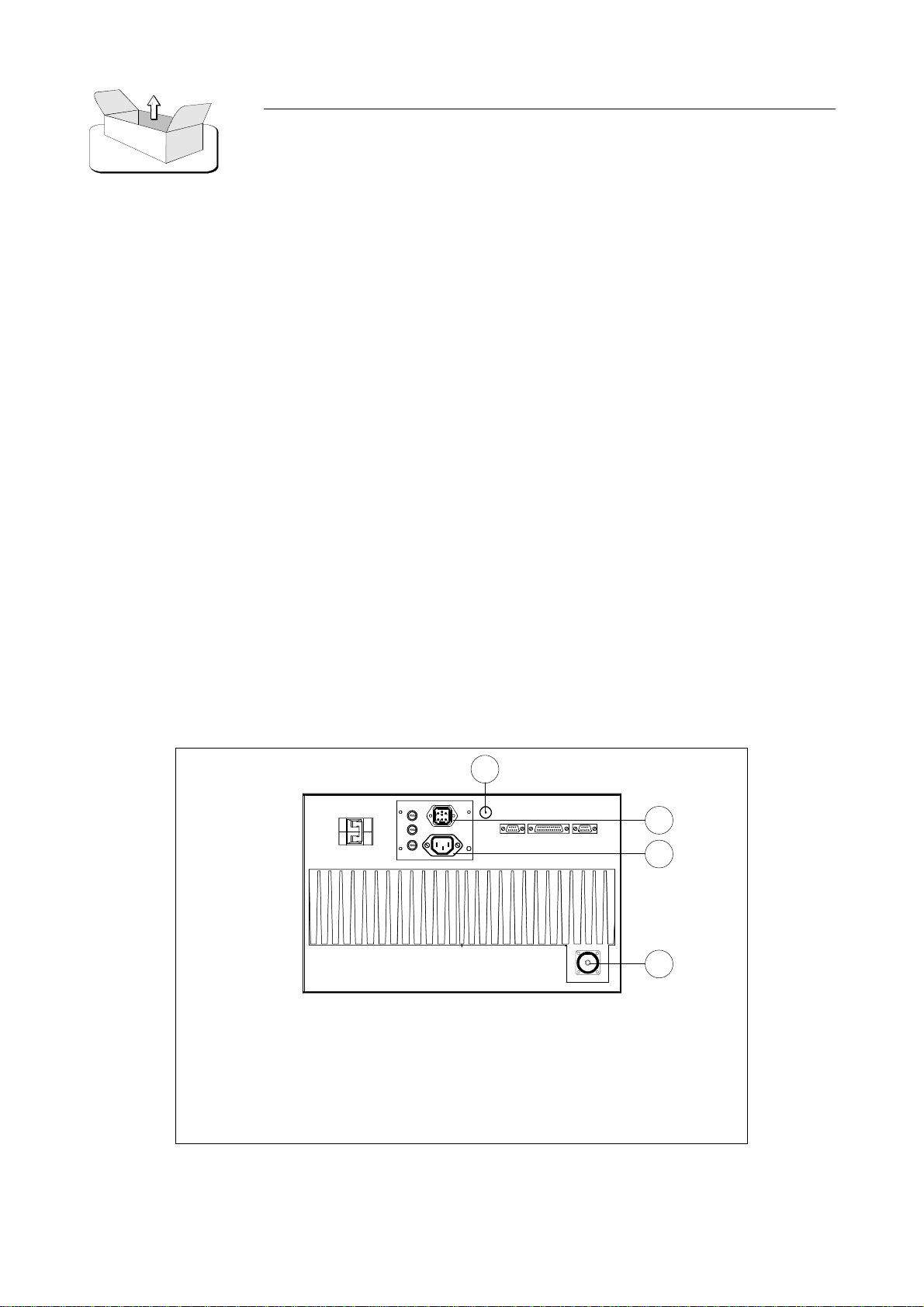

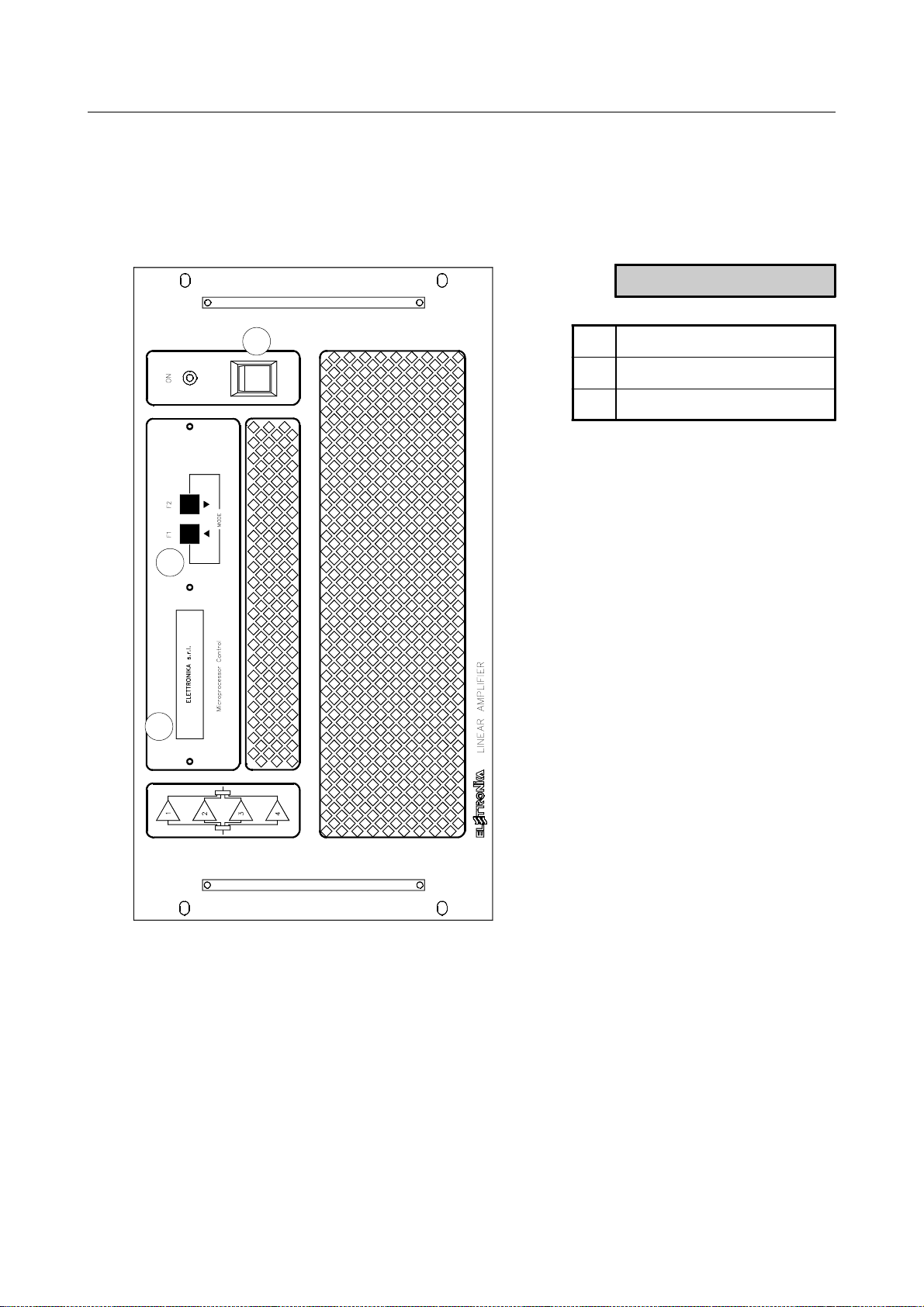

Front panel

DESCRIPT ION

2

1

3

1 LCD Disp la y

2 Func ti on k ey s

3Main switch

65

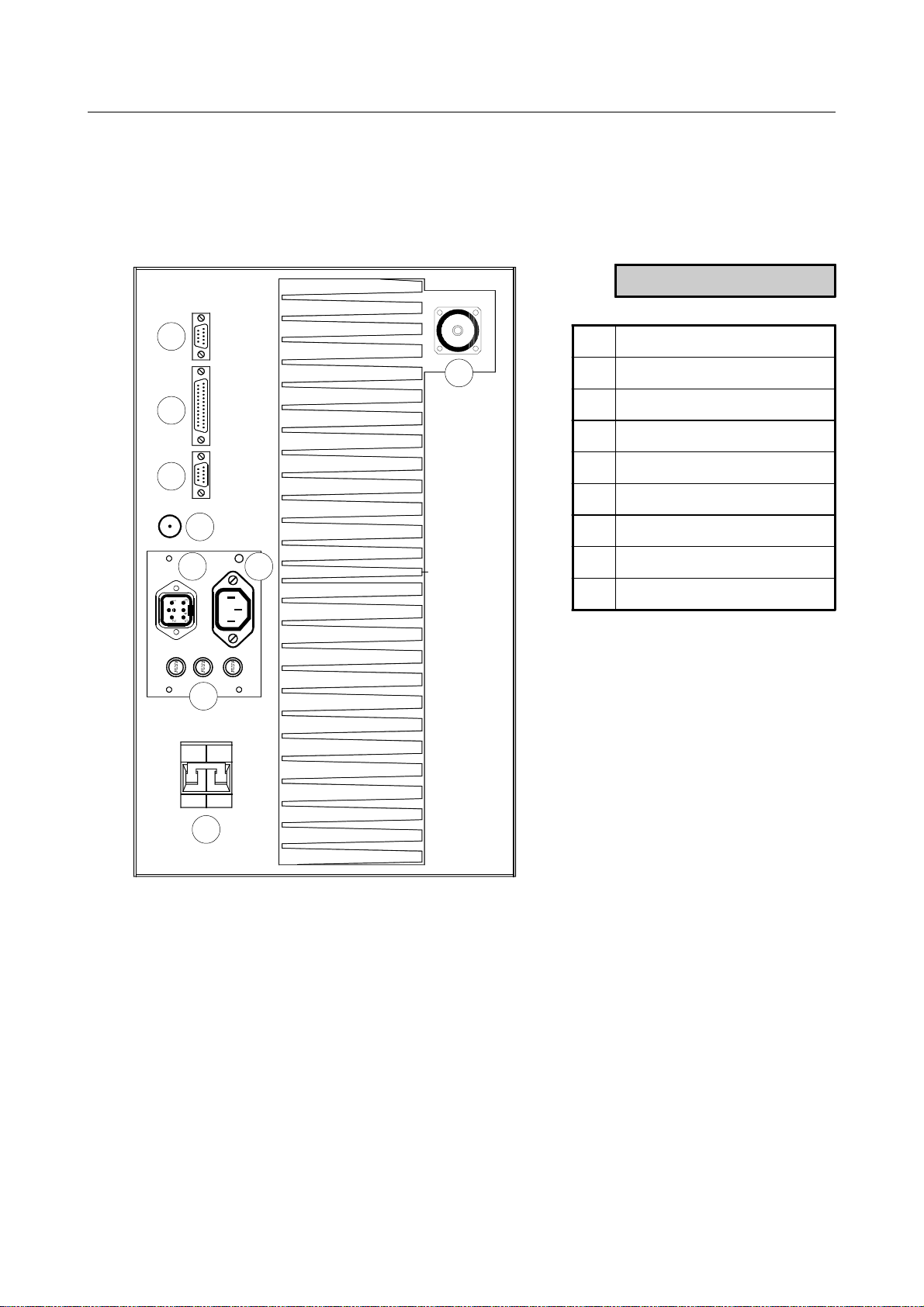

1 Breaker

Rear panel

DESCRIPTION

9

5 6 7

8

2

3

4

2 Power supply socket

3 Driver supply

4Fuse

2

5I

C BUS Socket

6 RS232 Socket

7 Telemeasuring socket

8 RF Input connector

9 RF Output connector

If there is the Isolator Transformer, the

amplifier is provided with cable and plug.

*

66

1

_______________________________________________________________________________________________

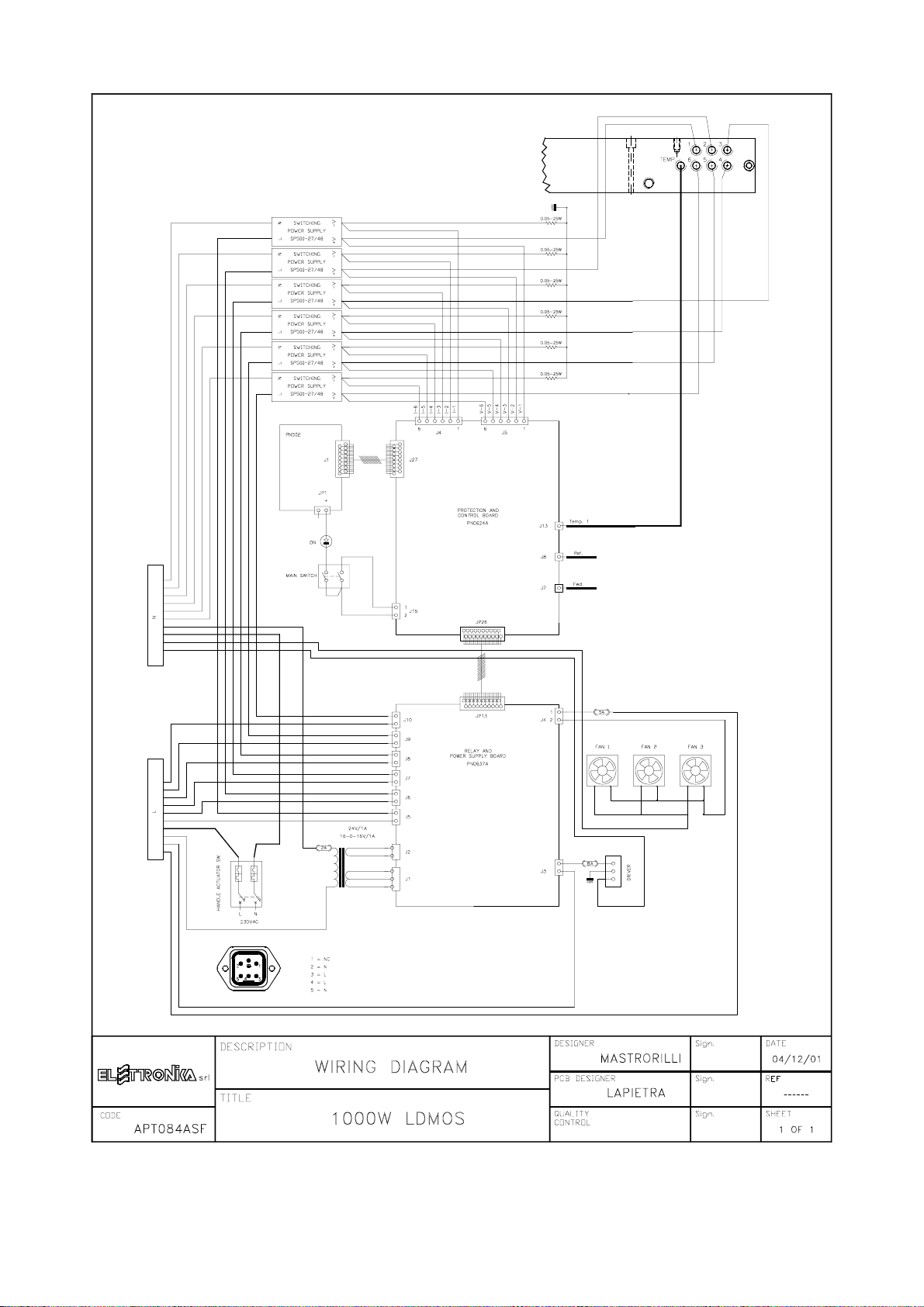

Section 3 - Diagram

Contents:

- Cable diagrams

- SCH0005AR1 (Protection board)

- SCH0004AR0 (Relay board)

- PN502 (Display board)

- MTF0050AR0 (1kW LDMOS Power mdoule)

- SP500-27/48 (Switching power supply)

- 06641 (UHF Band-pass filter)

67

686970

This page is intentionally blank

Component list APT084ASF - AUTV/1000LD

Part Name Code Description Qt y

MTF0050AR0 MODULO 1kW UHF LDMOS 1

16009 SCHEDA DISPLA Y x 1kW FM A MOSFET 1

SCH0005AR1 SCHEDA CONDIZ. PROTEZ. PIC PN624AR2 1

SCH0004AR0 SCHEDA UNITÀ 8 RELA YS PN637A 1

E0012 ALIM. SWITCHING SP-500-27 6

07522 INTERRUTTORE LUM. cod. I 4715 1

07541 PORTAFUS. 10A P ANN. cod. P1820 3

02830 PRESA VDE 10A cod. PX675 A63 1

Z0081 TA V ... SUPPOR. GUIDA DIN INT . MAG. 1

07527 INTERR. MAGNETOTERM. 25A cod. 23867 1

Z0021 TA V . 635/A TOND. OTT. x INT . MAGNET . 2

03065 PORTALED 5mm INNESTO A VITE 443.1613 1

03060 LED VERDE DIAM. 5mm 1

09546 TOR. P . 110/220 S.24V 1.5A 16/0/16 1A 1

02518 R114082000 PRESA SMB x RG174 3

08500 CA VO RG174 50Ω 4

02876 PRESA VOLANTE ILME 16A PENT APOLARE 3mt 1

02877 SPINA A P ANNELLO ILME 16A PENT APOLARE 1

02228 GE 15145 D/60 NF A VITONE 1

02502 J01150A0041 SMA x RG58/c 1

08503 CABLE RG303 50Ω 1,40

V0962 MORSETTIERA/GIUNZIONE ELECO E806 2

07925 PROTEZIONE IN GOMMA PVC PG 075 1

V0970 MORSETTIERA/EQUIPOTENZIALE 44672 2

07605C VENTOLA D2E097-CB01-02 3

07605D COND. 1,5uF 400V 3

FUS8A FUSIBILI 8A 5x20 RIT ARDA TI CT520280 1

FUS5A FUSIBILI 5A 5x20 RIT ARDA TI ST520250 1

FUS02A FUSIBILI 2A 5x20 RIT ARDA TI ST520220 1

CON0109 CON0109R1 LA T . 6U SX PROF . 755 x 1kW LDMOS 1

CON0110 CON0110R1 LA T . 6U DX PROF . 755 x 1kW LDMOS 1

CON0014 CON0014R5 POSTERIORE 6U 1.5kW FM ZN 1

05861 PANN. 6U T AV . 970/A AMPL. FM GRIGIO 1

05553B KIT MANIGLIE 5-6U cod. 235.013 2

Z0673 TAV. 1199 CHIUS. CONT . PROF . 775 ZN 2

CON0015 CON0015R5 CONVOGLIA TORE 1.5kW FM ZN 1

DET0135 DET0135R0 SUPPORTO SCHEDA PN624 1

DET0516 DET0516R0 SUPPORTO PRESE ZN 1

DET0513 DET0513R0 SUPPORTO COND. VENTOLE 1

DET0514 DET0514R0 ANGOLARE x VENTOLE 1

DET0515 DET0515R1 PAR T . FISSAGGIO VENTOLE 6

CON0111 CON0111R0 SOSTEGNO VENTOLE ZN 1

DET0575 DET0575R1 BARRA FISSAGGIO ALIM. SP500 6

SCH0168AR1 P ATCH PER PN0624A 1

71

This page is intentionally blank

72

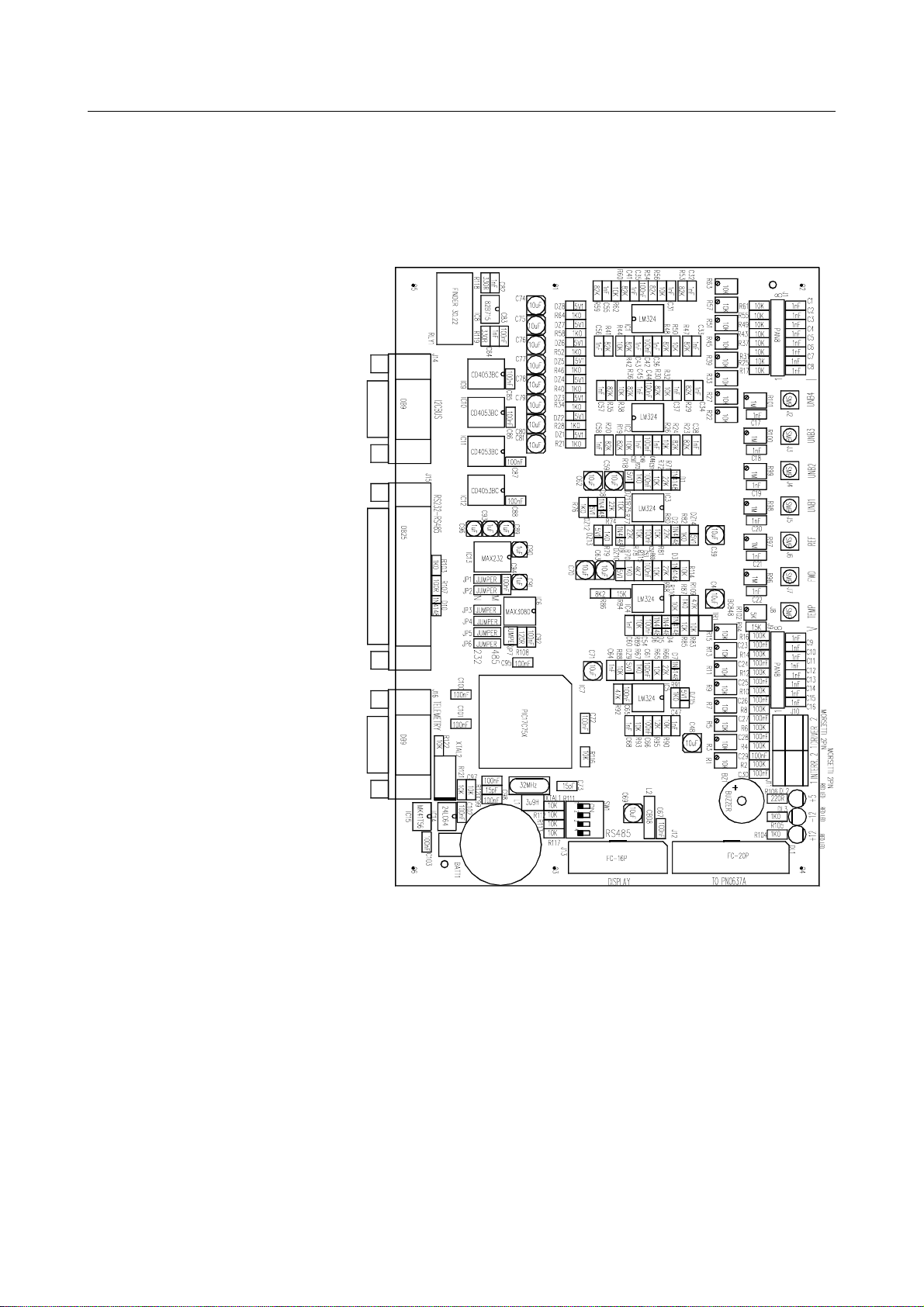

PROTECTION BOARD SCH0005AR1

DESCRIPTION

(Stand-alone configuration)

The SCH0005AR1 board is a microprocessor-based board designed to perform all the control

functions inside the amplifier module.

Both RF and power supply parameters are continuously monitored in

order to guarantee optimal performance in every working environment.

The board checks the power supply voltages and currents, the working temperature of the power modules, the forward and the reflected

RF power of the amplifier.

Various alarm conditions can be

detected by the board due to possible electrical failures during normal operation of the amplifier module.

The board automatically turns off

the amplifier or part of it when abnormal parameters are detected and

restores the initial working conditions if all the parameters return to

allowed values. The board is also

equipped with a serial port connector which, in a near future, will allow the remote control operation

through a local PC or a modem connection.

73

Loading...

Loading...