Elettronika TXUD500 User Manual

ATSC TRANSMITTER

Digital TV

CODE APD043A

APD047A

APD045A

TITLE ATSC TRANSMITTER REV 0 DATE 20/02/08

ATSC Transmitter Family

CODE MODEL

AP D 043A ATSC UHF TRANSMITTER

AP D 047A ATSC VHF-III TRANSMITTER

APD045A ATSC VHF-I TRANSMITTER

Registration number: IT-17686

Registration number: IT-24436

SS 96 Km 113

70027 Palo del Colle (Ba) ITALY

Tel. +39 (0)80 626755

Fax +39 (0)80 629262

E-mail: elettronika@elettronika.it

Web site: http://www.elettronika.it

Summaries

ATSC Transmitter Family .................................................................................................. 2

Summaries ......................................................................................................................... 3

Warning .............................................................................................................................. 7

Warranty ............................................................................................................................. 8

Introduction ....................................................................................................................... 9

Content of the manual ...................................................................................................... 9

Treatment of electrical shock ......................................................................................... 11

First-aid ......................................................................................................................... 12

Treatment of electrical burns ......................................................................................... 12

Note ............................................................................................................................... 12

RoHS Normative .............................................................................................................. 13

ATSC TRANSMITTER ...................................................................................................... 15

Section 1 - Information ................................................................................................... 17

1.1 Description .............................................................................................................. 18

1.2 Main Features ......................................................................................................... 18

1.3 Technical Characteristics......................................................................................... 19

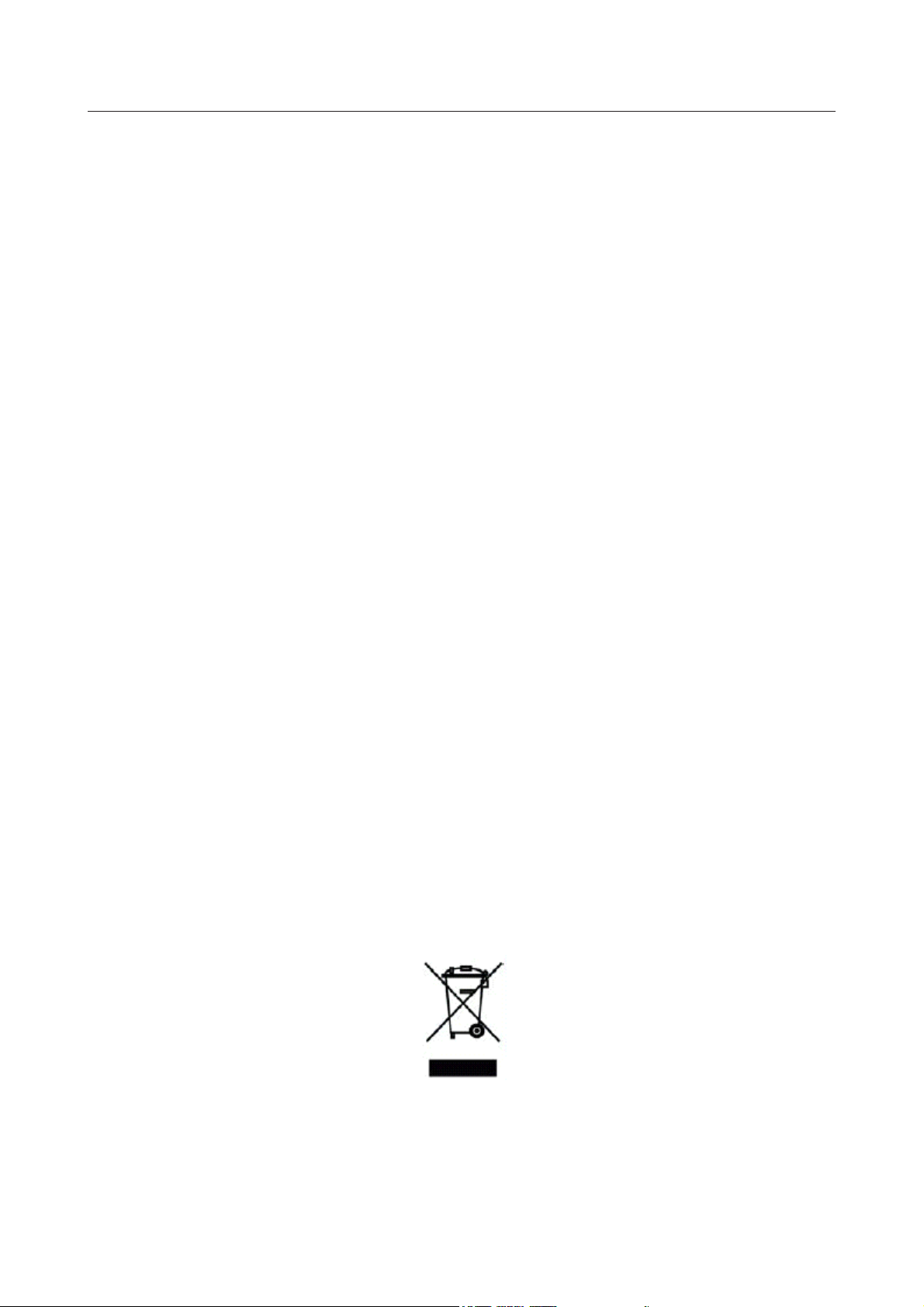

Front panel .................................................................................................................... 20

Rear panel ..................................................................................................................... 21

Block Diagram ...............................................................................................................22

1.4 Operational Details .................................................................................................. 23

1.4.1 TS Input Management ...................................................................................... 23

- Redundancy management .................................................................................. 23

- Reed Solomon FEC ............................................................................................ 24

- Bit rate adaptation ...............................................................................................24

- Squelch ............................................................................................................... 24

1.4.2 Synchronization and Clocks ............................................................................. 24

1.4.3 Output Signal ................................................................................................... 25

1.4.4 Non-Linear Precorrection ................................................................................. 25

1.4.5 Linear Precorrection ......................................................................................... 25

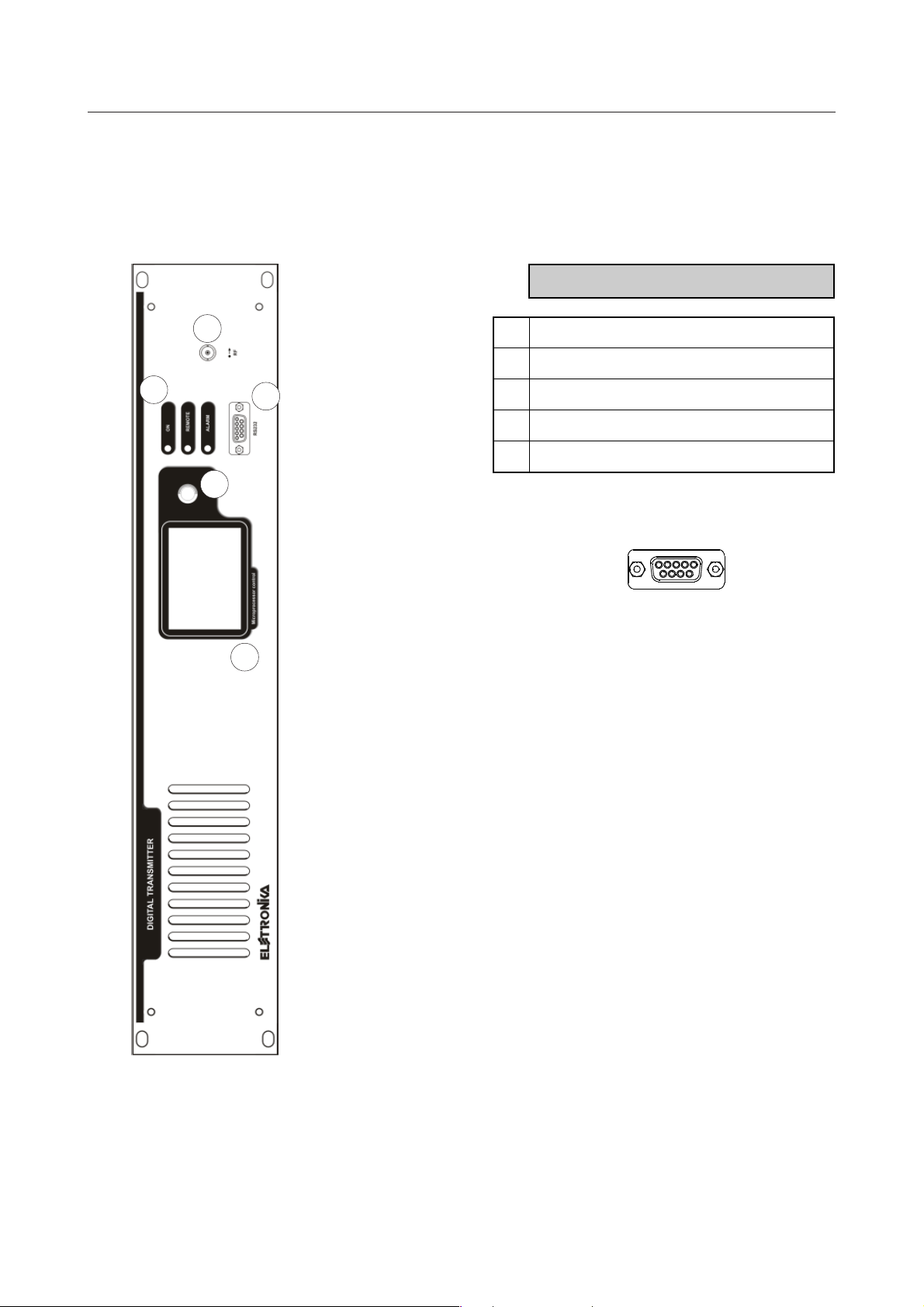

1.4.6 Control of the equipment .................................................................................. 26

1.4.7 Test Modes ....................................................................................................... 26

1.4.8 Power Handling ................................................................................................ 26

1.4.9 Alarms and Automation .................................................................................... 27

1.4.10 AGC: Implementation and Details .................................................................. 29

ATSC TRANSMITTER AGC Cable ............................................................................ 31

1.4.11 Log ................................................................................................................. 32

Section 2 - Installation .................................................................................................... 33

2.1 Operating Environment ........................................................................................... 34

2.2 First Installation ....................................................................................................... 34

2.3 ATSC TRANSMITTER with GPS Clock Source ...................................................... 35

2.4 ATSC TRANSMITTER remote control with Elettronika RCU ................................... 35

2.5 ATSC TRANSMITTER with PC ............................................................................... 36

Section 3 - Operation ...................................................................................................... 37

3.1 Local Control ...........................................................................................................38

3.2 LEDs ....................................................................................................................... 38

3.3 Menu Management ................................................................................................. 39

3.3.1 Title Bar ............................................................................................................ 39

3.3.2 Status Bar......................................................................................................... 39

3.3.3 Diagram Screen ............................................................................................... 40

3.3.4 Browsing the menus and parameters ............................................................... 41

3.3.5 Composition of a menu .................................................................................... 42

3.4 Parameters and menu description .......................................................................... 44

3.4.1 Input Menu ....................................................................................................... 44

- Configuration Submenu ...................................................................................... 44

- Stream1 Errors Submenu.................................................................................... 46

- Stream2 Errors Submenu.................................................................................... 46

3.4.2 Modulation Menu .............................................................................................. 47

3.4.3 RF Menu...........................................................................................................48

- Frequency Submenu ........................................................................................... 49

- Power Submenu.................................................................................................. 50

- Amplifier Submenu .............................................................................................. 52

- Output Submenu ................................................................................................. 53

- Precorrection Submenu ...................................................................................... 54

3.4.4 Setup Menu ...................................................................................................... 55

- Control Submenu ................................................................................................ 56

- Display Submenu ................................................................................................ 57

- Clock Submenu .................................................................................................. .57

- Power Supply Submenu...................................................................................... 58

- Versions Submenu .............................................................................................. 58

3.5 Log Screen ..............................................................................................................59

3.6 Alarm Screen ........................................................................................................... 59

3.7 Firmware Upgrade................................................................................................... 59

ATSC TRANSMITTER Menu Map ................................................................................. 61

Section 4 - Diagram ......................................................................................................... 63

- APD043A ATSC TRANSMITTER Cable Diagram ....................................................... 64

- APD047A ATSC TRANSMITTER Cable Diagram ....................................................... 65

- APD045A ATSC TRANSMITTER Cable Diagram ....................................................... 66

- APD043A_APD047A_APD045A ATSC TRANSMITTER Component list.................... 67

- SCH0135A Control Board and Display ....................................................................... 69

- Description .............................................................................................................. 69

- Dip-switch............................................................................................................ 69

- Technical Characteristics ........................................................................................ 69

- SCH0135A Top layer Component layout..................................................................... 70

- SCH0135A Bottom layer Component layout ............................................................... 71

- SCH0135A Component list ......................................................................................... 72

- SCH0135A Electric Diagram ....................................................................................... 74

- A1592 ATSC UHF Modulator Module .......................................................................... 77

- Description .............................................................................................................. 77

- Main Features .........................................................................................................77

- Connectors .............................................................................................................. 77

- A1703 ATSC VHF-I/III Modulator Module.................................................................... 78

- Description .............................................................................................................. 78

- Main Features .........................................................................................................78

- Connectors .............................................................................................................. 78

- MTF0116A 5W UHF RMS Amplifier Module................................................................ 79

- Description .............................................................................................................. 79

- Technical Characteristics ........................................................................................ 79

- MTF0116A Component list ...................................................................................... 79

- MTF0116A Component layout................................................................................. 80

- SCH0417A Component layout ................................................................................ 81

- SCH0417A Component list ..................................................................................... 82

- SCH0417A Electric Diagram ................................................................................... 83

- MTF0118A 5W VHF-I/III RMS Amplifier Module.......................................................... 86

- Description .............................................................................................................. 86

- Technical Characteristics ........................................................................................ 86

- MTF0118A Component list ...................................................................................... 86

- MTF0118A Component layout................................................................................. 87

- SCH0436A Component layout ................................................................................ 88

- SCH0436A Component list ..................................................................................... 89

- SCH0436A Electric Diagram ................................................................................... 91

- MTF0125A 5W VHF-I RMS Amplifier Module ............................................................. 92

- Description .............................................................................................................. 92

- Technical Characteristics ........................................................................................ 92

- MTF0125A Component list...................................................................................... 92

- MTF0125A Component layout ................................................................................ 93

- SCH0320A Component layout ................................................................................ 94

- SCH0320A Component list ..................................................................................... 95

- SCH0320A Electric Diagram ................................................................................... 96

- SCH0388B Power Supply Interface Board ................................................................. 97

- SCH0388B Power Supply Interface Board Component layout ............................... 97

- SCH0388B Component list ..................................................................................... 98

- SCH0388B Electric Diagram ................................................................................... 99

- E0064 SP-320-27/48 Switching power supply .......................................................... 100

- Main Features ....................................................................................................... 100

- Mechanical Specifications ..................................................................................... 100

- Technical Characteristics ...................................................................................... 101

WARNING

The apparatus described in this manual has been designed and manufactured with devices to safeguard the users. In any case it is recommended that during any operation of installation, maintenance,

miscellaneous interventions and calibrations requiring the apparatus to be switched on,

THE USER TAKES ALL THE

PRECAUTIONS AGAINST INCIDENTS

It is required to use the proper clothes and protection gloves in order to prevent damages from incidental contacts with high-voltage parts.

The manufacturer declines every responsibility in case the recommendations above are not followed.

IMPORTANT

The component lists attached to the relevant electrical diagrams indicate for each item the reference,

the description and the type normally used.

The Elettronika S.r.l. though reserves the right to use or supply as spare parts components with

equivalent characteristics but of a different type, assuring anyway the optimal work of the apparatus

in accordance with the specifications.

The enclosed monographs are solely owned by Elettronika S.r.l.

The use of anything enclosed in this technical manual without explicit authorization given by Elettronika

S.r.l. will be prosecuted by the law.

The data and technical characteristics of the apparatus described in this manual are not compelling for

the manufacturer.

The Elettronika S.r.l. reserves the right to make, without previous notice, modifications or updates in

order to improve the quality of the product.

The general conditions of supply and sale are described in the contracts.

The delivery time are in accordance with the products and quantities ordered.

7

Warranty

Summary of warranty

We, ELETTRONIKA S.r.l., SS096 Km 113 Z.I. PALO DEL COLLE (BA) ITALY, warrant to the ORIGINAL PURCHASER of a NEW product, for a

period of one (1) year from the date of purchase by the original purchaser (the “warranty period”) that the new ELETTRONIKA product is free of defects

in materials and workmanship and will meet or exceed all advertised specifications for such a product. This warranty does not extend to any subsequent

purchaser or user, and automatically terminates upon sale or other disposition of our product.

Items excluded from this ELETTRONIKA warranty

We are not responsible for product failure caused by misuse, accident, or neglect. This warranty does not extend to any product on which the serial

number has been defaced, altered, or removed. It does not cover damage to loads or any other products or accessories resulting from ELETTRONIKA

product failure. It does not cover defects or damage caused by use of unauthorized modificstions, accessories, parts, or service.

What we will do

We will remedy any defect, in material or workmanship (except as excluded), in our sole discretion, by repair, replacement, or refund. If a refund is

elected, then you must make the defective or malfunctioning component available to us free and clear of all liens or other encumbrances. The refund will

be equal to the actual purchase price, not including interest, insurance, closing costs, and other finance charges less a reasonable depreciation on the

product from the date of original purchase. Warranty work can only be performed at our authorized service centers or at our factory. Expenses in

remedying the defect will be borne by ELETTRONIKA, including one-way surface freight shipping costs within the United States. (Purchaser must bear

the expense of shipping the product between any foreign country and the port of entry in the United States and all taxes, duties, and other custom’s fee(s)

for such foreign shipments).

How to obtain warranty service

You must notify us of your need for warranty service not later than ninety (90) days after the expiration of the warranty period. We will give you an

authorization to return the product for service. All components must be shipped in a factory pack or equivalent which, if needed, may

Desclaimer of consequential and incidental damages

You are not entitled to recover from us any consequential or incidental damages resulting from any defect in our product. This includes any damage

to another product or products resulting from such a defect.

Warranty alterations

No person has the authority to enlarge, or modify this warranty. The warranty is not extended by the lenght of time for which you are deprived of

the use of the product. Repairs and replacement parts are provided under the terms of this warranty shall carry only the unexpired portion of this

warranty.

Design changes

We reserve the right to change the design of any product from time to time without notice and with no obligation to make corresponding changes in

products previously manufactured.

Legal remedies of purchaser

There is no warranty which extends beyond the terms hereof. This written warranty is given in lieu of any oral or implied warranties not contained

herein. We disclaim all implied warranties, including without limitation any warranties of merchantability or fitness for a particular purpose. No action

to enforce this warranty shall be commenced later than ninety (90) days after expiration of the warranty period.

Warranty for electronic tubes

The warranty applied for electronic tubes is the one given by the manufacturer of the tube. In the event that the product shows anomalies within the

deadline of the validity of the warranty given by the manufacturer of the product itself, the buyer will have to return it to the seller with the needed

documents and the written description of the defect. The seller will ship the broken tube to the manufacturer in order to effect the necessary technical

tests to find out the cause of the anomaly. Meanwhile the buyer of the tube who needs to use, and as such to replace immediately the product, will have

to buy a new one and provide to the relevant payment, further to the issuing by the seller of a regular commercial invoice. After the adequate tests made

by the manufacturer, should the result be positive, that is confirm the defect in manufacturing, the seller will issue a regular credit note in the name of

the buyer and return the amount paid. Should the result be negative, that is detect a negligence in the installation or use by the buyer, he will have no

right against the seller.

8

INTRODUCTION

The apparatus described in this manual is the latest of this series, offering high performances, remarkable reliability and a wide range of characteristics, it all at a competitive cost.

Its is easy to install and use. It only takes to follow the installation procedure as shown in this manual:

after having removed all from the package, you only have to follow step by step the description in the

various sections.

Before starting to use the apparatus, remember to:

read carefully the general safety information contained in this section;

follow the instructions for the installation and set up of the apparatus;

read all the remaining sections of this manual in order to know well the apparatus and learn

how to obtain the best of its characteristics.

CONTENTS OF THE MANUAL

The chapter composing this manual contain all the information concerning the use of the apparatus.

For more information refer to ELETTRONIKA S.r.l.

This manual is made up of different chapters, each made up of various sections.

9

WARNING!

The currents and voltages in this equipment are dangerous!

Personnel must at all times observe safety regulation!

This manual is intended as a general guide for trained and qualified personnel who are aware of the

dangers inherent in handling potentially hazaedous electrical and electronic circuits.

It is not intended to contain a complete statement of all safety precautions which should be observed by

personnel in using this or other electronic equipment.

The installation, operation, maintenance and service of this equipment involves risks both to personnel

and equipment, and must be performed only by qualified personnel exercising due care.

Elettronika S.r.l. shall not be responsible for injury or damage resulting from improper procedures or

from the use of improperly trained or inexperienced personnel performing such tasks.

During installation and operation of this equipment, local building codes and fire protection standards

must be observed.

WARNING!

Always disconnect power before opening covers,

doors, enclosures, gates, panels or shields.

Always use grounding nsticks and short out high

voltage points before servicing. Never make

internal adjustments, perform maintenance or

service when alone or when fatigued.

Do not remove, short-circuit or tamper with interlock switches on access covers, doors, enclosures,

gates, panels or shields.

Keep away from live circuits, know your equipment and don’t take chances.

WARNING!

In case of emergency ensure that power has been disconnected.

10

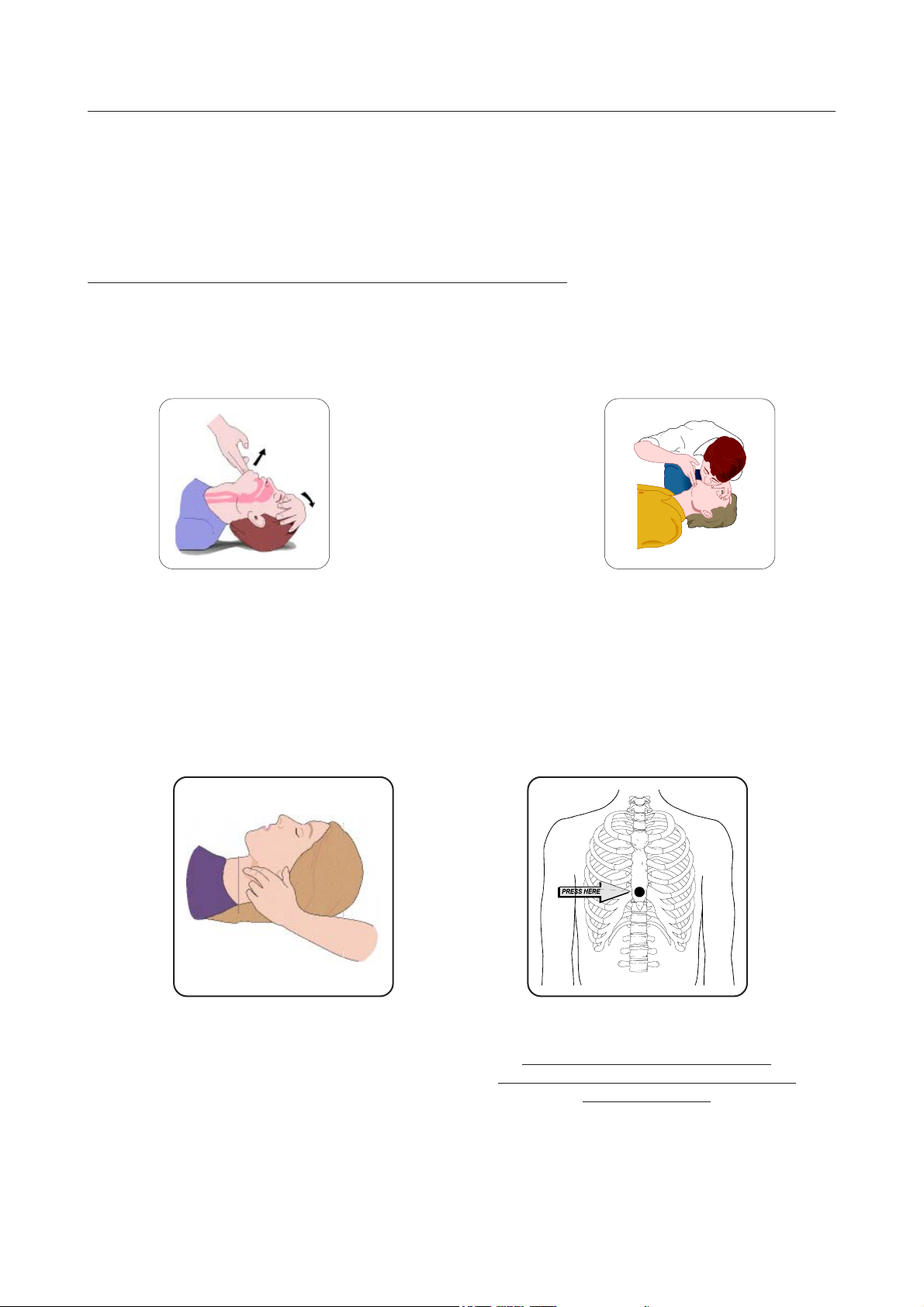

Treatment of electrical shock

1) If victim is not responsive follow the A, B, C’s of basic life support.

PLACE VICTIM FLAT ON HIS BACK ON A HARD SURFACE

A - AIRWAY

If unconscious, open airway lift up neck, push

forehead back, clear out mouth if necessary,

observe for breathing.

B - BREATHING

If not breathing, begin artificial breathing. Tilt

head, pinch nostrils, make airttght seal, 4 quick

full breaths. Remember mouth to mouth resuscita-

tion must be commenced as soon as possible.

C - CIRCULATION

Check carotid pulse. If pulse

absent, begin artificial circulation.

Call for medical assistance as soon as possible.

Approx. 80sec.: 1 rescuer, 15 compressions, 2 quick breaths.

Approx. 60sec.: 2 rescuers, 5 compressions, 1 breath.

NOTE: DO NOT INTERRUPT RHYTHM

OF COMPRESSIONS WHEN SECOND PERSON

IS GIVING BREATH.

11

2) If victim is responsive:

- keep them warm;

- keep them as quiet as possible;

- loosen their clothing (a reclining position is recommended).

FIRST-AID

Personnel engaged in the installation, operation, maintenance or servicing of this equipment are urged

to become familiar with first-aid theory and practices. The following information is not intended to be

a complete first-aid procedure, it is brief and is only to be used as a reference. It is the duty of all

personnel using the equipment to be prepared to give adequate Emergency First Aid and thereby prevent avoidable loss of life.

TREATMENT OF ELECTRICAL BURNS

1) Extensive burned and broken skin.

- Cover area with clean sheet or cloth (cleansed available cloth article);

- do not break blisters, remove tissure, remove adhered particles of clothing, or apply any salve or

ointment;

- treat victim for shock as required;

- arrange transportation to a hospital as quickly as possible;

- if arms or legs are effected keep them elevated.

NOTE

If medical help will not be available within an hour and the victim is conscious and not vomiting, give

him a weak solution of salt and soda: 1 level teaspoonful of salt and 1/2 level teaspoonful of baking

soda to each quart of water (neither hot or cold).

Allow victim to sip slowly about 4 ounces (half a glass) over a period of 15 minutes.

Discontinue fluid if vomiting occurs (do not give alcohol).

2) Less severe burns - (1st & 2nd degree).

- Apply cool (not ice cold) compresses using the cleansed available cloth article;

- do not break blisters, remove tissue, remove adhered particles of clothing, or apply salve or ointment;

- apply clean dry dressing if necessary;

- treat victim for shock as required;

- arrange transportation to a hospital as qickly as possible;

- if arms or legs are affected keep them elevated.

12

Communication N°1 -2002/95/CE - RoHS Directive

Further to the directives issued by the European Community, 2002/95/CE, 2002/95/CE and 2003/108/

CE, and to the Italian Decree of Law n° 151 dated 25 July 2005, this is to inform the customers of Elettronika

S.r.l. living within the boundaries of the European Community about the following obligations:

1) It is forbidden to trash RAEE products (which includes all broadcasting products which are not expressly

labelled as lead-free) along with normal wastes;

2) Such devices must be brought to proper centres able to perform the adequate processing in order to

recycle their parts where possible and dispose of the raw materials contained therein;

3) For equipment purchased from Elettronika after the 13th of August 2005, the gathering, transport, processing,

recycle and disposal operations are responsibility of Elettronika who will bear all related expenses;

4) For equipment purchased from Elettronika before the 13th of August 2005 , the gathering, transport,

processing, recycle and disposal operations are responsibility of Elettronika, who will bear all related expenses,

only if you are purchasing from us new equipment in substitution of the disposed one;

5) Electric and electronic devices contains lead in soldering, cables, etc. This substance pollutes the environment

and may be accumulated in the organism of plants and mammals. It is dangerous for humans because it may

affect blood, bone marrow, peripheral and central nervous system and kidneys, causing anaemia,

encephalopathies (e.g., convulsions), peripheral neuropathies, cramps of the abdomen and kidney damages.

Besides it affects human reproduction and growth.

These devices also contain mercury. From the environmental point of view, this substance is highly toxic for

aquatic life, and can be accumulated in the organism of fish.

Long-term damages to humans can affect the central nervous system and the kidneys, producing irritability,

emotional instability, tremors, damages to the mind and the memory, language disorders. It may also irritate

and whiten the gums, and its effects may be cumulative. Based on tests on animals, it may affect the human

reproduction or growth.

There is also chrome, which may result in irritation of the eyes and respiration system.

Cadmium is also present. In humans it may damage lungs, due to repeated or prolonged contact with its dust,

and kidneys. It may cause cancer.

6) The symbol below marks the devices which cannot be disposed of along with normal wastes, as stated in

1) and 2) above.

7) The payment of fees is foreseen for the non-allowed disposal of such devices.

13

This page is intentionally blank

14

DIGITAL TV

ATSC TRANSMITTER

User’s manual

15

This page is intentionally blank

16

Section 1 - Information

Contents:

1.1 Description

1.2 Main features

1.3 Technical characteristics

Front Panel

Rear Panel

Block Diagram

1.4 Operational details

17

ATSC TRANSMITTER

1.1 DESCRIPTION

The ATSC TRANSMITTER is an 8-VSB ATSC professional exciter, designed for the most demanding

digital TV broadcasting applications. It integrates a modulator module with up-to-date FPGA technology and

advanced digital signal processing algorithms in order to generate an absolutely accurate output 8-VSB signal,

with exceptionally optimized modulation and the output filtering techniques.

Very high linearity performances are possible thanks to very careful RF design over the entire VHF and UHF

bands and with an optimal digital precorrection engine working simultaneously in the time and frequency

domains. A high degree of reliability is guaranteed, moreover, by the use of oversized cooling devices and by

control circuits operated by modern microprocessor technologies.

The ATSC TRANSMITTER can be used as a stand-alone 5W RMS transmitter or as a driver stage for

amplifiers of greater power. The excellent spectral purity of the conversion oscillator lets the ATSC

TRANSMITTER radiate an 8-VSB signal with an excellent MER value.

The ATSC TRANSMITTER is equipped with a powerful ASI/SMPTE inputs management block which

allows to manage the Transport Stream (TS) inputs in a fully redundant configuration, thus significantly improving

the reliability of the whole broadcasting system in every operating condition.

The ATSC TRANSMITTER is totally compliant to the A53, A/54 and A/64 ATSC recommendations with

6MHz output channel bandwidth, in VHF and UHF bands.

1.2 MAIN FEATURES

- Compact and cost competitive;

- Top-quality air cooling system;

- Agile output frequency step 1Hz over VHF and UHF bands;

- Complies and exceeds the ATSC recommendations;

- Multi-platform remote control;

- User-friendly Graphical User Interface;

- Very high power efficiency thanks to accurate digital precorrection;

- Easy frequency synchronization.

18

1.3 TECHNICAL CHARACTERISTICS

SIGNAL PROCESSING SECTION

Reference Standard ATSC A/53, A/54, A/64

ATSC Mode 8-VSB 2/3 Trellis Code

Constellation 8-VSB

Code Rate 2/3

Network Support MFN

Bandwidth 6MHz

Digital Pre-Correction Linear and Non-Linear

Automatic PCR Restamping User enabled with Bitrate adaptation

Test Modes 23-bit PRBS Generator, Single-tone output

INPUT SECTION

TS Input 2 DVB-ASI + 2 SMPTE-310M inputs fully redundant

Input TS Format SPTS/MPTS, Burst Mode - Continuous Mode (ASI inputs)

MPEG-2 Packet Length 188/204 bytes (ASI), 188 bytes (SMPTE)

Input Data Rate 19.392658Mbit/s (SMPTE), up to 60Mbit/s (ASI)

Internal VCTCXO 10MHz reference

- Stability (full temperature range) < 1ppm (0-50°C)

- Aging < ±1ppm/year

- Tuning ±5ppm

10MHz output 0dBm ±3dB

External Frequency Reference 10MHz ±5ppm

Frequency Reference Interface BNC, 50Ω, -15dBm to +15dBm

OUTPUT SECTION

RF Output Frequency VHF band (57-240MHz) step 1Hz

Output Level 5W RMS

Output Interface N type connector, 50Ω

Spectrum Polarity Non-inverted and Inverted

Harmonics and Spurious < -50dBc

Pilot Carrier phase noise < -106dBc/Hz @20kHz

EVM < 2.5% without equalizer

Inband SNR > 32dB without equalizer

Shoulders > 50dB

Inband ripple < ±5dB

GENERAL

Physical Case 19”-2U, 420mm deep, 12kg

Remote Control Port RS232/RS485

Remote Control Options PSTN, GSM, Ethernet, SNMP (with external unit)

Front Panel User Interface LCD Display + Rotating knob + 3 LEDs

Power Supply Voltage 90 - 240VAC 50/60Hz

Power Consumption 150VA max

Operating Temperature 0 - 50°C

Specifications and characteristics are subject to change without notice

UHF band (470-860MHz) step 1Hz

19

Front panel

5

3

4

1 Graphical LCD

2 Rotating Knob

3 Status LEDs

4 RS232 Socket

5 RF Monitor Connector

DESCRIPTION

2

RS232 for Serial pin-to-pin connection

to PC with ERCos software

and for firmware upgrade

1

Pin 2: TX

Pin 3: RX

Pin 5: GND

20

Rear panel

2

DESCRIPTION

1 Main Switch

LINE SOCKET

2 AC Socket with Fuse-Holder (2A)

1

3 RS485 Socket

3

RS485

TELEMEASURES

4

ASI2

ASI1

5

SMPTE1

SMPTE2

4 Telemeasures Connector

TS Input Connectors

- ASI1 Input

5

- ASI2 Input

- SMPTE1 Input

- SMPTE2 Input

6 10MHz OUT Connector

7 10MHz IN Connector

8 RF Output Connector

IN

OUT

10MHz

10MHz

6

7

for Serial pin-to-pin connection

to RCU for remote control

Pin 2: RXPin 3: RX+

8

RF OUT

Pin 4: +5V

Pin 5: GND

Pin 6: +5V

Pin 7: TXPin 8: TX+

RS485

Pin 1: FWD power (Analog out)

Pin 2: REF power (Analog out)

Pin 3: Temperature (Analog out)

Pin 4: FWD power (Analog in)

Pin 5: GND

Pin 6-7:Alarm or Squelch (user selectable)

Pin 8: External AGC Alarm (Digital in)

Pin 9: Remote ON/OFF (Digital in)

Wired Telemeasures connector

Alarm: Open=Normal / Closed=Alarm

Squelch: Open=No Squelch / Closed=Squelch

(Digital out, Free contact relay)

Open=Normal / GND=Alarm

Open=ON / GND=OFF

21

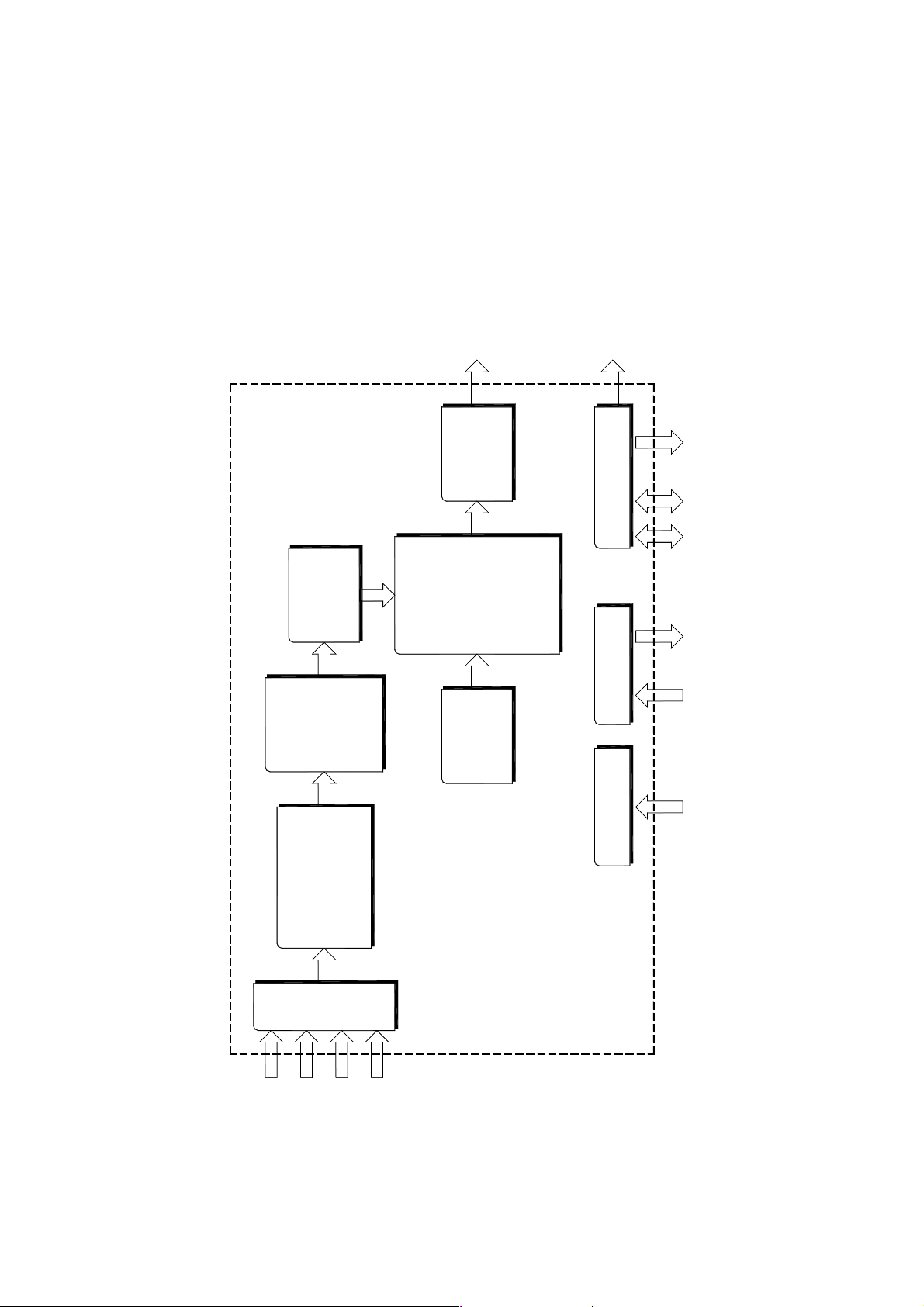

Block diagram

RF OUTPUT

OUTPUT

AMPLIFIER

DIGITAL-TO-ANALOG BANDPASS

8-VSB

FILTER

MODULATOR CONVERTER

DUAL-STAGE

FREQUENCY CONVERTER

SYNTHESIZER

AGILE LOW-NOISE

POWER SUPPLY SYNCHRONIZATION CONTROL & MONITORING MONITORING OUTPUT

CONTROL

REDUNDANCY

90-250Vac 10MHz IN 1 0MHz OUT RS232 TELEMEASURESRS485

22

ASI1 INPUT

ASI2 INPUT

SMPTE1 INPUT

SMPTE2 INPUT

1.4 OPERATIONAL DETAILS

All the sections of the ATSC TRANSMITTER, as showed in the block diagram above, are described in this

section in order to give the user a general understanding of the operations of the equipment.

1.4.1 TS INPUT MANAGEMENT

The ATSC TRANSMITTER is equipped with 2 ASI inputs and 2 SMPTE-310M inputs. Each input standard

is available with two inputs in order to enable redundant operation for the transport stream input. You can

decide to operate with SMPTE input or with ASI input depending on your network interfacing needs. In

either case a complete redundancy is guaranteed thanks to a duplicated input.

The ATSC transmission scheme is built over a very stable and accurate data stream clock. The SMPTE310M data clock shall have the exact standardized clock frequency. The modulator module takes its

synchronization from this input data stream to be able to recover the same clock frequency. If an external

clock reference is used (10 MHz), the global clock synchronization might be plesiochronous (i.e. not perfect

synchronization between the multiplexer clock and the modulator reference clock). In that case, it is

recommended to enable the "bit rate adaptation" on the ATSC TRANSMITTER.

When this mode of operation is enabled, the input processing module discards or inserts Null Packets in order

to adapt the MPEG-TS input bit rate to the precise bit rate defined by the ATSC recommendation. PCR restamping is then executed accordingly.

The switching is not expected to be seamless. However, in case of feeding the exact data stream on both

inputs (Primary & Secondary), then the ATSC TRANSMITTER performs a seamless switching from one to

the other input. Switching is always performed on a packet basis.

The user may enable or disable the automatic mute when an error on the SMPTE-310M or on the ASI input

is detected. The delay for the detection of the lost of SMPTE-310M is 1 second from its occurrence. In case

the user disables the automatic mute, null packets are inserted in order to feed the modulator section with the

exact ATSC bit rate.

Two test modes are available for testing and alignment procedures. The 23-bit PRBS test mode generates a

pseudo-random data sequence in order to produce a correct output spectrum even in absence of a valid TS

input. The single-tone test mode produces a sinusoidal output useful for frequency converters alignment. The

test modes are useful only for testing purposes and shall not be used for real broadcasting operation.

- Redundancy management

When set in Automatic Switching mode (default), the input management unit automatically detects the presence

of a valid MPEG Transport Stream (MPEG-TS) on the main or auxiliary inputs. If no valid MPEG-TS flow

23

is detected, the unit switches automatically to the other input. The periodic occurrence of the Sync byte in the

MPEG-TS packets is used to decide if a MPEG-TS flow is valid or not. If the user chooses to operate in

Manual switching mode then he has to force which input is active.

- Reed Solomon FEC

If the ASI incoming inputs (note: only for ASI input mode) include the Reed Solomon codes (204 bytes

packets), the module performs the error correction thanks to the 16 RS bytes.

- Bit rate adaptation

When operating in ASI input mode, the input management unit can perform an automatic bit-rate adaptation,

if required. When this mode of operation is activated, the unit automatically removes and/or inserts null packets

in order to adapt the incoming ASI bit-rate to the exact bit-rate defined by the ATSC recommendation. PCR

restamping is then executed in real time.

- Squelch

The RF output signal can be muted if one of the following conditions occurs:

- a hardware problem is present (for example, the amplifier temperature is too high, the modulator does not communicate

with the controller and so on);

- an error in the input signals is present (input TS missing and Mute on input error feature enabled).

In the first condition, the output is muted to protect valuable internal parts of the equipment and/or save power. In the

second condition, the output is muted because the signal is most probably unusable by receivers. This muting action

is known as Squelch.

In a dual drive or 1+1 transmitter, the changeover control unit should discriminate if the output power reduction is

caused by a hardware problem (the changeover takes place) or by an input signal problem (the changeover is not

performed). The user can change the meaning of the digital output in the TLM port choosing "Alarm" (useful to

interface a custom remote control system) or "Squelch" (useful to interface a changeover control unit).

1.4.2 SYNCHRONIZATION AND CLOCKS

The ATSC TRANSMITTER includes its own clock and synchronization generator. A high stability 10MHz

VCTCXO provides the internal clock reference to the clock system of the digital processing section of the

equipment. An external 10MHz reference may be used if a higher stability is needed, or if there is a need to

lock the modulator processing clock or the output carrier frequency to an external reference (i.e. operation in

frequency offset mode).

In special cases, the 10MHz internal clock may be locked to the system clock embedded into the ASI/

SMPTE input signal. In this case, you can not enable the Bit-Rate Adaptation function and the input bit rate

has to be the exact ATSC bit-rate (19.392658Mbit/s). If the ATSC TRANSMITTER is set up to operate

with either of the two external references (from ASI/SMPTE input or from the external 10MHz reference), it

will automatically switch to the internal reference if the external reference is missing. The switching from the

24

external 10MHz reference to the 10MHz internal clock is totally seamless. The processing clock of the numerical

section of the ATSC TRANSMITTER is always locked to the internal or to the external 10MHz reference.

1.4.3 OUTPUT SIGNAL

The ATSC TRANSMITTER output signal is available at the output labelled RF OUT on a 50Ω N-type

female connector. The frequency of the output signal can be set in the VHF and UHF bands, depending on the

model type. The frequency can be set by choosing the standard/channel/offset combination (for example,

UHF standard, channel 45 and offset 0Hz) or by choosing directly the center frequency of the output signal.

An attenuated version of the output signal is available at the RF Monitor terminal located on the front panel of

the equipment. The maximum nominal output level is 5W RMS, the output power level can be controlled in

AGC (Automatic Gain Control) mode or in manual mode and can be adjusted by the rotating knob located

on the front panel. The output signal may be muted either manually by the user or automatically depending on

some given conditions. The mute can be direct (abrupt muting) or progressive (linearly decreasing function).

1.4.4 NON-LINEAR PRECORRECTION

Any solid-state or tube power amplifier will produce intermodulation distortion when fed by the ATSC 8VSB signal. Non-linear precorrection is used to compensate the effects of these distortions in order to radiate

a signal with the maximum possible MER value.

The ATSC TRANSMITTER is able to perform non-linear precorrection over a 20MHz bandwidth. For this

purpose, two tables (AM-AM and AM-PM) of maximum 16 taps are used by the modulator.

The AM-AM precorrection table defines the AM-AM curve that will be applied to the output spectrum. For

each tap, the abscissa can be defined from -12dB to +12dB by 0.05dB step and the ordinate can be defined

from -6dB to +6dB by 0.05dB step.

The AM-PM precorrection table defines the AM-PM curve that will be applied to the output spectrum. For

each tap, the abscissa can be defined from -12dB to +12dB by 0.05 step and the ordinate can be defined

from -25 degrees to +25 degrees by 0.2 degrees step.

Up to 10 non-linear precorrection curves (10 AM-AM and 10 AM-PM tables) can be downloaded and

saved into the equipment memory. For each curve a 10-characters name is associated. By using the local or

remote control it is possible to disable the non-linear precorrection at all or activate one of the saved curves.

Besides the 10 customizable curves, a non-customizable "Null" curve is always available: the AM-AM and

AM-PM tables of this curve are filled by zeros.

1.4.5 LINEAR PRE-CORRECTION

Any output cavity filter will produce amplitude and group delay distortion over the ATSC 8-VSB signal

25

generated by the transmitter. Linear precorrection is used to exactly compensate these distortions in order to

generate a signal which is maximally flat both in amplitude and group delay. The ATSC TRANSMITTER is

able to perform amplitude and group delay correction over the full spectrum of the output signal.

The linear precorrection is a factory procedure, so the equipment is delivered with the optimal linear precorrection

curve already operating.

By operating on the front panel user interface, the user may decide to switch off or switch on the linear

precorrection curve stored by the Elettronika production department.

1.4.6 CONTROL OF THE EQUIPMENT

The ATSC TRANSMITTER can be controlled by means of a user-friendly LCD graphical interface with a

single rotating knob for the menu navigation and for the selections or remotely through a RS232, RS485 or

TELEMEASURES port. The functions of the local and remote control are:

- Setting the operating mode of the ATSC TRANSMITTER and the associated parameters. All these parameters

are stored in a local memory, so the previous operating mode is automatically restored each time after a power cycle.

- Monitoring the status of the equipment.

- Recording events and alarms.

- Firmware upgrades.

- Digital Precorrection through RS232 port and dedicated PC software interface.

1.4.7 TEST MODES

Two test modes are available, to be used only for laboratory or field test. The test modes are directly accessible

from the user menus and are:

1) PRBS Sequence: the ASI/SMPTE input signals are ignored and a 23-bit PRBS sequence replaces the in-

put payload of the MPEG-TS packets. This test allows measurements on the modulated signal without the

need of a valid ASI/SMPTE input signal.

2) Single Tone: the normal 8-VSB output spectrum is switched off and replaced by a sinusoidal output useful

for frequency converters alignment.

Note: If test mode 2) is active, the ATSC TRANSMITTER does not generate a valid ATSC 8-VSB signal.

1.4.8 POWER HANDLING

After the ATSC TRANSMITTER is powered on, it starts radiating a valid ATSC 8-VSB signal within a short

time. The maximum initial power-on delay is about 20s as factory default value. Any modification of this initial

power-on delay is to be done with the support of the Elettronika Customer Service.

26

If a valid MPEG-TS signal is received over one of the ASI/SMPTE inputs, then the equipment will immediately

generate the signal on the RF output. In absence of a valid MPEG-TS signal the equipment can be set to be

muted or not.

Enabling the muting function is possible by the user menus, as explained in the Menu Management section of

the present manual.

All the working parameters of the ATSC TRANSMITTER are stored into a non-volatile memory in the

modulator section, so that there is no need to restore the parameters after a power off/on cycle.

The power handling is characterized by 3 states: MUTE, POWER UP and POWER ON.

z MUTE (POWER LED off, fan off): the internal amplifier is switched off by inhibiting the RF transistors gate.

z POWER UP (POWER LED blinking, fan on): the internal amplifier is switched on and the output power,

starting from -3dB to the final level, is slowly increased following a linear ramp law.

z POWER ON (POWER LED on, fan on): the internal amplifier is switched on (normal working operation).

Moving from MUTE to POWER ON state (for example, after switching on or when an active alarm disappears)

is performed by moving through a temporary POWER UP state. Instead, moving from POWER ON to

MUTE state (for example, when a serious alarm occurs or the ASI/SMPTE inputs are corrupted or absent)

is immediate.

1.4.9 ALARMS AND AUTOMATION

The ATSC TRANSMITTER is fully protected against any malfunctioning event that could damage the expensive

internal components. The user should clearly understand what happens in presence of alarms and warnings,

in order to face these situations properly and reduce the inactivity time.

In case of any alarm condition, the ALARM LED on the front panel lights up and a bell icon appears in the

status bar of the display. When the alarm condition ceases, the ALARM LED is turned off and the bell icon

starts blinking, in order to show that an anomaly occurred since the last visit to the log. To know the details

about the alarm event (for example the time and date of its occurrence), the log menu can be used. Once the

user enters the log screen, the bell icon disappears. When you note an active alarm (the bell icon is shown and

not blinking and the ALARM LED

is on), go to the ALARM screen to see which alarms are present. For certain dangerous situations, the ATSC

TRANSMITTER immediately switches off the output power, by acting on the RF power transistors gate, in

order to save the internal parts from an unrecoverable damage. When the alarm disappears, the power is

automatically switched on again. Once the output power has been inhibited for 5 times, the ATSC

TRANSMITTER goes into "Lockout" state: the power remains off until the user resets the Lockout condition,

or switches the equipment off for repair. After one hour from the last alarm and without the Lockout condition,

the Lockout counter is automatically cleared. The list of the automatic interventions in case of anomalies can

be found below.

27

z Amplifier Voltage

An amplifier power supply voltage alarm occurs when the monitored voltage is outside the nominal level

±10% range. The nominal voltage level is a factory setting (usually, 28V). This alarm does not trigger a

powering off of the output signal. If the monitored voltage is near 0V, most probably the fuse located near the

power amplifier stage is burned.

z Amplifier Current

An amplifier power supply current alarm occurs when the monitored current drained by the amplifier is 20%

above the nominal level. The nominal current level is a factory setting. This alarm does not trigger a powering

off of the output signal.

z Amplifier Temperature

The temperature is monitored on the hottest point, located near the power amplifier stage on the cooling heat sink.

If the fans work well, and the ambient temperature is inside the working conditions limits, all of the internal parts

should reach safe temperature levels. In some circumstances (for example, when a fan is blocked or damaged), the

temperature may increase too much, and some internal components may break. In order to avoid this unpleasant

situation, a temperature alarm occurs when the temperature is over a maximum threshold (75°C). This alarm

triggers an immediate powering off of the output signal and an increase of the lockout counter.

The power will be switched on again only when the temperature goes below a second threshold, lower than the first

(70°C).

z Forward and Reflected Powers

A forward or reflected power alarm occurs when the relevant monitored power level is over a threshold

(factory setting). Both alarms trigger an immediate powering off of the output signal and an increase of the

lockout counter.

You can see the levels of the power thresholds in the Amplifier menu (see the Menu Management paragraph).

z Power supply voltages (+5V, +12V, -12V)

Besides the amplifier power supply voltage (+28V), the ATSC TRANSMITTER uses three additional main

voltages: +5V, +12V, -12V. These voltages are continuously monitored by the control system and any variation

above 10% of the nominal value generates an alarm condition. This alarm does not trigger a powering off of

the output signal.

z No communication with the modulator

The 8-VSB Modulator module continuously communicates with the control system. If this communication

fails, the control board triggers a "No communication" alarm.

This is a serious malfunction that must be solved as soon as possible.

In presence of a no communication alarm, the control system is not able to know the working condition of the

modulator (for example, the modulated output signal level), so it inhibits the power amplifier stage and the

output power is brought to zero level.

28

z External reference alarm

When external or ASI/SMPTE reference is set, the modulator continuously monitors the presence of such

reference. If it is not able to find a correct signal, it automatically switches to the internal reference. In this

situation, an external reference alarm is triggered. This alarm does not trigger a powering off event. See the

Synchronization and Clocks paragraph for more information.

z ASI/SMPTE inputs alarm

There are several conditions related to input streams that could trigger an alarm, depending on the working

conditions. They are:

- MPEG-TS synchronization missing;

- uncorrected input packet (only in 204 RS coded mode with ASI input mode);

- bit rate underflow/overflow (only if bit rate adaptation is performed).

The above conditions trigger an alarm only for the input which is currently used by the ATSC TRANSMITTER.

1.4.10 AGC: IMPLEMENTATION AND DETAILS

The use of external AGC helps the ATSC TRANSMITTER to maintain stable the output power of a highpower transmitter. With a menu setting (see the Menu Management paragraph) you can choose among

stabilizing the output power of the exciter (external AGC disabled) or stabilizing the output power of a highpower transmitter (external AGC enabled). In this case a proper cabling between the ATSC TRANSMITTER

and the high-power amplifier stage is necessary. The cable (AGC cable) shall be connected to the TLM port

of the ATSC TRANSMITTER on one side. In the following table the three signals and pins used in the TLM

port are listed. The pinout connection of the cable depends on the specific amplifier used. Refer to your

amplifier user's manual to find the port and pins of the corresponding signal.

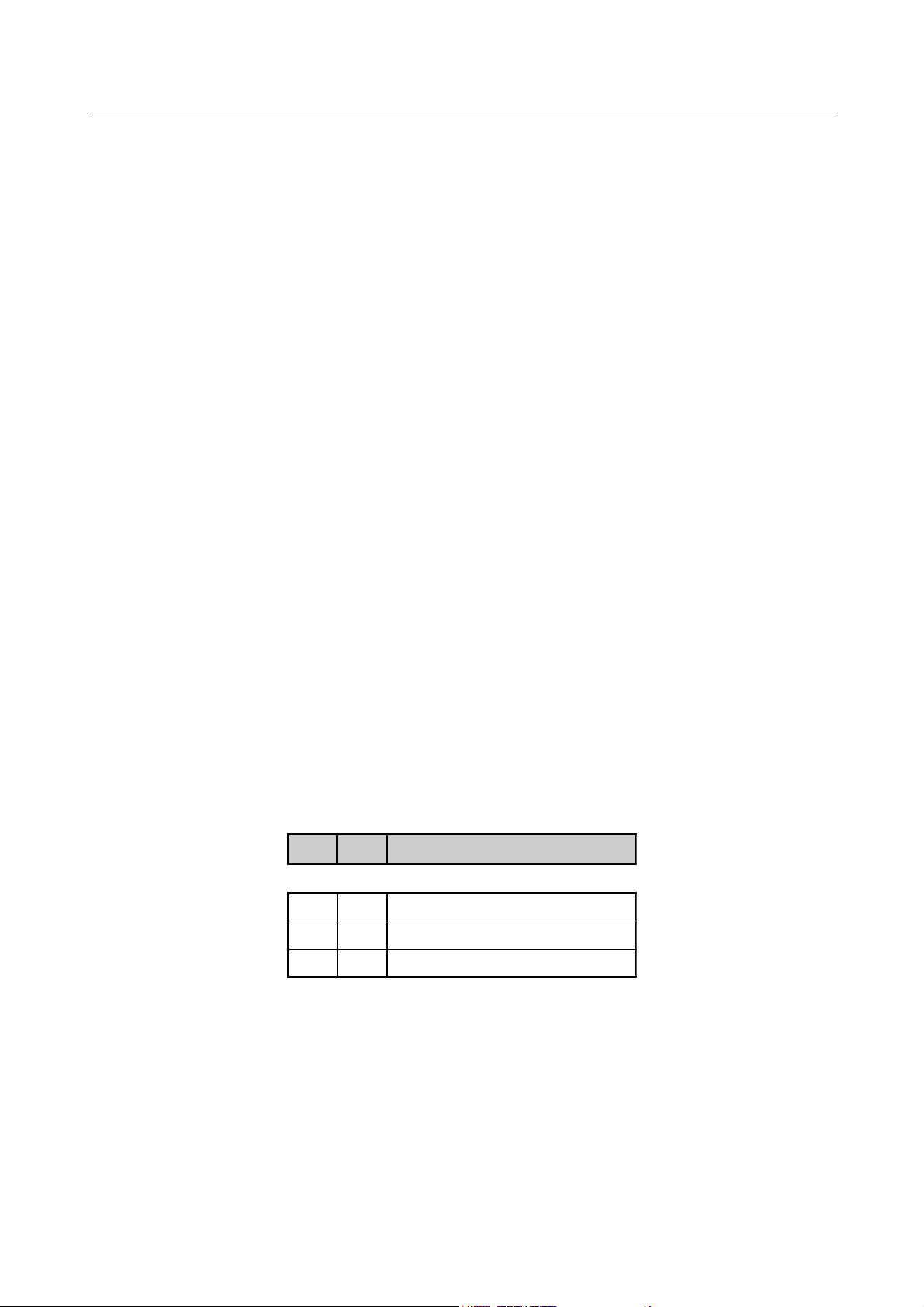

PIN I/O DESCRIPTION

4 I Forward Power (0-5V)

5-GND

8 I Alarm (GND=Alarm / Open=Normal)

The AGC goal is to maintain the output power stable. Output power in fact can change due to the increase of

the amplifier temperature. Note that when you change the operating frequency the output power changes due

to the different gain at different frequency, but this change is not stabilized by the AGC algorithm. The transmitter

power to be stabilized is read from TLM port.

To keep the power stable, the AGC changes the power gain of the ATSC TRANSMITTER.

The AGC algorithm is based on the acquisition of the optimal output power level, stored when you confirm the

29

output power level in the Power menu (see the Menu management paragraph) and the use of 4 thresholds

as below:

____action threshold

________goal threshold

___________optimal power value

________goal threshold

____action threshold

The distance of the thresholds from the optimal value is of ±20mV and ±30mV measured as monitor voltage.

The AGC changes the output power to bring the power from the amplifier inside the goal thresholds range.

When this goal is achieved, the AGC stops until the power goes outside the action thresholds range.

The AGC is stopped immediately (output power remains blocked to the value reached at the moment in

which the AGC stops) when one of the following conditions occurs:

z RF output is muted for an alarm condition or user setting;

z the AGC is chosen as external but the amplifier stage triggers an alarm;

z the ATSC TRANSMITTER output power is too low;

z the AGC has corrected the output power too much.

In order to simplify the understanding of the AGC behaviour, the status of the external AGC is written in the

Power menu (Ext AGC Status parameter). The possible statuses of the AGC are listed below.

z Disabled: external AGC is disabled.

z Idle: external AGC is stopped (for example, during the slow increase of the power immediately after swit-

ching on the equipment).

z Low Set: external AGC is stopped because external power reading was too low when the nominal output

power has been chosen.

z Alarm: external AGC is stopped because an alarm signal from the power amplifier stage is active.

z Locked: the transmitter output power has reached the desired level.

z Max/Min: external AGC is stopped because the power correction is too high.

z Pull Up/Down: external AGC is moving the power level up or down.

Warning! When changing from AUTO to MANUAL power control mode, the external AGC will be disabled.

30

Loading...

Loading...