Page 1

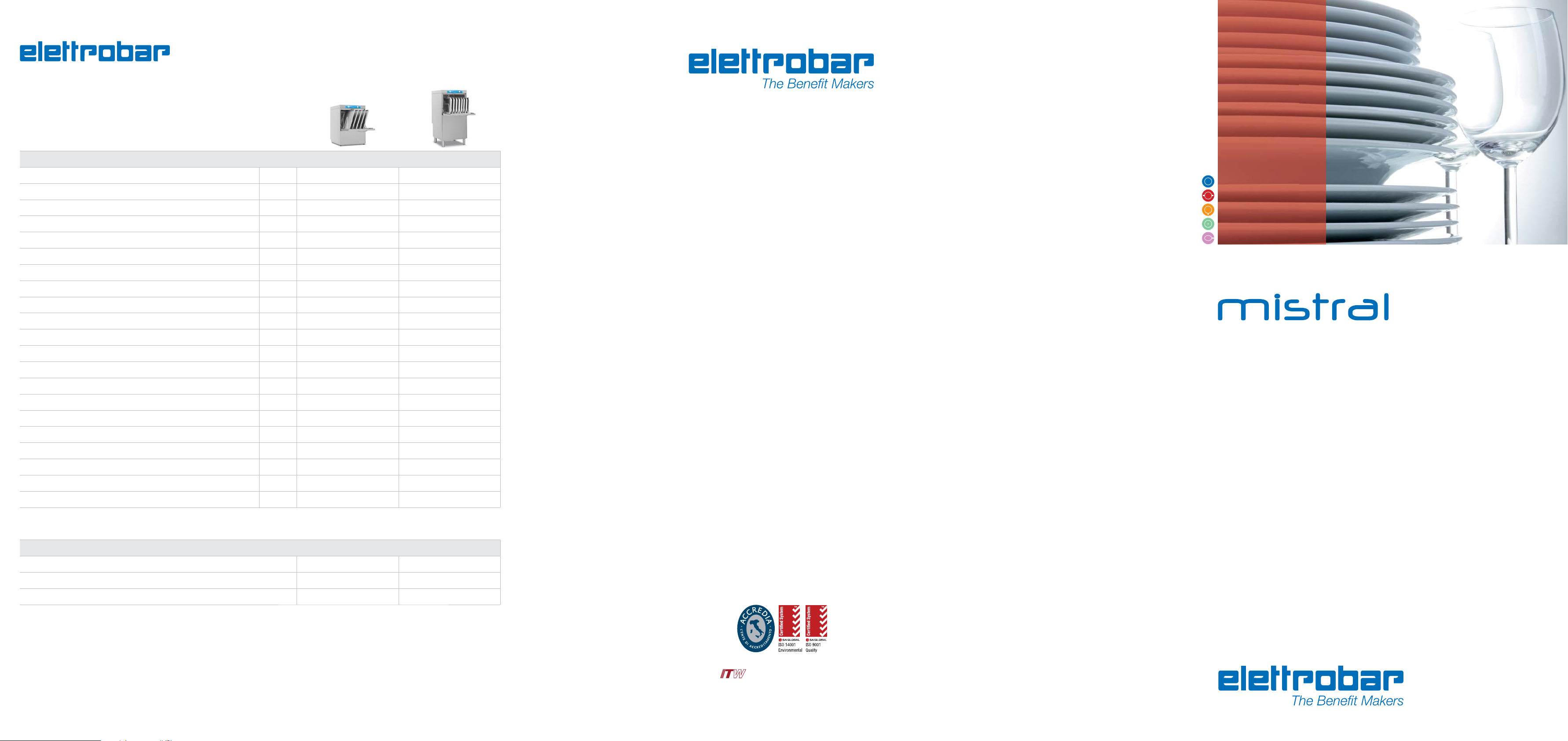

TECHNICAL DATA

Theoretical productivity racks/hour 30 30

Dimensions ( WxDxH ) cm 60x70x85 60x70x129

Door opening cm 40,5 40,5

Max. height of plates cm 41 41

Max. trays dimensions cm GN1/1 (53X32) GN1/1 (53X32)

Max. pans dimensions cm 60x40 60x40

Standard rack dimensions cm 50x60 50x60

Max. bread baskets dimensions cm 60x50x39 60x50x39

Tank capacity litres 23 23

Boiler capacity litres 7 7

Tank heating element kW 2,1 2,1

Boiler heating element kW 6 6

Wash pump kW 0,7 0,7

Rinse pump * kW 0,2 0,2

Drain pump * kW 0,04 0,04

Total power consumption kW 8,8 8,8

Power supply V 400V - 50Hz - 3N 400V - 50Hz - 3N

Max. current amp 16 16

Min.-max water supply pressure bar 2 → 4 (1 → 4 241CDE) 2 → 4 (1 → 4 242CDE)

MIstral 241 Mistral 242

During more than forty years of business, we have produced more than a million

industrial dishwashers at our two Italian plants. These numbers refl ect our unrivalled

experience in the sector. Building on this experience, we have continued to develop

competitively-priced innovative products for leading players in the catering industry,

providing effective, consistent benefi ts for their various enterprises. This is why we

at Elettrobar claim to be more than just a dishwasher manufacturer: we are benefi t

makers.

Our company is fully aware of the increasing importance of environmental

protection issues and for many years has played its part, developing and patenting

innovative technologies able to reduce water, energy and detergent consumption

without impairing performance.

We adopt extremely stringent ISO 9001:2008 certifi ed quality control procedures

to build products that can withstand even the harshest operating conditions. Our

dishwashers are manufactured at facilities that lead the way as regards workplace

safety and environmental impact, as confi rmed by ISO 14001:2004 certifi cation.

Eurotec Service

Our commitment to quality does not end when the machine leaves the factory, but

continues throughout the entire life-cycle of the product:

EurotecService is the specialised division that oversees both our replacement

parts service and our after-sales service, with particular emphasis on training and

qualifi cation of our extensive network of dealerships and service centres that covers

the whole of Italy.

This division is also responsible for pre-sales, logistics and customer care activities,

thereby promoting an intrinsically synergistic approach to all activities that have a

direct bearing on customer satisfaction.

Traywashers _ Utensil washers

Water supply temperature °C 15 - 60 15 - 60

Peristaltic rinse aid and detergent dispensers yes yes

* where present

AVAILABLE VERSIONS

D - Standard - yes

DE -

With partial drain with pump yes -

CDE - With atmospheric boiler with rinse pump and partial drain with pump yes yes

FOOD EQUIPMENT GROUP

Eurotec s.r.l. - divisione ELETTROBAR

37045 San Pietro di Legnago (VERONA) ITALIA - Tel. 0442 634311 - Fax 0442 629132

e-mail: info_elettrobar@itweurotec.it - www.elettrobar.eurotecgroup.com

07-2018

Page 2

2

Traywashers _ Utensil washers

Features

241

Undercounter, Trays and Utensil/Pot washers, 85 cm high with 50x60 cm

rack and 40.5 cm door opening.

Thanks to its wide door opening, the capacity of the wash chamber and the

use of dual-fl ow wash pumps with an upper and lower 3 spokes arms the

undercounter can wash perfectly 60x40 cm pans, ice cream tubs, trays,

whips, bread basket and any other type of tool.

In the wide range of specialized wash programs, in addiction of the three

standard, there are intensive cycles for the heavy dirt, programs for dishes

and cutleries and the sanitize ones.

Standard equipment includes a 50x60 cm universal stainless steel rack.

As optional some inserts, containers and support grids for the bread basket

are available.

Available versions: see tables on page 5.

Our cutting age undercounter utensil and pot washers, Mistral 241 and front-load Mistral 242 are designed to

achieve the best washing results on all equipment used in pastry and ice-cream shops, bakeries and delicatessens.

Thanks to their compact design they are also suitable for small environments.

Programs menu

PROGRAM MAIN USE

ProWork 2

ProWork 4

ProWork 6

ProSelf

STANDARDSPECIALISED

ProClean

ProDrain

ProLong

ProPlates

ProEco

ProActive 5

ProActive 7

ProSteel

ProSan

ProWork 8

ProWork 10

Light, fresh soiling 2,4 120

General use 3 240 ••••

Heavy soiling 3,5 360 ••••

Self-clean and automatic draining 4,0 120 •

Self-clean 20 240 •

Automatic draining - - • • •

Continuous wash 3,5 720 ••••

Specifi c cycle for plates 2,1 90 ••••

Blood and starch 3,5 300 ••••

Pans and utensils 5,0 300 • • •

Pans and utensils 5,0 420

Cutlery 3,5 720

Sanitisation to EN-ISO 15883-1/3 3,5 auto

Intensive use 1 3,9 480 •

Intensive use 2 3,9 600 •

Min consumption

l/cycle

Duration

sec.

Mistral

241DE

••••

•

Mistral

241CDE

•

••

••

••

Mistral

242D

•

•

Mistral

242CDE

•

Constructional features

Traywashers_Utensil washers constructed with widespaced double-skin side panels with fl at welded rack guides

and full double-skin door. The tank has deep-drawn base and is equipped with an integral stainless steel fi lter. The

wash chamber is free of internal pipes and sharp corners.

User interface

Electronic interface comprised of four soft-touch keys, a 4-character LED display and two lateral indicator bars that

enable the operator to check machine status at a glance. From the interface, the user can adjust the tank and boiler

temperatures and detergent dosing.

Wash programmes

All versions offer a choice of three standard wash programmes to suit different levels of soiling, plus nine specialised

programmes. Self-clean cycles are also provided as standard.

Equipment

Electronically-controlled peristaltic rinse aid and detergent dispensers are standard equipment on all versions, with

dosing adjustable from the operator interface. Atmospheric boiler version available for use in combination with the

WS140 reverse osmosis system.

242

Front-load Trays and Utensil/Pot washers, 129 cm high with 50x60 cm rack

and 40.5 cm door opening.

The worktop height of 81 cm from the fl oor means that the operator can load

and unload the machine without having to bend down.

Thanks to its wide door opening, the capacity of the wash chamber and the

use of dual-fl ow wash pumps with an upper and lower 3 spokes arms the

front-load can wash perfectly 60x40 cm pans, ice cream tubs, trays, whips,

bread basket and any other type of tool. In the wide range of specialized wash

programs, in addiction of the three standard, there are intensive cycles for the

heavy dirt, programs for dishes and cutleries and the sanitize ones.

Standard equipment includes a 50x60 cm universal stainless steel rack.

As optional some inserts, containers and support grids for the bread basket

are available.

Available versions: see tables on page 5.

Ø cm

H cm

H cm

cm

Ø cm

H cm

H cm

cm

Mistral 241

41

GN1/1 (53x32)

60x40

60x50x39

Mistral 242

41

GN1/1 (53x32)

60x40

60x50x39

Loading...

Loading...