Page 1

DIGITAL / ANALOG TRAINER

MODEL XK-700-SEMI

A COMPLETE MINI-LAB FOR BUILDING,TESTING

AND PROTOTYPING ANALOG AND DIGITAL CIRCUITS

Elenco Electronics, Inc.

Copyright © 1997 Elenco Electronics, Inc. REV-C Revised 2001 753045

Assembly & Instruction Manual

Page 2

INTRODUCTION

The XK-700-SEMI Digital/Analog Trainer is basically divided into four sections: Bredboard, Power Supply,

Analog and Digital. The bredboard was sent to you in an earlier kit.The PC board that contains the majority of

the circuits has come to you preassembled - HANDLE IT CAREFULL

Y as parts can be broken or moved and

could cause the circuit to malfunction. Follow the instructions carefully and perform all tests required. When

the assembly of the trainer has been completed, you will do a resistance and voltage analysis. If problems

occur, the troubleshooting chart at the end of each section will be helpful. After the Power Supply has been

established as functioning correctly, you will analyze the Analog Section ev en though it was preassemb led. That

confirms that the circuit is functioning properly when it is powered up. The same procedure will be followed up

when checking the Digital Section.

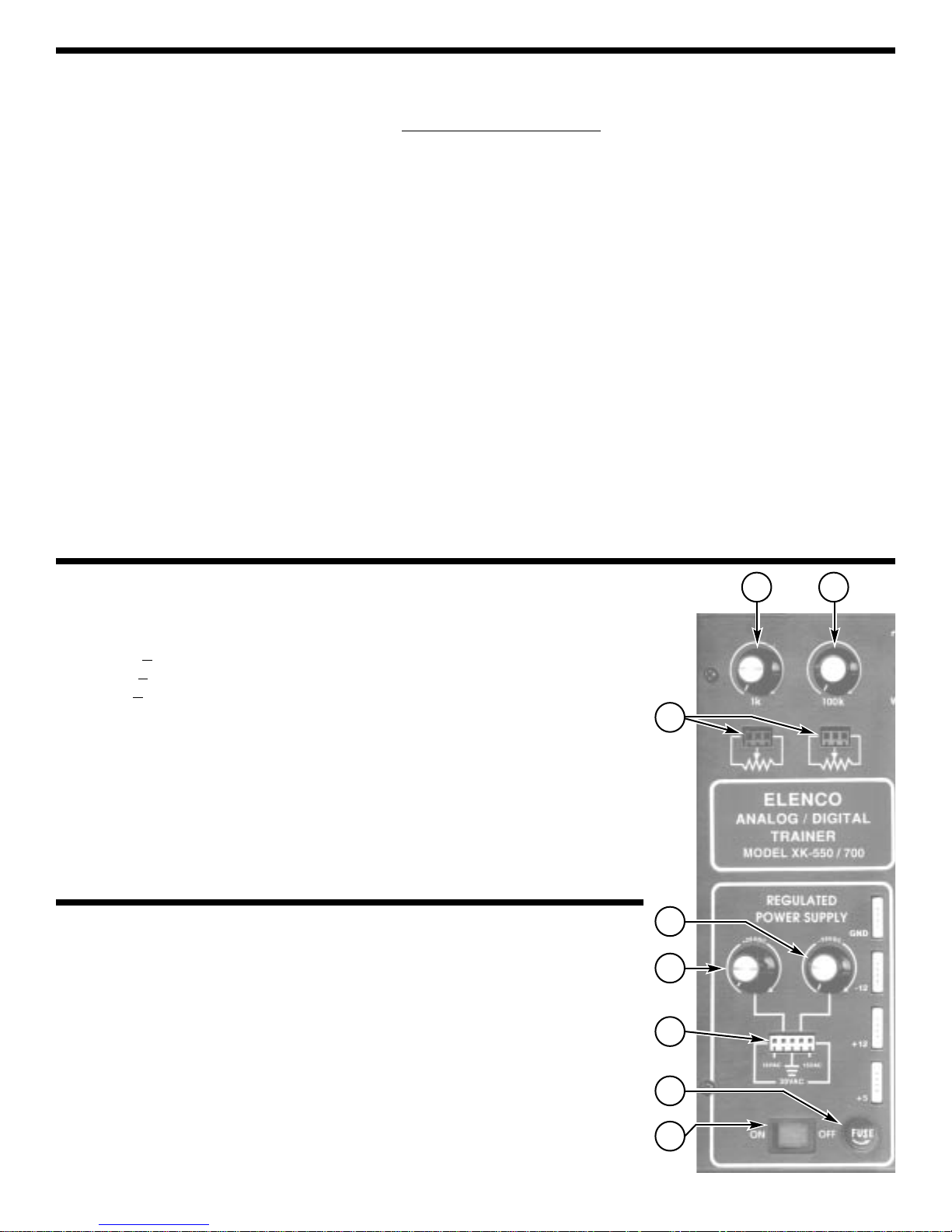

POWER SUPPLY

The XK-700-SEMI has five built-in power supplies which will satisfy most design needs. This includes two

variable power supplies giving up to +20 volts and -20 volts at .5 amp. Below 15V, the current available is 1

amp. Three fixed power supplies give you +12VDC, -12VDC or +5VDC at 1 amp each. These fixed voltages

are the most commonly used voltages for design w ork. All supplies are regulated to within 150mV. This means

that you can increase the current draw from no load to .5 amp and the voltage will change less than 150mV. All

supplies are also short circuit protected by using integrated circuit regulator devices.

ANALOG TRAINER SECTION FUNCTION GENERATOR

The analog trainer contains a complete function generator capable of producing sine, square and triangle

waveforms. The frequency of the generator is continuously variable from one hertz to over 100,000 hertz in five

steps. A fine tuning control makes the selection of any frequency easy. The output voltage amplitude is variable

between 0 to 15Vpp. The output impedance is approximately 330 ohms.

DIGIT AL TRAINER SECTION

The digital trainer has the necessary functions to do your digital experiments. They consist of a clock generator,

two no-bounce switches, eight LED indicator lamps and eight data switches.

POWER SUPPLY SPECIFICATIONS

Power Supplies:

• +1.25V to 20VDC @ .5 amp (1.25V to 15V @ 1 amp).

• -1.25 to -20VDC @ .5 amp (-1.25V to -15V @ 1 amp).

• +12V +

5% @ 1 amp.

• -12V +

5% @ 1 amp.

• +5V +

5% @ 1 amp.

• 30VAC center tapped @ 1 amp.

• Load regulation - all DC supplies less than .2V no load to .5A.

• Line regulation - all DC supplies less than .2V 105 to 135V.

• Hum and ripple - all DC supplies less than .01V RMS.

• Short protection - all DC supplies-inter nal IC ther mal cutoff.

• Fuse 1.25A 250V.

Variable Resistance (undedicated):

• 1kΩ Potentiometer

• 100kΩ Potentiometer

Bredboard - 2 bredboards containing 1,560 tie points.

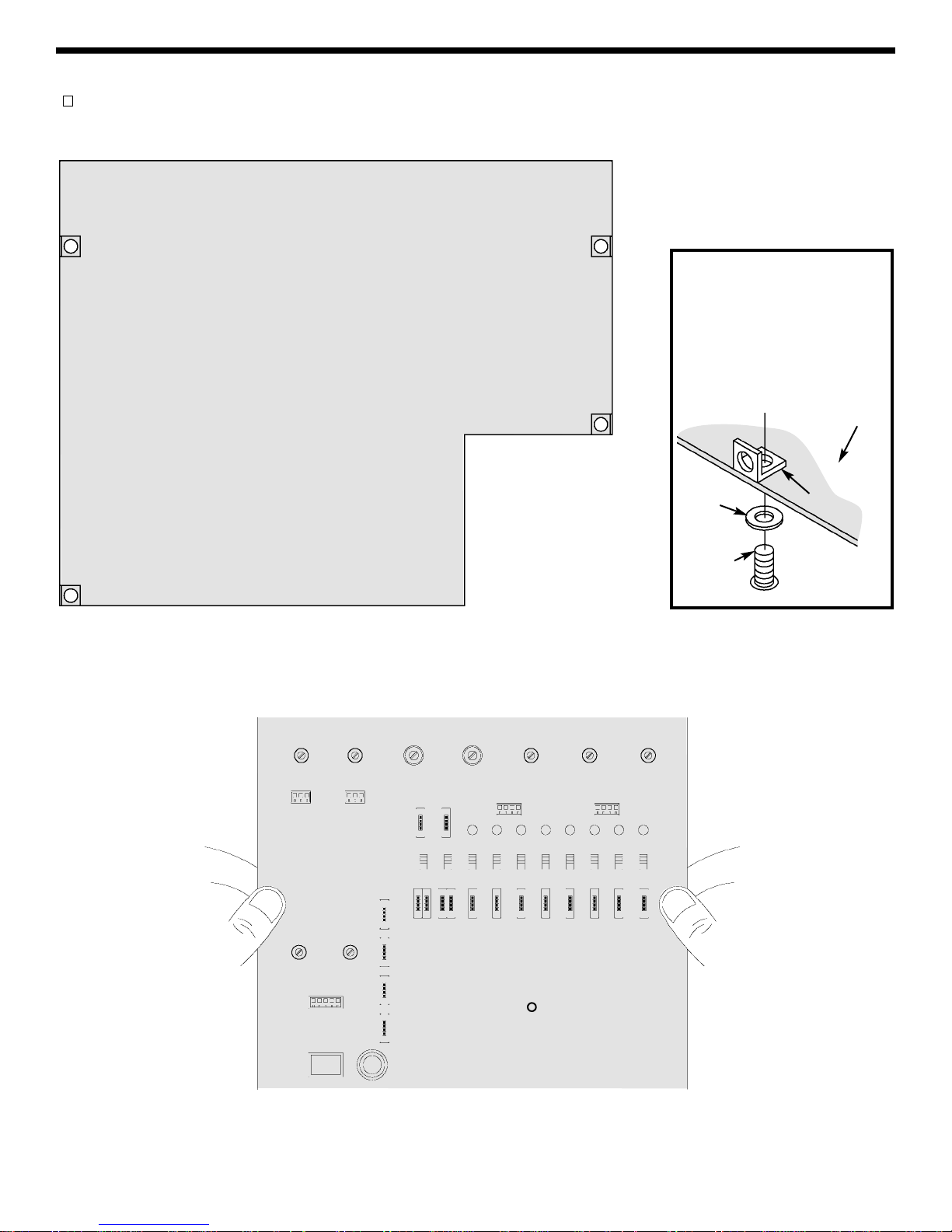

USERS DESCRIPTION OF FRONT PANEL CONTROLS

1) On/Off Switch - Allows power to be applied to all outputs. Switch will

light when on.

2) Fuse Holder - Easy access for replacement of 1.25A fuse.

3) Power Output Terminals - This provides 30VAC center-tapped at

15 VAC; also provides output terminal for positive and negative

variable voltages.

4) Variable Positive Voltage Control - Varies positive voltage from 1.25

to 20V at indicated output connector pin.

5) Variable Negative Voltage Control - Varies negative voltage from

-1.25V to -20V at indicated output connector pin.

6) Output terminals for 1k and 100k undedicated potentiometers.

7) 1kΩ undedicated potentiometer.

8) 100kΩ undedicated potentiometer.

-1-

1

2

3

4

5

6

7 8

Page 3

-2-

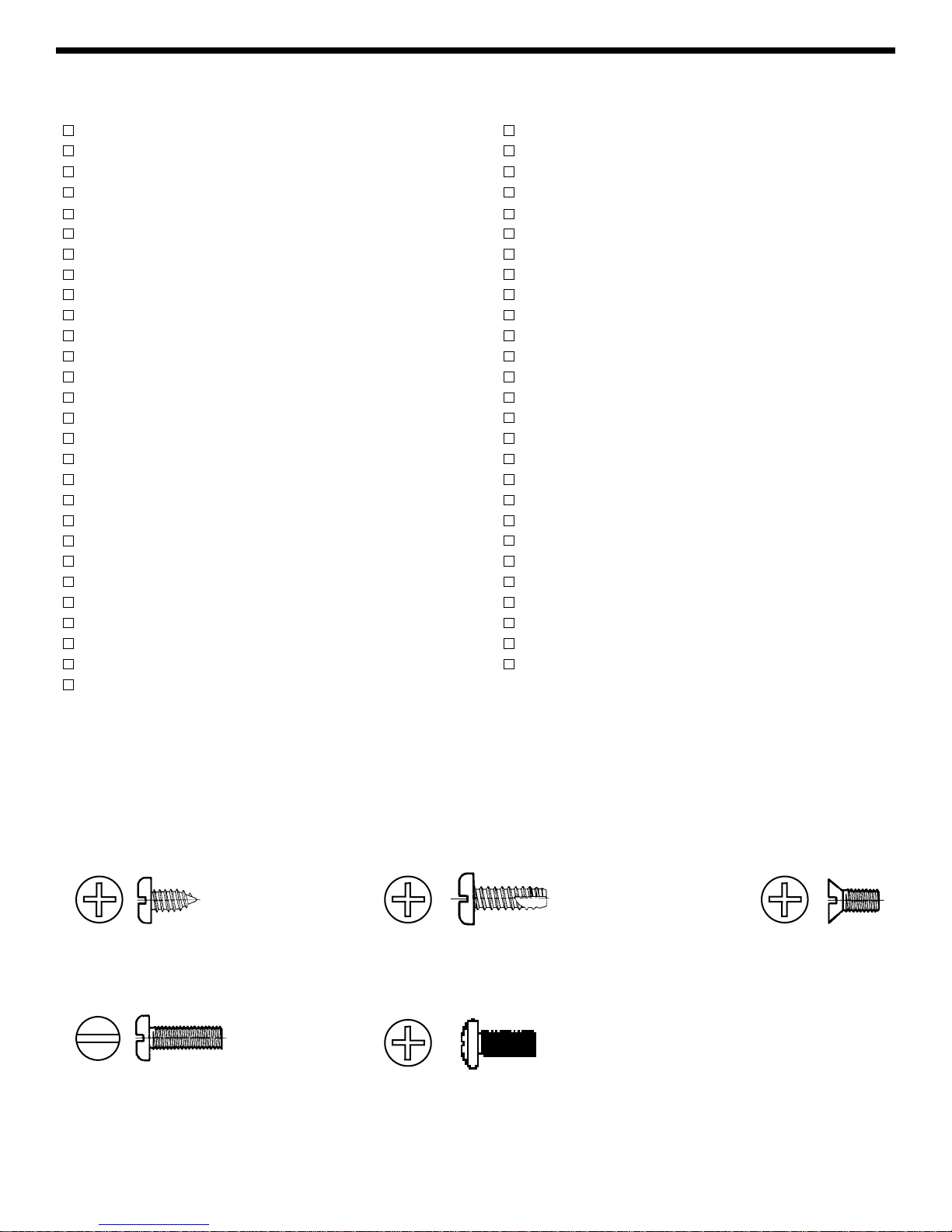

XK-700-SEMI DIGITAL/ANALOG TRAINER PARTS LIST

QTY DESCRIPTION PART #

1 LM317 Integrated Circuit (U1) 330317

1 LM337 Integrated Circuit (U5) 330337

1 LM7805 Integrated Circuit (U3) 337805

1 LM7812 Integrated Circuit (U2) 337812

1 LM7912 Integrated Circuit (U4) 337912

1 Transformer 44K500

1 Fuse 1.25A 530125

1 Switch Illuminated 541204

4 Bracket L 4-40 tap 613008

1 Panel Top 614108

1 Panel Side Left 614506

1 Panel Side Right 614507

1 Panel Back 614508

4 Plastic Plug * 621050

9 Knob 622009

1 Case 623051

1 Strain Relief 624003

1 Spacer Nylon 7/16” 4-40 Tap 624013

1 Connector Receptacle 626020

1 Connector Plug 626021

9 Screw 4-40 x 1/4” Slotted Machine 641430

1

Screw 4-40 x 1/4” Phillips Flat Head

641431

6 Screw 6-32 x 5/16” Slotted Machine 641641

2 Screw 8-32 x 3/8” Phillips Machine 641840

4 Screw #4 x 1/4” Phillips AB 642430

4

Screw 4-40 x 1/4” Phillips Thrd Ct (23)

642432

4 Screw #6 x 1/2” Phillips AB 642662

4

Screw #6 x 3/8” Phillips Thread Cutting (25)

643652

* Used in Trainer Case Conversion Section on page 35.

QTY DESCRIPTION PART #

7 Nut 7mm 644101

2 Nut 9mm 644102

6 Nut 6-32 644601

2 Nut 8-32 644800

7 Washer 8mm x 14mm 645101

2 Washer 9mm x 15mm 645103

4 Washer #6 Black 645400

4 Washer Fiber 645404

2 Lockwasher #8 External 646828

1 Lug Solder #8 661002

1 Fuse Holder 663000

2 Terminal Male Crimp 666010

2 Terminal Female Crimp 666011

1 Manual 753045

5 Insulator Mica 780002

5 Insulator Washer 780101

1 Silicon Grease 790004

6” Wire #20 Red Stranded 813210

1 Line Cord 862105

2” Shrink Tubing 3/16” 890120

1” Shrink Tubing 1/4” 890701

2” Shrink Tubing 1/2” 891101

2” Shrink Tubing 3/4” 899110

1 PC Board Assembly 920550HK

1 9426 Bredboard 99426

1 9830 Bredboard 99830

1 Solder Tube 9ST4

Screw Identification

Phillips AB Screw 4-40 Thread Cutting Screw

#6 Thread Cutting Screw

Phillips

Slotted Machine

Screw

Flat Head Screw

Phillips

Phillips Machine Screw

Page 4

-3-

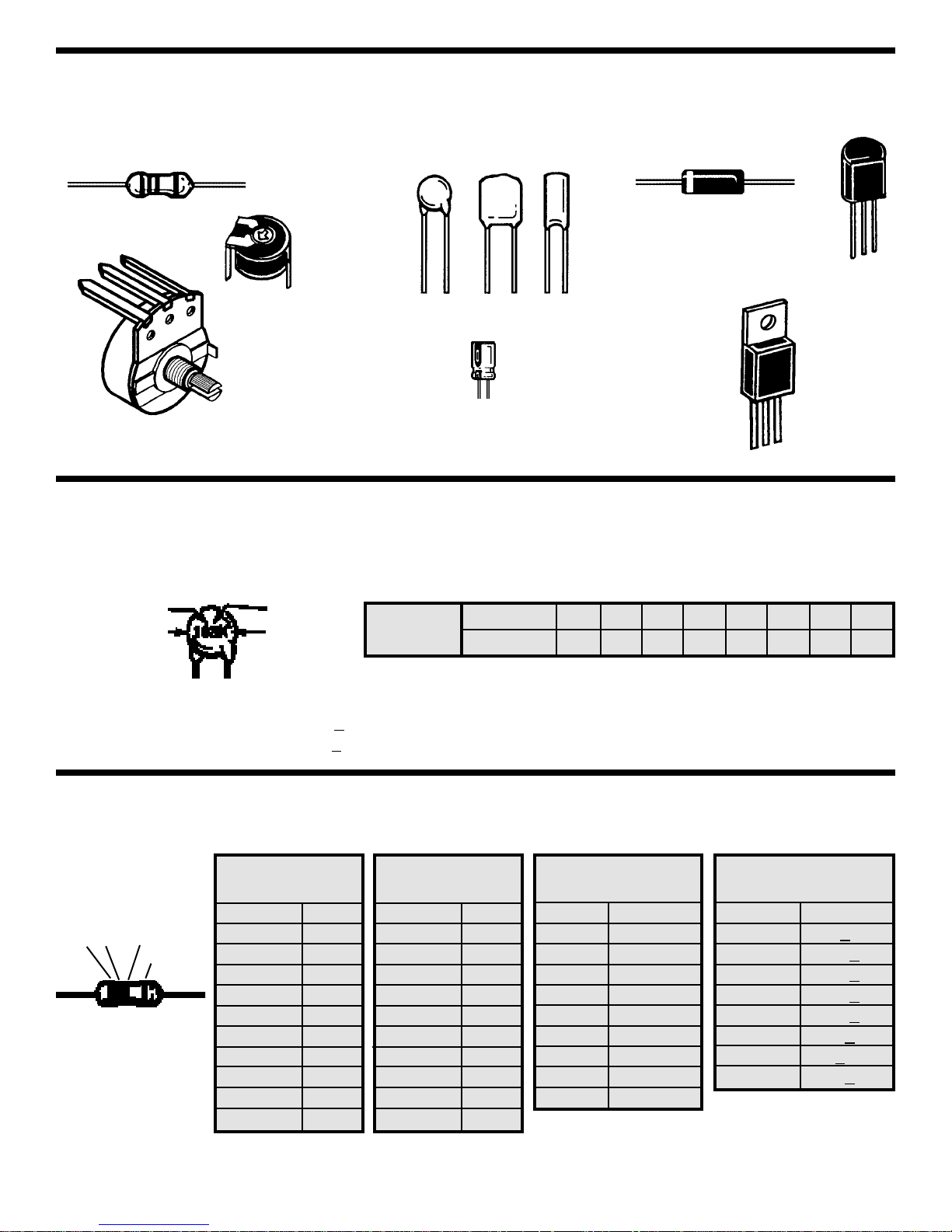

PARTS VERIFICA TION

Before beginning the assembly process, first familiarize yourself with the components and this instruction book.

Ver ify that all par ts are present. This is done best by checking off each item in the parts list.

RESISTORS CAPACITORS

Trim Pot

Pot

Discap Mylar

Electrolytic (radial)

(Lytic)

IC

SEMICONDUCTORS

INTEGRATED CIRCUIT

Diode

Transistor

IDENTIFYING CAPACITOR VALUES

Capacitors will be identified by their capacitance value in pF (picofarads), nF (nanofarads), or µF (microfarads).

Most capacitors will have their actual value printed on them. Some capacitors may have their value printed in

the following manner.

Second Digit

First Digit

Multiplier

Tolerance

The above value is 10 x 1,000 = 10,000pF or .01µF

The letter K indicates a tolerance of +

10%

The letter J indicates a tolerance of +5%

For the No. 01234589

Multiply By 1 10 100 1k 10k 100k .01 0.1

Multiplier

Note: The letter “R” may be used at times to

signify a decimal point; as in 3R3 = 3.3

IDENTIFYING RESISTOR VALUES

Use the following information as a guide in properly identifying the value of resistors.

BAND 1

1st Digit

Color Digit

Black 0

Brown 1

Red 2

Orange 3

Yellow 4

Green 5

Blue 6

Violet 7

Gray 8

White 9

BAND 2

2nd Digit

Color Digit

Black 0

Brown 1

Red 2

Orange 3

Yellow 4

Green 5

Blue 6

Violet 7

Gray 8

White 9

Multiplier

Color Multiplier

Black 1

Brown 10

Red 100

Orange 1,000

Yellow 10,000

Green 100,000

Blue 1,000,000

Silver 0.01

Gold 0.1

Resistance

Tolerance

Color Tolerance

Silver +10%

Gold +5%

Brown +

1%

Red +2%

Orange +

3%

Green +

.5%

Blue +.25%

Violet +

.1%

Bands

1 2

Multiplier

Tolerance

Page 5

-4-

CONSTRUCTION

Introduction

Assembly of your XK-700-SEMI Digital/Analog Trainer Kit will prove to be an exciting project and give you much satisfaction and personal

achievement. If you have e xperience in soldering and wiring techniques, then you should ha v e no problem with the assemb ly of this kit. Care

must be given to identifying the proper components and in good soldering habits. Above all, take your time and follow these easy step-bystep instructions. Remember, “An ounce of prevention is worth a pound of cure”. Avoid making mistakes and no problems will occur.

CAUTION: WEAR SAFETY GLASSES WHEN ASSEMBLING THIS KIT.

Assemble Components

In all of the following assembly steps , the components must be installed on the top side of the PC board unless otherwise indic ated. The

top legend shows where each component goes. The leads pass through the corresponding holes and the board is tur ned to solder the

component leads on the foil side. Solder immediately unless the pad is adjacent to another hole which will interfere with the placement

of the other component. Cut excessive leads with a diagonal cutter. Then, place a check mark in the box provided next to each step to

indicate that the step is completed. Be sure to save the extra leads for use as jumper wires if needed.

Soldering

The most important factor in assembling your XK-700-SEMI is good soldering techniques. Using the proper solder ing iron is of prime

importance. A small pencil type soldering iron of 25 - 40 watts is recommended. The tip of the iron must be kept clean at all times

and well tinned. Many areas on the PC board are close together and care must be given not to form solder shorts. Size and care of

the tip will eliminate problems.

For a good soldering job, the areas being soldered must be heated sufficiently so that the solder flows freely. Apply the solder

simultaneously to the component lead and the component pad on the PC board so that good solder flow will occur. Be sure that the

lead extends through the solder smoothly indicating a good solder joint. Use only rosin core solder of 60/40 alloy.

DO NOT USE ACID CORE SOLDER! Do not blob the solder over the lead because this can result in a cold solder joint.

1. Solder all components from

the copper foil side only.

Push the soldering iron tip

against both the lead and the

circuit board foil.

Component Lead

Soldering Iron

Circuit Board

Foil

2. First apply a small amount of

solder to the iron tip. This

allows the heat to leave the

iron and onto the foil.

Immediately apply solder to

the opposite side of the

connection, away from the

iron. Allow the heated

component and the circuit

foil to melt the solder.

Solder

Soldering Iron

Foil

Example 1

Poor solder connections occur

when the lead is not heated

sufficiently. The solder will not

flow onto the lead as shown.T o

correct. reheat the connection

and, if necessary , apply a small

amount of additional solder to

obtain a good connection.

Solder does not flow onto the

lead. A hard rosin bead

surrounds and insulates the

connection.

Poor solder

connection

Mount Part

Soldering iron

positioned incorrectly.

Example 2

A solder bridge occurs when

solder runs between circuit

paths and creates a short

circuit. This is usually caused

by using too much solder. To

correct this, simply drag your

soldering iron across the

solder bridge as shown.

4. Here is what a good solder

connection looks like. Cut

off excess leads.

3. Allow the solder to flow

around the connection.

Then, remove the solder and

the iron and let the

connection cool. The solder

should have flowed smoothly

and not lump around the wire

lead.

Solder

Soldering Iron

Foil

Bend Leads to Hold Part Solder and Cut Off Leads

Foil Side

Rx - 100Ω 5% 1/4W Resistor

(brown-black-brown-gold)

Page 6

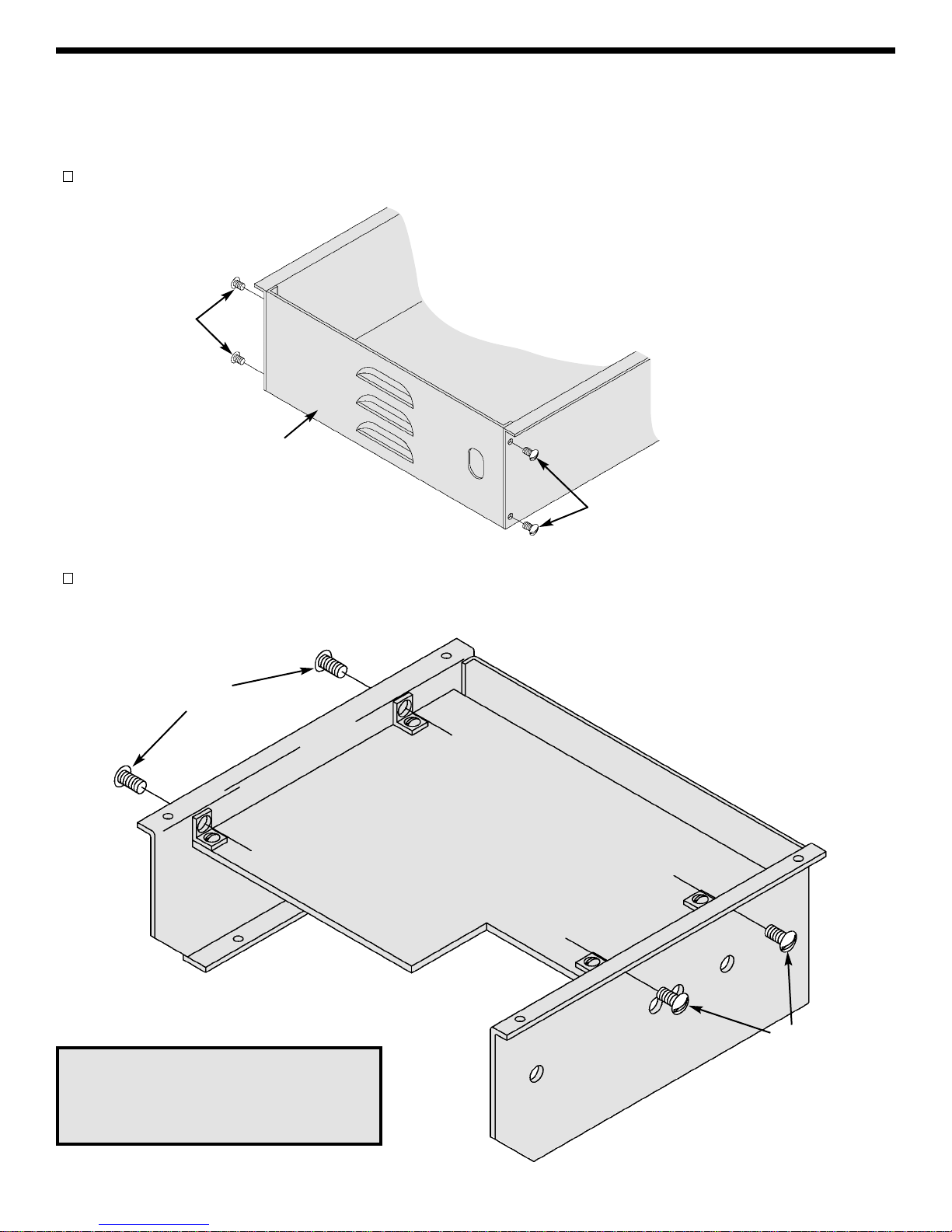

Note: One side of the bracket

is longer. Mount this side to

the PC board. Mount the

bracket to the top legend side

of the PC board with a 4-40 x

1/4” machine screw and a fiber

washer.

-5-

INSTALL COMPONENTS TO PC BOARD

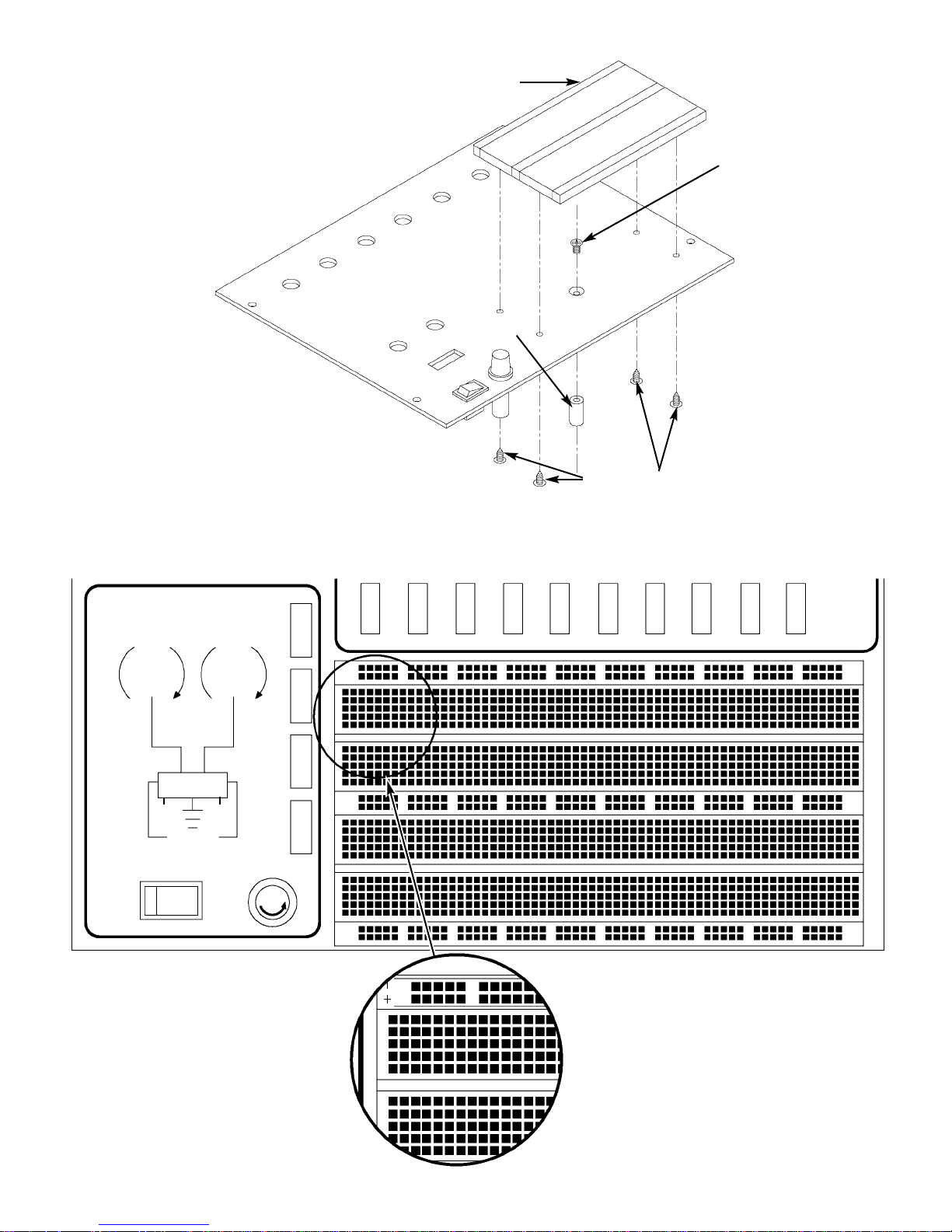

Install the four L-brackets in the positions shown in Figure A. Mount them into position as shown in Figure B.

Figure A Figure B

Place the top panel onto the PC board and align the components with the holes in the top panel.

4-40 x 1/4”

Machine

Screw

Top Legend

Side of

PC Board

Fiber

Washer

Longer Side

Page 7

-6-

MOUNTING THE PC BOARD

Note: The holes in the two side panels have been punched differently. Be sure that you have the correct side

panel when mounting them to the PC board.

Mount the back panel using four 4-40 x 1/4” thread cutting screws (see Figure C).

Mount the PC board with four 4-40 x 1/4” machine screws (see Figure D). Do not tighten the screws.

4-40 x 1/4” Thread

Cutting Screws

4-40 x 1/4” Thread

Cutting Screws

Back Panel

Figure C

Right Side

Left Side

Figure D

4-40 x 1/4”

Machine Screws

4-40 x 1/4”

Machine Screws

Top Legend Side

of PC Board

Note: From the f oil side of the PC board,

inspect the edges to be sure that there

are no component leads shorting against

the side panels.

Right Side

Left Side

Page 8

-7-

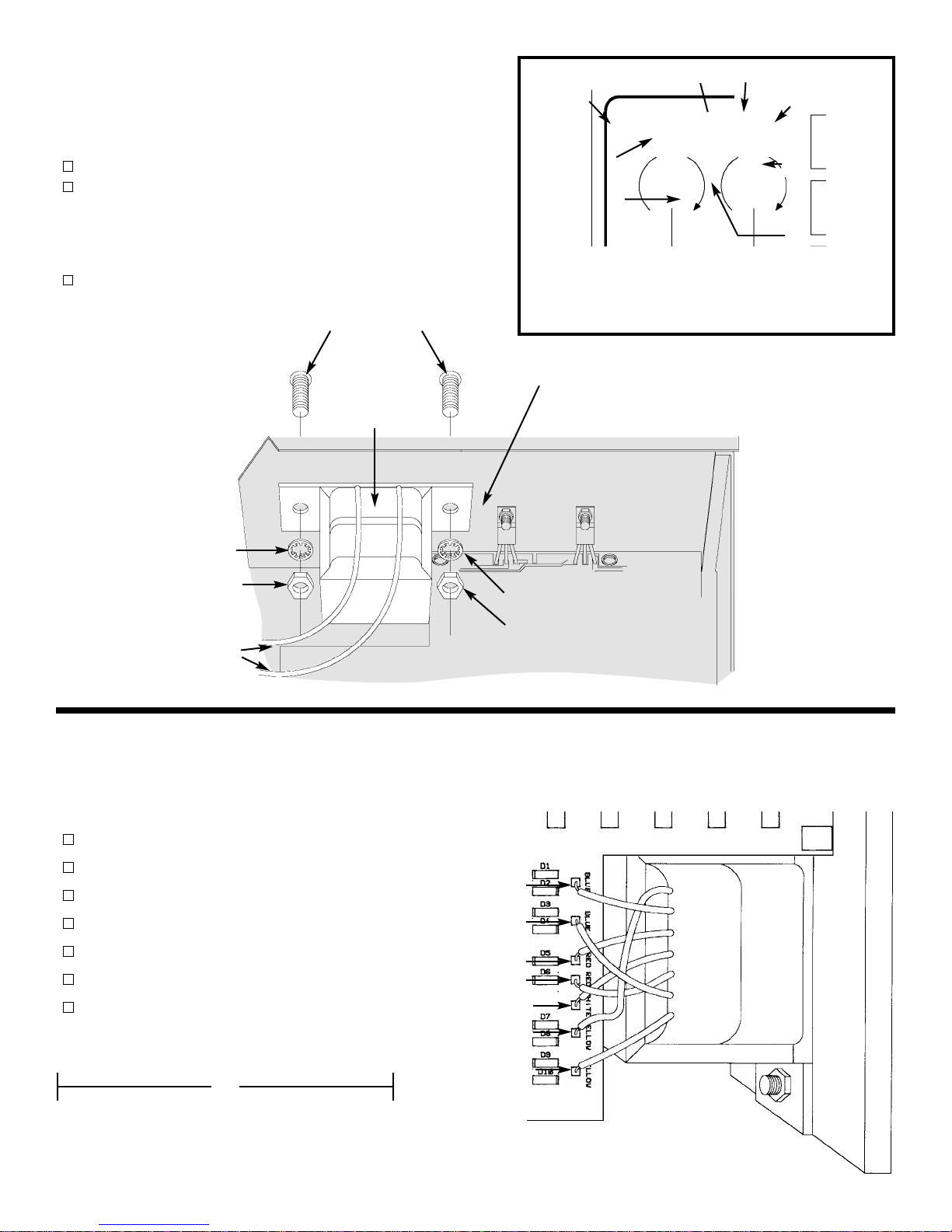

MOUNT COMPONENTS TO THE SIDE P ANELS

Mount U1, U3 and U5 to the left side panel as shown in Figure G.

Insert the pins of each IC into the holes of the PC board. Then,

with the hardware shown in Figure F, attach each IC to the side

panel. Solder the pins of the ICs to the PC board.

U3 - LM7805

U1 - LM317

U5 - LM337

Figure G

Mount the solder lug to the panel, as shown in Figure G, using a 6-32 x 5/16” screw and 6-32 nut.

Solder Lug

Mica

Side Panel

Insulator Washer

6-32 x 5/16”

Machine Screw

* Take a small amount of silicone grease from

the packet and apply it with a toothpick onto

the back of the ICs.

Figure F

6-23 Nut

* Silicone Grease

Mica

IC

IMPORTANT

Place the top panel on top of the unit. Push the PC board up until the

components come through the top panel and tighten the screws.

Adjust the PC

board height

with a 4-40 x

1/4” machine

screw.

Figure E

7805

LM317

LM337

Solder Lug

U5

U1

U3

6-32 Nut

6-32 x 5/16”

Screw

Left Side

Page 9

-8-

WIRE THE TRANSFORMER TO THE PC BOARD

Cut the blue, red, white and yellow wires on the transformer so they are 3” long and strip the insulation off of

the ends to expose 1/4”of bare wire. Solder the wires to the PC board starting with the top yellow wire as shown

in Figure I.

Yellow (F) wire to point F on the PC board

Blue (A) wire to point A on the PC board

Red (C) wire to point C on the PC board

White (E) wire to point E on the PC board

Red (D) wire to point D on the PC board

Blue (B) wire to point B on the PC board

Yellow (G) wire to point G on the PC board

Yellow (F)

Blue (A)

Red (C)

White (E)

Red (D)

Blue (B)

Yellow (G)

Figure I

3”

Mount U2 and U4 to the right side panel as shown in

Figure H. Insert the pins of each IC into the holes in the

PC board. Then, with the hardware shown in Figure FA,

attach each IC to the side panel. Solder the pins of the ICs

to the PC board.

U4 - LM7912

U2 - LM7812

Mount the transformer with the black wires as shown in

Figure H. Use the two 8-32 x 3/8” machine screws, #8

lockwashers, and 8-32 nuts.

Transformer mounted

#8-32 x 3/8” Machine Screws

6-23 Nut

IC

* Silicone Grease

Mica

Side Panel

Insulator Washer

6-32 x 5/16”

Machine Screw

* Take a small amount of silicone grease from the

packet and apply it with a toothpick onto the back of

the ICs.

Figure FA

Mica

Yellow (G)

Blue (B)

Blue (A)

Red (D)

White (E)

Yellow (F)

Red (C)

Right Side

U4

U2

7812

7912

Figure H

Black Wires

8-32 Nut

#8 Lockwasher

#8 Lockwasher

8-32 Nut

Transformer

Note: Make sure that the transformer

does not touch U4.

Page 10

-9-

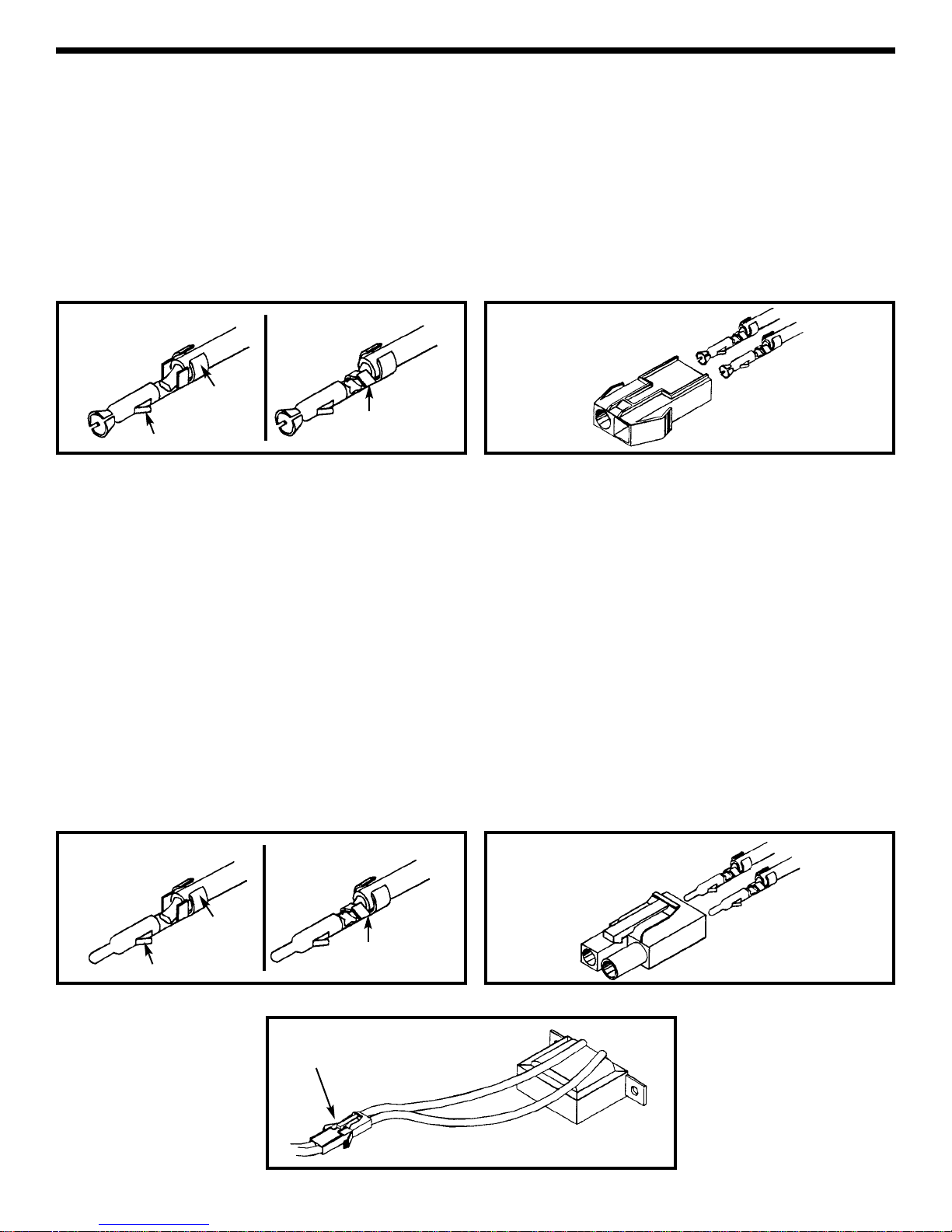

HOW TO INSTALL CONNECTORS ONTO TRANSFORMER WIRES

A connector will be placed in the primary wires of the transformer. This will allow you to remove the top panel

from the trainer. Follow the procedures below.

1. Cut a six inch length off of each black primary wire.

2. Strip the insulation off of each end of the six inch wires to expose 1/4” of bare wire.

3. Place one wire onto the female pin and crimp the outer crimp tabs with pliers over the insulation as shown

in Figure 1A.

4. Crimp the inner tabs with pliers onto the bare wire as shown in Figure 1B and then solder the wire to the pin.

5. Connect the other female pin to the other wire using the same procedures above.

A

B

Locking Tab

Female Pin

Solder

Outer

Crimp Tab

Inner

Crimp Tab

Female Housing

Figure 1

Figure 2

6. Insert the two pin/wire assemblies into the female housing as shown in Figure 2. Pull on the wire to check

that the pin is inserted all the way in. It should not pull out of the housing. The locking tabs should be bent

outward to hold the pin in the housing.

TRANSFORMER WIRES

1. Strip the insulation off of each of the black primary wires to expose 1/4” of bare wire.

2. Place the wire onto the male pin and crimp the outer crimp tabs with pliers over the insulation as shown in

Figure 3A.

3.

Crimp the inner tabs with pliers onto the bare wire and then solder the wire to the pin as shown in Figure 3B.

4. Connect the other male pin to the other primary wire using the same procedures above.

5. Insert the two pin/wire assemblies into the male housing as shown in Figure 4. Pull on the wire to check that

the pin is inserted all the way in. It should not pull out of the housing.

6.

Connect the male and female housing as shown in Figure 5. Note that the connector only fits together one wa y.

7. To detach the connector, push down on the end of the lock arm and pull the two apart.

Figure 3

Figure 4

A

B

Locking Tab

Male Pin

Solder

Outer

Crimp Tab

Inner

Crimp Tab

Male Housing

Lock Arm

Figure 5

Page 11

-10-

MOUNT COMPONENTS TO PANEL

Push the illuminated switch into the hole in the top panel with the lugs as shown in Figure J.

Install the fuse holder with the side lug in the position shown in Figure J. Fasten the fuse holder in place with

the nut as shown in Figure K. Unscrew the cap and inser t the fuse into the holder.

Back Side - Lower

Right Corner

Figure J

There is a raised area on the back side of the top panel. Screw the spacer to the raised area by inserting a

4-40 x 1/4” flat head screw into the hole in the raised area from the top side of the panel (see Figure L).

Put the two bredboards together as shown in Figure Ka.

When mounting the bredboard, use the holes shown in Figure Kb. Mount the plastic spacer with a 4-40 x

1/4” flat head screw as shown in Figure L. Next, mount the bredboards with two #4 x 1/4” AB black screws

from the back side of the top panel as shown in Figure L. The negative (blue) stripe should be on top and

the numbers reading from left to right should start with number 1 (see Figure M). CAUTION: Do not remove

the paper backing from the back of the bredboards. Do not over-tighten the black screws.

9426

9830

9830

9426

Use these

holes

Use these

holes

Figure Ka

Figure Kb

Side

Lug

Fuse Holder

Illuminated Switch

Nut

Top Panel

Plastic Washer

Fuse Holder

Figure K

Page 12

Spacer

4-40 x 1/4”

Flat Head

Screw

Top Panel

Bredboard

#4 x 1/4” AB Screws

Figure L

REGULATED

POWER SUPPLY

GND

-12

+12

+5

OFFON

30VAC

15VAC

c

d

e

f

g

h

i

j

1

5

10

Figure M

15VAC

-11-

+

2

0

V

D

C

-

-

2

0

V

D

C

Page 13

-12-

WIRE SWITCH AND FUSE HOLDER (see Figure N)

Fuse

Slide the line cord through the back panel as shown.

Spread the three line cord wires apart 6” from the end.

Strip the insulation off of both ends of the 6” red wire to expose 1/4” of bare wire. Pass the wire through the

1/2” diameter shrink tubing. Attach one end to the side lug on the fuse holder and then solder into place.

Strip 1/4” of insulation off of the smooth edged line cord wire. Pass the smooth edged line cord wire through

the 1/2” diameter shrink tubing and attach to the end lug on the fuse holder, solder into place.

Slide the shrink tubing over the fuse holder covering both lugs. Shrink the tubing for a snug fit. You may use

a hair dryer, heat gun (at lowest setting or you will melt the tubing) or the heat emitting from your soldering

iron (do not touch the tubing or the wires with the iron).

Switch

Disconnect the connector for the transformer.

Pass the 6” strip of red wire (leading from the side lug of the fuse holder), the (A) and (B) black transformer

wire, and the ribbed line cord wire through the 3/4” diameter piece of shr ink tubing.

Cut the 2” section of 3/16” diameter shrink tubing in half to create two 1” sections. Slide a 3/16” diameter

piece of shrink tubing over the loose end of the red wire. Attach the red wire to lug 1 on the switch and then

solder into place.

Pass the black transformer wire labeled (B) through a 3/16” diameter piece of shrink tubing. Attach the wire

to lug 2 on the switch and then solder into place.

Slide the shrink tubing over lug 1 and lug 2 on the switch. Shrink the tubing into place.

Strip the insulation off of the black transformer wire (A) and the ribbed edged line cord wire to expose 1/2” of

bare wire. Twist the two bare wires together. Pass the wires through the 1/4”diameter piece of shrink tubing.

Attach the wires to lug 3 on the switch and solder into place. Slide the tubing over the lug. Shrink the tubing

into place.

Slide the 3/4” diameter shrink tubing over the switch and shrink into place.

Reconnect the connector for the transformer.

Switch Pin-out

1

2

3

Fuse Holder

Side Lug

6” Red Wire

1/2” Dia. Shrink Tubing

3/16” Dia. Shrink Tubing

(B) Black T r ansf ormer Wire

Female Connector

(A) Black T r ansf ormer Wire

Smooth Line Cord Wire

Ribbed Line Cord Wire

Green Line Cord Wire

Solder Lug

3/4” Dia. Shrink Tubing

1/4” Dia. Shrink Tubing

Switch

Figure N

Page 14

-13-

RESISTANCE ANALYSIS OF POWER SUPPLY

Static testing of the power supply circuits. Do not plug the power supply into the 120VAC power supply

source until all resistance readings check out. The values given below are approximate.

See Figure O for locations of testing points.

Resistance

From To Circuit Ohms Measured

1 Right Side Panel Earth Ground less than 1Ω

2 3 On/Off Switch, Fuse Infinite (SW1 Off)

2 3 On/Off, Fuse 7Ω (SW1 On)

4 5 12V Secondar y 1.5Ω

6 7 5V Secondar y 1.2Ω

8 9 Variable Voltage 1.6Ω

10 GND 5-pin connector +12V Regulator Input greater than 20kΩ

11

(com) GND (VΩ)

5-pin connector

-12V Regulator Input greater than 20kΩ

12 GND (B1) +5V Regulator Input greater than 20kΩ

13 GND (B1) +Variable Regulator Input greater than 20kΩ

14

(com) GND (VΩ)

5-pin connector

-Variable Regulator Input greater than 20kΩ

25

(com) GND (VΩ)

5-pin connector

Voltage ADJ +20V Regulator greater than 1.4kΩ

26 GND (VΩ)

5-pin connector

Voltage ADJ -20V Regulator greater than 1.4kΩ

27 GND 5-pin connector +5V Regulator GND less than 1Ω

28 GND 5-pin connector +12V Regulator GND less than 1Ω

29 GND 5-pin connector -12V Regulator GND less than 1Ω

10 15 +12V Regulator Input less than 1Ω

11 16 -12V Regulator Input less than 1Ω

12 17 +5V Regulator Input less than 1Ω

13 18 +Variable Regulator Input less than 1Ω

14 19 -Variable Regulator Input less than 1Ω

20 GND 5-pin connector +Variable Regulator Output CCW 100Ω CW 2.10k

20

+20 5-pin connector +20

+Variable Regulator Output less than 1Ω

21

GND 5-pin connector -20

+Variable Regulator Output CCW 100Ω CW 2.10k

21 -20 5-pin connector -20 -Variable Regulator Output less than 1Ω

22 GND 5-pin connector +5V Regulator Output greater than 5kΩ

22 B4 +5V Regulator Output less than 1Ω

23 GND 5-pin connector +12V Regulator Output greater than 5kΩ

23 B3 +12V Regulator Output less than 1Ω

24 GND 5-pin connector -12V Regulator Output greater than 5kΩ

24 B2 -12V Regulator Output less than 1Ω

5

15VAC 5-pin connector right

15VAC less than 1Ω

4

15VAC 5-pin connector left

15VAC less than 1Ω

+30% Note: meter lead polarity CCW - Counter Clockwise CW - Clockwise VR1 & VR2 Adjustment

20A

2A COM VΩ

VΩ

COM

Page 15

-14-

Locations for Testing Points

•••

21

19

26

•••

18

20

25

•••

22

27

17

5 pin connector left

5 pin connector +20

5 pin connector right

5 pin connector -20

GND

Ground

•••

29

16

24

•••

15

28

23

9

8

7

6

5

4

10

11

12

13

14

+20V

Pot

-20V

Pot

Plug of line cord

Figure O

B1

LM-7812 LM-7912

LM-7805 LM-317

LM-337

On test points 4 - 14

use the leads of the

diodes.

1

3

2

Page 16

Place the top panel on top of the unit.

-15-

VOLTAGE ANALYSIS OF POWER SUPPLY

Proceed with the voltage analysis only if the resistance readings were satisfactory.

Place the top panel on the unit. If any capacitors are inserted backwards, the panel will shield you if

they explode. Make sure that the ON/OFF switch is in the OFF position. Plug the line cord into the 120VAC

power source. Turn the unit on and let it sit for a few minutes. Turn OFF the ON/OFF switch and remove the

top panel, placing it along the left side of the trainer. Turn ON the ON/OFF switch and measure the voltage point

as listed in the chart below. The values given are approximate.

See Figure O for locations of the testing points.

From To Circuit Volts Volts Measured

15 GND +12V Regulator Input +21V

B3 GND +12V Regulator Output +12V

16 GND -12V Regulator Input -21V

B2 GND -12V Regulator Output -12V

17 GND +5V Regulator Input +12.5V

B4 GND +5V Regulator Output +5V

18 GND +20V Regulator Input +28V

25 GND Voltage ADJ +20V Regulator CCW 0V CW +18V

+20

5-pin connector

GND +20V Output

CCW +1.25V CW +20V

19 GND -20 Regulator Input -28V

26 GND Voltage ADJ -20V Regulator CCW 0V CW -18V

-20

5-pin connector

GND -20V Output CCW -1.25V CW -20V

15VAC 15VAC 30VAC 30VAC

5-pin 5-pin

connector connector

left right

+30% CCW - Counter-Clockwise CW - Clockwise

Turn unit off.

FUSE REPLACEMENT

1.Turn the trainer off and unplug it from 120VAC power source.

2. Unscrew fuse holder cap and remove fuse.

3. Place the new fuse into the fuse holder cap and screw it back into the holder.

4. Plug trainer into 120VAC power source and turn the unit on.

When inserting a wire into

the connectors, make sure

that the insulation touches

the connector as shown.

This will prevent the bare

wire from shorting to the top

panel.

Top Panel

Page 17

-16-

POWER SUPPLY TESTING

Plug the trainer into a 120VAC outlet and switch to the “ON” position (the power switch should light). With a

digital voltmeter, measure the voltage outputs at the power blocks. The +12V should measure between 11.4

and 12.6 volts. The 5V supply should read between 4.75 and 5.25 volts. The -12V supply should read between

-11.4 and 12.6 volts.

Do not short the 15VAC output to ground.

Short the +12V, -12V and +5V supply to ground. They should turn off and recover when the short is removed.

If you have a 25Ω 10 watt resistor, place it across the output terminal (2 watt resistor will work, but use it only

for a few seconds). The output of the 12V supply should not change more than .20 volts. Do the same on the

5V supply using a 10Ω 5 watt resistor. Again, the output should not change more than .20 volts. In making this

test, the voltmeter leads should be clipped to the terminal directly and no to the load leads. This is to prevent

errors due to voltage drop from contact resistance of the load.

Check the variable voltage supplies in the same manner. Set the output voltage between 10-15 volts. Place

the 25Ω 10 watt resistor across the output terminal. The voltage should stay within .20 volts of the no load

voltage.

TROUBLESHOOTING CHART

This chart lists the condition and possible causes of several malfunctions. If a par ticular par t is mentioned as

a possible cause, check that part to see if it was installed correctly. Also, check it and the parts connected to it

for good solder connections. Note: The values given in this troubleshooting chart are an approximation.

PROBLEM POSSIBLE CAUSE

Switch doesn’t light. 1. Check fuse and line cord.

Fuse blows when the unit is turned on. 1. Voltage supply shorted to GND. Use resistance analysis

chart to find shor t.

No or low voltage at positive variable 1. Measure for an AC voltage of 18VAC at anode of D7 & D9.

output. A. Transformer and/or secondary connection to PC

board defective

2. Measure for a DC voltage of 28VDC at pin 3 of U1 LM317.

A. Diodes D7, D9 in backwards or defective, check

capacitor C1.

3. Set the voltage for minimum 1.25VDC and measure pin 2

of U1.

A. Voltage adjusts only from 7.8 - 9.8V R1 open or

defective.

B. Voltage 27V, check VR1 connections.

No or low voltage at positive variable 1. Check that capacitor C1 1000µF is inserted in the correct

output with load. polarity.

2. Check ripple on pin 3 of U1. 8VP-P Max.

A. Capacitor C1, and/or diodes D7, D9 defective.

Page 18

-17-

PROBLEM POSSIBLE CAUSE

No voltage at negative variable output. 1. Measure for an AC voltage of 18VAC at cathode of D8, D10.

A. Transformer and/or secondary connection to PC board

defective.

2. Measure DC voltage of -28VDC at pin 2 of U5 LM337.

3.

Set voltage for minimum -1.25VDC and measure pin 3 of U5.

A. Voltage adjusts only from -7.8 to -9.8V R2 open or

defective.

B. Voltage -27V, check VR2 connections.

No or low voltage at negative variable 1.Check to see if capacitor C5 1000µF is inserted in the

output with load. correct polarity.

2. Check ripple on pin 2 of U5. 6VP-P max.

A. Capacitor C5 and/or diodes D8, D10 defective.

No +12V at output. 1. Measure an AC voltage of 15VAC at anode of D1, D3.

A. Transformer and/or secondary connection to PC board

defective.

2. Measure for a DC voltage of 21VDC at pin 1 of U2 LM7812.

A. Diodes D1, D3 in backwards or defective, check

capacitor C1.

3. Measure for a DC voltage of 12VDC on pin 3 of U2.

A. U2 LM7812 defective or open ground.

No +12V at output with load. 1. Check capacitor C2 1000µF is inser ted in the correct

polarity.

2. Check ripple on pin 1 of U2. 7VP-P Max.

A. Capacitor C2 or diodes D1, D3 defective.

No -12V at output. 1. Measure an AC voltage of 15VAC at anode of D2, D4.

A.Transformer and/or secondary connection to PC board

defective.

2. Measure for a DC voltage of -21VDC at pin 2 of U4 LM7912.

A. Diodes D2, D4 in backwards or defective, check

capacitor C4.

3. Measure for a -12VDC voltage on pin 3 of U4.

A. U4 LM7912 defective or open ground.

No -12V at output with load. 1. Check capacitor C4 is inser ted in the correct polarity.

2. Check ripple on pin 2 of U3. 7VP-P Max.

A. Capacitor C4 and/or diodes D1, D3 defective.

No +5VDC at output 1. Measure an AC voltage of 9VAC at anode of D5, D6.

A. Transformer and/or secondary connection to PC board

defective.

2. Measure for a DC voltage of 12VDC at pin 1 of U3 LM7805.

A. Diodes D5, D6 in backwards or defective, check

capacitor C3.

3. Measure for a 5VDC voltage on pin 3 of U3 LM7805.

A. U3 LM7805 defective or open ground.

No +5VDC at output with load. 1. Check that capacitor C3 is inser ted in the correct polarity.

2. Check ripple on pin 1 of U3. 4VP-P Max.

A. Capacitor C3 and/or diodes D5, D6 defective.

Page 19

-18-

CIRCUIT DESCRIPTION

The power supply features two variable output voltages and three fixed 12V, -12V and 5V variable output

voltages are 1.25V to 20V and -1.25 to -20V at up to 1 ampere maximum current. All supplies are regulated to

better than .2V when going from no load to full load. Varying the input AC voltage from 105 to 135V will have

practically no effect on the output voltages. This is because of the specially designed ICs used in the XK-700

Digital/Analog Trainer. Severe over loading or even shorting the output circuits will not damage the supplies.

Special turn-off circuits in the ICs sense the overload and turn off the output.

THE POSITIVE 1.25 TO 20V POWER SUPPLY

Figure 1 shows a simplified circuit diagram of the positive supply. It consists of a power transformer, a DC

rectifier stage and the regulator stage.

TRANSFORMER

The transformer T1 serves two purposes. First, it reduces the 120VAC input

to 17VAC to allow the proper voltage to enter the rectifier stages. Second, it

isolates the power supply output from the 120VAC line. This prev ents the user

from dangerous voltages should he or she be standing in a grounded area.

AC T O DC CONVERTER

The AC to DC converter consists of diodes D1, D3 and capacitor C1.

Transformer T1 has two secondary windings which are 180 degrees out of

phase. The output at each winding is shown in Figure 2A and 2B.

Diodes are semiconductor devices that allow current to flow in only one

direction. The arrow in Figure 3 points to the direction that the current will

flow. Only when the transformer voltage is positive will current flow through

the diodes. Figure 3 shows the simplest possible rectifier circuit. This circuit

is known as a half-wave rectifier. Here the diode conducts only half of the

time when the AC wa v e is positiv e as shown in Figure 2C . Use of this circuit

is simple but inefficient. The big gap between cycles require much more

filtering to obtain a smooth DC voltage.

By the addition of a second diode and transformer winding we can fill in the

gap between cycles as shown in Figure 4. This circuit is called full-wave

rectification. Each diode conducts when the voltage is positive. By adding the

two outputs, the voltage presented to capacitor C1 is more complete, thus

easier to filter, as shown in Figure 2E. When used in 60 cycles AC input

power, the output of a full wave rectifier will be 120 cycles.

Capacitor C1 is used to store the current charges, thus smoothing the DC

voltage. The larger the capacitor, the more current is stored. In this design,

1000µF capacitors are used, which allows about 5 volts AC ripple when one

amp is drawn.

Figure 1

Simplified diagram of positive power supply

120VAC

Input

17VAC 20VDC

1.25 - 15V

Regulated

Output

Transformer

120V to 17V

AC to DC

Converter

Voltage

Regulator

Figure 2

Figure 3

Figure 4

Voltage Waveform for Supply

A) Transformer

Winding AB

B) Transformer

Winding BC

C) Output of

diode D1.

D) Output of

diode D2.

E) Total of diodes

D1 & D2.

20V

F) Output of capacitor C1

Ripple depends on load

current (expanded).

Half Wav e Rectifier

Full Wav e Rectifier

Page 20

-19-

In practice, the current through the diodes is not as shown in Figure 2C.

Because capacitor C1 has a charge after the first cycle, the diode will not

conduct until the positive AC voltage exceeds the positive charge in the

capacitor. Figure 5 shows a better picture of what the current flow looks

like assuming no loss in the diode. It takes a few cycles for the voltage to

build up on the capacitor. This depends on the resistance of the winding

and the diode. After the initial start-up, there will be a charge and

discharge on the capacitor depending on the current drawn by the output

load. Remember, current only flows through the diode when the anode is

more positive than the cathode. Thus, current will flow in short bursts as

shown in Figure 5.

The DC load current may be one ampere, but the peak diode current may be three times that. Therefore, the

diode rating must be sufficient to handle the peak current. The 1N4001 has a peak current rating of 10 amps.

REGULATOR CIRCUIT

The regulator circuit in the power supply consists of a LM-317 integrated circuit. This IC is specially designed

to perform the regulation function. Figure 6 shows a simplified circuit of how the LM-317 IC works.

Transistors Q1 and Q2 form a circuit known as a differential amplifier. The base

of transistor Q1 is connected to a stable 1.5V reference voltage. The base of

Q2 is connected to the regulator output circuit through a voltage divider

network. The collector of transistor Q2 is connected to a current source. This

basically is a PNP transistor biased to draw about 1mA of current. Transistor

Q2 sees the current source as a very high resistor of about 1 meg ohms. Thus,

the gain of transistor Q2 is extremely high.

Transistor Q5 is called the pass transistor. It controls the current reaching the

output. Transistor Q3 and Q4 are emitter followers. Their function is to raise the impedance of the pass

transistor. Note that transistors Q2, Q3, Q4, Q5 and resistor R1 form a closed loop. Also, note that the feedbac k

to the base of Q2 is negative, that is, when the base of Q2 goes positiv e , the output at emitter Q5 goes negative .

Now if the 2 volt output voltage goes down because of current drain at the output, the base of Q2 will drop,

forcing the collector voltage to go higher. This will bring the output voltage back to 2 volts. This is the basis of

all negative feedback regulators.

Another feature of the LM-317 regulator is to protect the IC against overload and output shor ts. If the IC is

overloaded, the junction of an ov erload transistor will overheat. A transistor will sense this overheating and shut

down transistor Q5.

The LM-317 IC is basically a 1.25 volt regulator. To be able to vary the output

from 1.25V to 20V, we stack the IC on the a DC voltage as shown in Figure 7.

When VR1 equals 0, the output voltage is 1.25 volts as determined by the LM317 IC. Note that the voltage across VR1 will equal the 1.25 volts across R1,

therefore the output voltage will be 2.5 volts. When VR1 is 5 times R1, the

output voltage is 6.25 volts. As you can see, varying resistor VR1 will vary the

voltage from 1.25 volts to 20 volts.

THE NEGATIVE VOLTAGE REGULATOR

The theory of the negative regulator is the same as the previously discussed positive regulator. The basic

difference is that diodes D1 and D3 are reversed, producing a negative voltage across capacitor C1. The LM337 IC is designed to operate from a negative supply.

Figure 5

Figure 6

Figure 7

A) Transformer

Winding

B) Voltage C1

C) Current

through diodes

20V

Peak

20V

2V

Output

R1

R2

Divider

Q1

Q2

1.5V

Q3

Q4

Q5

Current

Source

Equalized

to 1 Meg.

1.25 - 15V

R1

VR1

LM-317

Page 21

-20-

SCHEMATIC DIAGRAM - POWER SUPPLY SECTION

REV-E

Page 22

-21-

QUIZ - POWER SUPPLY SECTION

INSTRUCTIONS - Complete the following examination and check your answers carefully.

1. AC voltage is supplied to the rectifier stages by the . . .

A. step-up transformer.

B. step-down transformer.

C. 1 to 1 transformer.

D. AC to DC transformer.

2. The secondar y windings of the transformer are . . .

A. 90

O

out of phase.

B. 180Oout of phase.

C. 270

O

out of phase.

D. 320Oout of phase.

3. Diodes allow current to flow . ..

A. when the anode is more negative than the cathode.

B. when the cathode is more positive than the anode.

C. in one direction.

D. when a negative or positive voltage is on the anode.

4. What circuit is more efficient for rectifying AC to DC?

A. Har tley oscillator.

B. Half wave.

C. Schmitt trigger.

D. Full wave.

5. The DC voltage is smoothed by using a . . .

A. half-wave rectification circuit.

B. small value capacitor with a high voltage value.

C. Large value capacitor.

D. 90

O

out of phase.

6. An inefficient rectification circuit usually contains . . .

A. large gaps between cycles.

B. twice the AC voltage needed.

C. more diodes.

D. all of the above.

7. The maximum current that a diode can handle is deter mined by . ..

A. the transformer’s current rating.

B. the amount of AC ripple.

C. three times the diode rating.

D. peak current rating.

8. The LM-317 will shut down when . . .

A. the output voltage is too high.

B. no current is being drawn.

C. the junction overheats.

D. the output voltage drops to 1.25V.

9. The LM-317 regulator contains . . .

A. a pass transistor.

B. a constant current source.

C. a differential amplifier.

D. all of the above.

10. The LM-317 is basically . . .

A. a 1.25V regulator.

B. a 6.25V regulator.

C. a 2.5V regulator.

D. a negative voltage regulator.

Answers: 1. B;2. B; 3. C;4. D; 5. C;6. D; 7. D;8. C; 9. A; 10. A

Page 23

-22-

INTRODUCTION - ANALOG SECTION

The Analog Section of your XK-700-SEMI was sent to you pre-assembled and all of the circuits are on the main

PC board. To be certain that all circuits are functioning correctly and to become familiar with the circuit, we will

do a circuit analysis. Voltage and resistance readings will be taken. If a problem exists, a troubleshooting chart

will be helpful.

The Analog Section of your trainer contains a complete function generator capable of producing sine, square,

and triangle waveforms. The frequency of this generator can be continuously varied from 1 hertz to over

100,000 hertz in five steps: 10, 100, 1k, 10k, and 100k. A fine frequency control makes selection of any

frequency in between easy. The amplitude of the wavefor ms are adjustable from 0-15Vpp. A waveform of

function generator capable of producing sine, square and triangle waveform outputs has a wide range of

applications in electrical measurements and laboratory instrumentation. This complete function generator

system is suitable for experimentation and applications by the student. The entire function generator is

comprised of a single XR-2206 monolithic IC and a limited number of passive circuit components.

SPECIFICATIONS

Waveforms - Sine, square, triangle and complementar y square.

Frequency - 1Hz to 100kHz in 5 steps continuously var iable.

Fine frequency adjust - 10:1 approximate.

Amplitude variable 0-15 Vpp.

Output impedance 330 ohms: short protected.

DC offset change 10V from zero crossing.

1. WAVEFORM - Selects square, triangle or sine waveform at the FREQ output.

2. COURSE FREQUENCY - Selects five ranges of frequencies 10, 100, 1k, 10k and 100k hertz.

3. FINE FREQUENCY - Allows easy selection of desired frequency according to the frequency range.

4. AMPLITUDE - Controls the amplitude of the FREQ output signal from 0-15Vpp.

5. DC OFFSET - Controls the DC level of the FREQ output signal. The DC level may be varied 10 volts from

zero level.

6.

FREQ - A 4-pin output block for function generator’s signals, output is dependent on WAVEFORM selection

and frequency is set by COURSE FREQ control. The amplitude of the output is variable from 0-15Vpp.

1

2 3 4 5

6

USERS DESCRIPTION OF FRONT PANEL CONTROLS

Page 24

-23-

RESISTANCE ANALYSIS OF ANALOG SECTION

Static testing of the analog circuits. Do not plug in the power supply into 120VAC power source until all

resistance readings check out. The values given below are approximated.

SET SW3 TO SQUARE WAVE (refer to top panel).

From To Circuit Ohms Resistance Measured

Pin 11 (U6) Pin 3 (U10) Square Wave VR5 CCW 12.3kΩ

Pin 11 (U6) Pin 3 (U10) Square Wave VR5 CW 6.7kΩ

SET SW3 TO TRIANGLE WAVE

From To Circuit Ohms Resistance Measured

Pin 2 (U6) Pin 3 (U10) Triangle Wave VR5 CCW 14.7kΩ

Pin 2 (U6) Pin 3 (U10) Triangle Wave VR5 CW 4.7kΩ

Pin 13 (U6) Pin 14 (U6) Triangle Wave Greater than 1kΩ

SET SW3 TO SINE WAVE

From To Circuit Ohms Resistance Measured

Pin 2 (U6) Pin 3 (U10) Sine Wave VR5 CCW 14.7kΩ

Pin 2 (U6) Pin 3 (U10) Sine Wave VR5 CW 4.7kΩ

Pin 13 (U6) Pin 14 (U6) Sine Wave 200Ω

Pin 3 (U6) GND (B1) Mult. VR8 CCW < 10Ω

Pin 3 (U6) GND (B1) Mult. VR8 CW 100kΩ

Pin 4 (U6) +12V (B3) Vcc Less than 3Ω

Pin 7 (U6) -12V (B2) Fine Freq. Adj. VR7 CCW 108.2kΩ

Pin 7 (U6) -12V (B2) Fine Freq. Adj. VR7 CW 8.2kΩ

Pin 12 (U6) -12V (B2) GND Less than 3Ω

30% CCW - Counter-Clockwise CW - Clockwise

VR8

U10

U6

1

2

3

4

1

2

3

4

8

7

6

5

5

6

7810

9

11

12

13

14

15

16

SW3 SW2 VR7 VR5 VR6

Page 25

-24-

VOLTAGE ANALYSIS OF ANALOG SECTION

Proceed with the voltage analysis only if the resistance readings were satisfactory. The values given below

are approximate.

The following measurements will be taken from the copper side of the PC board. Tur n the unit on and place it

upside down.

See Figure P for locations of the testing points.

From To Circuit Volts Volts Measured

Pin 4 (U6) GND (B1) U6 Vcc +12V

Pin 12 (U6) GND (B1) U6 GND -12V

Pin 7 (U10) GND (B1) U10 Vcc +12V

Pin 4 (U10) GND (B1) U10 Vcc- -12V

TESTING THE FUNCTION GENERATOR

Note: Use the knobs when turning the switches.

TESTING THE SINE WA VE

1. Set your meter to the 200mV DC range.

2. Connect the red meter lead to the 4-pin breadblock marked FREQ and the black lead wire to the 4-pin

breadblock marked GND.

3. Set the WAVEFORM knob to SINE, COARSE FREQ UENCY knob to 1k and the FINE ADJ and AMPLITUDE

knobs fully clockwise.

4. Set the DC offset to the middle position. Then, turn on the trainer.

Turn unit right side up. Figure P

U10

U6

12

4

4

7

1

2

3

4

5

6

7810

9

11

12

13

14

15

16

1

2

3

4

8

7

6

5

Page 26

-25-

5. Set VR8 fully clockwise from the copper side of the PC board, and

adjust the DC OFFSET knob until the meter reads 0 volts DC.

6. Set the meter to the 20 volts AC range and slowly turn VR8 counter-

clockwise until the meter reads 5.5 volts AC.

Note: Adjusting the DC offset will affect the VAC readings.

TESTING THE TRIANGLE WA VEFORM

1. Switch the WAVEFORM knob to its triangle wave setting.

2. With the meter set to the 20 volts AC range, you should read about

6.3 volts AC.

TESTING THE SQUARE W A VEFORM

1. Switch the WAVEFORM knob to its square wave setting.

2. Set your meter to the 20 v olts AC range, you should now read about

12.5 volts AC.

Turn the unit off and unplug it from the AC outlet.

TROUBLESHOOTING CHART

This chart lists the condition and possible causes of several malfunctions. If a par ticular par t is mentioned as

a possible cause, check that part to see if it was installed correctly. Also, check it and the parts connected to it

for good solder connections.

PROBLEM POSSIBLE CAUSE

No wave for m at FREQ 1. Check voltage at pins 4 (+12V) and 12 (-12V) of U6.

2. Check for wave forms at pin 2 of U6 and pin 3 of U10.

A. Check R3-4, R7, R13, C18-22, C24, SW2-3, VR5 & VR7.

3. Measure voltage at pins 7 (+12V) and 4 (-12V) of U10.

4. Check R8, R9, R11, R14, R44-48, D16, D17, Q1 and Q2.

No sine, triangle or low amplitude 1. Check U6 pin 2 for wave form.

A. Check VR8, voltage to IC.

Saw wave in sine position 1. R5 wrong value.

Wave forms clip top or bottom 1.Measure voltage at pins 7 (+12V) and 4 (-12V).

2. Adjust VR8.

3. Check R7, R9, R11, R14, R44-49, D16-17 and Q2-3.

No CLK wave output or low amplitude 1. Check pin 11 of U6 for square wave.

A. Check Q2 shor ted to ground.

B. Check R10, R12 and Q3.

C. Defective IC.

No square wave or low amplitude 1. Check pin 11 of U6 for square wave.

(FREQ output) A. Check Q2 shor ted to ground.

B. Check R3, R49, SW3.

C. Defective IC.

Outputs wrong frequency 1. Check C18-22, C24, R13, SW2 and VR7.

DC offset not working 1.Check voltage on VR6 for +12V and -12V; check R8.

Trim Pot Adjustment

Page 27

-26-

CIRCUIT DESCRIPTION

The function generator frequencies are produced by an XR-2206

integrated circuit. This IC is capable of producing high quality sine,

square and triangle waveforms of high stability and accuracy. The

output wavefor m can be both amplitude and frequency modulated

by an external voltage. Figure Q shows the block diagram of the

XR-2206 IC.

The XR-2206 is comprised of four functions blocks, a voltage

controlled oscillator (VCO), an analog multiplier and sine shaper, a

unity gain buffer amplifier, and a set of current switches.

The VCO actually produces an output frequency proportional to an

input current. Across pins 5 and 6, a timing capacitor is switched

in to give 5 different ranges of frequencies via COARSE FREQ

switch. On pin 7, the FINE FREQ ADJ variab le resistor controls the

actual frequency output. These two components form the RC time constants for the oscillator frequency.

The VCO produces a square w a v e signal. This square wave is sent to a shaper and conv erted into a sine wav e .

QUIZ - ANALOG SECTION

INSTRUCTIONS: Complete the following examination and check your answers carefully.

1. The analog multiplier is par t of . ..

A. the voltage controlled oscillator.

B. unity gain buffer amplifier.

C. four function blocks.

D. timing capacitor circuit.

2. Increasing the current of the VCO will effect the .. .

A. amplitude.

B. DC offset.

C. AM modulation.

D. frequency.

3. The RC time constant is determined by . ..

A. pins 5 and 6.

B. voltage controlled oscillator.

C. pin 7 and a variable resistor.

D. components on pins 5, 6, and 7.

4. What pins on the 2206 IC are used to change the

sine wave to a saw wave?

A. 5, 6

B. 15, 16

C. 13, 14

D. 4, 12

5. Adjusting P4 from +12V to -12V effects . . .

A. sine wave amplitude.

B. modulation.

C. frequency stability.

D. DC offset.

6. Coarse frequency is set by . . .

A. P6.

B. capacitor C11 through C15.

C. C21.

D. P1 and SW9.

7. A 1 volt DC level on the FM input will .. .

A. shift the frequency 1kHz.

B. shift the frequency to DC.

C. have no effect.

D. shift the frequency 1MHz.

8. The square wave and CLK output are 180

O

out

of phase because . . .

A. Q2 inverts the CLK output.

B. Q1 inverts the square wave output.

C. a negative voltage is applied to P5.

D. pin 12 is tied to -12V.

9. Clipping of the sine wave outputs can be

corrected by . . .

A. P5.

B. the DC offset pot.

C. lowering the +5V power supply.

D. none of the above.

10. The sync output produces . . .

A. a sine wave.

B. a saw wave.

C. voltage spikes.

D. a square wave.

Functional Block Diagram

Figure Q

116

215

314

413

512

611

710

89

Symmetry

ADJ.

Waveform

ADJ.

Ground

Sync

Output

Bypass

FKS

Input

Timing

Resistor

Timing

Capacitor

V+

Mult. Out

Sine/Saw

Output

AM Input

+1

Multiplier

and

Sine

Shaper

VCO

Current

Switches

Answers: 1. C; 2. D; 3. D; 4. C; 5. D; 6. B;7.C;8.A; 9. D; 10. D

Page 28

-27-

SCHEMATIC DIAGRAM - ANALOG SECTION

Page 29

-28-

INTRODUCTION - DIGITAL SECTION

The Digital Section of your XK-700-SEMI also has been pre-assembled and all of the circuits are on the main

PC board. To be certain all of the circuits are functioning correctly and to become familiar with the circuit, we

will do a circuit analysis. Voltage and resistance readings will be taken. If a problem exists, the troubleshooting

chart will be helpful.

The Digital Section of your trainer contains all of the necessary functions to do your digital designs. They consist

of a clock generator, two no bounce logic switches, eight LED indicator lamps and eight data switches.

SPECIFICATIONS

• Data switches, eight DPDT, Hi 5V, low 0V.

• Logic switches, two no bounce with complementary output.

“On” voltage level 2.8V min., “Off” voltage level 1V max.

Input impedance 100kΩ.

• Eight LED readouts, 100kΩ input impedance.

• Clock frequency, 1Hz to 100kHz in 5 steps continuously variable.

• Clock amplitude, 5Vpp squarewave.

• Clock rise time, better than 100 nsec.

Page 30

-29-

USERS DESCRIPTION OF FRONT PANEL

1. CLK - A 4 pin output block for the function generator’s square wave. The amplitude of the signal is 5Vpp

and the frequency is set by COARSE FREQ control.

2. TWO LOGIC SWITCHES - These are no bounce logic switches. Give one signal state change per

movement of switch.

3. INPUT TERMINALS FOR LOGIC INDICATOR LEDs - “A” input corresponds with “A” lamp, etc.

4. LOGIC INDICATORS - Eight LEDs.

5. EIGHT DATA SWITCHES - Lets output of 5V or 0V depending on position.

6. OUTPUT TERMINAL - For all functions as stated. 4 pins per block.

1

2

3

4

5

6

Page 31

-30-

RESISTANCE ANALYSIS OF DIGITAL SECTION

Place the top panel onto the unit. Static testing of the digital section circuits. Do not plug the power supply into

a 117 volt power source until all of the resistance readings check out. The values given below are

approximate.

From To Switch Position Ohms Resistance Measured

SW1 GND In down position less than 1Ω

SW2 GND In down position less than 1Ω

SW3 GND In down position less than 1Ω

SW4 GND In down position less than 1Ω

SW5 GND In down position less than 1Ω

SW6 GND In down position less than 1Ω

SW7 GND In down position less than 1Ω

SW8 GND In down position less than 1Ω

SW1 GND In up position greater than 3kΩ

SW2 GND In up position greater than 3kΩ

SW3 GND In up position greater than 3kΩ

SW4 GND In up position greater than 3kΩ

SW5 GND In up position greater than 3kΩ

SW6 GND In up position greater than 3kΩ

SW7 GND In up position greater than 3kΩ

SW8 GND In up position greater than 3kΩ

SW1 +5V In up position less than 300Ω

SW2 +5V In up position less than 300Ω

SW3 +5V In up position less than 300Ω

SW4 +5V In up position less than 300Ω

SW5 +5V In up position less than 300Ω

SW6 +5V In up position less than 300Ω

SW7 +5V In up position less than 300Ω

SW8 +5V In up position less than 300Ω

LOGIC SW

DATA SWITCHES

XX

YY

SW1 SW2 SW3 SW4 SW5 SW6 SW7 SW8

Page 32

-31-

VOLTAGE ANALYSIS OF DIGITAL SECTION

Plug the power supply into a 117 volt power source. The values given below are approximate.

From To Switch Position Volts Volts Measured

X GND In up position 5V

X GND In up position less than 1V

Y GND In up position 5V

Y GND In up position less than 1V

SW1 GND In up position 5V

SW2 GND In up position 5V

SW3 GND In up position 5V

SW4 GND In up position 5V

SW5 GND In up position 5V

SW6 GND In up position 5V

SW7 GND In up position 5V

SW8 GND In up position 5V

X GND In down position less than 1V

X GND In down position 5V

Y GND In down position less than 1V

Y GND In down position 5V

SW1 GND In down position less than 1V

SW2 GND In down position less than 1V

SW3 GND In down position less than 1V

SW4 GND In down position less than 1V

SW5 GND In down position less than 1V

SW6 GND In down position less than 1V

SW7 GND In down position less than 1V

SW8 GND In down position less than 1V

High Positions

SW1-8

XX

YY

LOGIC SW

DATA SWITCHES

XX

YY

SW1 SW2 SW3 SW4 SW5 SW6 SW7 SW8

Page 33

-32-

TESTING THE DIGIT AL SECTION

TESTING THE LOGIC INDICATOR FUNCTION

There are eight logic indicators which you will be checking out. Put a wire to the 5V power supply and touch

the “A” logic indicator test pin. The “A” LED should light up. Remove the wire and the LED should go out. Do

the same for the B, C, D, E, F, G and H pins.

TESTING THE LOGIC SWITCHES

There are two logic switches and four conditions to be checked out. Connect a wire from the “X” test pin to the

“A” logic indicator test pin. Connect another wire to the “X” test pin to the “B” test pin.

Apply power and note that the “A”LED indicator should be lit when the logic switch is in the “X” position and the

“B” LED should light and the “A” LED not light. Check the “Y”logic switch in the same manner.

TESTING THE DA T A SWITCHES

There are eight data switches to be checked. The output of the switches are 5V or ground depending on the

position. Connect a wire to the SW1 test pin and the “A” test pin. The “A” LED should light when the switch is

placed toward the top of the case. Repeat the same test on SW2, SW3, SW4, SW5, SW6, SW7 and SW8.

Unplug the unit from the AC outlet.

DIGIT AL TROUBLESHOO TING CHART

PROBLEM POSSIBLE CAUSE

No +5V on data switch terminals. 1. Measure for a DC voltage of +5V across R15.

A. Check R15, J19, J23 and J13.

B. Switch shor ted to ground.

LED doesn’t light 1. Check that the LED is in correctly.

2. Check the input and output resistors.

3. Measure input for +5V and output at ground.

A. Shor t to ground or defective IC.

LED always on 1. Measure for zero voltage voltage at input pin.

A. Pin shor ted or defective IC

2. Measure voltage to output pin for +5V.

A. Pin shor ted or defective IC.

Logic switch terminal always high 1. Check that input resistor is grounded.

A. Bad ground connection or switch.

2. Measure for +5V on R16 - R19.

A. Check resistor.

3. Defective IC.

Page 34

FINAL ASSEMBLY

Fasten the front panel in place with four #6 x 3/8”

thread cutting screws, as shown in Figure S.

Fasten the PC board to the spacer

to the front panel with a fiber

washer and a 4-40 x 1/4”

machine screw (from Power

Supply Section) from the foil

side of the PC board, in the

location shown in Figure T.

Fasten the pots to the

front panel with an 8mm

washer and a 7mm nut, as

shown in Figure S.

Turn the shafts on the

two switches fully

counter-clockwise.

Push the knobs onto

the shafts so that

the line on the knob

is in line with the

“Squarewave” on the

wavef orm control and “10”on

the Coarse Frequency control

(see Figure U).

If the knobs are loose on the shafts, insert

a screwdriver into the slot and expand the slot

slightly (see Figure W).

Turn the shafts on the pots fully counter-clockwise. Push the

knobs onto the shafts so that the line on the knob is in line with the

end of the circle on the front panel, as shown in Figure V.

If the knobs are loose on the shafts, insert a screwdriver into the slot and expand the slot slightly (see Figure W).

-33-

#6 x 3/8” Thread

Cutting Screws

Figure U

Figure V

Figure T

4-40 x 1/4” Machine Screw

Figure W

10

100

1k

10k

100k

WAVE FORM COARSE FREQ

Knob

Nut 7mm

Washer 8mm

#6 x 3/8” Thread

Cutting Screws

Nut 8mm

Washer 9mm

Nut 8mm

Washer 9mm

Knob

Nut 7mm

Washer 8mm

Figure S

Page 35

-34-

INSTALL COMPLETED UNIT INTO CASE

Place the strain relief onto the line cord as shown in Figure X.

Squeeze the two sections together with pliers as shown in Figure Y. Then, insert the strain relief into the hole.

Lay the trainer inside of the case as shown in Figure Z.

Align the holes in the bottom case with those in the trainer and secure it into place with four #6 x 1/2 AB

screws and four #6 washer as shown in Figure AA.

Figure Y

Figure X

Back Panel

Back Panel

Figure Z

Figure AA

#6 x 1/2” AB Screw

#6 Washer

Page 36

-35-

CIRCUIT DESCRIPTION - DIGITAL SECTION

THE DATA SWITCHES

There are eight data switches labeled SW1 through SW8. The circuit is very simple. To perform the desired

functions, there is a double throw doub le pole s witch, wired as a single pole double throw. One end is connected

to the 5V, the other to ground and the center lug is connected to the output.

THE LOGIC SWITCHES

The logic switches are also DPDT switches wired as SPST switches. The logic switches perform the same

function as the data switches. That is, they produce high or low states. But there is one big difference. When

switching the data switches, many pulses may be produced due to bouncing of the contacts.

In the logic switches, only one pulse is produced at the IC output no matter

haw many times the contacts bounce. This is extremely impor tant if you

are producing pulses for counting circuits. Figure BB shows the wiring of

the logic switch. The two NAND gates are connected so that when the X

input is grounded, the X output goes high. Opening and closing the

ground at X will not change the output. Only when X is grounded will the

output change to low. Thus, only one output change is produced with one

movement of the X switch. There are two outputs from each logic switch.

There are two outputs from each logic switch, X and X or Y and Y.

THE LOGIC INDICATORS

There are eight logic indicators. Figure CC shows the circuit. It consists

of a 74HC04 IC. When the input is over 2.8V, the output of the IC will be

low, drawing current through the LED indicator. The 120Ω resistor limits

the current in the LED to less than 20mA. When there is no connection to

the input of the logic indicators, the two 100kΩ resistor bias the input to

GND. This insures that the LED will be off.

TRAINER CASE CONVERSION

After using your trainer for educational purposes, you can convert your trainer into a tool case by removing the

trainer from the case. There are four plastic hole plugs included for the conv ersion. Simply unscrew and remov e

the trainer from the case, and stick the plugs into the four hole locations shown. Then, insert the dividers in the

locations you desire.

Figure BB

Figure CC

Plastic Plug

Bottom View of Case

Plugs

Page 37

-36-

SCHEMATIC DIAGRAM - DIGITAL SECTION

Page 38

-37-

QUIZ - DIGITAL SECTION

INSTRUCTIONS: Complete the following examination, check your answers carefully.

1.The logic switches consist of . . .

A. two NAND gates and an SPST switch.

B. three OR gates.

C. two NAND gates and a DPDT switch.

D. one OR gate.

2.When the logic switch is thrown .. .

A. the contacts do not bounce.

B. a single transition is produced at the NAND gate output.

C. a multiple transition is produced at the NAND gate output.

D. none of the above.

3. If the X output is high, opening and closing the ground at X switch will . . .

A. cause the X output to go low.

B. cause the X output to go high.

C. cause the X output to go from high to low.

D. none of the above.

4.The logic indicator LED lights up when . . .

A. input voltage is 2V.

B. input voltage is greater than 2.8.

C. the IC output is high.

D. all of the above.

5.The logic switches use . . .

A. single pole single throw switches.

B. double pole double throw switches wires as single pole double throw switches.

C. two pole 5 position rotary switches.

D. 4 pole 3 position rotar y switches.

6.The 100kΩ resistor on the logic indicator input . . .

A. divides the input voltage in half.

B. bias the input to +5V.

C. bias the input to GND.

D. tur n on the LED.

7. When the logic switch is in the X position . ..

A. X is high, X is low.

B. X is high, X is high.

C. X is low, X is high.

D. X is low, X is low.

8. When the data switch is up and connected to the logic indicator . ..

A. the switch output is greater than 2.8V.

B. the switch output is GND.

C. the LED will be out.

D. none of the above.

9.The +5VDC power for the digital section comes from a .. .

A. 7805 IC.

B. 7905 IC.

C. 5V battery.

D. 7812 IC.

10. If pin 4 on U7B is high . . .

A. pin 3 is low.

B. pin 1 is low.

C. pin 2 and 6 are high.

D. pin 5 is high.

Answers: 1. C; 2. B; 3. D; 4. B; 5. B; 6. C;7.A;8.A; 9. A; 10. B

Page 39

-38-

PC BOARD PARTS LIST

RESISTORS

QTY SYMBOL VALUE COLOR CODE PART #

4

R1, R2,

R14, R44 100Ω 1/4W 5% brown-black-brown-gold 131000

8

R36 - R43

120Ω 1/4W 5% brown-red-brown-gold 131200

1 R5 200Ω 1/4W 5% red-black-brown-gold 132000

1 R15 220Ω 1/4W 5% red-red-brown-gold 132200

2 R46, R47 330Ω 1/4W 5% orange-orange-brown-gold 133300

5 R12, R16 - R19 1kΩ 1/4W 5% brown-black-red-gold 141000

1 R49 2kΩ 1/4W 5% red-black-red-gold 142000

2 R7, R11 4.7kΩ 1/4W 5% yellow-violet-red-gold 144700

1 R3 6.8kΩ 1/4W 5% blue-gray-red-gold 146800

1 R13 8.2kΩ 1/4W 5% gray-red-red-gold 148200

1 R10 10kΩ 1/4W 5% brown-black-orange-gold 151000

1 R6 12kΩ 1/4W 5% brown-red-orange-gold 151200

3 R4, R45, R48 22kΩ 1/4W 5% red-red-orange-gold 152200

1 R9 47kΩ 1/4W 5% yellow-violet-orange-gold 154700

1 R8 51kΩ 1/4W 5% green-brown-orange-gold 155100

16 R20 - R35 100kΩ 1/4W 5% brown-black-yellow-gold 161000

1 VR8 100kΩ Trim Pot 191610

1 VR3 1kΩ Pot PC MNT 192412

2 VR1, VR2 2kΩ Pot PC MNT 192421

1 VR5 10kΩ Pot PC MNT 192531

3 VR4, VR6, VR7 100kΩ Pot PC MNT 192612

CAPACITORS

QTY SYMBOL VALUE DESCRIPTION PART #

1 C27 5pF (5) Discap 205010

1 C26 22pF (22) Discap 212210

1 C23 100pF (101) Discap 221017

1 C18 .001µF (102) Mylar 231017

1 C25 .0022µF (222) Discap 232216

1 C19 .01µF (103) Mylar 241017

6 C6 - C10, C20 .1µF 100V (104) Mylar 251017

1 C21 1µF 50V Electrolytic 261047

2 C22, C24 10µF 25V Electrolytic 271045

7 C11 - C17 100µF 25V Electrolytic 281045

2 C3 1000µF 25V Electrolytic 291045

4 C1, C2, C4, C5 1000µF 35V Electrolytic 291046

SEMICONDUCTORS

QTY SYMBOL VALUE DESCRIPTION PART #

15 D1 - D15 1N4001 Diode 314001

2 D16, D17 1N4148 Diode 314148

2 Q1, Q3 2N3904 Transistor PNP 323904

1 Q2 2N3906 Transistor NPN 323906

1 U10 LF357 Integrated Circuit 330357

1 U6 XR2206 Integrated Circuit 332206

1 U7 SN7403 Integrated Circuit 337403

8 D18 - D25 LED Diode (red) 350002

2 U8, U9 74HC04 Integrated Circuit 39HC04

MISCELLANEOUS

QTY SYMBOL DESCRIPTION PART #

10 SW4 - SW13 Slide Switch SPDT 541009

1 SW2 Switch Rotar y 12-pin 542206

1 SW3 Switch Rotar y 16-pin 542405

1 S2, S3 Connector 3-pin 591032

2 S4, S5 Connector 4-pin 591042

1 S1 Connector 5-pin 591052

8 Spacer 1/4” #8 Plastic 624124

3 U7 - U9 14-Pin IC Socket 664014

1 U6 16-Pin IC Socket 664016

18 B1 - B18 4-Pin Bredblox 665204

Page 40

Elenco Electronics, Inc.

150 W. Carpenter Av en ue

Wheeling, IL 60090

(847) 541-3800

http://www.elenco.com

e-mail: elenco@elenco.com

Loading...

Loading...