Page 1

Deluxe Electronic

Soldering Station

MODEL SL-5

MODEL SL-5-40

MODEL SL-5-SPL

Instruction Manual

Elenco Electronics, Inc.

Copyright © 2002 Elenco Electronics, Inc. 753099

Elenco Electronics, Inc.

150 W. Carpenter Avenue

Wheeling, IL 60090

(847) 541-3800

http://www.elenco.com

e-mail: elenco@elenco.com

TWO YEAR WARRANTY

All Elenco models are guaranteed for two full years on all parts and

service. For the first three months, your soldering station is covered at

absolutely no charge. For the remaining 21 months, a nominal service

charge is required to cover shipping and handling. Soldering iron tip

not included in warranty.

When returning merchandise for repair, please include proof of

purchase, a brief letter of explanation of problem, and sufficient

packing material. Before returning any merchandise please call our

service department at (847) 541-3800 to obtain a return merchandise

authorization number (RMA).

Service Department

Page 2

-1- -10-

INTRODUCTION

The SL-5 series of soldering stations are quality products designed to

give the professional, student and hobbyist greater control in quality

soldering a broad range of soldering situations. The stations are

available with 40 watt soldering irons. The AC receptacle on the back

of the station allows soldering irons of up to 300 watts. The AC

receptacle also allows irons to be easily changed or replaced.

FEATURES

• Heavy Steel, Non-Slip Base

• Iron Holder Funnel - Reversible, left or right side

• Stainless Steel Tray for Sponge Pad

• Sponge Pad

• Power On/Off with Indicator Light

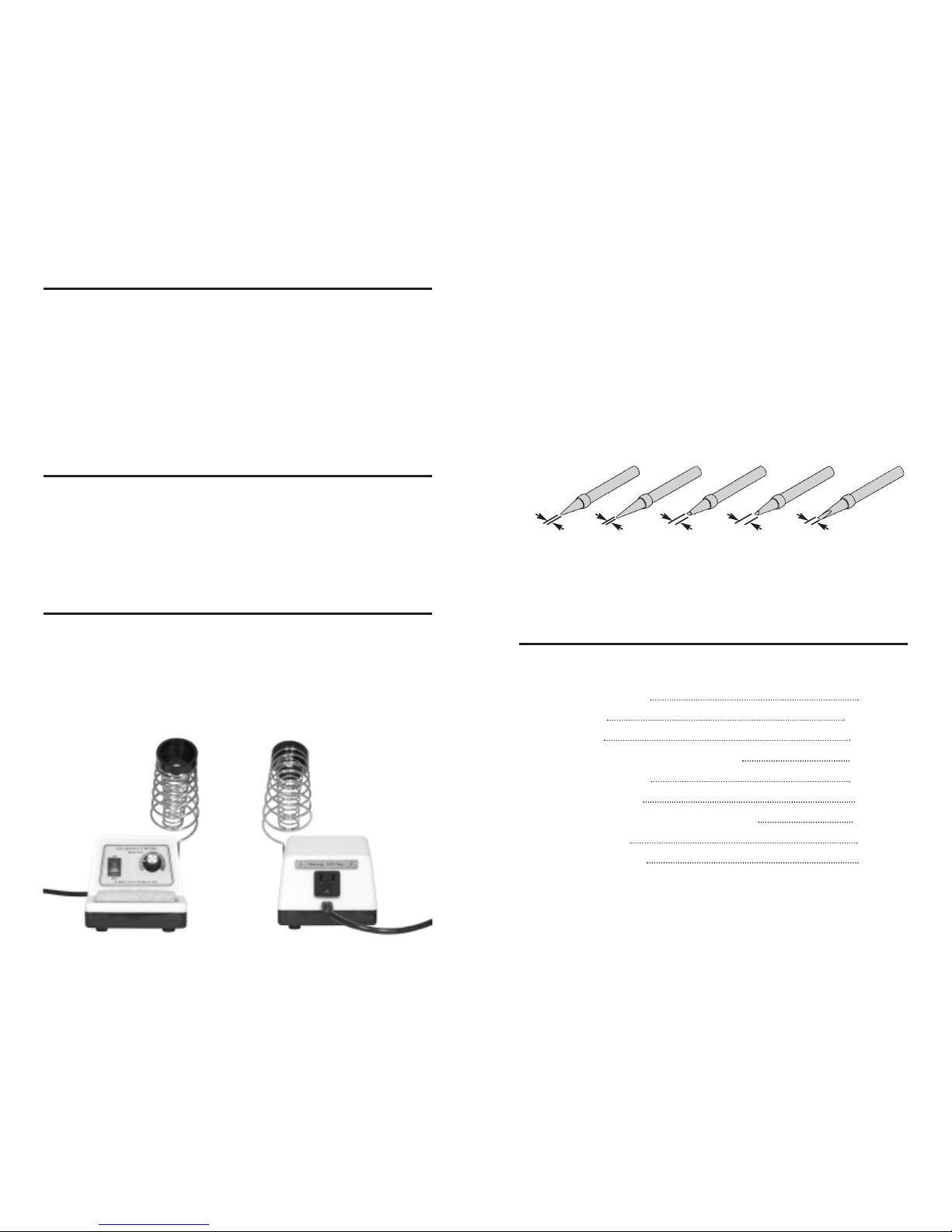

SOLDER STATION MODELS

The following instructions are for the following electronic soldering

stations. The model number of the electronic soldering station that you

have received, is marked on the end of the carton.

Model SL-5 is supplied without an iron.

Model SL-5-40 is supplied with a 40 watt soldering iron,

grounded plug, Model SR-6.

Model SL-5-SPL is custom packaged with an iron of your choice

and other soldering aids.

Replacements and Optional Solder Aids for SL-5

Series Solder Station

40W Soldering Iron SR-6

Conical Tip SR-2T2

Wedge Tip SR-2T

Tip Kit used with SR-6 Soldering Iron TIPK-1

Tip Tinner/ Cleaner TTC-1

Desoldering Wick SW-3

Solder 63/37 Rosin Core .032 dia. 10ft. ST-4A

Solder Ease Kit SE-1

Desoldering Pump SP-2

Tip Sizes

The tip sizes and shapes greatly effects the heating and heatrecovery.Today, tips are manufactured in a variety of different shapes.

Having a choice of tip styles allows you to choose the one best suited

for your soldering needs.

Shown below is a soldering iron tip package of 5 tip sizes (Model

TIPK-1) that can be used with Elenco’s soldering irons SR-2B and

SR-6. Due to high heat, removable tips can bond themselves to the

heating element if left in place for extended periods. Periodic removal

of the tip is therefore advisable.

1/32”

1/64” 1/16” 1/8” 3/64”

Tip Package Model TIPK-1

Page 3

Types of Poor Soldering Connections

1. Insufficient Heat - the solder

will not flow onto the lead

as shown.

2. Insufficient Solder - let the

solder flow over the connection

until it is covered. Use just enough

solder to cover the connection.

3. Excessive Solder - could make

connections that you did not intend

to between adjacent foil areas or

terminals.

-2--9-

OPERATION

• Carefully remove the SL-5 parts from the box.

• Insert the iron holder on either the right or the left side.

• Wet the sponge with preferably distilled or tap water, and then place

it into the tray.

• Set the On/Off switch to the Off position and the control knob at

minimum.

• Plug the soldering iron line cord into the AC receptacle on the back

of the station and place the soldering iron into the iron holder

funnel.

• Plug the line cord of the solder station into a 120-volt, 60Hz AC

receptacle.

• Turn the power switch On and set the temperature control to

maximum.

• We will now tin the tip by applying solder to the tip as it heats up

.

DO

IT before the tip becomes too hot.

• Set the temperature setting to the temperature desired for

soldering. If you are not going to use the iron immediately, set the

temperature in the park

position.

General Areas of Temperature Settings for 40W Iron

4. Solder Bridges - A solder

bridge occurs when solder

runs between circuit paths and

creates a short circuit. This is

usually caused by using too

much solder. To correct this,

simply drag your soldering iron

across the solder bridge as

shown.

Rosin

Soldering iron positioned

incorrectly.

Solder

Gap

Component Lead

Solder

Soldering Iron

Drag

Foil

Use these settings for

soldering temperature

sensitive components.

Use these settings for

general soldering and

connections that

require more heat.

Park Position

In these settings,

temperatures are too

low for soldering. Set

the station in these

positions when not

using it to reduce

oxidation of the

soldering iron tip.

300

550

750

670

Page 4

-3- -8-

SAFETY PRECAUTIONS

Like all electrical devices, the solder station must be handled with

care. The soldering iron and tip can reach high temperatures and

these simple safety rules should be followed.

1. Keep children out of reach of the soldering station.

2. To protect your eyes, use safety goggles.

3. Keep flammable material away from the soldering iron.

4. DO NO

T cool iron by dipping it into any liquid or water.

5. Always assume that the tip is hot to avoid burns.

6. Work in an area that is well ventilated.

7. Be careful that the hot soldering iron tip or the barrel of the iron

does not come in contact with any electrical cord.

8. Do not hold solder in your mouth. Solder contains lead and is

a toxic substance. Wash your hands thoroughly after handling

solder.

9. Locate solder station in an area where you do not have to go

around it or reach over it.

Soldering Surface Mount Components

Using tweezers or small long nose pliers, place the iron in contact

with the PC board foil. Apply a small amount of solder simultaneously

to the foil and components, allowing them to melt the solder.

Remove the iron and allow the solder to cool. The solder should have

flowed freely and not lumped around the component.

Apply the lowest heat possible while still having solder flow freely

(suggested temperature setting: 625

O

F).

Heat Sinking

Electronic components such as transistors, IC’s, and diodes can be

damaged by the heat during soldering. Heat sinking is a way of

reducing the heat on the components while soldering. Dissipating the

heat can be achieved by using long nose pliers, an alligator clip, or a

special heat dissipating clip. The heat sink should be held on the

component lead between the part and the solder joint.

Heat Sink

(this can be ordered as part of

Elenco’s Solder Ease Kit Model

SE-1 - see Page 10).

Soldering Iron

Solder

Heat Sensitive

Component (Diode)

PC Board

Tweezers or Pliers

Solder

Soldering Iron

Surface Mount Component

Page 5

-4--7-

Solder

Soldering Iron

Foil

3. Allow the solder to flow around the

connection. Then, remove the solder

and the iron and let the connection cool.

The solder should have flowed smoothly

and not lump around the wire lead.

4. Here is what a good solder connection

looks like.

Solder

Soldering Iron

Foil

2. Apply a small amount of solder to the

iron tip. This allows the heat to leave the

iron and onto the foil. Immediately apply

solder to the opposite side of the

connection, away from the iron. Allow

the heated component and the circuit foil

to melt the solder.

SOLDERING

A poorly soldered joint can greatly effect small current flow in circuits

and can cause equipment failure. You can damage a PC board or a

component with too much heat or cause a cold solder joint with

insufficient heat. Sloppy soldering can cause bridges between two

adjacent foils preventing the circuit from functioning.

What Good Soldering Looks Like

A good solder connection should be bright, shiny, smooth, and

uniformly flowed over all surfaces.

Soldering a PC board

1. Solder all components from the copper

foil side only. Push the soldering iron tip

against both the lead and the circuit

board foil.

Component Lead

Soldering Iron

Circuit Board

Foil

SOLDERING IRONS

Iron wattage varies from 15 to over 100 watts. For working on PC

boards, irons ranging from 15 to 40 watts is suitable. If a heavy-duty

soldering iron is required, a 60 watt iron should be considered. If you

use an iron with a higher wattage rating than 40 watts, you may

damage the copper tracks on the PC board. The higher wattage irons

are best suited for heavy-duty electrical connections.

Soldering Iron Tip

The tip is the very important part of the iron. The material that the tip

is made from is an important factor. The soldering iron tip contains

four different metals see figure below. The core consists of copper.

Since the copper is a soft material, it is plated with iron. Then the tip

is plated with tin, because it can be easily cleaned. Chrome plating

is used on the area where no soldering takes place to prevent

oxidation.

CopperIron Plating Chrome PlatingTin Plating

Tip Cleaning

A good clean solder tip makes soldering much easier. The tip should

be tinned by lightly coating it with solder to prevent it from oxidizing.

The tip can become pitted (black spots) from normal use. It is

important to clean the tip by wiping it with a wet sponge or rag. For

tips that need a good cleaning, the tip tinnier and cleaner (#TTC1)

should be used. Ne

ver use a file or abrasive material to clean the

tip. Using such methods will damage the plating and ruin the tip. Do

not remove the excess solder from the tip before storing. The excess

solder will prevent oxidation.

Page 6

-5- -6-

Surface Preparation

In order for the solder to adhere to the connection, the metals must

be clean and free of non-metallic materials. Flux in the solder can

remove oxides from metal but not other materials like dirt or grease.

To remove these, use a small steel brush or fine emery cloth.

Mechanical Connection

When all the surfaces are clean, the metals should have a solid

mechanical connection. Wires should be tightly wrapped around

each other or to the terminal. This will eliminate large gaps that create

weak solder joints. Solder should not be used as a mechanical

connection.

Solder

Rosin Core

Solder

Solder is a fusible alloy composed of tin and lead. Some solder may

contain small amounts of other material for use in special purposes

to enhance its characteristics. Solder has a melting temperature

around 361

O

to 370O, making it ideal for forming a metallic joint

between two metals.

Solder is identified by the ratio of tin-to-lead. The most common

ratios are 63/37 and 60/40. Solder with a greater tin content melts at

a lower temperature, takes less time to harden, and generally makes

it easier to do a good soldering job. The ratio of tin is a main factor in

the strength of the solder joint. Solder with a greater tin content has

a greater holding ability under stress. Rosin core solders (.031”

diameter) are ideal for use in soldering electronic circuits.

SolderWire Terminal

INTRODUCTION TO SOLDERING

Almost every electronic device today has a printed circuit (PC) board.

Whether you are assembling a PC board or repairing it, you must

understand the basics of working with these boards.

A poorly soldered joint can greatly effect small current flow in circuits

and can cause equipment failure. You can damage a PC board or a

component with too much heat or cause a cold solder joint with

insufficient heat. Sloppy soldering can cause bridges between two

adjacent foils preventing the circuit from functioning.

Good soldering requires practice and an understanding of soldering

principles. Solder (a tin-lead fusible alloy) is use to form a metallic

union or joint between two metals.

For best results, the soldering iron should be at least 100

O

F above the

melting point of solder (361OF). Generally, a minimum temperature of

650OF is desirable for printed circuit boards, while higher

temperatures are needed for proper soldering to heavier terminals.

Listed below are some basic steps that should be followed to make

good solder joints.

1. Make sure that the part that is to be soldered is clean.

2. Where possible, make good mechanical connections.

3. Use quality 63/37 or 60/40 rosin core solder. NEVER USE ACID

CORE SOLDER OR FLUX.

4. Apply heat to the base material or wires so that they become hot

enough to melt the solder.

5. Slide the soldering iron away from the joint to leave a neat joint.

6. After removing iron, do not move joint.

7. On temperature sensitive components such as transistors,

diodes, and IC’s, avoid too much heat. Use a heat sink to

dissipate heat away from the component.

Loading...

Loading...