Page 1

RADIO CONTROLLED CAR KIT

MODEL RCC-7K

Assembly and Instruction Manual

Elenco Electronics, Inc.

Copyright © 2001 Elenco Electronics, Inc. 753288-G

Page 2

PARTS LIST

Contact Elenco Electronics if any parts are missing or damaged. DO NOT contact your place of purchase

as they will not be able to help you.

CARD 1 - RESISTORS (in Bag 2)

QTY Symbol Value Marking Part #

1 R11 68W 5% 1/4W blue-gray-black-gold 126800

5 R12, R17, R18, R19, R20 100W 5% 1/4W brown-black-brown-gold 131000

1 R5 200W 5% 1/4W red-black-brown-gold 132000

2 R1, R21 560W 5% 1/4W green-blue-brown-gold 135600

2 R13, R14 1kW 5% 1/4W brown-black-red-gold 141000

2 R15, R16 1.5kW 5% 1/4W brown-green-red-gold 141500

1 R10 2.7kW 5% 1/4W red-violet-red-gold 142700

2 R4, R8 3.3kW 5% 1/4W orange-orange-red-gold 143300

2 R2, R3 22kW 5% 1/4W red-red-orange-gold 152200

1 R9 200kW 5% 1/4W red-black-yellow-gold 162000

2 R6, R7 3.9MW 5% 1/4W orange-white-green-gold 173900

CARD 2 - CAPACITORS (in Bag 2)

QTY Symbol Type Value Marking Part #

1 C1 Ceramic 10pF 10 211011

2 C2, C3 Ceramic 27pF 27 213010

1 C8 Ceramic 500pF 501 225080

1 C11 Ceramic or Mylar 2200pF 222 232217

1 C4 Ceramic or Mylar 3300pF 332 233310

2 C9, C10 Ceramic or Mylar 0.01mF 103 241031

1 C7 Ceramic or Mylar 0.1mF 104 251017

1 C5 Electrolytic 4.7mF 50V 4.7mF 264747

4 C6, C12, Electrolytic 220mF 10V 220mF 282244

C13, C14

CARD 2 - INDUCTORS & DIODES

QTY Symbol Type Value Part #

1 L2 Inductor 8.2mH (gray-red-gold-silver) 6RCC7K02E

1 D1 or D2 Zener Diode 3.0V (usually marked 3.0B2 or 3.6B1) 6RCC7K41

BAG 1 - PCB & SEMICONDUCTORS (6RCC7KB1E)

QTY Symbol Description Part #

1 IC1 IC GM2311A or AF2311 6RCC7K01E

1 IC1 IC socket, 16-pin 664016

1 T1 9 Turn inductor 6RCC7K03E

4 Q7, Q8, Q13, Q14 Transistor S8050, NPN 6RCC7K04

4 Q5, Q6, Q11, Q12 Transistor S8550, PNP 6RCC7K05

4 Q2, Q3, Q9, Q10 Transistor 9014, NPN 6RCC7K06E

1 Q1 Transistor C945, NPN 6RCC7K07E

1 - Printed Circuit Board 6RCC7K10E

-1-

Page 3

BAG 3 - SCREWS (6RCC7KB3E)

QTY DESCRIPTION PART #

1 Screws 0.4” x 0.1” (10mm x 2.6mm) 640101

5 Screws 0.4” x 0.115” (10mm x 3.0mm) 640101E

6 Screws 0.3” x 0.1” (8mm x 2.6mm), 0.15” head 640102

You may have been given different screws from

those specified here (and usually some spares).

Contact Elenco if it is not clear which to use.

BAG 4 - HARDWARE (6RCC7KB4E)

QTY DESCRIPTION PART #

2 Rear Springs 680023

1 Front Spring 680024

2 Shock Absorber Springs 680025

1 Rear Rod 0.8” x 0.075” 610808

(20mm x 2mm)

1 Steering Alignment Wire/Spring 6RCC7K11

2 Front Wheel Bars 6RCC7K12E

1 Battery Contact, + 6RCC7K13E

1 Battery Contact, - 6RCC7K14E

2 Battery Contact, + - 6RCC7K15E

1 Battery Contact, - + 6RCC7K16E

1 Switch, on/off 6RCC7K18E

1 Rear Axle 662019E1

1 Transmitter Antenna 484010E

BAG 5 - WIRES (6RCC7KB5E)

QTY DESCRIPTION PART #

1 Light Bulb, with wires attached 6RCC7K21

1 4” wire, red 6RCC7K22

1 4” wire, blue 6RCC7K23

1 4” wire, black 6RCC7K24

1 4” wire, green 6RCC7K25

1 4” wire, yellow 6RCC7K26

1 4” wire, orange 6RCC7K27

1 4” wire, white 6RCC7K29

1 Solder Roll 6RCC7K30

BAG 7 - GEARS (6RCC7KB7E)

QTY DESCRIPTION PART #

2 Locators for Rear Wheels 626019E3

2 Turning Posts for Front Wheels 6RCC7K34E

1 Steering Alignment Post 6RCC7K36E

1 Gear, Rear Wheels Axle 626019E4

1 Steering Motor Bracket 626018E2

1 Gear, middle of rear section 610809

BAG 8 - MOTORS (6RCC7KB8E)

QTY DESCRIPTION PART #

1 Driving Motor (larger) 6RCC7K39

1 Steering Motor (smaller) 6RCC7K40E

1 0.01mF Disc Capacitors 241031

1 0.1mF Disc Capacitors 251017

1 Driving Motor Gear 6RCC7K37

1 Steering Motor Gear 626019E5

PACKAGED SEPARATELY

QTY DESCRIPTION PART #

1 Bottom Frame 6RCC7K42E

1 Top Frame 6AK870TFE

1 Car Antenna 484011E

1 Remote Control Transmitter, 6AK870TAE

Assembled Except for Antenna

1 Decorative Decals (1 Sheet) 720063E

BAG 6 - COVERS (6RCC7KB6E)

QTY DESCRIPTION PART #

1 Front Section Cover 626018E1

1 Rear Section Cover 626019E

1 Steering Bar 626023E

1 Battery Cover 6RCC7K31E

2 Front Wheels 6RCC7K43E

2 Rear Wheels 626019E2

1 Top Light Bulb Cover 626022

-2-

Page 4

INTRODUCTION

The RCC-7K is a radio-controlled car that you put together. It has 7 control functions: forward, forward-left,

forward-right, backward, backward-left, backward-right, and stop. The remote control operates at a frequency

of 27.9 MHz. It uses 4 AA batteries and one 9V battery (not included). It takes about 7 hours to build.

Assembly of the RCC-7K will prove to be an exciting project and give much satisfaction and personal

achievement. If you have experience in soldering and wiring technique, you should have no problems. For the

beginner, care must be taken in identifying the proper components and in good soldering habits. Above all, take

your time and follow the easy step-by-step instructions. Remember, “An ounce of prevention is worth a pound

of cure”.

THEORY OF OPERATION

Remote Control Transmitter: (refer to the schematics and block diagram on p.31 as needed)

When the levers in the Remote Control Unit are pushed electrical contacts are made connecting the 9V battery

power to the transmitter and indicating which commands the user wants sent to the car. Forwards/Backwards

and Left/Right commands are controlled by different levers and use different sets of electrical contacts that are

used to encode a sequence of electrical pulses; the number of pulses depends on which command is being

sent. On some models Left/Right commands are only sent if Forwards/Backwards commands are also being

sent, since there is too much friction to turn the wheels unless the car is moving.

An electrical circuit that is tuned to a frequency of 27.9 MHz creates a signal that is sent to the antenna when

the pulses are active. The antenna converts this electrical energy into radio energy, creating a stream of radio

energy bursts, which travel through the air to be picked up by and understood by the radio receiver in the car.

The frequency of 27.9 MHz was selected for RCC-7K with the approval of the FCC (the US government) to

minimize radio interference between this product and all other electrical products.

Transmit Signals

Pulse Sequence

•••

27.9MHz Signal

•••

Transmitted Signal

•••

Characteristics of Radio Reception:

Many factors affect the ability of the RCC-7K to receive commands from its Remote Control Transmitter. A weak

battery in the Transmitter will result in a weaker transmitted signal; if the battery is very weak then the Transmitter

may not function at all. The Transmitter’s ability to convert electrical energy to radio energy is best when its

antenna is fully extended and degrades as the antenna length is reduced; the same thing also applies to the car

antenna’s ability to convert the radio signal back into electrical energy for the receiver. The Transmitter’s

antenna transmits energy in all directions so as the range between it and the car is increased less energy is

received at the car. When operated with strong batteries and in an open area the range will be at least 40 ft.

Obstacles such as walls, furniture, and trees will degrade the radio signal’s ability to travel through air and

reduce operating range, but will never block it completely. In some cases more radio energy may travel from

the Transmitter to the car by going around obstacles than by going through them. In the car, weak batteries will

•

•

•

4 synchronization bursts each

~

~ 1.8ms long with ~ 600µs

spacing.

~

{

Burst sequence, each ~ 600µs long with

~

~ 600µs spacing.

10 bursts for forward; 34 bursts for forward-left;

28 bursts for forward-right; 40 bursts for backward;

46 bursts for backward-left; 52 bursts for backward-right.

~

Note: some models use different sequence lengths

{

Sequence

Repeats

{

-3-

Page 5

reduce power to the Motor and degrade the receiver’s ability to filter, amplify, and decode commands from the

Transmitter.

Radio Receiver: (refer to the schematics and block diagram on p.31 as needed)

The car antenna collects radio energy and converts it back into electrical energy; the energy here will always

be much less than the energy originally applied to the transmitting antenna. If the car is turned on then the radio

receiver in the car is continuously monitoring the electrical energy from its antenna. The first stage of the

receiver is basically a filter which is tuned to amplify any energy around 27.9 MHz and block energy the antenna

picks up outside this region. If the Remote Control Transmitter is sending commands then its radio signal will

be picked up by the receiver and converted back into the original pulse sequence. Decoding circuitry then

determines which commands were sent by measuring the number of received pulses in the sequence. Signals

are then sent to the motors to execute the commands.

Take a closer look at the receiver schematic. The sub-circuit centered around transistor Q1 filters the antenna

output, if an RCC-7K transmitter is operating nearby then the 27.9 MHz burst signal may be visible at its

collector. Inductor L1 is tuned so that the circuit amplifies around 27.9 MHz while rejecting all other frequencies.

But we really want the pulse sequence that is hidden in the 27.9 MHz signal, so then C10 is used to filter out

the 27.9 MHz from the burst signal we received.This result is applied to pin 14 of the AF2311 integrated circuit.

Inside AF2311 the signal is amplified and filtered in two stages between pins 14, 15, 16, 1, and 3. Pin 3 (DI) is

the output pulse sequence that was picked up by the receiver; this is used as the input to the decoder. The

AF2311 scans for the 4 long (synchronization) pulses and then counts the number of short pulses after them to

determine which command was sent by the transmitter. The gain of the AF2311 stages is high enough to

produce a pulse sequence at pin 3 even if no signal from a transmitter is present (it amplifies random noise),

but the resulting sequence will seldom be identified as one of the transmitter commands. Note from above that

there are 4 long pulses and 10 - 52 short pulses for each command, less pulses could have been used but then

the car is more likely to activate on random noise.

Pins 4 and 5 of AF2311 are a 100 kHz (±30%) oscillator that is used as a reference by the decoder.

Car Steering Mechanism: (refer to the schematics on p.31 as needed)

When a command is received to turn left, the AF2311 creates a voltage at pin 7 which turns on transistor Q9.

This then turns on Q11 and Q14 and current flows from the batteries through Q11, then through the steering

motor, and then through Q14 to ground. This current through the Motor creates a magnetic field. Inside the

motor is a small magnet which is connected to the gear you see on the outside of the motor. The magnetic field

turns the magnet in the motor, which turns the gear.The “teeth” on the gear grab the Steering Bar and pull it to

one side. Since the Front Wheels are connected to the Steering Bar, the car will turn.

To turn right, the AF2311 creates a voltage at pin 6 instead of pin 7. This turns on Q10, Q12, and Q13, and

current flows through the steering motor in the opposite direction. In turn this causes the steering gear, the

steering bar, and the car to turn in the opposite direction.

Car Drive Mechanism: (refer to the schematics as needed)

The Driving Mechanism works the same as the Steering Mechanism. When a command is received to go

forwards the AF2311 creates a voltage at pin 11 which turns on Q2. This then turns on Q5 and Q8 and current

flows from the batteries through Q5, then through the driving motor, and then through Q8 to ground. Similarly

to go backwards the voltage is created at pin 10, and Q3, Q6, and Q7 are turned on. The small gear on the

Motor drives the Middle Gear, which drives the gear on the rear wheels axle, making the wheels move. Note

that the gears on the Motor and the rear wheels axle rotate forward and the Middle Gear rotates backward to

drive the car forward, this is because interlocking gears spin in opposite directions. Also notice that between

the Motor gear and the Middle Gear and again between the Middle Gear and the Rear Wheels axle gear, the

number of “teeth” is increased by 4:1 and 5:1 respectively, for 20:1 overall. The Motor must rotate 20 times to

rotate the rear wheels once. The reason for this is that if the Motor were to drive the wheels directly then the

RCC-7K would be very hard to control.

-4-

Page 6

CONSTRUCTION

Introduction

Assembly of your RCC-7K R/C Car Kit will prove to be an exciting project and give you much satisfaction and personal achievement. If

you have experience in soldering and wiring techniques, then you should have no problem with the assembly of this kit. Care must be

given to identifying the proper components and in good soldering habits. Above all, take your time and follow these easy step-by-step

instructions. Remember, “An ounce of prevention is worth a pound of cure”. Avoid making mistakes and no problems will occur.

CAUTION: WEAR SAFETY GLASSES WHEN ASSEMBLING THIS KIT.

Assemble Components

In all of the following assembly steps, the components must be installed on the top side of the PC board unless otherwise indicated. The

top legend shows where each component goes. The leads pass through the corresponding holes and the board is turned to solder the

component leads on the foil side. Solder immediately unless the pad is adjacent to another hole which will interfere with the placement

of the other component. Cut excessive leads with a diagonal cutter. Then, place a check mark in the box provided next to each step to

indicate that the step is completed. Be sure to save the extra leads for use as jumper wires if needed.

Foil Side

Rx - 100W 5% 1/4W Resistor

(brown-black-brown-gold)

Mount Part

Bend Leads to Hold Part Solder and Cut Off Leads

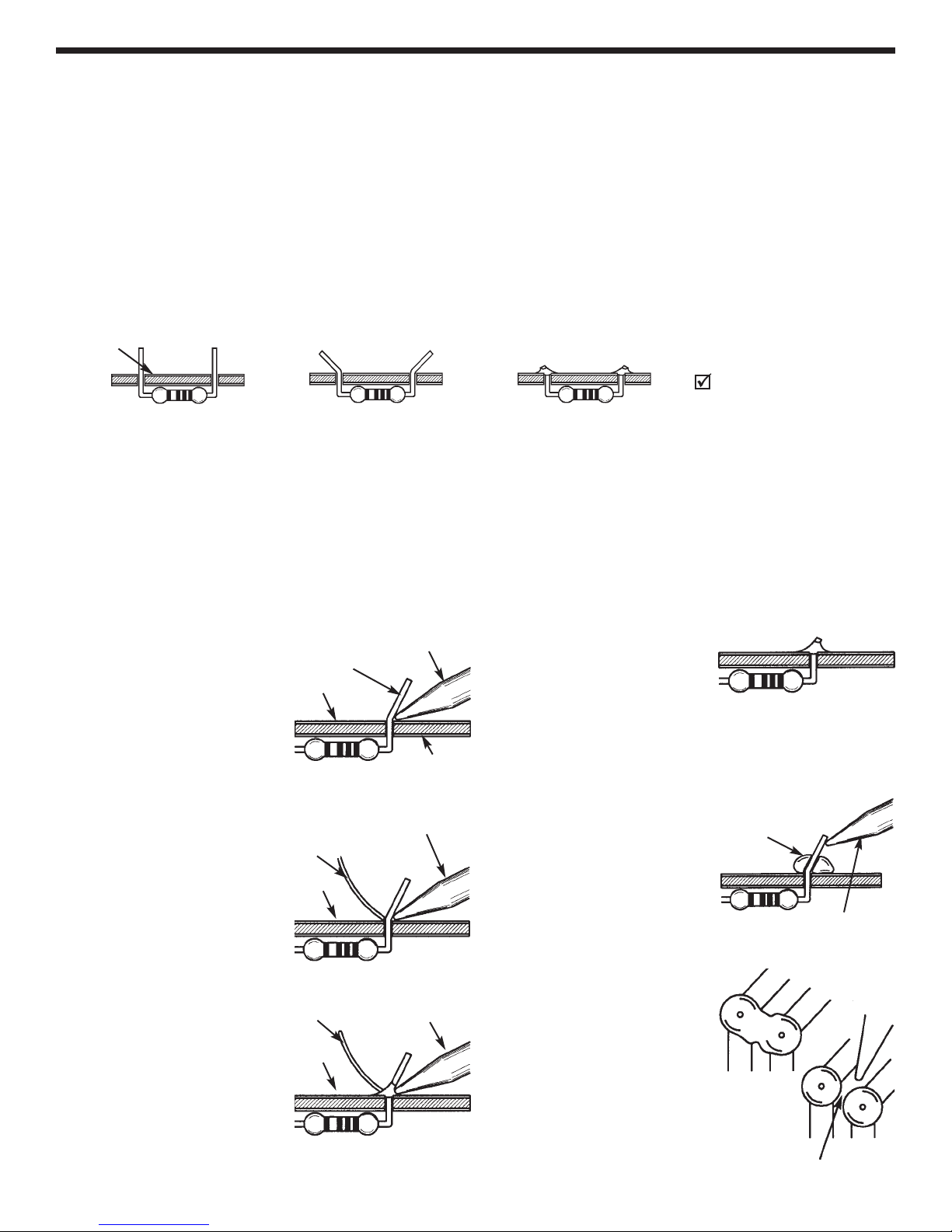

Soldering

The most important factor in assembling your R/C Car is good soldering techniques. Using the proper soldering iron is of prime

importance. A small pencil type soldering iron of 25 - 40 watts is recommended. The tip of the iron must be kept clean at all times

and well tinned. Many areas on the PC board are close together and care must be given not to form solder shorts. Size and care of

the tip will eliminate problems.

For a good soldering job, the areas being soldered must be heated sufficiently so that the solder flows freely. Apply the solder

simultaneously to the component lead and the component pad on the PC board so that good solder flow will occur. Be sure that the

lead extends through the solder smoothly indicating a good solder joint. Use only rosin core solder of 60/40 alloy.

DO NOT USE ACID CORE SOLDER! Do not blob the solder over the lead because this can result in a cold solder joint.

1. Solder all components from

the copper foil side only.

Push the soldering iron tip

against both the lead and the

circuit board foil.

2. First apply a small amount of

solder to the iron tip. This

allows the heat to leave the

iron and onto the foil.

Immediately apply solder to

the opposite side of the

connection, away from the

iron. Allow the heated

component and the circuit

foil to melt the solder.

Soldering Iron

Component Lead

Foil

Circuit Board

Soldering Iron

Solder

Foil

4. Here is what a good solder

connection looks like. Cut

off excess leads.

Example 1

Poor solder connections occur

when the lead is not heated

sufficiently. The solder will not

flow onto the lead as shown.To

correct. reheat the connection

and, if necessary, apply a small

amount of additional solder to

obtain a good connection.

Example 2

Solder does not flow onto the

lead. A hard rosin bead

surrounds and insulates the

connection.

Poor solder

connection

Soldering iron

positioned incorrectly.

3. Allow the solder to flow

Solder

around the connection.

Then, remove the solder and

Foil

the iron and let the

connection cool. The solder

should have flowed smoothly

and not lump around the wire

lead.

Soldering Iron

A solder bridge occurs when

solder runs between circuit

paths and creates a short

circuit. This is usually caused

by using too much solder. To

correct this, simply drag your

soldering iron across the

solder bridge as shown.

-5-

Page 7

IDENTIFYING CAPACITOR VALUES

Capacitors will be identified by their capacitance value in pF (picofarads) or mF (microfarads). Most capacitors

will have their actual value printed on them. Some capacitors may have their value printed in the following

manner.

Second Digit

First Digit

Multiplier

Tolerance

The above value is 10 x 1,000 = 10,000pF or .01mF

The letter K indicates a tolerance of +

The letter J indicates a tolerance of +5%

Multiplier

For the No.01234589

Multiply By 1 10 100 1k 10k 100k .01 0.1

Note: The letter “R” may be used at times to

10%

signify a decimal point; as in 3R3 = 3.3

IDENTIFYING RESISTOR VALUES

Use the following information as a guide in properly identifying the value of resistors.

BAND 1

1st Digit

Color Digit

Black 0

Brown 1

Red 2

Orange 3

Yellow 4

Green 5

Blue 6

Violet 7

Gray 8

White 9

BAND 2

2nd Digit

Color Digit

Black 0

Brown 1

Red 2

Orange 3

Yellow 4

Green 5

Blue 6

Violet 7

Gray 8

White 9

PART IDENTIFICATION CARDS

To help identify the resistors and diodes used in the construction of your car we have

mounted the resistors, capacitors, diodes, and an inductor onto cards. The card will

help you find the parts quickly. THE PARTS WILL NOT NECESSARILY BE LISTED IN

THE ORDER SHOWN IN THE PARTS LIST SECTION OR IN THE ASSEMBLY

PROCEDURE.

Multiplier

Color Multiplier

Black 1

Brown 10

Red 100

Orange 1,000

Yellow 10,000

Green 100,000

Blue 1,000,000

Silver 0.01

Resistance

Tolerance

Color Tolerance

Silver +10%

Gold +5%

Brown +

1%

Red +2%

Orange +3%

Green +

.5%

Blue +.25%

Violet +.1%

Gold 0.1

Multiplier

1

2

Tolerance

When you are ready to assemble the car kit, follow the procedure shown. For an

example refer to page 16. The first resistor called for is R13, 1kW resistor (brownblack-red-gold). Locate it on the card ( ), verify that it is the correct value. Some

resistors may be mounted backwards on the card so you must be certain that you are

reading the resistors correctly. When the correct value has been established, only

then will you mount it into its correct position on the PC board.

-6-

Page 8

ASSEMBLY INSTRUCTIONS

Inspection of Parts: Take a look at each of the parts bags and compare to the Parts List (on pages 1 &

1

2). Be sure that nothing was damaged during shipment and handling. Contact Elenco Electronics if you

have any problems (phone number is on the back of this manual).

2

9V Battery Slot

(Alkaline recommended)

Battery Contact,

Battery Cover

Snap In Tab

Note: Screw in tight.

Battery Contact, +

Battery Contact, +

Remote Control Transmitter

Transmitter Antenna

Switch Placement

Insert the switch onto the posts. Then,

secure by melting the plastic posts with

a soldering iron.

Switch

Posts

Back of

Bottom Frame

NOTE: Slide

the contacts into

the slots and then

fold back the tabs on

the top side to hold

in place.

Battery Contacts

+ ,

Red Wire

White Wire

Black Wire

-7-

Page 9

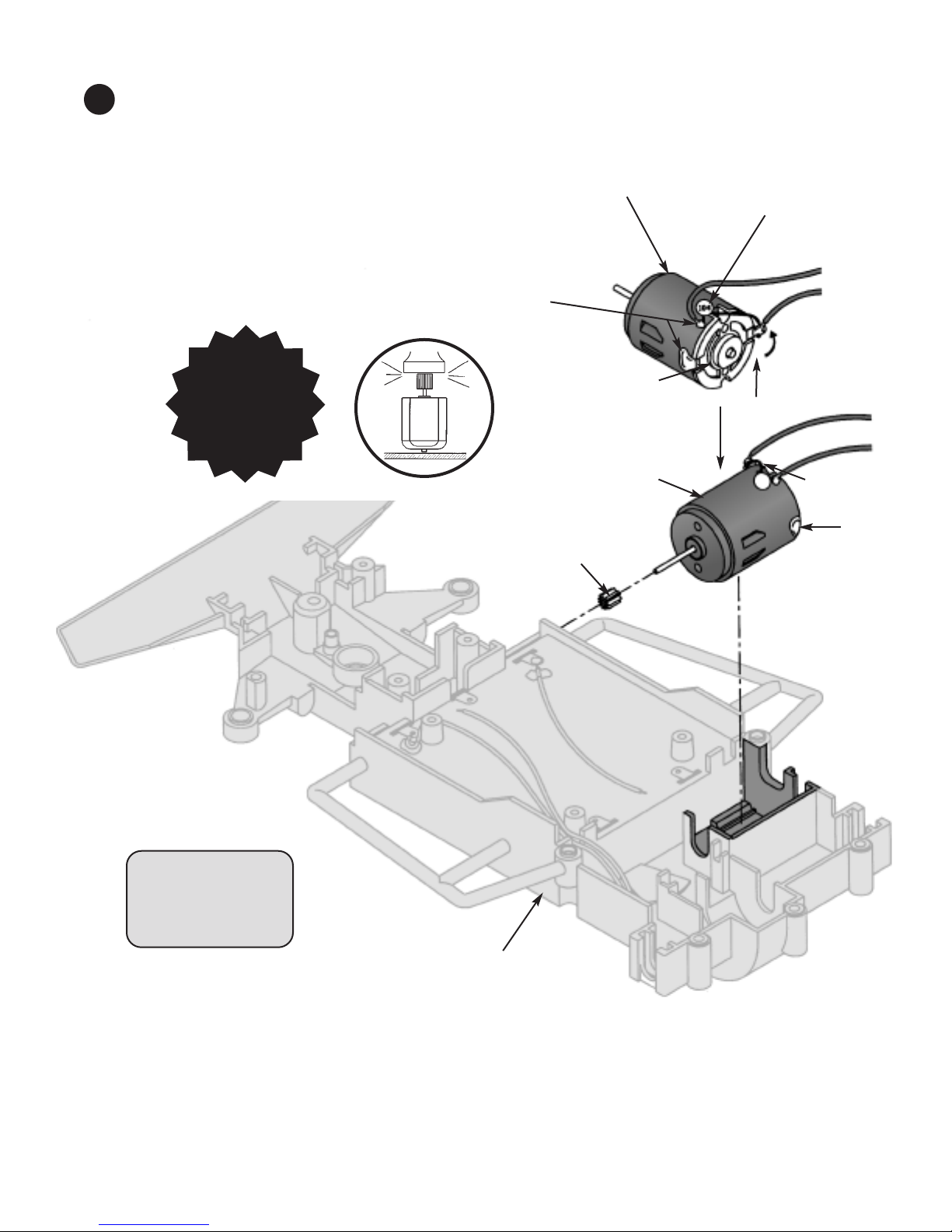

3

Driving Motor

(the larger motor; Yellow

wire goes to tab next to

Å marking in plastic)

0.1mF Capacitor

(marked 104):

Solder leads to motor

tabs, one lead is also

soldered to motor

shell.

You cannot get good connections

soldering to the motor shell unless

you first file or scrape away a

small area of the outer coating.

Green Wire

Yellow Wire

NOTE: If you

have a problem

putting the gear on

the shaft of the motor,

then gently tap the

gear on with a hard

object.

Side Tab:

bend tab back

180Oand solder

to motor shell

Driving Motor

Driving Motor

Gear

Å

Interior Tab:

Bend Tab 90O,

but don’t short

to motor shell.

Å

Interior Tab

Side

Ta b

Quick Test: Connect a

1.5V battery across the

motor wires with your

hands. The motor should

spin.

Bottom Frame

-8-

Page 10

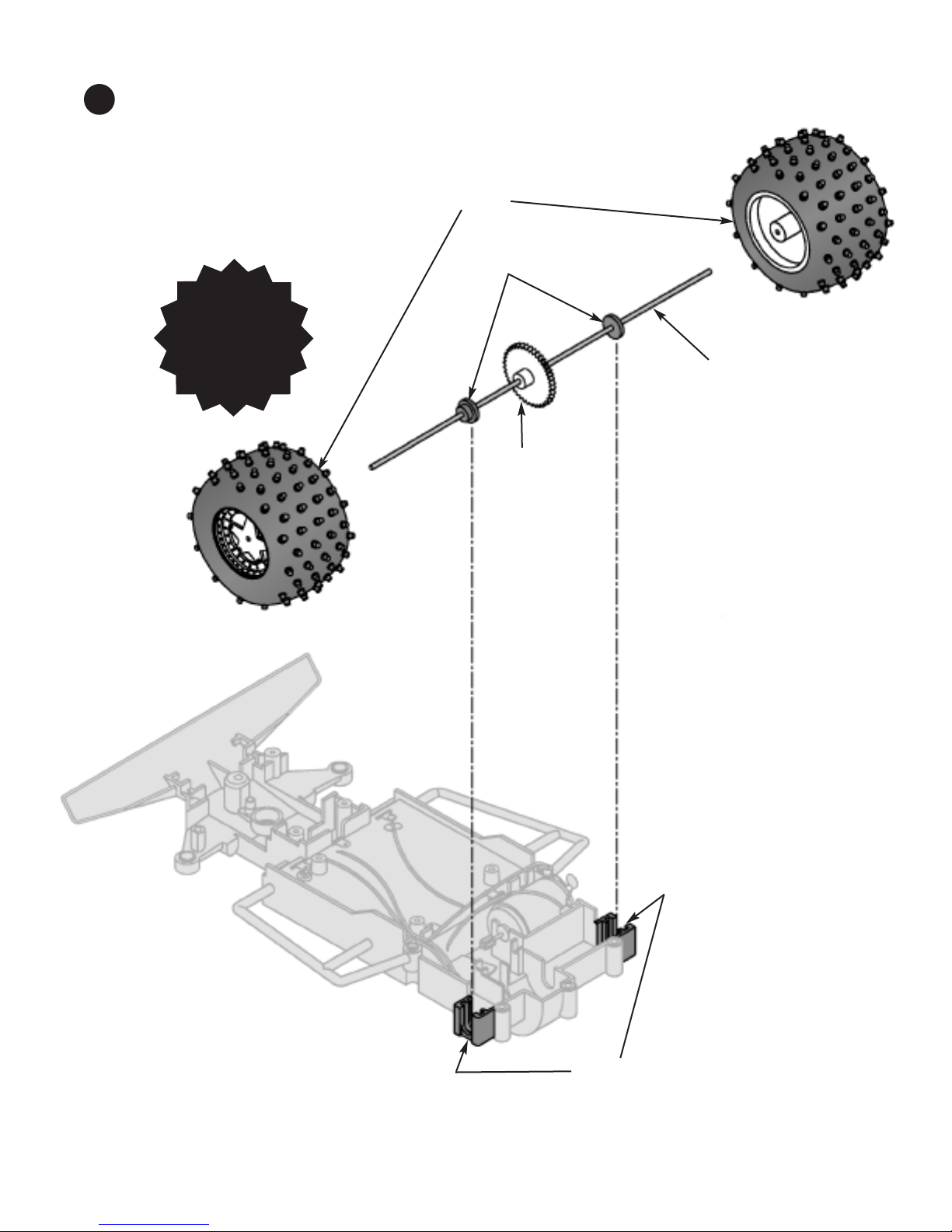

4

Rear Wheels

Locators

NOTE: The

next 3 steps will be

much easier if you

elevate the car about

1” using a small

object.

Gear for rear axle:

slide on until it is

firmly in the

“grips” on the axle

Rear Axle:

the “grip” near the

middle should be

toward the left

Locator Slots

-9-

Page 11

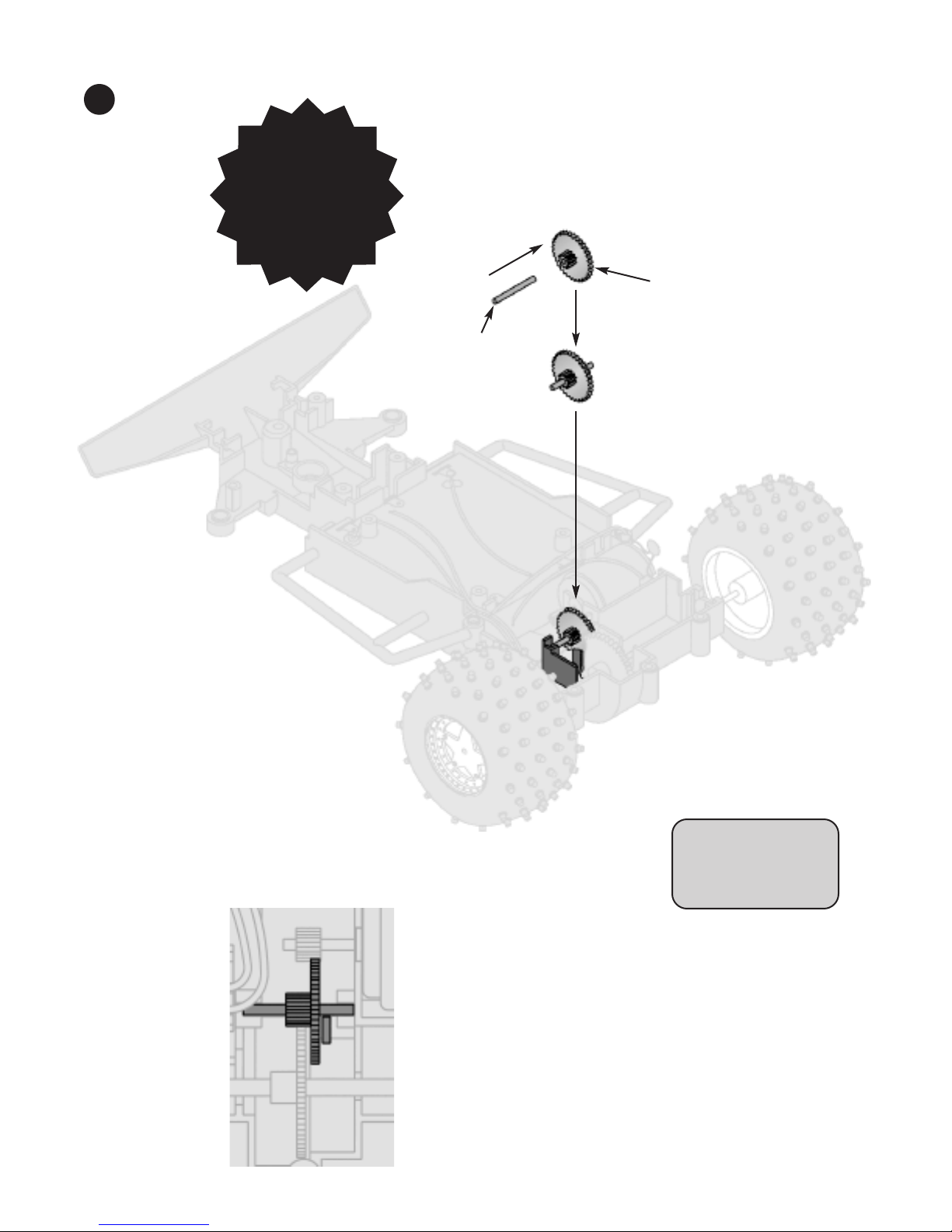

5

NOTE: Put some

Vaseline or grease into

the slots for the rod and

some on the teeth of all the

gears (motor gear, middle

gear, and the rear axle

gear). This will make the

car go faster.

Gear, Middle of rear section

Rear Rod

Quick Test: All 3 gears

should be lined up and

turning one of them by hand

should also turn the others.

Check the alignment of the

gears. The middle gear

must not be able to slide

out of alignment with the

other gears. Adjust the

positions of the gears on

the motor and rear axle if

necessary.

-10-

Page 12

Screw Used

6

(shown actual size)

X2

0.4” x 0.115”

0.4” x 0.115” Screws

Rear Section

Cover

Quick Test: Lift the wheels off the ground so they

may spin freely. Connect a 1.5V battery across the

motor wires with your hands, (+) terminal to green

wire. The wheels should spin forward slowly but

smoothly. Reverse the wires to the battery and the

wheels should spin backwards.

Note: Try to also press down on the forward part of

the rear cover while doing this, since the forward

screws for it have not been installed yet.

NOTE: Make

sure that the wires

from the ON/OFF switch

and the motor run out of

the rear section cover

through the slots (as

shown) without being

damaged.

-11-

Page 13

7

Spring for Steering

Centering

Bend wires to fit around post.

They must NOT be tight (or the

steering won’t work), stretch

the wire with your fingers to

loosen it if necessary.

Steering

Alignment

Adjustment

(triangular piece will

lean against this)

After inserting wire on it,

melt the top of this post

with a soldering iron to

keep the spring in place.

post is towards

front of car

front

of car

Steering Bar

Between the Wires

Wires

Turning Posts for

front wheels

Front

Wheel

Bars

Note direction

of post.

Front

Wheels

Hammer the

bars into the

wheels, but leave a

small space so that

the turning posts

may spin freely.

-12-

Page 14

Steering Motor

(the smaller motor; Blue

8

wire goes to tab next to

Å marking in plastic)

Solder leads to motor tabs, one lead is

also soldered to motor shell.

0.01mF Capacitor

(marked 103):

You cannot get good

connections soldering to

Orange Wire

the motor shell unless

you first file or scrape

away a small area of the

outer coating.

Å

Blue Wire

Screw Used

(shown actual size)

0.3” x 0.1”

NOTE: The

next 3 steps will be

much easier if you

elevate the car about

1” using a small

object.

Left Front Wheel

X2

0.3” x 0.1” Screws

Steering Motor

Gear

Side Tab:

bend tab back

180Oand solder

to motor shell

Quick Test: Connect a 1.5V

Å

battery across the motor wires

with your hands - the motor

should spin. Reverse the wires to

the battery and the motor should

spin in the opposite direction.

NOTE: If you

have a problem

putting the gear on

the shaft of the motor,

then gently tap the

gear on with a hard

Right Front Wheel

object.

NOTE: The gear

should lay on the

teeth of the steering

bar. Add some

Vaseline or grease to

the teeth.

Quick Test: Turning one

wheel by hand should also

turn the other wheel and

move the gear along the

steering bar.

-13-

Page 15

9

Front Spring

Front Wheel Shock Absorbers

Post

-14-

Page 16

10

0.3” x 0.1” Screws

Screw Used

(shown actual size)

X2

0.3” x 0.1”

Front Wheels Section Cover

Quick Test: Install 4 fresh AA alkaline batteries in

the battery cage, observing their polarity while

doing so. Lift the front wheels off the ground so they

may spin freely. Touch the steering motor wires to

the left-front and left-rear battery contacts with your

hands. The front wheels should turn to one side (as

the steering motor gear moves along the steering

bar). Reverse the wires to the batteries and the

wheels should turn in the opposite direction.

-15-

Page 17

11

ASSEMBLE THE FOLLOWING COMPONENTS TO THE PC BOARD

Review the soldering and parts identification instructions on p.5 at this time. In all of the following steps the

components must be installed on the top legend side of the PC board. The board is turned over to

solder the component leads.

L1 - 9 Turn Inductor (this part

has been pre-tuned, you do not

need to adjust it).

(see Figure A)

R13 - 1kW 5% 1/4W Res.

(brown-black-red-gold)

(see Figure B)

R14 - 1kW 5% 1/4W Res.

(brown-black-red-gold)

(see Figure B)

D2 - 3V Zener Diode

(see Figure C)

Note: “D1” (as marked on the

PC board) is not used. Place

the diode you were given (which

may be marked on your parts

card as D1) here.

Figure A

Figure B

Lay resistor flat against the

PC board.

Figure C

The marking on the board is

wrong for this part. Mount using

the 2 right holes, with the band

pointing towards the center hole.

This is shown here.

Band

this hole is not used

IC1 - 16-pin IC Socket

IC1 - AF2311 Integrated

Circuit (see Figure D)

Figure D

Align the notch on the socket (if any) with

the notch marked on the PC board. Solder

the socket to the PC board. Insert the IC

into the socket with the notch as shown.

Notch

-16-

Page 18

(see Figure E)

R21 - 560W 5% 1/4W Res.

(green-blue-brown-gold)

R10 - 2.7kW 5% 1/4W Res.

(red-violet-red-gold)

R4 - 3.3kW 5% 1/4W Res.

(orange-orange-red-gold)

R3 - 22kW 5% 1/4W Res.

R2 - 22kW 5% 1/4W Res.

(red-red-orange-gold)

R1 - 560W 5% 1/4W Res.

(green-blue-brown-gold)

R5 - 200W 5% 1/4W Res.

(red-black-brown-gold)

12

R3

Figure E

Stand resistor on end as shown with the

body inside the white circle (if a white

circle is present).

White

Circle

R6 - 3.9MW 5% 1/4W Res.

R7 - 3.9MW 5% 1/4W Res.

(orange-white-green-gold)

(see Figure E)

R11 - 68W 5% 1/4W Res.

(blue-gray-black-gold)

R18 - 100W 5% 1/4W Res.

R17 - 100W 5% 1/4W Res.

R12 - 100W 5% 1/4W Res.

(brown-black-brown-gold)

R15 - 1.5kW 5% 1/4W Res.

(brown-green-red-gold

R19 - 100W 5% 1/4W Res.

R20 - 100W 5% 1/4W Res.

(brown-black-brown-gold)

R16 - 1.5kW 5% 1/4W Res.

(brown-green-red-gold)

R9 - 200kW 5% 1/4W Res.

(red-black-yellow-gold)

R8 - 3.3kW 5% 1/4W Res.

(orange-orange-red-gold)

-17-

Page 19

(see Figure F)

C1 - 10pF (10) Capacitor

C10 - 0.01mF (103) Capacitor

C2 - 27pF (27) Capacitor

C3 - 27pF (27) Capacitor

C7 - 0.1mF (104) Capacitor

C8 - 500pF (501) Capacitor

C4 - 3,300pF (332) Capacitor

C9 - 0.01mF (103) Capacitor

C11 - 2,200pF (222) Capacitor

13

Figure F

Mount the ceramic or mylar

capacitor as shown below.

(see Figure G)

C6 - 220mF Lytic Capacitor

C12 - 220mF Lytic Capacitor

C13 - 220mF Lytic Capacitor

Figure G

Mount the

electrolytic

capacitor as

shown, noting the

polarity as

shown.

C5 - 4.7mF Lytic Capacitor

C14 - 220mF Lytic Capacitor

L2 - 8.2mH 10% Inductor

(gray-red-gold-silver)

Stand inductor on end as shown.

-18-

Page 20

14

(see Figure H)

Q5 - S8550 Transistor

Q6 - S8550 Transistor

Q8 - S8050 Transistor

Q2 - 9014 Transistor

Q3 - 9014 Transistor

Q7 - S8050 Transistor

Q14 - S8050 Transistor

Q12 - S8550 Transistor

Q9 - 9014 Transistor

Q10 - 9014 Transistor

Q13 - S8050 Transistor

Q11 - S8550 Transistor

Figure H

Mount the transistor with

the flat side in the same

direction marked on the

PC board.

1/8”

Q1 - C945 Transistor

Inspection:

Double check that you have installed all of your parts in

the proper places. Be sure they are not touching each

other and creating short circuits. Inspect all solder

connections and make sure none of them are weak. Use

a magnifying glass if you have one. Check all solder

connections for short circuits. Be thorough as it is much

easier to find and correct problems now rather than later.

-19-

Page 21

15

TRANSMITTER TESTING

If you have an oscilloscope then you may test the remote control

transmitter for basic operation. Set the scope for 1V/div vertical

scale and 1ms/div horizontal scale. Install a 9V battery in the

transmitter if you haven’t already done so. Connect your scope

probe to the transmitter antenna (leave the probe ground

unconnected), turn on the transmitter, and push the left transmitter

lever. You should see a stream of high-frequency bursts at least

1Vpp in amplitude, of either 0.6ms or 1.8ms duration, and

separated by 0.6ms. (This waveform is described in more detail in

the Theory of Operation section). You will not be able to get a clear

picture due to your lack of a good trigger for your scope - do not be

concerned. Most transmitter problems are due to connections

within the unit breaking loose during shipping, so this test is

primarily testing for the presence of a transmitted signal. Test the 6

transmitter functions: forward, forward-left, forward-right, backward,

backward-left, and backward-right (the 7th function is stop). Note

that on some models the steering lever only works if you are also

pressing the forward/backward lever. The burst patterns are slightly

different for each function, this is not of interest now but is described

in the theory of operation section. If your transmitter does not work

properly then refer to the troubleshooting section.

typical transmitted waveform (not to scale)

If you do not have an oscilloscope but do have a frequency counter, you can run the above test the same way

except instead of seeing a waveform on your scope your counter should measure a signal of 10 MHz to 50 MHz

(the actual frequency is 27.9 MHz but your counter may read differently due to the burst form of the signal).

-20-

Page 22

16

INTERCONNECTIONS & TESTING

VccWire

Solder the red wire from the ON/OFF switch

to this solder pad. BE CAREFUL TO AVOID

TOUCHING NEARBY PADS!

Red wire

from switch

Black wire from

battery contact

Ground Wire

Solder the black wire from the

battery contact to this solder

pad. BE CAREFUL TO AVOID

TOUCHING NEARBY PADS!

Resistance Tests

Remove one or all of the “AA” batteries from the car

for these tests.

Switch connections: Using a multimeter set to

ohms, measure from the front-left battery contact

(which has a wire to the ON/OFF switch) to

where you soldered the red wire (also from the

ON/OFF switch) to the printed circuit board

(PCB). This should be 0W when the ON/OFF

switch is ON and infinite when the switch is OFF.

to ground: Set the ON/OFF switch to ON.

V

cc

Measure from the front-left battery contact to the

front-right battery contact (which has the black

wire soldered to it). The resistance will initially be

<10kW but will slowly rise to around 45kW as the

capacitors in the circuit charge up.

If you don’t get these results then re-check your

work.

-21-

Page 23

17

Install 4 fresh AA alkaline (or re-chargeable nickelcadmium) batteries in the battery cage, observing their

polarity while doing so.

Snap in the battery cover to close it.

Battery Voltage: Using a multimeter set to DC volts,

measure between the front-left and front-right battery

contacts. You should measure about 6V.

Idle Current: Set the ON/OFF switch to OFF. Set your

multimeter to DC amps. Connect your probes between

the left-front battery tab and the red wire from

connection point 3 on the PCB. You should measure a

current of 18 mA ± 8 mA. Check your work if you don’t.

Battery Tests

Driving Voltage Tests

Set the switch to ON and your multimeter to DC volts.

Connect (-) probe to the front-right battery contact (DC

ground) for all these tests. Activate the transmitter for

forwards/backwards while measuring the voltage at pins

10 & 11 on the AF2311 IC.

Note: You may need to clip a wire from the antenna on the

remote control unit to the antenna solder pad (next to C1),

since the car’s antenna is not attached yet.

Pin 10 Pin 11

TX: forward 0 V 3.0 ± 0.5 V

TX: backward 3.0 ± 0.5 V 0 V

If you don’t get these voltages check your receiver and

AF2311 support circuitry. Refer to Theory of Operation as

needed.

Similarly, measure the voltages at the Q6-Q8 and Q5Q7 junctions while transmitting commands:

Q6-Q8 junction Q5-Q7 junction

TX: forward 0 V 6 ± 1 V

TX: backward 6 ± 1 V 0 V

If you don’t get these voltages check your driving circuit.

Q6-Q8 junction

Antenna solder pad

Q5-Q7 junction

-22-

Page 24

18

Activate the transmitter for left/right while measuring

the voltage at pins 6 & 7 on the AF2311 IC. (Note:

on some models the steering lever only works if you

are also pressing the forwards/backwards lever).

Notes:

You may need to touch the antenna on the remote

control unit to the antenna solder pad (next to C1), since

the car’s antenna is not attached yet.

The (-) voltage probe should be connected to DC ground

(the front-right battery contact) for all of these tests.

TX: left 3.0 ± 0.5 V 0 V

TX: right 0 V 3.0 ± 0.5 V

If you don’t get these voltages check your receiver and

AF2311 support circuitry.

Similarly, measure the voltages at the Q12-Q14 and

Q11-Q13 junctions while transmitting commands:

Steering Voltage Tests

pin 6 pin 7

Q12-Q14 junction

Antenna solder pad

Q11-Q13 junction

Q12-Q14 junction Q11-Q13 junction

TX: left 6 ± 1 V 0 V

TX: right 0 V 6 ± 1 V

If you don’t get these voltages check your steering

circuit.

Solder the blue wire from the steering motor to the

Q12-Q14 junction on the PCB. BE CAREFUL TO

AVOID ALSO TOUCHING NEARBY PADS.

Solder the orange wire from the steering motor to the

Q11-Q13 junction on the PCB. BE CAREFUL TO

AVOID ALSO TOUCHING NEARBY PADS.

Elevate the front of the car so that the front wheels

may turn freely. Activate the transmitter for left/right

and make sure the wheels turn properly.

Re-measure the voltages at PCB junctions Q12-Q14

and Q11-Q13 now that they are loaded by the

steering motor:

Q12-Q14 (loaded) Q11-Q13 (loaded)

TX: left 5 ± 1.5 V 0.3 ± 0.3 V

TX: right 0.3 ± 0.3 V 5 ± 1.5 V

Blue wire from

steering motor

Orange wire from

steering motor

If you don’t get these voltages or the front wheels don’t

turn then check your steering circuit. You should also redo the motor quick test in assembly step 10.

-23-

Page 25

19

Solder the yellow wire from the driving motor AND

one of the wires from the light bulb to the Q6-Q8

junction on the PCB. BE CAREFUL TO AVOID ALSO

TOUCHING NEARBY PADS..

Solder the green wire from the driving motor AND

the other wire from the light bulb to

junction on the PCB

TOUCHING NEARBY PADS.

Elevate the rear of the car so that the rear wheels may

spin freely. Make sure they won’t catch on any of your

wires. Activate the transmitter for forwards/backwards

and make sure the wheels spin properly. Note: Try to

also press down on the forward part of the rear cover

while doing this, since the forward screws for it have

not been installed yet.

Check that the light bulb is on whenever the rear

wheels spin.

Remeasure the voltages at the Q6-Q8 and Q5-Q7

junctions on the PCB now that they are loaded by the

driving motor:

Driving Motor Tests

.

BE CAREFUL TO AVOID ALSO

the Q5-Q7

Yellow wire from

driving motor

Light

Bulb

Green wire from

driving motor

Q6-Q8 (loaded) Q5-Q7 (loaded)

TX: forward 0.3 ± 0.3 V 5 ± 1.2 V

TX: backward 5 ± 1.2 V 0.3 ± 0.3 V

If you don’t get these voltages or the wheels don’t spin

properly then check your steering circuit. You should

also redo the motor quick test in assembly step 6.

Turn the ON/OFF switches to off.

-24-

Page 26

20

Top Frame

Light Bulb Cover

Light Bulb

NOTE: Tape

the light bulb wires

to the inside of the

top frame so that the

light bulb stays

above it.

0.4” x 0.1” Screw

Screw Used

(shown actual size)

X1

0.4” x 0.1”

-25-

Page 27

21

Receiver Alignment (recommended)

Although tunable inductor L1 has been pre-aligned, you may adjust it for optimum performance. You need

a very small screwdriver for this.

The Car Antenna must be screwed together with the PCB and bottom frame as shown below, to make

a good connection. Flip the ON/OFF switches to on. Activate the transmitter and move it away from the

car. (This is difficult to do by yourself unless you use a rubber band to keep the transmitter activated.)

Adjust tunable inductor L1 for best range. Be VERY GENTLE, since L1 is FRAGILE. It should turn

easily. If you apply too much force you may break it.

Turn the ON/OFF switches to off.

NOTE: Insert

the antenna

through the top

cover before

screwing it down.

NOTE: Orient

the PC board so

that L1 is on the

left side of the

car.

Car Antenna

Top Frame

0.3” x 0.1”

0.3” x 0.1”

Screws

Screws Used

(shown actual size)

X2 X3

0.4” x 0.115”

NOTE: Be careful

not to stress or break

any of the wires and

connections. You may

also want to tape the

wires down to keep

them inside the car.

0.4” x 0.115” Screw

0.4” x 0.115” Screws

-26-

Page 28

22

Ta b Ta b

Tabs

Rear Springs

Decorative Decals: Place these on now, using your RCC-7K box as a guide. Note that some models

23

may not use all of the stickers provided.

Steering Alignment: Your car is ready for use. If it does not go straight when you release the right

24

control lever, then adjust the steering alignment on the bottom front of the car until it works properly.

Front

Steering Alignment Adjustment

You have now completed the assembly of the RCC-7K Radio

Controlled Car. Refer to HOW TO USE IT on the next page. If the

car does not work, refer to TROUBLESHOOTING .

There are many other projects: Telephones, Cassette

Player, Talking Clocks, AM/FM Radio, etc. Ask your store about

these projects or call at (847) 541-3800.

-27-

Page 29

HOW TO USE IT

Place the car in a flat, open area, turn the ON/OFF switches in the car and Remote Control to ON, and extend

the antenna on the Remote Control.

The LEFT lever on the Remote Control:

Push forward (or forward-right) to make the RCC-7K go forward.

Push backward to make the RCC-7K go backward.

Push to center or let go to stop.

The RIGHT lever on the Remote Control:

Push left to make the RCC-7K turn left.

Push right to make the RCC-7K turn right.

Push to center or let go to go straight.

NOTE: On some models the steering (RIGHT lever) only works when forwards/backwards commands are

being sent, in which case you must also be pressing the LEFT lever.

The RCC-7K operates best on a wood or tile floor or in your driveway. Never operate the car in the street.

These suggestions will help make your car last for years of fun:

· Never drive your car in rain, snow, mud, sand, dirt, or on a wet floor, as damage may result.

· Do not drive your car on carpet since lint may damage the wheel mechanism.

THE FCC

The Federal Communications Commission (FCC) regulates use of the radio frequency spectrum in the United

States to prevent products from interfering with each other.

FCC regulations for your RCC-7K require you to accept any interference from authorized sources and that you

shut down if you are causing interference with other authorized products. Contact Elenco Electronics if you

need assistance.

You should never modify the electrical circuit components inside your Remote Control transmitter as this may

cause malfunctions or violate FCC regulations for this product.

-28-

Page 30

TROUBLESHOOTING GUIDE

Symptom: Car does not go in a straight line when you release the right control lever.

· Adjust the front wheels alignment control on the underside of the Bottom Frame, as you did in assembly

step 24.

Symptom: Car doesn’t work at all.

· Make sure that the batteries in both the car and the Remote Control Transmitter are strong and that they

are installed with the positive and negative terminals positioned properly. Alkaline or rechargeable nickelcadmium batteries are highly recommended, and new ones will last for 30-40 minutes of continuous use.

Do not mix old and new, and and different types of batteries.

· Make sure the ON/OFF switches on both car and transmitter are ON.

· Move the Transmitter antenna close to the car antenna to be sure your range is not degraded. If range is

degraded, see the symptom for reduced range (next).

· Be sure that none of the wiring connections were broken, are contacting any other metal (creating a short

circuit), or are wired wrong.

· Be sure that there is no soldering problems or “short circuits” on the Circuit Board. Use the schematic and

theory of operation section as guides.

· Test the Remote Control Transmitter as in assembly step 15.

Symptom: Car has reduced range.

· Make sure that the batteries in both the car and the Remote Control Transmitter are strong and that they

are installed with the positive and negative terminals positioned properly.

· Make sure your antenna is properly extended.

· Nearby CB and amateur radio transmitters can interfere with your control of the RCC-7K. Try moving away

from them.

· Re-tune inductor T1 as per the Receiver Alignment on page 26.

· Make sure the wire between the Circuit Board and the antenna in the car is intact and that the antenna

screw is tight. Try to verify that the antenna actually touches its metal pad on the circuit board.

· Be sure that there is no solder problems or “short circuits” on the Circuit Board. Use the schematic and

theory of operation section as guides.

Symptom: Car runs even though the Remote Control Transmitter is off.

· Disconnect the battery in your Transmitter to make sure it is not malfunctioning.

· Nearby CB and amateur radio transmitters are interfering with your control of the RCC-7K. Try moving away

from them.

Symptom: Transmitter fails the transmitter test.

· Check that the 9V battery is installed correctly and that your antenna is screwed in tight.

· Unscrew the 2 screws on the bottom of the unit nearest the battery, and snap off the top. Inspect the

transmitter circuit board for problems and broken wires, since most problems are due to connections

breaking loose during shipping. You may use the schematic and theory of operation section as guides.

Symptom: Front wheels do not turn or barely turn.

· Lift up the front section (to remove friction with the ground) and see if the wheels turn now.

· Turn one of the front wheels with your hand and be sure that the other wheel turns in the same direction

and that the Steering Motor Gear is moved along the Front Wheels Steering Bar smoothly.

· Be sure you are pressing both transmitter levers, as per the How To Use It section.

· Check the wiring to the Steering Motor and your assembly of the front section.

· Be sure that there is no soldering problems or short circuits on the Circuit Board. Redo the tests in section

18 Use the schematic and theory of operation section as guides.

-29-

Page 31

Symptom: Car does not go forwards/backwards or does so erratically.

· Be sure all the car batteries are strong and all your wires make strong connections.

· Make sure the wheels are all free of thread, lint, or hair and that the black rubber on the wheels is not

coming off.

· Spin the rear wheels with your hands. You should feel and hear the Middle and Motor gears spin smoothly,

if not check your assembly of the rear section. Add Vaseline or grease if necessary.

· Lift up the rear section (to remove friction with the ground) and disconnect the Driving Motor wires from the

Circuit Board. Reconnect the Motor wires across a 1.5V battery with your hands, the wheels should spin

smoothly. If nothing happens (the motor gear does not spin) then inspect your motor for problems.

· The Rear Wheels gear must be tight on its rod and the Middle Gear must NOT be tight on its rod.

· Retune inductor T1 as per the Receiver Alignment on page 26.

· Be sure that there is no soldering problems or short circuits on the Circuit Board. Redo the tests in section

19 Use the schematic and theory of operation section as guides.

If you need additional assistance or replacement parts, contact:

Elenco Electronics, Inc.

150 W. Carpenter Avenue http://www.elenco.com

Wheeling, IL 60090 e-mail: elenco@elenco.com

(847) 541-3800 Fax: (847) 520-0085

Say that you have version:

DO NOT contact your place of purchase as they will not be able to help you.

G

-30-

Page 32

SCHEMATICS AND BLOCK DIAGRAM

TRANSMITTER SCHEMATIC

RECEIVER SCHEMATIC

(2.0V)

SCREW

10pF

(1.1V)

L T2 X Y PC V

R T1 VSS B F TB ENC

(3.0V)

DD EC

(1.8V)

(3.1V)

DRIVING CIRCUIT

(6V)

GREEN

YELLOW

(1.1V)

(0.8V)

(0.25V)

(0.25V)

(1.8V)

V3 V2 V1 V

V4 VSS DI X Y R L RX_

(1.7V)

(1.7V)

RECEIVER CIRCUIT

(VOLTAGES ARE FOR DC IN IDLE MODE)

DD TB F B LX_

(1.7V)

RED

BLUE

ORANGE

BLACK

STEERING CIRCUIT

-31-

Page 33

27.9 MHz

Signal

BLOCK DIAGRAM

HOW IT WORKS

L

R

F

B

Encoding

Circuitry

Pulse Sequence,

length depends on

which command is

being sent

ON/OFF

Driving

Motor

YELLOW

GREEN

Filter/

Amplifier

Sequence

of Radio

Frequency

Pulses

PCB WIRING PLAN

Light

Bulb

Filter/

Amplifier

Decoding

Driving Motor

Circuitry

Steering Motor

Pulse Sequence,

length depends on

which command

was sent

BLUE

Steering

Motor

RED

BLACK

AF2310 PIN DESCRIPTION

# NAME DESCRIPTION

1 R RIGHT STEERING FUNCTION

2 T1 TEST USE ONLY

3 VSS NEGATIVE POWER SUPPLY

4 B BACKWARD FUNCTION

5 F FORWARD FUNCTION

6 TB DO NOT USE

7 ENC ENCODING SIGNAL (NO CARRIER)

8 EC ENCODING SIGNAL (WITH CARRIER)

9 VDD POSITIVE POWER SUPPLY

10 PC POWER CONTROL OUTPUT

11 Y OSCILLATOR OUTPUT

12 X OSCILLATOR INPUT

13 T2 TEST USE ONLY

14 L LEFT STEERING FUNCTION

ORANGE

AF2311 PIN DESCRIPTION

# NAME DESCRIPTION

1 V4 INVERTER 2 OUTPUT FOR AMPLIFIER

2 VSS NEGATIVE POWER SUPPLY

3 DI INPUT PIN OF THE DECODING SIGNAL

4 X OSCILLATOR INPUT

5 Y OSCILLATOR OUTPUT

6 R RIGHT STEERING OUTPUT

7 L LEFT STEERING OUTPUT

8 RX_ RIGHT DISABLE (NOT USED)

9 LX_ LEFT DISABLE (NOT USED)

10 B BACKWARD OUTPUT

11 F FORWARD OUTPUT

12 TB DO NOT USE

13 VDD POSITIVE POWER SUPPLY

14 V1 INVERTER 1 INPUT FOR AMPLIFIER

15 V2 INVERTER 1 OUTPUT FOR AMPLIFIER

16 V3 INVERTER 2 INPUT FOR AMPLIFIER

-32-

Page 34

QUIZ

1. The antenna in the Remote Control Transmitter converts electrical energy into . . . . .

A - radio energy.

B - mechanical energy.

C - geothermal energy.

D - nuclear energy.

2. The commands to be sent from the Remote Control Transmitter are encoded onto a sequence of electrical pulses by

changing . . . . .

A - the spacing between the pulses.

B - the duty cycle of the pulses.

C - the number of pulses in the sequence.

D - the amplitude of the pulses.

3. On some models the Remote Control Transmitter only sends Left/Right commands if Forwards/Backwards commands

are also being sent because . . . . .

A - The left/right lever is not electrically connected to anything.

B - Otherwise the transmitted signal would be too weak to be picked up by the car.

C - Otherwise the transmitter would interfere with your TV reception.

D - there is to much friction to turn the front wheels unless the car is moving.

4. If there is an obstacle between the Transmitter and the car then radio energy can travel to the car by going . . . . .

A - through the obstacle.

B - around the obstacle.

C - both A and B.

D - not possible, the obstacle blocks radio reception completely.

5. If the batteries in the RCC-7K are weak, the main effects you will notice are . . . . .

A - reduced remote control range and reduced power to the motor.

B - the light bulb blinks to tell you to change the batteries.

C - interference with your TV set.

D - the car goes faster.

6. The first stage of the receiver is basically a . . . . .

A - speaker.

B - integrated circuit.

C - power supply.

D - filter.

7. Using less synchronization pulses or less pulses to represent each of the transmitter commands makes . . . . .

A - it take longer to transmit each command.

B - the transmitter battery last a lot longer.

C - the car more likely to activate on random noise.

D - the car go faster.

8. Reversing the voltage to the steering motor will cause . . . . .

A - the motor to explode.

B - the motor and the car to turn in the opposite direction.

C - the motor to spin faster.

D - the motor to stop spinning.

9. Interlocking gears . . . . .

A - spin in the same direction.

B - serve no useful purpose.

C - jam together and prevent each other from spinning.

D - spin in opposite directions.

10. To spin the rear wheels once, the driving motor must spin . . . . .

A - 100 times.

B - 20 times.

C - 9 times.

D - 4 times.

Answers: 1. A, 2. C, 3. D, 4. C, 5. A, 6. D, 7. C, 8. B, 9. D, 10. B

-33-

Page 35

Here are some other exciting projects from Elenco you can build.

EDUCATIONAL KITS

Motion Detector Kit with training course

Model AK-510

Simple and fun to build, compact, portable and adds safety to

your home or office. Learn the basics of motion detector

technology while building this motion detector kit that uses a

pyroelectric infrared sensor. Comes complete with all parts,

PC board, case, schematic and extensive training manual.

Requires one (1) 9V battery.

Strobe Light Kit

Model AK-520

Stereo Cassette Player Kit

Model AK-200

Easy-to-build kit teaches you basic mechanical and

electronic circuits. You will have fun building this kit and

learning how a tape player works. Lesson manual teaches

magnetic recording, audio amplifier theory, speed control,

mechanical switching and much more. Comes complete

with all parts including Stereo Headphones. Clear plastic

case allows you to show you friends your accomplishments.

Requires two (2) “AA” batteries.

Pulse/Tone Telephone Kit

Model AK-700

This deluxe strobe light makes learning fun and easy. You will

have fun building this kit and learn how strobe lights work.

Comes complete with all components and lesson manual. Kit

uses high energy xenon flash tube. Learn about transistors,

oscillators, step-up transformers, trigger circuits, flash tubes,

and more! Easy-to-follow instructions include lesson manual

and self-test. Requires two (2) “C” size batteries.

Build your own working pulse/tone telephone with last

number redial and ringer on/off switch. See the neon nights

flash through the transparent case when the phone rings!

This FCC approved telephone is also fully modular and

desk/wall mountable.

Detailed assembly manual included.

-34-

Page 36

Elenco Electronics, Inc.

150 W. Carpenter Avenue

Wheeling, IL 60090

(847) 541-3800

http://www.elenco.com

e-mail: elenco@elenco.com

Loading...

Loading...