Page 1

From the Makers of

TTC-895

10 +

ASSEMBLY & INSTRUCTION MANUAL

Page 2

Content

Introduction

Tools You May Need

Mechanical Parts List

Plastic Parts

Before Assembly

Head Module Assembly

Gear Box Module Assembly

Rear Gear Box Testing (1)

Rear Gear Box Testing (2)

Accessory Module Assembly

Coding Wheel Assembly

About the Coding Wheel

How to Install Coding Buttons

............................................................................................................

.................................................................................................

................................................................................................

...........................................................................................................

......................................................................................................

..............................................................................................

........................................................................................

..........................................................................................

..........................................................................................

.......................................................................................

............................................................................................

............................................................................................

......................................................................................

How to Install the Coding Wheel

...................................................................................

1

1

1

2

3

4

5

7

9

13

13

14

14

15

How the Coding Buttons Work

Drawing-bot Assembly

Drawing-bot

............................................................................................................

Forklift-bot Assembly

Forklift-bot

..............................................................................................................

Throwing-bot Assembly

Throwing-bot

..........................................................................................................

Gripper-bot Assembly

Gripper-bot

............................................................................................................

Soccer-bot Assembly

Soccer-bot

.............................................................................................................

...............................................................................................

.................................................................................................

..............................................................................................

................................................................................................

................................................................................................

How to Replace the Batteries

Trouble Shooting

.....................................................................................................

.....................................................................................

......................................................................................

18

21

23

24

26

27

29

30

32

33

35

36

37

Page 3

Introduction

The mechanical coding wheel is the heart of the Mech.5 Mechanical Coding Robot. It steers its coded courses and

programmed tasks. Coding is executed effortlessly by snapping the coding buttons onto the coding wheel directing

your robot to perform its basic functions – move forward, backward, right or left, spin or pause. Thanks to this simple

to follow approach, coding and performing more challenging tasks like throwing, lifting, kicking or drawing, become

achievable as the user’s coding skills increase.

This mission-based, entry level STEM coding robot is designed to inspire users to learn about mechanical

engineering principles and coding basics. It encourages children to think while also developing their

problem-solving and troubleshooting skills when faced with different tasks and difficulties. Engage in the coding

world and beyond by challenging yourself with your very first coding robot.

Tools You May Need

Diagonal Cutter

Screwdriver

Battery(AAA) x 2

Alkaline batteries

are recommended

Ruler

Marker (Fine) Safety Glasses

Mechanical Parts List

• Important: If any parts are missing or damage, DO NOT RETURN TO THE

RETAILER. E-mail us at support@elenco.com or call (800) 533-2441

• Product contains functional edges and sharp points.

P1 P2 P3 P4

P5 P7 P8

Pinion Gear (White) Gear 36/10T (Black) Gear 36/10T (Yellow) Gear 36T (Orange)

QTY

1

Gear 10T (Black) Shaft Tapping Screw Spring (Small)

QTY

P6

QTY1QTY

1

QTY2QTY

QTY

2

QTY

QTY

1

QTY

1

P9 P10 P11

Spring (Big) Steel Ball

QTY

2

P12 P13

DC 3V

Battery Holder with Connector

2

QTY

1:1

QTY

1

1

1

15

Sponge

Motor with PC Board

2

QTY

2

QTY

1

Page 4

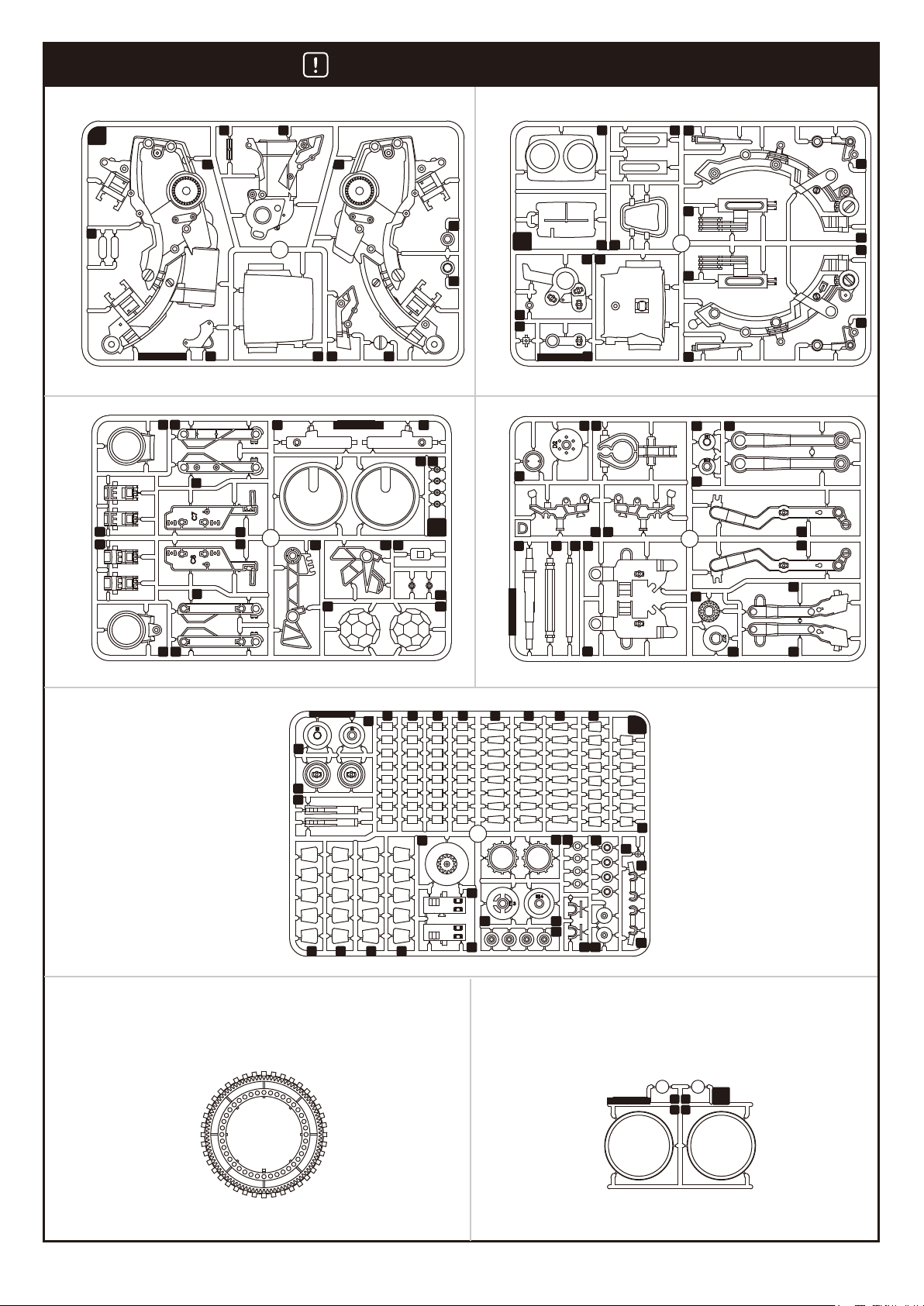

Plastic Parts

Cut off the plastic parts when they are required. Do not cut them in advance.

A

1

3

2

4

5

6

A B

7

C

MADE IN TAIWAN

1

2

3

8

5

6

7

8

11

15 16 17

9 10 11

MADE IN TAIWAN

12

13 14

C

D

B

7

8

MADE IN TAIWAN

1

6 7 8 9

2

5 6

9

3

4 5

1

3

4

2

10

11

12

14

15

13

16

10

11

13

12

14

15

9

4

10

MADE IN TAIWAN

1

3

4

19

5 5 5 5

2

E

18

20

9

8888

MADE IN TAIWAN

6 6 6 7

10

13

11

12 16

14

15

10

19 20

16

E

17

7

18

21

22

18

1917

F G

G

MADE IN TAIWAN

1 1

2 2

2

Page 5

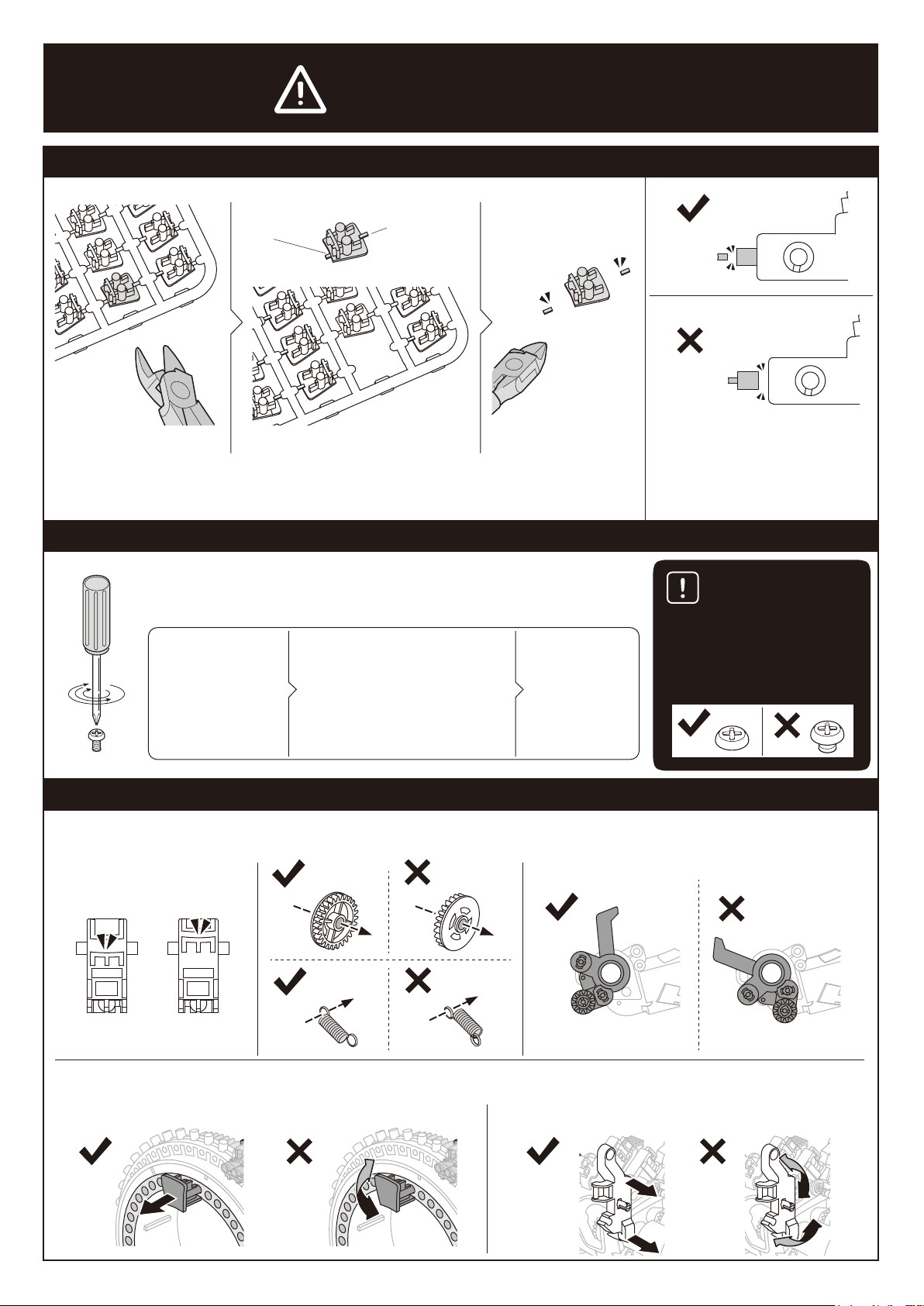

Please Read Before Assembly

Remove burrs

Unnecessary

burrs

Unnecessary

burrs

Some burrs are left at the edge of plastic parts after cutting them off.

Make sure the burrs are completely removed to avoid operation malfunction.

Fasten tapping screws

Use corresponding (size-compatible) screwdriver. By following steps

below, you can fasten the tapping screws perfectly.

Put the screwdriver

towards the top of

screws.

(1) Screw in

(2) Feel the tension getting higher

(3) Keep screwing

Repeat until

screws are

tightly fastened.

Correct

Incorrect

Trim off the burrs ONLY. Do not

trim off the protrusion of the original

plastic parts. All features of parts

should be kept completely.

Please lock screws all the way

down to the bottom. If they are not

fastened tightly enough, parts may

come off. The robot may

consequently not work.

Correct

Incorrect

Shape, assembly direction, and position of parts

Some parts may look quite similar. They should be assembled in the designated direction and position shown in manual.

Correct

Correct

Coding buttons can be removed for new programming. Remove them straight up off the coding wheel. Do not torque them to

avoid damage.

Correct Correct

Incorrect Incorrect

Incorrect

Incorrect

Correct

Incorrect

3

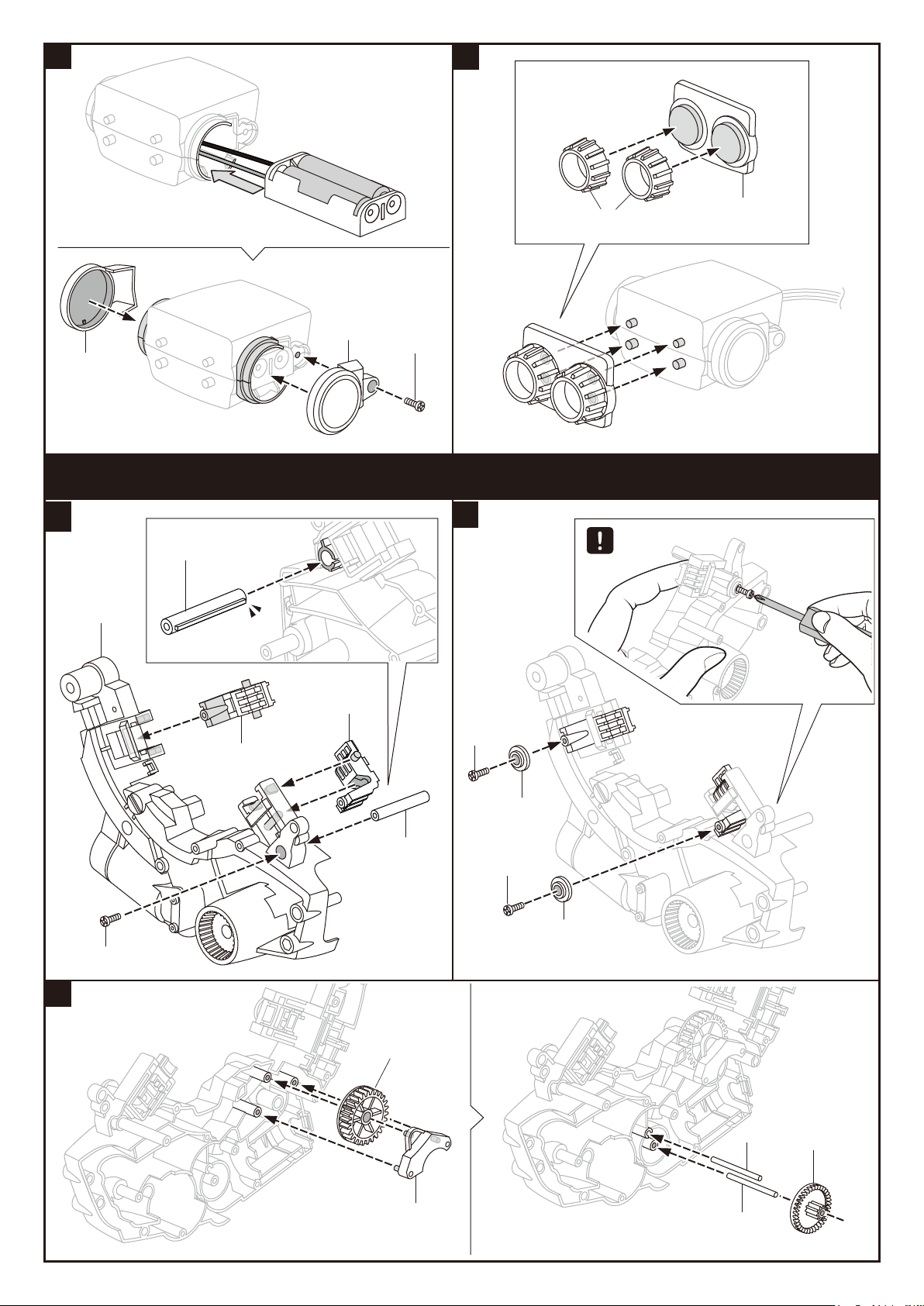

Page 6

Head Module Assembly

1

• Installation, removal and replacement of batteries

should be carried out by an adult or under adult

supervision.

• Avoid short circuiting the contacts in the battery

compartment or the battery terminals.

• Do not mix used batteries and new batteries or

batteries of different types.

• Do not mix alkaline, standard (carbon-zinc) , or

rechargeable (nickel-cadmium) batteries.

• Batteries are to be inserted with the correct polarity.

• Do not attempt to recharge non-rechargeable

batteries.

• Remove exhausted batteries from the product to

avoid leakage.

P12

AAA(x2)

Insert “–” on battery first

Making a mark

B6

Mark

2.36” (6 cm)

1 2 3 4 5 6 7 8 9 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 3010

cm

Marker Pen (Fine)

Blue

Scale 1:1

Orange

B6

2

A9

B3

B8

P7

4

Page 7

3

4

E12

C4

P7

C1

B1

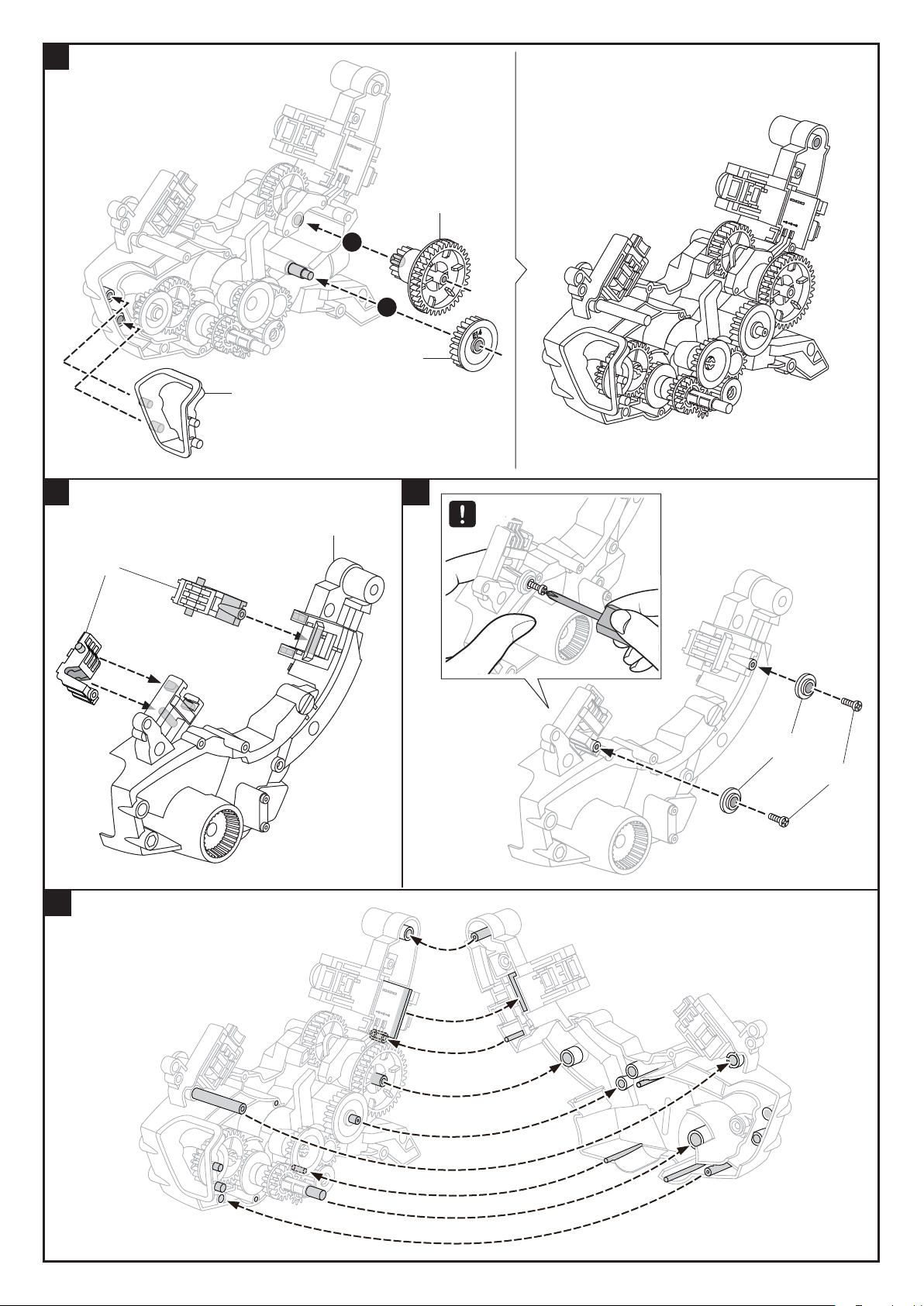

Gear Box Module Assembly

1

E18

A2

2

Tip

C3

P7

C3

E15

E18

P7

E15

P7

3

D2

P6

P2 (Black)

A8

P6

5

Page 8

4

Correct

6

A4

P10

P1

P13

Incorrect

C17

P7

A10

7

B7

2

3

B5

D12

1

Correct

Correct

Incorrect

Incorrect

5

P4 (Orange)

P5 (Black)

Incorrect

8

P3 (Yellow)

P3 (Yellow)

1

2

3

P5 (Black)

P4 (Orange)

P3 (Yellow)

P3 (Yellow)

P7

P2 (Black)

6

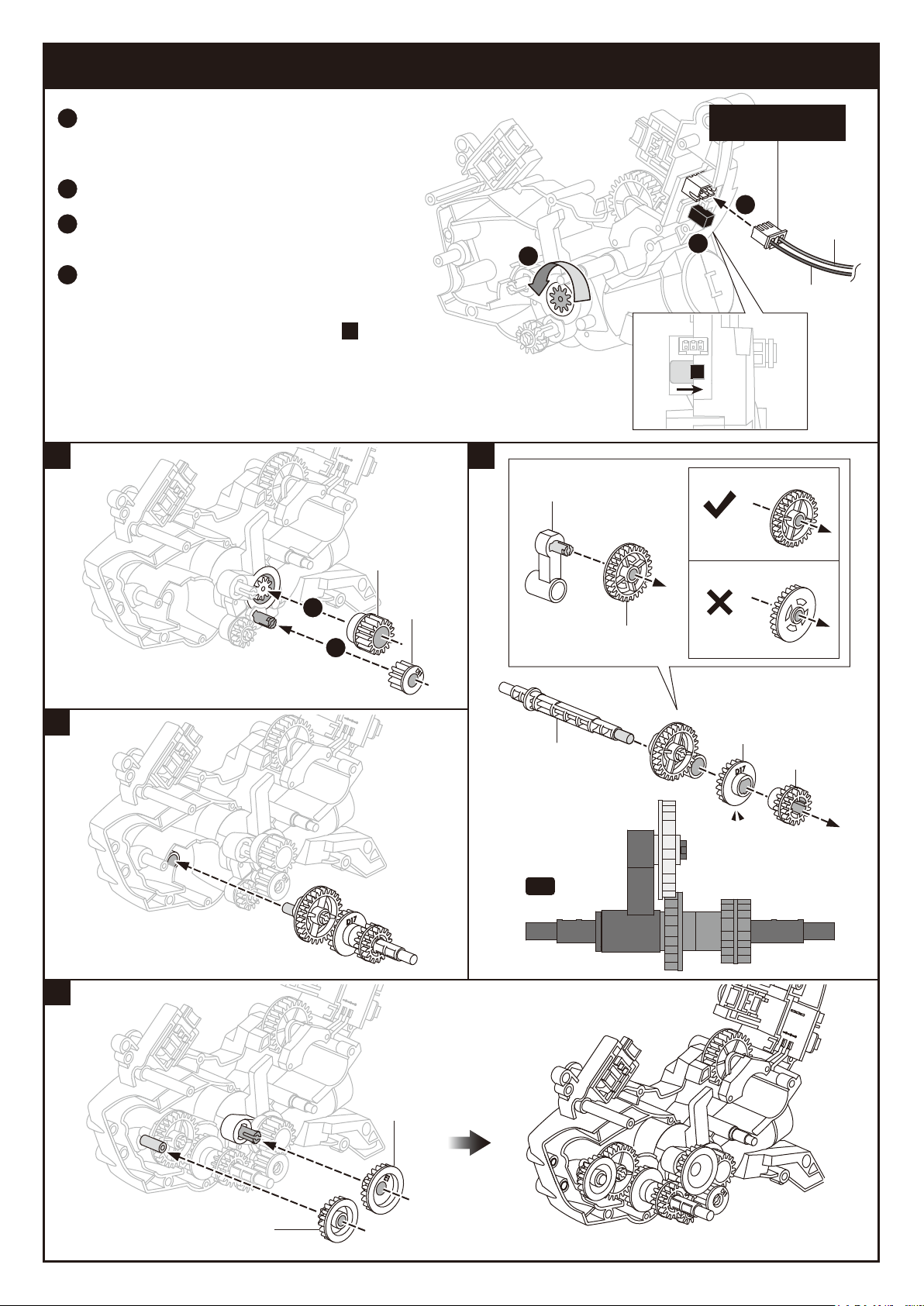

Page 9

Rear Gear Box Testing (1)

Connect the power supply cable of assembled

1

head (Refer to page 4: Head Module Assembly)

to the terminal base.

Move the switch to the right to turn the power on.

2

The gear will run counterclockwise as

3

illustration.

4

Switch off and remove the power supply

cable after the testing. If the gear box

doesn’t run smoothly or there is abnormal

noise, please go back to page 5 step to

reassemble.

9

Head Module

Power Supply Cable

1

Orange

2

3

Blue

1

10

B9

Correct

D1

11

12

1

2

D11

1:1

D6

E13

Incorrect

D17

D16

E2

E1

7

Page 10

13

1

2

E14

B4

14 15

A5

E9

TipTip

16

C2

E15

P7

8

Page 11

17

P7

P7

Rear Gear Box Testing (2)

Connect the power supply cable of assembled head

1

(refer to page 4: Head Module Assembly) to the terminal base.

2

Move the switch to the right to turn the power on.

3

The gear will run counterclockwise as illustration.

Switch off and remove the power supply cable after the testing.

4

If the gear box doesn’t run smoothly or there is abnormal

noise, please go back to page 5 step to reassemble.

1

Head Module

Power Supply Cable

18

P7

3

2

Correct

1

Orange

Blue

B11

C18

P8

Incorrect

19

C14

B13

B2

A6

A1

G1

9

Page 12

20

B16

C18

P8

21

Correct

B12

Incorrect

C14

B2

A7

22

G1

A1

C13

G2

x2

10

Page 13

23

B14

B15

24

P7x3

25

E22

1

2

E21

1

2

11

Page 14

30 32

A11

31

Correct

Incorrect

33

Completed

2

1

12

Page 15

Accessory Module Assembly

MODULE

1

C7

P11

MODULE

2

P11

C8

MODULE

3

E16

P9

E17

MODULE

4

x2

Coding Wheel Assembly

A3

C19

C20

F

13

Page 16

About the Coding Wheel

CODING WHEEL

Correct

Assignment

coding track

Incorrect

Backward

coding track

Start point

Left

coding track

(Right coding track is on the other side)

How to Install Coding Buttons

Assignment

coding button

(Only for forklift)

E4

Correct

Correct

Correct

Incorrect

Incorrect

Assignment

coding button

E7

Backward

coding button

E8

E5

angle coding button

90 degree

Incorrect

E6

45 degree

angle coding button

Correct

Incorrect

Correct

14

Incorrect

Correct

Incorrect

Page 17

1

Unlock Coding Wheel Clips

How to Install the Coding Wheel

Top View

Push the four

clips as shown

PUSH

PUSH

2

PUSH

PUSHPUSH

PUSH

PUSHPUSH PUSHPUSH

PUSHPUSH

PUSHPUSH

1

1. Rotate clips outward to unlock.

2

2. Tilt shaded section forward.

2

1

1

1

15

Page 18

3

Correct

Coding Wheel Coding Wheel

Incorrect

Set the “Start Point” to

Home Postion

Correct

Incorrect

16

Page 19

4

Pull the four clips outward to secure

coding wheel.

PULL

PULL

PULL

Front View

PULL PULL

PULL

PULL PULL

5 6

1

E21

2

2

E22

17

Page 20

E6

How the Coding Buttons Work

45° Right Turn 90° Right Turn

E8

Right Coding TrackRight Track

45° Left Turn 90° Left Turn

E6

Left Coding TrackLeft Coding Track

E8

18

Page 21

45° Back Right Turn 90° Back Right Turn

Space

Backward Track

E7x2

E6

Right Coding Track

Backward Track

Right Coding Track

E8

E7x3

45° Back Left Turn

Backward Track

E6

Left Coding Track Left Coding Track

90° Back Left Turn

Backward Track

E7x2

Space

E8

E7x3

19

Page 22

Page 23

Drawing-bot AssemblyDrawing-bot Assembly

1

D10

D9

2 3

D3

C15

E19

D7

21

Page 24

4

Marker Pen (Fine)

E19

Scale 1:1

3.75” (9.5 cm)

3.75” (9.5 cm)

Video Tips

To better understand the assembly and operations of each project,

view the sample video listed in Video Tips on the project page.

22

Page 25

Drawing-bot

Parts Required:

Video Tips

View a video on this project at https://www.elenco.com/teachtech/

CODING

CODING WHEEL

Left side

E8

5 pcs

E5x10

Insert the Coding buttons as shown.

Note the position and sequence on both sides of the coding

Start point

E8x5

E5

10 pcs

CODING WHEEL

Right side

Start point

First test the program with the pen cap on. Place the unit on a 2.5’ x 2.5’ piece of paper. Turn the Draw-BOT on,

it moves forward then draws a 13’ diameter circle. Note: Turn the unit off before it repeats the program. Now,

remove the pen cap and run the program again. Using the coding buttons create your own program.

1. If it does not follow the coding program correctly, please go back to page 21 step 2

Trouble Shooting

to check if parts D3 and C15 are assembled in the right way.

2. Check the coding buttons and wheel installation.

3. See page 37

23

Page 26

Forklift-bot Assembly

Forklift-bot Assembly

1

D10

D9

D18

E3

2

E19

D7

E3

D19

3

E19

C16

1

2

24

Page 27

4

C12

MODULE

1

C 11

MODULE

2

E10

E11

B10

B10

5

C10

C6

C9

C5

25

Page 28

Forklift-bot

Parts Required:

E4x2 E5x6 E6x5 E7x6 E8x11

Insert the E8 and E5 buttons as shown.

CODING

Note the position the sequence on both sides of the coding wheel.

CODING

Insert the coding buttons as shown.

Note the position the sequence on both sides of the coding wheel.

View a video on this project at https://www.elenco.com/teachtech/

Video Tips

CODING WHEEL

Left side

E8

6 pcs

E6

2 pcs

E7

6 pcs

E5

6 pcs

E8

5 pcs

E4

CODING WHEEL

Right side

2 pcs

E6

3 pcs

Anytime when you want to add “lifting” to your current coding program,

install mission buttons as illustrated below to enable the movement.

Correct

Incorrect

Trouble Shooting

1. Check the coding buttons and wheel installation, refer to pages 14-15

2. See page 37

26

Page 29

Throwing-bot AssemblyThrowing-bot Assembly

1

E11

C6

C5

C10

C11

E10

C9

Tip : disassemble assembly

as shown below

2

MODULE

Refer to page 12

C12

D15

MODULE

3

3

D14

27

D8

MODULE

3

Page 30

3

2

D7

E19

1

C15

4

4

D13

D13

E20

3

E20

3

2

1

2

E19

28

Page 31

Throwing-bot

Parts Required:

Video Tips

View a video on this project at https://www.elenco.com/teachtech/

CODING

CODING WHEEL

Left side

E8

4 pcs

E5x2 E6x3

E8x10

Insert the coding buttons as shown.

Note the position the sequence on both sides of the coding wheel.

E6

2 pcs

E6

1 pc

E5

2 pcs

CODING WHEEL

Right side

E8

6 pcs

Trouble Shooting

MODULE

4

For safety concern, users should not use any dangerous

materials as throwing object, such as steel balls or sharp items.

1. If it does not follow the coding program correctly, please go back to page 17

step 5 to check if parts E21 and E22 are assembled in the right way.

2. Check the coding buttons and wheel installation

3. See page 37

29

Page 32

Gripper-bot AssemblyGripper-bot Assembly

1

1

D10

D9

E3

D18

E3

D19

2

C5

MODULE

1

D4

C6

MODULE

2

C9

D5

C10

30

Page 33

3

E19

D7

4

MODULE

3

5

C16

6

7

31

E19

Page 34

Gripper-BOT

Parts Required:

CODING

Video Tips

View a video on this project at https://www.elenco.com/teachtech/

E5x9 E6x2 E7x6 E8x9

Insert the coding buttons as shown.

Note the position the sequence on both sides of the coding wheel.

CODING WHEEL

Left side

E8

4 pcs

E7

6 pcs

E6

1 pc

E5

9 pcs

E6

1 pc

CODING WHEEL

Right side

E8

5 pcs

Trouble Shooting

1. If it does not follow the coding program correctly, please go back to page 31

step 5 to check if part C16 is assembled in the right way.

2. Check the coding buttons and wheel installation, refer to pages 13-15

3. See page 37

32

Page 35

Soccer-bot AssemblySoccer-bot Assembly

1

1

MODULE

3

MODULE

3

2

E20

D4

D3

D5

E20

Gear Box

2

D10

D9

33

Page 36

3

4

C16

5

E19

D7

6

E19

C10

D18

C 11

C12

D19

C9

34

Page 37

Soccer-bot

Parts Required:

Video Tips

View a video on this project at https://www.elenco.com/teachtech/

CODING

CODING WHEEL

Left side

E8

2 pcs

E5x4

Insert the coding buttons as shown.

Note the position the sequence on both sides of the coding wheel.

E8x5

E5

4 pcs

CODING WHEEL

Right side

E8

3 pcs

Trouble Shooting

MODULE

4

1. If it does not follow the coding program correctly, please go back to page 34

step 4 to check if part C16 is assembled in the right way.

2. Check the coding buttons and wheel installation, refer to pages 13-15

3. See page 37

35

Page 38

How to Replace the Batteries

1

REMOVE

2

3

REMOVE

Battery( AAA) x 2

Insert “–” on battery first

Removal and replacement of batteries should be carried out by

adults or under adult supervision.

Avoid short circuiting the contacts in the battery compartment or

the battery terminals.

Do not mix used batteries and new batteries or batteries of different

types.

Do not mix alkaline, standard (carbon-zinc) , or rechargeable

(nickel-cadmium) batteries.

Batteries are to be inserted with the correct polarity.

Do not attempt to recharge non-rechargeable batteries.

Remove exhausted batteries from the product to avoid leakage.

36

Page 39

Trouble Shooting

1. Ensure all coding buttons are assembled correctly (refer to page 14).

2. Ensure the coding wheel is assembled correctly (refer to pages 15–17, steps – ).

1 6

3. If the robot does not move smoothly or appropriately when turning right/left or stopping,

18

please go back to pages 9–10 and ensure steps – are correctly executed.

21

4. If the robot does not move smoothly or appropriately when going backward, please go

back to page 6 step to check if parts B5, B7, and D12 are assembled in the right way.

7

5. If the Drawing-bot does not follow the coding program correctly, please go back to page

21 step to check if parts D3 and C15 are assembled in the right way.

2

6. If the Forklift-bot does not follow the coding program correctly, please go back to page 26

to check if part E5 is assembled in the right way.

7. If the Throwing-bot does not follow the coding program correctly, please go back to

page 17 step to check if parts E21 and E22 are assembled in the right way.

5

8. If the Gripper-bot does not follow the coding program correctly, please go back to page 31

5

step to check if part C16 is assembled in the right way.

9. If the Soccer-bot does not follow the coding program correctly, please go back to page 34

4

step to check if part C16 is assembled in the right way.

37

Page 40

150 Carpenter Ave.

Wheeling, IL 60090, USA

(847) 541-3800 or (800) 533-2441

elenco.com

CHOKING HAZARD. Small Parts.

Not for children under 3 years old.

No part of this book shall be reproduced by any means: electronic, photocopying,

or otherwise without written permission from the publisher.

Printed in Taiwan

Patents Pending

Not responsible for typographical errors.

Teach TechTM is a trademark of Elenco Electronics Inc.

Copyright© 2019 Elenco Electronics Inc. All rights reserved.

753173

4350008951

Loading...

Loading...