Page 1

DIGITAL MULTIMETER KIT

MODEL M-1006K

Assembly and Instruction Manual

Elenco Electronics, Inc.

Copyright © 2001 Elenco Electronics, Inc. 753096

Page 2

PARTS LIST

If you are a student, and any parts are missing or damaged, please see instructor or bookstore.

If you purchased this meter kit from a distributor, catalog, etc., please contact Elenco Electronics

(address/phone/e-mail is at the back of this manual) for additional assistance, if needed. DO NOT contact your

place of purchase as they will not be able to help you.

RESISTORS

(Parts mounted on card.)

Qty. Symbol Value Color Code Part #

1R9 .01Ω Shunt Wire 100161

1R8 .99Ω .5% 1/4W black-white-white-silver-green 109930

1R7 9Ω .5% 1/4W white-black-black-silver-green 119000

1 R13 100Ω 5% 1/4W brown-black-brown-gold 131000

1 R6 100Ω .5% 1/4W brown-black-black-black-green 131050

1 R5 900Ω .5% 1/4W white-black-black-black-green 139050

1 R17 910Ω 1% 1/4W white-brown-black-black-brown 139130

1 R12 1kΩ 5% 1/2W brown-black-brown-gold 141000

1 R14 4.7kΩ 5% 1/4W yellow-violet-red-gold 144700

1R4 9kΩ .5% 1/4W white-black-black-brown-green 149050

1 R15 30kΩ 1% 1/4W orange-black-black-red-brown 153030

1 R3 90kΩ .5% 1/4W white-black-black-red-green 159050

1 R25 100kΩ 5% 1/4W brown-black-yellow-gold 161000

3 R10, R11, R24 220kΩ 5% 1/4W red-red-yellow-gold 162200

1 R2 352kΩ .5% 1/2W orange-green-red-orange-green 163551

5 R18 - R22 470kΩ 5% 1/4W yellow-violet-yellow-gold 164700

1 R1 548kΩ .5% 1/2W green-yellow-gray-orange-green 165451

1 R23 1MΩ 5% 1/4W brown-black-green-gold 171000

Placed in bag with carded parts.

1 R16 200Ω (201) Potentiometer 191310

CAPACITORS

Qty. Symbol Value Description Part #

1 C1 100pF (101) Disc 221017

4 C2, C3, C4, C6 .1µF (104) Mylar (small yellow) 251017S

1C5 .1µF (104) Mylar 251017

SEMICONDUCTORS

Qty. Symbol Value Description Part #

1 D1 1N4007 Diode (mounted on resistor card) 314007

MISCELLANEOUS

-1-

Qty. Description Part #

1 LCD 351115

2 Zebra 500006

1 PC Board IC Installed 516101

1 Fuse 0.2A, 250V 533002

1 Batter y 9V 590009

1 Batter y Snap 590098

1 Selector Knob 622104

1 Case Top (Black) 623113

1 Case Bottom (Black) 623209

1 Zebra Frame 629012

3 Screw 2mm x 6mm 643439

Qty. Description Part #

2 Screw 2mm x 10mm 643447

2 Fuse Holder Clips 663100

1 Socket Transistor 664007

3 Input Socket 664101

2 Ball Bearing 666400

6 Slide Contact 680013

2 Spring 1/4” (Selector Knob) 680014

1 Label Front 724012

1 Grease 790004

1 Solder Tube 9ST4

1 Test Lead Set RWTL1000B

NOTE:

Not used but printed on PC board: R26 - R29, T1

The 7106 IC1 is already installed on the PC board. This type of installation is called C.O.B. (chip on

board). The IC is tested after it is installed on the PC board.

Page 3

-2-

IDENTIFYING RESISTOR VALUES

Use the following infor mation as a guide in proper ly identifying the value of resistors.

5 Bands

1 2

Multiplier

Tolerance

Resistors

PARTS IDENTIFICATION

PC Board with IC

Potentiometer

Ball Bearing

Selector Knob

Battery Snap

Fuse

Clip

Slide

Contact

Transistor

Test Socket

Fuse

Input Socket

3

4 Bands

1

2

Multiplier

Tolerance

Diode

Shunt Wire

LCD Assembly

Zebras/LCD/Frame/Cover

Capacitors

Discap

Mylar

C5

Abbreviation Means Multiply Unit By Or

p pico .000000000001 10

-12

n nano .000000001 10

-9

µ micro .000001 10

-6

m milli .001 10

-3

– unit 1 10

0

k kilo 1,000 10

3

M mega 1,000,000 10

6

1,000 pico units = 1 nano unit

1,000 micro units = 1 milli unit

1,000 units = 1 kilo unit

1,000 nano units = 1 micro unit

1,000 milli units = 1 unit

1,000 kilo units = 1 kilo unit

METRIC UNITS AND CONVERSIONS

IDENTIFYING CAPACITOR VALUES

Capacitors will be identified by their capacitance value in pF (picofarads), nF (nanofarads), or µF (microfarads). Most

capacitors will have their actual value printed on them. Some capacitors may have their value pr inted in the following

manner. The maximum operating voltage may also be printed on the capacitor.

Second Digit

First Digit

Multiplier

Tolerance*

For the No.01234589

Multiply By 1 10 100 1k 10k 100k .01 0.1

Multiplier

Note: The letter “R” may be used at times to

signify a decimal point; as in 3R3 = 3.3

10µF 16V

103K

100V

The letter M indicates a tolerance of +20%

The letter K indicates a tolerance of +

10%

The letter J indicates a tolerance of +5%

Maximum Working Voltage

The value is 10 x 1,000 =

10,000pF or .01µF 100V

*

Zebra

Frame

Zebras

LCD

Page 4

-3-

Introduction

The most important factor in assembling your M-1006K Digital Multimeter Kit is good soldering techniques.

Using the proper soldering iron is of prime impor tance. A small pencil type soldering iron of 25 - 40 watts is

recommended.The tip of the iron must be kept clean at all times and well tinned.

Safety Procedures

• Wear eye protection when soldering.

•

Locate soldering iron in an area where you do not have to go around it or reach over it.

• Do not hold solder in your mouth. Solder contains lead and is a toxic substance. Wash your hands

thoroughly after handling solder.

• Be sure that there is adequate ventilation present.

Assemble Components

In all of the following assembly steps, the components must be installed on the top side of the PC board unless

otherwise indicated. The top legend shows where each component goes. The leads pass through the

corresponding holes in the board and are soldered on the foil side.

Use only rosin core solder of 63/37 alloy.

DO NOT USE ACID CORE SOLDER!

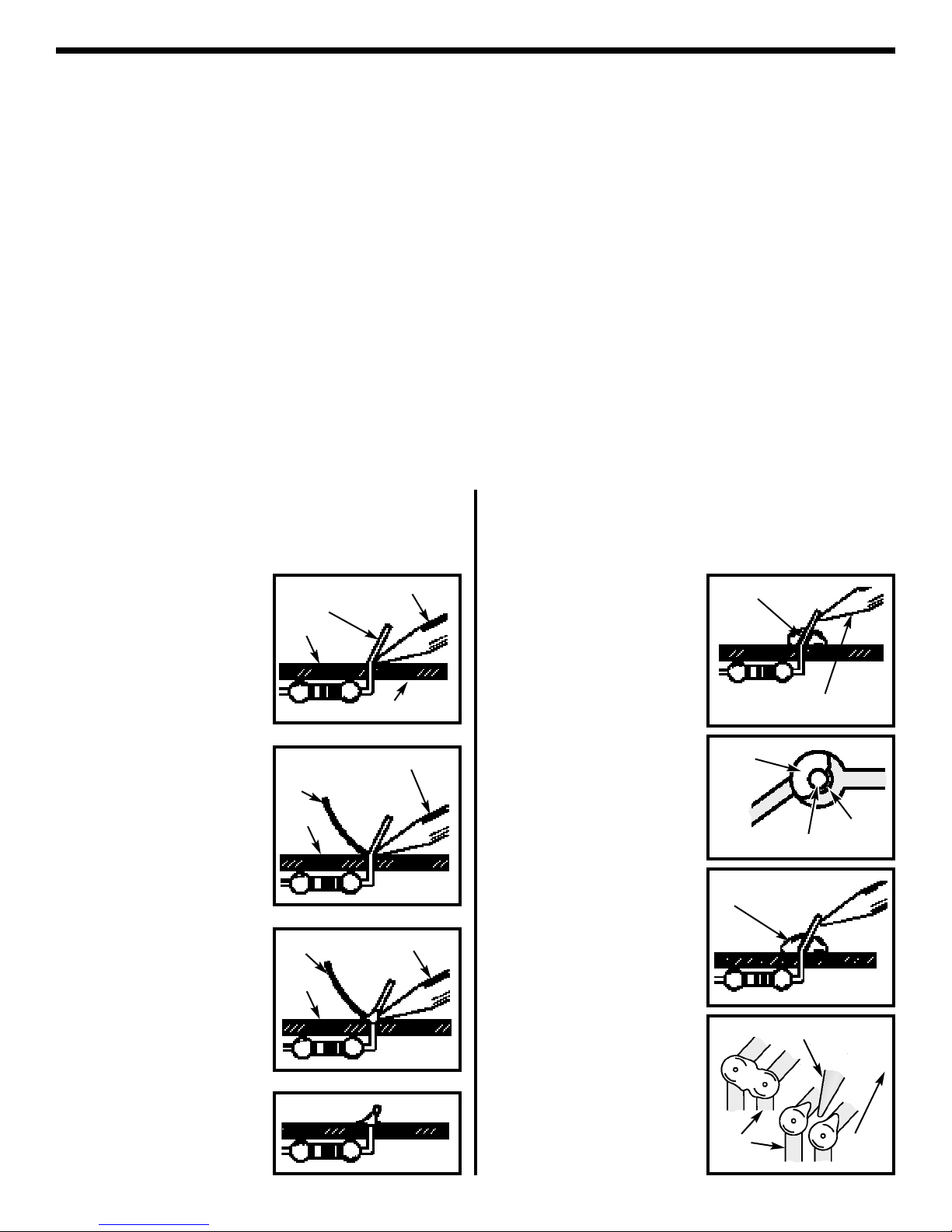

CONSTRUCTION

Solder

Soldering Iron

Foil

Solder

Soldering Iron

Foil

Component Lead

Soldering Iron

Circuit Board

Foil

Rosin

Soldering iron positioned

incorrectly.

Solder

Gap

Component Lead

Solder

Soldering Iron

Drag

Foil

1. Solder all components from

the copper foil side only.

Push the soldering iron tip

against both the lead and

the circuit board foil.

2. Apply a small amount of

solder to the iron tip. This

allows the heat to leave the

iron and onto the foil.

Immediately apply solder to

the opposite side of the

connection, away from the

iron. Allow the heated

component and the circuit

foil to melt the solder.

1. Insufficient heat - the

solder will not flow onto the

lead as shown.

3. Allow the solder to flow

around the connection.

Then, remove the solder

and the iron and let the

connection cool. The

solder should have flowed

smoothly and not lump

around the wire lead.

4.

Here is what a good solder

connection looks like.

2. Insufficient solder - let the

solder flow over the

connection until it is

covered. Use just enough

solder to cover the

connection.

3. Excessive solder - could

make connections that you

did not intend to between

adjacent foil areas or

terminals.

4. Solder bridges - occur

when solder runs between

circuit paths and creates a

short circuit. This is usually

caused by using too much

solder. To correct this,

simply drag your soldering

iron across the solder

bridge as shown.

What Good Soldering Looks Like

A good solder connection should be bright, shiny,

smooth, and uniformly flowed over all surfaces.

Types of Poor Soldering Connections

Page 5

-4-

ASSEMBLY INSTRUCTIONS

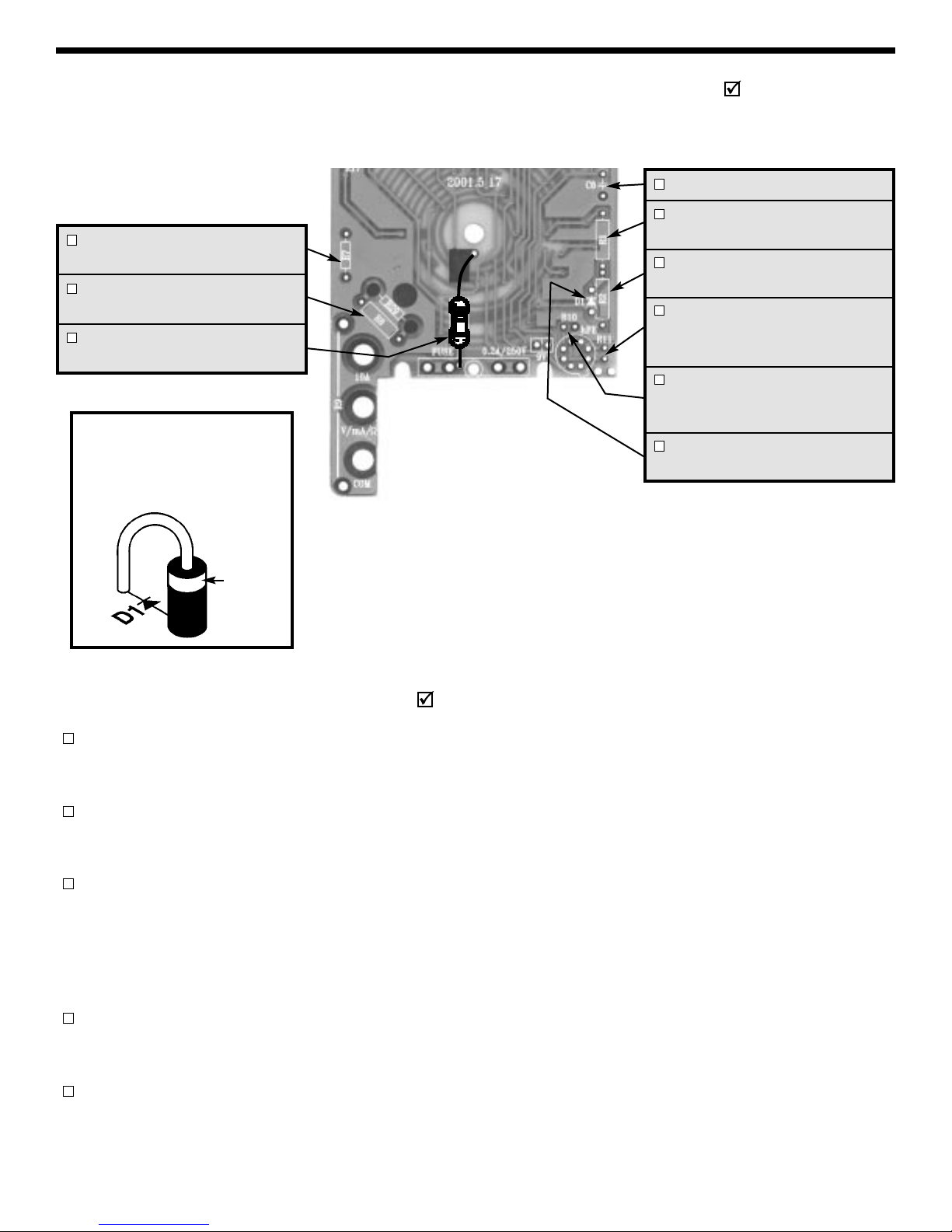

Identify and install the following parts as shown. After soldering each part, mark a check in the box provided.

Be sure that solder has not bridged to an adjacent pad.

Figure BFigure A

Stand resistor on end as

shown. Solder and cut

off the excess leads.

C1 - 100pF (101) Discap

C2 -

.1µF (104) Mylar (small yellow)

R22 - 470kΩ 5% 1/4W Resistor

(yellow-violet-yellow-gold)

(see Figure A)

R21 - 470kΩ 5% 1/4W Resistor

(yellow-violet-yellow-gold)

(see Figure A)

R25 - 100kΩ 5% 1/4W Resistor

(brown-black-yellow-gold)

(see Figure A)

R15 - 30kΩ 1% 1/4W Resistor

(orange-black-black-red-brown)

(see Figure A)

R16 -

200Ω (201) Potentiometer

(see Figure B)

R17 - 910Ω 1% 1/4W Resistor

(white-brown-black-black-brown)

(see Figure A)

R14 - 4.7kΩ 5% 1/4W Resistor

(yellow-violet-red-gold)

(see Figure A)

R13 - 100Ω 5% 1/4W Resistor

(brown-black-brown-gold)

(see Figure A)

R19 - 470kΩ 5% 1/4W Resistor

R18 - 470kΩ 5% 1/4W Resistor

(yellow-violet-yellow-gold)

(see Figure A)

Mount the potentiometer to the PC board as shown.

R20 - 470kΩ 5% 1/4W Resistor

(yellow-violet-yellow-gold)

(see Figure A)

C5 - .1µF (104) Mylar

R24 - 220kΩ 5% 1/4W Resistor

(red-red-yellow-gold)

(see Figure A)

C4 -

.1µF (104) Mylar (small yellow)

C3 -

.1µF (104) Mylar (small yellow)

R23 - 1MΩ 5% 1/4W Resistor

(brown-black-green-gold)

(see Figure A)

R6 - 100Ω .5% 1/4W Resistor

(brown-black-black-black-green)

(see Figure A)

R5 - 900Ω .5% 1/4W Resistor

(white-black-black-black-green)

(see Figure A)

R4 - 9kΩ .5% 1/4W Resistor

(white-black-black-brown-green)

(see Figure A)

R3 - 90kΩ .5% 1/4W Resistor

(white-black-black-red-green)

(see Figure A)

Page 6

-5-

ASSEMBLY INSTRUCTIONS

Identify and install the following parts as shown. After soldering each part, mark a check in the box provided.

Be sure that solder has not bridged to an adjacent pad.

Figure C

Stand diode on end. Mount

with band as shown on the top

legend.

C6 -

.1µF (104) Mylar (small yellow)

R1 - 548kΩ .5% 1/2W Resistor

(green-yellow-gray-orange-green)

R2 - 352kΩ .5% 1/2W Resistor

(orange-green-red-orange-green)

R11 - 220kΩ 5% 1/4W Resistor

(red-red-yellow-gold)

(see Figure A)

R10 - 220kΩ 5% 1/4W Resistor

(red-red-yellow-gold)

(see Figure A)

D1 - 1N4007 Diode

(see Figure C)

R7 - 9Ω .5% 1/4W Resistor

(white-black-black-silver-green)

R8 - .99Ω .5% 1/4W Resistor

(black-white-white-silver-green)

R12 - 1kΩ 5% 1/2W Resistor

(brown-black-brown-gold)

Band

Insert the narrow end of the three input sockets into the PC board from the solder side, as shown in Figure D.

Solder the sockets to the PC board on the component side only. The solder should extend completely around

the socket (see Figure D).

Insert the shunt wire (R9) into the PC board holes from the component side as shown in Figure D. Adjust

the wire so that it sticks out the other (solder) side of the PC board 3/16 of an inch. Solder the wire to the

PC board on the component side only.

Be sure that the 8-pin transistor socket will slide easily through its hole in the top case from either direction.

If it does not, carefully slide it through the hole several times in each direction to remove any burrs. Do not

push on the socket leads or they may be damaged.

Insert the socket into the PC board holes from the solder side as shown in Figure D. Be sure that the tab

lines up with the hole as shown in the figure. Solder the socket to the PC board on the component side of

the PC board as shown in the figure and cut off excess leads.

Feed the battery snap wires up through the holes in the PC board from the solder side as shown in Figure D.

Insert the red wire into the hole marked (9V+) and black wire into hole marked (9V–) as shown. Solder the

wires to the PC board.

Insert the two fuse clips into the PC board holes as shown in Figure D. Be sure that the tabs are on the

outside as shown in the figure. Solder the clips to the PC board.

Install the following parts. Then, mark a check in the box provided.

Page 7

-6-

Close-up view of the

transistor socket and

PC board.

Solder Side

Solder Side

Figure D

Tab

Input Sockets

Shunt Wire

Red Wire

Black Wire

Solder

Battery Snap

Transistor

Socket

Fuse Clips

Remove the clear protective film from the front of the LCD (Note:

DO NOT remove the silver bac king). Place the LCD, zebra fr ame,

and zebras into the top case as shown in Figure E. Be sure that

the LCD tab is in the same direction as shown in the figure.

Cut open the plastic envelope containing the grease and put a

small amount of grease in each spring hole of the selector knob

as shown in Figure F. Then, insert a 1/4” spring into each hole as

shown in the figure.

Clear Protective Film

Figure F

Spring Holes

1/4” Springs

Figure E

LCD

Zebras

Tab

Zebra Frame

Top Case

Page 8

Put the bearings into two opposite indents in the case top as shown in Figure G.

Place the six slide contactors on the selector knobs as shown in Figure G.

Place the selector knob into the case top so that the springs fit over the bearings as shown in Figure G.

Place the PC board over the selector knob. Be sure that the 8-pin socket slides into its hole. Then fasten

the PC board with two 6mm screws as shown in Figure G.

Insert the 0.25A, 250V fuse into the fuse clips. Your fuse may be unmarked.

Peel the backing off of the front label and place it on the case top.

Connect a 9V battery to the battery snap.

-7-

Figure G

PC Board

6mm Screws

Slide Contactor

Rib

Close-up View

Bearings

Battery Compartment

Case Top

Selector Knob

Page 9

CALIBRATION

Refer to the METER OPERATION section for test lead connections and measurement procedure.

A/D CONVERTER CALIBRATION

Turn the range selector switch to the 20V position and connect the test leads. Using another meter of known accuracy,

measure a DC voltage of less than 20 volts (such as a 9V battery). Calibrate the kit meter by measuring the same voltage

and adjusting R16 until the kit meter reads the same as the accurate meter (do not use the kit meter to measure its own

battery). When the two meters agree, the kit meter is calibrated. T urn the knob to the OFF position and remove the voltage

source.

SHUNT WIRE CALIBRA TION

To calibrate the shunt wire, you will need a 5 amp current source such as a

5V power supply and a 1 ohm, 25 watt resistor. If a 5 amp source is not

available, you can use a lower current (2 amps). If no supply is available, it is

not important to do this test. Set the range switch to the 10A position and

connect the test leads as shown in Figure H. If the meter reads higher than

5A, resolder the shunt wire so that there is less wire between the 10A DC and

COM sockets.

If the meter reads low, resolder the shunt wire so that there is more wire

between the sockets.

1) ACV Range: 750 0 0.0

200 0 0 0

2) DCA,10A Ranges: 200µ 0 0.0

2000µ 0 0 0

20m 0.0 0

200m 0 0.0

10A 0.0 0

3) Ohms, Diode and hFE Ranges: B indicates blank.

hFE 0 0 0

Diode ( ) 1 B B B

200 1 B B.B

2000 1 B B B

20k 1 B.B B

200k 1 B B.B

2000k 1 B B B

4) DCV Range: 200m 0 0.0

2000m 0 0 0

20 0.0 0

200 0 0.0

1000 0 0 0

-8-

TESTING, CALIBRA TION, AND TROUBLESHOOTING

TESTING OF LCD

With no test leads connected to the meter, move the selector switch around the dial. You should obtain the following

readings. A (–) sign may also be present or blinking.

If any of these tests fail:

a) Check that the batter y is good.

b) Check the values of resistors R14, R15, R19, R20, R23 - R25.

c) Check the values of capacitors C1 - C6.

d) Check the PC board for solder bridges and bad solder connections.

e) Check that the slide contactors are seated correctly.

f ) Check that the LCD and zebras are seated correctly.

If the calibration fails:

a) Check the PC board for solder bridges and bad solder connections.

b) Check the value of resistors R7 - R9, R23, and capacitor C3.

10A DC

VΩmA

COM

Figure H

1Ω

25 Watts

Power Supply

5VDC

–

+

123

Page 10

AC V OLTS TEST

To test the ACV ranges, we will need a source of AC voltage. The AC power line is the most convenient.

CAUTION: Be very careful when working with 120VAC. Be sure that the range switch is in the 200 or 750VAC

position before connecting the test leads to 120VAC.

1) Set the range to 200VAC and measure the AC power line. The voltage should be about 120VAC. Compare

the reading to a meter of known accuracy.

2) Set the range to 750VAC and measure the AC power line. The voltage should be about 120VAC. Compare

the reading to a meter of known accuracy.

If either if the above tests fail:

a) Check the values and the soldering of resistors R1 - R6, R22.

b) Check that diode D1 is mounted as shown in the assembly instructions.

DC AMPS TEST

1) Set the range switch to 200µA and connect the meter as in Figure J. With RA equal to 100kΩ the current

should be about 90µA. Compare the reading to a known accurate meter.

2) Set the range switch and R

A as in the following table. Read the currents shown and compare to a known

accurate meter.

If any of the above tests fail:

a) Check the fuse.

b) Check the value and soldering of resistors R7, R8, and R9.

DC VOLTS TEST

1) If you have a variable power supply, set the supply to about the midpoint of each of the DCV ranges and compare the

kit meter reading to a meter known accuracy.

2) If you do not have a variable power supply, make the following two tests:

a) Set the range switch to 2000mV and measure the voltage across the 100 ohm resistor of Figure Ia. You should get

about 820mV. Compare the reading to a meter of known accuracy.

b) Set the range switch to 200mV and measure the voltage across the 100 ohm resistor of Figure Ib. You should get

about 90mV. Compare the reading to a meter of known accuracy.

If any of these tests fail:

a) Recheck the meter

calibration.

b) Check the value and the

soldering of resistors R1R6, R12-R17, R21-R24,

and capacitor C3.

-9-

Figure J

Figure Ia Figure Ib

1kΩ

10A DC

VΩmA

COM

100Ω

9V

123

10kΩ

10A DC

VΩmA

COM

100Ω

9V

123

Range Switch R

A

Current (approx.)

2000µA 10kΩ 900µA

20mA 1kΩ 9mA

200mA 470Ω 19mA

VΩmA

COM

10A DC

123

Accurate

Meter

R

A

9V

Page 11

-10-

RESIST ANCE/DIODE TEST

1) Measure a resistor of about half of the full scale value of each resistance range. Compare the kit meter

readings to those from a meter of known accuracy.

2) Measure the voltage drop of a good silicon diode. You should read about 700mV. Power diodes and the

base to emitter junction of power transistors may read less.

If any of these tests fail:

a) Check the values and the soldering of resistors R1 - R6, and R12.

h

FE

1) Set the range switch to hFEand insert a small transistor into the appropriate NPN or PNP holes in the

transistor socket.

2) Read the h

FE

of the transistor. The hFEof transistors varies over a wide range, but you will probably get a

reading between 100 and 300.

If this check fails:

a) Check that the transistor socket is aligned according to Figure D.

b) Check the value and soldering of resistors R10, R11, and R29.

FINAL ASSEMBLY

Snap the case bottom onto the case top and fasten with the two 10mm screws as shown in Figure K.

Case

Bottom

Screws

Case Top

Figure K

Battery

Page 12

-11-

THEORY OF OPERATION

A block diagram of the M-1006K is shown in Figure 1. Operation centers around a custom LSI chip. This chip

contains a dual slope A/D (analog to digital) converter, display latches, seven segment decoder and display

drivers. A block diagram of the IC functions is shown in Figure 2. The input voltage or current signals are

conditioned by the selector switches to produce an output DC voltage with a magnitude between 0 and 199mV.

If the input signal is 100VDC, it is reduced to 100mVDC by selecting a 1000:1 divider. Should the input be

100VAC, it is first rectified and then divided down to 100mVDC. If current is to be read, it is converted to a DC

voltage by internal shunt resistors.

Figure 1

Input

Selector

Switches

AC

Converter

Ohms

Converter

Current

Shunt

V

V

Ω

I

Voltage

Divider

Selector

Switches

V

A/D

Converter

& Display

Driver

Display

Decimal

Point

DC

Analog

Data

For resistance measurements, an internal voltage source drives the test resistor in series with a known resistor.

The ratio of the test resistor voltage to the known resistor voltage is used to deter mine the value of the test

resistor.

The input of the 7106 IC is fed to an A/D conver ter. Here the DC voltage is changed to a digital format. The

resulting signals are processed in the decoders to light the appropriate LCD segments.

Timing for the overall operation of the A/D converter is derived from an external oscillator whose frequency is

selected to be 25kHz. In the IC, this frequency is divided by four before it clocks the decade counters. It is then

further divided to form the three convert-cycles phases. The final readout is clocked at about two readings per

second.

The digitized measurements are presented to the display as f our decoded digits (seven segments) plus polarity .

The decimal point position on the display is determined by the selector switch setting.

A/D CONVERTER

A simplified circuit diagram of the analog portion of the A/D converter is shown in Figure 3. Each of the switches

shown represent analog gates which are operated by the digital section of the A/D converter. The basic timing

for switch operation is keyed by the external oscillator. The conversion process is continuously repeated. A

complete cycle is shown in Figure 3.

Any given measurement cycle performed by the A/D converter can be divided into three consecutive time

periods, autozero (AZ), integrate (INTEG) and read. A counter deter mines the length of the time per iods. The

integrate period is fixed at 1,000 clock pulses. The read per iod is a var iable time that is proportional to the

unknown input voltage. It can vary from zero counts for zero input voltage to 2,000 counts for a full scale input

voltage. The autozero period varies from 1,000 to 3,000 counts. For an input voltage less than full scale

autozero gets the unused portion of the read period. The value of the voltage is determined by counting the

number of clock pulses that occur during the read period.

During autozero a ground reference is applied as an input to the A/D conver ter. Under ideal conditions, the

output of the comparator would also go to zero . However, input-offset-voltage errors accumulate in the amplifier

loop and appear at the comparator output as an error voltage. This error is impressed across the AZ capacitor

where it is stored for the remainder of the measurement cycle. The stored lev el is used to pro vide offset v oltage

correction during the integrate and read periods.

Page 13

-12-

The integrate period begins at the end of the autozero period. As the period begins, the AZ switch opens and

the INTEG switch closes. This applies the unknown input voltage to the input of the A/D converter. The voltage

is buffered and passed on to the integrator to determine the charge rate (slope) on the INTEG capacitor At the

end of the fixed integrate period, the capacitor is charged to a level proportional to the unknown input voltage.

During the read period, this voltage is translated to a digital indication by discharging the capacitor at a fixed

rate and counting the number of clock pulses that occur before it retur ns to the or iginal autozero level.

As the read period begins, the INTEG switch opens and the read switch closes . This applies a known reference

voltage to the input to the A/D conver ter. The polarity of this voltage is automatically selected to be opposite

that of the unknown input voltage, thus causing the INTEG capacitor to discharge at a fixed rate (slope). This

rate is determined by the known reference voltage. When the charge is equal to the initial starting point

(autozero level), the read per iod is ended. Since the discharge slope is fixed during the read per iod, the time

required for discharge is proportional to the unknown input voltage. Specifically, the digital reading displayed is

1000 (V

IN / VREF

).

The autozero period and thus a new measurement cycle begins at the end of the read period. At the same time

the counter is released for operation by transferring its contents (the previous measurement value) to a series of

latches. This stored data is then decoded and buffered before being used to drive the LCD display.

Page 14

-13-

Figure 2

7106 IC Functions

Figure 3

a

b

a

b

cde

f

g

TYPICAL SEGMENT OUTPUT

0.5mA

2mA

V+

Segment

Output

Internal Digital Ground

LCD PHASE DRIVER

LATCH

7 Segment

Decode

7 Segment

Decode

7 Segment

Decode

Thousand

Hundreds

Tens Units

*

CLOCK

To Switch Drivers

From Comparator Output

-4

LOGIC CONTROL

Internal Digital Ground

200

BACKPLANE

28

V+

TEST

V

500Ω

3

8

6.2V

1V

* Three inverters.

One inverter shown for clarity.

7

6

4

OSC 1

OSC 2

OSC 3

DIGITAL SECTION

ANALOG SECTION of 7106

C

REF

R

INT

C

AZ

C

INT

INT

C

REF

+

REF HI

REF LO

C

REF

BUFFER

V+

35

42 44 43

41

36

37

1

AUTO

ZERO

+

A-Z &

Z1

A-Z &

Z1

A-Z

DE (+)

DE (+)

DE (-)

DE (-)

IN HI

COMMON

IN LO

40

39

INT

10µA

V+

38

INT

+

+

+

2.8V

A-Z & DE(+)

& Z1

34

V

Z1

6.2V

A-Z

COMPARATOR

ZERO

CROSSING

DETECTOR

POLARITY

FLIP/FLOP

TO

DIGITAL

SECTION

INTEGRATOR

+ REF

(Flying

Capacitor)

Unknown

Input

Voltage +

Read

Integ.

AZ

AZ

Integ.

To

Digital

Control

Logic

AZ Integ. Read

AZ

+

.20

.15

.10

.05

0

10000

160ms

Counter Output

0

500 1000 1500 2000

DUAL SLOPE A/D CONVERTER

Page 15

-14-

DC VOLTA GE MEASUREMENT

Figure 4 shows a simplified diagram of the DC voltage

measurement function. The input voltage divider resistors

add up to 1 megaohm. Each step down divides the voltage

by a factor of ten. The divider output must be within the

range –0.199 to +0.199 volts or the over load indicator will

function. The overload indication consists of a 1 in the most

significant digit and blanks in the remaining digits.

AC V OLTA GE MEASUREMENT

Figure 5 shows a simplified diagram of the AC voltage

measurement function. The AC voltage is first rectified and

passed through a low pass filter to smooth out the

wavefor m. A scaler reduces the voltage to the DC value

required to give the correct RMS reading.

CURRENT MEASUREMENT

Figure 6 shows a simplified diagram of the current

measurement function. Internal shunt resistors convert the

current to between –0.199 to +0.199 volts which is then

processed in the 7106 IC to light the appropriate LCD

segments. When current in the range of 10A is to be read,

it is fed to the 10A input and does not pass through the

selector switch.

Figure 4 Simplified DC Voltage Measurement Diagram

7106

100mV

REF

Low Pass

Filter

200mV

2V

1kV

200V

20V

900kΩ

90kΩ

100Ω

900Ω

9kΩ

Volts

Common

Figure 5 Simplified AC Voltage Measurement Diagram

Volts

Common

7106

100mV

REF

Low Pass

Filter

Rectifier

Low Pass

Filter - Scaler

750V

200V

100Ω

900Ω

Figure 6

Simplified DC Amps Measurement Diagram

Common

10A

A

9Ω

.99Ω

.01Ω

20mA

2000µA

200µA

200mA

10A

900Ω

100Ω

2000µA

200µA

20mA

200mA

10A

7106

100mV

REF

Low Pass

Filter

Page 16

DIODE CHECK

RANGE RESOLUTION MAX TEST CURRENT MAX OPEN CIRCUIT VOLTAGE

DIODE 1mV 1.4mA 2.8V

TRANSISTOR hFE TEST

RANGE TEST RANGE TEST CURRENT TEST VOLTAGE

NPN/PNP 0 - 1000 Ib = 10µA Vce 3V

-15-

SPECIFICATIONS

GENERAL

DISPLAY 3 1/2 digit LCD, with polarity

OVERRANGE INDICATION 3 least significant digits blanked.

MAXIMUM COMMON MODE

VOLTAGE 500V peak.

STORAGE ENVIRONMENT –15

O

C to 50OC.

TEMPERATURE COEFFICIENT (0OC to 18OC and 28OC to 50OC)

less than 0.1 x applicable accuracy

specification per

O

C.

POWER 9V alkaline or carbon zinc batter y.

DIMENSIONS 128 x 75 x 24mm.

DC VOLT A GE

RANGE RESOLUTION ACCURACY

200mV 0.1mV +

0.5% rdg + 2d

2000mV 1mV +0.5% rdg + 2d

20V 10mV +

0.5% rdg + 2d

200V 100mV +0.5% rdg + 2d

1000V 1V +

0.5% rdg +

2d

MAXIMUM ALLOWABLE INPUT 1000VDC or peak AC.

INPUT IMPEDANCE 1MΩ.

DC CURRENT

RANGE RESOLUTION ACCURACY

200µA 0.1µA+

1% rdg +

2d

2000µA1µA+1% rdg + 2d

20mA 10µA+1% rdg + 2d

200mA 100µA+

1.2% rdg + 2d

10A 10mA +

2% rdg + 3d

OVERLOAD PROTECTION .25A/250V fuse (mA input only).

AC VOL T AGE

RANGE RESOLUTION ACCURACY

200V 100mV +1.2% rdg + 10d

750V 1V +1.2% rdg + 10d

MAXIMUM ALLOWABLE INPUT 750Vrms.

FREQUENCY 45 - 450Hz.

RESISTANCE

RANGE RESOLUTION ACCURACY

200Ω 0.1Ω +0.8% rdg + 2d

2000Ω 1Ω +

0.8% rdg + 2d

20kΩ 10Ω +

0.8% rdg + 2d

200kΩ 100Ω +

0.8% rdg + 2d

2000kΩ 1kΩ +1% rdg + 2d

MAXIMUM OPEN CIRCUIT VOLTAGE 2.8V.

RESISTANCE MEASUREMENT

Figure 7 shows a simplified diagram of the resistance measurement

function. A simple series circuit is formed by the voltage source, a

reference resistor from the voltage divider (selected by the selector

switches), and the test (unknown) resistor. The ratio of the two resistors

is equal to the ratio of their respective voltage drops. Therefore, since

the value of one resistor is known, the value of the second can be

determined by using the voltage drop across the known resistor as a

reference. This determination is made directly by the A/D converter.

Overall operation of the A/D converter during a resistance

measurement is basically as described earlier with one exception. The

reference voltage present during a v oltage measurement is replaced b y

the voltage drop across the reference resistor. This allows the voltage

across the unknown resistor to be read during the read period.

hFE MEASUREMENT

Figure 8 shows a simplified diagram of the h

FE measurement function.

Internal circuits in the 7106 IC maintain the COMMON line at 2.8 volts

below V+. When a PNP transistor is plugged into the transistor socket,

base to emitter current flows through resistor R10. The voltage drop in

resistor R10 due to the collector current is fed to the 7106 and indicates

the h

FE of the transistor. For an NPN transistor, the emitter current

through R11 indicates the h

FE of the transistor.

Figure 7

Simplified Resistance Measurement Diagram

Ω

900kΩ

Tes t

Resistor

100Ω

900Ω

2000Ω/Dio

200Ω

7106

Reference

Voltage

Low Pass

Filter

Voltage

Source

Common

90kΩ

9kΩ

2000kΩ

20kΩ

200kΩ

Figure 8

R10

220kΩ

Common

R23

10Ω

R11

220kΩ

PNP

NPN

7106

100mV

Ref.

Low Pass

Filter

V+

EC

CE

BB

Page 17

-16-

METER OPERATION

PRECAUTIONS AND PREPARATIONS FOR MEASUREMENT

1) Be sure the battery is connected to the batter y snap and correctly placed in the batter y compartment.

2) Before connecting the test leads to the circuit, be sure the range switch is set to the correct position.

3) Be sure that the test leads are connected to the correct meter terminals before connecting them to the

circuit.

4) Before changing the range switch, remove one of the test leads from the circuit.

5) Operate the instrument only in temperatures between 0 and 50

O

C and in less than 80% RH.

6) Pay careful attention to the maximum rated voltage of each range and terminal.

7) When finished making measurements, set the switch to OFF. Remove the battery when the instrument will

not be used for a long period of time.

8) Do not use or store the instrument in direct sunlight or at high temperature or humidity.

VOLTAGE MEASUREMENTS

1) Connect the black test lead to the “COM” ter minal.

2) Connect the red test lead to the “VΩMA” terminal.

3) Set the range switch to the desired “V ”or “V~” position. If the magnitude of the voltage is not known, set

the switch to the highest range.

4) Connect the leads across the points to be measured and read the display. If the range switch is too high,

reduce it until a satisfactory reading is obtained.

DCA MEASUREMENTS

HIGH CURRENTS (200mA to 10A)

1) Connect the black test lead to the “COM” ter minal.

2) Connect the red test lead to the 10ADC terminal.

3) Set the range switch to the 10A position.

4) Open the circuit to be measured and connect the leads in series with the load to be measured.

5) Read the display. If the display read less than 200mA, follow the low current procedure below.

6) Turn off all of the power to the circuit being tested and discharge all of the capacitors before disconnecting

the test leads.

LOW CURRENTS (less than 200mA)

7) Connect the black test lead to the “COM” ter minal.

8) Connect the red test lead to the VΩMA terminal.

9) Set the range switch to the desired A position. If the magnitude of the current is not known, set the switch

to the highest position.

10)Open the circuit to be measured and connect the leads in ser ies with the load to be measured.

11)Read the display. If the range switch is too high, reduce it until a satisfactory reading is obtained.

12)T urn off all power to the circuit being tested and discharge all capacitors before disconnecting the test leads.

Page 18

-17-

RESISTANCE MEASUREMENTS

1) Connect the black test lead to the “COM” terminal.

2) Connect the red test lead to the “VΩMA” terminal.

3) Set the range switch to the desired “Ω” position.

4) If the resistance being measured is connected to a circuit, turn off the power to the circuit being tested and

discharge all of the capacitors.

5) Connect the leads across the resistor to be measured and read the display. When measuring high

resistance, be sure not to contact adjacent points even if insulated. Some insulators have relatively low

resistance and will cause the measured resistance to be lower than the actual resistance.

DIODE CHECK

1) Connect the black test lead to the “COM” terminal.

2) Connect the red test lead to the “VΩMA” terminal.

3) If the diode being measured is connected to a circuit, turn off all power to the circuit and discharge all

capacitors.

4) Set the range switch to “ ”.

Forward V olta ge Check

5) Connect the red lead to the anode and the black lead to the cathode of the diode. Nor mally the forward

voltage drop of a good silicon diode reads between 450 and 900mV.

Reverse Voltage Check

6) Reverse the leads to the diode. If the diode is good, an overrange indication is given (a 1 in the most

significant digit and blanks in the remaining digits). If the diode is bad, “000” or some other value is

displayed.

hFEMEASUREMENTS

1) Set the range switch to hFEand insert the test transistor into the appropriate NPN or PNP

holes in the transistor socket.

2) Read the hFEof the transistor.

BATTERY & FUSE REPLACEMENT

If “ ” appears on the display, it indicates that the battery should be replaced.

To replace battery and fuse (250mA/250V), remove the 2 screws in the bottom of the case.

Simply remove the old fuse/battery and replace with a new fuse/battery.

QUIZ

1. The function of the A/D converter is to . . .

A) convert digital to analog.

B) divide the analog signal by 2.

C) convert analog to digital.

D) convert AC to DC.

2. The divider used for DC voltage measurements is a .. .

A) divide by 20.

B) capacitance divider.

C) divide by 5.

D) resistor divider.

3. When the AC voltage is measured, it is first .. .

A) divided by 2.

B) rectified.

C) divided by 100.

D) sent to a high pass filter.

4. When measuring current, the shunt resistors convert the

current to . . .

A) –0.199 to +0.199 volts.

B) –1.199 to +1.199 volts.

C) –0.099 to +0.099 volts.

D) –199 to +199 volts.

5. The DC voltage divider resistors add up to . . .

A) 100Ω.

B) 1000Ω.

C) 100kΩ.

D) 1MΩ.

Answers: 1. C, 2. D, 3. B, 4. A,

5. D, 6.A, 7. B, 8.C, 9.B, 10. B

6. Resistance measurements are made by . . .

A) comparing voltage drops in the unknown resistor and a

reference resistor.

B) measuring the current in the unknown resistor.

C) measuring the current in the reference resistor.

D) equalizing the voltage drops in the unknown and the

reference resistors.

7. The measurement cycle performed by the A/D converter can be

divided into time periods known as . . .

A) long and short.

B) autozero, integrate and read.

C) zero, read and interphase.

D) convert, integrate and display.

8.

A resistor with the band colors green-black-green-brown-green is . . .

A) 50.5kΩ +5%.

B) 5.15kΩ +

10%.

C) 5.05kΩ +

.5%.

D) 5.05kΩ +

1%.

9. The M-1005K has . . .

A) A 3 digit display.

B) A 3 1/2 digit display.

C) A 4 1/2 digit display.

D) None of the above.

10.

When measuring 450mA, the meter leads should be connected to . . .

A) COM and VΩmA.

B) COM and 10A.

C) 10A and VΩmA.

D) COM and Building GND.

+

Page 19

-18-

SCHEMATIC DIAGRAM

Page 20

Elenco Electronics, Inc.

150 W. Carpenter Avenue

Wheeling, IL 60090

(847) 541-3800

www.elenco.com

e-mail: elenco@elenco.com

Loading...

Loading...