Page 1

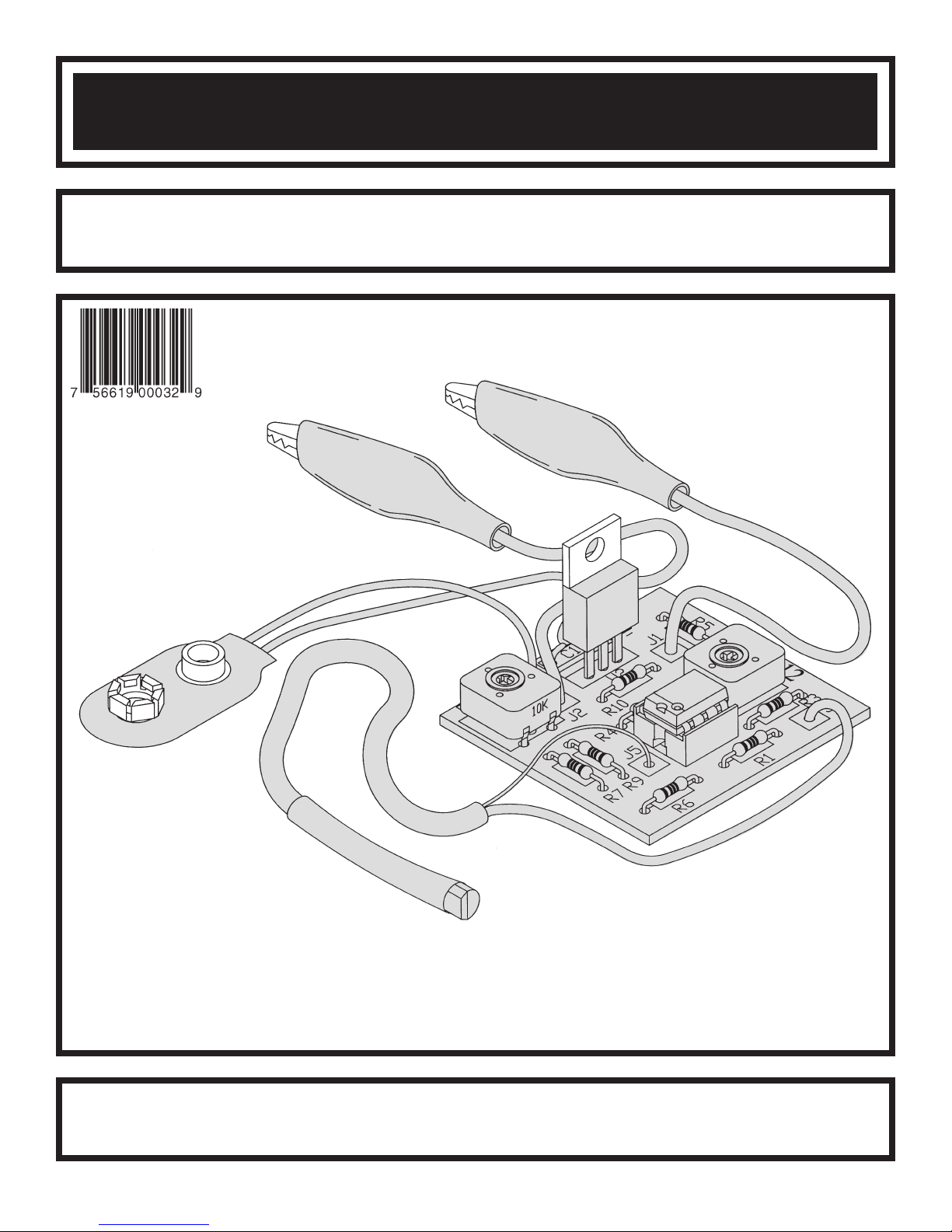

TEMPERATURE ADAPTER KIT

MODEL TA-12/K-40

Assembly and Instruction Manual

Elenco®Electronics, Inc.

ight © 2005, 1994 b

yr

Cop

t of this book shall be reproduced b

No par

y Elenco

®

Electronics

y means;

y an

, Inc.

electronic

ights reser

All r

, photocopying, or otherwise without written permission from the publisher.

ved. Revised 2005 REV-C 753125

Page 2

PARTS LIST

If you are a student, and any parts are missing or damaged, please see instructor or bookstore.

If you purchased this kit from a distributor, catalog, etc., please contact Elenco

mail is at the back of this manual) for additional assistance, if needed. DO NOT contact your place of purchase

as they will not be able to help you.

RESISTORS

Qty. Symbol Description Color Code Part #

2 R5, R6 1kΩ 5% 1/4W brown-black-red-gold 141000

1 R7 3.3kΩ 5% 1/4W orange-orange-red-gold 143300

2 R1, R10 3.9kΩ 5% 1/4W orange-white-red-gold 143900

2 R4, R9 10kΩ 5% 1/4W brown-black-orange-gold 151000

1 R3 47kΩ 5% 1/4W yellow-violet-orange-gold 154700

2 R2, R8 10kΩ Trim Pot 191510

CAPACITORS

Qty. Symbol Description Part #

1 C1 .01µF, 50V (103) 241031

SEMICONDUCTORS

Qty. Symbol Description Part #

1 Q1 2N3904 NPN Transistor 323904

1 U1 LM1458N Op-Amp Integ

1 U2 MC7805 5V Regulator 337805

rated Circuit (IC) 331458

®

Electronics (address/phone/e-

MISCELLANEOUS

. Description Part #

Qty

1 PC Board

518040

1 Solder Roll 24” 551124

1 Battery Snap

1 IC Soc

ket 8-pin 664008

590098

1 Alligator Clip Black 680001

1 Alligator Clip Red 680002

1 Solid Black Wire 22ga. 6” 814120

1 Solid Red Wire 22ga. 6” 814220

Cable 2 Conductor 24” 876090

1

1 #7 Shrink Tubing 1/2” 890050

1 3/16” Dia. Shrink Tubing 1 1/2” 890120

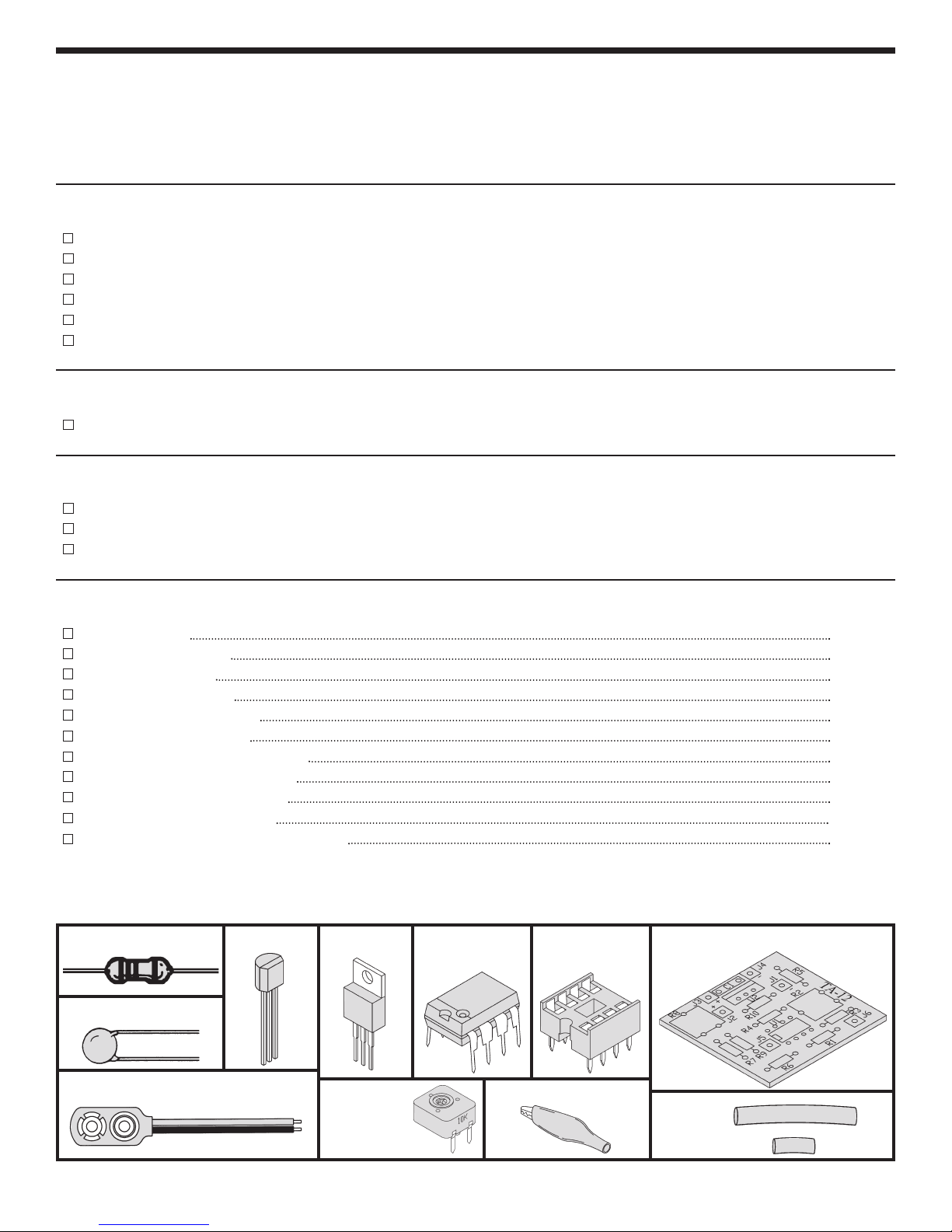

PARTS IDENTIFICATION

Resistor Transistor

Capacitor

Regulator

Integrated

Circuit

IC Socket

8-pin

PC Board

Battery Snap

Trim Pot

-1-

Alligator Clip

Shrink

Tubing

3/16”

#7

Page 3

INTRODUCTION

The TA-12/K-40 Temperature Adapter Kit is used in

c

onjunction with a digital multimeter to read

temperature. The Temperature Adapter consists of

THEORY OF OPERATION

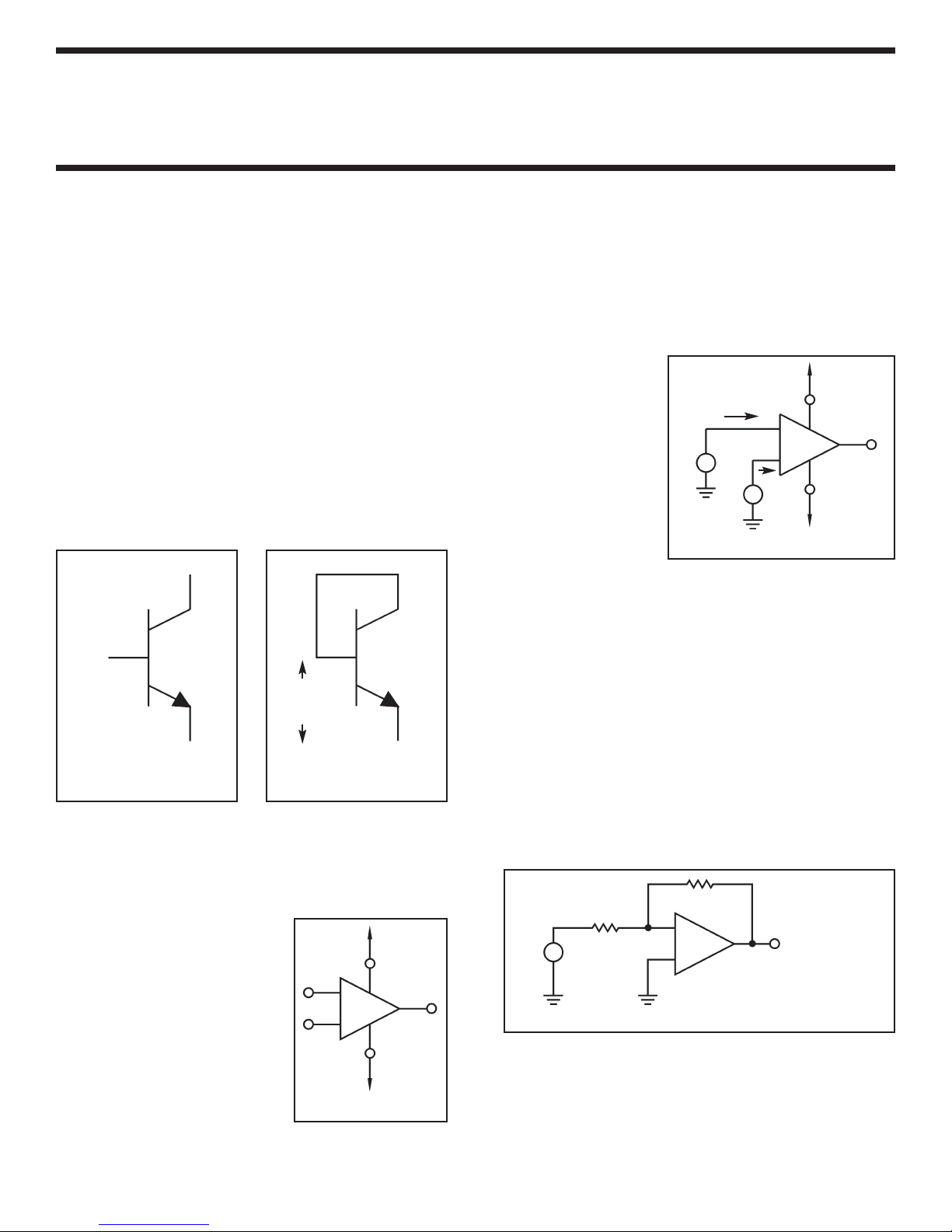

VOLTAGE REGULATOR

The MC7805 (U2) is the voltage regulator which is

used to supply a constant voltage of about 5V to the

circuit.

TEMPERATURE SENSOR

The Temperature Sensor is an NPN transistor

(2N3904). The NPN transistor has three

terminals: the collector, base, and emitter as

shown in Figure 1. When the collector and base of

this transistor are shorted together as shown in

Figure 2, they behave exactly like a diode, which is

a temperature-sensitive device. At a constant

current, the voltage across the base to emitter

junction decreases by approximately 1mV for

every 1

O

F increase in temperature.

Collector

three main sections: • Voltage Regulator

•

Temperature Sensor

• Op-Amp

The op-amp senses the difference between the

voltage signals applied at its two terminals (that is,

the quantity v2 - v1), multiplies this by the open loop

gain A, and causes the resulting voltage A(v2 - v1)

to appear at output terminal 3 as shown in Figure 4.

In an ideal op-amp,

V+

the input impedance

is infinite, the output

impedance is zero

and the open loop

gain A is very large

and ideally infinite. In

, the open

actice

pr

loop gain is usually

greater than 100,000.

V1

i1 = 0

+

–

i2 = 0

+

V2

–

Figure 4

1

2

–

+

4

A(V2 - V1)

5

V–

3

Base

2N3904 NPN

Transistor

Base and

Emitter

Junction

Emitter

Figure 1

2N3904 NPN

Transistor

Figure 2

OP-AMP

The op-amp (LM1458) has tw

one output terminal. Figure 3 shows the op-amp

symbol. Terminals 1 and 2 are the input terminals,

and terminal 3 is the output

terminal. Many op-amps use

o DC po

tw

o terminals, 4 and 5, are

tw

connected to a positiv

wer supplies. The

e voltage

(V+) and negative voltage

(V–), respectively. The TA12/K-40 uses a single supply

with g

round tied to the

input.

o input terminals and

V+

1

2

V–

4

–

+

5

V–

Figure 3

3

In order to control the gain of our circuit we use

feedback to close the loop around the op-amp as

shown in Figure 5.

This circuit consists of an opamp and two resistors R1 and R2. Resistor R2 is

connected from the output terminal of the op-amp,

minal 3, back to the negative input ter

ter

minal,

terminal 1. We speak of R2 as applying negative

feedback; if R2 were connected between terminals

3 and 2, we would call this

positive feedback

. Note

that R2 closes the loop from the output terminal

k around to the input terminal of the op-amp. In

bac

this circuit, the closed loop gain (G) of the op-amp,

from the input Vi to the output terminal, depends on

the ratio of R2 to R1.

R2

1

+

Vi

R1

–

–

2

+

3

+

V0 = –(R2/R1) Vi

–

or

V0 = – GVi

Figure 5

For example, if R2 = 100 and R1 = 10, the gain G =

R2/R1 = 100/10 = 10. Thus, the output voltage V0

at terminal 3 would be equal to –10(Vi). The (–) sign

indicates that the output and input v

.

opposite polar

ity

oltages are of

-2-

Page 4

CONSTRUCTION

Introduction

The most important factor in assembling your TA-12/K-40 Temperature Adapter Kit is good soldering techniques.

Using the proper soldering iron is of prime importance. A small pencil type soldering iron of 25 - 40 watts is

recommended. The tip of the iron must be kept clean at all times and well tinned.

Safety Procedures

• Wear eye protection when soldering.

Locate soldering iron in an area where you do not have to go around it or reach over it.

•

• Do not hold solder in your mouth. Solder contains lead and is a toxic substance. Wash your hands

thoroughly after handling solder.

• Be sure that there is adequate ventilation present.

Assemble Components

In all of the following assembly steps, the components must be installed on the top side of the PC board unless

otherwise indicated. The top legend shows where each component goes. The leads pass through the

corresponding holes in the board and are soldered on the foil side.

Use only rosin core solder of 63/37 alloy.

Foil Side

DO NOT USE ACID CORE SOLDER!

What Good Soldering Looks Like

A good solder connection should be bright, shiny,

smooth, and uniformly flowed over all surfaces.

1. Solder all components from

the copper foil side only.

Push the soldering iron tip

against both the lead and

the circuit board foil.

2. Apply a small amount of

solder to the iron tip. This

allows the heat to leave the

iron and onto the f

Immediately apply solder to

the opposite side of the

connection, away from the

iron. Allow the heated

component and the circuit

oil to melt the solder.

f

Allow the solder to flo

3.

around the connection.

Then, remove the solder

and the iron and let the

connection cool.

solder should have flowed

smoothly and not lump

around the wire lead.

4.

Here is what a good solder

connection looks like.

oil.

The

Component Lead

Foil

Solder

Foil

w

Solder

F

oil

Soldering Iron

Circuit Board

Soldering Iron

Soldering Iron

Mount Part

Bend Leads to

Hold Part

Solder and

Cut Off Leads

Types of Poor Soldering Connections

1. Insufficient heat - the

solder will not flow onto the

lead as shown.

2. Insufficient solder - let the

solder flow over the

connection until it is

vered. Use just enough

co

solder to co

connection.

3. Excessive solder - could

make connections that you

did not intend to between

adjacent foil areas or

minals.

ter

4. Solder bridges - occur

when solder runs between

circuit paths and creates a

short circuit. This is usually

caused by using too much

solder. To correct this,

simply dr

iron across the solder

bridge as shown.

ag y

ver the

our solder

ing

Rosin

Soldering iron positioned

incorrectly.

Solder

Component Lead

Solder

Solder

Foil

ing Iron

Dr

Gap

ag

-3-

Page 5

ASSEMBLE COMPONENTS TO THE PC BOARD

R2 - 10kΩ Trim Pot

see Figure A)

(

R5 - 1kΩ 5% 1/4W Resistor

(brown-black-red-gold)

R10 - 3.9kΩ 5% 1/4W Resistor

(orange-white-red-gold)

C1 - .01µF, 50V (103) Discap

U2 - MC7805 5V Regulator

(see Figure B)

R4 - 10kΩ 5% 1/4W Resistor

(brown-black-orange-gold)

R8 - 10kΩ Trim Pot

(see Figure A)

Figure A

Insert the trim pot into the PC board

as shown. Solder and cut off excess

leads.

10kΩ Trim Pot

Figure B

Insert the regulator into the PC board

in the direction shown. Solder and cut

off excess leads.

MC7805

Regulator

R3 - 47kΩ 5% 1/4W Resistor

yellow-violet-orange-gold)

(

R1 - 3.9kΩ 5% 1/4W Resistor

(orange-white-red-gold)

U1 - IC Socket 8-pin

U1 - LM1458N Op-Amp IC

(see Figure C)

R6 - 1kΩ 5% 1/4W Resistor

(brown-black-red-gold)

R9 - 10kΩ 5% 1/4W Resistor

(brown-black-orange-gold)

R7 - 3.3kΩ 5% 1/4W Resistor

(orange-orange-red-gold)

Figure C

Insert the 8-pin IC socket into the PC

board in the direction shown. Solder

and cut off excess leads. Then, insert

the LM1458N op-amp IC into the

socket in the same direction shown.

PC Board

PC Board

LM1458N

Op-Amp IC

ket

IC Soc

8-pin

PC Board

-4-

Page 6

FINAL ASSEMBLY

Black

J3 - Battery Snap Red Wire

J4 - Battery Snap Black Wire

J2 - Black Multimeter Lead

(see Figure D)

J1 - Black Multimeter Lead

(see Figure D)

Red

6 - Large Sensor Wire

J

J5 - Small Sensor Wire

(see Figure E)

Figure D

Pull the boot off of the alligator clip (to remove boot, clip

the alligator clip onto a pencil, then pull off boot). Insert

the wire (red wire for red boot, black wire for black boot)

into the alligator clip as shown. Crimp the tabs over the

wire as shown and solder the wire to the clip. Cut off any

excess wire from the solder joint. Slide the boot back onto

the alligator clip.

Figure E

Prepare the ends of the 24” cable as shown in Step A

to the right. Very carefully strip off 1” of casing on

both ends of the cable to expose the two wires inside.

Then strip the insulation off of both ends of the

insulated wire to expose 1/4” of bare wire. On one

end, cut the bare wire so that it is 1/4”

Solder the 2N3904 tr

ansistor to the end of the cable

wire with the 1” bare wire as shown in Step B to the

ight. Slide the 1/2” section of #7 shrink tubing over

r

the bare wire

. Solder the bare wire to the base (B)

and collector (C) leads of the transistor. Slide the #7

tubing over the solder joint. Put your hot soldering

iron or heat gun close to the tubing (do not touch the

tubing). The heat from your iron or heat gun will

shrink the tubing into place. Solder the insulated

wire to the emitter (E) transistor lead.

Slide the 1 1/2” section of 3/16” shrink tubing over the

transistor to cover the exposed wires as shown in

Step C to the right. Shrink the tubing in place with

your iron or heat gun.

Solder the other end of the cable to the PC board.

The insulated wire goes to point J6 and the bare wire

to point J5.

long.

Insulated

Step A

1/4”

Wire

Step B

Step C

Boot

1”

Bare

Wire

1 1/2” Section of

Shrink Tubing

dia.

3/16”

Alligator Clip

¼” ¾”

0 1”

1/4”

½”

Casing

#7 Shrink

ubing

T

Crimp Tabs

1”

(E)

(B) & (C)

Solder

2N3904

ansistor

r

T

1/4”

-5-

Page 7

CALIBRATION

1

. Connect a 9V battery to the battery snap.

2. Connect the positive probe of your digital multimeter to point J1, and the negative probe to GND.

3. Adjust R2 for a reading of about 2.5 to 3V.

4. Then, connect the positive probe of the digital multimeter to J2 and the negative probe to J1.

5. Adjust R8 for the correct temperature reading on the digital multimeter. If you use the 2 volt range, you can

read the temperature to one tenth of a degree (that is, if the reading on the digital mulitmeter shows 0.733,

then you should read the temperature as 73.3

O

F).

COMPONENT CHECK

1. Recheck all of the values of the resistors, and make sure that they are placed in their exact location.

2. Be sure that the temperature sensor (2N3904) wire are soldered to their correct positions.

3. Be sure the notch of the op-amp (1458) is installed in the same direction as the marking on the PC board.

4. Be sure the regulator (7805) is mounted as instructed in the manual.

TROUBLESHOOTING

Contact Elenco®Electronics if you have any problems. DO NOT contact your place of purchase as they will not

be able to help you.

1. One of the most frequently occurring problems is poor solder connections. Tug slightly on all parts to make

sure that the

2. All solder connections should be shiny. Resolder any that are not.

3. Solder should flow into a smooth puddle rather than a round ball. Resolder any connection that has formed

into a ball.

4. Have any solder bridges formed? A solder bridge may occur if you accidentally touch an adjacent foil by

using too much solder or by dragging the soldering iron across adjacent foils. Break the bridge with your

soldering iron.

y are indeed soldered.

SCHEMATIC DIAGRAM

-6-

Page 8

QUIZ

Fill in the blanks and check your answers below.

1. The three main sections of the TA-12/K-40 are

________________, ________________, and

________________.

2. The output voltage of the LM7805 regulator is

_____ volts.

3. Name the three terminals of the transistor:

__________, __________, and __________.

4. The __________ and __________ leads of the

transistor are shorted together to make the

sensor.

5. At a constant current, the voltage across the base

to emitter junction decreases by approximately

______ f

or ever

y ______ increase in temper

ature.

6. The op-amp has ______ inputs terminals and

______ output terminal.

7. The TA-12/K-40 circuit uses __________

feedback to control the gain of the op-amp.

8. In the TA-12/K-40 circuit, a __________ supply is

used to power the op-amp.

9. In an ideal op-amp, the input impedance is

________, the output impedance is ________

and the open loop gain A is ideally ________.

10. You adjust trim pot ______ for the correct

temperature reading on the meter.

Elenco®Electronics, Inc.

150 Carpenter Avenue

Wheeling, IL 60090

(847) 541-3800

Website: www.elenco.com

e-mail: elenco@elenco.com

F; 6. two, one; 7. negative; 8. single; 9. infinite, zero, infinite; 10. R8

O

5. 1mV, 1

Answers: 1. voltage regulator, temperature sensor, op-amp; 2. five; 3. collector, base, emitter; 4. collector, base;

Loading...

Loading...