Page 1

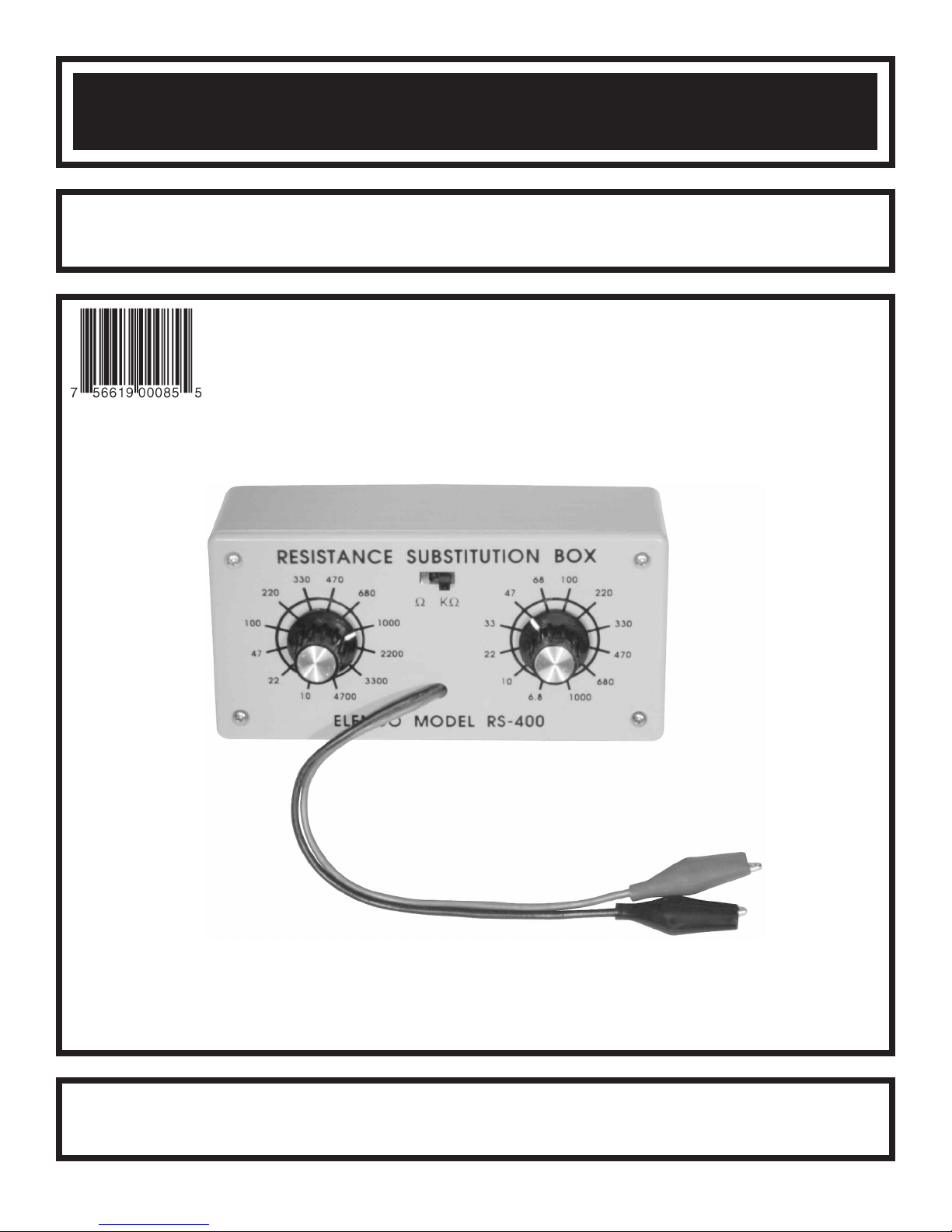

RESISTANCE SUBSTITUTION BOX

MODEL K-37

Assembly and Instruction Manual

Elenco®Electronics, Inc.

ight © 2004 b

yr

Cop

t of this book shall be reproduced b

No par

y Elenco

®

Electronics

y an

y means;

, Inc.

ights reser

All r

electronic

ved. 753400

, photocopying, or otherwise without written permission from the publisher.

Page 2

The Resistance Substitution Box is a convenient instrument in determining the desired resistance values in

circuits under design or test. The values selected for your resistance substitution box were determined to be

the most commonly used in modern solid-state circuits. The values are from 10W to 1,000kW (1 meg) in 24

steps. All resistors are 5% tolerance 1/2 watt.

PARTS LIST

If you are a student, and any parts are missing or damaged, please see instructor or bookstore.

If you purchased this kit from a distributor, catalog, etc., please contact Elenco®Electronics (address/phone/email is at the back of this manual) for additional assistance, if needed. DO NOT contact your place of purchase

as they will not be able to help you.

RESISTORS

Qty. Symbol Description Color Code Part #

1 R1 10W 5% 1/2W brown-black-black-gold 121001

1 R2 22W 5% 1/2W red-red-black-gold 122201

1 R3 47W 5% 1/2W yellow-violet-black-gold 124701

1 R4 100W 5% 1/2W brown-black-brown-gold 131001

1 R5 220W 5% 1/2W red-red-brown-gold 132201

1 R6 330W 5% 1/2W orange-orange-brown-gold 133301

1 R7 470W 5% 1/2W yellow-violet-brown-gold 134701

1 R8 680

1 R9 1k

1 R10

1 R11

1 R12 4.7kW 5% 1/2W yello

1 R13 6.8k

1 R14

1 R15

1 R16

1 R17 47kW 5% 1/2W yello

1 R18 68kW 5% 1/2W

1 R19 100k

1 R20 220k

1 R21

1 R22 470kW 5% 1/2W yellow-violet-yellow-gold 164701

1 R23 680kW 5% 1/2W blue-gray-yellow-gold 166801

R24 1M

1

W 5% 1/2W

W 5% 1/2W

2.2k

W 5% 1/2W

3.3kW 5% 1/2W or

W 5% 1/2W

10k

W 5% 1/2W

22k

W 5% 1/2W red-red-or

33kW 5% 1/2W or

W 5% 1/2W

W 5% 1/2W

330k

W 5% 1/2W or

W 5% 1/2W

blue-gray-brown-gold 136801

brown-blac

red-red-red-gold

ange-or

w-violet-red-gold

blue-gray-red-gold 146801

wn-blac

bro

ange-or

w-violet-or

blue-g

brown-blac

red-red-yellow-gold

ange-orange-y

brown-black-green-gold 171001

k-red-gold

ange-red-gold 143301

ange-gold 151001

k-or

ange-gold 152201

ange-orange-gold

ange-gold 154701

ange-gold 156801

ray-or

k-yello

w-gold

ellow-gold 163301

141001

142201

144701

153301

161001

162201

Qty. Description Part #

1 PC Board 517007

1 Switch SPDT PC Mount 541103

2 Switch 12 Position 542013

2 Knob 622009

1

4

2 Nut 9mm 644102

2 Washer 9mm x 15mm 645103

1 Alligator Clip Black 680001

1 Alligator Clip Red 680002

1

1

1 Solder 9ST4

Case with Co

Screw 4 x 1/2” Phil A 642465

Wire Blac

Wire Red Str

ver 62RS400

k Stranded 12” 814210

anded 12”

MISCELLANEOUS

814215

-1-

Page 3

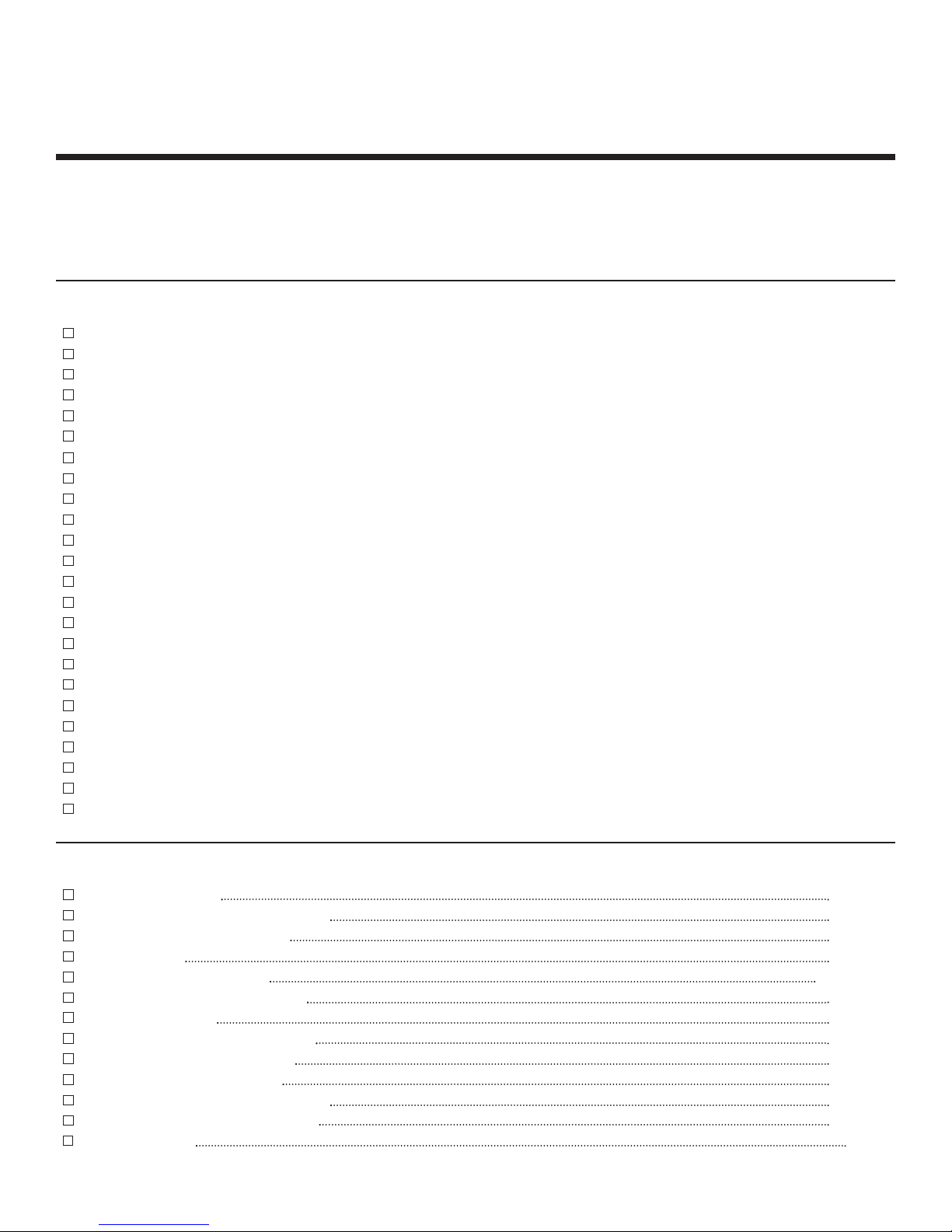

PARTS IDENTIFICATION

Switch PC Mount

witch 12 Position

S

9mm Nut

PC Board

Resistor

Washer

Alligator Clip

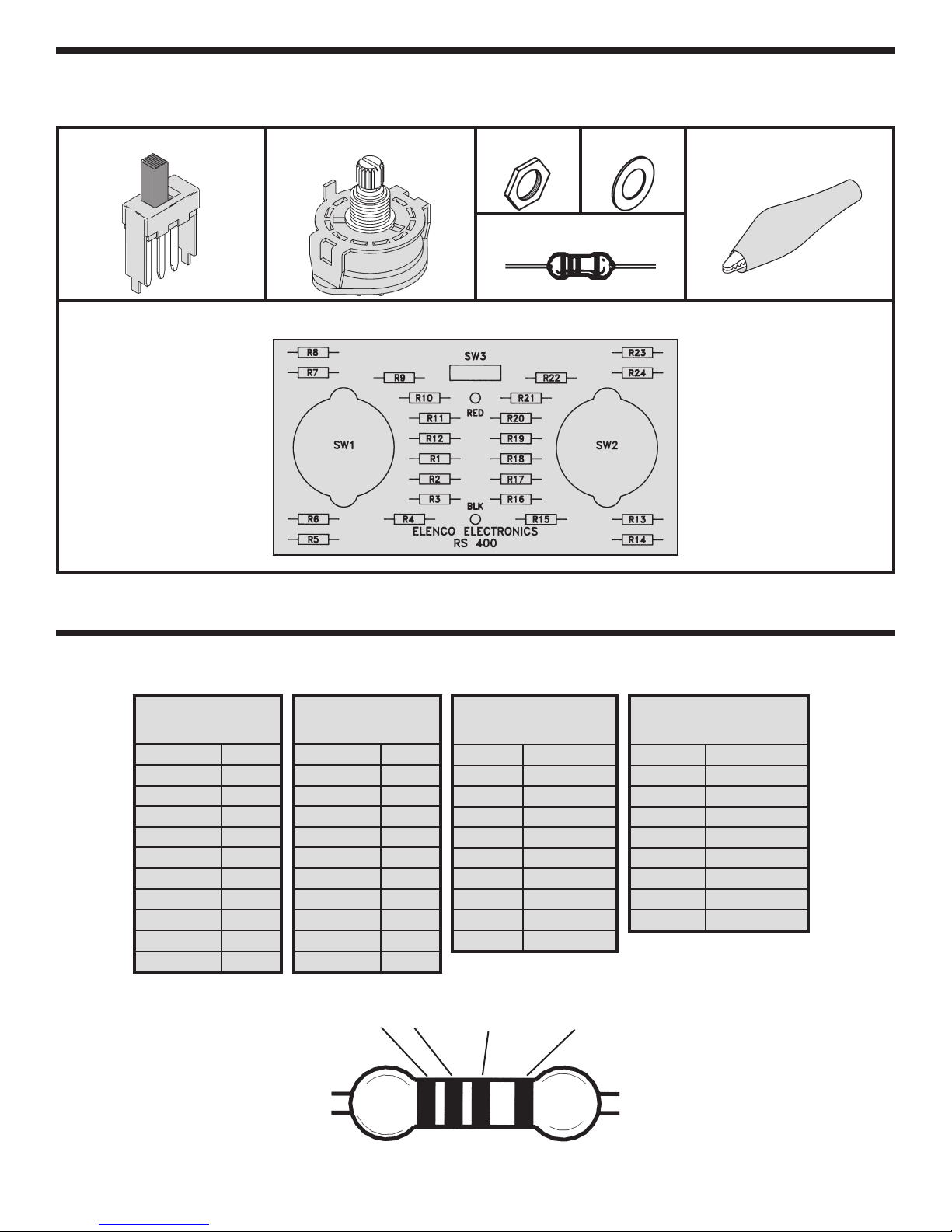

IDENTIFYING RESISTOR VALUES

Use the follo

wing inf

Color Digit

Blac

Brown 1

Red 2

Orange 3

Yellow 4

Green 5

Blue 6

Violet 7

ay

Gr

White 9

ormation as a guide in proper

BAND 1

1st Digit

k

0

8

BAND 2

2nd Digit

Color Digit

k

Blac

Brown 1

Red 2

Orange 3

Yellow 4

Green 5

Blue 6

Violet 7

ay

Gr

White 9

1

ly identifying the v

Multiplier

Color Multiplier

0

8

Black 1

Brown 10

Red 100

ange

Or

Yellow 10,000

Green 100,000

Blue 1,000,000

Silver 0.01

Gold 0.1

BANDS

2 Multiplier T

alue of resistors.

Color Tolerance

Silver ±10%

Gold ±5%

Brown ±1%

1,000

oler

ance

Red ±2%

Orange ±3%

Green ±0.5%

Blue ±0.25%

Violet ±0.1%

Resistance

Tolerance

-2-

Page 4

CONSTRUCTION

Introduction

The most important factor in assembling your K-37 Resistance Substitution Box Kit is good soldering

techniques. Using the proper soldering iron is of prime importance. A small pencil type soldering iron of 25 40 watts is recommended. The tip of the iron must be kept clean at all times and well tinned.

Safety Procedures

• Wear eye protection when soldering.

Locate soldering iron in an area where you do not have to go around it or reach over it.

•

• Do not hold solder in your mouth. Solder contains lead and is a toxic substance. Wash your hands

thoroughly after handling solder.

• Be sure that there is adequate ventilation present.

Assemble Components

In all of the following assembly steps, the components must be installed on the top side of the PC board unless

otherwise indicated. The top legend shows where each component goes. The leads pass through the

corresponding holes in the board and are soldered on the foil side.

Use only rosin core solder of 63/37 alloy.

DO NOT USE ACID CORE SOLDER!

What Good Soldering Looks Like

A good solder connection should be bright, shiny,

smooth, and uniformly flowed over all surfaces.

1. Solder all components from

the copper foil side only.

Push the soldering iron tip

against both the lead and

the circuit board foil.

2. Apply a small amount of

solder to the iron tip. This

allows the heat to leave the

iron and onto the f

Immediately apply solder to

the opposite side of the

connection, away from the

iron. Allow the heated

component and the circuit

oil to melt the solder.

f

Allow the solder to flo

3.

around the connection.

Then, remove the solder

and the iron and let the

connection cool.

solder should have flowed

smoothly and not lump

around the wire lead.

4.

Here is what a good solder

connection looks like.

oil.

The

Component Lead

Foil

Solder

Foil

w

Solder

F

oil

Soldering Iron

Circuit Board

Soldering Iron

Soldering Iron

Types of Poor Soldering Connections

1. Insufficient heat - the

solder will not flow onto the

lead as shown.

2. Insufficient solder - let the

solder flow over the

connection until it is

vered. Use just enough

co

solder to co

connection.

3. Excessive solder - could

make connections that you

did not intend to between

adjacent foil areas or

minals.

ter

4. Solder bridges - occur

when solder runs between

circuit paths and creates a

short circuit. This is usually

caused by using too much

solder. To correct this,

simply dr

iron across the solder

bridge as shown.

ag y

ver the

our solder

ing

Rosin

Soldering iron positioned

incorrectly.

Solder

Component Lead

Solder

Solder

Foil

ing Iron

Dr

Gap

ag

-3-

Page 5

ASSEMBLY INSTRUCTIONS

B

egin the PC board assembly with resistor R12. Be sure to identify the correct value by reading the color code.

P

lace the resistor into the PC board with the leads coming out on the copper foil side. Solder in place and clip

off the excess leads, close to the connection.

R12 - 4.7kW 5% 1/2W Resistor

(yellow-violet-red-gold)

R11 - 3.3kW 5% 1/2W Resistor

(orange-orange-red-gold)

R10 - 2.2kW 5% 1/2W Resistor

(red-red-red-gold)

R8 - 680W 5% 1/2W Resistor

(blue-gray-brown-gold)

R7 - 470W 5% 1/2W Resistor

(yellow-violet-brown-gold)

R9 - 1kW 5% 1/2W Resistor

(brown-black-red-gold)

R1 - 10W 5% 1/2W Resistor

(brown-black-black-gold)

R2 - 22W 5% 1/2W Resistor

(red-red-black-gold)

R3 - 47W 5% 1/2W Resistor

(yellow-violet-black-gold)

R5 - 220W 5% 1/2W Resistor

(red-red-brown-gold)

R19 - 100kW 5% 1/2W Resistor

(brown-black-yellow-gold)

R20 - 220kW 5% 1/2W Resistor

(red-red-yellow-gold)

R21 - 330kW 5% 1/2W Resistor

(orange-orange-yellow-gold)

R23 - 680kW 5% 1/2W Resistor

(blue-gray-yellow-gold)

R24 - 1MW 5% 1/2W Resistor

(brown-black-green-gold)

R22 - 470kW 5% 1/2W Resistor

(yellow-violet-yellow-gold)

R18 - 68kW 5% 1/2W Resistor

(blue-gray-orange-gold)

R17 - 47kW 5% 1/2W Resistor

(yellow-violet-orange-gold)

R16 - 33kW 5% 1/2W Resistor

(orange-orange-orange-gold)

R14 - 10kW 5% 1/2W Resistor

(brown-black-orange-gold)

R6 - 330W 5% 1/2W Resistor

(orange-orange-brown-gold)

R4 - 100W 5% 1/2W Resistor

(brown-black-brown-gold)

R13 - 6.8kW 5% 1/2W Resistor

(blue-gray-red-gold)

R15 - 22kW 5% 1/2W Resistor

(red-red-orange-gold)

-4-

Page 6

SW3 - PC Mount Switch

SW1

Mount SW3 in the place shown on the PC board.

Solder into place.

Red Test Lead

Black Test Lead

Cut off 1 1/2” of wire off of both the red and black

wires (SAVE them for later use). Strip 1/4” of

insulation off both ends of the 10 1/2” red and black

wires and insert them into the holes as marked on

the PC board. Solder into place. Tie a knot with

both wires 1 1/2” from the surface of the PC board

as shown in Figure 1. Pull the wires through the

hole in the cover. Slide the alligator boots onto the

wires. Solder the wires to the alligator clips. Then,

slide the boots onto the clips.

SW2

Bend the tab on the switches

down (see Figure 2). Attach the

two switches loosely to the front

panel with the 9mm nuts and

washers. Line up the holes of

the PC board with the switch

lugs, as shown in Figure 3. Be

sure that the board lays flat,

then solder the lugs into place.

Tighten down the 9mm nuts.

Washer

9mm Nut

Figure 3

Bend Tab Over

Figure 2

PC Board

Cover

Bend T

Figure 1

Wiper Pin

abs

Over Wire

Strip 1/4”

red and black wires. Solder one end of the wire to the

wiper pin on the 12 position switches and the other to

the pad without a hole

Place the knobs loosely on the switch posts. Push

the slide switch to the “W” position. Connect an ohm

meter to the output.

with the v

knob onto the shaft. Push the slide switch to the

“KW” position and repeat the same procedure.

Jumper Wires

Jumper wire from SW1

Jumper wire from SW2

of insulation off of both ends of the 1 1/2”

, as sho

wn in Figure 4.

Installation of Knobs if an Ohm Meter is A

Line up the pointer of the knob

alue shown on your meter, then push the

Wiper Pin

vailab

le

SW2

SW1

Figure 4

-5-

Page 7

Installation of Knobs without an Ohm Meter

C Board

P

ug

L

If an ohm meter is not available, turn both switches

so that the wiper contact is in the position shown in

Figure 5. Start with switch SW1, follow the copper

run on the PC board from the lug in contact with the

wiper to the 470W (R7) resistor, to be sure that the

switch is set in the proper position. Align the knob

iper Contact

on the SW1 (W) switch to the 470 position, push the

W

knob onto the shaft. Follow the same procedure for

switch SW2 (KW), except follow the copper run to

the 6.8KW (R13) resistor. Align the knob on the

SW2 (KW) switch to the 6.8 position.

Figure 5

TESTING THE CIRCUIT

The following test is to be made with your meter to determine that the resistors are in their correct circuit

positions. The resistors used in your circuit are gold banded with a tolerance of +5%. That means that a 10kW

resistor could measure between 9,500W and 10,500W and be correct. Each of the 24 resistance value positions

will be tested and recorded in the chart below.

SW1 WWPOSITION

Value Position Meter Reading

10W

22W

47W

100W

220W

330W

470W

680W

1000W

2200W

3300W

4700W

SCHEMATIC DIAGRAM

SW2 KWWPOSITION

Value Position Meter Reading

6.8KW

10KW

22KW

33KW

47KW

68KW

100KW

220KW

330KW

470KW

680KW

1MW

-6-

Page 8

Elenco®Electronics, Inc.

150 Carpenter Avenue

Wheeling, IL 60090

(847) 541-3800

Web site: www.elenco.com

e-mail: elenco@elenco.com

Loading...

Loading...