Page 1

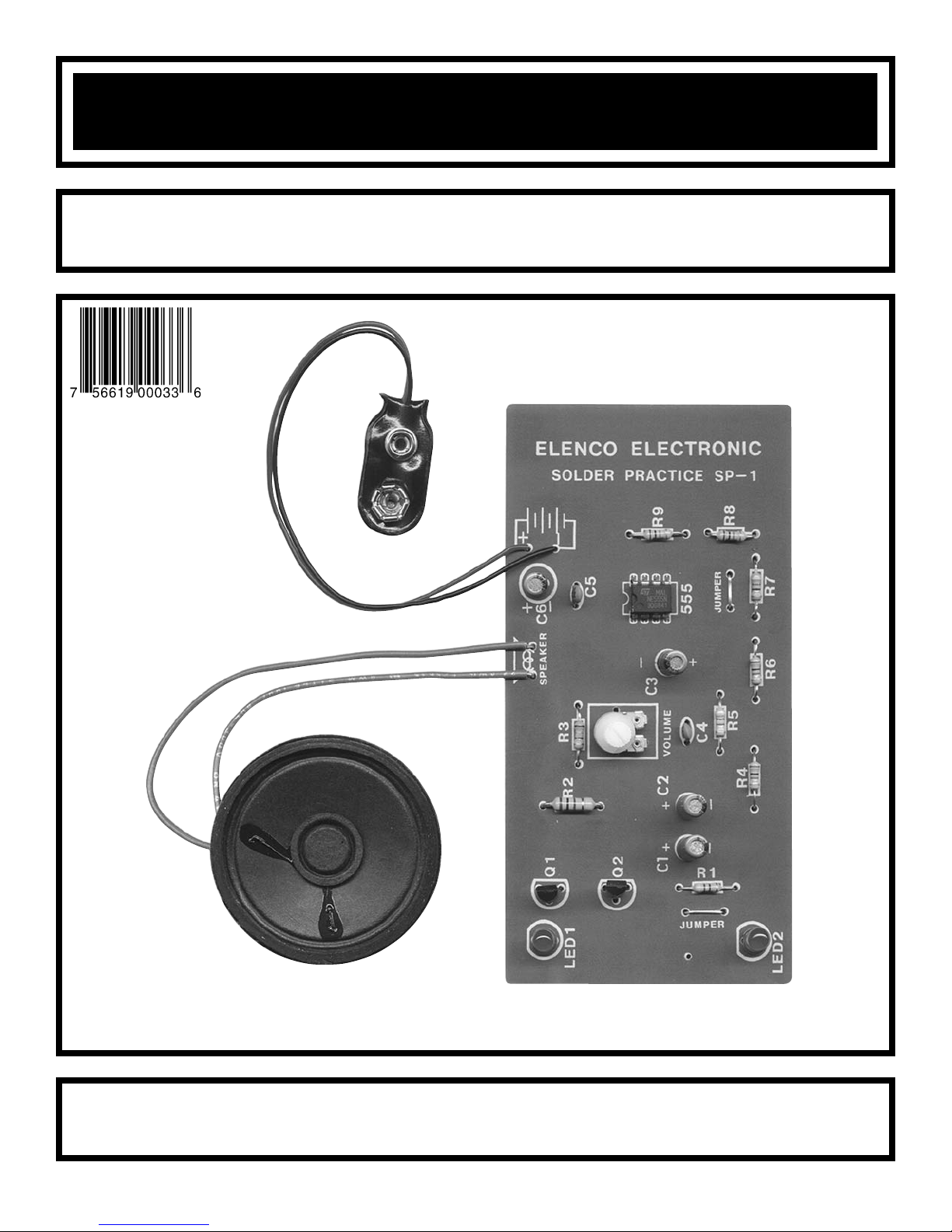

SOLDER PRACTICE KIT

MODEL AK-100 / SP-1A

Assembly and Instruction Manual

Copyright © 2004, 1994 by Elenco®Electronics, Inc. All rights reserved. Revised 2004 REV-I 752601

No part of this book shall be reproduced by any means; electronic, photocopying, or otherwise without written permission from the publisher.

Elenco®Electronics, Inc.

Page 2

PARTS LIST

If you are a student, and any parts are missing or damaged, please see instructor or bookstore.

If you purchased this kit from a distributor, catalog, etc., please contact Elenco®Electronics (address/phone/email is at the back of this manual) for additional assistance, if needed. DO NOT contact your place of purchase

as they will not be able to help you.

RESISTORS

Note: Please refer to page 13 for the resistor reading exercise. This will familiarize you with the resistor color

band coding.

Qty. Symbol Value Color Code Part #

1R3 68Ω 5% 1/4W blue-gray-black-gold 126800

2 R1, R7 470Ω 5% 1/4W yellow-violet-brown-gold 134700

1R2 1kΩ 5% 1/2W brown-black-red-gold 141001

2 R8,R9 10kΩ 5% 1/4W brown-black-orange-gold 151000

2 R4, R6 22kΩ 5% 1/4W red-red-orange-gold 152200

1 R5 47kΩ 5% 1/4W yellow-violet-orange-gold 154700

2 R4A, R6A 56kΩ 5% 1/4W green-blue-orange-gold 155600

1 VR1 200Ω Trim Pot 191321

CAPACITORS

Qty. Symbol Value Description Part #

2 C4, C5 .02μF (203) or .022μF (223) Discap 242010

3 C1, C2, C3 10μF Electrolytic (Lytic) 271045

1 C6 100μF Electrolytic (Lytic) 281044

SEMICONDUCTORS

Qty. Symbol Value Description Part #

2 Q1, Q2 2N3904 Transistor NPN 323904

1 IC1 555 or 1455 Integrated Circuit (Timer) 330555

2 LED1, LED2 Red LED (Light Emitting Diode) 350002

MISCELLANEOUS

Qty. Symbol Description Part #

1 PC Board 511500

1 Solder Wick 556000

1 Battery Snap 590098

1 Speaker 590102

3 Wire 22AWG Topcoat Blue 12” (save one piece for the speaker assembly) 814600

1 Solder Tube Lead-free 9LF96

For AK-100 only:

1 Soldering Iron 9SR1

1 Side Cutters 9ST1

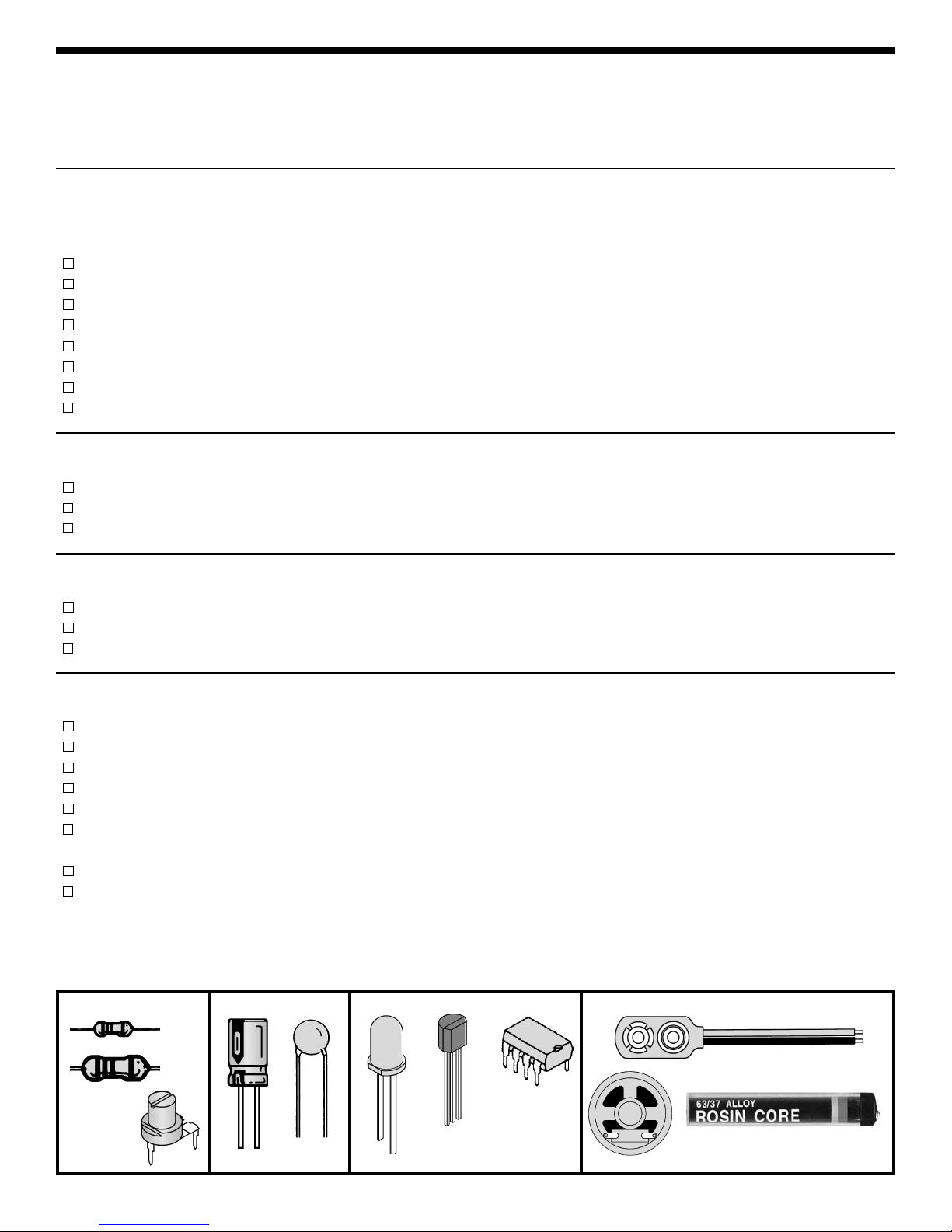

Resistors

Capacitors

PARTS IDENTIFICATION

Electrolytic

Miscellaneous

-1-

Battery Snap

LED

Transistor

Speaker

1/2W

1/4W

Integrated

Circuit (IC)

8-pin

Solder

Discap

Tr i m Po t

Semiconductors

Page 3

-2-

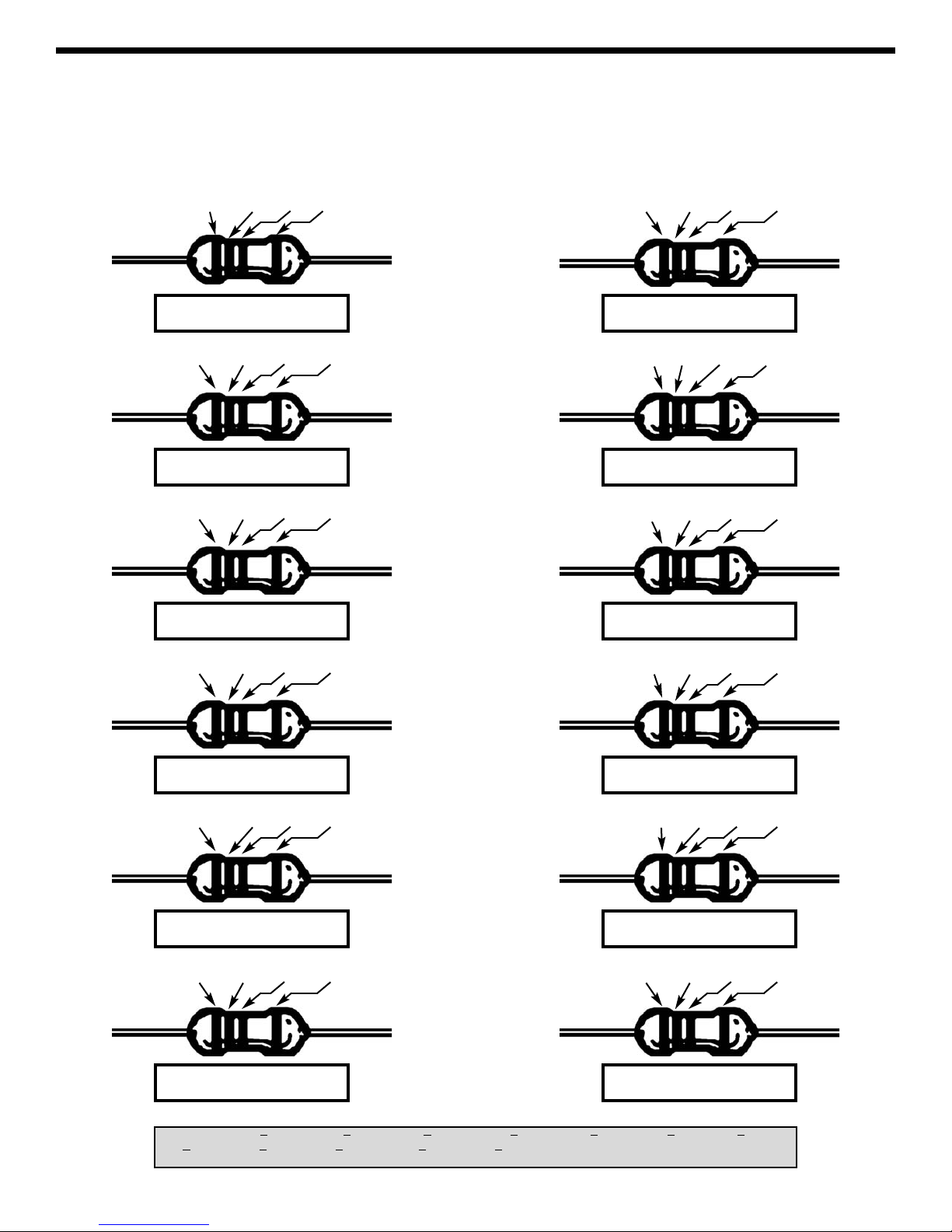

IDENTIFYING RESISTOR VALUES

Use the following information as a guide in properly identifying the value of resistors.

BAND 1

1st Digit

Color Digit

Black 0

Brown 1

Red 2

Orange 3

Yellow 4

Green 5

Blue 6

Violet 7

Gray 8

White 9

BAND 2

2nd Digit

Color Digit

Black 0

Brown 1

Red 2

Orange 3

Yellow 4

Green 5

Blue 6

Violet 7

Gray 8

White 9

Multiplier

Color Multiplier

Black 1

Brown 10

Red 100

Orange 1,000

Yellow 10,000

Green 100,000

Blue 1,000,000

Silver 0.01

Gold 0.1

Resistance

Tolerance

Color Tolerance

Silver +10%

Gold +

5%

Brown +1%

Red +2%

Orange +

3%

Green +.5%

Blue +.25%

Violet +

.1%

BANDS

1

2 Multiplier Tolerance

IDENTIFYING CAPACITOR VALUES

Capacitors will be identified by their capacitance value in pF (picofarads), nF (nanofarads), or μF (microfarads). Most

capacitors will have their actual value printed on them. Some capacitors may have their value printed in the following

manner. The maximum operating voltage may also be printed on the capacitor.

Second Digit

First Digit

Multiplier

Tolerance

The letter M indicates a tolerance of +

20%

The letter K indicates a tolerance of +10%

The letter J indicates a tolerance of +5%

For the No.01234589

Multiply By 1 10 100 1k 10k 100k .01 0.1

Multiplier

Note: The letter “R” may be used at times

to signify a decimal point; as in 3R3 = 3.3

103K

100V

Maximum Working Voltage

The value is 10 x 1,000 = 10,000pF or .01μF 100V

10μF 16V

METRIC UNITS AND CONVERSIONS

Abbreviation Means Multiply Unit By Or

p Pico .000000000001 10

-12

n nano .000000001 10

-9

μ micro .000001 10

-6

m milli .001 10

-3

– unit 1 10

0

k kilo 1,000 10

3

M mega 1,000,000 10

6

1. 1,000 pico units = 1 nano unit

2. 1,000 nano units = 1 micro unit

3. 1,000 micro units= 1 milli unit

4. 1,000 milli units = 1 unit

5. 1,000 units = 1 kilo unit

6. 1,000 kilo units= 1 mega unit

Page 4

-3-

RESISTOR READING EXERCISE

Before starting assembly of your solder practice project, you should be thoroughly familiar with the 4-band color

code system. Many of the resistor values will be identified by color bands and it is easy to mistake their value

if you read the colors incorrectly or read the value from the wrong end. Do the following exercise in resistor

values. Place your answer in the box beneath the resistor. Answers are on the bottom of this page.

(1) brown-green-red-gold

(3) brown-black-yellow-gold

(5) yellow-violet-brown-gold

(7) yellow-violet-black-gold

(9) orange-orange-red-gold

(11) brown-black-green-gold

(2) brown-black-orange-gold

(4) red-red-orange-gold

(6) blue-gray-orange-gold

(8) brown-blue-brown-gold

(10) green-brown-red-gold

(12) brown-gray-orange-gold

Answers to Resistor Reading Exercise: 1) 1.5kΩ+5%; 2) 10kΩ+5%; 3) 100kΩ+5%; 4) 22kΩ+5%; 5) 470Ω+5%;

6) 68kΩ+

5%; 7) 47Ω+5%; 8) 160Ω+5%; 9) 3.3kΩ+5%; 10) 5.1kΩ+5%; 11) 1MΩ+5%; 12) 18kΩ+5%

Page 5

Almost every electronic device today has a printed

circuit board. Whether you are assembling a PC

board or repairing it, you must understand the basics

of working with these boards.

Good soldering requires practice and an

understanding of soldering principles. This solder

practice project will help you achieve good soldering

techniques, help you to become familiar with a

variety of electronic components, and provide you

with dynamic results. If the circuit has been

assembled and soldered properly, two LED’s will

alternately flash, and the speaker will produce a

wailing sound.

Safety Precautions

Like all electrical devices, the solder station must be

handled with care. The soldering iron and tip can

reach high temperatures and these simple safety

rules should be followed.

• Keep children out of reach of the soldering station.

• To protect your eyes, use safety goggles.

• Keep flammable material away from the soldering

iron.

• DO NOT cool iron

by dipping it into any liquid or

water.

• Always assume that the tip is hot to avoid burns.

• Work in an area that is well ventilated.

• Be careful that the hot soldering iron tip or the

barrel of the iron does not come in contact with any

electrical cord.

• Do not hold solder in your mouth. Solder

contains lead and is a toxic substance. Wash your

hands thoroughly after handling solder.

• Locate soldering iron in an area where you do not

have to go around it or reach over it.

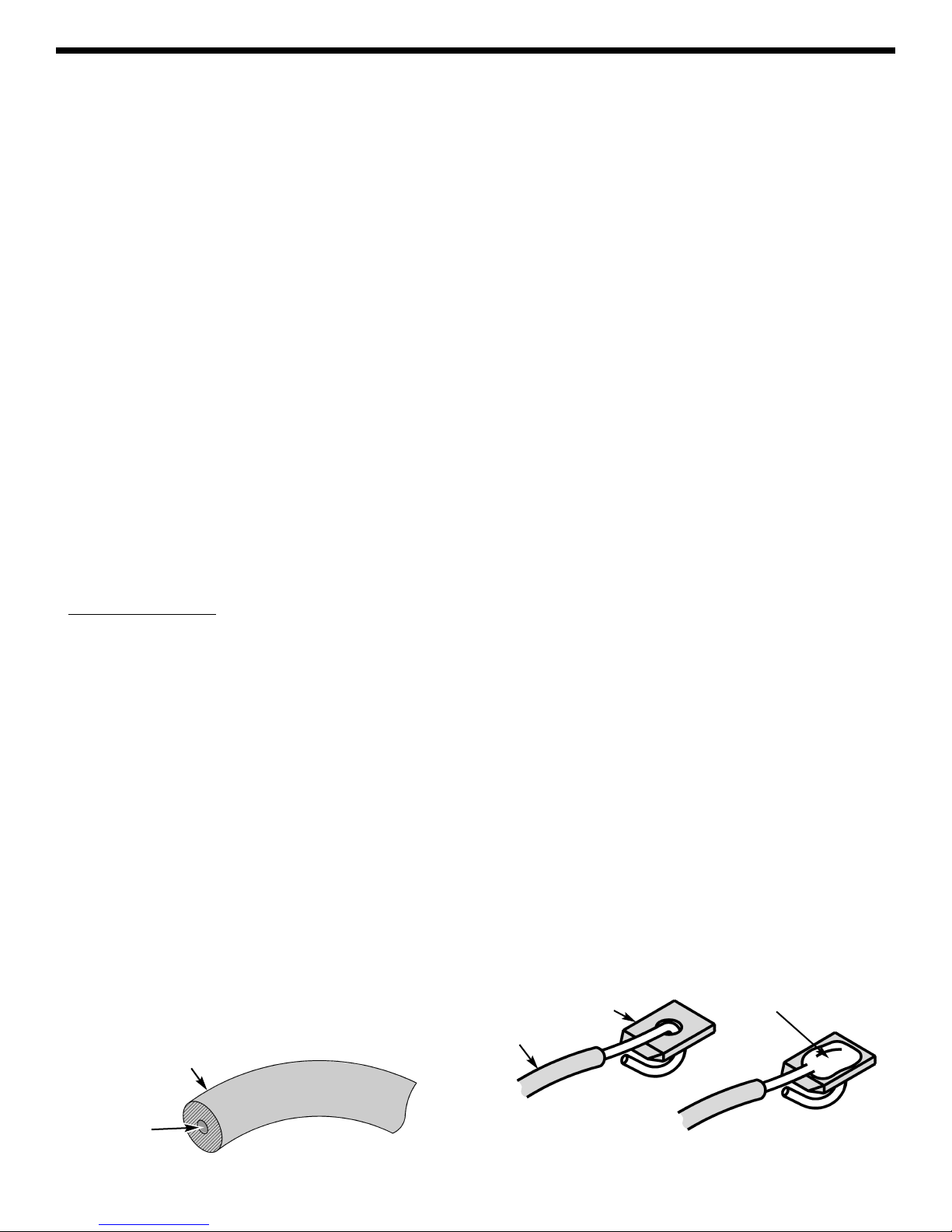

Solder

Solder is a fusible alloy composed of tin and lead.

Some solder may contain small amounts of other

material for use in special purposes to enhance its

characteristics. Solder has a melting temperature

around 360

O

to 370O, making it ideal for forming a

metallic joint between two metals.

Solder is identified by the ratio of tin-to-lead. The

most common ratios are 63/37, 60/40, and 50/50.

The first number indicates the amount of tin, and the

second is lead. A 60/40 solder has 60% tin and 40%

lead. Solder with a greater tin content melts at a

lower temperature, takes less time to harden, and

generally makes it easier to do a good soldering job.

The ratio of tin is a main factor in the strength of the

solder joint. Solder with a greater tin content has a

greater holding ability under stress. Solder with a tin

ratio of 60% is the strongest, while solder with less

than 30% would be undesirable.

Flux

Most solder contains flux in the hollow core of the

solder allowing it to be applied automatically when

you heat the solder. The flux will remove any oxide

film on the metals soldered creating a good metal-tometal contact. This is called “wetting the metal”.

There are three types of solder fluxes: chloride,

organic and rosin. In the electronics industry, only

the rosin type is used. Rosin flux comes in two types,

pure and active. The most reliable is the pure type,

since it doesn’t cause dendrites between tracks on

the PC board as the active type does. Due to the

highly corrosive and moisture attracting

characteristics of the chloride and organic type

fluxes, they should not be used in electronics.

Surface Preparation

In order for the solder to adhere to the connection,

the metals must be clean and free of nonmetallic

materials. Flux in the solder can remove oxides from

metal but not other materials like dirt or grease. To

remove these, use a small steel brush or fine emery

cloth.

Mechanical Connection

When all the surfaces are clean, the metals should

have a solid mechanical connection. Wires should

be tightly wrapped around each other or to the

terminal. This will eliminate large gaps that create

weak solder joints. Solder should not be used as a

mechanical connection.

INTRODUCTION

-4-

Solder

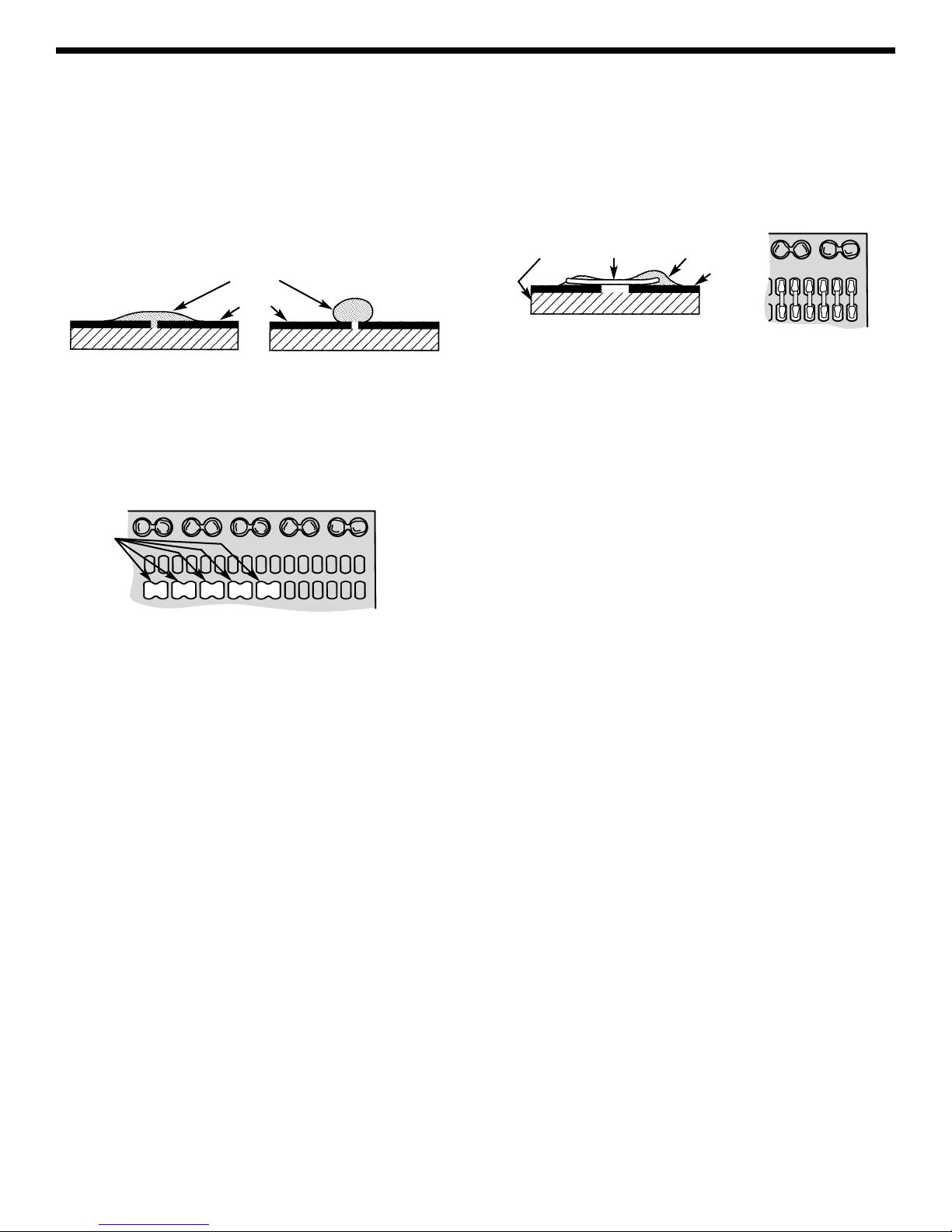

Figure 1

Rosin Core

Solder

Wire

Terminal

Figure 2

Page 6

-5-

Types of Soldering Devices

A number of different types of soldering devices:

irons, guns and stations are available today. Irons

are used for light to medium work and guns are for

medium to heavy-duty work. The station type can

range from light to heavy-duty For working on PC

boards, irons ranging from 15 to 40 watts are

suitable, or a station with a range of 15 to 40 watts.

If you use an iron with a higher wattage rating than

40 watt, you may damage the copper tracks on the

PC board. The higher wattage irons are best suited

for heavy-duty electrical jobs.

Solder Tips

The tip is the very important part of the iron. The

material that the tip is made from is an essential

factor. The soldering iron tip contains four different

metals as shown in Figure 3. The core consists of

copper. Since the copper is a soft material, it is

plated with iron. Chrome plating is used on the area

where no soldering takes place to prevent oxidation.

Then the tip is plated with tin, because it can be

easily cleaned.

Today, tips are manufactured in a variety of different

shapes (see figure below). The chisel shape is one

of the most common. Having a choice of tip styles

allows you to choose the one best suited for your

soldering needs. Due to the high heat, removable

tips can bond themselves to the heating element if

left in place for extended periods of time. Periodic

removal of the tip is therefore advisable.

Tip Cleaning

A good clean solder tip makes soldering much

easier. The tip should be tinned by lightly coating it

with solder to prevent it from oxidizing. The tip can

become pitted (black spots) from normal use. It is

important to clean the tip by wiping it with a wet

sponge or rag. For tips that need a good cleaning,

the tip tinner and cleaner (#TTC1) should be used.

Never use a file or abrasive material to clean the

tip. Using such methods will damage the plating and

ruin the tip. Do not remove the excess solder from

the tip before storing. The excess solder will prevent

oxidation.

Clean Connections

Proper solder adhesion requires that the metal

surface to be free of dirt and grease. The flux only

removes the oxides so a brush or rag can be used to

clean metal. There are contact cleaners in aerosol

cans and other solvents available.

Desoldering

Great care should be taken when repairing or

correcting a mistake on a PC board. The metal foil

can be easily pulled up or broken from excessive

heat. Use the least amount of heat as possible. You

can use a desoldering tool, bulb, wick or a station.

These tools will remove the solder enabling you to

correct the problem.

Soldering Iron

Soldering Gun

Soldering Station

Desoldering Pump Bulb

Solder Wick

CopperChrome Plating Iron Plating

Tin Plating

Figure 3

Desoldering Station

1/32”

1/64”

1/16”

1/8”

3/64”

Page 7

-6-

Double Pads

Before we begin to assemble and solder

the components to the solder practice

PC board, we will start first by practice

soldering to the double pads on the

edge of the PC board (see Figure 3).

1. Apply a small amount of solder to the iron tip. This

allows the heat to leave the iron and onto the foil.

2. Place the iron on the top half of pad and then

apply the solder (see Figure 4). Allow the solder

to flow around the pad. Then, remove the solder

and the iron and let the solder cool. The solder

should be neat and smooth.

3.

Repeat step 2 on the top row of the pads (see Fig. 4).

Single Pads

Now practice using the single pads. Use the same

soldering procedures as the large double pads. Be

sure there are no solder bridges between the pads.

(Refer to the Solder Bridge Section below).

Solder Bridge

Solder bridges occur when solder runs between

circuit paths and creates a short circuit. This is

usually caused by using too much solder. Using the

top row of single pads, try intentionally to make a

solder bridge on each section (see Figure 5). Then,

remove it by simply dragging your soldering iron

across the solder bridge as shown. It is best to wipe

the iron tip with a wet sponge to remove the solder.

You can also use solder wick as described on page 7.

Solder Resist

The PC board is covered with solder resist over

areas that are not to be soldered. This is done to

reduce soldering shorts to adjacent metal runs. On

the large pad, note that half of the pad is covered

with solder resist. Try soldering to the covered pad.

You will find that it is impossible to solder.

Note: There are three pieces of wire included.

Save one piece for the speaker assembly.

Tack Soldering

You will make 14 tack solder connections by

soldering seven wires to the top row of pads.

1. Cut seven 1 1/2” wires and strip 1/8" insulation off

both ends (see figure below).

2. Place the iron and the wire on top right pad as

shown in Figure 7. Allow the solder to flow around

the wire. Then, remove the iron and let the solder

cool. You may need to add some more solder.

The solder should be neat and smooth.

3. Pull the wire to make sure you have a good solder

joint.

4. Bend the wire and solder it to the next pad, as

shown in Figure 7.

5. Now solder the remaining wires to the pads as

shown in Figure 7.

Figure 3

SOLDER PRACTICE

Figure 4

Solder

Soldering Iron

Figure 5

Soldering Iron

Drag Iron

Solder Bridges

PC Board

Figure 6 Practice Solder Area

Tack Solder

Pad

Small

Pads

Large

Pads

Figure 7

Soldering Iron

Solder

1 1/2”

(Actual Size)

1/8”

1/8”

Page 8

-7-

Hairline Cracks

The hairline cracks can develop in the copper foil if

the PC board is flexed. This can be easily repaired

by making a solder bridge across the two foils. The

solder should smoothly flow across the foil as shown

in Figure 8. If the solder does not adhere to the foil,

it will sit on the foil as a blob as shown in Figure 9.

1.

Make five solder bridges using the second row of

single pads, starting from the left side (see Figure 10).

Reinforcing a Repair

A solder bridge repair can be reinforced using a solid

wire. Now add a wire to the five solder bridges you

just made.

1. Strip a 1/2" of insulation off one end of the wire

and then tin it.

2. Hold the tinned wire on top of the solder bridge.

3. Place the iron on the wire until the solder melts.

4. Remove the iron while holding the wire in place

against the foil. Make sure the wire does not

move until the solder hardens.

5. Check for a good solder connection.

6. Cut the wire off as close to the solder joint as

possible.

7. Practice this procedure four more times.

Wide Gaps

For wider gaps in a copper foil, a solder bridge can

not be used. A small wire would be used to bridge

the copper as shown in Figure 11. Six bridges will be

made across the two rows of small pads.

1. Place the iron on the top half of pad and then

apply the solder. Allow the solder to flow around

the pad. Then, remove the solder and the iron

and let the solder cool. The solder should be neat

and smooth.

2. Repeat Step 1 on the lower pad.

3. Strip 1/2" of insulation off one end of the wire and

then tin it.

4. Hold the wire on the top pad and then place the

iron on the wire. The solder will melt and the wire

will press down against the pad (see Figure 11).

Remove the iron while holding the wire in place

against the foil. Make sure the wire does not

move until the solder hardens.

5. Check for a good solder connection.

6. Solder the wire to the lower pad.

7. Cut the wire off as close to the solder joint as

possible (see Figure 11).

8. You can hold the wire down with a screwdriver

and resolder the wire.

9. Practice this procedure four more times on

remaining pads.

Figure 8 Figure 9

Solder

Foil

Figure 11

Solder

Foil

Bare Wire

Board

Figure 10

Solder

Bridges

PC BOARD REPAIR

Page 9

-8-

Desoldering wick is a braided wire coated with noncorrosive rosin flux. It is the simplest and safest tool

for removing solder from a solder connection. When

the braided wire is heated, the flux cleans and

breaks up the surface tension so the melted solder

from the connection flows into the braid by capillary

action.

Included in this kit is a six inch length of solder wick

(desoldering braid).

Place the solder wick on one of the pads and the

iron on top of it (see Figure 12).

As the solder melts, it will be drawn into the wick.

When the iron and wick are removed, the solder

should be removed. You need to repeat the

process if some solder remains.

If necessary, repeat the procedure until all of the

unwanted solder is removed.

After the excess solder has been wicked away by the

desoldering braid, clip off and discard the soldersaturated portion of the braid. For best results,

always use a fresh area of the braid for each

procedure.

Figure 12

Figure 13

Using solder wick to remove excess solder.

A close-up view of the accumulation of solder onto

the solder wick (desoldering braid).

Excess Solder

Solder Wick

Soldering Iron Tip

Foil Side of PC board

CAUTION: Wick gets

HOT - use long nose

pliers to hold wick.

REMOVING EXCESS SOLDER USING SOLDER WICK

Using the Solder Wick

Page 10

-9-

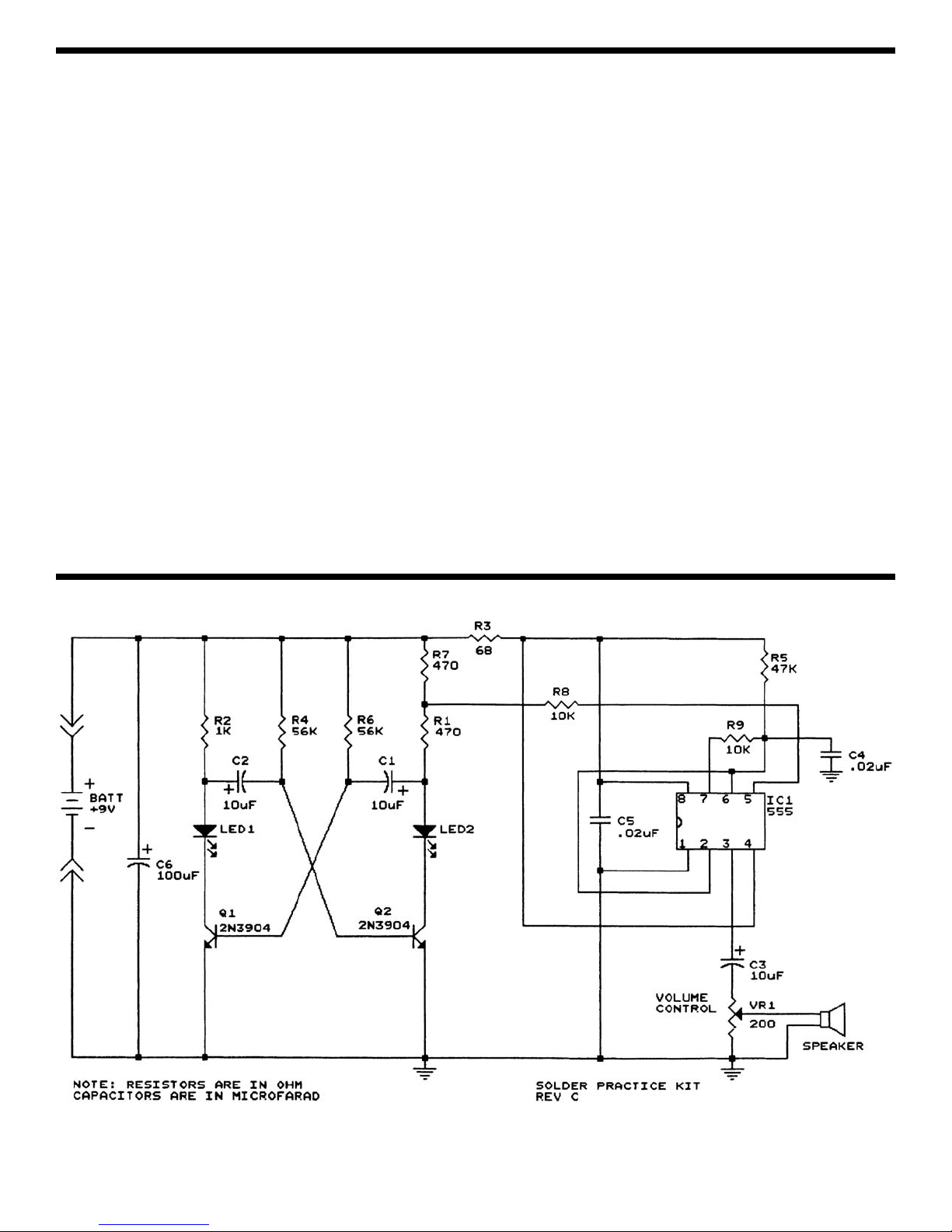

The solder practice kit consists of a circuit oscillating

at one hertz (one cycle per second). The oscillator

consists of two transistors Q1 and Q2, and resistors,

R1 - R11 and capacitors C1 and C2. This

configuration is known as a multivibrator circuit.

The solder practice kit produces the sound of the

European siren. It consists of two oscillators, a one

hertz (one cycle per second) and a 1500Hz. The one

hertz oscillator consists of two transistors Q1 and

Q2, and resistors R1, R2, R6 and R7 capacitors C1

and C2. This configuration is known as a

multivibrator circuit.

When voltage is first applied to this multivibrator

circuit, one transistor (possibly Q1) will conduct

faster, causing transistor Q2 to stay off. Q1 will

continue to conduct until it saturates. At this point,

Q2 will start to conduct, causing Q1 to rapidly cutoff.

This process continues alternately causing Q1 or Q2

to conduct. The output will be a square wave. The

frequency is determined by the time constants of

resistor R6 and capacitor C1, also R4 and C2. Two

LED diodes are placed in the collectors of the

transistors. The LED's will light when current is

passing through them. Resistors R2, R1 and R7

determine the current passing through the LED’s.

Integrated circuit IC1 is the heart of the second

oscillator. A 555 timer IC is used in the circuit. This

IC contains many transistors and resistors on a

silicon chip and thus eliminates many external parts.

The frequency of this oscillator is determined by

resistors R5, R9 and capacitor C4. Capacitor C3

couples the output of operations of IC1 via resistor

R8. This changes the operations of IC1 during one

half cycle of the multivibrator causing the frequency

to change from 1500Hz to 2200Hz. This results in a

speaker output that varies constantly in pitch. The

multivibrator circuit not only causes the LED to flash,

but also varies the pitch at the speaker output.

THEORY OF OPERATION

SCHEMATIC DIAGRAM

Page 11

What Good Soldering Looks Like

A good solder connection should be bright, shiny,

smooth, and uniformly flowed over all surfaces.

Soldering a PC board

1. Solder all components from the copper foil side

only. Push the soldering iron tip against both the

lead and the circuit board foil.

2. Apply a small amount of solder to the iron tip.

This allows the heat to leave the iron and onto

the foil. Immediately apply solder to the

opposite side of the connection, away from the

iron. Allow the heated component and the

circuit foil to melt the solder.

3. Allow the solder to flow around the connection.

Then, remove the solder and the iron and let the

connection cool. The solder should have flowed

smoothly and not lump around the wire lead.

4.

Here is what a good solder connection looks like.

Types of Poor Soldering Connections

1. Insufficient heat - the solder will not flow onto

the lead as shown.

2. Insufficient solder - let the solder flow over the

connection until it is covered. Use just enough

solder to cover the connection.

3. Excessive solder - could make connections

that you did not intend to between adjacent foil

areas or terminals.

Heat Sinking

Electronic components such as transistors, IC’s, and

diodes can be damaged by the heat during

soldering. Heat sinking is a way of reducing the heat

on the components while soldering. Dissipating the

heat can be achieved by using long nose pliers, an

alligator clip, or a special heat dissipating clip. The

heat sink should be held on the component lead

between the part and the solder joint.

SOLDERING

A poorly soldered joint can greatly affect small current flow in circuits and can cause equipment failure. You can

damage a PC board or a component with too much heat or cause a cold solder joint with insufficient heat.

Sloppy soldering can cause bridges between two adjacent foils preventing the circuit from functioning.

Solder

Soldering Iron

Foil

Solder

Soldering Iron

Foil

Component Lead

Soldering Iron

Circuit Board

Foil

Rosin

Soldering iron positioned

incorrectly.

Solder

Gap

Component Lead

Solder

Heat Sink

(this can be ordered as part of Elenco’s

Solder Ease Kit Model SE-1).

Soldering Iron

Solder

Heat Sensitive

Component (Diode)

PC Board

-10-

Page 12

-11-

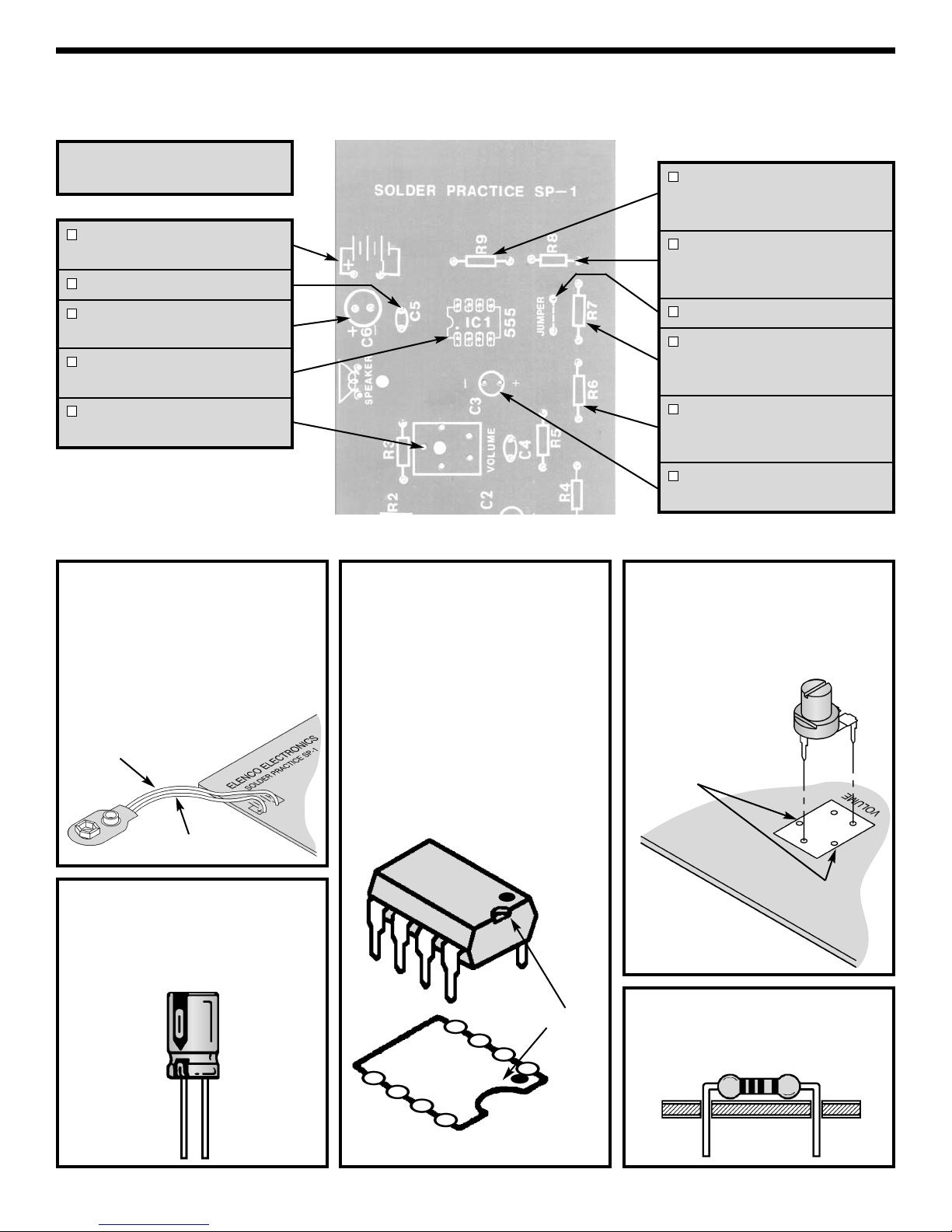

PC BOARD ASSEMBLY

NOTE: Before beginning assembly, please refer to page 13 for the resistor reading exercise. This will familiarize

you with the resistor color band coding.

Battery Snap

(see Figure A)

C5 - .02μF or .022μF Discap

C6 - 100μF Electrolytic (Lytic)

(see Figure B)

IC1 - 555 or 1455 Timer

(see Figure C)

VR1 - 200Ω Potentiometer

(see Figure D)

R9 - 10kΩ 5% ¼W Resistor

(brown-black-orange-gold)

(see Figure E)

R8 - 10kΩ 5% ¼W Resistor

(brown-black-orange-gold)

(see Figure E)

Jumper Wire (see Figure F)

R7 - 470Ω 5% ¼W Resistor

(yellow-violet-brown-gold)

(see Figure E)

R6 - 22kΩ 5% ¼W Resistor

(red-red-orange-gold)

(see Figure E)

C3 - 10μF Electrolytic (Lytic)

(see Figure B)

Figure E

Mount the resistor flat against the PC

board as shown.

Figure B

Electrolytic capacitors have polarity.

Be sure to mount them with the

negative (–) lead (marked on side) in

the correct hole.

(+)

(–)

Figure A

Solder the Red Positive (+) lead of

the battery snap to the hole marked

(+) on the PC board. Solder the

Black Negative (–) lead to the hole

marked (–) on the PC board. Cut off

the excess leads.

Figure C

Mount IC1 in the location shown

below onto the PC board. Be sure

that the notch or dot on the IC is in

the same direction as the marking on

the PC board (see drawing below).

Solder and cut off the excess leads.

NOTE: Do not keep the soldering

iron on the IC leads for extended

periods of time. You run the risk of

overheating the IC, thus damaging it.

Figure D

Mount VR1 into the three holes in the

PC board as shown below. Note that

the other two holes are not used.

Solder and cut off the excess leads.

Solder the following parts to

the PC board.

Notch

or Dot

Red Wire

Black Wire

Holes Not Used

Page 13

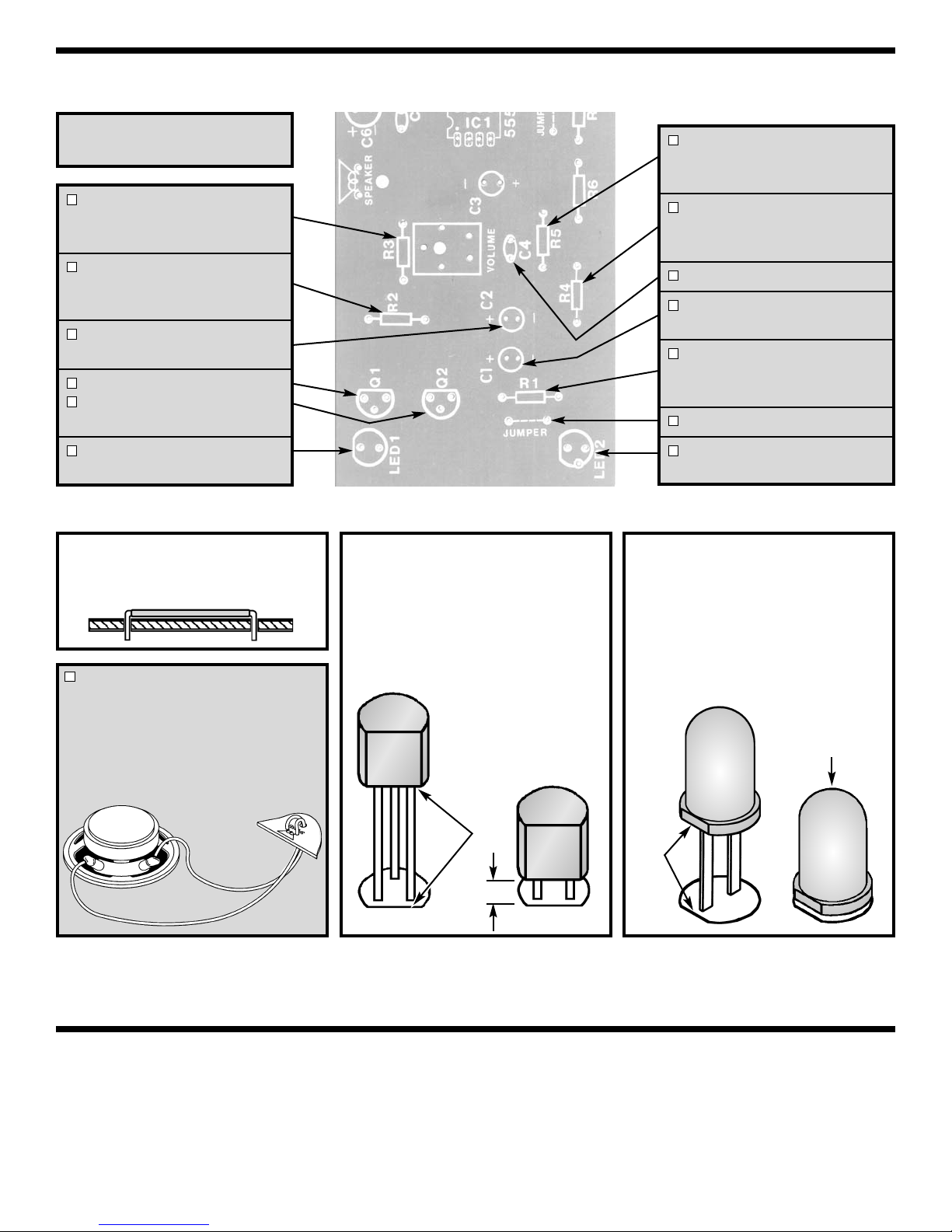

-12-

Figure H

Mount the LED onto the PC board

with the flat side of the LED in the

same direction as marked on the PC

board. Be sure to mount the LED

flush with the PC board as shown

below.

Solder and cut off the excess leads.

Figure G

Mount the IC with the flat side in the

same direction as marked on the PC

board. Leave about 1/8” of space

between the transistor and the PC

board as shown below. Solder and

cut off the excess leads.

PC BOARD ASSEMBLY (continued)

Figure F

Cut a 1” wire and strip 1/8” of

insulation off of both ends.

R3 - 68Ω 5% ¼W Resistor

(blue-gray-black-gold)

(see Figure E)

R2 - 1kΩ 5% ½W Resistor

(brown-black-red-gold)

(see Figure E)

C2 - 10μF Electrolytic (Lytic)

(see Figure B)

Q1 - 2N3904 Transistor

Q2 - 2N3904 Transistor

(see Figure G)

LED1 - Light Emitting Diode

(see Figure H)

R5 - 47kΩ 5% ¼W Resistor

(yellow-violet-orange-gold)

(see Figure E)

R4 - 22kΩ 5% ¼W Resistor

(red-red-orange-gold)

(see Figure E)

C4 - .02μF or .022μF Discap

C1 - 10μF Electrolytic (Lytic)

(see Figure B)

R1 - 470Ω 5% ¼W Resistor

(yellow-violet-brown-gold)

(see Figure E)

Jumper Wire (see Figure F)

LED2 - Light Emitting Diode

(see Figure H)

Flat

1/8”

OPERATION

After completing the assembly of the kit, double back to see that the soldering looks good and all of the

components are in their proper place. If everything is all right, attach the 9V battery to the battery snap. The

LED’s should alternately light and the speaker should sound a wobbling siren.

Continue to the Desoldering Practice/Component Replacement Secton.

Note: Refer to the Troubleshooting Section if your circuit does not work.

Flat

Mount Flush

to PC Board

Cut the 12” wire in half and the strip

1/8” of insulation off of both ends.

Insert the speaker wire through the

PC board as shown. Then, insert

the wires into the speaker holes

and solder. Solder the other end of

the wires to the speaker.

Solder the following parts to

the PC board.

Page 14

-13-

If any parts are missing or damaged, see instructor

or bookstore. DO NOT contact your place of

purchase as they will not be able to help you.

Contact Elenco

®

Electronics (address/phone/e-mail

is at the back of this manual).

If you are experiencing a problem, first read the

theory of operation to familiarize yourself with the

operation.

Component Check

1. Be sure that all components have been mounted

in their correct places.

2. Make sure that C1 and C2, the electrolytic

capacitor is mounted correctly. The negative lead

should be in the hole as shown on the top legend.

3. Have LED’s LED1 and LED2 been installed

correctly? The flat side of their bodies should be

in the same direction as marked on the top

legend. If the LED’s are in backwards, they will

not light.

4. Pay close attention to the red and black wires of

the battery snap. The red wire should be installed

in the positive (+) hole and the black wire in the

negative (–) hole. Snap in a fresh 9-volt battery.

Problems

1. No LED’s Light

• Check the solder connections for the battery

wires and switch.

• Check that all parts are in the correct way.

2. LED1 Does Not Light

• Check C1, LED1 and Q1.

3. LED2 Does Not Light

• Check C2, LED2 and Q2.

4. LED1 or LED2 is Always On

• Check C1 and C2 for opens.

• Check Q1 and Q2 for shorts.

Remember that there are two oscillators. If no sound

comes out of the speaker, but the LED flashes

alternately, then the 555 timer is not working. Be

sure that the volume control is at maximum. Check

the components IC1, R5, R8, R9, C3, C4 and C5. Be

sure that the IC is in properly.

If a steady sound (not wobbling) comes out of the

speaker, then the multivibrator is not working. Check

the components associated with transistor Q1 and

Q2. Check the LED by shorting the transistor

collector to the emitter. The LED should light. If not,

then the LED is either open or backward.

TROUBLESHOOTING

In this exercise you will replace the 22kΩ resistors

R4 and R6 with two 56kΩ resistors. You unsolder the

resistors using the solder wick and then install new

resistors.

1. Remove the battery from the battery snap.

2. Locate the pads that resistor R4 is soldered to.

3. Place the solder wick on one of the pads and the

iron on top of it (refer to page 8).

4. As the solder melts, it will be drawn into the wick.

5. When the iron and wick are removed, the solder

should be removed. You need to repeat the

process if some solder remains.

6. Unsolder the other lead and remove then remove

the resistor.

7.

Follow the same procedure and remove resistor R6.

Now use the resistors R4A and R6A mounted on the

component card, and install them on the PC board.

Reconnect the battery and the kit should oscillate at

the correct frequency.

DESOLDERING PRACTICE/COMPONENT REPLACEMENT

Page 15

-14-

WORD GLOSSARY

Capacitor An electrical component that can

store electrical pressure (voltage)

for periods of time.

Cold Solder Joint Occurs because insufficient heat

was applied or the connection

was moved before the solder had

set. Connection looks crystalline,

crumbly, or dull.

Flux A substance that is used to

cleanse the surface of oxide

before it is soldered. Always

used in electronics work. Most of

the solder used in electronics has

flux built right into it.

Heat Sinking A process of keeping the

component from becoming

overheated during soldering. Any

metal object that can be clamped

to the component lead will work

as an effective heat sink. An

alligator clip or pliers work well.

Integrated Circuit (IC) A type of circuit in which

transistors, diodes, resistors, and

capacitors are all constructed on

a semiconductor base.

Jumper Wire A wire that is connected from one

place to another on a PC board,

thereby making a connection

between two pads.

LED Common abbreviation for light

emitting diode.

Light Emitting Diode A diode made from gallium

arsenide that has a turn-on

energy so high that light is

generated when current flows

through it.

Oxidation Most metals, when exposed to

air, form an oxide on their surface

which prevents solder from

adhering to the metal.

Polarity The division of two opposing

forces or properties.

Printed Circuit Board A board used for mounting

electrical components.

Components are connected

using metal traces “printed” on

the board instead of wires.

Resistor Component used to control the

flow of electricity in a circuit. It is

made of carbon.

Rosin Core Solder The most common type of solder

used in electronics generally

referred to as 63/37 rosin core

solder.

Solder A tin/lead alloy that melts at a

very low temperature, used to

join other metals together. It

produces excellent electrical

connections.

Solder Bridge An unwanted solder connection

between two points that are close

together.

Solder Melting Point The temperature at which a

tin/lead alloy (solder) melts. The

common solder used in

electronics (63% tin / 37% lead)

has a melting point of 370

O

F.

Solder Wick Braided wire coated with flux to

effectively remove solder from a

connection.

Soldering The process of joining two or

more metals by applying solder to

them.

Tack Soldering A connection where the lead or

wire does not have any

mechanical support.

Tinning the Tip A process of coating the

soldering iron tip with solder to

minimize the formation of oxide

on the tip, which would reduce

the amount of heat transfer.

Transistor An electronic device that uses a

small amount of current to control

a large amount of current.

Wire Gauge Refers to the size of the wire. The

bigger the number, the smaller

the diameter of the wire.

18 gauge to 24 gauge is

generally used for hook-up in

electronics.

Page 16

Elenco®Electronics, Inc.

150 Carpenter Avenue • Wheeling, IL 60090

Phone: (847) 541-3800 • Fax: (847) 520-0085

Web site: www.elenco.com • e-mail: elenco@elenco.com

1. Solder is comprised of what two materials?

A. Gold and copper

B. Tin and lead

C. Zinc and copper

D. Lead and aluminum

2. What type of flux should be used in electronics?

A. Chloride

B. Organic

C. Rosin

D. Corrosive

3. When working on PC boards, what wattage range

of iron is ideal?

A. 15-40 watts

B. 50-100 watts

C. 1-10 watts

D. 100-200 watts

4. Tinning the soldering tip will prevent it from . . .

A. heating.

B. melting.

C. soldering.

D. oxidizing.

5. Proper solder adhesion requires that the metal

surface to be . . .

A. solder free.

B. clean.

C. greasy.

D. cold.

6. Solder wick is used to . . .

A. remove solder.

B. solder in small parts.

C. cleaning the soldering iron tip.

D. removing flux.

7. A cold solder joint is caused by . . .

A. a solder bridge.

B. using 60/40 solder.

C. insufficient heat.

D. acid core solder.

8. When two adjacent foils accidentally touch, it is

called . . .

A. a jumper.

B. a blob.

C. a solder hole.

D. a solder bridge.

9. What ratio has the greatest amount of tin?

A. 20/60

B. 40/60

C. 50/50

D. 60/40

10. A good solder connection should be . . .

A. dull and rough.

B. shiny, bright and smooth.

C. lumped around the connection.

D. soldered on one side of the connection.

QUIZ

Answers: 1. B, 2. C, 3. A, 4. D, 5. B, 6. A, 7. C, 8. D, 9. D, 10. B

Loading...

Loading...