Variants Operating Instructions

vario EL cube

Analyzer

Version 17.02.2017

Elementar Analysensysteme GmbH

Variants Operating Instructions vario EL cube ©Elementar Analysensysteme GmbH

Copyright ©Elementar Analysensysteme GmbH

All rights reserved

This document contains proprietary information of Elementar Analysensysteme GmbH. Reprint is

prohibited.

Due to continued product development this information may change without notice. The information

and intellectual property contained herein is confidential between Elementar Analysensysteme GmbH

and the client and remains the exclusive property of Elementar Analysensysteme GmbH. If you find

any problems in the documentation, please report them to us. Elementar Analysensysteme GmbH

does not warrant that this document is error-free.

No part of this publication may be reproduced, stored in a data storage system, or transmitted in any

form or by any means, electronic, mechanical, photocopying, recording or otherwise without the prior

written permission of Elementar Analysensysteme GmbH.

Windows®, Windows XP®, Windows 7® and Windows 10®are trademarks of Microsoft Corporation.

MS-Excel® und MS-Access® are trademarks of Microsoft Corporation.

Elementar Analysensysteme GmbH

Elementar-Straße 1

63505 Langenselbold

Germany

+49 (0) 6184 9393 0

E-Mail: info@elementar.de

Internet: http://www.elementar.de

Variants Operating Instructions vario EL cube ©Elementar Analysensysteme GmbH

Contents 3

Contents

CHAPTER 1 General 7

Revision history ............................................................................................................................................. 8

About this document ...................................................................................................................................... 9

Display conventions .................................................................................................................................... 10

Working with the operating instructions ....................................................................................................... 10

General information on the operating instructions ....................................................................................... 10

Notes regarding modification ....................................................................................................................... 11

Warning notes during operation .................................................................................................................. 11

CHAPTER 2 Oxygen determination with TCD 13

Analytical characteristics and technical specifications ................................................................................. 14

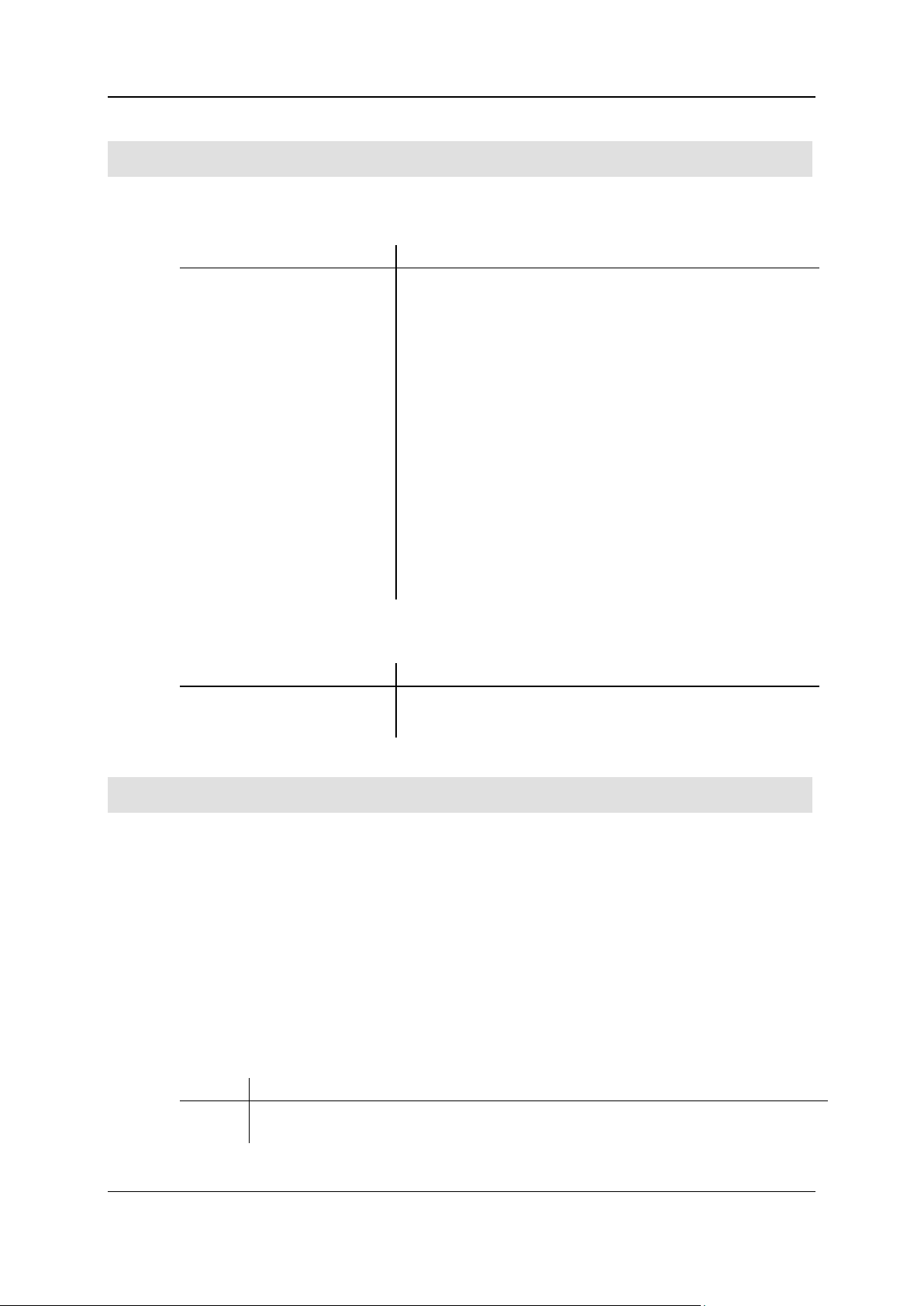

Substance digestion and functional diagram ............................................................................................... 14

Separation of the reaction gases ................................................................................................................. 17

Detection ..................................................................................................................................................... 17

Tube fillings ................................................................................................................................................. 18

Modification to O Mode ............................................................................................................................... 19

Conditioning the pyrolysis tube ................................................................................................................... 23

Changing of the pyrolysis crucible ............................................................................................................... 24

Establishing of the analysis readiness ......................................................................................................... 25

Notes on performing calibration .................................................................................................................. 26

Oxygen analyses in routine operation ................................ ................................................................ ......... 27

Application notes for oxygen determination ................................................................................................. 29

Pyrolysis temperature ...................................................................................................................... 30

Difficult matrices ............................................................................................................................... 30

Lifetime of the pyrolysis tube ............................................................................................................ 31

Additional error messages in O mode ......................................................................................................... 32

CHAPTER 3 Oxygen determination with NDIR 33

Analytical characteristics and technical specifications ................................................................................. 34

Substance digestion and functional diagram ............................................................................................... 34

Detection ..................................................................................................................................................... 38

Tube fillings ................................................................................................................................................. 38

Modification to O Mode ............................................................................................................................... 40

Conditioning the pyrolysis tube ................................................................................................................... 46

Changing of the pyrolysis crucible ............................................................................................................... 47

Establishing of the analysis readiness ......................................................................................................... 48

Notes on performing calibration .................................................................................................................. 49

Oxygen analyses in routine operation ................................ ................................................................ ......... 50

Application notes for oxygen determination ................................................................................................. 52

Pyrolysis temperature ...................................................................................................................... 53

Difficult matrices ............................................................................................................................... 53

Lifetime of the pyrolysis tube ............................................................................................................ 54

Variants Operating Instructions vario EL cube ©Elementar Analysensysteme GmbH

Contents 4

Additional error messages in O mode ......................................................................................................... 55

CHAPTER 4 Oxygen determination with combined NDIR for measuring CO and SO2 57

Analytical characteristics and technical specifications ................................................................................. 58

Substance digestion and functional diagram ............................................................................................... 58

Detection ..................................................................................................................................................... 62

Tube fillings ................................................................................................................................................. 62

Modification to O Mode ............................................................................................................................... 64

Conditioning the pyrolysis tube ................................................................................................................... 71

Changing of the pyrolysis crucible ............................................................................................................... 72

Establishing of the analysis readiness ......................................................................................................... 73

Notes on performing calibration .................................................................................................................. 74

Oxygen analyses in routine operation ................................ ................................................................ ......... 74

Application notes for oxygen determination ................................................................................................. 76

Pyrolysis temperature ...................................................................................................................... 77

Difficult matrices ............................................................................................................................... 77

Lifetime of the pyrolysis tube ............................................................................................................ 78

Variants Operating Instructions vario EL cube ©Elementar Analysensysteme GmbH

Contents 5

Additional error messages in O mode ......................................................................................................... 79

CHAPTER 5 Sulfur determination with NDIR 81

Special features........................................................................................................................................... 82

Functional diagram ...................................................................................................................................... 83

Modification to S operation .......................................................................................................................... 84

CHAPTER 6 Sulfur determination with combined NDIR for measuring CO and SO2 89

Special features........................................................................................................................................... 90

Functional diagram ...................................................................................................................................... 91

Modification to S operation .......................................................................................................................... 92

CHAPTER 7 Chlorine determination with EC cell 97

Analytical characteristics and technical specifications ................................................................................. 98

Substance digestion and functional diagram ............................................................................................... 98

Detection ................................................................................................................................................... 100

Tube fillings ............................................................................................................................................... 100

Notes on performing calibration ................................................................................................................ 102

Chlorine analyses in routine operation ...................................................................................................... 103

Notes on sensitivity and measuring range ................................................................................................. 104

Cross-sensitivity of the EC cells ................................................................................................................ 105

Quantitative conversion from Cl to HCl ..................................................................................................... 106

Maintenance of the HCl EC cells ............................................................................................................... 106

Leak test .................................................................................................................................................... 107

Modification to Cl operation ................................................................................................ ....................... 108

CHAPTER 8 TIC solids module 115

General information ................................................................................................................................... 116

Scope of delivery ....................................................................................................................................... 116

Safety instructions ..................................................................................................................................... 116

Technical specifications ............................................................................................................................ 117

Analytical characteristics ........................................................................................................................... 118

Functional diagram TIC module ................................................................................................................ 119

The components........................................................................................................................................ 121

Tube fillings ............................................................................................................................................... 121

Installation and initial start up of the TIC module ....................................................................................... 123

Selecting the operating mode .................................................................................................................... 126

General measuring principle TIC ............................................................................................................... 127

Analysis run ............................................................................................................................................... 128

Defining custom standard substances ....................................................................................................... 130

Maintenance work ..................................................................................................................................... 130

CHAPTER 9 CHNS determination with the liquid autosampler vario LS 133

CHNS determination with vario LS ............................................................................................................ 134

Tube fillings ............................................................................................................................................... 137

Selecting the operating mode .................................................................................................................... 139

CHNS routine operation ............................................................................................................................ 139

Setting device parameters ......................................................................................................................... 139

Defining custom standard substances ....................................................................................................... 142

Defining custom methods .......................................................................................................................... 142

Modification into CHNS liquid mode .......................................................................................................... 143

Calibration ................................................................................................................................................. 145

View of the analytical results ..................................................................................................................... 147

Check list, prior to the analysis run ............................................................................................................ 147

Shut-down for measuring breaks............................................................................................................... 148

Variants Operating Instructions vario EL cube ©Elementar Analysensysteme GmbH

Contents 6

CHAPTER 10 CHN determination with the liquid autosampler vario LS 149

CHN determination with vario LS .............................................................................................................. 150

Tube fillings ............................................................................................................................................... 153

Selecting the operating mode .................................................................................................................... 155

CHN routine operation ............................................................................................................................... 155

Setting device parameters ......................................................................................................................... 156

Defining custom standard substances ....................................................................................................... 158

Defining custom methods .......................................................................................................................... 158

Modification into CHN liquid mode ............................................................................................................ 159

Calibration ................................................................................................................................................. 161

View of the analytical results ..................................................................................................................... 163

Check list, prior to the analysis run ............................................................................................................ 163

Shut-down for measuring breaks............................................................................................................... 164

CHAPTER 11 Upgrade kit for manual injection 165

Scope of the upgrade kit for manual injection ........................................................................................... 166

Removal of components not needed ......................................................................................................... 167

Installation of the required parts ................................................................................................................ 168

Functional diagram varioELcube CHNS ................................................................................................ .... 170

Functional diagram varioMACROcube CHN ............................................................................................. 172

Functional diagram varioMACROcube CHNS ........................................................................................... 174

Functional diagram varioMICROcube ....................................................................................................... 176

CHAPTER 12 Modification kit for special applications 179

Removing/installing and conditioning the special reaction tubes ............................................................... 180

Removing the special reaction tubes from the furnace .................................................................. 181

Installing special reaction tubes in the furnace and conditioning .................................................... 183

Emptying and filling special reaction tubes ................................................................................................ 188

Emptying special reaction tubes, CHNS / CNS / S mode ............................................................... 189

Filling the special reduction tube, CHNS / CNS / S mode .............................................................. 189

Filling the special combustion tube, CHNS / CNS / S mode .......................................................... 191

Emptying special reaction tubes, CHN / CN / N mode ................................................................... 194

Filling the special reduction tube, CHN/ CN/ N mode..................................................................... 194

Filling the special combustion tube, CHN/ CN/ N mode ................................................................. 196

Index 199

Variants Operating Instructions vario EL cube ©Elementar Analysensysteme GmbH

Purpose

In this chapter

Revision history .............................................................................................................................. 8

About this document ....................................................................................................................... 9

Display conventions .......................................................................................................................10

Working with the operating instructions .........................................................................................10

General information on the operating instructions .........................................................................10

Notes regarding modification .........................................................................................................11

Warning notes during operation ....................................................................................................11

C H A P T E R 1

General

This chapter contains general topics of the document.

Variants Operating Instructions vario EL cube ©Elementar Analysensysteme GmbH

1 - General 8

Revision history

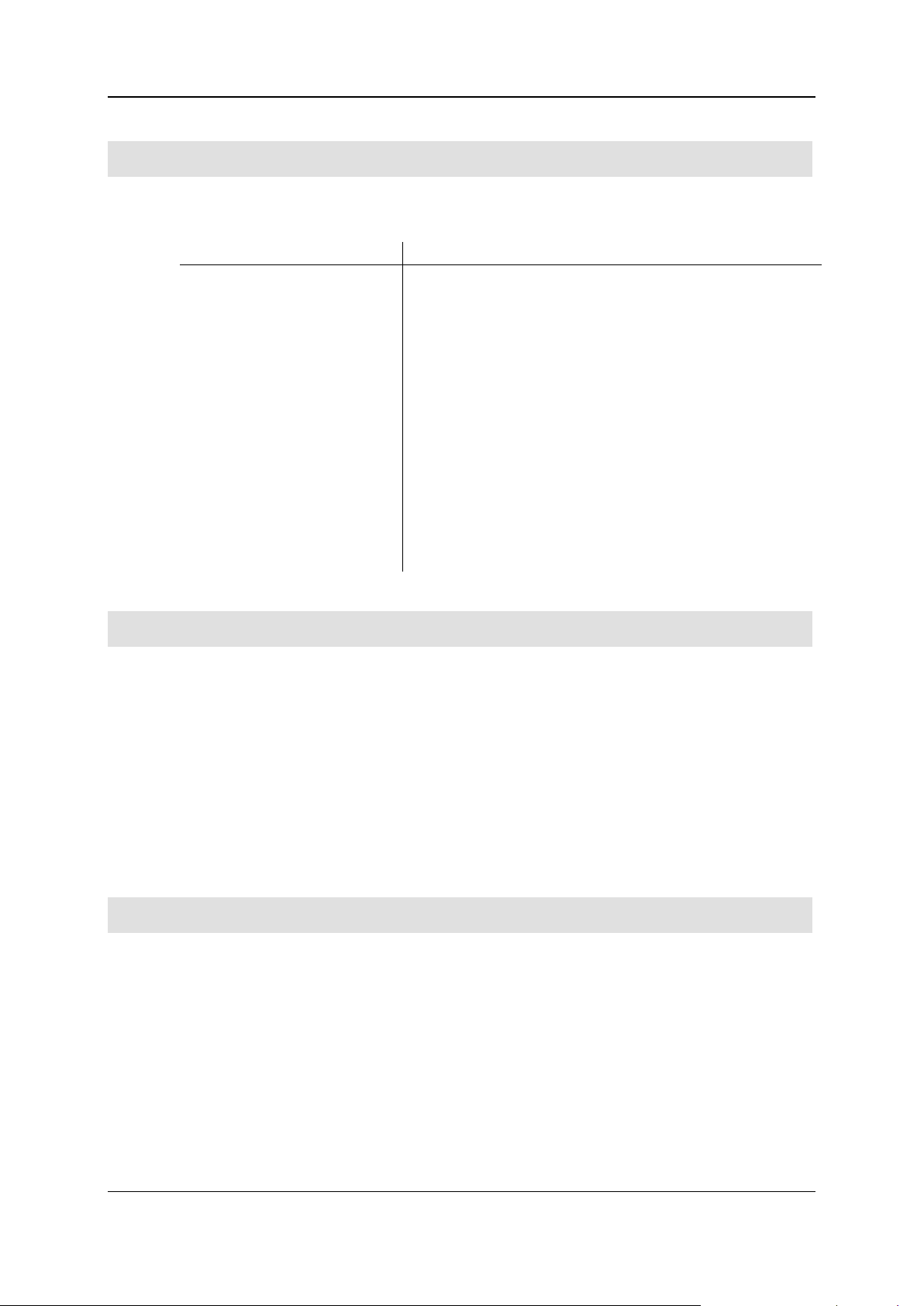

Date

Modification

20.10.2011

Creation.

03.04.2012

Tube 309 omitted.

29.05.2012

Length of empty ash finger in the Cl combustion tube modified.

02.01.2013

Replacing the tube no. 61 (omitted) to no. 108 (added)

14.05.2013

Picture with tube no. 108 removed

14.08.2013

Chapter "Manual injection" added

12.11.2013

Chapter "Modification kit for special applications" added.

18.06.2014

Desorption temperature CO from 260°C to 150°C changed.

19.11.2014

made different small text changes

09.06.2016

Reduction tube filling in CHNS mode with VLS changed

23.08.2016

Combustion tube and reduction tube filling in the CHNS mode with VLS

changed and made further small edits.

15.09.2016

Change of address Langenselbold

17.02.2017

Contents checked

List of modifications in this document up to now

Variants Operating Instructions vario EL cube ©Elementar Analysensysteme GmbH

1 - General 9

About this document

Status of the operating instructions

The status of the operating instructions is: 17.02.2017.

Identification number

The operating instructions identification number is: 19.00-5006.

Validity

The operating instructions are valid for all instruments as from serial number: 19105046.

Variants Operating Instructions vario EL cube ©Elementar Analysensysteme GmbH

1 - General 10

Display conventions

Formatting convention

Type of information

Triangular bullet ()

Step by step procedure. You can follow these instructions to

complete a specific task.

Special bold

Items you must select, such as menu options (e. g. File > New),

command buttons (e. g. Cancel), or common accentuation.

Italics

Used to emphasize the importance of an item or for variable

expressions such as parameters.

CAPITALS

Names of keys on the keyboard, for example, SHIFT, CTRL, or

ALT.

KEY+KEY

Key combinations for which the user must press and hold down

one key and then press another, for example, CTRL+P, or

ALT+F4.

"Quotation marks"

Denote amongst others the names of dialogs in the software, e. g.

the "Replace part" dialog.

{Symbolic name}

Denotes a symbolic name, e. g. {Element} stands for the

corresponding name of an element.

Before you start using this guide, it is important to understand the terms and typographical

conventions used in the documentation. The following kinds of formatting in the text identify special

information.

Working with the operating instructions

Operating the analyzer

Read the operating instructions thoroughly before performing work with the analyzer.

Storing the operating instructions

Store the operating instructions carefully and make sure the instructions are accessible for all relevant

personnel.

Passing on the operating instructions

If you pass on the analyzer, always pass on the operating instructions, too.

General information on the operating instructions

Pictures

The instruments of Elementar underlie a permanent development and adjustment regarding the

optimum parameter settings. This may lead to deviations in terms of picture display of the manual and

the current instrument status which are not relevant for the understanding of the instrument operation.

The valid numbers of the parameter settings and/or variables can be found in the current text part.

Therefore, numbers in the pictures of software dialogs are mainly replaced by spaces or only reflect

examples. They do not reflect the proper, recommended set values.

Reading aids

Subheadings are displayed in the left margin as reading aids. They sum up the content of the

particular section and are useful for quick navigation.

Variants Operating Instructions vario EL cube ©Elementar Analysensysteme GmbH

1 - General 11

Index

Warning

Gas pressure and caustic substances in the instrument

Consumables may escape under pressure and cause chemical burns. Before

performing the work:

Shut off the gas supply. To do so, execute the Options > Maintenance >

Replace parts command.

Caution

Lack of ventilation of the analyzer!

A lack of ventilation leads to overheating of the analyzer. Before you switch off the

instrument:

Ste the setpoint temperatures of the furnaces to 0 °C. To do so execute the

command Options > Settings > Parameter > Temperatures

Allow the furnaces to cool down until the temperature displayed is less than

55 °C

Warning

Hot components in the instrument

When working inside the instrument there is a risk of burning as many parts of the

instrument are hot.

When working inside the instrument always wear protective glasses and the

enclosed heat protection gloves.

An index is given at the end of the operating instructions that helps you locate certain topics more

easily. Index entries always refer to the first page of the section in which the index term is found.

Therefore, don't be confused if the index term does not appear on the first page but rather on one of

the following pages.

Notes regarding modification

Note

Due to the modular design of the analyzer, a large variety of modifications are possible. The individual

modifications described in these instructions are limited to established scenerios in order to keep the

comprehensiveness of the instructions within certain limits.

Warning notes during operation

Note

Always pay attention to careful handling when working with the instrument, especially for

modifications, maintenance and repairing works. The following notes have to be strictly observed

when performing the corresponding works.

Also observe the safety and warning notes in the operating instructions of the basic instrument.

Gas pressure

Please observe the following instruction:

Switching off the instrument

Please observe the following instruction:

Hot instrument parts

Please observe the following instruction:

Variants Operating Instructions vario EL cube ©Elementar Analysensysteme GmbH

1 - General 12

Changing mode

Caution

Overheating if tube fillings are not appropriate for the operating mode!

Overheated tube fillings melt, run into the furnace area and destroy the furnace.

Make sure that the tube fillings correspond to the selected operating mode.

Warning

Sharp pieces of broken glass!

When cold quartz or glass components break there is a risk of cut injuries.

Wear the enclosed protective leather gloves and protective glasses when

handling cold quartz and glass parts.

Caution

Cutting sealing elements apart/out (o-rings, quad rings, half shells, ferrules).

When cutting sealing elements apart/out with a knife you may damage sealing

surfaces.

Never remove sealing elements with a knife but rather with tweezers.

Warning

Hot components in the instrument

When working inside the instrument there is a risk of burning as many parts of the

instrument are hot.

When working inside the instrument always wear protective glasses and the

enclosed heat protection gloves.

Caution

Overheating if tube fillings are not appropriate for the operating mode!

Overheated tube fillings melt, run into the furnace area and destroy the furnace.

Make sure that the tube fillings correspond to the selected operating mode.

Please observe the following instruction:

Filling reaction tubes

Please observe the following instructions:

Installing and conditioning the reaction tubes

Please observe the following instructions:

Variants Operating Instructions vario EL cube ©Elementar Analysensysteme GmbH

Target group

In this chapter

Analytical characteristics and technical specifications ...................................................................14

Substance digestion and functional diagram .................................................................................14

Separation of the reaction gases ...................................................................................................17

Detection .......................................................................................................................................17

Tube fillings ...................................................................................................................................18

Modification to O Mode ..................................................................................................................19

Conditioning the pyrolysis tube ......................................................................................................23

Changing of the pyrolysis crucible .................................................................................................24

Establishing of the analysis readiness ...........................................................................................25

Notes on performing calibration .....................................................................................................26

Oxygen analyses in routine operation ...........................................................................................27

Application notes for oxygen determination ...................................................................................29

Additional error messages in O mode ...........................................................................................32

C H A P T E R 2

Oxygen determination with TCD

Personnel involved with the instrument.

Purpose

This section describes the special features of the oxygen determination with TCD.

Variants Operating Instructions vario EL cube ©Elementar Analysensysteme GmbH

2 - Oxygen determination with TCD 14

Analytical characteristics and technical specifications

Analytical characteristic

Comments

Analysis method

Oxygen determination by pyrolysis of samples, separation of

foreign gases, separation of the desired measuring components,

thermal conductivity detection.

Detector

Thermal conductivity detector (TCD)

Sample weight/sample volume

Approx. < 1 to 10 mg depending on the substance.

Working range

(depending on kit and measuring

mode)

O: 0.03 - 5 mg

Precision / standard deviation

<0,2 % with benzoic acid (approx. 2 mg)

Duration of analysis

(depending on element content

and sample weight)

O: 8 - 15 min

Calibration

Linear and non-linear curve adjustment; total work range.

Data storage and data output

Storage on hard disk or external storage media.

LIMS transfer possible.

Data output to screen and printer.

Reference value

Technical specifications

Supply gases

Helium, purity 99.995%

Consumption of supply gases

Per analysis approx. 1.4 to 2.6 liters helium

Phase

Process

1

The substance to be analyzed is digested in reductive atmosphere at a temperature of

approx. 1,170 °C by means of pyrolysis (cracking).

Analytical characteristics

The following table explains the analytical characteristics:

Technical specifications

The following table contains the technical specifications of the gas supply:

Substance digestion and functional diagram

Introduction

The following section explains:

Which procedures in the pyrolysis tube of the furnace are processed.

How the reaction gas mixture is prepared for adsorption and separation into its constituents.

Processes during substance digestion and preparation of the reaction gas mixture

The substance digestion will be improved with and additive of approx. 8 mg polyethylene (PE)

(temporarily there is a H2 concentration of > 10% in ambiance of the sample).

The O recovery becomes more matrix independent. The PE can be inserted in the carousel in a

second boat.

Substance digestion and preparation of the reaction gas mixture is divided into the following phases:

Variants Operating Instructions vario EL cube ©Elementar Analysensysteme GmbH

Variants Operating Instructions vario EL cube ©Elementar Analysensysteme GmbH

2 - Oxygen determination with TCD 15

2

For the digestion weigh in the sample into silver boats (for liquid samples silver capsules are

available). The folded boat is thrown into the quartz glass pyrolysis tube by means of an

autosampler.

3

The oxygen containing radicals formed in the pyrolysis tube are converted quantitatively at a

carbon contact (special carbon black) into carbon monoxide (Boudouard equilibrium).

4

Acidic pyrolysis products like e.g. H2S, HCN, HCl etc. are absorbed at NaOH by means of

an absorption tube which is downstream of the pyrolysis tube.

5

Usually, water is set free during the reaction of NaOH with an acidic medium. Therefore, the

gas mixture is dried once again after the NaOH layer.

6

Other pyrolysis products like e.g. N2 and CH4 are led to a separation and measuring system

together with the carbon monoxide to be detected.

2 - Oxygen determination with TCD 16

Notes

Two-way valve

Pressure sensor

Gas separation

For a better understanding see also the following illustration (tubing diagram, oxygen determination).

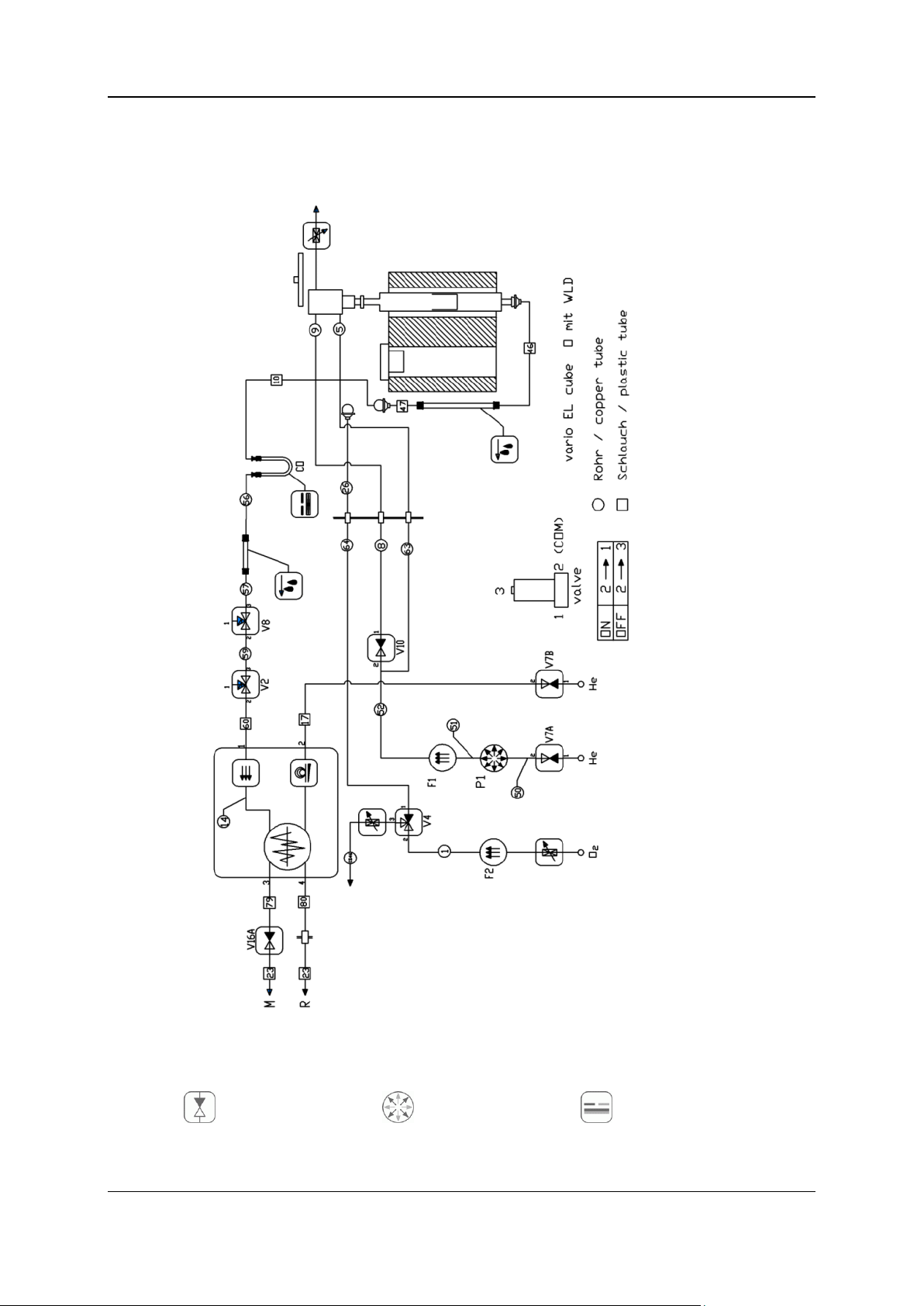

Symbols

The following list names the functional and basic symbols:

Variants Operating Instructions vario EL cube ©Elementar Analysensysteme GmbH

2 - Oxygen determination with TCD 17

Three-way valve

Loop

Measuring cell

Check valve

Heated tube

Sensor

Throttle

Drying

Hose line

Flow controller

Combustion

Copper tube

Flow sensor

Post combustion

Reduction

Pressure contoller

Actuator

Phase

Process

1

The gas mixture of CO and the by-products N2, H2and CH4 flow through the adsorption

column at a temperature of 40 °C.

Thus, the CO is removed quantitatively from the gas stream.

2

As the first component, the by-products unaffected by the adsorption column enter into the

TCD together with the carrier gas helium.

3

The measurement of the N2, H2 and CH4 fractions takes place. The result is ignored

(dummy peak).

4

The adsorption column loaded with CO is heated up to 150°C whereby the CO is desorbed

quickly and flushed by helium into the TCD.

5

A fan cools the adsorption column to cooling temperature of 40 °C and, thus making it ready

for the next analysis sample.

Separation of the reaction gases

Introduction

The following section explains how the individual measuring components in the reaction gas mixture

are separated from each other.

Procedures during separation

The separation of the measuring components is divided into the following phases:

Note

Samples containing fluorine and phosphorus may cause false O results. Fluorine my cause damages

in the instrument, particulary at the quartz parts. Alkaline, earth alkaline and sulfurous samples have

to be loaded with a 1:1 mixture of hexamethylentetramine and ammonia chloride. When measuring

heavy alkaline/earth alkaline samples the pyrolysis tube will corrode.

Detection

Introduction

The method of detection is described under Detection of measuring components and evaluation of

the measuring signal in the vario EL cube operating instructions.

Variants Operating Instructions vario EL cube ©Elementar Analysensysteme GmbH

2 - Oxygen determination with TCD 18

Variations relevant for the oxygen determination

Legend:

1 Ash finger (used as protection tube)

2 Ash crucible

3 Graphite felt (10 mm)

4 Carbon black (55 mm)

5 Support rod (110 mm)

6 Quartz chips, coarse (2-4 mm)

7 Quartz wool (2 mm)

O integration

After the dummy peak integration has been finished, the following is possible:

Directly heat-out the CO collected on the adsorption column (approx. 260°C).

Heat-up the adsorption column to an "interim temperature" (approx. 60°C) in order to

separate hydrocarbons from the CO if necessary.

Prior to the start of the CO integration, another autozero alignment is carried out.

The O integration has been finished if the process time "peak anticipation time for O" (factory set

to 150 sec) has expired, and the dector signal is smaller than the cut-off threshold "O peak"

(defined internally).

Tube fillings

Requirements:

Before starting work, the following requirements must be met:

All quartz and glass components must be cleaned before their usage. Clean the tubes from

fingerprints by means of a suitable solvent (e.g. acetone) before installing. Otherwise there is a

risk of crystallization which will lead to premature ageing of the quartz.

Use chemicals necessary for the tube fillings only in the appropriate quality. Delivery directly from

the instrument manufacturer.

Safety instruction

Strictly observe the safety instruction "Filling reaction tubes" under Warning notes during operation

(on page 11).

Filling of the quartz pyrolysis tube (crack tube) for O determination

The arrangement of the filling must be carried out as shown in the following illustration.

The insert in the core of the tube contains the solid pyrolysis residue as well as the melted silver from

the silver boats.

Variants Operating Instructions vario EL cube ©Elementar Analysensysteme GmbH

2 - Oxygen determination with TCD 19

Removal of traces of moisture and other contaminations from the carrier gas

Legend:

1 Cotton

2 NaOH

3 Quartz wool (10 mm)

4 Sicapent®

5 Gas inlet

For gas drying insert commercial cleaning cartridges between gas delivery point and instrument, if

necessary.

Humid carrier gas causes a CO base which will be collected as a blank on the adsorption column.

Filling the NaOH absorption tube

The following picture shows the filling of the absorbtion tube:

Proceed as follows:

Fill the tube with NaOH (on carrier) and with Sicapent® (identical fill heights).

Close the tube ends with cotton.

Insert the NaOH tube into the already mounted clamps at the left side of the combustion furnace.

Modification to O Mode

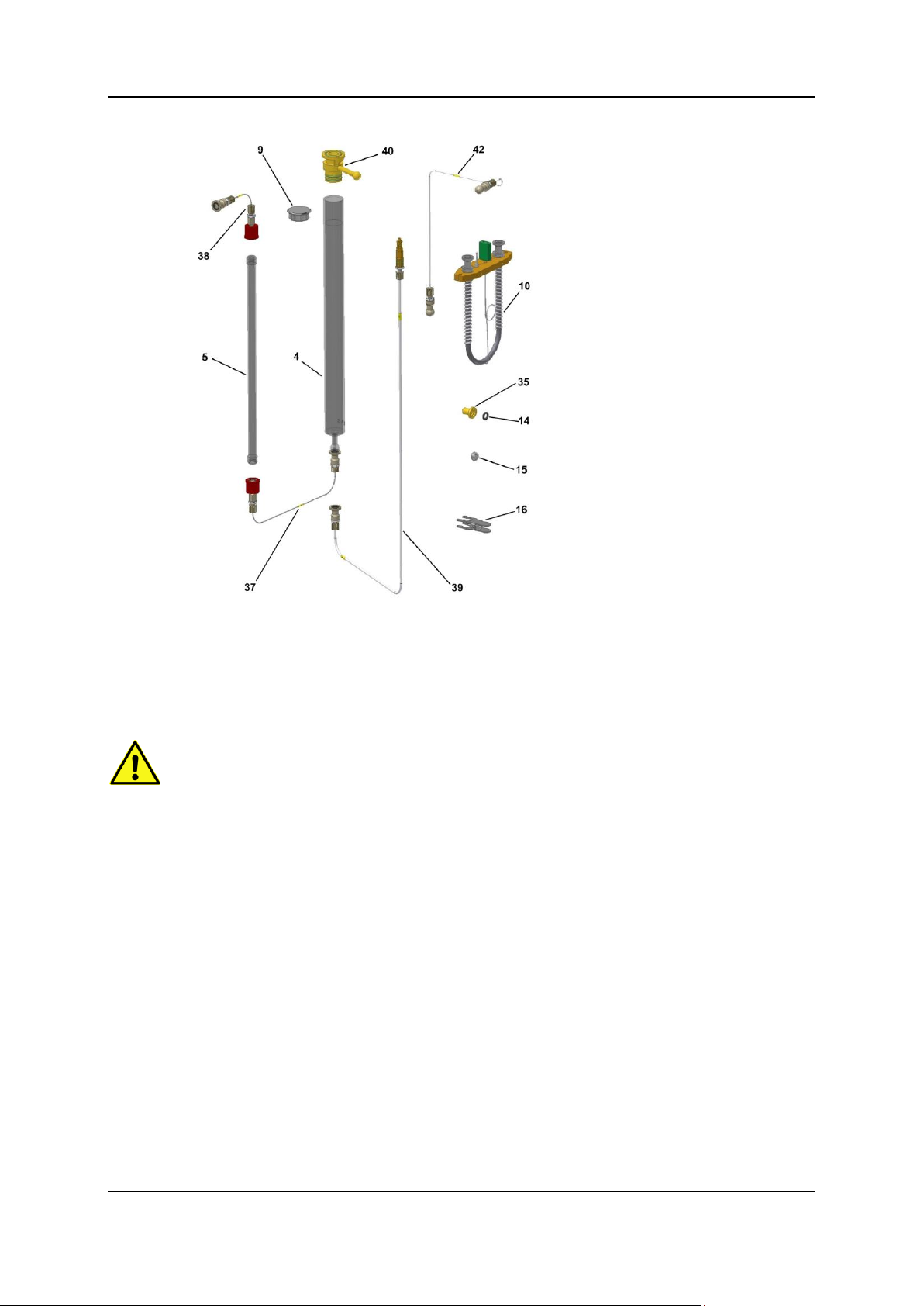

Scope of the modification kit for oxygen determination

Variants Operating Instructions vario EL cube ©Elementar Analysensysteme GmbH

All parts necessary for the tube modification are included in the O upgrade kit for detecting oxygen

with TCD and are labeled with numbers.

2 - Oxygen determination with TCD 20

Legend:

4 Pyrolysis tube

5 Glass tube

9 Insulation plug

10 Adsorption column

14 Quad ring, black

15 Ball

16 Ground-in clamp

35 Pan, closed

37 Tube no. 46

38 Hose line no. 47

39 Hose line no. 48

40 Combustion tube flange

42 Hose line no. 10

Safety instruction

Note

Process

Phase 1: Removal of components not needed

The following parts are also part of the kit but are not pictured.

Sheath tube

Ash crucible

D-sub-adapter

Software update CD.

Strictly observe the safety instruction "Gas pressure" under Warning notes during operation (on

page 11).

To remove/install the tubes proceed as described in chapter Removing standard reaction tubes of the

vario EL cube main operating instructions.

The modification is divided into the following phases:

Removal of components not needed

Modification

Installation of components necessary for the O operation

Proceed as follows:

Before starting the installation of the pyrolysis tube, remove the components as following listed:

O2 supply line

Variants Operating Instructions vario EL cube ©Elementar Analysensysteme GmbH

2 - Oxygen determination with TCD 21

Quartz glass bridge

Combustion tube

Reduction tube with plug

Tube no. 108 (heated)

These components are not needed for the oxygen operation mode.

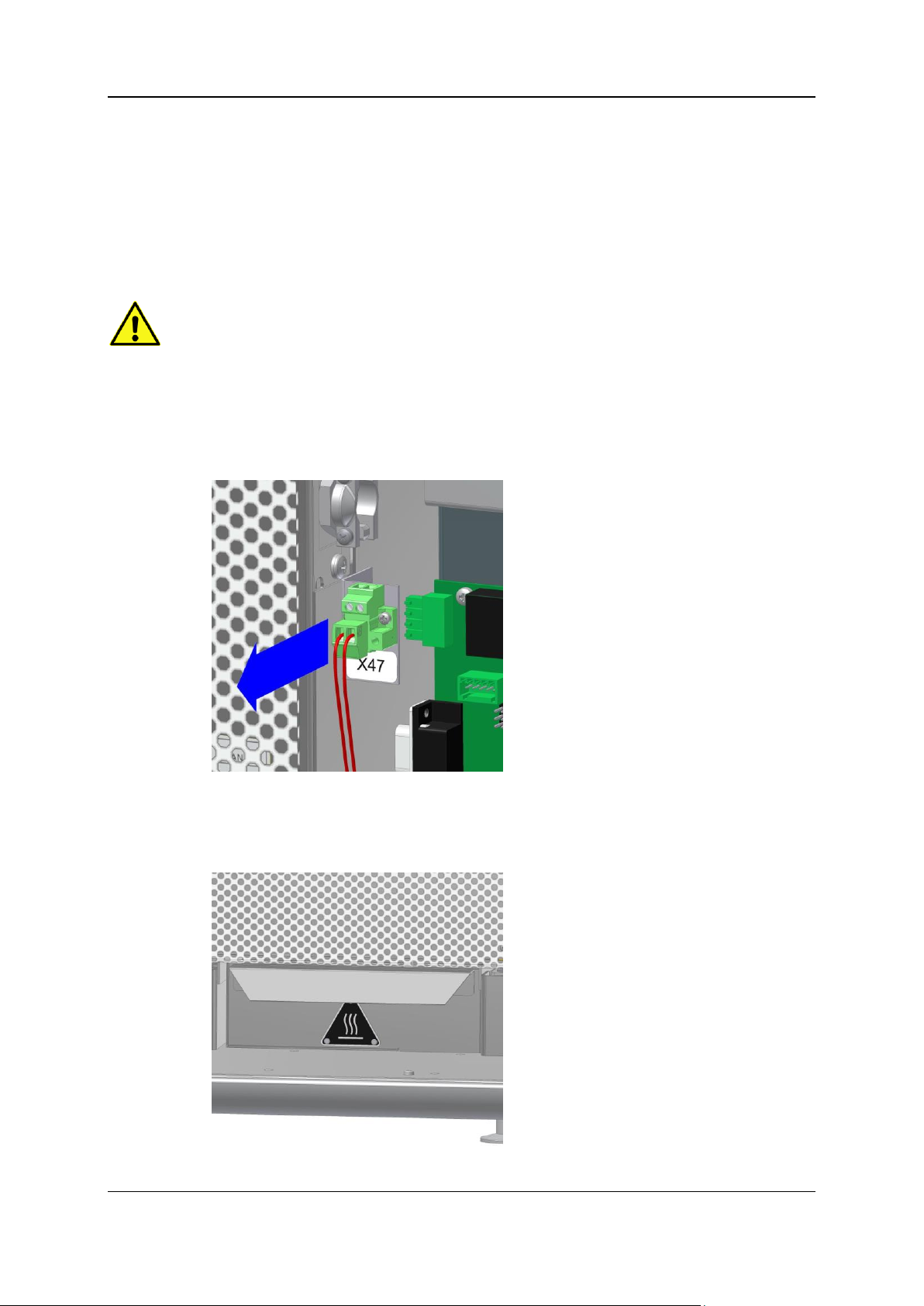

Phase 2: Modification

Safety instruction

Strictly observe the safety instruction "Hot instrument parts" under Warning notes during operation

(on page 11).

Proceed as follows:

Open the right side door.

Loosen the plug of the heating cartridge holder (X47) and close the right side door.

Note: For a modification to a mode with quartz glass bridge, the plug of the heating cartridge

holder has to be plugged back into socket X47!

Open the front door.

Remove the heat protection below the furnace.

Variants Operating Instructions vario EL cube ©Elementar Analysensysteme GmbH

2 - Oxygen determination with TCD 22

If not already done, loosen all connections to the reaction tubes.

Pull the furnace out of the instrument.

Remove the ground-in clamps, the quartz glass bridge and the combustion tubes.

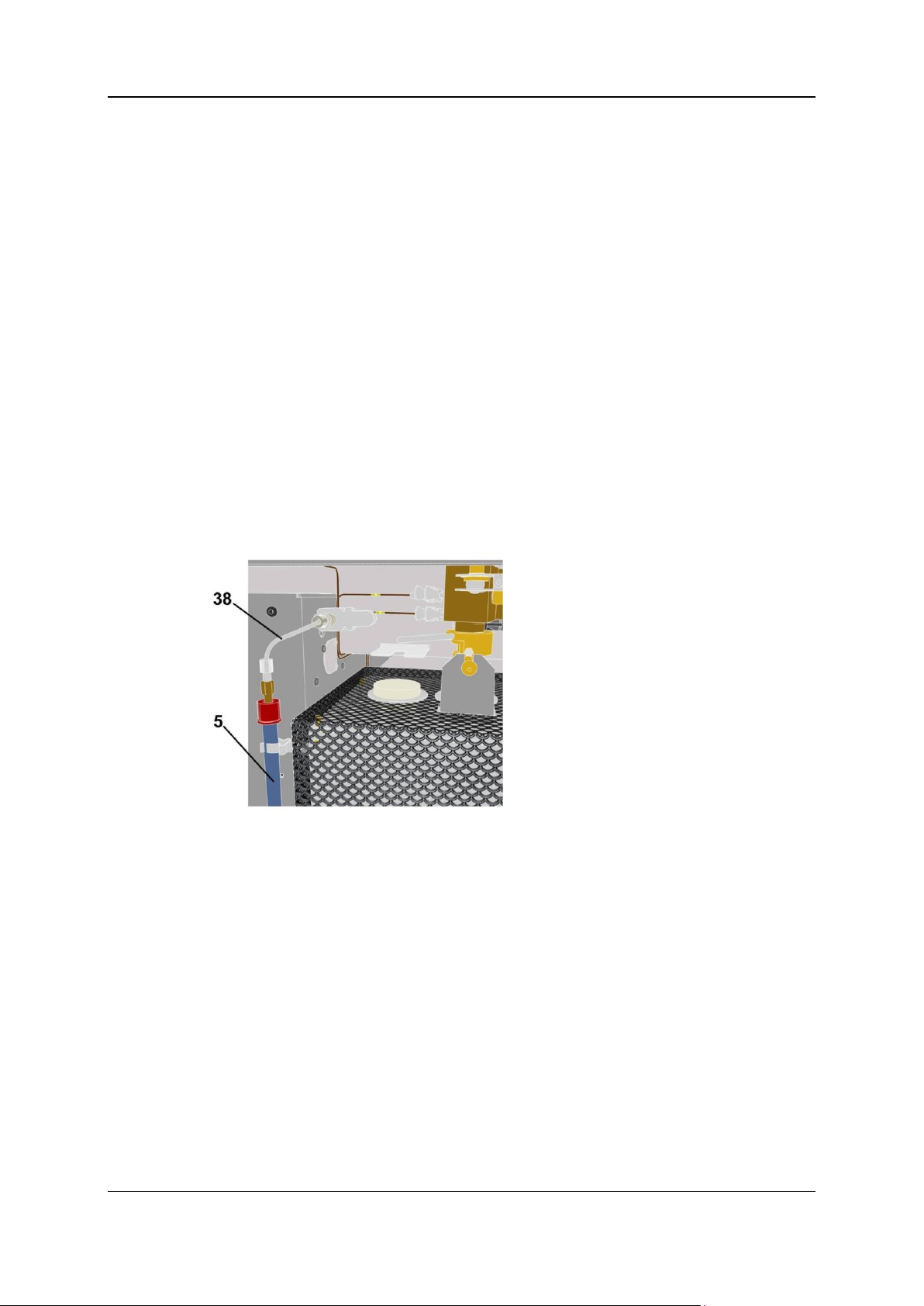

Phase 3: Installation of components necessary for the O operation

The numbers shown in parentheses refer to the illustration above "Scope of the upgrade kit".

Proceed as follows:

Insert the pyrolysis tube (4) which is filled and mounted with the combustion tube flange (40) into

the right tube of the furnace.

Note:

The top o-ring used for sealing of the bayonet catch has to be checked frequently for mechanical

damages and replaced if necessary.

Push carefully the filled absorption tube (5) into the clamps located at the left side of the furnace.

Observe that the NaOH layer is on the bottom (gas inlet).

Connect the pyrolysis tube outlet with the NaOH tube inlet by means of the tube No. 46 (37).

Push the furnace back into the instrument.

Connect the outlet of the NaOH absorption tube (top) with tube no. 47 (38). Connect the other

end of the tube by means of the ground-in clamp to the ball of hose line no. 10 located at the

instrument.

For that purpose the ball joint has to be turned to 90° and pushed into the appropriate clamp.

Close the left heating tube by means of the insulation plug (9).

Fasten the pyrolysis tube to the ball valve by means of the bayonet catch. The centering bolt has

to be within the notch of the centering angle (lock against rotation).

Close the tube 26 with the ball (15) and ground-in clamp (16).

Close the open tube at the combustion tube flange with the pan (35).

Exchange the CO2 adsorptions column against the CO adsorption column (10).

Proceed as described under Removing/installing and conditioning the adsorption column of the

vario EL cube main operating instructions.

Connect tube no. 10 (42) with the CO column (10) by means of the ground-in clamp.

The modification has now been completed and the instrument is ready for the O determination in

routine operation.

Variants Operating Instructions vario EL cube ©Elementar Analysensysteme GmbH

2 - Oxygen determination with TCD 23

View after the modification has been completed

The following picture shows the oxygen mode after the modification has been completed.

Conditioning the pyrolysis tube

Introduction

The following section describes in detail how to condition the pyrolysis tube.

Prior to routine analysis the pyrolysis tube has to be conditioned. For this purpose flush the carbon

black filling for approx. 12 hours at 1,170°C under helium in the instrument; subsequently, analyze 5

samples polyethylene (weight 8 mg).

Conditioning the pyrolysis tube

Proceed as follows:

Turn on PC and printer. Wait until the boot process has been finished.

Switch on the instrument.

The instrument performs now a reference run of the ball valve and autosampler.

Switch on the operating gas. Set the intake pressure at the delivery point to 0.5 bar.

Open the gas connection to the NaOH tube.

Connect tube no. 48 with the outlet of the pyrolysis tube. Lead the end of the hose line through

the crack in the door into the open. The front door has to be closed.

Variants Operating Instructions vario EL cube ©Elementar Analysensysteme GmbH

2 - Oxygen determination with TCD 24

Note

Connect th end of tube no. 48 with the furnished black hose (Article No. 03 651 010, 25 m) and

lead the gases resulting from conditioning (e.g. H2S, water vapor) into an exhaust hood or into

the open.

Start the instrument software and select in the menu System > Mode the operation mode "O",

option "TCD" checked.

Leave the mode menu by clicking OK; if necessary a new initialization of the instrument occures.

To heat up the furnace call the menu Options > Settings > Parameters. Set the temperature of

oven 1 to 1170 °C.

Note: The modification of the instrument parameters is only possible with the appropriate

access rights.

After reaching the setpoint temperture (after approx. 1.5 hours) heat-out the pyrolysis tube for

another 12 hours (over night).

Remove tube no. 48.

Connect the 25 m long exhaust hose with the outlet at the instrument rear.

Close the gas connection at the NaOH tube and adjust the intake pressure at the delivery point

until the PC displays a pressure of approx. 1.2 bar.

Analyze 5 samples polyethylene each 8 mg (conditioning) and 10 samples benzoic acid each

approx. 1.5 mg (stability test) after the flush process.

Now the instrument is ready for the O determination in routine operation.

Samples containing fluorine and phosphorus may cause false O results. Fluorine my cause damages

in the instrument, particulary at the quartz parts. Alkaline, earth alkaline and sulfurous samples have

to be loaded with a 1:1 mixture of hexamethylentetramine and ammonia chloride. When measuring

heavy alkaline/earth alkaline samples the pyrolysis tube will corrode.

Changing of the pyrolysis crucible

Changing of the pyrolysis crucible

In addition to the common maintanance work, the replacement of the pyrolysis crucible for oxygen

determination will be described here. The crucbile has to be emptied after approx. 80 samples, if you

work with the polyethylene additive.

Safety instruction

Strictly observe the safety instruction "Hot instrument parts" under Warning notes during operation

(on page 11).

Proceed as follows:

Cool the furnace down to approx. 600°C.

Open the front door.

Initiate a pressure drop by clicking the menu command Options > Maintenance > Replace

parts.

After completion of the pressure drop procedure detach the ground-in clamp at the NaOH tube

outlet.

Open the bayonet catch at the ball valve.

Pull the furnace out of the instrument.

Pull the combustion tube flange out of the pyrolysis tube.

Variants Operating Instructions vario EL cube ©Elementar Analysensysteme GmbH

2 - Oxygen determination with TCD 25

Pull the sheath tube and the crucible with the tongs out of the pyrolysis tube.

Empty the crucible.

Install...

... either the emptied crucible once again, or

... a new crucible immediately after the filled crucible has been removed. This has to be

conditioned by running 5 samples polyethylene (weight 8 mg).See Conditioning the

pyrolysis tube TCD (on page 23).

Push the furnace into the instrument. Observe that the ball valve adaptor is centered in the

bayonet catch.

Close both the bayonet catch at the ball valve and the ground-in ball-and-socket joint at the

NaOH tube.

Leave the "Replace part" dialog by clicking Finish.

Flush the apparatus for approx. 1 hour and set the furnace temperature back to 1,170 °C.

Wait until the PC display of the baseline of the detector is stable.

The flushing time depends on the amount of atmospheric nitrogen penetrated into the apparatus

during the replacement of the tube insert.

In unpropitious cases, the flushing procedure can last up to 45 minutes.

Establishing of the analysis readiness

Establishing of the analysis readiness

Proceed as follows:

Turn on PC and printer and wait until the boot process has been completed.

Switch on the instrument.

The instrument performs now a reference run of the ball valve and carousel.

Switch on the operating gases.

Launch the operating software.

Open the "Analysis mode" dialog in the operating software by selecting System > Mode. Select

the desired operation mode ("O" for oxygen).

Set the detector mode to "TCD".

Leave the mode dialog by clicking OK; a re-initialization of the system takes place.

Defining test/standard substances

By means of the menu Options > Settings > Standards you can see whether the test substances to

be used are stored there.

A description how to define a new and/or modify an existing standard is given under Edit standard

samples in the vario EL cube operating instructions.

If no modifications have been carried out in the standard samples dialog, leave it by clicking Close,

otherwise by clicking Save followed by Close.

Note:

If the value "0" stands for the element content percentage of a test substance, this test substance will

be ignored for the respective element during calibration and/or during the calculation of the daily

factor.

Variants Operating Instructions vario EL cube ©Elementar Analysensysteme GmbH

2 - Oxygen determination with TCD 26

Routine operation

For a description of the particular software terms refer to Menu and dialog descriptions in the vario EL

cube operating instructions.

Setting the furnace temperature

Proceed as follows:

Open the "Device parameter" dialog in the operating software by selecting Options > Settings >

Parameters.

Check and/or enter the following oven temperature (oven 2 is not needed here):

For operating mode O: Pyrolysis tube (oven 1): 1170 °C

Leave the dialog by clicking OK (or by clicking Cancel). The modules are now re-initialized if

necessary.

In the sataus view you can observe how the temperature of oven 1 increases.

The heat-up time takes approx. 60 minutes.

For an optimum lifetime of the instrument, the tubes and the consumables, we recommend to

leave the instrument turned on.

Once the setpoint temperature has been reached the instrument is ready to measure.

Notes on performing calibration

Background

The calibration serves for creating a correlation between the measured peak area of the individual

element and the concentration of the element in the sample.

This correlation is established via the so called calibration coefficients which are calculated from the

calibration run.

Checking the calibration

Prior to the beginning of each series of measurements, it has to be checked if the instrument is

calibrated.

Proceed as follows:

Open the "Calibration coefficients" dialog in the operating software by selecting Math. >

Coefficients.

The coefficients dialog allows manual input of the calibration coefficients as well as of the limit

values of the corresponding calibration range.

Sample weights

In practice, the following sample sequence has proven for a measuring range of 0.03 mg to 2.0 mg O:

10 conditioning samples of benzoic acid, approx. 2 -3 mg each for O conditioning

3 conditioning samples, 0.1-0.15 mg each

27 samples with sample weights as follows:

0.1 - 0.1 - 0.15 - 0.2 - 0.25 - 0.3 - 0.4 - 0.5 - 0.6 - 0.7 - 0.8 - 0.9 - 1.0 - 1.5 - 2.0 - 2.5 - 3.0 - 4.0 -

4.5 - 5.0 - 5.5 - 6.0 - 6.5 - 7.0 - 7.5 - 8.0 mg.

If the measuring range is to be extended, the following sample weights can be added:

Benzoic acid 9 - 10 - 12 - 14 - 16 - 18- 19 mg.

Thus, a measuring range up to 5 mg absolute oxygen will be covered.

Variants Operating Instructions vario EL cube ©Elementar Analysensysteme GmbH

2 - Oxygen determination with TCD 27

Polyethylene additive

Sample weight

polyethylene

Blank value area

8,014

504

8,03

508

8,04

505

8,006

502

The poylethylene additive improves the absolute accuracy and/or recovery. In practise an addition of

approx. 8.0 mg per sample has proven to be of value.

Attention should be paid to:

Conditional of manufacturing, polyethylene contains minor concentrations of oxygen (approx. 0.2 ...

0.4%).

Prior to a measuring series start, especially during the calibation, the blank value of the used

polyethylene has to be determined. Enter the blank value area in the column "O-blank", e.g. the mean

value from 4 or 5 measurements.

Example:

The mean value of the blank value area is 505 and has to be entered for the analysis samples /

calibration samples in the column "O-blanks".

To ensure a correct calculation of the calibration select the manual calculation under Options >

Settings > Calculation > Blank Value Determination > Manual Input.

Subsequently, start the calcuation of the calibration under Math. > Calibrate, where the mathematical

treatment of the blank values is done automatically.

Oxygen analyses in routine operation

Sample sequence

In routine operation, the following sample sequence (if necessary with PE additive of each 8 mg per

sample) is recommended:

3 x conditioning sample (approx. 2.0 mg benzoic acid)

4 x benzoic acid (approx. 2.0 mg) for the determination of the daily factor

20 real samples

3 x benzoic acid (approx. 2.0 mg) for the monitoring of the daily factor

20 real samples

3 x benzoic acid (approx. 2.0 mg) etc.

The sample weight values can be entered either directly from a connected balance or manually via

the keyboard.

Parameter menu settings

The instrument has factory set analysis parameters for test substances defined in the standards

menu (e.g. acetanilide, benzoic acid).

Note: The modification of the instrument parameters is only possible with the appropriate

access rights.

Variants Operating Instructions vario EL cube ©Elementar Analysensysteme GmbH

2 - Oxygen determination with TCD 28

Temperature parameters

Parameter

Meaning

Factory setting

Oven 1 (pyrolysis tube) in O

mode

Pyrolysis tube

1,170 °C

Furnace 2

not used

Ads. col. standby

Adsorption temperature of the CO column

40 °C

Adsorp. column, Cooling temp.

At the end of analysis, the program waits until

column temperature drops below this value.

50 °C

Parameter

Meaning

Factory setting

Flushing time

Time in which the blind hole of the ball valve

is flushed, so the atmospheric oxygen will be

removed.

10 s

Integrator reset delay dummy

This time comes into effect for the first peak

of the respective operation mode after the

sample is fed and prevents the ensuing

detector instabilities from being jointly

integrated.

2 sec, operating

mode O

Integrator reset delay peak O

See above.

2 s

Desorpt. mid.

1 s

Parameter

Meaning

Factory setting

Autozero delay dummy

On starting up, the autozero alignment is

carried out after the autozero delay.

2 sec, operating

mode O

Autozero delay O

See above.

2 s

Peak Anticipation dummy

The anticiaption time comes into effect after

the integrator reset. During this time the

integrator waits for a measuring peak. If the

measuring peak does not appear within this

time, the integration is concluded and the

next analysis is started.

250 s

Peak anticipation O

See above.

150 s

Desorpt. O

Corresponds to the desorption temperature of

the column in O/TCD mode.

260 °C

Desorpt. midtemp.

40 °C

The following table shows the pre-set temperatures and explains the meaning of the parameters:

Time parameters

The following table shows the pre-set times and explains the meaning of the parameters:

Further process times and parameters are set via the "Method" dialog:

Variants Operating Instructions vario EL cube ©Elementar Analysensysteme GmbH

2 - Oxygen determination with TCD 29

Application notes for oxygen determination

In this section

Pyrolysis temperature ....................................................................................................................30

Difficult matrices ............................................................................................................................30

Lifetime of the pyrolysis tube .........................................................................................................31

Target group

Personnel with basic knowledge of chemistry and experience with laboratory work, e. g. chemistry

laboratory workers.

Purpose

This section gives additional notes about the application for oxygen determination.

Variants Operating Instructions vario EL cube ©Elementar Analysensysteme GmbH

2 - Oxygen determination with TCD 30

Pyrolysis temperature

Pyrolysis temperature

The method provides correct results only, if the carbon black filling in the pyrolysis tube is operated at

a temperature of at least 1120°C.

In order to set the correct pyrolysis temperature, some samples of benzoic acid (approx. 2,0 mg) are

analyzed with different pyrolysis temperatures.

The optimum temperature value has been reached if the analysis results with the increase of

temperature do no longer vary significantly (< 0.2 % absolute).

Difficult matrices

Organic substances

Samples hard to digest (crackable) may be digested by hyrogen containing, carbon containing and/or

chlorine containing additives like graphite, polyethylene, hexamethylentetramine or NH4Cl .

The additives must be dry and must not contain any oxygen.

Substances containing fluorine

Substances containing fluorine react with the quartz glass forming silicon tetrafluoride and discharge

oxygen which will be measured as CO.

Additives, containing blank values

Partially, the recommended additives are hygroscopic and therefore they will deliver a oxygen blank

value.

This blank value has to be determined in order to be able to correct the analysis results.

Procedure example:

6 x analysis of 15 - 16 mg additive.

If the results are stable, compute the mean value from samples 4, 5 and 6 and then subtract this

value from all samples which have been weighed in with an additive. (Input in column "Blank")

Measuring alkaline/earth alkaline samples

When measuring alkaline/earth alkaline samples the pyrolysis tube will corrode and its lifetime will be

shortened.

The system pressure will bloat the tube until it eventually bursts.

This may lead to destruction of the furnace.

It is recommended to check the tube regulary for bloatings and to replace it in time with original spare

parts.

Notes on matrix dependency

Due to the nature of pyrolysis, differences in recovery may occur, depending on the molecular

structure and bond type of the oxygen. This fact has to be considered when very precise

measurements are required.

To guarantee the absolute accuracy of the measuring results, it is recommended to use standard

substances for calibration and daily factor determination which have the same bond type like oxygen.

For general measurements of unknown substances use the average daily factor of 2 measured

standards.

Variants Operating Instructions vario EL cube ©Elementar Analysensysteme GmbH

2 - Oxygen determination with TCD 31

The following table shows some examples for determining the daily factor and/or the calibration:

Analysis of ...

Calibration and/or daily factor substance

amino acids

Glutamic acid

nitrates

KNO3, AgNO3

Coal

commercially available coal standard

general applications,

unknown substance classes

calibration with benzoic acid;

daily factor averaged from benzoic acid and acet anilide

Lifetime of the pyrolysis tube

Lifetime of the pyrolysis tube (and/or the carbon black filling)

Permanent flushing the tube with carrier gas has proven to be the most efficient procedure. The tube

can be stored for example in an exsiccator during longer breaks, and then used again.

Note that under the existing measuring conditions the quality of the quartz glass is very important.

Under the prevailing circumstances use only original spare parts from Elementar to avoid the

destruction of the furnace.

If the pyrolysis tube is used again, a conditioning of the tube prior to the actual measurements shall

be done.

Flush for approx. 2 hours with carrier gas at 1170 °C

Measurement of 5 samples polyethylene and 10 samples benzoic acid each approx. 2 mg.

Only if the carbon black filling in the pyrolysis tube has decreased significantly, the installation of a

newly filled pyrolysis tube with subsequent flushing and conditioning is recommended.

Variants Operating Instructions vario EL cube ©Elementar Analysensysteme GmbH

2 - Oxygen determination with TCD 32

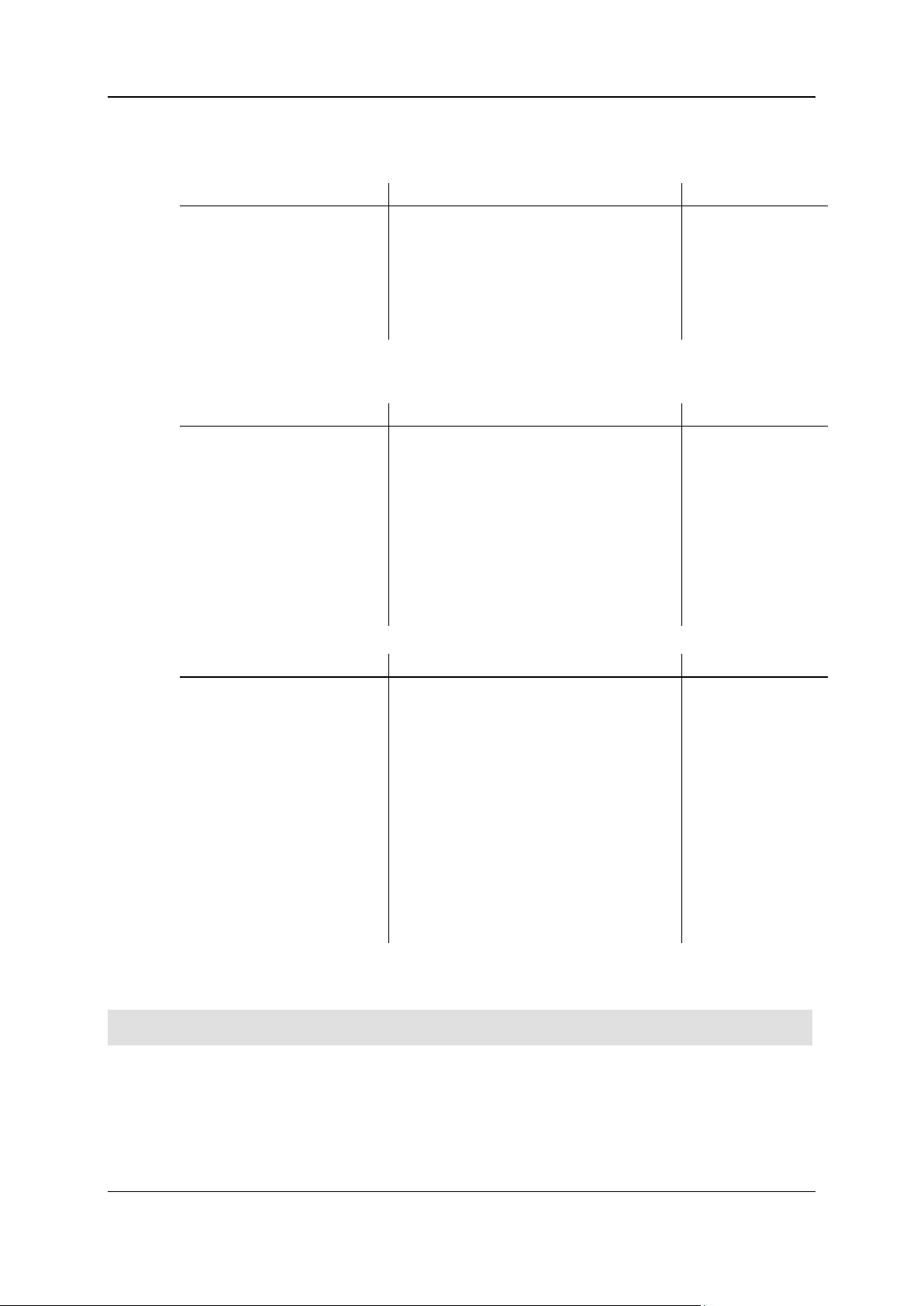

Additional error messages in O mode

Error

Possible causes

Corrective action

Wide peaks with test

substances

Contaminated carbon black

filling in the pyrolysis tube.

Replace pyrolysis tube.

Used up carbon black filling in

the pyrolysis tube.

Replace pyrolysis tube.

Pyrolysis crucible

contaminated.

Replace and/or empty crucible by more

than 80 samples.

Wide peaks with

samples

Indicates to uncompleted

pyrolysis.

Add additives as decribed under

Difficult matrices (on page 30).

Wide peaks

Contamination of the CO

adsorption column.

Bake out CO adsorption column.

Measuring values vary

Contaminated carbon black

filling in the pyrolysis tube.

Replace pyrolysis tube.

Used up carbon black filling in

the pyrolysis tube.

Replace pyrolysis tube.

Pyrolysis crucible

contaminated.

Replace and/or empty crucible by more

than 80 samples.

Leakages

Carry out leak test, eliminate leak if

necessary.

Varying boat blank values.

Run at least 20 blank samples with

empty silver boats.

Peak end error

Sample weight too high.

Reduce sample weight.

Element content of sample

too high.

Increase peak end threshold of dummy

peak.

The following table lists possible error messages, explaining the causes of the errors and giving tips

for troubleshooting:

Variants Operating Instructions vario EL cube ©Elementar Analysensysteme GmbH

Target group

In this chapter

Analytical characteristics and technical specifications ...................................................................34

Substance digestion and functional diagram .................................................................................34

Detection .......................................................................................................................................38

Tube fillings ...................................................................................................................................38

Modification to O Mode ..................................................................................................................40

Conditioning the pyrolysis tube ......................................................................................................46

Changing of the pyrolysis crucible .................................................................................................47

Establishing of the analysis readiness ...........................................................................................48

Notes on performing calibration .....................................................................................................49

Oxygen analyses in routine operation ...........................................................................................50

Application notes for oxygen determination ...................................................................................52

Additional error messages in O mode ...........................................................................................55

C H A P T E R 3

Oxygen determination with NDIR

Personnel involved with the instrument.

Purpose

This section describes the special features of the oxygen determination with NDIR.

Variants Operating Instructions vario EL cube ©Elementar Analysensysteme GmbH

3 - Oxygen determination with NDIR 34

Analytical characteristics and technical specifications

Analytical characteristic

Comments

Analysis method

Oxygen determination by pyrolysis of the samples, specific

detection of the measuring component CO with NDIR.

Detector

NDIR detector

Sample weight/sample volume

Approx. < 1 to 10 mg depending on the substance.

Working range

(depending on kit and measuring

mode)

O: 0.005 - 2 mg

Precision / standard deviation

<0,2 % with benzoic acid (approx. 2 mg)

Duration of analysis

(depending on element content

and sample weight)

O: 8 - 15 min

Calibration

Linear and non-linear curve adjustment; total work range.

Data storage and data output

Storage on hard disk or external storage media.

LIMS transfer possible.

Data output to screen and printer.

Reference value

Technical specifications

Supply gases

Forming gas N2/H2 95/5 (95 % N2, 5 % H2), water free, CO2 free, O2

free

Consumption of supply gases

Per analysis approx. 1.4 to 2.6 liters.

Phase

Process

1

The substance to be analyzed is digested in reductive atmosphere at a temperature of

approx. 1,150 °C (1,170 °C) by means of pyrolysis (cracking).

2

For the digestion weigh in the sample into silver boats (for liquid samples silver capsules are

available). The folded boat is thrown into the quartz glass pyrolysis tube by means of an

autosampler.

3

The oxygen containing radicals formed in the pyrolysis tube are converted quantitatively at a

carbon contact (special carbon black) into carbon monoxide (Boudouard equilibrium).

Analytical characteristics

The following table explains the analytical characteristics:

Technical specifications

The following table contains the technical specifications of the gas supply:

Substance digestion and functional diagram

Introduction

The following section explains:

Which procedures in the pyrolysis tube of the furnace are processed.

How the reaction mixture is prepared for the detection.

Processes during substance digestion and preparation of the reaction gas mixture

Substance digestion and preparation of the reaction gas mixture is divided into the following phases:

Variants Operating Instructions vario EL cube ©Elementar Analysensysteme GmbH

Variants Operating Instructions vario EL cube ©Elementar Analysensysteme GmbH

3 - Oxygen determination with NDIR 35

4

Acidic pyrolysis products like e.g. H2S, HCN, HCl etc. are absorbed at NaOH by means of

an absorption tube which is downstream of the pyrolysis tube.

5

Usually, water is set free during the reaction of NaOH with an acidic medium. Therefore, the

gas mixture is dried once again after the NaOH layer.

6

Other pyrolysis products like e.g. N2 and CH4 are led to a measuring system together with

the carbon monoxide to be detected.

Since the NDIR detector does only respond to CO, foreign gases, like e.g. N2 and CH4 does

not have to be separated.

3 - Oxygen determination with NDIR 36

Oxygen determination with single NDIR detector CO

For a better understanding see also the following illustration (tubing diagram, oxygen determination).

Variants Operating Instructions vario EL cube ©Elementar Analysensysteme GmbH

3 - Oxygen determination with NDIR 37

Oxygen determination with dual NDIR detector CO/SO2

Two-way valve

Pressure sensor

Gas separation

For a better understanding see also the following illustration (tubing diagram, oxygen determination).

Symbols

The following list names the functional and basic symbols:

Variants Operating Instructions vario EL cube ©Elementar Analysensysteme GmbH

3 - Oxygen determination with NDIR 38

Three-way valve

Loop

Measuring cell

Check valve

Heated tube

Sensor

Throttle

Drying

Hose line

Flow controller

Combustion

Copper tube

Flow sensor

Post combustion

Reduction

Pressure contoller

Actuator

Detection

Introduction

The detection of the measuring component CO is carried out with a CO specific NDIR detector.

Depending on the individual application, either the single NDIR detector CO or the dual NDIR detector

CO/SO2 is used. The resulting differences are described in this chapter at the relevant positions.

O integration

After the analysis start, first the auto zero adjust of the NDIR takes place.

Subsequently, insertion of the sample takes place.

Shortly after the sample feeding the CO peak starts and the peak integration with it.

The O integration has been finished if the process time "peak anticipation time for O" (factory set to

150 sec) has expired, and the dector signal is smaller than the cut-off threshold "O peak" (defined

internally).

To secure an optimum accuracy of the measuring results, the cut-off threshold is set very low.

Tube fillings

Requirements:

Before starting work, the following requirements must be met:

All quartz and glass components must be cleaned before their usage. Clean the tubes from

fingerprints by means of a suitable solvent (e.g. acetone) before installing. Otherwise there is a

risk of crystallization which will lead to premature ageing of the quartz.

Use chemicals necessary for the tube fillings only in the appropriate quality. Delivery directly from

the instrument manufacturer.

Safety instruction

Strictly observe the safety instruction "Filling reaction tubes" under Warning notes during operation

(on page 11).

Variants Operating Instructions vario EL cube ©Elementar Analysensysteme GmbH

3 - Oxygen determination with NDIR 39

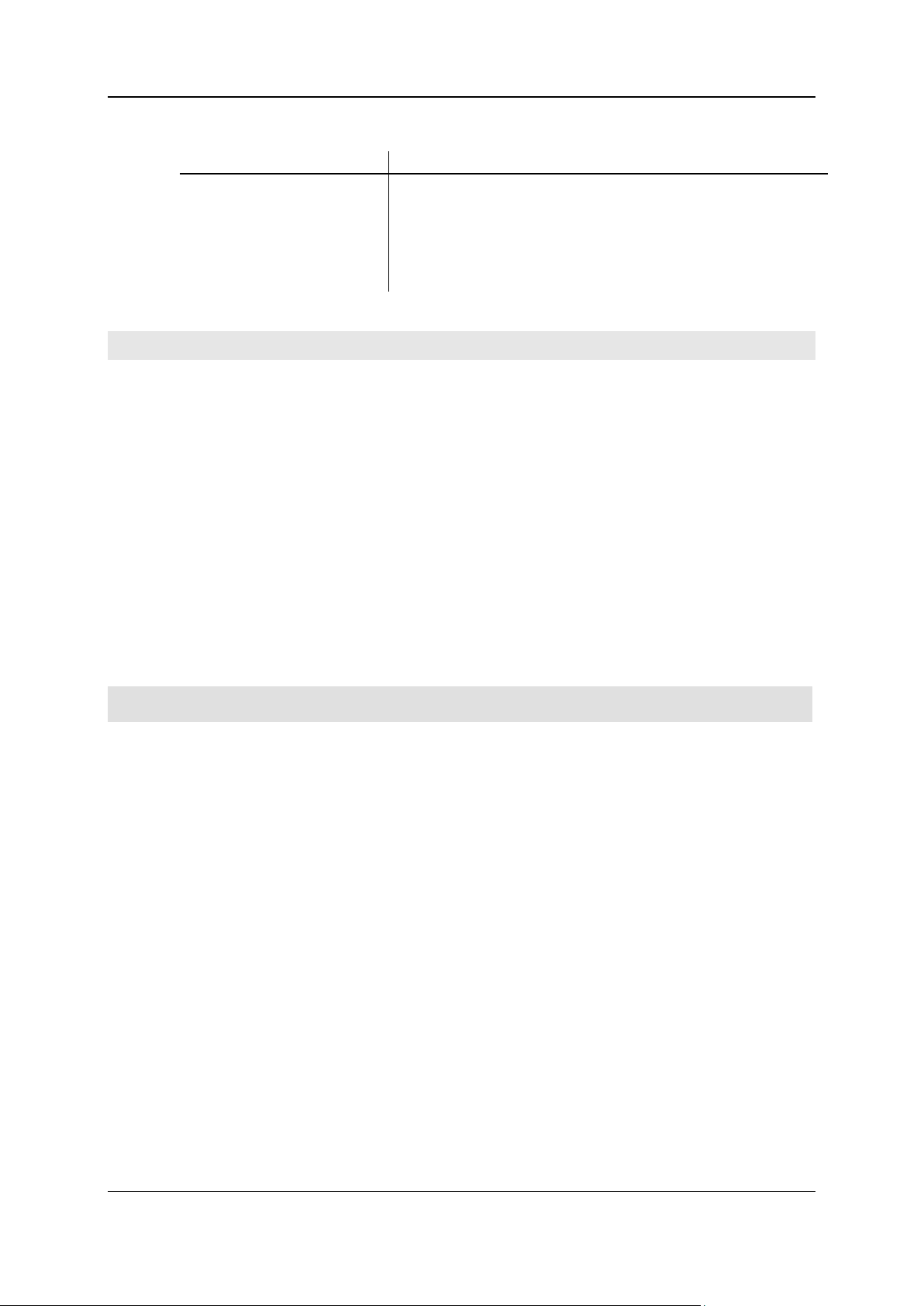

Filling of the quartz pyrolysis tube (crack tube) for O determination

Legend:

1 Ash finger (used as protection tube)

2 Ash crucible

3 Graphite felt (10 mm)

4 Carbon black (55 mm)

5 Support rod (110 mm)

6 Quartz chips, coarse (2-4 mm)

7 Quartz wool (2 mm)

Legend:

1 Cotton

2 NaOH

3 Quartz wool (10 mm)

4 Sicapent®

5 Gas inlet

The arrangement of the filling must be carried out as shown in the following illustration.

The insert in the core of the tube contains the solid pyrolysis residue as well as the melted silver from

the silver boats.

Removal of traces of moisture and other contaminations from the carrier gas

For gas drying insert commercial cleaning cartridges between gas delivery point and instrument, if

necessary.

Humid carrier gas causes a CO base which will be collected as a blank on the adsorption column.

Filling the NaOH absorption tube

The following picture shows the filling of the absorbtion tube:

Proceed as follows:

Fill the tube with NaOH (on carrier) and with Sicapent® (identical fill heights).

Variants Operating Instructions vario EL cube ©Elementar Analysensysteme GmbH

Close the tube ends with cotton.

Insert the NaOH tube into the already mounted clamps at the left side of the combustion furnace.

3 - Oxygen determination with NDIR 40

Modification to O Mode

Legend:

4 Pyrolysis tube

5 Glass tube

9 Insulation plug

12 Pan UNF ¼"

13 Blind plug UNF 1/4"

14 Quad ring, black

15 Ball

16 Ground-in clamp

17 RS 232 module

19 Hose line no. 37

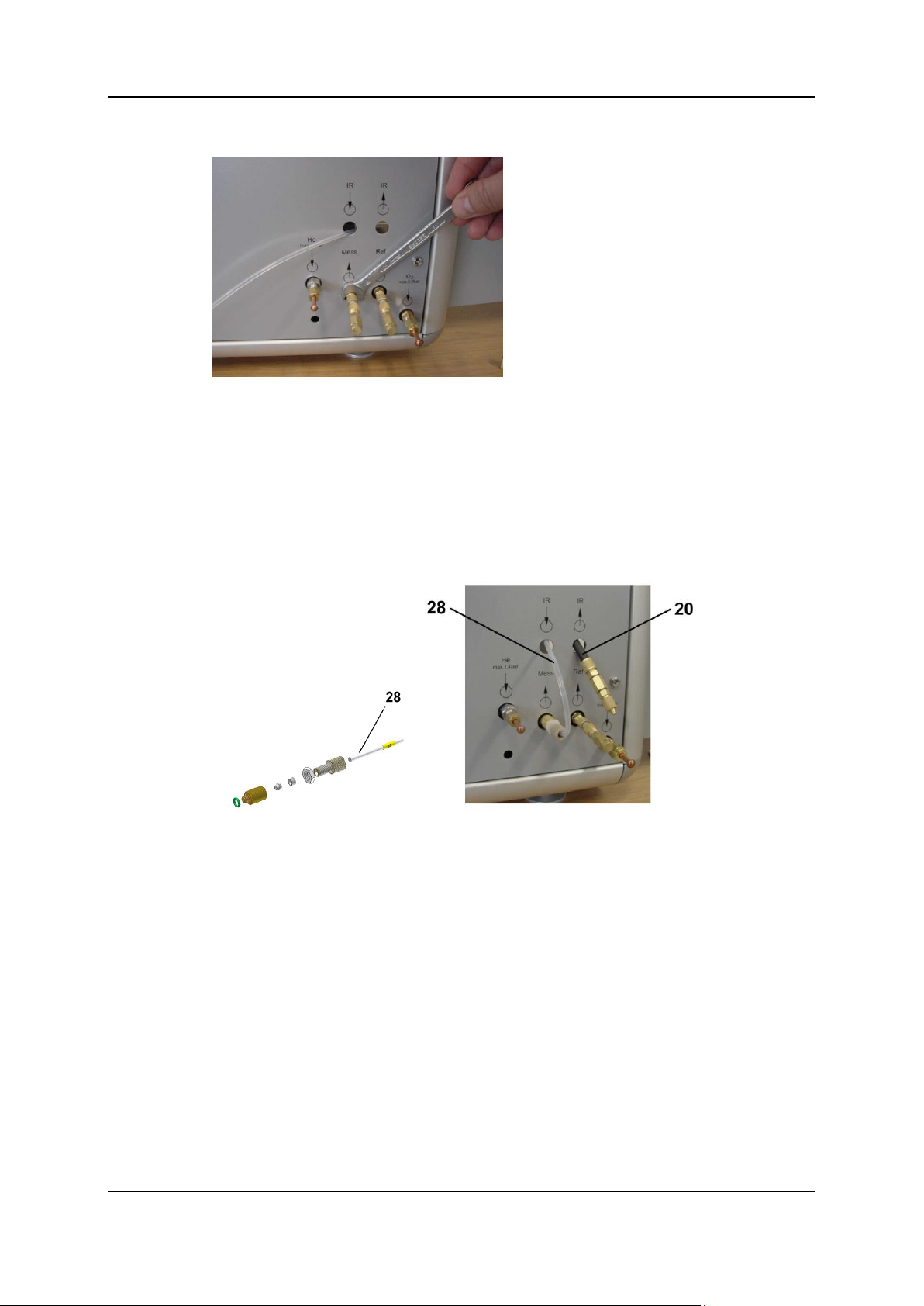

20 Hose line no. 29

21 Screw M3x6

22 Serrated washer, 3.2

24 Guidance angle

25 Screws M4x8

35 Pan, closed

36 Hose seal 1/16"

37 Tube no. 46

38 Hose line no. 47

39 Hose line no. 48

40 Combustion tube flange

42 Hose line no. 10

Scope of the modification kit for oxygen determination

All parts necessary for the tube modification are included in the O upgrade kit for detecting oxygen

with NDIR and are labeled with numbers.

With the new delivery of a complete system the RS 232 module and the NDIR detector are already

installed in the instrument (NDIR: left instrument side, behind the left side door, RS 232 module: right

instrument side, electronics).

The following parts are also part of the kit but are not pictured.

Sheath tube

Ash crucible

D-sub-adapter

Software update CD.

Safety instruction

Strictly observe the safety instruction "Gas pressure" under Warning notes during operation (on

page 11).

Note

To remove/install the tubes proceed as described in chapter Removing standard reaction tubes of the

vario EL cube main operating instructions.

Process

The modification is divided into the following phases:

Removal of components not needed

Modification

Installation of components necessary for the O operation

bridge the adsorption column

Variants Operating Instructions vario EL cube ©Elementar Analysensysteme GmbH

3 - Oxygen determination with NDIR 41

Installation of components necessary for the O operation, continued