elem MTBT59-CC139L Original Instructions Manual

Original Instructions

TILLER THERMAL

MTBT59-CC139L

S44 M11 Y2018

Read this manual carefully before putting the unit in operation

This machine is delivered WITHOUT OIL OR GASOLINE in the engine

1. Unit

■

The lightweight tiller is together with a high-efficient 4 strike engine. This design is ideal for tilling

close-planted crops with semi-hard soils. When in operation, it runs steady and is quite silent.

The tiller is made of a little special wearable steel so it provides for good cost-effectiveness. A

special shape of blades provides for thrifty and efficient tilling. The turning guide wheel keeps the

tiller operation easily. Start-up system responding to a button pressing (the tiller will run upon

pressing an operation button in rest (state) improves the labor safety.

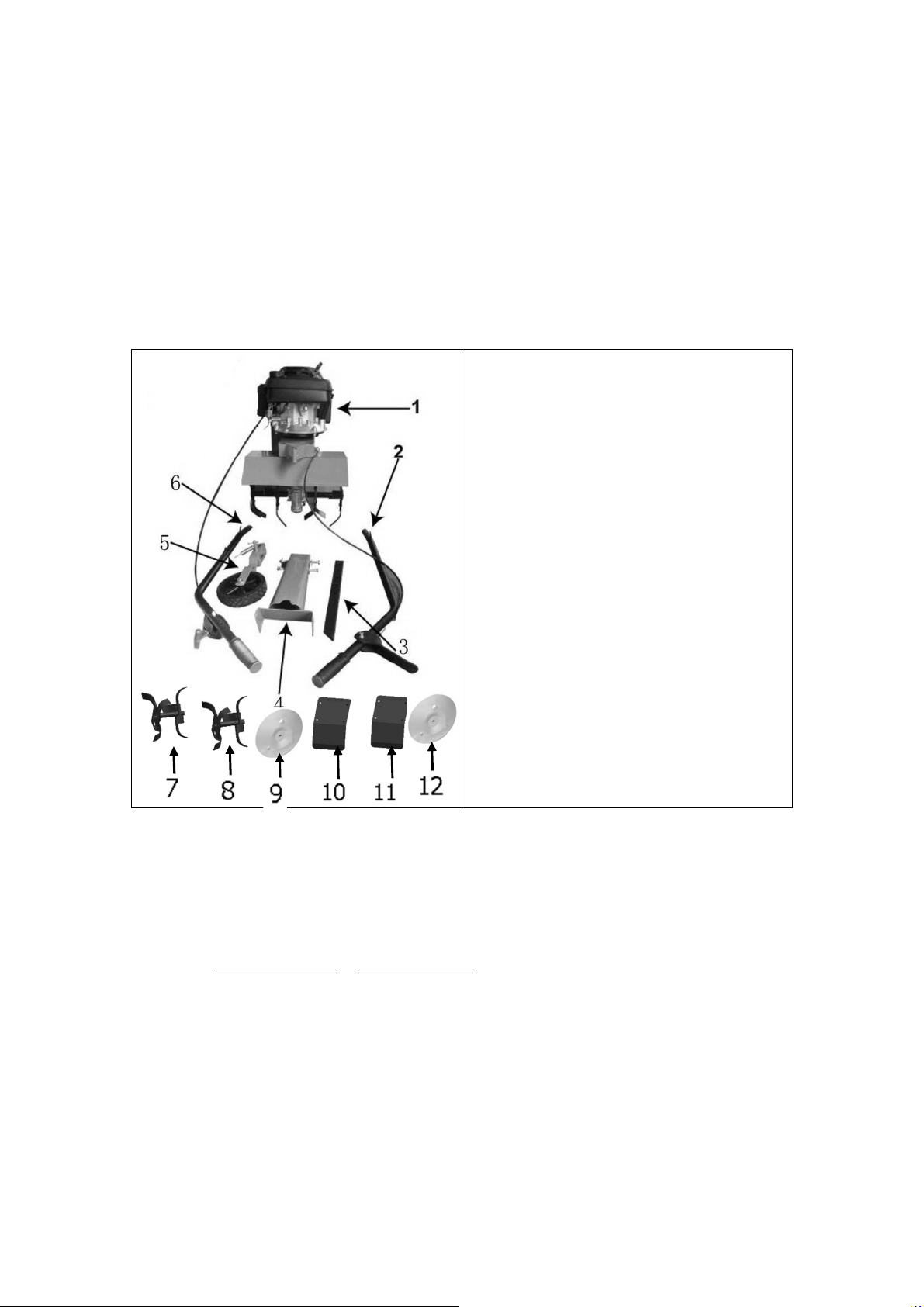

◆Scope of delivery

1. carriage

2. left-hand handle(driving lever)

3. depth limiter

4. bracket and handle

5. wheel

6. right-hand handle (on/off, speed)

7. right-hand blade

8. left-hand blade

9. Left-hand Blade protector

10. Right mudguard

11. Left mudguard

12.right-hand Blade protector

2. General safety instructions

■

Prior to the initial use of the unit, the operating instructions should be read completely. If in

doubt with regard to connection and operation of the unit, consult the manufacturer (servicing

department).This machine shall always be used in this instructions laid down in the instruction

handbook.

FOLLOW THE INSTRUCTIONS BELOW CAREFULLY IN ORDER TO SECURE A HIGH DEGREE OF

SAFETY:

CAUTION!

1. Pay attention to the conditions of the area, which you are working in. after the engine is

started; power machine will produce poisonous flue gas. The gas may be invisible and

odorless. Hence never work with the machine closed or poorly ventilated areas. Provide for

good lighting when cutting. Provide for stability when cutting in wet, snow or icy weather

conditions on slopes or rough ground.

2. Do not let any unauthorized person approach the machine. The visitors and viewers

primarily the children, the ill and infirm persons should not have any access to the working

info@eco-repa.com / www.eco-repa.com

area. Prevent other person from any contact with the machine.

3. Make provision for the tools storage. The machines not in current use should be kept in a

dry place, elevated or locked where practicable so that any access to them is prevented.

4. Always use a correct tool for the job to be done. E.g. avoid using small tools and accessories

for work that should be actually done with a heavy tool. Use the tools only for the purposes

they were designed for.

5. Pay attention to adequate clothing. The clothing should fit the purpose and should not put

any limits to you when working.

6. Use personal protection equipment. Wear safety shoes with steel toes and antiskid or rough

sole.

7. Wear goggles. Object may be thrown against you.

8. Wear ear protectors. Wear personal protective equipment to protect your ears, such as ear

protectors.

9. Hand protection. Wear hard gloves-gloves of chrome tanned side leather give a good

protection.

10. Transport. The tiller should be always transported with the driving wheel in transport

position. Make sure that nobody is exposed to risk when the tiller is put out of services.

Secure the unit against tilting, damage and fuel leakage.

11. Remove the wrench etc. Any wrenches/spanners etc. must be removed before the tiller is

put on.

12. Be attentive any time. Mind what you are doing. Use common sense. Do not use the tiller

when tired. Never work with the cursed when influence by alcohol, drugs or medicaments

affecting the concentration capability.

13. Refueling. Always switch the engine off before refueling. Open the tank closure carefully for

overpressure run out slowly and the fuel ejaculation be prevented. When working with the

tiller, the unit body temperature increases. Let the unit cool down before refueling.

Otherwise, the fuel could ignite and persons get burnt. Beware of overfilling the tank. If there

is a spill, remove it and clean the unit. After finishing the refueling, make sure the screwed

closure is tight to avoid loosening in result of vibrations.

14. Watch out for any damaged parts. Inspect the machine before use. Are any parts damaged?

Ask yourself seriously when detecting slight damage whether the machine will work perfectly

and safely despite that. Watch out for proper aligning and adjustment of any moving parts.

Do the parts fit one in another properly? Are the part damaged? Is everything installed as

appropriate? Are any other prerequisites of proper working in place? Damaged protective

devices etc. must be repaired or replaced by authorized entities unless the operation manual

expressly says otherwise. Any defective switches must be replaced at an authorized servicing

centre. Do not use the machine if it can’t be put on and off with the switch. When repairs are

necessary, kindly turn to your local servicing centre :

info@eco-repa.com / www.eco-repa.com

15. Switch the engine off before any adjustment and maintenance. That applies to the blades

replacement in the first place.

16. Use approved parts only. Use only identical spare parts for maintenance and repairs.

Request advice of an authorized servicing centre for this purpose.

1) training

a) Read the instructions carefully. Be familiar with the controls and the proper use of the

equipment;

b) Never allow children or people unfamiliar with these instructions to use the machine.

Local regulations can restrict the age of the operator.

c) Never work while people, especially children, or pets are nearby;

d) Keep in mind that the operator or user is responsible for accidents or hazards occurring

to other people or their property.

2) Preparation

a) While working. Always wear substantial footwear and long trousers. Do not operate the

equipment when barefoot or wearing open sandals;

b) Thoroughly inspect the area where the equipment is to be used and remove all objects

which can be thrown up by the machine;

c) WARNING – Petrol is highly flammable;

Store fuel in containers specifically designed for this purpose

-Refuel outdoors only and do not smoke while refueling;

-add fuel before starting the engine. Never remove the cap of the fuel tank or add petrol

while the engine is running or when the engine is hot;

-If petrol is spilled, do not attempt to start the engine but move the machine away from

the area of spillage and avoid creating any source of ignition until petrol vapor has

dissipated;

-Replace all fuel tank and container caps securely;

d) Replace faulty silencers;

e) Before using, always visually inspect to see that the tools are not worn out or damaged.

Replace worn out or damaged elements and bolts in sets to preserve balance.

3) Operation

a) Do not operate the engine in a confined space where dangerous carbon monoxide fumes

can collect;

b) Work only in daylight or in good artificial light;

c) Always be sure of your footing on slopes;

d) Walk, never run with the machine;

e) For wheeled rotary machines, work across the slopes, never up and down;

f) Exercise extreme caution when changing direction on slopes;

g) Do not work on excessively steep slopes;

h) Use extreme caution when reversing or pulling the machine towards you;

i) Do not change the engine governor settings or over speed the engine;

j) Start the engine carefully according to manufacturer instructions and with feet well away

from the tool(s);

k) Do not put your hands or feet near or under rotating parts;

l) Never pick up or carry a machine while the engine is running;

m) Stop the engine:

-Whenever you leave the machine;

-Before refueling;

n) Reduce the throttle setting during engine shut down and, if the engine is provided with

A shut-off valve, turn the fuel off at the conclusion of working;

4) Maintenance and storage

a) Keep all nuts, bolts and screws tight to ensure the equipment is in safe working

condition;

b) Never store the equipment with petrol in the tank inside a building where fumes can

reach an open flame or spark;

c) Allow the engine to cool before storing in any enclosure;

d) To reduce the fire hazard, keep the engine, silencer, battery compartment and petrol

storage area free of vegetative material and excessive grease;

e) Replace worn or damaged parts for safety;

f) If the fuel tank has to be drained, this shall be done outdoors.

SYMBOLS

Denotes risk of personal

injury or damage to the

Read manual before use

tool.

Risk of injury caused by

rotating machine parts!

Clutch handle released,

unit is running in idle.

Wear goggles and ear

defenders when using the

device.

Wearing of protective

shoes advised

Wear gloves

Engine exhaust contains

carbon monoxide, Never

operate the product in an

enclosed area!

No naked flame

Choke, cold start setting

Maximum motor

revolutions

Minimum motor

revolutions.

Add engine oil.

Hot! Do not touch exhust

system or engine until cool

Risk of injury due to flying

parts! Always maintain a

sufficient safety distance

Risk of projections.

No smoking

There is a risk of flying

objects while using the

machine.

Flammable. Do not fill fuel

tank in an enclosed area

or while unit is running.

Clutch handle pulled, tine

turns

Allow engine to cool at

least 2 minutes before

re-fueling.

Motor off

Loading...

Loading...