Elektror 1SD 310, 1SD 410, 1SE 410, 1SD 510, 1SD 510 FU Operating And Assembly Instructions Manual

...

1SD

2SD

Puhalo s stranskim kanalom

Elektror

Navodila za uporabo in montažo

SL

1SD 210, 1SE 210, 1SD 310, 1SD 410, 1SE 410, 1SD 510, 1SD 510 FU/FUK

2SD 220, 2SD 320, 2SD 420, 2SD 520, 2SD 720, 2SD 820, 2SD 920

Elektror side

channel blower

Operating and

assembly

instructions

EN

1SD 710, 1SD 810, 1SD 910

2SD 740, 2SD 840

Elektror airsystems gmbh

Hellmuth-Hirth-Straße 2, D-73760 Ostfi ldern

Postfach 1252, D-73748 Ostfi ldern

Telefon +49 711 31973-0

Telefax +49 711 31973-5000

info@elektror.de

www.elektror.de

Navodila za uporabo in montažo 1SD, 2SD www.elektror.com

SL

2

VSEBINA

1 PODATKI O STROJU

2 INFORMACIJE O TRANSPORTU, RAVNANJU IN

SKLADIŠČENJU STROJA

3 INFORMACIJE O PRVEM ZAGONU

4 PODATKI O OBRATOVANJU IN UPORABI

5 PODATKI O VZDRŽEVANJU

6 INFORMACIJE V ZVEZI Z VARNOSTJO PRI

JEMANJU IZ OBRATOVANJA IN RAZSTAVITVI

7 JAMSTVO IN IZKLJUČITEV JAMSTVA

8 IZJAVA ZA VGRADNJO V SKLADU S PRILOGO II 1 B

9 TEHNIČNI PODATKI

10 RISBA V RAZSTAVLJENEM STANJU

11 SPLOŠEN SEZNAM NADOMESTNIH DELOV

Ta navodila za uporabo morajo biti ves čas dostopna upravljalnemu osebju. Ta navodila za uporabo pred montažo in

prvim zagonom puhala s stranskim kanalom natančno preberite.

Pridržujemo si pravico do sprememb. V primeru dvoma se je

treba posvetovati s proizvajalcem. Ta dokument je zaščiten

z avtorskimi pravicami. Brez našega izrecnega soglasja tretjim osebam ni dovoljeno omogočiti dostopnosti dokumenta.

Vsaka vrsta razmnoževanja ali kopiranja in shranjevanja v

elektronski obliki je prepovedana.

1 PODATKI O STROJU

Naš naslov najdete na sprednji strani.

Področje veljavnosti teh navodil za uporabo in montažo poiščite v priloženi izjavi za vgradnjo v skladu s Prilogo II 1 B

Direktive o strojih.

Tehnični podatki, navedeni na straneh 18, veljajo za serijsko izvedbo. Vaše puhalo s stranskim kanalom lahko odstopa od teh podatkov (glejte tablico s podatki). V tem primeru

upoštevajte priloženo dokumentacijo, ki velja poleg teh navodil, ali posebna navodila za uporabo in montažo, ki veljajo

za vaše puhalo.

Tablica s podatki

Za priključitev, vzdrževanje in naročilo nadomestnih delov so

merodajni izključno podatki na tablici. Na tablici s podatki o

puhalu s stranskim kanalom najdete tudi serijsko številko naprave in leto njene izdelave.

D-73760 Ostfildern

Germany

Typ Nr.

Mot. EN 60034-1 IP W-Kl.F

kW cos kW cos

Hz min

V V

A A

-1

-1

min

Hz

• lepljive,

• strupene,

• eksplozivne ali

• kondenzirajoče

medije ni dovoljena.

Dovoljena temperatura medija za črpanje pri standardni izvedbi znaša od –20 °C do +40 °C. Trdne snovi v črpalnem

mediju ali nečistoče je treba odstraniti s fi ltriranjem pred vsto-

pom v puhalo s stranskim kanalom.

Kompresor s stranskim kanalom ni primeren za vgradnjo na

prostem brez dodatnih ukrepov. Kompresor s stranskim kanalom je konstruiran za neprekinjeno obratovanje (S1). Dovoljenih je največ 30 preklopov na uro.

Kompresor s stranskim kanalom v serijski izvedbi ni primeren za postavitev v ali črpanje eksplozivnih ozračij.

Posebne izvedbe za uporabo, ki se razlikuje od zgoraj opisanih načinov uporabe, so na voljo na zahtevo. Predelovanje in

spreminjanje kompresorja s stranskim kanalom ni dovoljeno.

Pri posebnih napravah morate upoštevati navodila v dodatno

priloženih navodilih za uporabo in vgradnjo. Ta se v posameznih podrobnostih razlikujejo od teh navodil za uporabo

in vgradnjo.

Kompresorje s stranskim kanalom Elektror odlikuje velika zanesljivost obratovanja. Ker gre pri kompresorjih s stranskim

kanalom za zelo zmogljive stroje, morate zaradi preprečeva-

nja telesnih poškodb, gmotne škode in škode na stroju strogo upoštevati naslednja varnostna navodila.

Kompresorje s stranskim kanalom Elektror odlikuje velika zanesljivost obratovanja. Ker gre pri kompresorjih s stranskim

kanalom za zelo zmogljive stroje, morate zaradi preprečeva-

nja telesnih poškodb, gmotne škode in škode na stroju strogo upoštevati naslednja varnostna navodila.

1.2 Mehanske nevarnosti

Mehanske nevarnosti so pri puhalih s stranskim kanalom

Elektror na podlagi njihove skladnosti s trenutnim stanjem

tehnike in zahtevami za varstvo in zaščito zdravja ustrezno

majhne. Za izključitev preostalih nevarnosti, do katerih

lahko pride pri ravnanju, priporočamo, da v vseh fazah življenjske dobe naprave uporabite primerno zaščitno opremo

oz. jo nosite (prosimo, da upoštevate ustrezne napotke v

nadaljevanju).

1.3 Nevarnosti zaradi posegov v napravo

V notranjosti naprave med njenim delovanjem zaradi vrtečih

se delov obstaja visoka nevarnost telesnih poškodb. Napravo pred odpiranjem, seganjem vanjo ali vstavljanjem orodij v

vsakem primeru izklopite in počakajte, da se vsi gibljivi deli

umirijo. Napravo v celotnem obdobju zanesljivo zavarujte

pred ponovnim zagonom.

Ravno tako zagotovite, da ne more priti do nevarnosti zaradi

ponovnega zagona po mirovanju, npr. zaradi prekinitve ali

blokade oskrbe z energijo.

1.4 Teža, varen položaj

Še posebej med transportom in postavitvijo obstajajo nevarnosti zaradi prevrnitve ali padca. Glejte 2.1 – Transport in

ravnanje ter 3.2 – Postavitev, montaža.

1.1 Predvidena uporaba

Uporaba puhala s stranskim kanalom je dovoljena samo v

mejah podatkov, navedenih na tablici naprave. Napotke v

naslednjih poglavjih je treba upoštevati in se jih držati.

Ta puhala s stranskim kanalom so primerna izključno za transport čistega zraka.

Uporaba za

• agresivne,

• grobe,

1.5 Število vrtljajev

Opozorilo!

Na sesalni nastavek se lahko prisesajo predmeti,

oblačila in lasje. Nevarnost telesnih poškodb!

Med delovanjem se ne zadržujte v bližini sesalne

odprtine. Ventilatorja ni dovoljeno uporabljati z

odprtim sesalnim nastavkom, zato ga je treba

pokriti z zaščitno mrežo po standardu DIN EN

ISO 13857 (nevarnost telesnih poškodb zaradi

rotorja!).

9016329 01.20/09

www.elektror.com Navodila za uporabo in montažo 1SD, 2SD

1.6 Sesalno delovanje

Puhala s stranskim kanalom ustvarjajo zelo visoko sesalno moč.

Opozorilo!

Na sesalnem nastavku lahko pride do sesanja

predmetov, oblačil in tudi las. Nevarnost poškodbe! Med obratovanjem se ne zadržujte v bližini

sesalne odprtine. Puhala s stranskim kanalom

nikoli ni dovoljeno uporabljati z odprto sesalno

odprtino. Odprto sesalno mesto mora biti prekrito

z zaščitno rešetko v skladu z DIN EN ISO 13857.

Ne segajte v sesalno odprtino.

1.7 Temperatura

Opozorilo!

Ohišje motorja/puhala se med delovanjem segreje. Ko temperatura naraste nad +50 °C, mora

obratovalec (lastnik naprave) puhalo s stranskim

kanalom zaščititi pred neposrednim dotikom

(nevarnost opeklin!).

1.8 Zaščitno stikalo motorja

Pred začetkom uporabe kompresorja s stranskim kanalom je

treba pogonski motor zavarovati z motorskim zaščitnim stikalom (ne velja za naprave s frekvenčnim pretvornikom). Pri

napravah s frekvenčnim pretvornikom je treba na frekvenčni

pretvornik priključiti in preverjati vgrajeno temperaturno tipalo (PTC) ali temperaturni nadzornik (kontakt NC).

1.9 Nastajanje hrupa

Napotek!

Med delovanjem nosite zaščito sluha od dnevne

ravni izpostavljenosti 80 dB (A) in / ali najvišje

ravni zvočnega tlaka 135 dB (C).

Če ne upoštevate, lahko pride do okvare sluha.

Hrup, ki ga oddaja puhalo s stranskim kanalom, ni konstanten za vsa področja zmogljivosti. Vrste oddanega hrupa poiščite v preglednici na strani 18.

V določenih neugodnih posameznih primerih je potrebna

zvočna izolacija (priporočajo se meritve obratovalca). Zvočno izolacijo mora izvesti obratovalec, da ne pride do preseganja zakonsko dovoljenih maksimalnih vrednosti na delovnih mestih v okolici puhala s stranskim kanalom.

Nobena vrsta zvočne izolacije pa ne sme privesti do nedovoljenega povečanja temperature v okolici nad največ +40 °C

pri pogonskem motorju.

Ventilatorji stranskih kanalov so zasnovani tako, da običajno

ne pride do resonanc s konstantno hitrostjo delovanja.

Če puhalec stranskih kanalov deluje na frekvenčnem pretvorniku, lahko v določenih okoliščinah pride do vzbujanja

s spremenjeno hitrostjo. Na te okoliščine vplivajo tudi specifi čne zahteve za namestitev uporabnika ali prezračevalni

priključek.

Če so te naravne frekvence v območju hitrosti kompresorja

stranskih kanalov, jih je treba izključiti z ustrezno parametrizacijo frekvenčnega pretvornika.

Največja frekvenca (glejte

tablico z močjo)

Najmanjša frekvenca

50 Hz 5 Hz

60 Hz 5 Hz

> 60 Hz 20 Hz

1.11 Električne nevarnosti

Nevarnost!

Nevarnost zaradi električnega toka!

Komponente z električno napetostjo so pod

električnim tokom in povzročajo smrtne telesne

poškodbe!

Pred odpiranjem, poseganjem v napravo ali

vstavljanjem orodij izklopite delovanje naprave,

preverite odsotnost električne napetosti in napravo zavarujte pred ponovnim zagonom.

2 INFORMACIJE O TRANSPORTU,

RAVNANJU IN SKLADIŠČENJU STROJA

2.1 Transport in ravnanje

• Pred montažo in zagonom vse dele preverite glede

poškodb pri transportu. Poškodovano puhalo s stranskim

kanalom lahko pomeni povečano tveganje za varnost in

ga zato ni dovoljeno uporabljati.

• Puhala s stranskim kanalom ne skladiščite na prostem

brez zaščite (zaščitite ga pred vlago).

• Dvižno sredstvo varno pritrdite na napravo. Uporabljajte

samo dvižna sredstva in priprave za dvig bremena z

zadostno nosilnostjo. Zavarujte poti transporta naprave.

SL

3

1.10 Hitrosti

Opozorilo!

Da bi se izognili telesnim poškodbam, je na

žigosano ploščico motorja odtisnjeno

največja hitrost ne sme biti nikoli prekoračena.

Preti nevarnost mehanskega uničenja kompresorja stranskih kanalov grozi.

To je nevarnost poškodb in smrti!

Vsaka komponenta kompresorja na stranskem kanalu ima

posamezne naravne frekvence. Te lahko vzbudijo določene

hitrosti kompresorja stranskih kanalov, kar povzroči možno

resonančno delovanje.

9016329 01.20/09

Napotek!

Bolt oko na motorju se ne smejo uporabljati za

dvigovanje celotno pihalo. To je unsed če motorja

mora biti (dis-) sestavljeni.

2.2 Skladiščenje

• Zagotovite, da sta sesalni priključek in tlačni priključek zaprta.

• Puhalo s stranskim kanalom

-> po možnosti odložite v originalni embalaž

-> v zaprtem prostoru

-> na suhem mestu brez prahu in vibracij.

Navodila za uporabo in montažo 1SD, 2SD www.elektror.com

SL

• Področje temperature skladiščenja naj bo med

–20 °C in +60 °C.

• Naprave je dovoljeno skladiščiti največ 2 leti.

3 INFORMACIJE O PRVEM ZAGONU

STROJA

3.1 Osnovni napotki

• Pred prvim in pred vsakim ponovnim zagonom je treba

izvesti skrbno preverjanje naprave glede njenega brezhib nega stanja. Naprave, ki imajo npr. pri dobavi ali namestitvi

vidne poškodbe, je treba dati strokovno preveriti.

• Postavitev, montažo, obratovanje in vzdrževanje sme izva jati samo strokovno ustrezno osebje s primernimi izkušnja mi in znanjem. Obratovanje po napačno izvedeni montaži,

vzdrževanju ali neusklajeni zamenjavi sestavnih delov

privede do nepredvidene uporabe in izgube jamstva. Tako

nastalo tveganje prevzame stranka ali sam obratovalec na prave.

3.2 Postavitev, montaža

• Puhalo s stranskim kanalom postavite zaščiteno pred vre menskimi vplivi, vremenom in sončnimi žarki. Glejte tudi

napotke za postavitev pod 1.1, Predvidena uporaba.

• Naprave ne izpostavljajte obremenitvam zaradi nihanja ali

udarcev. Dopustne vrednosti nihanja puhala s stranskim

kanalom: Glejte ISO 14694, BV-3.

• Puhalo s stranskim kanalom s podnožjem: Na mestu upo rabe napravo postavite na ravno, trdno, dovolj nosilno pod lago brez prenosa nihanja ali obremenitev.

• Puhala s stranskim kanalom je treba zavarovati pred zvijanjem.

1SD 5... / 2SD 5... 53 2,09

1SD 7... / 2SD 7... 53 2,09

1SD 8... / 2SD 8... 53 2,09

1SD 9... / 2SD 9... 53 2,09

3.3 Montaža stranskih dušilcev zvoka, serija 2SD *2*

3

5

• Vstavek za dušenje zvoka (1) potisnite v ohišje dušilca zvoka (2).

• Tesnilo (3) poravnajte s pomočjo vijakov (4), nameščenih v

dušilcu zvoka, in komponente pritrdite na ohišju ventilatorja

(5).

3.4 Električni priključek

Napotek!

Dela, opisana v tem poglavju, sme izvajati samo

elektrotehnik. Priključek je treba izvesti v skladu z

vezalno shemo v omarici s sponkami in veljavnimi

predpisi na mestu izvedbe.

1

2

4

• Noge oz. konzole kompresorja s stranskim kanalom so

konstruirane samo za lastno težo kompresorja.

• Odprto sesalno ali pihalno odprtino prekrijte z zaščitno

rešetko v skladu z DIN EN ISO 13857.

4

• Poskrbite za zadostno prezračevanje motorja. Dovoljene

temperature okolja pri:

Elektro motor z nazivno napetostjo 50 Hz ali 60 Hz, posebnimi napetostmi, multi-napetostnimi motorji, FU-združljivimi

različicami, FUK različicami, UL-certifi ciranimi napravami:

• Temperatura okolice -20°C do + 40°C

Opomba!

Motorji Elektror so skladno s standardom IEC

60038 na splošno konstruirani za razširjeno napetostno območje ±10 %.

• Stanje vgradnje na sistem prezračevanja pogonskega

motorja ne sme vplivati.

Minimalna razdalja pokrova ventilatorja

(za sesanje hladnega zraka)

Eno- in dvostopenjsko

puhalo s stranskim

kanalom

1SD 2... / 2SD 2... 34 1,34

1SD 3... / 2SD 3... 34 1,34

1SD 4... / 2SD 4...

1SE 4...

Minimalna razdalja pokrova

ventilatorja s sesanjem

[mm] [palcev]

34 1,34

Kot pogonski motorji se uporabljajo motorji s trifaznim ali izmeničnim tokom. To je na napravi označeno s črko D (trifazni

tok, 3~) ali E (enofazni izmenični tok 1~).

• Pogonski motor je treba zavarovati z zaščitnim stikalom

motorja (ne velja za naprave, ki delujejo s frekvenčnim

pretvornikom). Za naprave, ki delujejo s frekvenčnim

pretvornikom, je treba na pretvornik priključiti obstoječi

nadzornik temperature (odpiralni kontakt) in izvesti anali zo.

• Preverite, ali se omrežna napetost ujema s podatki na

tablici naprave.

• Priključek zaščitnega vodnika je na voljo v omarici s

sponkami.

Napotek!

Pri obratovanju pogonskega motorja s frekvenčnim pretvornikom je treba dodatno upoštevati

naslednje:

• Oskrbovalna napetost frekvenčnega pretvornika

sme brez fi ltra motorja znašati največ 400 V. Pri

daljših napeljavah, višjih oskrbovalnih napetostih

pretvornika in/ali prekoračitvi vršnih napetosti

(maks. 1.300 Vpk) na sponkah motorja, je treba

namestiti primerne priprave, npr. fi lter motorja za

njegovo zaščito. V zvezi s tem se obrnite na dobavitelja pretvornika. Če je fi lter motorja del obsega

dobave, ga je treba namestiti med pretvornikom

in motorjem. Poskrbite za dovolj prostega prostora v stikalni omarici in upoštevajte predpise

za namestitev in montažo v navodilih za uporabo proizvajalca frekvenčnega pretvornika/fi ltra

motorja.

• Maksimalna dolžina napeljav med motorjem

in frekvenčnim pretvornikom ne sme preseči 20

m in jo je treba izvesti s primernim oklepljenim

9016329 01.20/09

www.elektror.com Navodila za uporabo in montažo 1SD, 2SD

kablom, po možnosti po neposredni poti in brez

dodanih spončnih/vtičnih povezav.

• Oklepni oplet na priključnem kablu mora biti

neprekinjeno in na obeh straneh, se pravi na

frekvenčnem pretvorniku in na motorju, električno nizko uporovno povezan z ozemljitvenim

sistemom. Na strani motorja je treba v ta namen

uporabiti primerna EMC-kabelska privitja, ki imajo

nizko uporovni stik z oklepom kabla po vsem

obsegu.

Nadaljnje informacije o primerni, elektromagnetno združljivi

namestitvi in montaži poiščite v napotkih v navodilih za uporabo in montažo dobavitelja frekvenčnega pretvornika.

3.4.1 Vezava za trifazno puhalo s stranskim kanalom

Opozorilo!

Nevarnost zaradi razrahljanih in napačno prite-

gnjenih spojev!

Napačno pritegnjeni in razrahljani spoji povzro-

čijo električne udare, požare, stvarno in osebno

škodo!

Preverite rahlost spojev in jih pritegnite v skladu

s priteznimi navori v spodnji preglednici.

W2 U2 V2

U1 V1 W1

W2 U2 V2

U1 V1 W1

L1 L2 L3 L1 L2 L3

(L3) (L1) (L3) (L1)

-vezava Y-vezava

(nizka napetost) (visoka napetost)

Navojni vijak Kažejo navor

M4 1,2 Nm

M5 2,0 Nm

M6 3,0 Nm

M8 6,0 Nm

Preverjanje smeri vrtenja

Puhalo s stranskim kanalom vklopite. Smer teka rotorja se

mora ujemati s smerno puščico na pokrovu ventilatorja.

Smer pretoka zraka se mora ravno tako ujemati s smernimi

puščicami na ohišju dušilca zvoka. V primeru napačne smeri

vrtenja je treba zamenjati L1 in L3.

Zagon zvezda-trikot

Motorji z več kot 3,0 kW moči so predvideni za zagon zvezda-trikot na oskrbovalnem omrežju. Za neposreden vklop

(visok kratkostični tok v trenutku vklopa) se v zvezi s pogoji

posvetujte s svojim podjetjem za električno oskrbo.

3.4.2 Vezava za puhalo s stranskim kanalom na

enofazni izmenični tok

3.4.3 Dodatne sponke

Priključne sheme za nadzornik temperature (odpiralni kontakt) so priložene v omarici s sponkami motorjev.

4 PODATKI O OBRATOVANJU IN

UPORABI

4.1 Osnovni napotki

Upoštevajte napotke o predvideni uporabi, opisane v točki

1.1, ter varnostne napotke, opisane v točkah 1.2 do 1.11.

Če med obratovanjem pride do prekoračitve nazivnega toka

pogonskega motorja, preverite, ali se omrežna napetost in

frekvenca ujemata s podatki naprave.

Po zaščitnih odklopih kot npr. sprožitev zaščitnega stikala

motorja, reakcija nadzornika temperature (odpiralni kontakt)

ali zaščitni odklop prisotnega frekvenčnega pretvornika je

ponovni zagon naprave dovoljen šele po identifi kaciji in od-

pravi vzroka motnje.

Pri puhalih s stranskim kanalom, ki jih ni mogoče uporabljati

v skladu z vsemi karakteristikami, lahko v primeru prevelikega upora naprave pride do preobremenitve motorja (previsoka vhodna moč).

Če preobremenitve zaradi upora naprave ni mogoče izključiti, je treba predvideti omejevalni ventil na tlačni oziroma na

sesalni strani.

Napotek!

Serije 2SD ni dovoljeno uporabljati z omejevalnim

ventilom kot trajno preobremenitveno zaščito.

Puhala s stranskim kanalom ni dovoljeno izpostavljati obremenitvam zaradi nihanja ali udarcev.

4.2 Delovanje frekvenčnega pretvornika

Z uporabo frekvenčnega pretvornika je možno obsežnejše

področje nastavljanja števila vrtljajev, pri tem pa se med

praznim tekom in maks. obremenitvijo puhala s stranskim

kanalom pojavi samo majhna razlika v številu vrtljajev, ki je

odvisna od obremenitve.

Za nemoteno obratovanje puhala s stranskim kanalom je

pomembno, da pretvornik izpolnjuje naslednje zahteve:

• Moč pretvornika je enaka ali večja od moči motorja *)

• Tok pretvornika je enak ali večji od moči motorja *)

• Izhodna napetost pretvornika je enaka nazivni napetosti

motorja

• Napajalna napetost max. 480V, vključno s 5% napetostno

toleranco

• Frekvenca pulzov pretvornika mora znašati 8 kHz, ker

nižja frekvenca pulzov povzroča močan hrup motorja

•

Vrednosti za največje in najmanjše frekvence so pod 1.10.

• Pretvornik mora imeti priključek za nadzornik temperature

(odpiralni kontakt)

*) glede vrednosti glejte tablico s podatki

Motor se lahko uporablja s trikotno ali zvezdno vezavo, odvi-

sno od vhodne napetosti pretvornika.

SL

5

Z2 U2

U1 Z1

L1 N L1 N

Tek v desno Tek v levo

9016329 01.20/09

Z2 U2

U1 Z1

Navodila za uporabo in montažo 1SD, 2SD www.elektror.com

SL

6

Obvezno je treba nastaviti spodnjo dodelitev U/f na

pretvorniku.

B

prepovedano

območje

f

B

f

0

in UB = glejte tablico s podatk

B

V primeru neupoštevanja se tok motorja nesorazmerno poveča in pogonski motor ne doseže nazivnega števila vrtljajev.

Napotek!

V nobenem primeru ni dovoljeno na pretvorniku nastaviti višje frekvence (števila vrtljajev) od

frekvence (fB), ki je navedena na tablici s podatki,

ker sicer pride do preobremenitve motorja ali pa

uničenja puhala s stranskim kanalom zaradi povečanega števila vrtljajev. Na pretvorniku tudi ni

dovoljeno nastaviti tako imenovane „ojačitve (an.

Boost)“, ker bi tako prišlo do prekomerno visokega segrevanja pogonskega motorja. Temperaturna tipala je treba v zaščito pogonskega motorja

priključiti na ustreznih vhodih pretvornika. Motorji

z enofaznim izmeničnim tokom niso primerni za

delovanje s pretvornikom.

Obvezno je treba upoštevati napotke za namestitev in varnost, navedene v priročnikih za uporabo

in namestitev, ki jih priložijo dobavitelji frekvenčnih pretvornikov, da tako zagotovite varno in

nemoteno obratovanje.

Zaščita s pomočjo zaščitnega stikala za okvarne tokove

(zaščitno FI-stikalo):

Frekvenčni pretvorniki IGBT načeloma ustvarjajo uhajave

tokove >=3,5 mA. Ti uhajavi tokovi lahko privedejo do napačnih sprožitev v napravah, ki so zavarovane z zaščitnim

FI-stikalom za diferenčni tok 30 mA.

V primeru napake lahko okvarni tokovi tudi tečejo kot enosmerni tok po zaščitnem vodniku. Če je na oskrbovalni strani

potrebna zaščita s pomočjo zaščitnega FI-stikala, je treba

obvezno uporabiti zaščitno FI-stikalo z občutljivostjo na vse

vrste tokov (tipa B). Uporaba napačnega zaščitnega FI-stikala drugega tipa kot B lahko v primeru napake privede do

smrti ali težkih poškodb.

Za izpolnjevanje standarda EN 61800-5-1 je treba povezavo

z zaščitnim vodnikom izvesti dvojno, preko ločenih sponk ali

s presekom zaščitnega vodnika najmanj 10 mm² Cu.

Obratovanje in priključitev na javna oskrbovalna omrežja:

Večina frekvenčnih pretvornikov je predvidena za uporabo

na industrijskih oskrbovalnih omrežjih.

Če naj se pretvornik

za uporabo priključi neposredno na oskrbovalno omrežje, je

morebiti treba v omrežno napeljavo vgraditi dodatne priprave

za odpravljanje motenj, na primer omrežno dušilko. Nadaljnje informacije najdete v navedbah proizvajalca pretvornika.

5 PODATKI O VZDRŽEVANJU

Obrabni deli so podvrženi priporočenim vzdrževalnim intervalom in zanje veljajo jamstveni zahtevki (glejte 5.1 do 5.4).

Življenjska doba obrabnih delov (krogličnih ležajev in fi ltrov)

je odvisna od obratovalnih ur, obremenitve in drugih vplivov

kot temperatura itd.

Ukrepe za in pri vzdrževanju in servisiranju smejo izvajati

samo osebe z ustreznim strokovnim znanjem in izkušnjami,

ki se za to področje redno usposabljajo. Pri tem je treba poleg ustreznih navodil za uporabo naprave in predpisov ter

priporočil celotne naprave upoštevati naslednje:

Intervali za preglede in vzdrževanje:

Odvisno od obratovalnih ur, obremenitev in pogojev uporabe

mora obratovalec sam določiti intervale čiščenja, pregledovanja in vzdrževanja.

Takojšnji pregled in vzdrževanje:

Pri pojavu vibracij in nihanj, zmanjšani zmogljivosti zraka.

Napotek!

Popravila sme izvajati samo proizvajalec. Pri

popravilih: v primeru sprememb ali zamenjave

sestavnih delov, ki jih izvedejo tretje osebe, ne

prevzamemo nobene odgovornosti in jamstva.

5.1 Kroglični ležaji

Opomba!

Kompresorji s stranskim kanalom so opremljeni

z zaprtimi žlebastimi krogličnimi ležaji, ki jih ni

treba dodatno mazati.

Opomba!

Pri vzdrževanju in pred vsakim ponovnim zagonom preverite kroglične ležaje.

Obratovanje je dovoljeno samo z brezhibnimi

krogličnimi ležaji!

Opomba!

Pri pogostem speljevanju in ustavljanju je potrebna predčasna zamenjava ležajev. Za določitev

časa potrebne menjave ležajev je odgovorno

vzdrževalno in servisno osebje po lastni presoji.

Naprave

Serija 1SD/2SD

Priporočilo za menjavo krogličnih ležajev

- Pred dosegom najkrajše življenjske dobe

- Najkasneje 30 mesecev po predaji

- Po 6 mesecih preverite čas skladiščenja, po potrebi jih

zamenjajte

Najkrajša življenjska doba

krogličnih ležajev

vodoravna

motorna gred

22.000

Ure

navpična

motorna gred

11.000

Ure

5.2 Fini fi lter

Stopnjo umazanosti fi ltrirnih vstavkov je treba preverjati v re-

dnih časovnih razmikih, odvisno od pogojev uporabe/okolice.

Prepustnost fi ltrov mora torej obratovalec zagotavljati. Fini

fi lter je treba namestiti vodoravno, da pri vzdrževalnih delih

v puhalo s stranskim kanalom ne more zaiti umazanija. Pri

navpični vgradnji fi nega fi ltra je treba pred začetkom čišče-

nja/vzdrževanja z naprave demontirati celotni fi lter.

9016329 01.20/09

www.elektror.com Navodila za uporabo in montažo 1SD, 2SD

5.3 Omejevalni ventil

Omejevalni ventil je varnostni ventil, pri katerem je treba v rednih razmikih odvisno od pogojev uporabe preveriti delovanje. Pri preverjanju je treba zapreti obratovalno stran. Omejevalni ventil se mora odzivati pri maksimalni vrednosti tlaka.

Napotek!

Popravila sme izvajati samo proizvajalec. Če

popravila izvede tretja oseba, ne prevzamemo

nobene odgovornosti.

5.4 Čiščenje

Čiščenje ali vzdrževanje ne sme privesti do poškodb ali sprememb naprave in njenih sestavnih delov, neugodno vplivati

na varnost in zaščito zdravja, ravno tako ne sme priti do poslabšanja uravnoteženosti rotorja.

6 INFORMACIJE V ZVEZI Z VARNOSTJO

PRI JEMANJU IZ OBRATOVANJA IN

RAZSTAVITVI

Ločevanje električnih povezav in vse druge elektrotehnične

ukrepe v povezavi z jemanjem naprave iz obratovanja sme

izvajati samo elektrotehnik.

Razstavljanje naprave je dovoljeno šele, ko so se zaustavili

vsi vrteči deli in ponovni zagon ni več mogoč.

SL

Pri razstavljanju in prevažanju morate upoštevati predpise v

poglavju 2.1 Prevoz in ravnanje. Pri odstranjevanju napravo

obravnavajte kot industrijski odpadek.

Deli naprave so iz materialov, ki jih je mogoče reciklirati, na

primer aluminija, nerjavnega jekla, bakra in umetnih mas.

Določeni deli pa zahtevajo posebno obravnavo (npr. frekvenčni pretvornik). Upoštevati je treba nacionalne in krajevne zakonske predpise za odstranjevanje ter recikliranje.

7 JAMSTVO IN IZKLJUČITEV JAMSTVA

Odgovornost za predvideno uporabo naprave nosi obratovalec.

Podj. Elektror odklanja vsakršno odgovornost za nepredvideno uporabo njegovih naprav in komponent.

To še posebej velja za posebne načine in pogoje uporabe, ki

niso izrecno usklajeni s podj. Elektror.

Elektror poleg tega odklanja vsakršno odgovornost za spremembe ali predelave dobavljene naprave in njenega pribora.

Podj. Elektror tudi ne odgovarja za nestrokovno, prepozno

izvedena ali neizvedena vzdrževalna dela in popravila ali za

primere, ko teh ni izvedlo strokovno osebje podj. Elektror, ter

za njihove morebitne posledice.

7

9016329 01.20/09

Navodila za uporabo in montažo 1SD, 2SD www.elektror.com

SL

8 IZJAVA O VGRADNJI V SKLADU S PRILOGO II 1 B

IZJAVA O SKLADNOSTI V SKLADU S 4. ČLENOM 1. ODSTAVKA DIREKTIVE EVPG

Podjetje

Elektror airsystems gmbh

Hellmuth-Hirth-Straße 2

D-73760 Ostfi ldern

kot proizvajalec izjavlja, da izdelek, na katerega se nanaša ta izjava, ustreza spodaj navedenim bistvenim zahtevam Direktive o

strojih (2006/42/ES).

Opis delno dokončanega stroja:

Enostopenjsko puhalo s stranskim kanalom: 1SD 210, 1SE 210, 1SD 310, 1SD 410, 1SE 410, 1SD 510, 1SD 510 FU/FUK,

1SD 710, 1SD 810, 1SD 910

Dvostopenjsko puhalo s stranskim kanalom: 2SD 220, 2SD 320, 2SD 420, 2SD 520, 2SD 720, 2SD 820, 2SD 920

Dvosmerni kompresor stranskih kanalov: 2SD 740, SD 840

Serijska številka in leto izdelave sta navedena na tablici s podatki in pripadajoči dobavnici.

Navedba bistvenih zahtev Direktive o strojih (2006/42/ES), s katerimi je delno dokončan stroj v skladu:

Direktive o strojih (2006/42/ES), Priloga I, členi 1.1.2, 1.1.3, 1.1.5, 1.3.2, 1.3.3, 1.3.4, 1.3.7, 1.5.1, 1.6.1, 1.7.1, 1.7.3

Direktiva o elektromagnetni združljivosti (2014/30/EU)

Direktiva o okoljsko primerni zasnovi izdelkov, povezanih z energijo (2009/125/ES).

Naveden delno dokončan stroj poleg tega izpolnjuje vse določbe Direktive o električni opremi (2006/95/ES) v skladu s Prilogo I,

št. 1.5.1. Direktiva o strojih.

Dajanje delno dokončanega stroja v obratovanje je prepovedano, dokler ni dokončan stroj, v katerega bo vgrajen, razglašen za

skladnega z določbami Direktive o strojih (2006/42/ES).

Uporabljeni so naslednji harmonizirani standardi:

DIN EN ISO 12100 2011 Varnost strojev – Osnovni pojmi, splošna načela načrtovanja,

1. del: Osnovna terminologija, metodologija

DIN EN 60034-1 2011 Električni rotacijski stroji, 1. del: Nazivni podatki in preskus lastnosti

DIN EN 60034-5 2007 Električni rotacijski stroji, 5. del: Stopnja zaščite, ki jo

zagotavlja celovita zasnova rotacijskih električnih strojev (koda IP) – Razvrščanje

DIN EN 60034-30-1 2014 Rotacijski električni stroji – 30. del: opredelitev učinkovitosti trifaznih motorjev s

kletkastim rotorjem, brez motorjev z možnostjo menjave polov (koda IE)

DIN EN 60204-1 2019 Varnost strojev – Električna oprema strojev,

1. del: Splošne zahteve

DIN EN 60664-1 2008 Uskladitev izolacije za opremo v okviru nizkonapetostnih sistemov,

1. del: Načela, zahteve in preskusi

8

Podjetje Elektror airsystems gmbh se kot proizvajalec obvezuje, da bo ustrezno dokumentacijo v zvezi s tem delno dokončanim

strojem na zahtevo predložil pristojnim nacionalnim organom v elektronski obliki ali na papirju.

Ustrezna tehnična dokumentacija za ta delno dokončani stroj v skladu s Prilogo VII del B je bila sestavljena.

Pooblaščena oseba za dokumentacijo je gospod Kevin Kargar, tel. +49 711 31973-1179.

Kreher (poslovodja)

Ostfi ldern, 10.01.2020

9016329 01.20/09

www.elektror.com Navodila za uporabo in montažo 1SD, 2SD

SL

9016329 01.20/09

9

Operating and assembly instructions 1SD, 2SD www.elektror.com

EN

10

CONTENT

1 MACHINE SPECIFICATIONS

2 INFORMATION ON TRANSPORTATION, HANDLING

AND STORAGE OF THE MACHINE

3 INFORMATION ON PUTTING INTO SERVICE

4 INSTRUCTIONS FOR OPERATION AND USE

5 INSTRUCTIONS FOR MAINTENANCE

6 SAFETY RELATED INFORMATION ON TAKING OUT

OF OPERATION AND REMOVAL

7 LIABILITY AND EXCLUSION OF LIABILITY

8 DECLARATION OF INSTALLATION CONFORMITY

PURSUANT TO ANNEX II 1 B

9 TECHNICAL SPECIFICATIONS

10 BROKEN VIEW DRAWING

11 GENERAL SPARE PART LIST

These Operating Instructions must be available to operating

personnel at all times. Read these Operating and Assembly

Instructions carefully before installing and putting the side

channel blower into service.

Subject to change without prior notice. If in any doubt, the

manufacturer should be consulted. This document is protected by copyright. It must not be disclosed to third parties without our express written consent. Any form of duplication or

recording and storage in electronic equipment is forbidden.

1 MACHINE SPECIFICATIONS

Please refer to the cover sheet for our address.

For the area of validity of these Operating and Assembly Instructions, please refer to the Declaration of Installation Conformity contained in Annex II 1 B.

The technical specifi cations on page 18 apply to the stand-

ard version. Your side channel blower’s specifi cations may

diff er from these specifi cations (refer to nameplate). If this is

the case, please refer to the enclosed, additionally applicable

documents or your own applicable Operating and Assembly

Instructions.

Nameplate

The data on the rating plate is applicable to connection,

maintenance and ordering of spare parts. Also refer to the

nameplate for the serial number of the appliance and its year

of manufacture.

D-73760 Ostfildern

Germany

Typ Nr.

Mot. EN 60034-1 IP W-Kl.F

kW cos kW cos

Hz min

V V

A A

1.1 Designated use

Operation of the side channel blower is only permissible

within the limits specifi ed on the nameplate. The information

in the following sections must be noted and observed.

The side channel blowers are exclusively designed for conveying gaseous media without solids. Any solid matter or impurities in the medium to be conveyed must be fi ltered out

before they enter the side channel blower.

Use of the side channel blowers for

• aggressive

-1

-1

min

Hz

• abrasive

• sticky

• toxic

• potentially explosive or

• condensate-forming

media is not permissible.

The permissible conveyed medium temperature for the

standard version is -20°C to +40°C. Solid particles or contaminants must be removed by a fi lter unit before entering

the side channel blower.

The ambient temperature must not exceed +40°C or undershoot a minimum of –20°C.

The side channel blower is not suitable for installation outdoors without special measures. The side channel blower is

fundamentally designed for S1 operation (continuous operation). However, a maximum of 30 switching operations per

hour are permitted.

The standard version of the side channel blower is not suitable for use in explosive atmospheres.

Special versions for applications not mentioned above are

available on request. Remodelling and modifi cation of the

side channel blower are not permitted. In the case of special

equipment, the enclosed supplementary Operating and Assembly Instructions must be observed and adhered to. The

supplementary instructions diff er in certain respects from

these Operating and Assembly Instructions.

Elektror side channel blowers off er a high level of operational

reliability. As the side channel blowers are high-powered machines, the safety instructions must be strictly observed in

order to avoid injuries, damage to objects and to the machine

itself.

1.2 Mechanical hazards

The mechanical hazards in Elektror side channel blowers

have been minimised in accordance with the current state

of the art, as well as the requirements for safety and health

protection. To eliminate any further risk on the part of the operator, we recommend that suitable protective gear be used

and worn during all lifecycle phases of the appliance (please

refer to the instructions below).

1.3 Danger of hand injury

The rotating parts inside the appliance pose a high risk of

injury during operation. Before opening, reaching in or inserting tools into the appliance, always shut it down and wait

until all moving parts come to a standstill. Make sure the appliance is reliably protected against restarting while work is

in progress.

Also make sure that no hazardous situation can occur as a

consequence of restarting after shutdown, e.g. as a result of

a power cut or blockage.

1.4 Weight and stability

Beware of falling hazards during transportation and installation in particular. Refer to 2.1 – Transportation and handling,

as well as 3.2 – Installation and assembly.

1.5 Suction eff ect

The side channel blowers produce a powerful suction eff ect.

Warning!

Objects, items of clothing and also hair can be

sucked into the intake port. Risk of injury!

Do not stand near the intake opening during operation. The side channel blower must not under

any circumstances be operated with the intake

port open, and should, therefore, be covered with

a wire guard in conformity with DIN EN ISO 13857

(danger of injury from impeller!)

9016329 01.20/09

Operating and assembly instructions 1SD, 2SDwww.elektror.com

1.6 Blowing eff ect

Warning!

The blowing eff ect is very powerful on the ex-

haust side. Sucked in objects may be ejected at

very high speed (danger of injury).

The side channel blowers are designed for

delivery of clean air only. To reliably prevent the

sucking-in of foreign objects or contaminants,

which might be discharged, these objects have to

be removed before entering into the side channel

blower by installing a fi lter.

Do not reach into the exhaust.

1.7 Temperature

Warning!

The motor-/ side channel blower housing heats

up during operation. If the temperature rises

above +50°C, the side channel blower must be

protected by the operating company against

direct contact (risk of burning!).

1.8 Motor circuit breaker

Before putting the side channel blower into operation, be sure

to safeguard the drive motor with a motor circuit-breaker (this

does not apply to frequency-converter-operated appliances).

Where appliances are frequency-converter-operated, the existing temperature switch (normally-closed contact) must be

connected to the converter and evaluated.

1.9 Noise emission

Note!

Wear hearing protection during operation at a

daily exposure level of 80 dB(A) and above, and/

or a peak sound pressure level of 135 dB(C) and

above.

Failure to do so may cause hearing damage.

The noise generated by a side channel blower is not constant throughout the performance range. For details of radiated noise level, please refer to the table on page 18.

In some cases, sound insulation may be necessary (it is

recommended that emission levels be measured by the

operator). Sound insulation must be provided by the operator to avoid exceeding the statutory maximum levels at the

workplace and in the immediate vicinity of the side channel

blower.

No sound insulation of any kind whatsoever should cause

the ambient temperature to exceed +40°C at the drive motor

(this is not permissible).

The side channel blowers are designed in such a way that

resonance does not generally occur at a constant operating

speed.

This may be induced in certain circumstances when the

speed is changed if the side channel blower is operated on

a frequency converter. These circumstances are also infl u-

enced by the customer’s individual installation situation or

ventilation connection.

These natural frequencies must be excluded by parametrising the frequency converter accordingly should they be present within the speed range of the side channel blower.

Maximum frequency (see

rating plate)

Minimum frequency

50 Hz 5 Hz

60 Hz 5 Hz

> 60 Hz 20 Hz

1.11 Electrical hazards

Danger!

Danger from electric current!

Live components carry current and cause fatal

injuries!

Deactivate the device before opening it, reaching

into it or inserting tools into it; check that components are not live and secure it against reactivation.

2 INFORMATION ON TRANSPORTATION, HANDLING AND STORAGE OF

THE MACHINE

2.1 Transportation and handling

• Before installation and putting into service, check all parts

for transit damage. A damaged side channel blower is a

potential safety hazard and, therefore, should not be put

into service.

• Do not leave the side channel blower unprotected in the

open (protect against ingress of moisture).

• Attach hoist securely. Only use hoists and load suspension

devices with suffi cient load-carrying capacity. Secure the

route of transportation.

EN

11

1.10 Speeds

Warning!

The maximum speed stamped on the motor

rating plate must never be exceeded in order to

prevent personal injury. The side channel blower

is at risk of mechanical damage if the speed is

exceeded. This can cause serious injury or death!

Each component on the side channel blower has unique natural frequencies. These can be induced by certain side channel blower speeds, which may result in resonance mode.

9016329 01.20/09

Note!

The eye bolt on the motor must not be used to lift

the entire side channel blower. This is unsed if

the motor needs to be (dis-)assembled.

2.2 Storage

• Ensure that the discharge and intake connection is locked

• Store the side channel blower

-> preferably in the original packaging

-> in a closed room

Operating and assembly instructions 1SD, 2SD www.elektror.com

EN

12

-> dry and free of dust and vibration

• Range of storage temperature: from -20°C to +60°C

• After a storage period of 6 months, the bearings should

be checked before they are mounted in the side channel

blower.

• Devices may be stored for a maximum of 2 years.

3 INFORMATION ON COMMISSIONING

THE MACHINE

3.1 Basic information

• Prior to the fi rst start-up and before any other start-up, the

proper operating status of the unit must be inspected.

Units that, for example, are found to be defective upon de

livery or during installation, must be examined by qualifi ed

technicians.

• Installation, assembly and operation must only be

performed by properly trained and qualifi ed specialists.

Operation following incorrect installation, maintenance or

unapproved replacement of components constitutes non designated use and renders the warranty void. The result

ant risk shall be borne solely by the customer or owner.

3.2 Installation and assembly

• Protect the side channel blower from the weather and

install it in a horizontal position - see also 1.1. For outdoor

use, protection from the weather must generally be pro vided that fulfi ls the requirements listed in 1.1 Intended

Use and protects the side channel blower from the infl u-

ences of the weather.

• Do not expose to vibrations or shocks. Permissible

vibrational load on side channel blower: refer to ISO

14694, BV-3.

• Standard side channel blowers with base: Bolt securely

to a level and fi rm surface at the place of use, making

sure that the surface has adequate load-bearing capacity

and avoiding vibration transmission or vibrational load.

• Side channel blowers must be secured against turning.

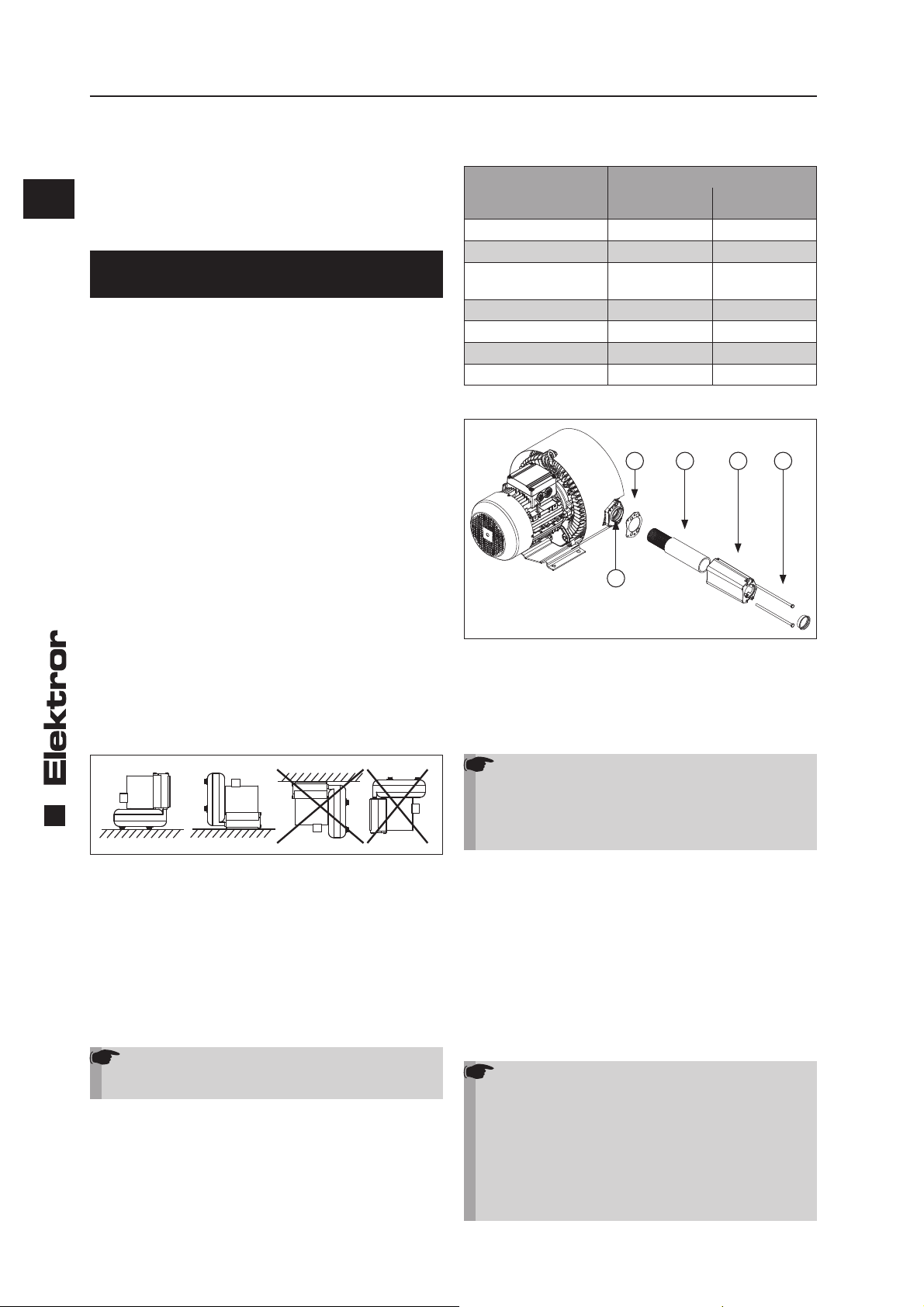

Minimum distances to side channel blower guard

(for sucking in cooling air)

Single- and doublestage side channel

blower

1SD 2... / 2SD 2... 34 1,34

1SD 3... / 2SD 3... 34 1,34

1SD 4... / 2SD 4...

1SE 4...

1SD 5... / 2SD 5... 53 2,09

1SD 7... / 2SD 7... 53 2,09

1SD 8... / 2SD 8... 53 2,09

1SD 9... / 2SD 9... 53 2,09

3.3 Assembling of laterally silencer 2SD *2*-range

• Insert the silencer cartridge (1) in silencer housing (2).

• Adjust the sealing (3) with the in the silencer inserted

screws (4) and fi x it on the side channel blower housing

(5).

3.4 Electrical connection

Note!

The work described in this section may only be

performed by a qualifi ed electrician. Connect the

appliance to the power supply in the terminal box

as per the wiring diagram and in compliance with

the applicable local regulations.

Minimum distance to fan guard

[mm] [inches]

34 1,34

4213

5

• Side channel blower feet and consoles must be designed

only for the respective side channel blower’s own weight.

• Cover open intakes or outlets with protective grating

according to DIN EN ISO 13857.

• Ensure that the motor has adequate ventilation.

Permitted ambient temperatures with:

Elektror motor and a rated voltage of 50 Hz or 60 Hz,

Special voltages, multi-voltage motors, FU-compatible

versions, FUK versions, UL-certifi ed devices:

• Ambient temperature -20°C to +40°C

Note!

As per IEC 60038 Elektror motors are generally

designed for an extended voltage range of ±10%.

• The performance of the drive motor’s ventilation system

must not be impaired by the installation situation.

Three-phase or a.c. motors can be used as drive motors.

In the appliance designation, the letter D stands for threephase a.c. and the letter E for single-phase a.c.

• The drive motor must be protected using a motor overload

switch (this does not apply to frequency converter oper ated appliances). Where appliances are frequency converter-operated, the existing temperature switch

(normally-closed contact) must be connected to the

converter and evaluated.

• Check that the mains voltage matches the ratings on

the nameplate.

• The safety earth terminal can be found in the terminal box.

Note!

For operation of the drive motor with a frequency

converter, the following points should also be

noted:

• The frequency converter supply voltage must

only be a maximum of 400 V without the motor

fi lter. Appropriate measures, such as a motor

fi lter to protect the motor, must be installed on

the motor terminals with longer cables, higher

frequency converter supply voltages and/or if

9016329 01.20/09

Operating and assembly instructions 1SD, 2SDwww.elektror.com

the pulse voltages are exceeded (max. 1000 Vpk

for drive motors up to 0.75 kW, maximum 1300

Vpk for drive motors larger than 0.75 kW). Please

contact the converter supplier in this case. If a

motor fi lter is included in the delivery, this must

be installed between the converter and the motor.

Please ensure that there is suffi cient space in the

switch cabinet and take into account the installation and assembly requirements in the operating

instructions of the frequency converter/motor

fi lter manufacturer.

• The wire running between the motor and the

frequency converter must not exceed a length of

20 m, confi gured as a suitable, shielded cable and

laid by as direct a route as possible, without any

additional plug/clamp connections.

• The braided screen in the connecting cable

must cover the full length of the cable on both

sides, i.e. be connected to the earthing system at

the frequency converter and to the motor using a

low electrical resistance. For this purpose, suitable EMC cable couplings must be used on the

motor side. They must contact the cable shield

around its full circumference and have a low

resistance.

For further information about EMC compliant installation and

assembly, refer to the Operating and Assembly Instructions

issued by the frequency converter manufacturer.

3.4.1 Confi guration for three-phase current side

channel blowers

Warning!

Danger due to loose or improperly tightened con-

nections!

Improperly tightened and loose connections

cause electric shocks, fi res, property damage and

personal injuries!

Check for loose connections and tighten in

accordance with the tightening torques in the following table.

W2 U2 V2

U1 V1 W1

W2 U2 V2

U1 V1 W1

L1 L2 L3 L1 L2 L3

(L3) (L1) (L3) (L1)

-circuit Y circuit

(low voltage) (high voltage)

Threaded bolt Tightening torque

M4 1,2 Nm

M5 2,0 Nm

M6 3,0 Nm

M8 6,0 Nm

Checking the direction of rotation

Switch on the side channel blower. The running direction of

the impeller should correspond to the direction arrow on the

side channel blower cowling. The direction of the air fl ow

must also match the directional arrows on the silencer housing. If the impeller rotates in the wrong direction, then interchange L1 and L3.

Star-delta start-up

Motors with an output above 3.0 kW are provided at the supply mains for star-delta start-up. For direct on-line starting

(high short circuit current at the instant the motor is energised), please contact your local utility for details of conditions.

3.4.2 Confi guration for single-phase a.c.

side channel blowers

Z2 U2

U1 Z1

Z2 U2

U1 Z1

L1 N L1 N

Clockwise rotation Anti-clockwise rotation

3.4.3 Additional clamps

Terminal diagrams for temperature switch (normally-closed

contact) can be found in the motor terminal box.

3.5 Declaration concerning the EMC Directive

(2014/30/EU)

Our side channel blowers are components that are designed

to be installed in other machines or systems by qualifi ed per-

sonnel, i.e. not intended for consumers. The manufacturer

of the fi nal system/machine must guarantee/confi rm that the

fi nal system/machine complies with the EMC Directive.

Side channel blowers with mains operation:

With mains operation to a sinusoidal AC voltage, the asynchronous motors with a squirrel-cage rotor that are built into

the devices meet the requirements of the EC “Electromagnetic Compatibility” Directive 2014/30/EU, taking into account the standards EN 61000-6-4 (Emitted interference in

industrial environments) and EN 61000-6-3 (Emitted interference in residential environments).

Side channel blowers with frequency converter operation (FU):

Prior to the start-up and during operation of the device on a

frequency converter (provided that this is suitable) it is essential that the EMC instructions from the frequency converter manufacturer and the information in the Elektror operating

and assembly instructions are observed in order to meet the

requirements of the EC “Electromagnetic Compatibility” Directive 2014/30/EU.

If the device is delivered together with a frequency converter

package for switch cabinet or wall mounting closer to the motor, it is possible to comply with EN 61800-3 category C2 (Industrial environments), taking into consideration the abovementioned EMC instructions.

Warning!

This product may cause high-frequency interference in a residential environment that may

require screening measures.

Side channel blowers with an in-built frequency converter (FUK):

Devices with an in-built frequency converter meet the requirements of the EC “Electromagnetic Compatibility” Directive 2014/30/EU under consideration of EN 61800-3 Category C2 (industrial environment), taking into account the EMC

instructions from the frequency converter and the information

in the Elektror operating and assembly instructions.

EN

13

9016329 01.20/09

Operating and assembly instructions 1SD, 2SD www.elektror.com

EN

14

Warning!

This product may cause high-frequency interference in a residential environment that may

require screening measures.

A CE conformity assessment with the relevant standards and

guidelines must be carried out in all cases before the startup.

4 INSTRUCTIONS FOR OPERATION

AND USE

4.1 Basic information

Please observe the notes on designated use in section 1.1,

as well as the safety guidelines in sections 1.2 to 1.11.

If electrical current drops below the rated current of the drive

motor during operation, check to see if the mains voltage and

frequency match the appliance ratings.

After protective shutdowns, e.g. tripping of the motor circuitbreaker, activation of the temperature switch (normally-closed

contact), or after a protective shutdown of the frequency converter during FU applications, the appliance must not be restarted until the problem has been identifi ed and eliminated.

If the side channel blower cannot be operated over the whole

range of the characteristic curve, the motor may overload

if the system resistance is too low (excessive current consumption). If the possibility of overload due to system resistance cannot be excluded, a relief valve must be provided on

the discharge or intake side

Note!

It is not permitted to operate the 2SD range

with a relief valve as permanent overload protection.

The side channel blower must not be subjected to vibration

or impact loads.

4.2 Frequency converter operation

A frequency converter is used, allowing a wide range of

speed adjustments. There is only a small, load-related diff er-

ence in rpm between idle state and the max. load of the side

channel blowers.

To ensure trouble-free operation of the side channel

blowers, it is important that the converter meet the

following requirements:

• Converter output equal to or greater than motor power

output *)

• Converter current equal to or greater than motor current *)

• Converter output voltage equal to rated motor voltage

• Supply voltage max. 480V, including 5% voltage tolerance

• The pulse frequency of the converter should be 8 kHz,

since a lower pulse frequency can cause very noisy motor

operation.

• The values for the maximum/minimum frequency can be

found at 1.10.

• The converter should have a connection for a temperature

switch (normally-closed contact)

*) Refer to the rating plate for data

The motor can be operated in a delta or star-point confi gu-

ration, depending on the input voltage of the converter.

.

The following U/f assignments must be confi gured at the

converter.

B

Prohibited

range

0

f

If this is ignored, the motor current will increase disproportionately and the drive motor will fail to achieve its rated speed.

and UB = refer to rating plate

B

Warning!

To avoid personal damage, destruction of the

side channel blower or motor overload, a higher

frequency (speed) than the frequency (fB) specifi ed on the rating plate must never be set on the

converter otherwise the motor may be overloaded

or the side channel blower destroyed due to

the increased speed. The temperature sensors

are connected to the corresponding converter

inputs to protective the drive motor. Single-phase

alternating current motors are not suitable for

converter operation.

It is absolutely essential that you observe the

installation and safety instructions described in

the respective operating or application manuals

provided by the frequency converter supplier to

guarantee a safe and trouble-free operation.

It is also important to note that special ambient

conditions may lead to a high level of contamination of the cooling fi ns with the FUK devices. The

frequency converter switches off if the cool-

ing output on the cooling fi ns is not adequate.

Regular cleaning is required for devices in these

environments.

Note!

The following times apply for the respective

device motor output class (see rating plate) with

run-up/expiry as well as speed changes in order

to to avoid high component loads and faults in

the converter operation:

Device motor output

f

B

Run-up time

[s]

Expiry time

[s]

Motor output < 0.25 kW 5 10

0.25 kW < Motor output

<=3.0 kW

3.1 kW < Motor output

<= 7.5 kW

7.6 kW < Motor output

<= 11.0 kW

11.1 kW < Motor output

<= 30.0 kW

A uniform run-up and expiry must be guaranteed within the

run-up and expiry times.

No speed changes must occur during operation that exceed

the speed change during run-up and expiry.

10 20

20 40

30 60

30 100

Protection by residual-current-operated circuit breaker

(FI circuit-breaker):

IGBT frequency converters produce discharge currents of

>=3.5 mA due to their design principle. These discharge currents can lead to unwanted tripping in systems protected by

9016329 01.20/09

Operating and assembly instructions 1SD, 2SDwww.elektror.com

a 30 mA-FI circuit-breaker.

If a fault occurs, fault currents can also discharge through the

PE conductor as direct current. If protection is needed on the

supply side by means of an FI circuit-breaker, then an ACDC

sensitive (type B) FI circuit-breaker must be used. Use of an

FI circuit-breaker other than type B can cause death or serious injury if a fault occurs.

To meet the EN 61800-5-1 standard, the PE conductor must

be duplexed and routed through separate terminals or have

a cross-section of at least 10 mm² Cu.

Operation and connection to public grids:

See 3.5

5 INSTRUCTIONS FOR MAINTENANCE

Wear parts are subject to the recommended maintenance intervals and are an element of valid warranty claims (see 5.1

to 5.4). The service life of wearing parts (ball bearings and

fi lters) depends on the operating hours, the load and other

infl uences, such as temperature, etc.

Maintenance and servicing may only be performed by persons with the necessary expertise and regular training. In addition to the appliance’s operating instructions and the regulations and recommendations for the system as a whole, the

following points should be observed:

Inspection and maintenance intervals:

The operator must set the cleaning, inspection and maintenance intervals himself according to operating hours, load

and operating conditions.

Immediate inspection and maintenance

The side channel blower must be inspected immediately if

vibrations or reduced air fl ow are observed.

Note!

Repairs must be carried out by the manufacturer.

We cannot accept any liability for modifi cations

or the replacement of components carried out by

third parties.

5.1 Ball bearings

Note!

The side channel blowers from Elektror are equipped with sealed deep groove ball bearings, which

do not require relubrication.

Note!

Check the ball bearings during servicing and

prior to recommissioning.

Operation is only permitted with fl awless ball

bearings!

Note!

In the event of frequently starting up and shutting

down, premature replacement of the bearings

will be required. Determining the time for replacing the bearings is the sole responsibility of the

maintenance and servicing personnel, who must

make a safety judgement.

Devices

1SD/2SD range

9016329 01.20/09

Minimum ball bearing service

life

Horizontal

motor shaft

22.000

Hours

Vertical motor

11.000

shaft

Hours

Ball bearing change recommendation

- Prior to reaching the minimum service life

- 30 months following delivery at the latest

- Check after 6 months’ storage time; change if necessary

5.2 Micro-fi lters

The degree of clogging of the fi lter elements should be

checked at regular intervals, depending on the ambient

conditions / conditions of use. This means that the user is

responsible for ensuring that the fi lters are permeable. The

micro-fi lter must be positioned horizontally to prevent con-

tamination entering the side channel blower during maintenance work. With vertical micro-fi lter installation, the com-

plete fi lter must be removed from the unit before starting

cleaning/maintenance.

5.3 Relief valve

The relief valve is a safety valve and its operation must therefore be checked at regular intervals depending on application

conditions. The operating side must be closed during inspection. The relief valve must respond at the maximum pressure

value.

Note!

Repairs must be carried out by the manufacturer.

We cannot accept any liability for modifi cations

or the replacement of components carried out by

third parties.

5.4 Cleaning

There is a high risk of injury on the inside of the device due to

rotating parts during operation. Decommission the device in

all cases and wait until all moving parts have stopped before

opening, reaching in or inserting tools into the device.

Secure the device reliably against it being accidentally restarted during the entire period.

Also make sure that no other dangerous situation can arise

when restarting after a standstill, e.g. as a result of a power

failure or blockages.

Cleaning or maintenance must not lead to damage or modifi cations to the device and its components that would infl u-

ence safety or health protection and, for example, impair the

balanced state of the impeller.

When starting up the side channel blower, make sure that

all tools or other foreign objects have been removed from

inside the device and that all covers and protective grilles

have been attached correctly.

6 SAFETY RELATED INFORMATION

ON TAKING OUT OF OPERATION AND

REMOVAL

The disconnection of all electrical connections and any other

electrical work in connection with decommissioning must

only be carried out by a qualifi ed electrician.

The device should be dismantled only when all rotating parts

have come to a standstill and cannot be restarted.

The guidelines set out in 2.1 Transport and Handling must be

observed when dismantling and removing it.

Treat the device as industrial waste when disposing of it.

The device parts are made of recyclable material, such as

aluminium, (stainless) steel, copper and plastic.

EN

15

Operating and assembly instructions 1SD, 2SD www.elektror.com

However, there are components that need special treatment

(e.g. frequency converters). The statutory national and local

disposal and recycling regulations must be observed.

EN

7 LIABILITY AND EXCLUSION OF

LIABILITY

The owner shall bear the responsibility for the correct use of

the device.

Elektror shall not accept any liability for any use of its products and components which is contrary to their intended use.

This shall also apply in particular to use in special applications and under operating conditions that have not been specifi cally agreed with Elektror.

Elektror shall not accept any liability for any modifi cations or

alterations to the device or accessories supplied.

Likewise, Elektror shall not be liable for improper, delayed,

neglected maintenance. Neither shall it be liable for any

cleaning and repair work not carried out by qualifi ed Elektror

specialists, nor for the possible consequences.

16

9016329 01.20/09

Operating and assembly instructions 1SD, 2SDwww.elektror.com

8 DECLARATION OF INCORPORATION ACCORDING TO APPENDIX II 1 B

DECLARATION OF CONFORMITY IN ACC. WITH EVPG (ENERGY CONSUMPTION

RELEVANT PRODUCTS ACT).SECTION 4 PARAGRAPH 1

The manufacturer,

Elektror airsystems gmbh

Hellmuth-Hirth-Str. 2

D-73760 Ostfi ldern

hereby declares that the product to which this declaration refers meets the basic requirements of the Machinery Directive

(2006/42/EC) as set forth below.

Description of incomplete machine:

Single stage side channel blower: 1SD 210, 1SE 210, 1SD 310, 1SD 410, 1SE 410, 1SD 510, 1SD 510 FU/FUK,

1SD 710, 1SD 810, 1SD 910

Double stage side channel blower: 2SD 220, 2SD 320, 2SD 420, 2SD 520, 2SD 720, 2SD 820, 2SD 920

Double fl ow side channel blower: 2SD 740, 2SD 840

Serial number and year of manufacture can be found on the nameplate and on the accompanying delivery slip.

Description of the essential requirements of Machinery Directive (2006/42/EC), with which the partially completed machine

complies:

Machinery Directive (2006/42/EC): Annex I, Articles 1.1.2, 1.1.3, 1.1.5, 1.3.2, 1.3.3, 1.3.4, 1.3.7, 1.5.1, 1.6.1, 1.7.1, 1.7.3

Electromagnetic Compatibility Directive (2014/30/EU)

Eco-design Directive for Energy-related Products (2009/125/EC)

EN

The partially completed machine described here continues to fulfi l the protective regulations of the Low Voltage Directive

(2014/35/EC) according to Annex I, No. 1.5.1 of the Machinery Directive.

The commissioning of the partially completed machine is not permitted until it has been verifi ed that the machine in which the

partially completed machine is to be installed, complies with the provisions of the Machinery Directive (2006/42/EC).

The following harmonised standards were applied:

DIN EN ISO 12100 2011 Safety of machinery, general principles for design,

risk assessment and risk minimisation

DIN EN 60034-1 2011 Rotating electrical machines, Part 1: Rating and performance

DIN EN 60034-5 2007 Rotating electrical machines, Part 5: Degrees of protection provided

by the integral design of rotating electrical machines (IP code) – Classifi cation

DIN EN 60034-30-1 2014

cage-induction motors (IE code)

DIN EN 60204-1 2019 Safety of machinery – Electrical equipment of machines,

Part 1: General requirements

DIN EN 60664-1 2008 Insulation coordination for equipment within low-voltage systems,

Part 1: Principles, requirements and tests

The manufacturer, Elektror airsystems gmbh, undertakes to make the special documentation on this incomplete machine available,

electronically or in hardcopy, to national authorities on demand.

The special technical documentation belonging to this incomplete machine was prepared in accordance with Annex VII Part B.

Mr Kevin Kargar, tel. +49 711 31973-1179, is responsible for the documentation.

Kreher (Managing Director)

Ostfi ldern, 10.01.2020

Rotating electrical machines - Part 30: Effi ciency classes of single-speed, three-phase,

17

9016329 01.20/09

Betriebs- und Montageanleitung 1SD/2SD www.elektror.de

DE

18

9 TEHNIČNI PODATKI / TECHNICAL SPECIFICATIONS

Enostopenjsko puhalo s stranskim kanalom | Single stage side channel blowers

Model

Type

1SD 210

1SE 210

1SD 310

1SD 310

1SD 410

1SD 410

1SD 410

1SD 410

1SE 410

1SD 510

1SD 510

1SD 510

1SD 510

FU/FUK

1SD 510

1SD 510

1SD 510

1SD 710

1SD 710

1SD 710

1SD 710

1SD 710

Mejne vrednosti

Razred

učinkovi-

tosti

Effi ciency

class

-

-

dušilne krivulje

Nadtlak

Frekvenca

V. max.

performance when

used as blower

Frequency

V. max.

[Hz] [m³/min] [mbar] [m³/min] [mbar] [kW] [V] [A] [db (A)] [kg]

Maximum

max. V. max.

pt

max. V. max.

pt

50 1,33 130 1,33 120 0,37 207-253 / 360-440 1,8 / 1,04 53 10

60 1,63 160 1,63 150 0,63 220-250 / 415-480 2,4 / 1,4 56 10

- - 50 1,33 130 1,33 120 0,37 230 2,7 53 10

- - 60 1,63 160 1,63 150 0,43 230 3,2 56 10

-

-

-

-

-

-

-

-

50 1,92 150 1,92 150 0,75 207-253 / 360-440 2,95 / 1,7 55 13

60 2,33 140 2,33 150 1,30 220-250 / 415-480 4,8 / 2,8 57 13

50 1,92 170 1,92 150 1,10 207-253 / 360-440 4,35 / 2,5 55 13

60 2,33 180 2,33 150 1,50 220-250 / 415-480 5,0 / 2,9 57 13

50 2,42 160 2,42 160 0,75 207-253 / 360-440 2,95 / 1,7 63 16

60 2,92 160 2,92 160 1,30 220-250 / 415-480 4,8 / 2,8 64 16

50 2,42 200 2,42 170 1,10 207-253 / 360-440 4,35 / 2,5 63 16

60 2,92 220 2,92 210 1,50 220-250 / 415-480 5,0 / 2,9 64 16

IE3 - 50 2,42 150 2,42 160 0,75 230/400 2,94/1,71 63 19

IE3 - 60 2,92 140 2,92 140 0,86 480 1,67 64 19

IE3 - 50 2,42 210 2,42 180 1,10 230/400 4,0/2,31 63 21

IE3 - 60 2,92 220 2,92 210 1,30 480 2,34 64 21

- - 50 2,42 190 2,42 150 1,10 230 7,3 63 16

- - 60 2,92 190 2,92 180 1,30 230 8,3 64 16

-

-

-

-

-

-

50 3,50 170 3,50 170 1,10 207-253 / 360-440 4,35 / 2,5 64 22

60 4,25 140 4,25 150 1,50 220-250 / 415-480 5,0 / 2,9 70 22

50 3,50 190 3,50 200 1,60 207-253 / 360-440 7,5 / 4,3 64 23

60 4,25 210 4,25 220 2,20 220-250 / 415-480 8,0 / 4,6 70 23

50 3,50 270 3,50 220 2,20 207-253 / 360-440 8,1 / 4,6 60 25

60 4,25 290 4,25 260 3,80 220-250 / 415-480 13,0 / 0,75 70 25

- - 80 5,4 300 5,2 300 3,80 400 7,5 73 28

-

IE3 -

IE3 -

IE3 -

IE3 -

IE3 -

IE3 -

-

-

-

-

-

-

50 3,50 150 3,50 150 1,10 230/400 4,0/2,31 64 29

60 4,25 130 4,25 140 1,30 480 2,34 70 29

50 3,50 220 3,50 230 1,50 230/400 5,2/3,0 64 32

60 4,25 200 4,25 210 1,75 480 2,90 70 32

50 3,50 310 3,50 250 2,20 230/400 7,53/4,35 64 40

60 4,25 320 4,25 280 2,55 480 4,17 70 40

50 5,30 200 5,30 210 2,20 207-253 / 360-440 8,1 / 4,6 69 30

60 6,27 200 6,27 210 3,80 220-250 / 415-480 13,0 / 7,5 72 30

50 5,30 290 5,30 270 3,00 207-253 / 360-440 15,2 / 7,2 69 36

60 6,27 230 6,27 250 4,60 220-250 / 415-480 14,7 / 8,5 72 36

50 5,30 330 5,30 290 4,00 360 - 440 9,0 69 42

60 6,27 330 6,27 330 6,00 415 - 480 10,9 72 42

IE3 - 50 5,30 190 5,30 200 2,20 230/400 7,53/4,35 69 49

IE3 - 60 6,27 180 6,27 190 2,55 480 4,17 72 49

IE3 - 50 5,30 280 5,30 280 3,00 230/400 9,90/5,70 69 54

IE3 - 60 6,27 270 6,27 280 3,46 480 5,40 72 54

Mejne vrednosti

dušilne krivulje

Podtlak

pt

max.

Maximum

performance when

used as extractor

pt

max.

A variable speed drive must be installed with this blower.

Nazivne vrednosti motorja

Moč

motorja

Rated

output

Napetost Vhodna moč

Motor ratings

Voltage

Current

consumption

Maks.

raven

zvočnega

tlaka L

Sound

pressure

level L

A

A

Teža

(pribl.)

Weight

(approx.)

9016329 01.20/09

www.elektror.de Betriebs- und Montageanleitung 1SD/2SD

9 TEHNIČNI PODATKI / TECHNICAL SPECIFICATIONS

Model

Type

1SD 710

1SD 810

1SD 810

1SD 810

1SD 810

1SD 810

1SD 810

1SD 910

1SD 910

1SD 910

1SD 910

1SD 910

1SD 910

Mejne vrednosti

Razred

učinkovi-

tosti

Effi ciency

class

dušilne krivulje

Nadtlak

Frekvenca

V. max.

performance when

used as blower

Frequency

V. max.

[Hz] [m³/min] [mbar] [m³/min] [mbar] [kW] [V] [A] [db (A)] [kg]

Maximum

max. V. max.

pt

max. V. max.

pt

IE3 - 50 5,30 350 5,30 290 4,00 400/690 7,45/4,30 69 63

IE3 - 60 6,27 360 6,27 330 4,60 480 7,40 72 63

-

-

-

-

-

-

50 8,83 200 8,83 200 4,00 360 - 440 9,0 70 54

60 10,33 160 10,33 160 6,00 415 - 480 10,9 74 54

50 8,83 300 8,83 300 5,50 360 - 440 13,3 70 63

60 10,33 280 10,33 300 8,60 415 - 480 15,3 74 63

50 8,83 430 8,83 320 7,50 360 - 440 16,7 70 66

60 10,33 400 10,33 350 9,80 415 - 480 18,2 74 66

IE3 - 50 8,83 180 8,83 200 4,00 400/690 7,45/4,30 70 62

IE3 - 60 10,33 150 10,33 160 4,60 480 7,40 74 62

IE3 - 50 8,83 300 8,83 300 5,50 400/690 10,1/5,83 70 73

IE3 - 60 10,33 250 10,33 270 6,30 480 9,60 74 73

IE3 - 50 8,83 420 8,83 340 7,50 400/690 13,5/7,8 70 77

IE3 - 60 10,33 400 10,33 350 8,60 480 12,90 74 77

-

-

-

-

-

-

50 17,5 190 17,5 210 8,50 360 - 440 18,2 74 93

60 20,8 140 20,8 180 9,80 415 - 480 18,2 84 93

50 17,5 280 17,5 280 12,5 360 - 440 28,0 75 116

60 20,8 260 20,8 270 14,5 415 - 480 26,0 84 116

50 17,5 460 17,5 360 18,5 360 - 440 37,0 75 126

60 20,8 420 20,8 380 21,3 415 - 480 26,5 84 126

IE3 - 50 17,50 190 17,50 200 7,50 400/690 13,5/7,8 74 118

IE3 - 60 20,80 160 20,80 170 8,60 480 12,90 84 118

IE3 - 50 17,50 280 17,50 290 11,00 400/690 19,6/11,3 75 140

IE3 - 60 20,80 260 20,80 270 12,60 480 18,70 84 140

IE3 - 50 17,50 500 17,50 350 18,50 400/690 32,5/18,8 75 162

IE3 - 60 20,80 460 20,80 380 21,30 480 32,40 84 162

Mejne vrednosti

dušilne krivulje

Podtlak

pt

max.

Maximum

performance when

used as extractor

pt

max.

Nazivne vrednosti motorja

Moč

motorja

Rated

output

Napetost Vhodna moč

Motor ratings

Voltage

Current

consumption

Maks.

raven

zvočnega

tlaka L

Sound

pressure

level L

A

A

Teža

(pribl.)

Weight

(approx.)

DE

19

Dvostopenjsko puhalo s stranskim kanalom | Double stage side channel blowers

2SD 220

2SD 320

2SD 420

2SD 420

2SD 420

2SD 420

2SD 520

9016329 01.20/09

-

-

-

-

-

-

-

IE3 - 50 2,50 310 2,50 320 1,50 230/400 5,2/3,0 66 32

IE3 - 60 3,00 280 3,00 300 1,75 480 2,90 69 32

IE3 - 50 2,50 420 2,50 320 2,20 230/400 7,53/4,35 66 35

IE3 - 60 3,00 470 3,00 400 2,55 480 4,17 69 35

-

-

50 1,47 240 1,47 210 0,55 207-253 / 360-440 2,70 / 1,57 55 14

60 1,72 250 1,72 250 0,94 220-250 / 415-480 4,0 / 2,3 61 14

50 2,00 290 2,00 280 1,10 207-253 / 360-440 4,35 / 2,5 58 18

60 2,42 400 2,42 300 1,50 220-250 / 415-480 5,0 / 2,9 60 18

50 2,50 280 2,50 280 1,60 207-253 / 360-440 7,5 / 4,3 66 25

60 3,00 310 3,00 320 2,20 220-250 / 415-480 8,0 / 4,6 69 25

50 2,50 440 2,50 330 2,20 207-253 / 360-440 9,7 / 5,6 66 27

60 3,00 420 3,00 350 3,80 220-250 / 415-480 13,0 / 7,5 69 27

50 3,83 410 3,83 340 3,00 207-253 / 360-440 12,5 / 7,2 72 39

60 4,58 360 4,58 380 4,60 220-250 / 415-480 14,7 / 8,5 74 39

Betriebs- und Montageanleitung 1SD/2SD www.elektror.de

DE

20

9 TEHNIČNI PODATKI / TECHNICAL SPECIFICATIONS

Model

Type

2SD 520

2SD 520

2SD 720

2SD 720

2SD 720

2SD 720

2SD 720

2SD 720

2SD 720

2SD 820

2SD 820

2SD 820

2SD 820

2SD 820

2SD 820

2SD 920

2SD 920

2SD 920

2SD 920

2SD 920

2SD 920

2SD 920

Mejne vrednosti

Razred

učinkovi-

tosti

Effi ciency

class

-

-

dušilne krivulje

Nadtlak

Frekvenca

V. max.

performance when

used as blower

Frequency

V. max.

[Hz] [m³/min] [mbar] [m³/min] [mbar] [kW] [V] [A] [db (A)] [kg]

Maximum

max. V. max.

pt

max. V. max.

pt

50 3,83 440 3,83 390 4,00 360 - 440 10,0 72 44

60 4,58 480 4,58 410 6,00 415 - 480 10,9 74 44

IE3 - 50 3,83 450 3,83 380 3,00 230/400 9,9/5,7 72 53

IE3 - 60 4,58 410 4,58 410 3,46 480 5,40 74 53

-

-

-

-

-

-

-

-

50 5,33 260 5,33 280 3,00 230 / 400 12,5 / 7,2 73 48

60 6,42 200 6,42 230 4,60 277 / 480 14,7 / 8,5 76 48

50 5,33 380 5,33 360 4,00 360 - 440 9,0 73 54

60 6,42 320 6,42 350 6,00 415 - 480 10,9 76 54

50 5,33 500 5,33 440 5,50 360 - 440 13,3 73 66

60 6,42 500 6,42 440 8,60 415 - 480 15,3 76 66

50 5,33 610 5,33 440 7,50 360 - 440 16,7 73 77

60 6,42 660 6,42 460 9,80 415 - 480 18,2 76 77

IE3 - 50 5,33 370 5,33 400 4,00 400/690 7,45/4,30 73 67

IE3 - 60 6,42 320 6,42 350 4,60 480 7,40 76 67

IE3 - 50 5,33 530 5,33 420 5,50 400/690 11,8/6,8 73 82

IE3 - 60 6,42 490 6,42 440 6,30 480 9,60 76 82

IE3 - 50 5,33 610 5,33 420 7,50 400/690 13,5/7,8 73 88

IE3 - 60 6,42 670 6,42 440 8,60 480 12,90 76 88

-

-

-

-

-

-

50 8,67 400 8,67 400 8,5 360 - 440 18,2 74 86

60 10,33 330 10,33 360 9,8 415 - 480 18,2 78 86

50 8,67 600 8,67 430 11,0 360 - 440 19,9 74 104

60 10,33 600 10,33 460 17,3 415 - 480 33,5 78 104

50 8,67 670 8,67 460 15,0 360 - 440 30,5 74 120

60 10,33 750 10,33 490 21,3 415 - 480 36,5 78 120

IE3 - 50 8,67 360 8,67 380 7,50 400/690 13,3/7,68 74 103

IE3 - 60 10,33 320 10,33 330 8,60 480 13,30 78 103

IE3 - 50 8,67 570 8,67 460 11,00 400/690 19,6/11,3 74 135

IE3 - 60 10,33 540 10,33 460 12,60 480 18,70 78 135