Page 1

ElektroPhysik

Technical Manual and Operating

Instructions

Ultrasonic Coating

Thickness Measuring System QuintSonic 7

Page 2

ElektroPhysik

Dr. Steingroever GmbH & Co. KG

Pasteurstr. 15

50735 Köln

Deutschland

Tel.: +49 221 752040

Fax.: +49 221 7520467

Internet: http://www.elektrophysik.com/

Mail: info@elektrophysik.com

© ElektroPhysik

Version 0.92 13.08.2013 /Rh/bo-r

Subject to change without notice

© ElektroPhysik QuintSonic 7 2 von 184

Page 3

Table of Contents

Table of Contents

1 Introduction .......................................................................................................................... 8

1.1 General Remarks ............................................................................................................ 8

1.2 Field of Applications ........................................................................................................ 8

1.3 Measuring Procedure ...................................................................................................... 8

1.4 The QuintSonic 7 Measuring System ............................................................................... 9

2 First Steps .......................................................................................................................... 11

2.1 Insert batteries and connect sensor ............................................................................... 11

2.2 Switching-on and taking readings .................................................................................. 12

2.2.1 Setting language .................................................................................................... 13

2.2.2 Taking readings ..................................................................................................... 14

3 Description of the System ................................................................................................. 16

3.1 Display unit .................................................................................................................... 16

3.1.1 General properties ................................................................................................. 16

3.1.2 Operating keys ....................................................................................................... 16

3.1.3 Sockets and Interfaces .......................................................................................... 17

3.1.4 Power Supply......................................................................................................... 18

3.2 Sensor ........................................................................................................................... 19

3.2.1 SIDSP®-Technology ............................................................................................... 19

3.2.2 Measuring ranges .................................................................................................. 21

4 User Interface ..................................................................................................................... 22

4.1 Important Menu Screens ............................................................................................... 22

4.1.1 Start screen ........................................................................................................... 22

4.1.2 Measure mode – numerical and graphical screen .................................................. 23

4.1.3 Measure mode – Large numerical screen .............................................................. 24

4.1.4 Measure Mode – A-screen Image with Echo Signal ............................................... 25

4.1.5 Statistics screen ..................................................................................................... 26

4.1.6 Main menu ............................................................................................................. 27

4.2 How to navigate in the main menu ................................................................................. 28

4.3 Parameter setting .......................................................................................................... 29

4.3.1 Setting a switch parameter (Example: Backlight) ................................................... 29

4.3.2 Setting selection parameters (Example: language) ................................................ 30

4.3.3 Setting a numerical parameter (Example: pos. clip-limit) ........................................ 30

4.3.4 Alphanumercial parameter entries (Example: directory name) ............................... 31

5 Calibration .......................................................................................................................... 33

5.1 Particularities of ultrasonic coating thickness measurement systems ............................ 33

5.2 How to calibrate for the sound velocity .......................................................................... 33

6 Measure Mode .................................................................................................................... 36

© ElektroPhysik QuintSonic 7 3 von 184

Page 4

Table of Contents

6.1 Important remarks on ultrasonic measurement .............................................................. 36

6.2 Limits to the measurement technique ............................................................................ 37

6.3 Settings to make prior to measurement ................................................................ ......... 39

6.3.1 Using the Direct Mode ........................................................................................... 39

6.3.2 How to create or select a batch .............................................................................. 40

6.3.3 Selecting a measuring range ................................................................................. 40

6.4 How to prepare Measurement ....................................................................................... 41

6.4.1 Taking a reference signal ................................................................ ....................... 41

6.4.2 Selecting a couplant............................................................................................... 42

6.4.3 Checking / carrying out calibration ......................................................................... 43

6.5 Taking Readings............................................................................................................ 44

6.5.1 How to use the sensor ........................................................................................... 44

6.5.2 Measuring procedure ............................................................................................. 45

7 Signification and Use of A-scan Images ................................ .......................................... 47

7.1 Introduction .................................................................................................................... 47

7.2 Description of A-scan Image Types ............................................................................... 48

7.2.1 Reference signal .................................................................................................... 48

7.2.2 Raw measuring signal ............................................................................................ 49

7.2.3 Echo signal with echo lines .................................................................................... 50

7.3 Application ..................................................................................................................... 52

7.3.1 Reference signal .................................................................................................... 52

7.3.2 Raw measuring signal ............................................................................................ 52

7.3.3 Echo signal with echo lines ................................................................................... 52

7.4 How to use the A-scan screen ....................................................................................... 59

7.4.1 Zoom-in and zoom-out in amplitude direction......................................................... 61

7.4.2 Zoom- in and zoom-out in time direction ............................................................... 61

7.4.3 Graphics cursor and displacement in time direction ............................................... 62

7.4.4 Zoom and position indicator ................................................................................... 63

7.4.5 A-scan image menu ............................................................................................... 63

7.4.6 Measure mode with A-scan image being shown .................................................... 65

7.4.7 Icons to identify invalid echoes .............................................................................. 65

7.4.8 Quit the A-scan image ........................................................................................... 66

8 Echo Signal Processing .................................................................................................... 67

8.1 Introduction .................................................................................................................... 67

8.2 Levels of Processing ..................................................................................................... 68

8.3 Preprocessing ............................................................................................................... 68

8.3.1 General remarks .................................................................................................... 68

8.3.2 Time-clipping ......................................................................................................... 69

© ElektroPhysik QuintSonic 7 4 von 184

Page 5

Table of Contents

8.3.3 Amplitude-clipping ................................................................................................. 69

8.4 Least-Squares Optimisation .......................................................................................... 73

8.5 Postprocessing .............................................................................................................. 74

8.5.1 General remarks .................................................................................................... 74

8.5.2 Multiple-echo suppression ..................................................................................... 74

8.5.3 Manual echo selection ........................................................................................... 75

8.5.4 Blocked domains ................................................................................................... 76

8.5.5 Expectancy domains .............................................................................................. 77

8.5.6 Number criteria ...................................................................................................... 78

9 Tips and tricks ................................................................................................................... 81

9.1 Cross-section ................................................................................................................ 81

9.2 Measuring range............................................................................................................ 81

9.3 How to proceed for a new setting of task ....................................................................... 81

9.4 Amplitude clipping with optimisation enabled ................................................................ . 82

9.5 High level of unwanted echoes in the layers .................................................................. 82

9.6 Inhomogeneous bases .................................................................................................. 83

9.7 Multiple reflections ......................................................................................................... 83

9.8 Measuring object of unidentified nature ......................................................................... 83

9.9 Interaction of preprocessor, optimisation and postprocessor parameters ...................... 84

10 Application examples ........................................................................................................ 86

10.1 Three-layer paint on plastic ........................................................................................... 86

10.2 One-layer paint on wood ................................................................................................ 86

10.3 Two-layer paint on steel ................................................................................................. 87

10.4 Thin one-layer paint on body sheet ................................................................................ 88

10.5 Wall thickness measurement ......................................................................................... 89

10.6 Multi-layer plastics foil ................................................................................................... 89

11 Data Management .............................................................................................................. 91

11.1 Introduction .................................................................................................................... 91

11.1.1 Batches .................................................................................................................. 91

11.1.2 Memory capacity / using the data memory ............................................................. 91

11.1.3 Parameter sets ...................................................................................................... 91

11.2 Data base ................................ ................................................................ ...................... 92

11.2.1 General remarks / How to call the data base.......................................................... 92

11.2.2 Directories ............................................................................................................. 92

11.2.3 Batches .................................................................................................................. 97

11.2.4 Parameter sets .................................................................................................... 104

12 Setting Parameter Sets .................................................................................................... 106

12.1 Edit a parameter set (alphanumerically) ...................................................................... 106

© ElektroPhysik QuintSonic 7 5 von 184

Page 6

Table of Contents

12.1.1 General ................................................................................................................ 108

12.1.2 Preprocessor ....................................................................................................... 108

12.1.3 Optimisation ......................................................................................................... 110

12.1.4 Postprocessor ...................................................................................................... 111

12.1.5 Edit the User-values table .................................................................................... 118

12.2 Edit a parameter set (graphically) ................................................................................ 120

12.2.1 How to call the menu ........................................................................................... 121

12.2.2 Clipping ................................................................................................................ 121

12.2.3 Blocked domains ................................................................................................. 131

12.2.4 Expectancy domains ............................................................................................ 134

13 Statistics / Batches ................................................................................................ .......... 139

13.1 General remarks .......................................................................................................... 139

13.2 View statistics .............................................................................................................. 139

13.2.1 Statistical values .................................................................................................. 139

13.2.2 Readings ............................................................................................................. 140

13.2.3 Histogram ............................................................................................................ 141

13.2.4 Trend diagram ..................................................................................................... 142

13.2.5 Help / Extras ........................................................................................................ 143

13.3 Delete a reading from a batch ...................................................................................... 143

13.3.1 Delete single readings ......................................................................................... 143

13.3.2 Delete all readings ............................................................................................... 144

13.3.3 Delete a current value .......................................................................................... 144

14 Data Output / Data Transfer ............................................................................................ 145

14.1 Data print-out ............................................................................................................... 145

14.2 Transfer data to a PC (terminal program) .................................................................... 146

14.3 Data transfer to a PC (QSoft 7) .................................................................................... 148

15 The Menu .......................................................................................................................... 149

15.1 Main menu ................................................................................................................... 149

15.2 Submenu “Database“ .................................................................................................. 149

15.3 Submenu “Statistics” ................................................................................................... 149

15.4 Submenu “A-scan image” ............................................................................................ 149

15.5 Submenu “Active batch” .............................................................................................. 150

15.5.1 Properties ............................................................................................................ 150

15.5.2 Readings ............................................................................................................. 150

15.5.3 Configuration ................................................................ ....................................... 151

15.6 Submenu “Setup” ........................................................................................................ 152

15.6.1 General remarks .................................................................................................. 152

15.6.2 Display ................................................................................................................. 152

© ElektroPhysik QuintSonic 7 6 von 184

Page 7

Table of Contents

15.6.3 Date / time ........................................................................................................... 153

15.6.4 Data output .......................................................................................................... 153

15.6.5 User preferences ................................................................................................. 156

15.6.6 Gauge specifications ............................................................................................ 157

16 Special Functions ............................................................................................................ 158

16.1 Initialisation .................................................................................................................. 158

16.2 Special functions menu................................................................................................ 159

16.3 Sensor service menu ................................................................................................... 160

16.3.1 Call the service menu .......................................................................................... 160

16.3.2 A-scan images for servicing purpose ................................................................... 160

16.3.3 Readjust the magnetic switch .............................................................................. 161

16.3.4 Readjust the sensor tip echo suppression ............................................................ 162

16.3.5 Readjust the temperature compensation reference point ..................................... 162

17 Connectable accessories ................................................................................................ 164

17.1 General remarks .......................................................................................................... 164

17.2 Direct connection ......................................................................................................... 164

17.3 Connection via the multi-purpose connection box ........................................................ 166

18 Care and Maintenance ..................................................................................................... 167

18.1 Care ............................................................................................................................ 167

18.1.1 Using NiMH storage batteries .............................................................................. 167

18.2 Maintenance.................................................................................................................... 167

19 Technical Data ................................................................................................................. 168

19.1 Gauge specifications ................................................................................................... 168

19.2 1 Gauge specifications ................................................................................................ 168

19.3 Sensor ......................................................................................................................... 169

20 Supply Schedule, Accessories ....................................................................................... 171

20.1 Supply schedule .......................................................................................................... 171

20.2 Accessories ................................................................................................................. 172

21 Appendix .......................................................................................................................... 173

21.1 Error messages and trouble shooting .......................................................................... 173

21.2 Statistical Terms .......................................................................................................... 178

21.3 Safety Notes ................................................................................................................ 180

21.4 Declaration of Conformity ................................................................................................ 181

21.4 After-sales Service ...................................................................................................... 182

22 Change-history ................................................................................................................ 183

23 Index ................................................................................................................................. 183

© ElektroPhysik QuintSonic 7 7 von 184

Page 8

Introduction

1 Introduction

1.1 General Remarks

This instruction manual describes how to use the ultrasonic coating thickness measuring system

QuintSonic 7 and provides all necessary information on the manifold application options offered by

the system.

Section 2 provides short instructions along with an operating example. All further sections deal with

the individual subjects. For technical data and general information on care and maintenance,

supply schedule and accessories, please refer to the end of this manual.

1.2 Field of Applications

QuintSonic 7 is an ultrasonic coating thickness measuring system for measuring paint, lacquer and

plastic layers applied on metal, plastic, wood, glass or ceramic. Up to five layers can be measured

non-destructively in one operation. Thanks to the innovative technology, QuintSonic 7 is the first

gauge of its kind to determine exactly the layer thickness applied on components made of GRP or

CRP material. QuintSonic 7 offers a wide range of applications in the automotive industry,

aerospace or any other industrial branch. Additional feature: QuintSonic 7 can also be used for

measuring thin bases through the coating, especially the wall thickness of thin metal sheets

starting from 50 µm.

1.3 Measuring Procedure

The working principle of QuintSonic 7 is based on the reflection of ultrasonic waves at the

interfaces between the individual layers of a coating system. For measurement, a liquid or pasty

couplant is applied on the sample at the point of measurement. The sensor is put on the measuring

spot. The high-frequency ultrasonic sound generator of the sensor head emits an ultrasonic pulse

of a broad bandwidth to travel through sensor head, couplant and finally through the coating

system. At each interface between two layers as well as at the interface to the base, some of the

sonic energy reflects. These portions of pulse – also referred to as “echoes” – return to the

measuring head at different velocities and the receive signals are registered in the measuring

head. As the time of travel is a function on the sound velocity in the respective material, it can be

used as indicator for the coating thickness. Thickness is calculated according to the time of travel

and sound velocity, transferred to the gauge and shown on display.

Unlike in wall thickness measurement, the layers to be measured with ultrasonic coating thickness

gauges are extremely thin and thus travel times very short, i.e. in the nanoseconds range (a

© ElektroPhysik QuintSonic 7 8 von 184

Page 9

Introduction

billionth of a second). As a consequence, the sound echoes may overlap in the receive signal.

Before the signal evaluation can take place, it is necessary to separate the individual echoes with

respect to their travel times. This is done in a complex mathematical process. Thanks to the high

computing power of the sensor, the complete measuring result is made available not later than

after one second approximately.

Some measuring samples such as GRP or CRP materials exhibit material discontinuities

(inhomogeneities) or inclusions in the base that may cause false echoes. QuintSonic 7 offers a

wide range of methods for the suppression of unwanted echoes so that only the “true” echoes, i.e.

the sound waves reflected from the layer interfaces, will be used for evaluation.

1.4 The QuintSonic 7 Measuring System

The portable system consists of two elements:

The intelligent ultrasonic SIDSP®-technology based sensor (see section 3.2.1)

The operating and display unit

Both elements are cable connected.

Designed for user-friendly operation, QuintSonic 7 features an intuitive menu control with context-

sensitive online help. Large backlit control keys allow extra comfort. Excellent viewing conditions

provided by the large backlit graphics display allow convenient usage at night and in conditions of

poor visibility.

Special feature of QuintSonic 7: A-scan images (see section 7) are shown directly on the gauge

display for immediate quality assessment of the readings obtained without the need to connect a

computer. On the other hand, additional PC software is available (see below) to provide largesized coloured A-scan images on your computer. This makes QuintSonic 7 the ideal tool for both,

portable use on site or use in the laboratory.

The advanced PC-like data management offers quick creation of folders and easy set-up of

customized batches. QuintSonic 7 simplifies the calibration and parameter set-up allowing to solve

also difficult settings of task in a minimum of time without the need for special skills.

The „QSoft7 Basic“ PC software (supplied with the gauge) enables easy parameter setting via the

usual input devices (keyboard, mouse) of your computer. In addition, large, colour A-scan images

can be displayed on your computer screen.

As an option, the PC software “QSoft 7 Professional” is available, for convenient set up and

evaluation of measuring groups and export in various data formats. The software exports data as

text documents, Excel® spread sheets or in the PDF file format and allows entries of notes and

annotations. Also pictures of your measuring samples may be added to the data reports.

Featuring numerous interfaces, QuintSonic 7 connects to peripheral devices such as the portable

printer MiniPrint 7000 (available as an option). The standard supply schedule of the QuintSonic 7

includes an infrared interface (IrDA® 1.0) as well as a USB adapter cable. Via this cable, a USB

© ElektroPhysik QuintSonic 7 9 von 184

Page 10

Introduction

interface is available. As an option, a multi-purpose adapter unit can be supplied to provide an

extra USB interface for connecting a mains unit, headphones, a footswitch and or an alarm device.

If only single functions are requested, an RS232 adapter cable as well as an IR/ USB converter

unit (for connecting a PC) can be supplied.

© ElektroPhysik QuintSonic 7 10 von 184

Page 11

First Steps

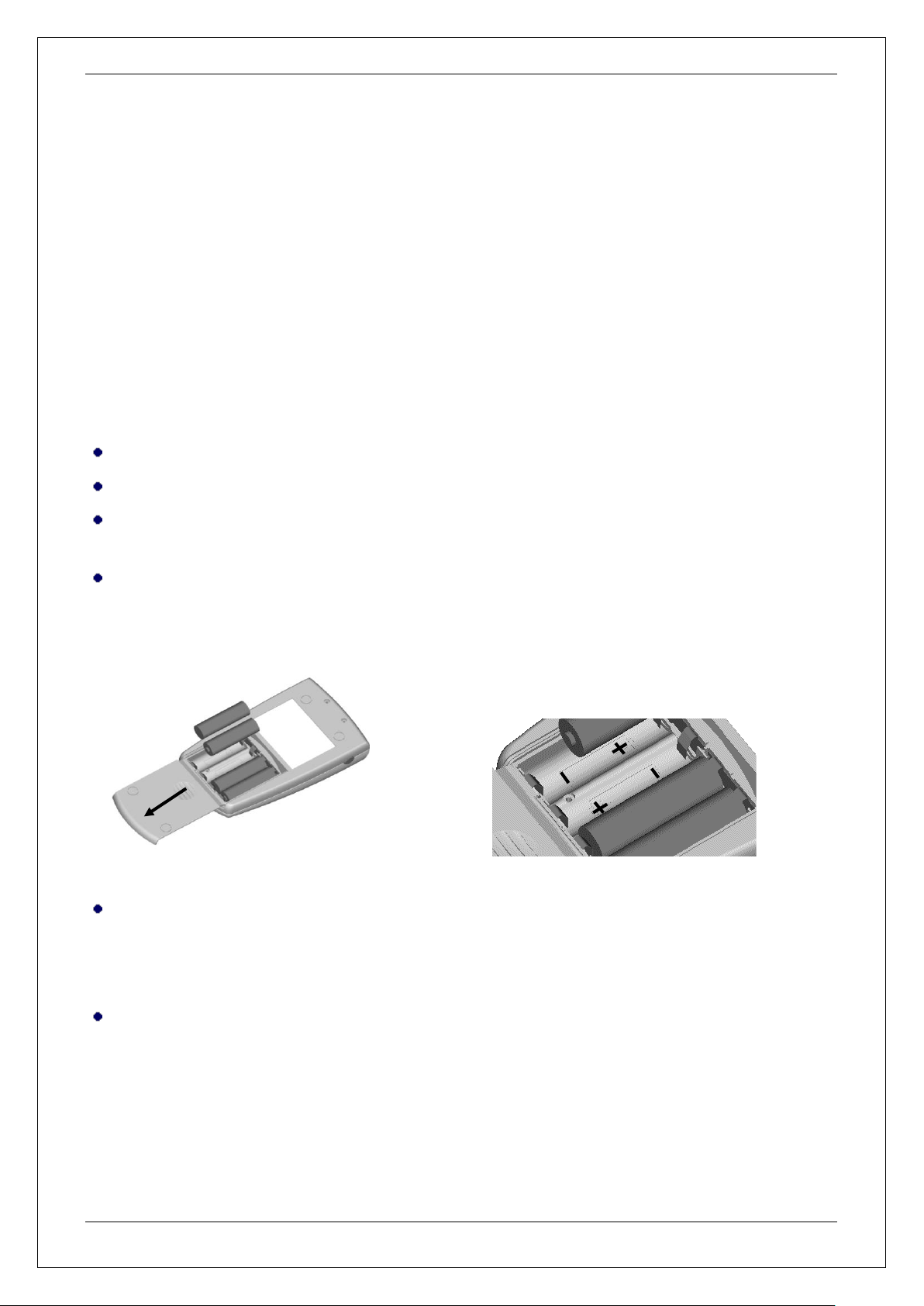

Open the battery compartment

Insert batteries

2 First Steps

This section is addressed to persons to use the gauge for the first time. It explains the main

features of the gauge and how to take readings. For a better overview and simplification, this

section will not discuss all details. For a detailed description of all subjects please refer to the

relevant sections later in this manual.

2.1 Insert batteries and connect sensor

Take gauge and batteries from the carrying case.

Push the battery compartment lid in direction of the arrow (as shown below).

Insert the batteries supplied with the gauge into the battery compartment. Respect polarities

(as shown below).

Push the battery lid over the housing and close housing.

Take the sensor form the carrying case and connect it to the sensor socket on top of the base

unit (see fig. below). Make sure the nib of plug is correctly inserted into the guide way of

socket. The red marking at the connector must be positioned correctly to the red marking of the

socket.

Fully engage the sensor plug into the sensor socket all the way to the stop.

© ElektroPhysik QuintSonic 7 11 von 184

Page 12

First Steps

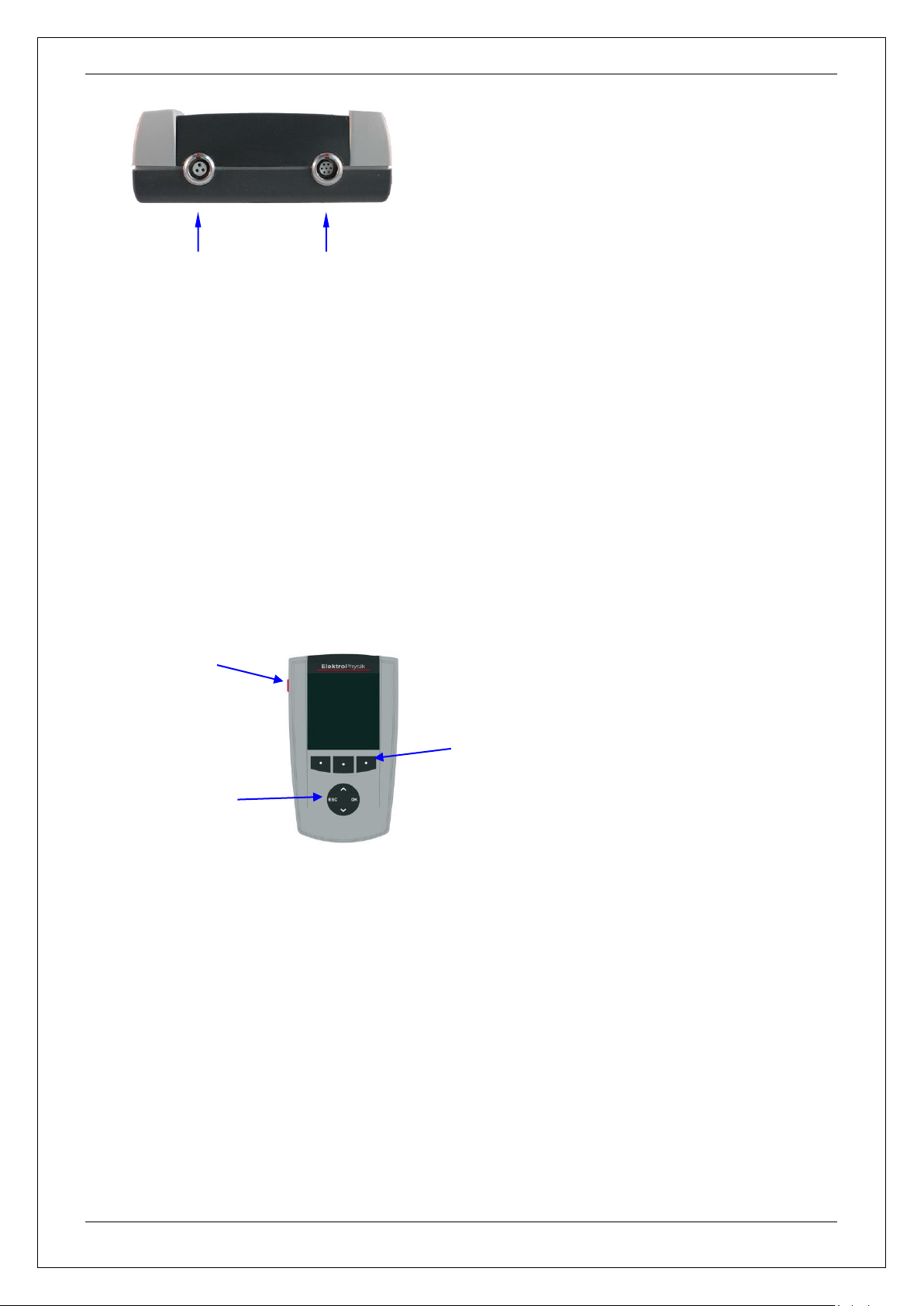

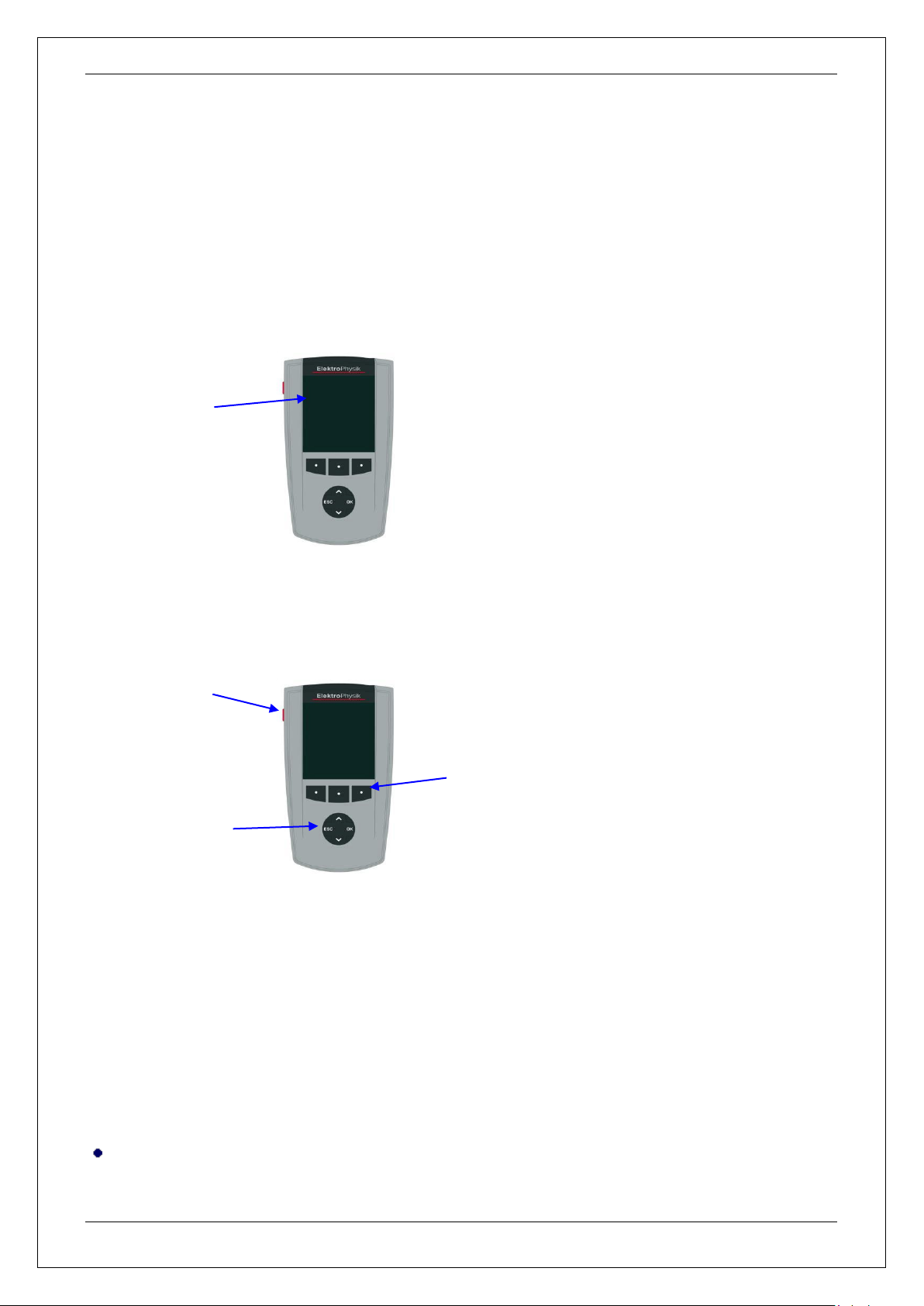

sensor

socket

multi-purpose

socket

Function keys

ON/OFF-button

Command and

navigation block

2.2 Switching-on and taking readings

The gauge is equipped with a round-shaped navigation key block with the following functions:

“ESC“, ““ and ““ (arrow up/down).

Three functions keys are located below the display. Their current function is shown above the

respective key at the bottom of display.

The “ON/OFF“ -button is located on the left side of gauge.

Prior to the initial operation of the gauge, please proceed according the instructions below. The

menu will guide you through the procedure.

© ElektroPhysik QuintSonic 7 12 von 184

Page 13

First Steps

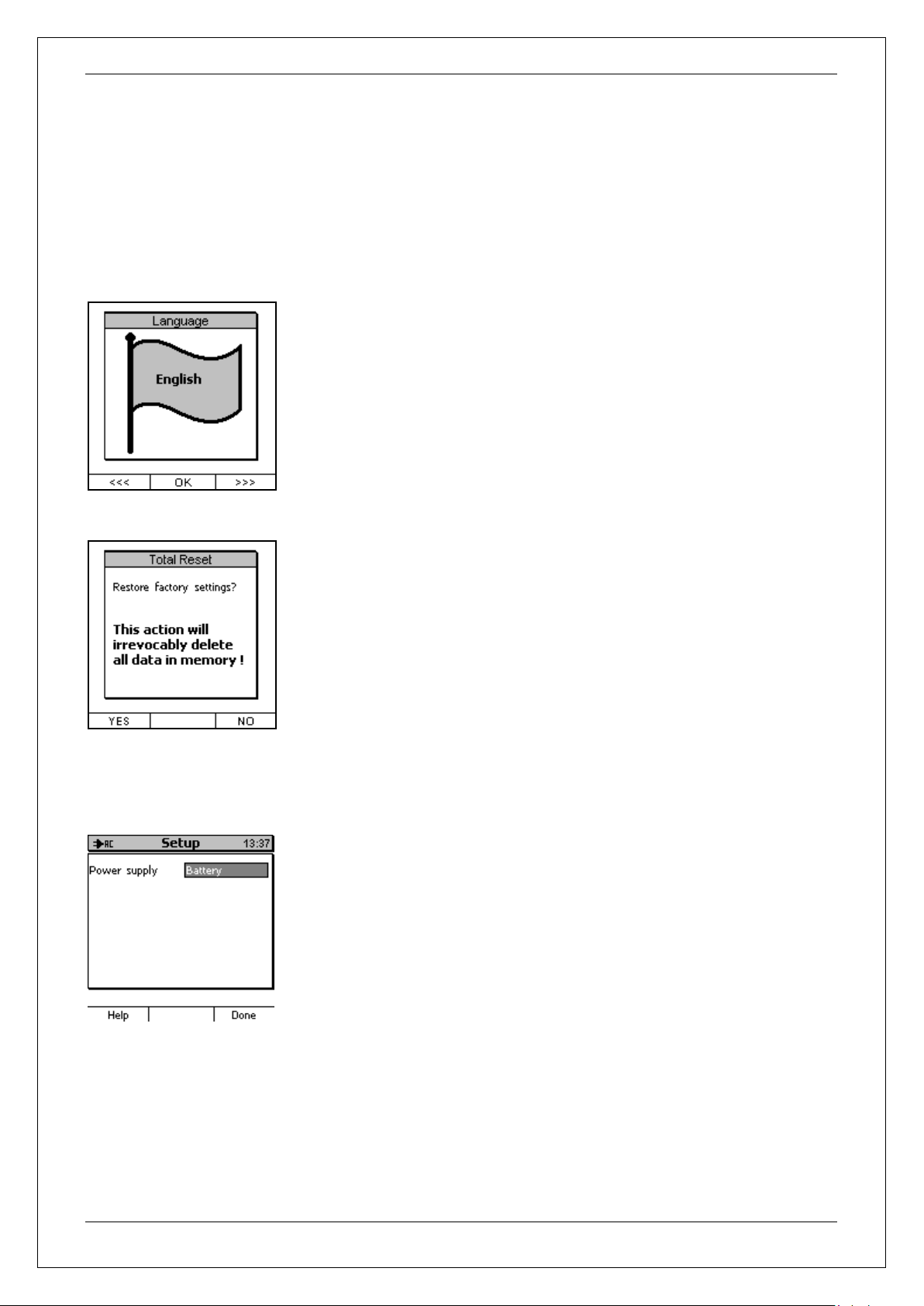

A banner appears with the currently set language.

Use arrow arrow up/down-keys to go to the requested language

option.

Press OK-key or OK-function key to confirm.

Now “Total Reset” appears on display. A Total Reset restores the

factory settings. For the initial operation, there is no need to carry out

this function.

Therefore press the “NO” function key.

To complete the initialisation procedure, the type of power supply is

displayed. Do not change this setting. Just confirm by pressing

“Finish” (Done).

2.2.1 Setting language

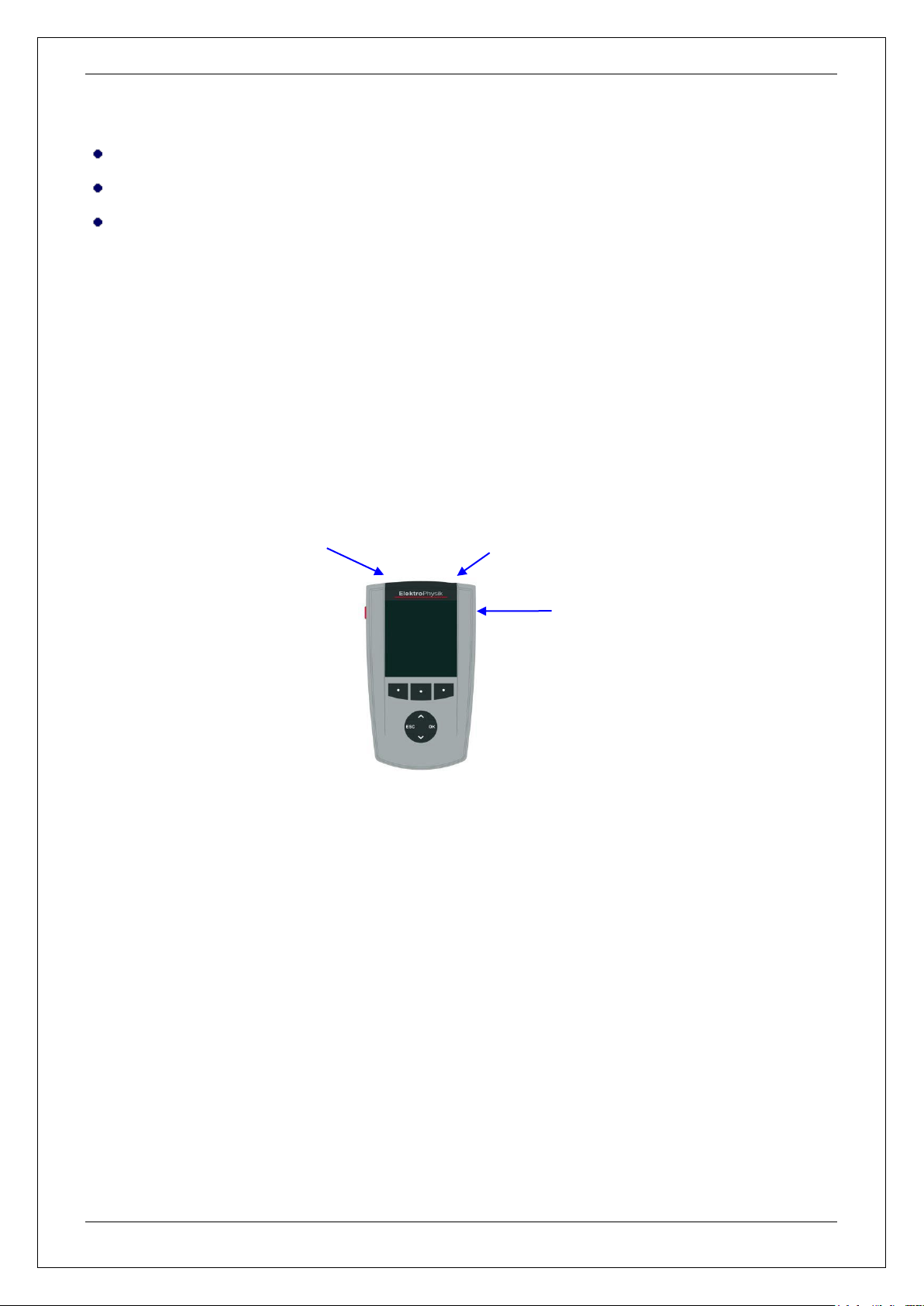

Press the red ON/OFF button on the left side of gauge and ESC simultaneously. First release

ON/OFF key. The initialisation menu will appear.

© ElektroPhysik QuintSonic 7 13 von 184

Page 14

2.2.2 Taking readings

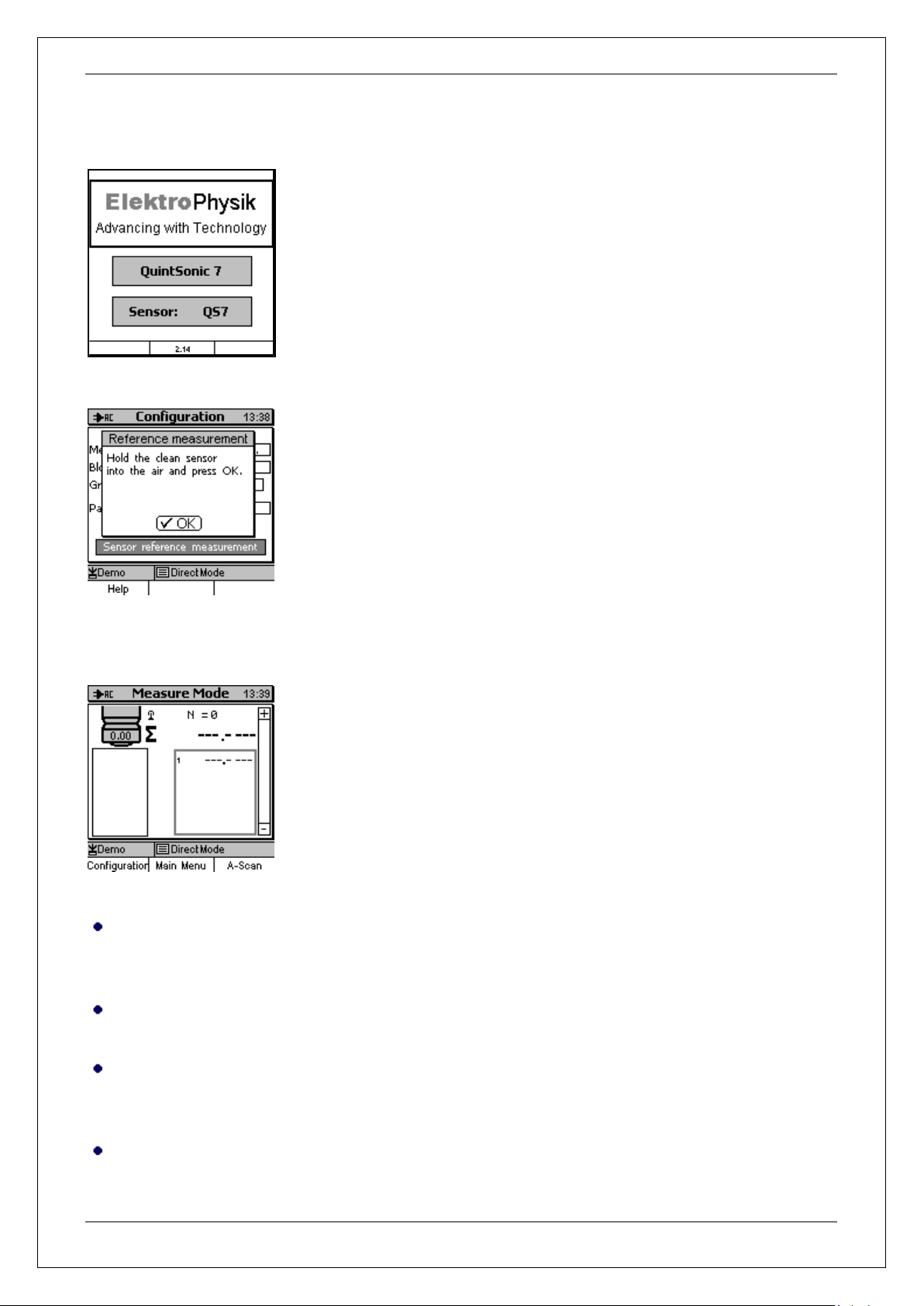

The start screen appears for about 3 seconds showing company

logo, gauge version and the type of connected sensor.

You will be requested to hold the sensor into the air for taking a

reference signal. Please check the transparent measuring surface of

the sensor tip. Make sure it is clean and free of dust, dirt, grease or

couplant residuals. If necessary, use a moist soft cloth for cleaning.

Lift the sensor and hold it in the air. Press OK to proceed on

acquisition of the reference signal.

Once the signal has been taken, the gauge will switch automatically

to measuring mode.

The gauge is ready for measurement and the measuring screen

appears. At this point, no reading is available.

First Steps

The "Direct mode“ (see section 6.3.1) along with the parameter set "Demo“ are preset. The

current setting is always shown in the status line. In this setting you can take readings at a

medium accuracy. It is not necessary to make further settings prior to measurement.

Take the test foil from the case. Open the bottle with couplant by raising the measure pourer.

Apply a small quantity of couplant on one side of the centre of foil.

Hold the grey spring-loaded sleeve of the sensor with one hand and place the sensor vertically

onto the measuring spot where you have applied the couplant. Push the sensor sleeve fully

down to the stop.

Measurement will launch automatically. This will take around one second.

© ElektroPhysik QuintSonic 7 14 von 184

Page 15

Lift the sensor from the measuring spot. The reading is shown on display (see below).

Schematic

representation of the

layer system (here: one

layer only

Active parameter set (in

this figure “Demo“)

Active batch

(here: “Direct mode”)

Current properties of the function

keys

Number of readings

stored in the batch

Coupling

index

flashing antenna icon

(if sensor is connected)

Time

Total thickness

Thickness #1

Sensor

icon

First Steps

Repeat measurement as requested. Make sure a sufficient quantity of couplant is applied on

the measuring surface of the sensor, otherwise no readings will be obtained and an error

message appears “Coupling echo faulty !”. If necessary, apply some more couplant.

After measurement has been completed, use a clean cloth to clean the foil and the sensor

measuring surface. Briefly press ON/OFF-button to switch off the gauge.

The figure above shows all data displayed on the measuring screen. For more details please

refer to the following sections of this manual.

© ElektroPhysik QuintSonic 7 15 von 184

Page 16

3 Description of the System

Function keys

ON/OFF button

Command and

navigation key-block

Graphical display

160 x 160 dots

Large backlit display for easy reading of

measuring values, A-scan image, statistical data,

histogram and trend diagram.

Robust scratch resistant plastics housing.

3.1 Display unit

3.1.1 General properties

Description of the System

3.1.2 Operating keys

Use the ON/OFF button to switch the gauge ON or OFF. If, at switch on, you press ON/OFFbutton and ESC simultaneously, the initialising procedure will be launched (for more details please

refer to section 16.1). If you press the ON/OFF-button for a longer time while the gauge is in

switched-on state, the Special Functions menu will be called (s. section 16.2).

The Function keys may assume different functions according to the screen content. Their current

properties are shown on display upper to the function keys.

The command and navigation key block may also assume different functions:

Press OK to confirm settings, store values or select items from the menu.

© ElektroPhysik QuintSonic 7 16 von 184

Page 17

Description of the System

Multi-purpose socket

Sensor socket

Infrared interface

Press ESC to abort actions or quit submenus.

Use arrow up/down-keys to navigate through the menu or change settings.

If the alphanumerical block has been activated, OK and ESC keys will also assume navigation

functions.

In poor-lit conditions, the function keys and the command and navigation key-block may be backlit

(see also section 15.6.2).

Most screens dispose of a “Help” Function key for calling the context-oriented on-line “Help“.

Press the “Help” Function key on the left to call the direct help.

3.1.3 Sockets and Interfaces

The sensor socket connects to all SIDSP® coating thickness sensors of the MiniTest 7 series, also

to sensors such as the F-, N- or FN-type (magnetic induction and/or eddy currents principle), i. e.

you only need one display unit and can operate several sensors. The multi-purpose socket is used

for connecting the plug-in mains unit or other optional accessories such as the foot switch, the

alarm device, RS232 interface cable, USB interface cable, headphones or the multi-purpose

connection box (see sections 15.6.4 and 17).

Note:

This manual only describes the operation of the QuintSonic 7 as an ultrasonic coating thickness

gauge. If you wish to connect the display unit to an F, N or FN sensor, please refer to the MiniTest

7400 operating instructions.

© ElektroPhysik QuintSonic 7 17 von 184

Page 18

Description of the System

3.1.4 Power Supply

3.1.4.1 Batteries and storage batteries

The QuintSonic 7 gauge is powered by a set of four alkaline-manganese cells, 1.5V, AA LR6 size,

(batteries included in the standard supply schedule). As an alternative, it may be operated on

rechargeable NiMH storage batteries (type AA-HR6 or via a plug-in mains unit (available as an

option). Please use only products recommended by ElektroPhysik. Please also refer to section 17

“Accessories”.

If you wish to use the storage batteries, they must be recharged using the external charger unit

(available as an option). Make sure to adjust the gauge to storage battery operation (see section

16.1). For more details on the use of batteries and storage batteries, please also refer to section 18

“Care and maintenance”.

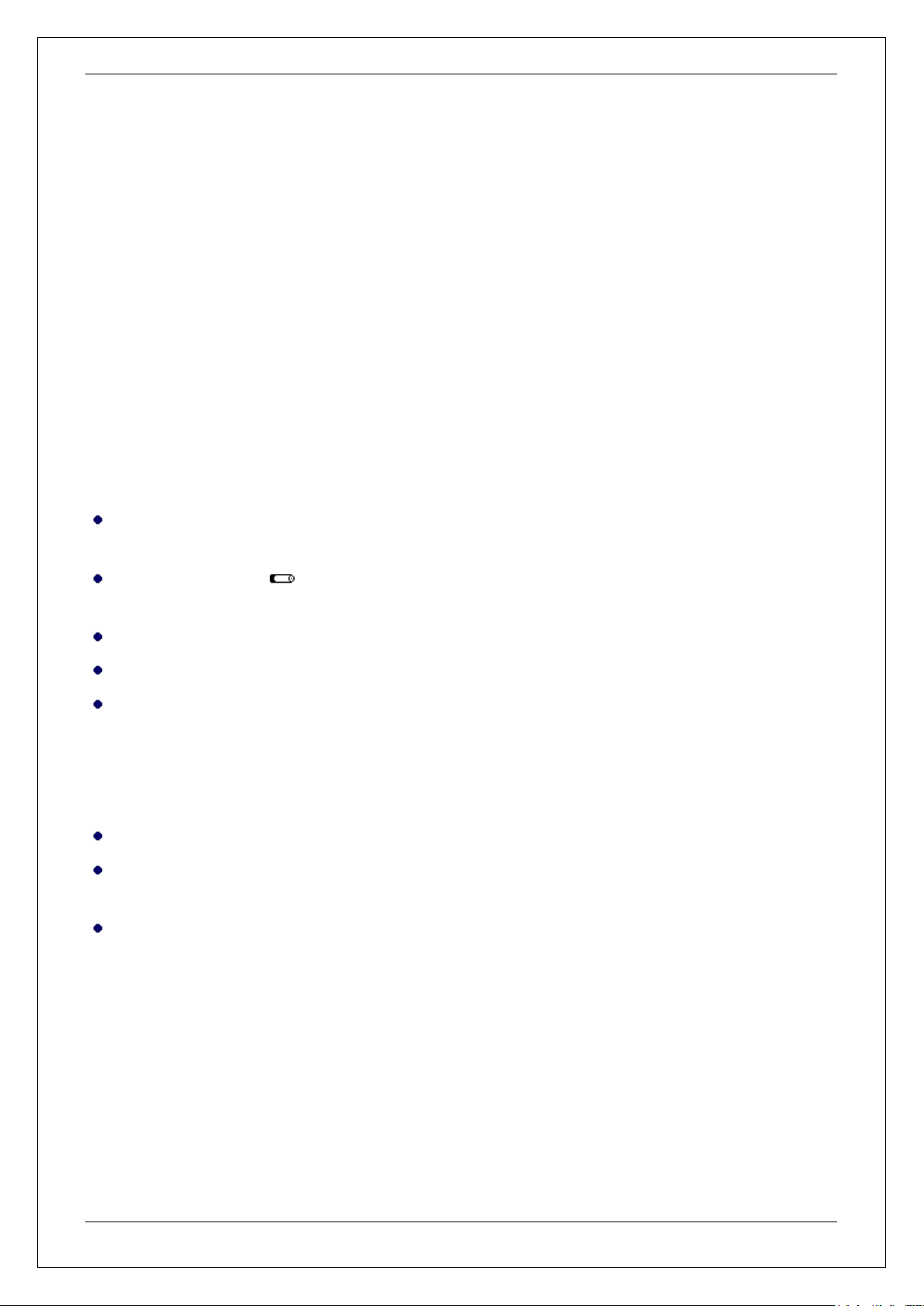

Important notes:

Remove batteries or storage batteries from the instrument if you are not going to use the gauge

for a longer period of time.

The battery symbol indicates the battery/storage battery state in 6 stages: (0, 20,

40,…100%).

If the lowest stage has been reached, “Battery almost empty” will be indicated.

In case of total discharge, “Battery too low” will be indicated and the gauge will switch off.

Make sure to replace empty batteries within a period of about one minute after you have

removed the exhausted ones. If the gauge remains longer without power, date and time

settings will get lost. If the time interval for battery change has been exceeded, “Check clock

setting” is shown after you have inserted fresh batteries (see also section 15.6.3). Batches and

calibration values, however, are retained in memory.

For field use, replacement batteries should be made available.

Erratic readings due to low battery voltage do not occur. If voltage is too low, the gauge

switches off or will not switch on at all.

Used or defective batteries or storage batteries may contain hazardous substances and must

be disposed according to the legal provisions of your country.

3.1.4.2 Plug-in mains unit

For mains operation, the plug-in mains unit must be used. If operated via the plug-in mains unit,

batteries should be inserted to supply the internal time clock; otherwise the settings of the real-time

clock will get lost approximately one minute after the mains supply has bee cut.

© ElektroPhysik QuintSonic 7 18 von 184

Page 19

Description of the System

The plug-in mains unit comes with two different adapter plug versions (Euro and US plug). If the

adapter plug does not match your socket, simply change the adapter plug accordingly.

For this purpose, remove the adapter from the plug-in mains unit and fix the other one as required.

Note: The adapter is not designed for frequent change.

3.1.4.3 USB-Interface

The QuintSonic 7 can also be powered via the USB interface of a PC. For this purpose, please use

the USB adapter cable (supplied as an option). Connect the gauge to your PC. The gauge

switches on automatically. It is recommended to operate the gauge in the permanent mode (see

section 15.6.5) to make sure it is always switched on.

3.2 Sensor

3.2.1 SIDSP®-Technology

SIDSP® is world wide leading state-of-the-art-technology for coating thickness sensors developed

by ElektroPhysik. With this new technology, ElektroPhysik has set another new benchmark for

innovative magnetic induction or eddy-currents based coating thickness gauges. With QuintSonic

7, this new technology has also made its entry into the ultrasonic coating thickness measurement.

Compared to the conventional procedures, the new technology offers considerable advantages

that will be explained in detail in the following section.

SIDSP® stands for sensor-integrated digital signal processing. With this technique, all necessary

measuring signals are generated and processed inside the sensor itself.

The sensor of the QuintSonic sensor emits the ultrasonic signal at a peak voltage of approx.140V.

Unlike conventional methods, the new SIDSP® technology does not transfer this signal via a

cable, but the signal is directly generated in the sensor to be transferred via the shortest way to the

measuring head. As a consequence, an impact on the transmit signal through the cable can be

excluded and at the same time, an optimum protection against contact is given, even if the cable is

damaged.

Conventional methods transfer signals via cable. With the new technology, however, the sensitive

ultrasonic signal is not transferred via cable, but processed directly in the sensor. As a

consequence, an optimal protection against interferences of any kind is given. The complete

process from mathematical editing up to the coating thickness value is performed by a 32-bits

controller. The calculated coating thickness values are available in digital form to be transformed

flawlessly via the sensor cable to the gauge.

© ElektroPhysik QuintSonic 7 19 von 184

Page 20

Description of the System

With the SIDSP® technology, adverse interferences through changing cable properties (as they

often occur with conventional methods) that might affect readings can be totally excluded. As a

result, QuintSonic 7 provides long-term stability enabling the user to take full advantage of the

precision and reliability of the system.

During the manufacture of a sensor, sensor calibration values are determined. Such values are

vital for the precision of a sensor. They are stored in the sensor itself to make them available at

any time. They will be retained even if the sensor is connected to another QuintSonic 7 gauge, in

other words, you can use a QuintSonic 7 sensor and connect it to any QuintSonic 7 gauge as

requested.

© ElektroPhysik QuintSonic 7 20 von 184

Page 21

Description of the System

3.2.2 Measuring ranges

The sensor offers five different measuring ranges with the following properties:

Measuring range 1: Range limit = 300 ns, resolution = 0.2 ns

Measuring range 2: Range limit = 750 ns, resolution = 0.4 ns

Measuring range 3: Range limit = 1600 ns, resolution = 0.8 ns

Measuring range 4: Range limit = 3300 ns, resolution = 1.7 ns

Measuring range 5: Range limit = 6300 ns, resolution = 3.3 ns

All ranges start at 10 ns. This is the minimum distance required between a layer interface echo and

the second coupling echo (for more details please see section 7.3.3)

As the measuring principle is based on a time-interval measurement, the measuring ranges are

scaled in units of time. The obtainable coating thickness ranges are a function of the ultrasonic

velocities of the materials to be measured. Please refer to the technical data of section 19 for the

different coating thickness ranges resulting from an ultrasonic velocity of 2375 m/s (average values

for industrial coatings).

The resolution represents the smallest possible time unit a multiple thereof the echo positions can

be represented as (see section 7.3.3). This is also referred to as “quantisation unit”. Example: In

the measuring range # 2, echo positions can be obtained only in time intervals of 10.0 ns, 10.4 ns,

10.8 ns, etc. Intermediate values do not occur. Resolution is highest in the lowest measuring

range, whereas it is lowest in the highest measuring range.

© ElektroPhysik QuintSonic 7 21 von 184

Page 22

User Interface

4 User Interface

The following sections provide an overview of the most important QuintSonic 7 menu screens

including a short description of the same. For more detailed information, please refer to the

relevant paragraphs.

For a complete description of the menu system, please see section 15.

In section 4.3 you will learn how to enter your settings for the different parameter types.

4.1 Important Menu Screens

4.1.1 Start screen

At switch-on, the start screen appears showing company logo, gauge and type of sensor being

connected.

The start screen is shown for about 3 seconds during which the initialising procedure is running.

Once completed, the system switches to measuring mode.

You will be requested whether to continue the last active batch. If the direct mode (see section

6.3.1) has been set, there will be no such request and you can immediately proceed on

measurement.

© ElektroPhysik QuintSonic 7 22 von 184

Page 23

User Interface

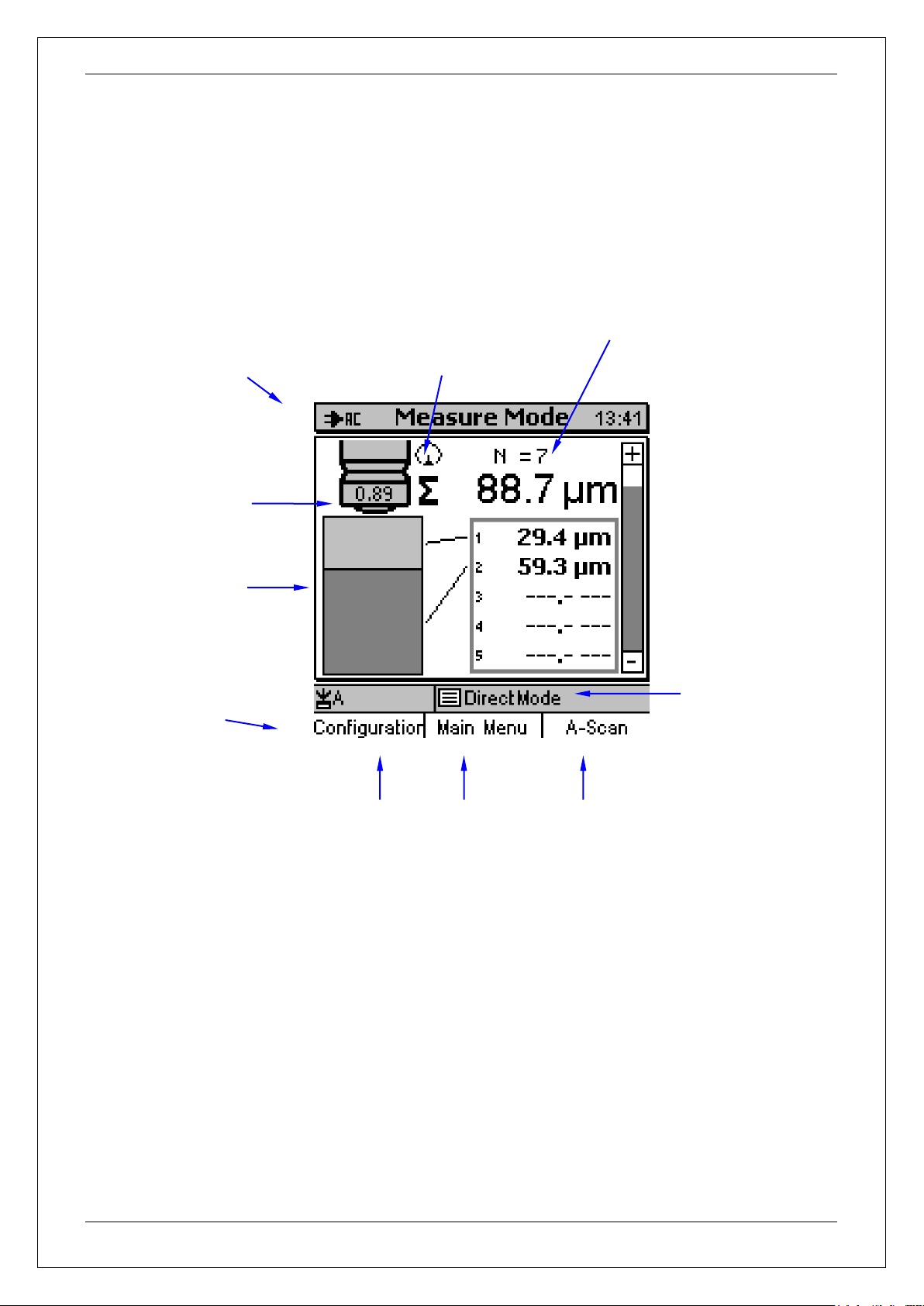

Mains or battery operation

with state of charge

Time

Layer thickness 1

Layer thickness 2

Active

parameter set

Number of readings taken

Antenna icon, flashing if

sensor is connected

Coupling index

Total thickness

Active batch

Structure of

layers,

geometric model

Current property of function key

4.1.2 Measure mode – numerical and graphical screen

The screen appears each time a reading has been taken unless you have selected the A-screen

image (see sections 4.1.4 and 7.4.6). The measure mode screen includes a comprehensive and

clear overview of all measuring data.

The total thickness and the individual layers are represented in numerical form (on the right edge

of screen). In addition, readings are shown as a geometric layer model on the left side of screen

with the height of the individual layers being determined by their layer thickness.

The coupling index (on the left) indicates the quality of coupling (see section 6.5.2) achieved during

measurement.

On the upper right, the number of readings stored in the current batch is shown along with the

name of active batch and the name of parameter set relating to this batch (bottom line).

© ElektroPhysik QuintSonic 7 23 von 184

Page 24

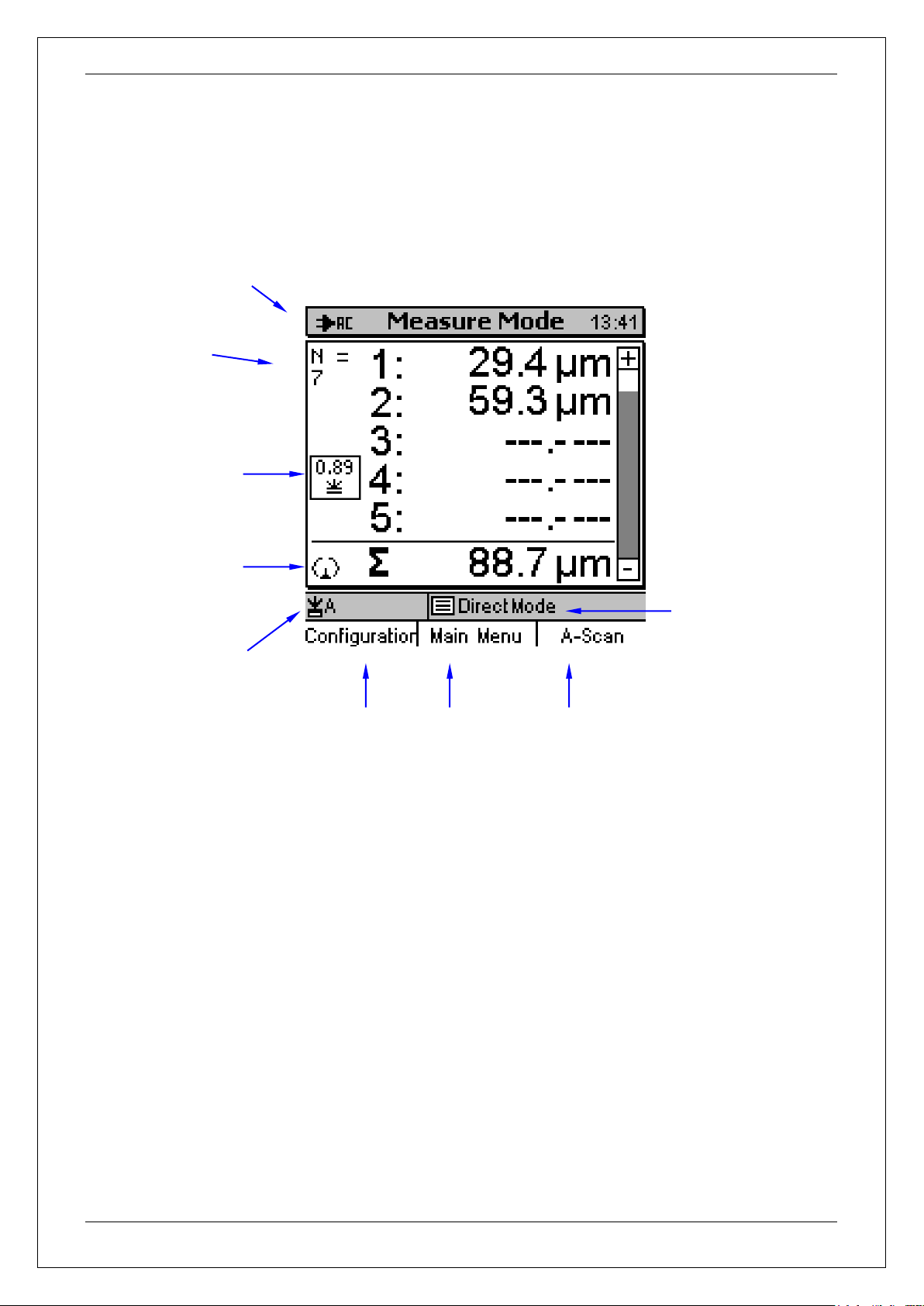

4.1.3 Measure mode – Large numerical screen

Mains or battery operation

with state of charge

Time

Layer thickness 1

Layer thickness 2

Active

parameter set

Antenna icon,

flashing if

sensor is

connected

Active batch

Number of

readings

Coupling index

Total thickness

Current property of function key

User Interface

If a good readability of readings has priority, it is recommended to call the numerical screen as

shown above. This screen is only includes readings and some additional information such as

coupling index and number of readings. This screen offers sufficient space to represent large

numerical values to enable good readability from the distance.

To call this screen the “Graphics” parameter must be disabled. Go to the “Configuration” submenu

and press the “Configuration” function key (see section 15 5. 3 “Configuration”).

© ElektroPhysik QuintSonic 7 24 von 184

Page 25

4.1.4 Measure Mode – A-screen Image with Echo Signal

Current property of function keys

Layer thickness 1

Amplitude value at

cursor position

Crosshair

cursor

Time value at

cursor position

Here the function

keys assume cursor

move functions

Time

Amplitude zoomdetail [%]

Coupling index

Mains or battery operation

with state of charge

Time [ns] on the

left edge of

screen

Time [ns]

(on the right

edge of screen)

Echo pulse

Echo line

Clipping

limits

Percentage [%]

for clipping

limits

Zoom and

position indicator

Layer thickness 2

User Interface

This screen represents the behaviour in time of the so-called echo signal that has been computed

from the measuring signal. The time axis runs from left to right with the time values being

displayed on the left or right side respectively.

The extracted echoes are represented as vertical lines within the echo pulses. Each echo is

marked with an icon to indicate its state and origin.

On the left screen, the thickness of the individual layers is displayed as a numerical value.

The A-scan image includes a crosshair cursor that can be used for moving along the signal curve.

This enables you to read the amplitude value at any point of the curve (numerical value on the

upper right of screen).

The broken lines represent the clipping lines. For their signification and use please refer to section

8.

The A-scan image also includes a zoom function to zoom in or out sections as requested (see also

section 7.4).

© ElektroPhysik QuintSonic 7 25 von 184

Page 26

User Interface

Current properties of function keys

Mains or battery operation

with state of charge

Active

parameter set

Time

Active

batch

If a reading is taking whilst the A-scan image is being active, the reading will be immediately shown

on the A-scan image (see section 7.4.6). A previous change to the measure screen will not take

place.

For a detailed description of the A-screen, its significance and how to use it, please refer to

sections 7 and 8.

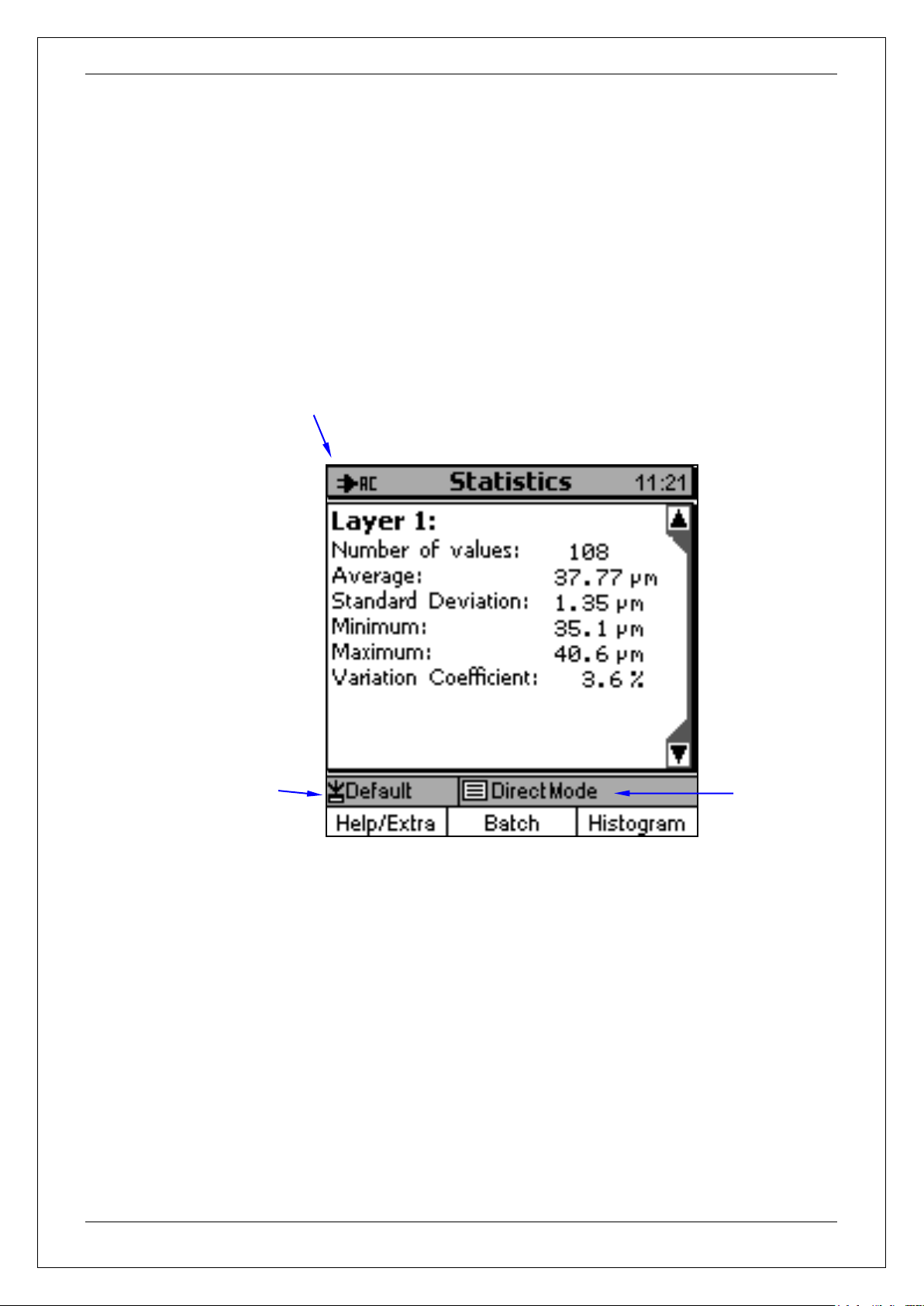

4.1.5 Statistics screen

All statistical values of a batch will be reported in tabular form.

The figure above represents Layer 1.

Statistics are available for each individual layer as well as for the total thickness.

For more details on the statistical functions please refer to section 13.

© ElektroPhysik QuintSonic 7 26 von 184

Page 27

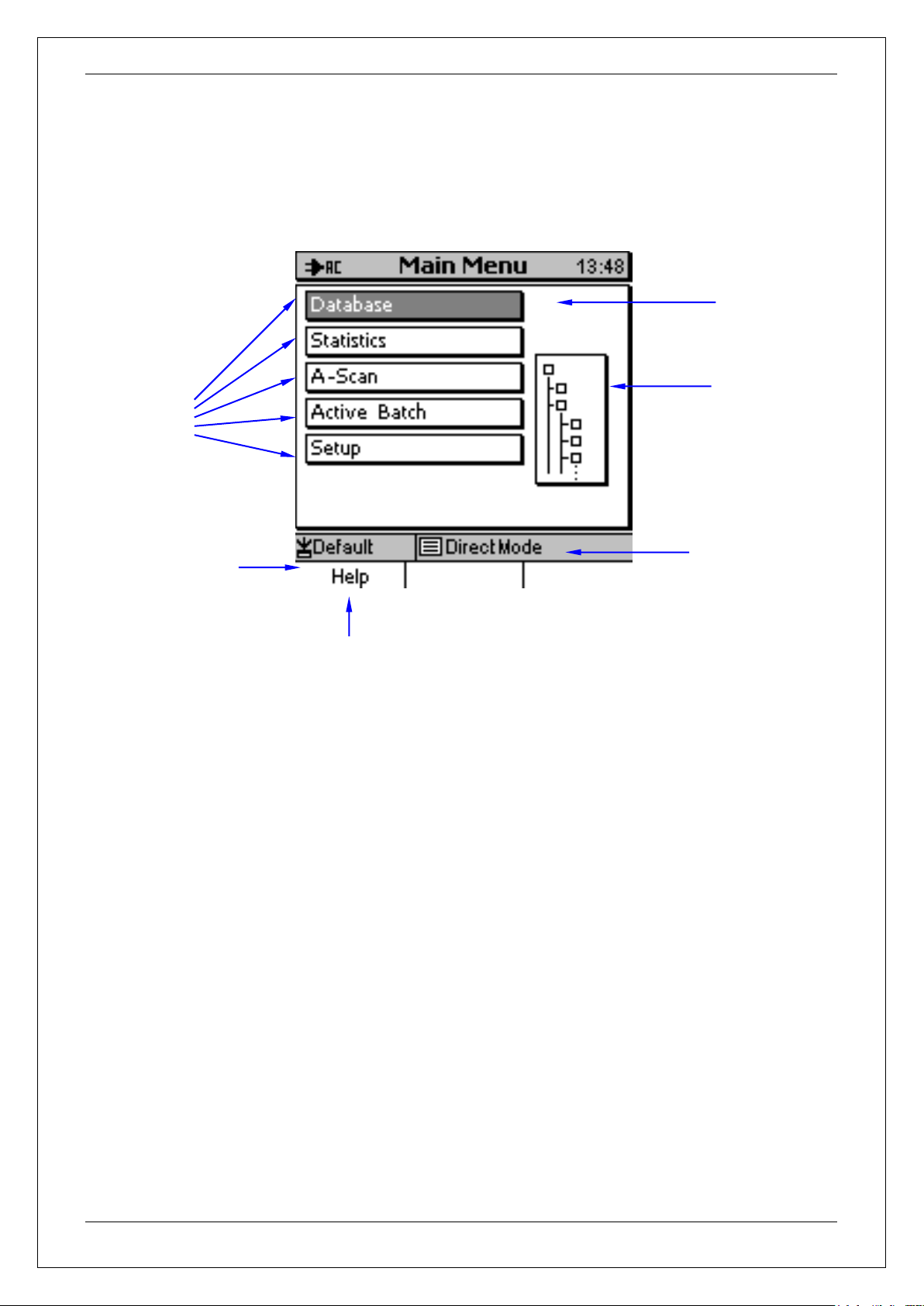

4.1.6 Main menu

Active

parameter set

Active batch

Submenus

Icon for your

selected menu

item

Selected

menu item

Main menu help

User Interface

The figure above shows the main menu. It is the highest menu level (start level). From numerous

screens, this menu can be accessed via the function key “Main Menu”.

Press ”Main menu“ and use the arrow keys to scroll through the submenus. Press OK to confirm

your submenu selection.

From any submenu you can return to the main menu by pressing the ESC-key repeatedly. If you

press ESC in the main menu, you will go back to the measure screen.

The typical items of a menu are shown on the figure above.

Press the Help-key on the left to call up the help menu relating to the currently active menu. A

context oriented help is available for many of the different screens.

For more detailed information please refer to section 4.2.

© ElektroPhysik QuintSonic 7 27 von 184

Page 28

User Interface

4.2 How to navigate in the main menu

The numerous QuintSonic 7 functions can be accessed via the hierarchically structured user

menu. The main menu represents the highest menu level. From the main menu you can get

access to various submenus and their respective submenus or to other screens such as statistics

or parameter screens. In this section, a few examples are given to show you how to navigate

through the menu.

Press function key “Main menu” to call the main menu. Note: Some of the screens do not feature a

”Main menu“ function key. In such case, please press ESC repeatedly until you access a screen

featuring such key.

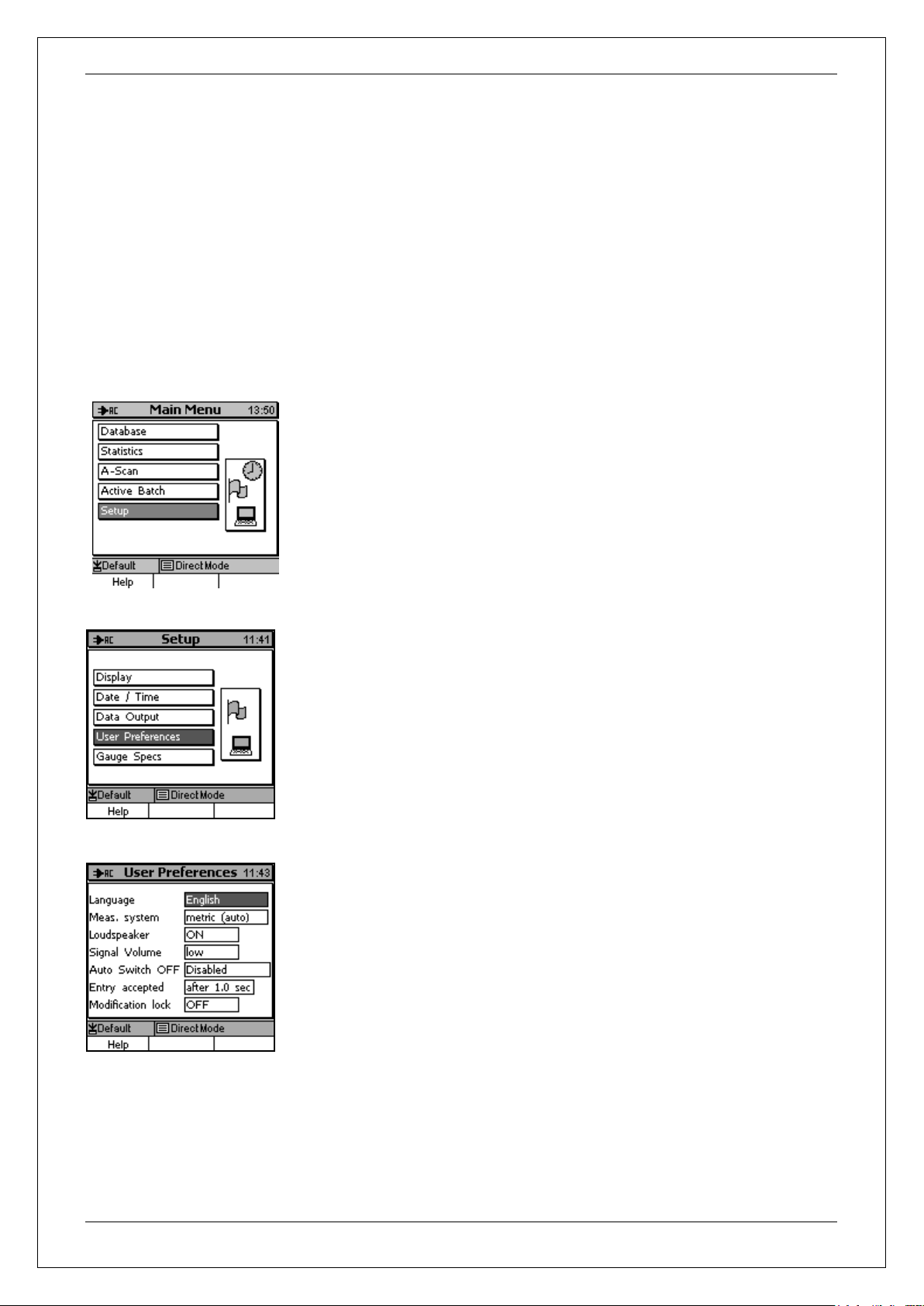

From the main menu, press arrow-up or -down key to select the

requested item, for instance “Setup”. Press OK to confirm. The selected

item will be called up.

The „Setup“ menu includes a submenu. Use arrow keys to select

“User Preferences” and confirm by OK to call up your selection.

The “User Preferences“ menu does not lead to submenus but it

includes a list of parameter options. The following section 4.3

provides more information on parameter options.

.

Press ESC-key to go back to the previous menu level. If you press ESC from the main menu, the

measure screen will appear. By means of the above navigation instructions you can move through

the complete menu and access any menu as requested.

© ElektroPhysik QuintSonic 7 28 von 184

Page 29

User Interface

4.3 Parameter setting

Many of the screens do not represent submenus but list parameter setting options. Most of the

parameters are user adjustable. Their setting may vary according to the type of parameter. In this

section, a few examples are given to show you how to set the different types of parameters.

Your parameter selection will be highlighted in grey. Use the arrow-keys to scroll through the

options. If you scroll down over the maximum, the cursor will skip aback to the beginning. This is

for quicker setting action. The cursor does only mark your parameter option without making any

changes to it. How to reach the editing mode for changing a parameter will be explained in the

relevant sections relating to the different parameter types.

Some of the parameters cannot be changed such as “active batch” / “batch properties”. You will

quickly identify such parameters if no selection cursor is available.

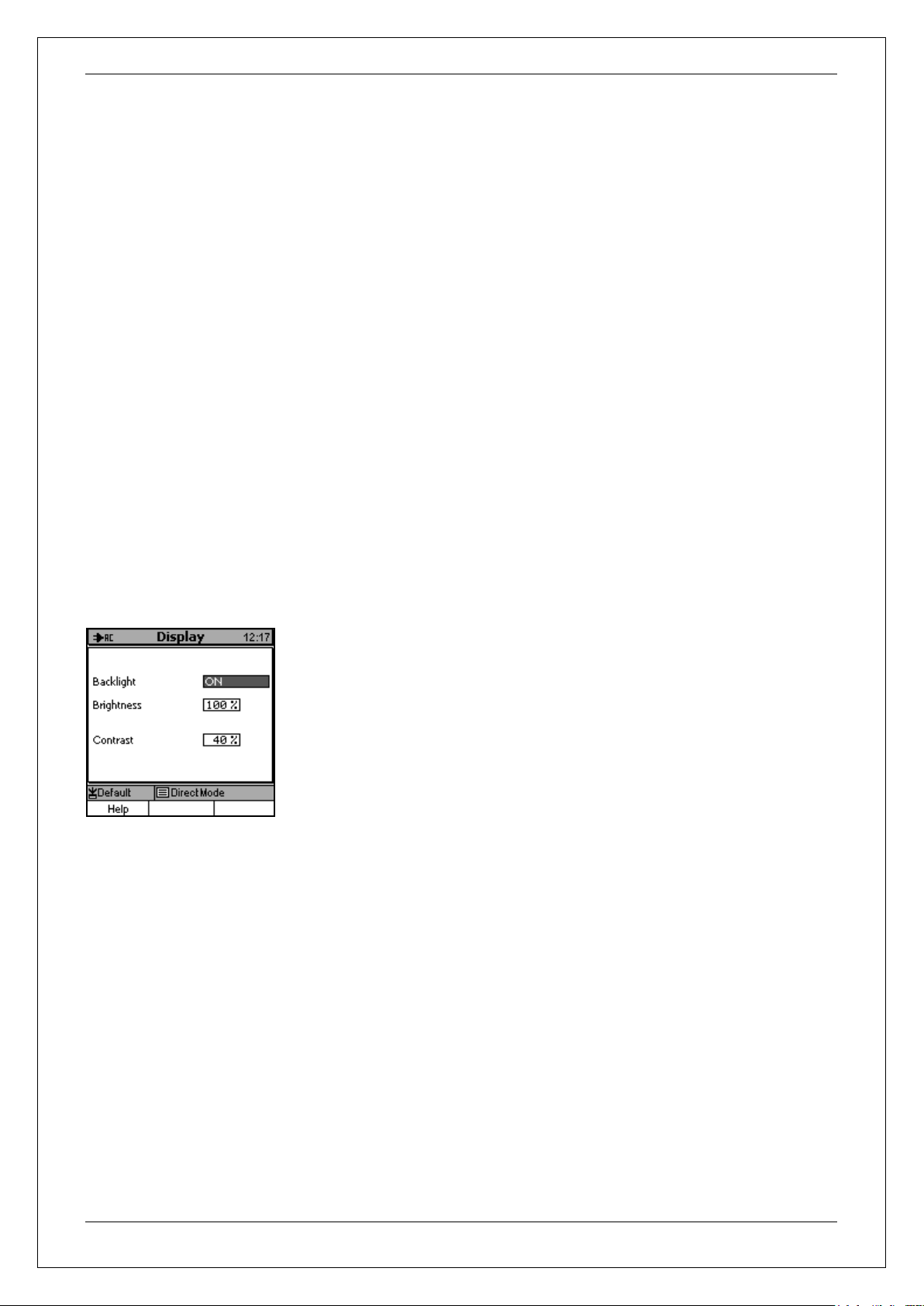

4.3.1 Setting a switch parameter (Example: Backlight)

Some parameters only offer two settings such as on/ off or

enabled/disabled. This kind of parameters are referred to as “switch

parameters”.

Example: “Backlight” from the submenu “Setup\Display”.

Select “Setup” followed by “Display” and choose “Backlight”.

Press OK and the parameter will change its state.

If you press again, it will switch back, etc.

The state highlighted state is being active.

© ElektroPhysik QuintSonic 7 29 von 184

Page 30

4.3.2 Setting selection parameters (Example: language)

Selection parameters offer more than two states.

Example: “Language” from the submenu “Setup\User Preferences”.

Select “Setup” followed by “User Preferences” and choose

“Language”. Press OK to confirm.

On the left of the options field an arrow up/down symbol will appear to

indicate that you can now set this parameter.

Use the arrow keys from the navigation block to scroll through the

options. Press arrow keys until you reach your requested option, e.g.

“English” and press OK to confirm.

Your setting has become active and the arrow symbol disappears.

If you do not want to change the setting, press ESC instead of

confirming by OK.

User Interface

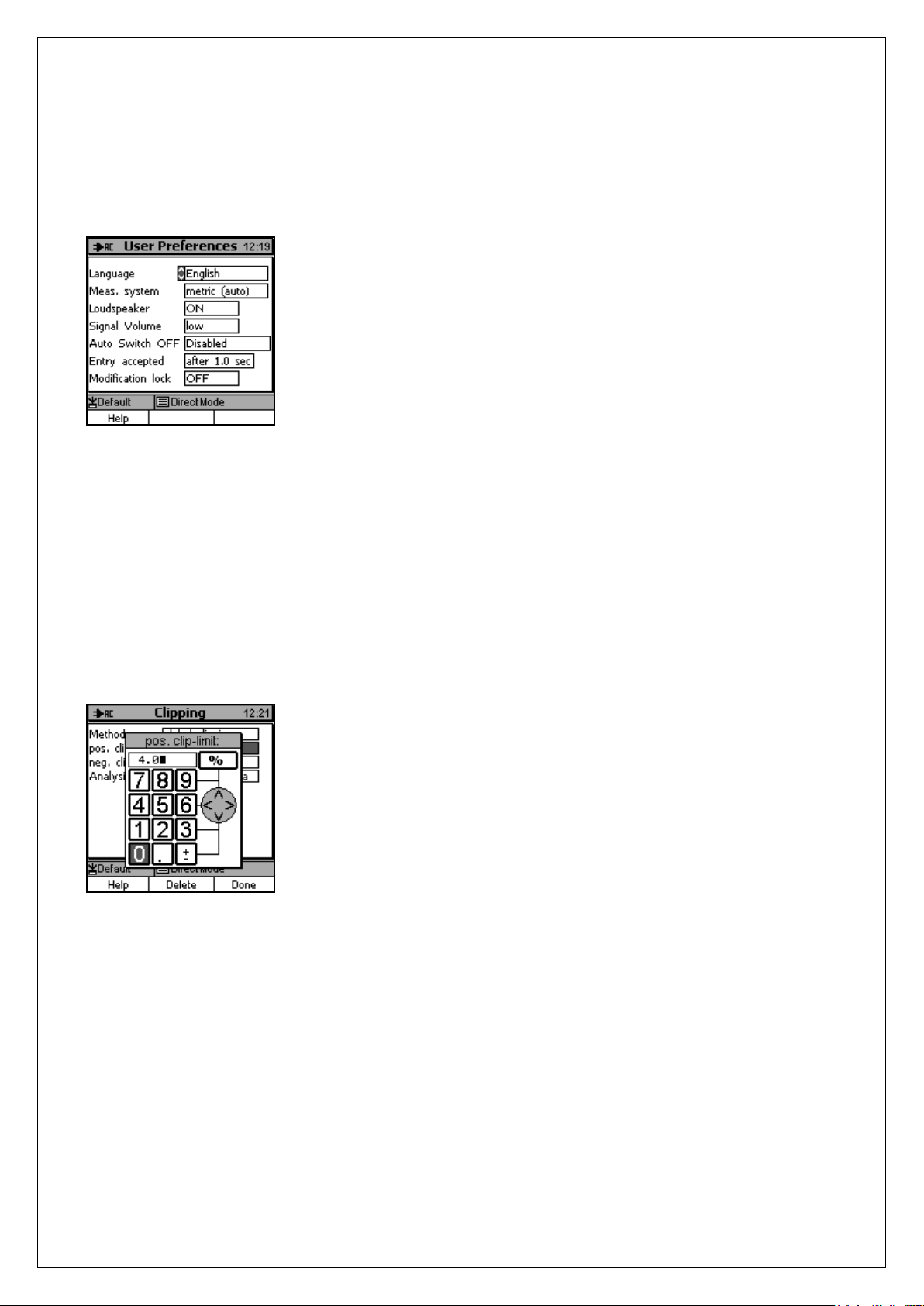

4.3.3 Setting a numerical parameter (Example: pos. clip-limit)

Some parameters require a numerical setting. Once you select such

parameter, a special entry screen will appear.

Example: “pos. clip limit” from the batch configuration menu. See

section 12.1.2.1 “Clipping”.

The ESC- and OK-keys assume navigation functions to the left/right.

The arrow keys assume their standard navigation function up/down.

The entry method is similar to writing a text message on a mobile

phone. Use ESC, OK or arrow key to move the cursor over the

numerical entry field. Once you have reached the requested value,

wait until the auto-save time delay has passed and the value will be

accepted automatically. The auto-save time delay can be set via

Setup/User Preferences/ Entry accepted: after….sec. See section

15.6.5.

If you wish to enter the same value again, just move the cursor to any

other value and go back immediately to the requested value. If you

have mistyped, you can delete the unwanted value from the entry line

by pressing the “Delete” function key. If necessary, press repeatedly.

© ElektroPhysik QuintSonic 7 30 von 184

Page 31

User Interface

Shift key enabled

Once you have entered the requested value, press the “Done“

function key. A confirmation query will appear. Press OK to save this

value as parameter setting. Press ESC if you do not wish to save

changes. In such case, the previous setting will remain valid.

4.3.4 Alphanumercial parameter entries (Example: directory name)

When setting a parameter that requires an alphanumerical entry, a

special entry window will appear.

Example: How to enter a directory name when creating a new subdirectory (see also section 11.2.2.1).

You may generate a name of 15 characters maximum.

The ESC- and OK-keys assume navigation functions to the left/right.

The arrow keys assume their standard navigation function up/down.

The entry method is similar to writing a text message on a mobile

phone. Use ESC, OK or arrow key to move the cursor over the

alphanumerical entry field. Once you reached the requested

character, wait until the auto-save time delay has passed and the

value will be accepted automatically. The auto-save time delay can

be set via Setup/User Preferences/ Entry accepted: after….sec. See

section 15.6.5.

If you wish to enter the same character again, just move the cursor to

any other character and go back immediately to the requested

character. If you have mistyped, you can delete the false character

from the entry line by pressing the “Delete” function key. If necessary,

press repeatedly.

For typing one single capital letter, first navigate to „Shift“. An arrow

will appear to indicate the Shift key is enabled. Once you have

entered the capital letter, the arrow will disappear. This mode is the

default factory setting.

© ElektroPhysik QuintSonic 7 31 von 184

For permanent input of capital letters, move to the CAPS-field.

Enabling the CAPS-field sets an input mode in which all typed letters

are in upper case (and vice versa). A bold-typed arrow will appear to

indicate the CAPS-key is enabled.

Page 32

User Interface

The ”Special Character“ field offers another window for special

characters (also for vowel mutations). Once you have entered a

special characters, this window will close automatically.

Once you have completed your text, press “Done“ to confirm. You will

be asked whether to save changes or not. Press OK to confirm or

ESC to abort. If you abort, the previous setting will remain valid.

© ElektroPhysik QuintSonic 7 32 von 184

Page 33

Calibration

5 Calibration

5.1 Particularities of ultrasonic coating thickness

measurement systems

In ultrasonic measurement, the primary measured variables are the differences in travel times of

the various components of the transmit and receive signal. In ultrasonic coating thickness

measurement, travel times range from a few nanoseconds to several hundreds of nanoseconds (a

nanosecond (ns) is one billionth of a second). The precision at which such travel times can be

measured directly influence the accuracy that can be achieved for measurement. The SIDSP®sensor of the QuintSonc 7 is a crystal oscillator based time measurement system with a typical

accuracy of 50 ppm (0.005%). This value is so small that, in practical operation, it can be

neglected against all other factors that might impair accuracy. Unlike the conventional measuring

methods used for coating thickness measurement, the QuintSonic 7 measuring system does not

need any calibration. However, there is one decisive factor of influence resulting from the

measuring object itself that you must be calibrated for: the sound velocity in the material to be

measured.

When converting the differences of travel times as determined in the measuring object into coating

thickness, the sound velocities in the individual layers act as constants of proportionality. These

variables are properties of the measuring object, not of the measuring system and depend on the

material and temperature involved. Most times, these variables are not exactly known. As a

consequence, their determination through indirect methods is required. Most times this is done

through optical evaluation of a material cross-section. Once determined, the variables can be

made available to the measuring system in the form of a sound velocity calibration. This explains

why the sound velocity calibration is vital for the precision of an ultrasonic coating thickness gauge.

5.2 How to calibrate for the sound velocity

QuintSonic 7 offers several methods for a sound velocity calibration. The methods are described in

the following section. For the practical operation, please refer to section 12.1.4.4.

a) Enter numerical values for the sound velocities

A prerequisite for this method is that the numerical values of the sound velocities are know for

each individual layer. For calibration, simply enter these values manually into the sound

velocity table of the current batch. This method is very simple. In practical operation, however,

this method is not applicable, as in most cases, the sound velocity of the materials to be

measured is not know.

© ElektroPhysik QuintSonic 7 33 von 184

Page 34

Calibration

b) Using the table of literature values

The QuintSonic 7 menu offers two selection tables from which you can choose a sound velocity

according to the material to be measured.

In the table of ”literature values“ you will find a list of commonly used plastic materials and

other materials such as steel, brass, wood, etc.

Once you have defined a layer by selecting a material from the table, the calibration for this

layer is completed. Repeat this procedure for all layers of the layer system. Please note that

the values listed in the literature value table are average values only. Due to material

variations, the actual sound velocity of the material to be measured may deviate significantly

from the values indicated in the table.

c) Using the table of „User values“

In this table you can define your own material / sound velocity combinations and define the

different layers of your layer system accordingly. Once you have defined the different layers

and their matching sound velocities, the calibration is completed. If the sound velocities have

been confirmed by reliable methods such as a material cross-section, the “User values” table

represents an excellent method for a quick and easy calibration. However, it must be

considered that variations of raw material or batch-related product variations may be present.

For that reason it is recommended to verify regularly whether the sound velocities you have

defined in the table are still applicable for the material batch to be measured. If not, it is

recommended to make a cross section of the new material batch and use the calibration

standard resulting from this material cross section accordingly.

d) Using the preset value for industrial coatings

The sound velocities for most industrial coatings are in the range of 2375 m/s ±15%.

If this default value of 2375 m/s is used for measuring industrial coating systems, as a

consequence, a maximum error of ±15% can be expected (the sound velocity will be included

in the calculation of coating thickness as a constant of proportionality). This is not good enough

for absolute measurements. For some applications, however, the main aspect is focussed on

keeping an absolute coating thickness constant that has previously been determined by

another measuring method (cross-section). In such case, the displayed absolute value has little

significance only. For that reason, it is recommended to carry out measurement on a reference

sample. The individual layers of this sample should represent the same thickness as the target

thickness to be expected. The displayed readings that to not match the actual coating

thickness, will be used as setpoint for the measurements to follow. All further measurements

will only provide the variations from the setpoint. This is important for process control, for

instance. In this connection, default sound velocities can be used to a limited extend only.

However, this does not represent a calibration in the strict sense. For the configuration of a

measuring series, QuintSonic offers to use the above value as a preset value.

© ElektroPhysik QuintSonic 7 34 von 184

Page 35

Calibration

e) Calibration using a defined coating thickness (calibration standard)

For this method, a so called calibration standard must be available. The layer composition of

such standard must be the same as that of the object to be measured.

The individual layers of the standard have been determined previously by another measuring

method such as a cross-section, for instance.

Now enter the defined values of the individual layers into the table. Once completed, use

QuintSonic 7 to take several measurements on the calibration standard. For each layer, the

gauge will calculate an average from the set of readings you have taken.

Make sure to use the same measuring spot as during measurement with the other method. Of

course, after a cross-section, this will be possible to a very limited extend only.

The system now processes the deviations from the thickness values that have been entered

previously and the sound velocities are calculated accordingly. The sound velocities can later

be used for further measurements. The calibration procedure is completed at this point.

As the calibration accuracy determines the accuracy of later measurement, the calibration

procedure should be carried out under optimum conditions. It is highly recommended to take a

reference signal before starting the calibration (see section 6.4.1).

© ElektroPhysik QuintSonic 7 35 von 184

Page 36

Measure Mode

6 Measure Mode

6.1 Important remarks on ultrasonic measurement

Before using QuitSonic 7, it is recommended to read this information carefully. Make sure to

understand and follow the instructions in order to avoid errors during measurement that might lead

to erratic readings. Erratic readings can have serious consequences and lead to personal injury or

damage to property.

Particularities with ultrasonic coating thickness measurement systems

After careful perusal of this manual you will be able to operate the QuintSonic 7 gauge correctly.

Please note that apart from operating errors, there are a lot of other factors that might impair

measurement.

Special attention should be paid to sections 6.2 to 6.5 and 7 to 9 providing essential information on

the properties and particularities of measuring objects within the scope of ultrasonic measurement.

In addition the above mentioned sections, this manual include instructions on the steps required to

prepare measurement, on the use of the sensor, on how to avoid interference and on the correct

interpretation of measuring results.

Skills required for operating the gauge

For using an ultrasonic measuring system, a basic training in the field of ultrasonic measuring

techniques is recommended to make available sufficient knowledge on the following topics:

Theory of sound wave propagation

Effects of the sound velocity in the measuring object

Behaviour of the sound waves at the layer interfaces of different materials

Propagation of the sound beam at the measuring point

Influence of sound attenuation in the coating materials and influence of the surface structures

of samples

For training and support in the field of ultrasonic coating thickness measurement, please contact

ElektroPhysik.

Preparing measurement (see also sections 6.3 and 6.4

For using an ultrasonic coating thickness gauge, it is necessary to take a certain number of

preparatory steps such as:

Setting the correct parameters to the measuring system

Calibrate the measuring system (see section 5)

Setting the measuring range (number and position of measuring points)

© ElektroPhysik QuintSonic 7 36 von 184

Page 37

Measure Mode

Setting the processing parameters (limits of readings, admissible standard deviation, etc.)

The person in charge of measurement shall be responsible to instruct any person involved in

measurement on the necessary preparatory steps and to make sure they are carried out

appropriately. Any experience with similar measuring objects might be a useful base for such

preparatory works.

6.2 Limits to the measurement technique

As any measuring technique, also the ultrasonic coating thickness measurement is subject to

certain limitations – mostly of physical nature. The following section will refer to such limitations,

their origin and how to deal with it.

Formulating conclusions to non-inspected areas

The results obtained from measurement solely relate to areas of the sample that have been

inspected. Conclusions to other areas of the measurement object are not admissible. They are

only allowed if extensive experience on the process of manufacture is available and if appropriate

methods for statistical evaluation can be applied.

Differences in acoustic impedance

The acoustic impedance values of layer interfaces must vary sufficiently in order to ensure the

reflection coefficient at the layer interface is high enough for being evaluated. If this is not the case,

the ultrasonic thickness measurement is pushed to its physical limits. If impedance values do not

vary sufficiently, a clear separation of the layers is not possible any more. For more details please

refer to sections 7 to 9.

Sound velocities

Ultrasonic coating thickness measurement is based on the measurement of travel times taking into

account the sound velocities in the individual layers. For the calculation of the layer thickness, it is

presumed on the assumption that the velocities in the individual layers are known and constant.

For reliable measurement, all conditions must be fulfilled. As the sound velocity is used as a

constant of proportionality to calculate the coating thickness, a sound velocity error of 5% will result

in the an error of 5% accordingly. For that reason, it is vital to adjust the correct sound velocity.

If the sound velocities of the materials to be measured are not known (as this generally is the case

with industrial coatings because of strong material variations that may occur), it is required to

determine the sound velocities prior to measurement. This can be done by means of an optical

evaluation of sample cross-sections. First the cross-sections of samples are measured by means

of the QuintSonic 7 gauge. After this, the measuring system can be calibrated according to the

results obtained by the cross-section. Through the calibration procedure, the correct sound

velocities will be adjusted automatically.

If a material presents discontinuities (caused by the manufacturing process, for instance,) the

sound velocity in this material may vary. The variations may occur continuously or in steps. In such

© ElektroPhysik QuintSonic 7 37 von 184

Page 38

Measure Mode

case, an average sound velocity should be used. To determine the average sound velocity, a

sample cross-section should be made for optical evaluation. If the sound velocity jumps at certain

points, additional sound wave reflections will be produced at such points and lead to erratic

readings if disregarded (see also section 7.3.3.5).

If dramatic changes of the sound velocity are to be expected (e.g. if two material batches vary due

to different production parameters), it is recommended either to readjust the sound velocity within

shorter time intervals or to adjust to the actual batch-related sound velocities. This is to avoid

erratic readings.

Wall thickness measurement

Measuring objects with steel bases mostly exhibit a constant sound velocity in the base, even if the

alloying elements vary. For wall thickness measurement of the steel base, it is important to know

that the variations of sound velocity are so small that they can almost be neglected as far as their

influence on the measuring precision is concerned.

In other materials, however, such as non-ferrous metals or plastics, the sound velocity is subject to

higher levels of variation that may impair the measuring precision. For that reason it is required to

determine the sound velocity by means of a suitable method such as mechanical thickness

measurement of the uncoated sample. For thinner bases, it is recommended to make a material

cross sections.

Also strong sound attenuation may impair measurement. It occurs in some kinds of plastic

materials, for instance. In such materials, sound attenuation becomes stronger with increasing wall

thickness. When reaching a certain material thickness (depending on the type of material), the

sound attenuation is so strong that the amplitude of the reflected sound wave will not be strong

enough for being processed. This may be the case with plastic materials of around 1 to 2 mm

thickness. For such materials, the ultrasonic method is not suitable. If you have a new measuring

tasks, it is recommended first to create an A-scan image (see section 17) to check whether the

amplitude of the receive signal is strong enough to ensure reliable testing.

Variations of the sound velocities as function of material temperature

The sound velocity is also influenced by the temperature in the material layers. The temperature

coefficients also depend on the type of material with some materials exhibiting a non-constant

temperature profile.

The QuintSonic 7 sensor features an integrated temperature compensation for the sound velocities

of layers. The temperature compensation is adjusted to an average temperature coefficient of

typical industrial coating materials.

The temperature compensation will only work if sensor head and measuring object have the same

temperature. Generally, ultrasonic coating thickness measurement systems are not able to record