Page 1

PoroTest® 7

Technical Reference and Operating Manual

Advancing with T echnology ElektroPhysik

Page 2

© B13-A6 08/2014

Subject to change without notice.

ElektroPhysik Dr. Steingroever GmbH & Co. KG

Pasteurstr. 15

D-50735 Cologne, Germany

Tel. +49 (0) 221-75204-0; Fax +49 (0) 221 75204-67

www.elektrophysik.com; info@elektrophysik.com

ElektroPhysik USA

778 West Algonquin Rd., Arlington Heights IL 60005

Phone (847) 437-6616; Fax (847) 437-0053

epusa@elektrophysik.com

Caution!

Safety Note

Please refer to the safety notes in section 2 before starting

operation of PoroT est® 7.

Page 3

Table of contents

Table of Contents

1. General Information...........................E-3

1.1 Applications............................................ E-3

1.2 Description ................................................. E-3

1.3 Supply schedule .................................... E-3

1.4 Accessories............................................. E-4

2. Safety notes.......................................E-4

3. Preparing PoroTest® 7 for

operation ..........................................E-5

4. Preparing the test object....................E-6

5. Selection of the test electrode ...........E-6

6. Instrument settings ..........................E-6

6.1 T est parameters (test volt age) ................. E-7

6.2 Sensitivity.................................................. E-7

6.3 Limit for pores .......................................... E-8

6.4 High voltage trigger ................................. E-8

6.5 Signal LED ................................................ E-8

6.6 Display contrast ......................................... E-9

6.7 Display backlight ....................................... E-9

6.8 Language ................................................... E-9

6.9 Setting mode ............................................ E-9

6.10 Display mode ........................................... E-9

7. General remarks on Operation and

Application .....................................E-10

7. 1 T esting procedure....................................E-1 1

8. Power supply ...................................E-12

9. Charging storage batteries............E-12

10. Changing storage batteries ...........E-12

1 1.Error Messages ...............................E-13

12. Battery charging messages...........E-14

13. T est principle..................................E-15

14. T echnical specification ..................E-16

15.After-sales service ...........................E-18

Index......................................................E-20

ElektroPhysik E-i

Page 4

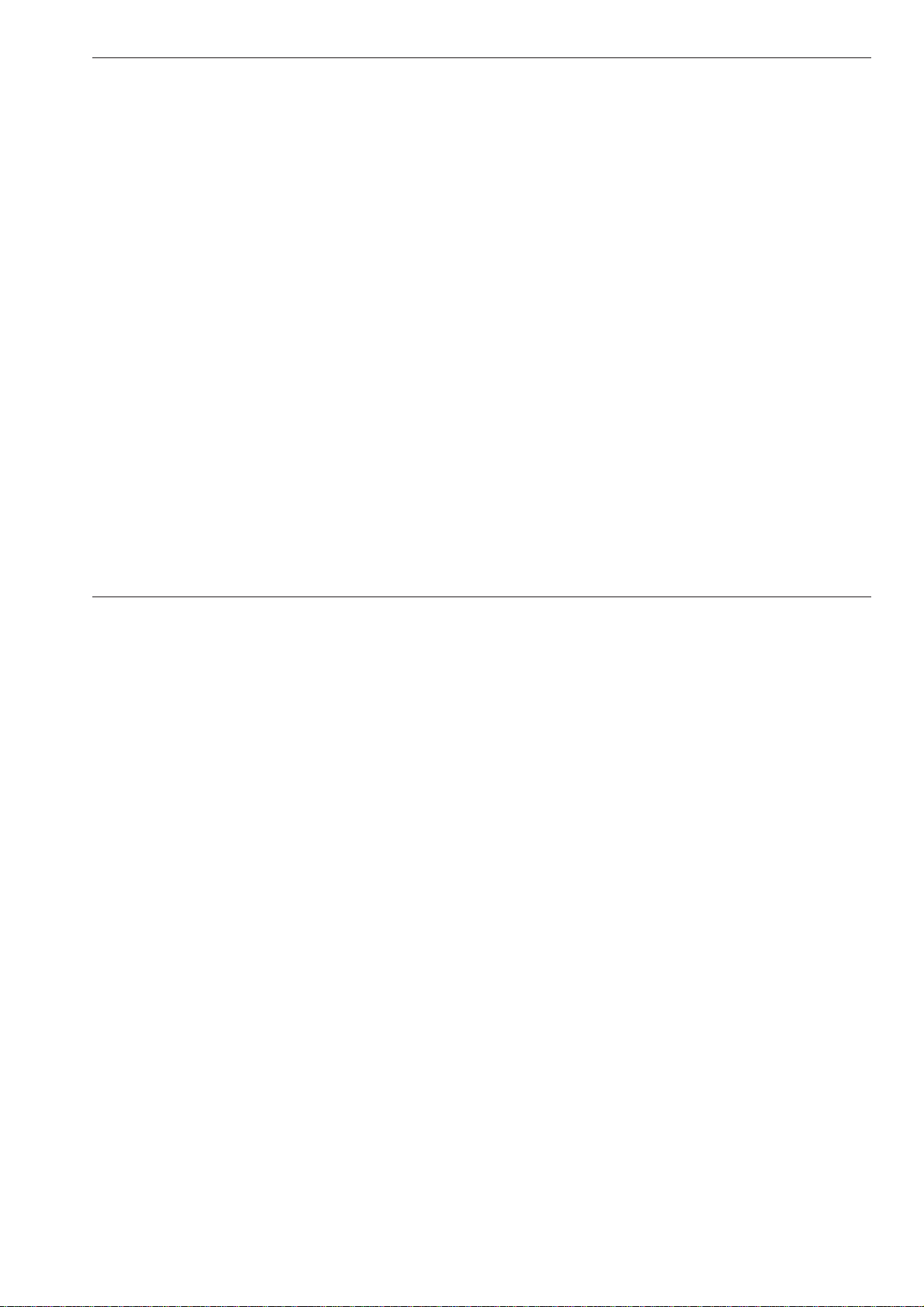

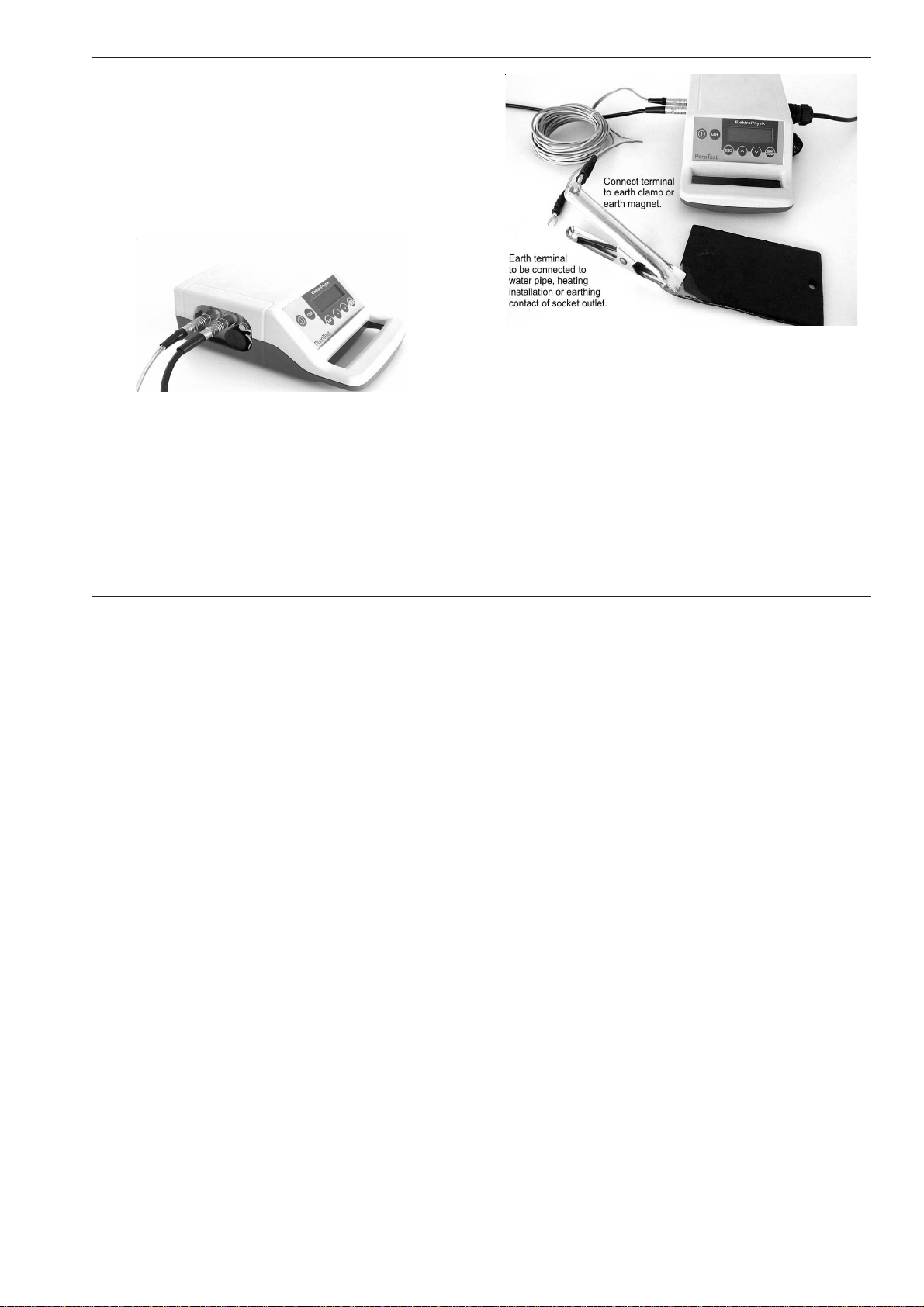

Fig. 1

PoroTest® wiring

5 Cable lug for protection earth with earth clamp

1 PoroTest® control unit

2 Mains cable

3 Equipotential cable (Earting cable) (green/yellow)

4 Connecting cable (probe-control unit) (black)

ElektroPhysik E-1

6 Cable lug for earth magnet or earth clamp

7 High voltage probe

8 Silicon-rubber electrode

9 Metall sweeper electrode

Page 5

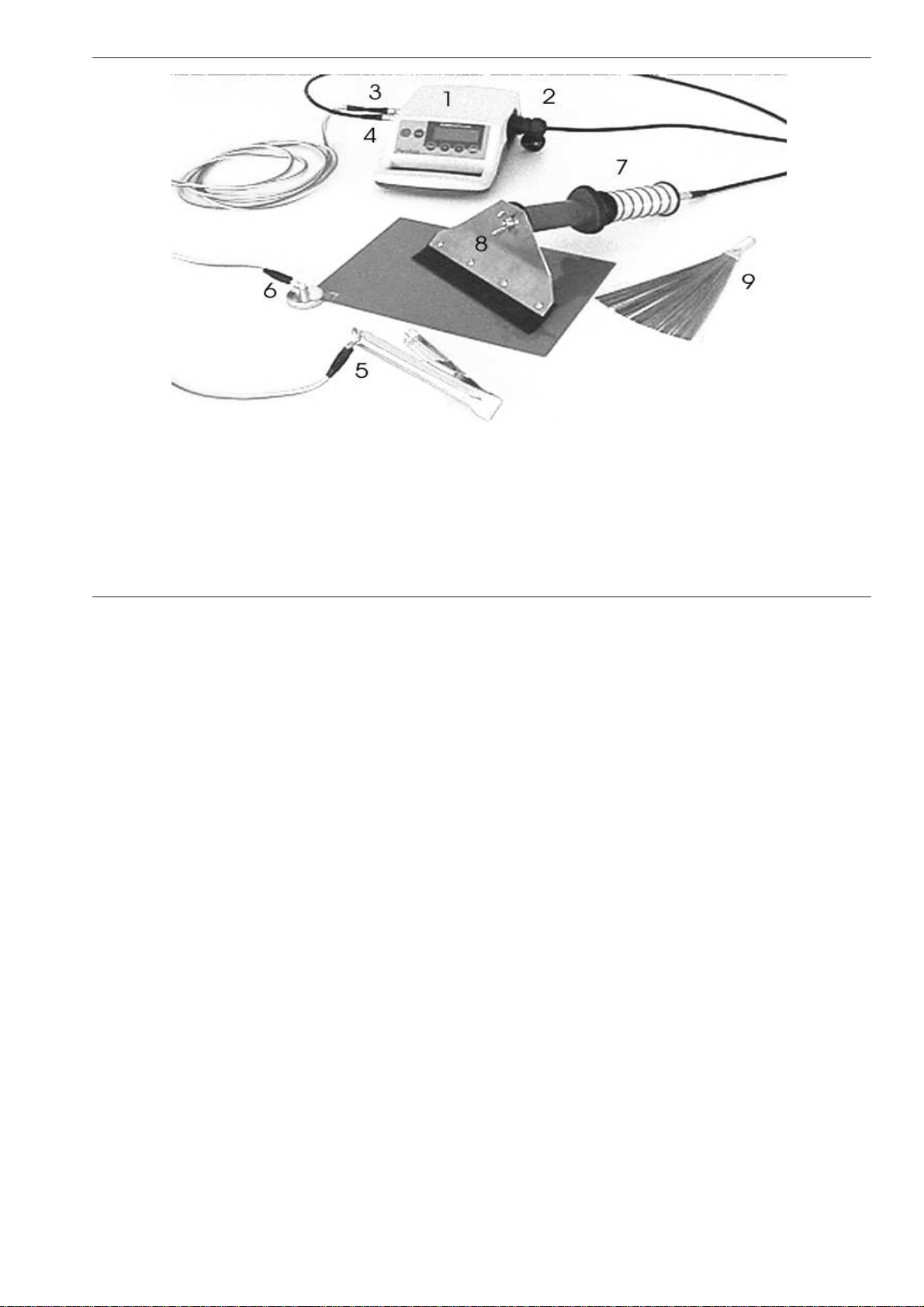

PoroTest® sockets

Mains cable socket

Sockets for earthing cable and high voltage probe

connecting cable

Fig. 3

Fig. 2

E-2 ElektroPhysik

Page 6

General information, Supply schedule

1. General Information

Designed for high voltage porosity detection, PoroT est®

7 conforms to the following industrial standards:

DIN 55670

DIN 50191 (VDE 0104)

DIN EN 61010 /Teil 1 (VDE 0411/ Part 1)

1.1 Applications

PoroTest® 7 holiday detector detects pores and holes

in insulating materials on conductive substrates such

as steel, aluminum, etc. Typical applications: Testing

linings and coatings applied on ducts, pipes, hulls, oil

and storage tanks , enamel, paint, rubber and bitumen

linings, vessels and tanks, GFK and other plastics

materials.Tanks or vessels must be filled with water or

other conductive material. To detect porosity, the

appropriate test voltage specific to the material thickness

is set on the control unit which applies, when activated,

a spark discharge at the moment a material flaw is

detected. In addition to the spark discharge, flaws are

counted and indicated by a visible and audible signal.

Depending on the test electrode, test voltage can be set

from 0.5...7 kV (P7) for coatings from 30 microns to

1.7mm or from 6 to 35kV (P35) for coatings from 1.4mm

to 11,3mm.

1.2 Description

The test instrument consists of a high voltage probe with

an integrated high voltage generator and a test electrode

connected to the probe. The control unit features a digital display and control pad. The control unit housing is

fully portable and made of rugged ABS plastic with an

integrated handle. The high voltage probe and control

unit are connected via a rugged cable

1.3 Supply schedule

- rugged plastics carrying case

- control unit with integrated storage battery

- connecting cable (probe - control unit)

- high voltage probe (optional accessories)

- metal sweeper electrode

- earth magnet

- earth clamp

- equipotential cable, 5 m (16 ft.) length

- mains cable

- shoulder belt

ElektroPhysik E-3

Page 7

Accessories, Safety notes

1.4 Accessories

· Aluminium case

· Brush, rolling spring, ring and right-angle

electrodes in various designs, silicon-rubber

electrode, 200 mm (7.8 ft.) width

· 3-pin plug, cable-free, directly plugs into the

integrated signal contact (make/break

contact).The signal contact is automatically

actuated if a pore is detected and may be used

for an external signal devices.

· Earthing rod

· Earthing/equipotential cable, 10 m (32 ft.) length

· Connecting cable for control unit and high voltage

probe in special lengths: 5m (16 ft.), 10m ( 32 ft.)

· Non-destructive coating thickness gauges, help

you to adjust test voltage specific to coating

thickness

2. Safety notes

- PoroTest® 7 is designed for safe use. When observing the safety notes, operation of the

instrument is absolutely risk free to the operator.

Current and capacitance limits conform to the

German standards DIN EN 61010/ Part 1 (VDE

0411/Part 1).

- Persons with cardiac pacemakers should consult

their physician about the possibility of interference

with the instrument.

- Caution!

Never use unearthed equipment! Before

use, make sure both, PoroT est® 7 and the test

object are well earthed (see section 3.)

- Only use rechargeable NiMH C-cells. Non

rechargeable batteries pose an explosion hazard

if on charge!

- After the control unit has been switched off,

discharge the high-voltage generator to earth.

- Do not carry out high voltage discharge to the

instrument or to the connecting cable between

instrument and probe.

E-4 ElektroPhysik

Page 8

Preparing PoroTest® 7 for operation

3. Preparing PoroTest® 7 for

operation

1. Plug the yellow/green earth cable into the twopin earth socket of the gauge. Connect one of

the wire ends to the earth clamp or the earth

magnet (for magnetic substrates). Fix the earth

clamp or the earth magnet to an uncoated spot of

the test object (Fig. 5)

Fig. 5

3. Use the wing nut to connect the test electrode to

Fig. 4

Earth cable (yellow / green), left

High voltage cable (black), right

2. Build-up an additional protection earth by securely

connecting the second end of the yellow/green

earth cable to a water pipe, heating installation,

to the earthing contact of a socket-outlet or to

another suitable earthed metal construction. For

in the field testing, the earth rod (available as an

option) should be used.

ElektroPhysik E-5

the high voltage probe (Fig. 1). The met al sweeper

electrode can directly be connected to the high

voltage probe.

4. Use the black high-voltage cable to connect the

high voltage probe to the control unit (4-pin

socket).

5. Hold the high voltage probe by the metal handle

to prevent static charge.

Page 9

Preparing / Instrument settings

6. Switch on the control unit (red button). A short

bleep indicates that the instrument is ready for

operation. If no bleep sounds, the storage

batteries should be recharged or replaced by new

ones.

Safty note:

As soon as the earth cable is disconnected from the

instrument, the feed of the high voltage probe will be

interrupted.

4. Preparing the test object

Make sure the surface of the test object is dry and clean.

5. Selection of the test electrode

For surfaces susceptible to scratches we recommend

to use the silicon rubber electrode. For uneven surfaces,

the metal sweeper electrode is recommended. Special

electrodes available upon request

6. Instrument settings

1. Swtich the gauge on. Press Menu/Enter key.

The following message appears:

Current readings

XXX...

Press Menu/Enter to go to the Main menu (your

selection is shaded on display).

2. Using Arrow-keys the following parameters can

be selected and adjusted according to your

requirements.

• Test parameters

• Sensitivity

• Limit for pores

E-6 ElektroPhysik

Page 10

Instrument settings

• High voltage trigger

• Signal LED

• Contrast

• Display backlight

• Language

• Setting mode

• Display mode

3. Use Arrow-keys to make your selection and

confirm by pressing Menu/Enter. Use Arrow-keys

to set and select your custom settings. Confirm

by pressing Menu/Enter. You will automatically

go back to the main menu and to the last

parameter selected.

4. To reset a changed parameter to the factory

setting, call requested parameter and press CLR.

Confirm by pressing Menu/Enter. The parameter

has been reset to default value.

5. By pressing ESC, you can quit parameter setting

and go back to the main menu without storing

your changes.

6.1 Test parameters (test voltage)

Excessive test voltage may damage the surface through

spark discharge whereas insufficient test voltage

prevents reliable porosity detection. An appropriate test

voltage must be set according to the thickness of the

coating to be tested.

Use Arrow-keys to adjust to the requested coating

thickness. T est volt age changes automatically according

to the adjusted coating thickness.

Test parameters

• Coat. thickn. XXX kV (default setting: 20.0 kV)

• Test voltage XXX mm (default setting: 5.97 mm)

6.2 Sensitivity

Sensitivity is adjustable from

• 1...15 (Default setting: 13)

Sensitivity can be adjusted from 1...15 (low...high). If the

pores to be expected are very large, sensitivity should

be adjusted to a low level so that the instrument will be

insensitive to very small pores.

ElektroPhysik E-7

Page 11

Instrument settings

High air humidity, moist surfaces, build-up of dust or

graphite may make the test object slightly conductive

causing leakage current to the surface. In such case,

sensitivity should also be controlled to a low level.

6.3 Limit for pores

Pore limit is the admissible number of pores. When

exceeding such limit, an alarm tone will sound. You can

choose from

• 0...255 (default setting: 0)

6.4 High voltage trigger

You can choose from

• Auto-off (default setting) = push-button

• No auto-off = (switch)

Auto-off = Push-button function:

The black rubber ring at the high voltage probe operates

as a bush-button. As long as you keep it pressed down,

voltage remains switched on.

Switch function :

The black rubber ring at the high voltage probe operates

as a switch. If you press once, voltage is switched on. If

you press again, voltage is switched off.

In both modes, push-button and switch mode, the red

ring a the high voltage probe lights up as long as high

voltage is fed.

6.5 Signal LED

You can choose from:

• All 3 indicators (Equipm. ON, Pores, Resid. voltage; default

setting)

• Pores & resid. voltage

• Equipm. ON & res. voltage

• Residual voltage

• Equipm. ON & pores

• Pores

• Equipm. ON

• Signal OFF

E-8 ElektroPhysik

Page 12

Instrument settings

6.6 Display contrast

Contrast can be set from

• 0...100% (default setting: 50%)

The higher the value, the higher the contrast.

The display contrast is susceptible to changes in ambient

temperature. Low temperatures result in poor contrast,

high temperatures increase contrast. Make sure to adjust

contrast not below a readable level, otherwise you will

not be able to make further settings or operate the gauge.

6.7 Display backlight

You can choose from

• ON (Display and keys are backlit)

• OFF (default setting)

6.8 Language

Y ou can choose from

• German

• French

• Spanish

• English (default setting)

• further languages upon request

6.9 Setting mode

For the dialogue „Test parameters“ you can choose

from

• Thickness [mm] ⇒ [kV] (default setting)

• Thickness [mils] ⇒ [kV]

Test voltage changes automatically according to the

adjusted coating thickness.

• Voltage[ kV] ⇒ [mm]

• Voltage [kV] ⇒ [mils]

If you change the parameter „voltage“, the coating

thickness will change accordingly.

6.10 Display mode

For the dialogue „Current readings“ you can choose

from:

• No. of pores

• Test voltage

• Pores and voltage (default setting)

ElektroPhysik E-9

Page 13

7. General remarks on Operation

and Application

- For highly conducting surfaces or surfaces subject

to capacitance loading, it is recommended to

select a sensitivity value low enough to prevent

damage but high enough to ensure a reliable pore

detection.

- The relationship between high voltage adjustment

and coating thickness as defined in the setting

menue conforms to the DIN 55670 regulations.

As test conditions may vary according to

configuration, this relationship should only be

considered as a rough setting. We recommend

to select sensitivity as follows:

1. For each test object, the minimum test voltage

should be determined at which pores can be

detected reliably.

2. After the minium test voltage has been

determined, the maximum test voltage at which

spark discharge starts to damage the test object

should be determined

A suitable test volt age results from the mean value

evaluated from these two values (minium and

maximum voltage).

E-10 ElektroPhysik

- If the high voltage probe is slowly approaching

ground - i.e. without any test sample being in

between - a reliable pore detection will only take

place if the distance between probe and ground

equals to the ajusted „layer thickness“. Hower, low

energy spark discharges may take place even

before the adjusted layer thickness has been

reached.

Please note: This is NOT a malfunction of the

instrument!

7. 1 Testing procedure

After you have carried out earthing according to chapter

3, after setting the instrument into operation and after

setting the instrument according to your requirements

press ESC to quit the main menu. Then choose „Current

readings“

Current values

No. of pores (default setting: 0)

Page 14

Testing procedure / Power supply

Please note:

The number of pores can be reset to Zero by pressing

CLR.

Please proceed as follows:

1. Hold the high voltage probe by the metal grip to

prevent static charge.

2. Switch on high voltage.

3. Slowly sweep the test electrode in parallel rows

across the surface to be tested. Make sure to scan

over the complete surface to be tested. The

scanning speed should not exceed 40 cm/s ( 15,8

inches/s). For counting pores and fissures, the

test speed should be around 2-5 cm/s (0.8…2

inch).

4. A sp ark discharge only occurs at the presence of

an interconnected pore or flaw. At the same time,

an alarm tone will sound and the red ring at the

high voltage probe will light up to indicate a pore

or flaw.

Please note:

- Even if voltage supply is turned off, residual

voltage remains at the high voltage probe. The

red ring flashing indicates residual voltage. The

higher the flashing frequency, the higher the

residual voltage. Residual voltage is available until

the red light goes off.

- Insufficient coating thickness or air bubbles will

not be detected.

- Coatings containing metal particles or carbon

powder are electrically conductive. They are not

suitable for being tested with PoroTest® 7 since

such particles would result in spark discharges

and thus simulate porosity.

8. Power supply

PoroTest® 7 is storage battery fed by four rechargeable

NiMH C-cells. The battery state is tested continuously

during operation. Erratic measurings due to low battery

do not occur. The battery state is indicated by the number

of bars appearing on the right display edge.

• Battery symbol and four bars (fully charged) to

• Battery symbol and zero bars (battery run down)

ElektroPhysik E-11

Page 15

Charging / changing storage batteries

The lower the number of bars, the lower the battery

charge. If batteries run down, the high voltage generator

fails to build up test voltage. PoroTest® 7 is not

serviceable until the batteries are recharged.

Important Note:

• Deep discharge of batteries must be avoided

otherwise they might be destroyed.

• If not in use for a longer period of time, batteries

must be fully recharged before storing them.

• It is recommended to recharge the batteries every

two months.

• It is highly recommended to use solely batteries

that have been tested and supplied by

ElektroPhysik.

Caution - Explosion hazard!

Only use rechargeable NiMH C-cells. Non rechargeable

batteries pose an explosion hazard if on charge!

9. Charging storage batteries

If you connect PoroTest® 7 to the mains, the message

„Mains connected“ appears and there will be an

automatic test whether recharge of batteries is necessary

or not.. If recharge is necessary, the message „On

charge...“ appears, if not, „Mains operation“ appears.

You can interrupt the recharge procedure at any time

by pressing Menu/Enter (see chapter 12 „Battery

charging messages“).

The recharging procedure is completely menu controlled.

Please follow the instructions on display.

10. Changing storage batteries

1. Switch the instrument off.

2. Open the battery compartment (black, round

covers at bottom side). Remove old batteries.

3. Replace with fresh ones. Note polarity . Plus must

be connected to battery cover direction.

4. Place cover on battery compartment, push

batteries down and make sure lid fits tightly.

E-12 ElektroPhysik

Page 16

11. Error Messages

Error Message Cause Remedy

Probe or GND error Probe connecting or earthing error

Check probe cable for damages.

Connect probe cable properly.

Earth equipment properly.

Probe connection error

Data communication failure. Connection

between probe and control unit has been

interrupted during operation.

Check probe cable for damages.

Connect probe cable properly.

Probe voltage drop Voltage drop between control unit and probe

Recharge battery or switch to mains supply or

attach a shorter connecting cable

Low battery. Please

recharge!

Low battery Recharge will be necessary soon.

Battery run down. Please

recharge.

Insufficient battery charge Immediate recharge necessary.

Long bleep - instrument

switches off automatically

Deep discharge protection Immediate battery discharge necessary.

!

Data have been changed or deleted from

memory

Please send the instrument to your dealer for

repair.

Error messages

After troubleshooting, all error messages can be quit by pressing ESC. If you press Menu/Enter you

will go back to the main menu.

ElektroPhysik E-13

Page 17

12. Battery charging messages

Message Cause Remedy

Mains connected Mains connected successfully --

Mains connection

interrupted

Mains connection interrupted

Check connections.

Check mains supply.

Check safety fuse of control unit (next to

the mains socket)

Mains operation

Battery charge completed or

batteries not available

--

please wait... Checking battery state --

On charge... Charging in progress

Charging procedure can be interrupted

by the operator.

Charging completed Battery charge completed --

Charge interrupted

Battery charge has been interrupted

by the operator

--

Storage batteries

removed or faulty

Batteries have been removed during

charge or faulty batteries

Insert batteries or replace by fresh ones.

Storage batteries faulty

or temperature too high

Deep discharge or faulty batteries or

or excessive temperature situation

(unsuitabel for battery charge)

Replace batteries.

Keep PoroTest 7 cool when recharging

batteries.

Confirm all messages by Menu/Enter-key.

Battery charging messages

E-14 ElektroPhysik

Page 18

13. Test principle

electrically conductive electrode

protection earth

insulating coating

earth clamp

conductive base

When scanning the high voltage probe over the nonconductive material, a spark discharge is produced at

the presence of a pore. The gauges identifies the sparks

to register and count them accordingly.

Test principle

ElektroPhysik E-15

Page 19

14. T echnical specification

High voltage probe P 7 P 35

Test voltage ranges: 0.5…7 kV 6…35 kV

Coating thickness

0.03 mm...1.7 mm

1 mils …67 mils

1.4 mm...11.3 mm

55 mils …444 mils

Type of voltage: Direct current (DC)

Test voltage indication: 3-digit LC display

Accuracy of voltage setting: ±(0.1 kV + 3% of reading)

Dimensions / weight of

high voltage probe:

274mm x 63 mm (l x dia.) / 550 g 10.8" x 2.48" / 1lbs. 3oz

Dimensions / weight of control unit

225 mm x 150 mm x 85 mm (L x W x H) / 1400 g

8.87" x 5.9" x 3.35" (L x W x H) / 3 lbs. 1 oz

Alarm signal: 90 dB, 0.1s / pore, continuous tone in case of short-circuit

Signal output: potential free, Umax: 100V, lmax: 0,1A

Storage battery: 4 C cells. IEC LR 14, 3,5 Ah, NiMH, replaceable

Storage battery life at maximum voltage:

PoroTest 7-P 7 approx. 20 h

continuous operation

PoroTest 7-P 35: approx. 10 h

continuous operation

T echnical specification

E-16 ElektroPhysik

Page 20

Technical specification

Storage battery charging time:

approx. 4 hours

Mains voltage: 115 to 230 V, 50/60Hz, automatic switch

Operating temperature: 0°...+50°C / 32°…122°F

Type of protection: IP 65 (dust and hoseproof)

Probe cable: standard length approx. 1.5m / 59"; 10 m / 393.70" (max.)

Earth cable: 2 x 5m / 2 x 196.85" green/yellow, flexible

Mains cable: 2 m / 78.74" mains plug with earthing contact

Humidity: avoid dew on the surface (refer to DIN 55 670)

Safety fuse: 2,5 A time-lag fuse

Industrial standards and regulations

DIN 55670

DIN 50 191 (VDE 0104)

DIN EN 61010/Part 1 (VDE 0411/Part 1)

ElektroPhysik E-17

Page 21

15. After-sales service

ElektroPhysik’s manufacturing practices and quality

management systems according to DIN EN ISO 9001

ensure highest quality of this product.

Any operating problems or trouble should be reported

to the ElektroPhysik service department. Plesase include

a short description of the problem.

For any further question regarding application, use or

techncial data please call your dealer or directly refer to

ElektroPhysik.

Please refer to the next page for ElektroPhysik contact

addresses.

After-sales service

E-18 ElektroPhysik

Page 22

D

ElektroPhysik Dr. Steingroever GmbH

Pasteurstr. 15

D-50735 Cologne, Germany

Tel: +49 (0) 221 75204 0

Fax: +49 (0) 221 75204 67

www.elektrophysik.com

info@elektrophysik.com

USA

ElektroPhysik USA

778 West Algonquin Rd.

Arlington Heights, IL 60005

Tel: +1 847 437 6616

Fax: +1 847 437 0053

www.elektrophysik.com

epusa@elektrophysik.com

ElektroPhysik E-19

Page 23

Index

electrically conductive E-11

erratic measurings E-12

F

Symbole

4-pin socket E-5

A

air bubbles E-11

alarm tone E-11

Auto-off E-8

B

bars E-12

battery compartment E-12

black rubber ring E-8

C

C-cells E-4, E-12

carbon powder E-11

control unit E-1, E-3, E-4, E-5, E-6

E

earth socket E-5

earthing cable E-2

E-20 ElektroPhysik

flashing E-11

H

high voltage probe connecting cable E-2

I

insulating E-3

M

mains E-1, E-2, E-3, E-8, E-11, E-12

mains cable socket E-2

metal particles E-11

N

NiMH E-4, E-12

number of bars E-12

number of pores E-11

P

polarity E-12

protection earth E-1, E-5

Push-button E-8

Page 24

push-button E-8

R

recharging procedure E-12

red button E-6

red ring E-8, E-11

red ring flashing E-11

residual voltage E-11

rubber ring E-8

S

scanning speed E-11

signal contact E-4

spark discharge E-3, E-7, E-11, E-15

static charge E-5, E-11

Switch on E-6, E-11

T

Test voltage E-7, E-9

test voltage E-3, E-4, E-7, E-12

troubleshooting E-13

two-pin earth socket E-5

ElektroPhysik E-21

Loading...

Loading...