Page 1

ElektroPhysik

Operating instructions

Coating thickness gauges

MiniTest 2500 and MiniTest 4500

Page 2

© ElektroPhysik MiniTest 2500 - MiniTest 4500 2 of 73

© ElektroPhysik

Version 1.0 14.06.2018

Gauge software Version: from 1.0.1

Sensor Software: from 1.0

Subject to technical change without notice.

ElektroPhysik

Dr. Steingroever GmbH & Co. KG

Pasteurstr. 15

50735 Cologne

Germany

Tel.: +49 221 752040

Fax.: +49 221 7520467

Internet: http://www.elektrophysik.com/

Mail:: info@elektrophysik.com

Page 3

Index

© ElektroPhysik MiniTest 2500 - MiniTest 4500 3 of 73

Index

1. Introduction ............................................................................................................................... 8

2. First steps .................................................................................................................................. 9

2.1 Inserting batteries and connecting the sensor ....................................................................... 9

2.2 Operation of the gauge ........................................................................................................ 10

3. Description of the measuring system.................................................................................... 11

3.1 Gauge ................................................................................................................................. 11

3.1.1 General ....................................................................................................................... 11

3.1.2 Front view ................................................................................................................... 11

3.1.3 Operating keys ............................................................................................................ 12

3.1.3 Interfaces .................................................................................................................... 12

3.1.4 Power supply .............................................................................................................. 12

3.1.4.1 Batteries and rechargeable batteries ........................................................................ 12

3.2 Sensors ............................................................................................................................... 13

3.2.1 Sensors of the MiniTest 1100 – 2100 - 3100 - 4100 series.......................................... 13

3.2.1.1 Adaptation of sensor types F05, F1.6, F3, F1.6/90, F2/90, F10, F20, N.08 Cr,

N02, N1.6, N1.6/90, N2/90, CN02 and FN1.6, FN1.6P, FN 1.6/90, FN2/90 ....................... 13

3.2.1.2 Adaptation of sensor types N10, N20 and N100. ................................................ 14

4. Measuring, Storage and Data Processing in DIRECT or APPL-BATCH mode .................... 15

4.1 Switch on / start-up screen .................................................................................................. 15

4.2 Structure of the APPL-BATCH system ........................................................................... 17

4.3 Switching APPL-BATCH mode on / off ................................................................ .......... 18

4.4 Displaying the number of active APPL-BATCH .............................................................. 19

4.5 Selection of an APPL memory ....................................................................................... 19

4.6 Selection of a BATCH memory ...................................................................................... 19

5. Measuring ................................................................................................................................ 20

5.1 Important Notes on Coating Thickness measurement ......................................................... 20

5.1.1 Interpretation of readings ............................................................................................ 20

5.2 Basic settings ...................................................................................................................... 20

5.3 Preparing measurement ...................................................................................................... 21

5.3.1 Calibration ................................................................................................................... 21

5.4 Taking readings ................................................................................................................... 21

5.4.1 Taking readings without using the sensor stand .......................................................... 21

5.4.2 High-precision stand ................................................................................................... 22

5.4.3 Duplex coating systems .............................................................................................. 22

5.5 Errors during measurement ................................................................................................. 22

5.6 Measurement on high temperatures using high-temp sensors ............................................ 22

Page 4

Index

© ElektroPhysik MiniTest 2500 - MiniTest 4500 4 of 73

6. Calibration ............................................................................................................................... 24

6.1 General notes on calibration ................................................................................................ 24

6.2 Calibration methods ............................................................................................................ 25

6.2.1 Factory pre-setting ...................................................................................................... 25

6.2.2.1 Zero Calibration ..................................................................................................... 25

6.2.2.2 Two-point Calibration ............................................................................................. 25

6.2.2.3 Multi-point Calibration ............................................................................................ 25

6.2.2.4 Two-point Calibration without zero ......................................................................... 26

6.2.2.5 Calibration through a coating (CTC) ...................................................................... 26

6.4.3.1 Calibration of FN-type sensors ................................................................ ............. 26

7. Calibration ............................................................................................................................... 27

7.1 Activate factory settings ................................................................................................. 27

7.2 Zero Calibration ............................................................................................................. 27

7.3 Two-point calibration (zero setting plus one calibration foil) ........................................... 28

7.3 Multi-point calibration (zero setting plus up to four calibration foils) ............................... 29

7.5 Two-point calibration using two calibration foils without zero calibration ........................ 30

7.6. Calibration Through the Coating .................................................................................... 33

7.7. Sensors N10 and N20 ................................................................................................... 34

7.7.1 Standardization (Acquisition of Infinite Value) ............................................................. 34

7.7.2 Two-point calibration (zero setting plus one calibration foil) ................................... 34

7.7.3 Elimination of dielectric interferences of the coating material ................................. 35

7.8 N100 Sensor ................................................................................................................. 35

7.8.1 Standardization (Acquisition of Infinite Value) ........................................................ 35

7.8.2 Two-point calibration (zero setting plus one calibration foil) ................................... 36

7.8.3 Elimination of dielectric interferences of the coating material ................................. 36

7.9 Sensor F20 .................................................................................................................... 37

7.10 Sensor F50 .................................................................................................................... 37

7.11 Tube sensors F1.6/90, F2/90, N1.6/90 and N2/90 ................................ ......................... 38

7.12 Chrome Coatings on Copper ......................................................................................... 38

7.13 Sensor CN02 ................................................................................................................. 38

7.14 Recalibration in an APPL memory line .............................................................................. 38

7.15 Shot-blasted and rough surfaces .................................................................................. 40

7.15.1 General .................................................................................................................. 40

7.15.2 Method A (roughness Rz > 20µm) ......................................................................... 40

7.15.3 Method B (roughness Rz < 20µm) ......................................................................... 40

7.15.3 Method C Calibration with two calibration foils of different thickness ...................... 40

8. Data Management ................................................................................................................... 41

8.1 Batches ............................................................................................................................... 41

Page 5

Index

© ElektroPhysik MiniTest 2500 - MiniTest 4500 5 of 73

8.1.1 General ....................................................................................................................... 41

8.2 Offset .................................................................................................................................. 41

8.3 Block size ............................................................................................................................ 41

8.4 Upper limit / Lower limit ................................................................................................. 41

8.5 Single values / Continuous measurement mode ............................................................ 42

8.6 Measuring with statistics ..................................................................................................... 42

8.7 Taking a series of measurement with statistical calculation ........................................... 43

8.8 Deleting outliers or erratic readings ............................................................................... 43

8.9 Storage capacity overflow .............................................................................................. 44

8.10 Display or print-out of a series of measurements ............................................................... 44

8.10.1 Single value statistics ............................................................................................. 44

8.10.2 Block value statistics .................................................................................................. 45

9. Deletion.................................................................................................................................... 46

9.1 Deleting the last reading ................................................................................................ 46

9.2 Deleting statistical values ................................ .............................................................. 46

9.4 Deleting a series of measurements including limits and statistics within an APPL-BATCH

memory ..................................................................................................................................... 46

9.5 Deleting limit values within an APPL-BATCH memory ......................................................... 46

9.6 Deleting all series of measurements incl. statistics, limits and calibration values of an

APPL memory ........................................................................................................................... 47

9.7 Total Reset .................................................................................................................... 47

10. Data output and transfer ....................................................................................................... 48

10.1 Printing data ...................................................................................................................... 48

10.2 Data transfer to PC (terminal program) .............................................................................. 48

10.3 Read out data via a PC ..................................................................................................... 49

11. Further functions .................................................................................................................. 50

11.1 Initialization ....................................................................................................................... 50

Initial functions and settings ................................................................................................. 50

11.1.1 Total Reset ........................................................................................................ 50

11.1.2 LCD Segment Test ............................................................................................ 50

11.2 Gauge configuration .......................................................................................................... 50

11.2.1 Blockgröße ................................................................................................................ 50

11.2.2 Display illumination ................................ ................................................................ 51

11.2.3 Keypad illumination ................................................................................................ 51

11.2.4 Acoustic signal ....................................................................................................... 51

11.2.5 Time and date stamp ............................................................................................. 51

11.2.6 Time and date ........................................................................................................ 51

11.2.7 Measuring unit: ‘metrical’ - Inch’ (imperial) ............................................................. 52

11.2.8 Automatic data transfer in continuous mode .......................................................... 52

Page 6

Index

© ElektroPhysik MiniTest 2500 - MiniTest 4500 6 of 73

11.2.9 Timestamp ............................................................................................................. 52

11.2.10 Setting of display colours for measurements ...................................................... 52

11.2.11 Setting of display colours for readings above preset limits ................................. 53

11.2.12 Setting of display colours for readings below preset limits .................................. 53

11.2.13 Optional alarm output – Setting of signal length of the measuring value............. 53

11.2.14 Optional alarm output – Setting of signal length for readings above limits .......... 53

11.2.15 Optional alarm output – Setting of signal length for readings below limits .......... 53

11.2.16 Configuration of the optional foot switch ............................................................. 53

11.2.17 Pairing of a BLUETOOTH printer ....................................................................... 53

11.2.19 Format of logged measuring values ................................................................... 54

11.2.20 SENSOR INIT .................................................................................................... 54

11.2.21 „POWER SUPPLY“ Setting ................................................................................ 54

11.2.22 „POWER OFF“ Switch off time ........................................................................... 55

11.2.23 SYSINFO ........................................................................................................... 55

11.2.24 Table of basic settings for MiniTest 4500 ................................................................ 56

11.2.25 Table of basic settings for MiniTest 2500 ................................................................ 57

12. Accessories ........................................................................................................................... 58

12.1 General ............................................................................................................................. 58

13. Care and maintenance .......................................................................................................... 59

13.1 Care ................................ ................................................................................................ .. 59

13.1.1 Using NiMH rechargeable batteries ........................................................................... 59

13.2 Maintenance...................................................................................................................... 60

14. Technical data ....................................................................................................................... 61

14.1 Gauge specification ........................................................................................................... 61

14.2 Sensor specifications ................................................................................................ ........ 62

14.3 Standard supply ................................................................................................................ 65

14.3.3 Coating thickness gauge MiniTest 2500/ 4500 with interchangeable sensor ............. 65

14.3.4 Interchangeable sensors for MiniTest 2500/4500 ................................ ...................... 65

14.4 Accessories ....................................................................................................................... 66

15. Annexe ................................................................................................................................... 67

15.1 Error messages and trouble shooting ................................................................................ 67

15.2 Statistical terms ................................................................................................................. 68

15.3 Safety notes ................................ ................................................................ ...................... 69

15.4 Declaration of conformity according to EU directive ........................................................... 70

15.5 Return of used equipment ................................................................................................. 70

15.6 Service-Adressen ................................ ................................................................ .............. 71

16. Change history ...................................................................................................................... 72

17. Index ...................................................................................................................................... 73

Page 7

Index

© ElektroPhysik MiniTest 2500 - MiniTest 4500 7 of 73

Page 8

1. Introduction

© ElektroPhysik MiniTest 2500 - MiniTest 4500 8 of 73

1. Introduction

The new coating thickness gauges MiniTest 2500 and MiniTest 4500 combine high precision modern

measuring technique and a classic handling concept.

Coating thickness gauges MiniTest 2500 and MiniTest 4500 measure non-destructively according

to the magnetic induction or the eddy current principle depending on the sensor type connected to

the gauge. The gauges comply with the following standards:

DIN EN ISO 1461

DIN EN ISO 2064 DIN EN ISO 2178

DIN EN ISO 2360

DIN EN ISO 2808

DIN EN ISO 19840

ASTM B244

ASTM B499

ASTM D7091

ASTM E376-03

AS 3894.3-2002

SS 18 41 60

SSPC-PA 2

The portable gauge is used for quick and precise non-destructive coating thickness measurement in

the field of industrial corrosion protection and is used by manufacturers and end users of corrosion

protected products, by authorities and inspectors,in electroplating and paint shops as well as in

chemical industry, automotive production, ship building, aviation and tool and machine engineering.

MiniTest coating thickness gauges are equally qualified for use in a laboratory as well as in rough

industrial environments or construction sites thanks to their particularly rugged housing designed in

protection class IP65.

A broad selection of measuring sensors is available for the MiniTest 2500/4500 line of coating

thickness gauges allowing to handle standard applications as well as more complex measuring tasks

as for example measurement in tubes or thick coatings up to 100mm coating thickness.

The intelligent MiniTest-sensors also cope with sophisticated applications such as measurement of

objects with unusual geometry or coatings with special material properties. This wide range of

applications is possible through memorization of corresponding key data within the sensor which are

automatically taken into account at each measurement

The scope of application is determined by the sensor connected to the gauge:

F-type sensors work according to the principle of magnetic induction and can measure non-

magnetic coatings such as paint, enamel, rubber, aluminum, chrome, copper, zinc etc applied on

iron and steel (including steel alloys and hardened magnetic steels).

N-type sensors work according to the eddy current principle and measure insulating coatings

such as paint, anodizing, ceramics etc. applied on all non-ferrous metals (for example aluminum,

copper, zinc die cast, brass etc.) including austenitic steels.

FN-type sensors combine both principles and identify the substrate underneath the coating thus

automatically switching to the correct measuring principle to measure on base material steel or

non-ferrous metal.

Modern data administration allows simple access to the internal data memory with maximum

storage capacity of up to 2 million measuring values. MiniTest 4500 features a data memory with

‘APPL-BATCH mode’ allowing measurement and storage of readings in a user definable memory.

A total of up to 2,000,000 readings and more than 9,800 batches can be evaluated according to

different statistical principles. The option limit setting (LIMIT) offers to determine Cp and Cpk

values.

Both models feature a USB interface to connect to notebooks and PCs. MiniTest 4500 additionally

offers a Bluetooth interface for wireless data transfer to mobile devices like Smartphones and

printers directly on site..

Page 9

2. First steps

© ElektroPhysik MiniTest 2500 - MiniTest 4500 9 of 73

2. First steps

This section addresses first time users of a MiniTest coating thickness gauge introducing the basic

functions of the gauge and demonstrating how to take readings.

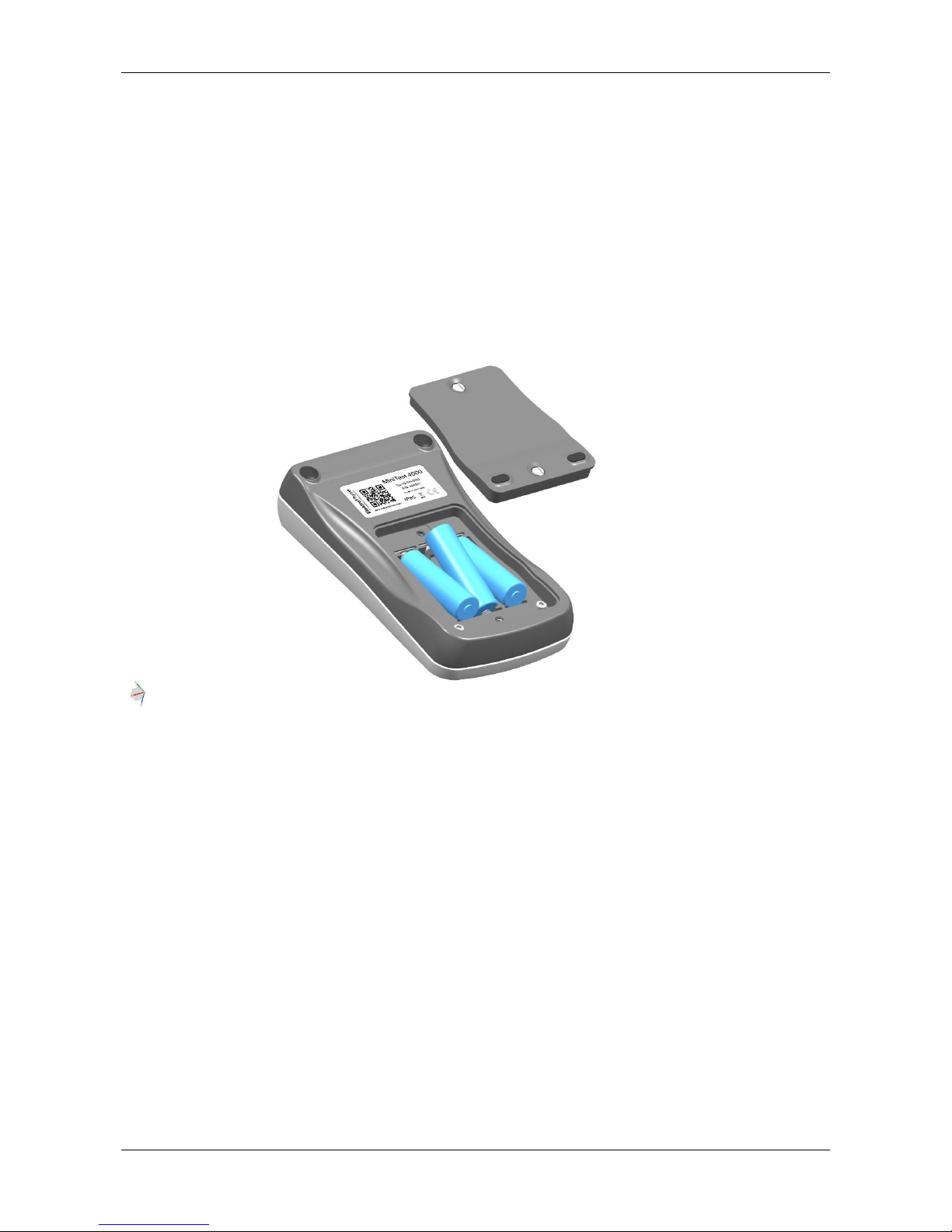

2.1 Inserting batteries and connecting the sensor

a) Withdraw the gauge and the batteries from the storage case.

b) Untighten the screws of the battery compartment on the back of the gauge using for example a

coin and open the battery compartment.

c) Insert the batteries from the supply schedule observing correct polarity (see illustration).

d) Close the battery compartment and fix the lid with the screws.

Page 10

2. First steps

© ElektroPhysik MiniTest 2500 - MiniTest 4500 10 of 73

2.2 Operation of the gauge

Press the red ON-OFF key to switch the gauge on.

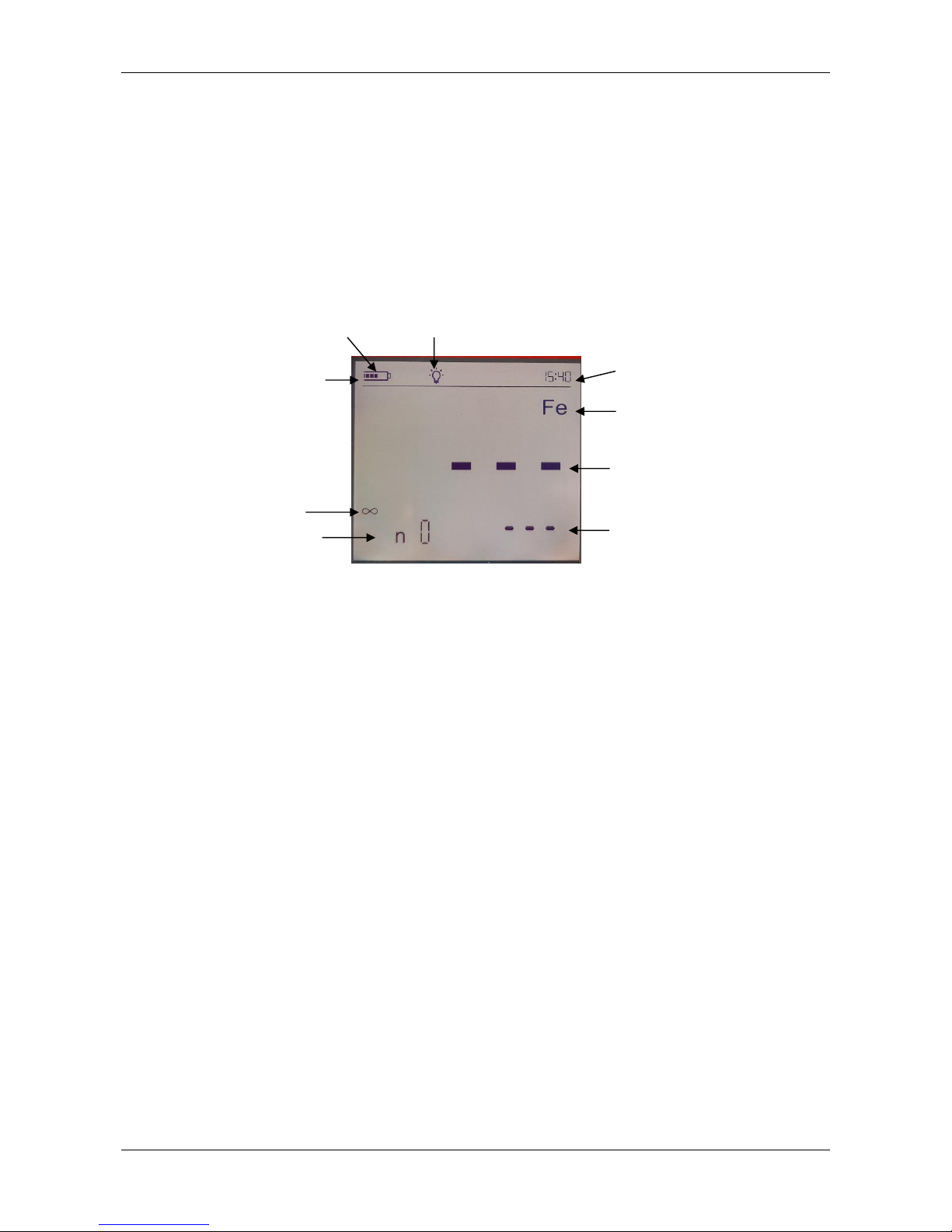

a) The gauge is now switched to measuring mode (see illustration.) and is ready to measure. The

display shows the measurement screen without measuring value.

b) Upon initial operation the measuring series is set to „Direct Mode“ and factory calibration is

preset (For more detailed information on „Calibration” refer to chapter 6).

c) The factory pre-setting is recommended for quick and easy measurement and if a medium

measuring accuracy is sufficient. For a detailed description of different calibration methods refer

to chapter 6.2.

d) To take readings, place the sensor in right angle onto the measuring object. The coating

thickness will be displayed on the screen after a short while (less than a second). Remove sensor

and take next reading.

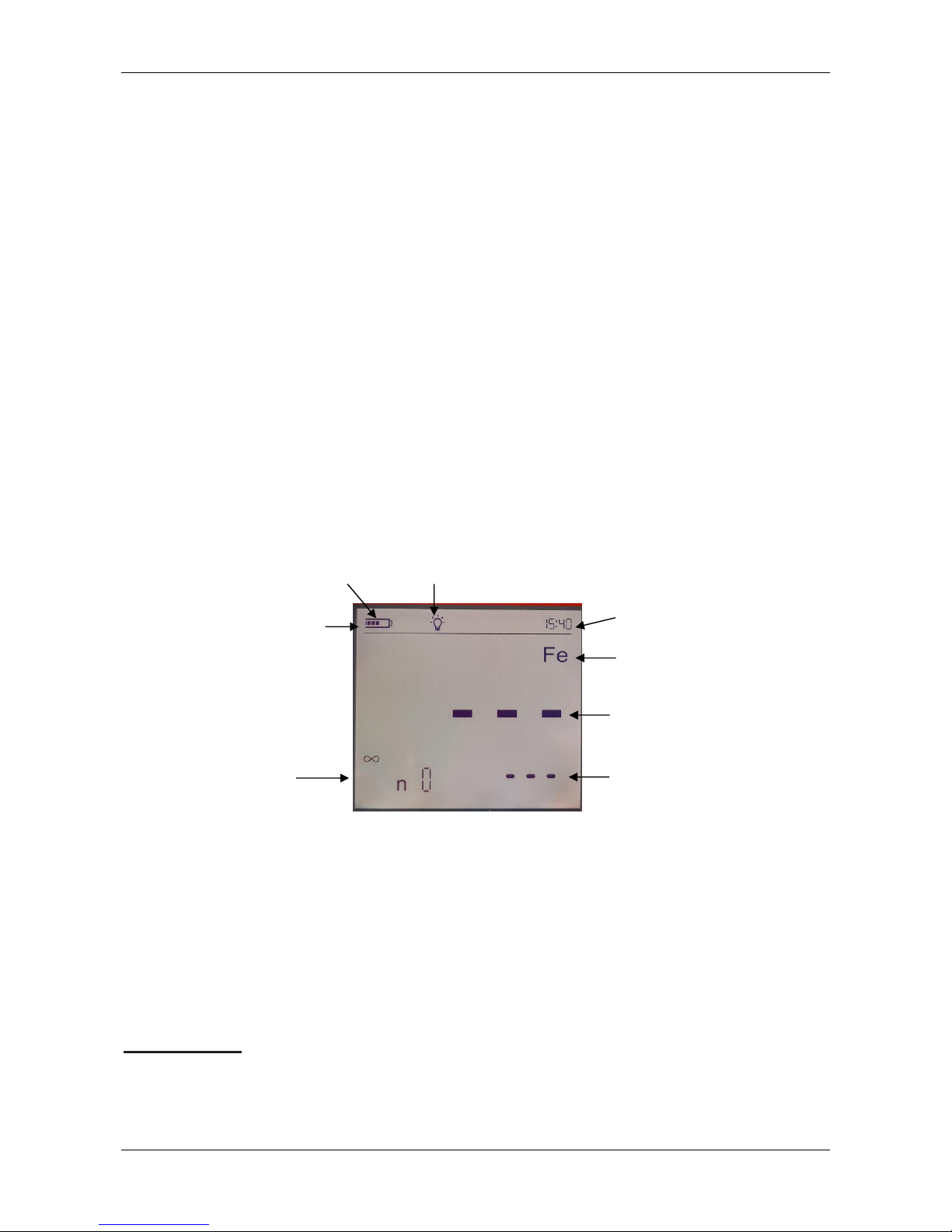

Status bar

Display Illumination

Battery-

level

Activated measuring

principle: Fe

Time

Number of

readings

Measuring

unit

current

reading

Sensor is lifted

from surface

Page 11

3. Description of the measuring system

© ElektroPhysik MiniTest 2500 - MiniTest 4500 11 of 73

3. Description of the measuring system

3.1 Gauge

3.1.1 General

A large optionally backlit display allows easy reading of measuring values and statistical data.

The colour of the backlit display is user definable thus offering for example quick marking of a

reading within limits in green and outside limits in red.

The housing is made of an impact-proof and scratch-resisting material and conforms to protection

class IP 65.

3.1.2 Front view

1. USB-Interface

2. Battery charge level

3. Note: Selected APPL-Batch group

4. Offset note: Offset is activate

5. Limit note: Limits are active

6. Note: Reading is within, above or below preset limits

7. Note: Statistical value (here: Mean value)

8. Note: Readings are blocked

9. Note: Number of readings

10. Zero key to calibrate zero without calibration standard/

Double assignment Recording of infinite value when

working with sensor types N10, N20, N100

11. Calibration key for calibration with precision standards /

Double assignment Calibration through a coating (CTC)

12. Key to select measuring principle Ferrous, Non-Ferrous

or Auto FN when using FN sensors /

Double assignment Switch to continuous mode

13. Activation key for DIRECT- or APPL-BATCH Mode

14. Key to access a subgroup (BATCH) within an

APPLICATION /

Double assignment Activate / Deactivate Bluetooth

Interface

15. Key to enter limit values /

Double assignment Key to enter an Offsets

16. Arrow keys for navigation in settings, e.g. calibration and

limit values, key lock

17. Key to confirm an action /

Double assignment ESCAPE or QUIT function

18. Arrow keys for navigation in settings, e.g. calibration and

limit values, key lock

19. Delete key

20. ON/OFF switch and initial functions

21. Key to visualize statistical values and transfer measuring

and statistical values to printer, PC or APP Miniview

22. Measuring unit: Automatically selected according to

preselection of the sensor connected: µm, mm or mils,

inches

23. Current reading

24. Active calibration method is displayed; here ZERO

25. Active measuring principle N-Fe (when measuring on

non-ferrous metal) or FERROUS (when measuring on

steel

26. Display of time

27. Sensor plug

28. Note: Bluetooth active/paired

29. Optional socket: 1. To connect an external trigger (e.g.

footswitch), 2. To trigger a signal confirming the

measuring value (optical or acoustical), RS 232 Interface

30. Note: PC connection via USB active

31. Note: Keypad locked

2

3

4

5

7

8

22 6 9

15

14

16

17

18

19

21

20

10

11

12

13

23

24

25

1

26

27

29

28

30

31

Page 12

3. Description of the measuring system

© ElektroPhysik MiniTest 2500 - MiniTest 4500 12 of 73

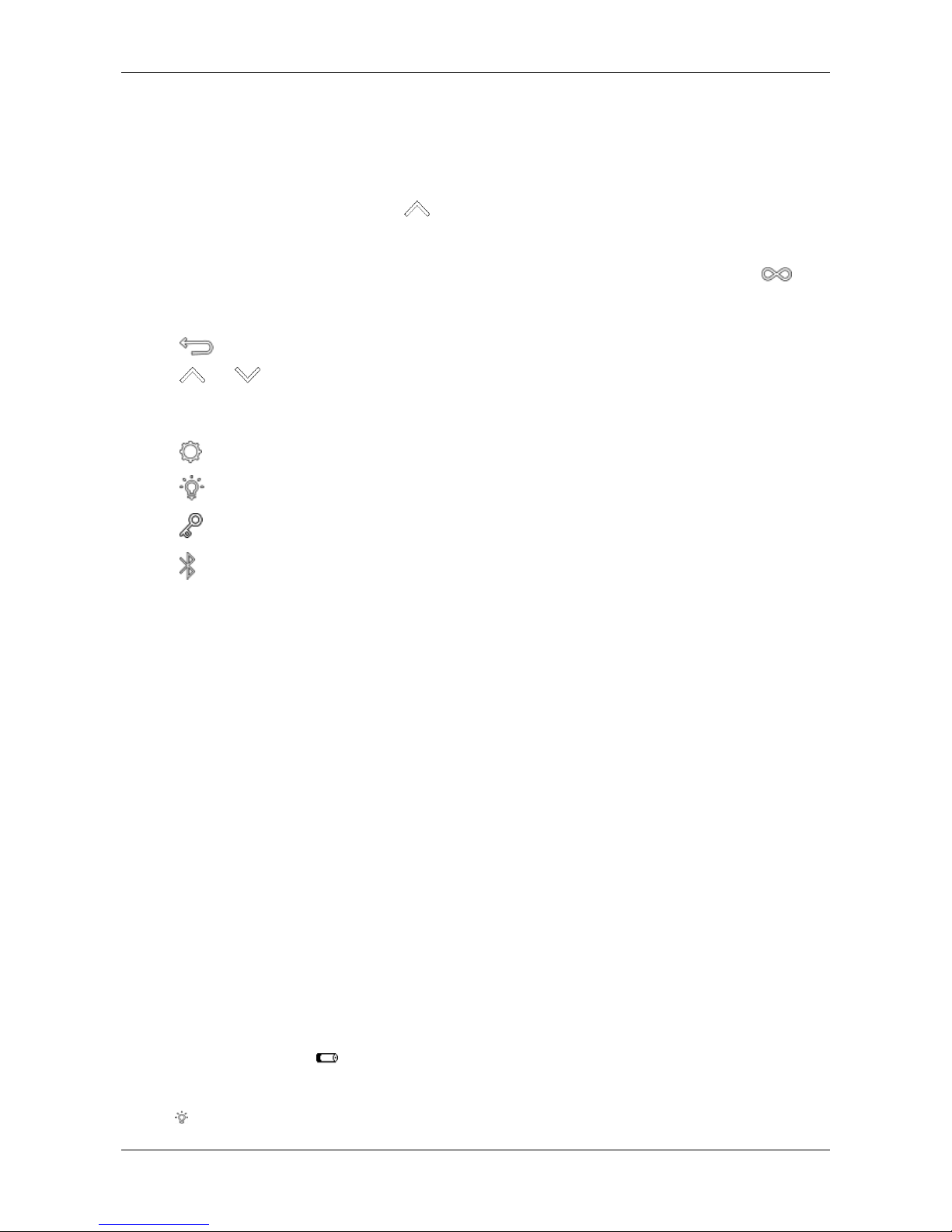

3.1.3 Operating keys

MiniTest 2500 and MiniTest 4500 are equipped with a generous keypad. One key pressure is

sufficient to access functions like calibration, limit setting, and display of statistics.

The ON-OFF-key serves to switch the gauge on or off. Switching the gauge on by simultaneously

pressing the ON-OFF key and the keys + Clear, a total reset is carried out and the gauge returns

factory settings (For more detailed information on initial functions refer to section 11.1).

All keys have a double assignment. Simple pressure of a key will access the functions shown in

major writing like ‘Zero’ and ‘Stats’ (Statistics). Functions shown in minor grey writing like ‘ ’ and

‘Send’ are accessed by keeping the key depressed for approximately 0.5 seconds.

- ‘OK’ confirms settings and selects menu points.

- ‘ ’ quits an action or a menu.

- ‘ ’ or ‘ ’ modify settings and navigate within initial functions.

- ‘Clear’ deletes the last reading, the statistics, an application ‘Appl’, a series of measurements

‘Batch’ or limit and offset values.

- ‘ ’ opens the table of initial functions

- ‘ ’ activates and deactivates display and keypad illumination

- ‘ ’ locks the keypad with a password

- ‘ ’ activates and deactivates the Bluetooth Interface (only MiniTest 4500).

3.1.3 Interfaces

The model MiniTest 4500 is equipped with a USB and Bluetooth interface. MiniTest 2500 is only

equipped with a USB interface.

3.1.4 Power supply

3.1.4.1 Batteries and rechargeable batteries

Coating thickness gauges MiniTest 2500 and 4500 are powered by three alkaline-manganesebatteries 1.5V, type AA / LR6 (included in standard supply); alternatively, the gauge can be operated

on rechargeable NiMH batteries type AA / HR6. Please use only the battery types recommended

by ElektroPhysik (see section 13.1 Accessories).

When working with rechargeable batteries, the settings of the gauge must be adapted to

rechargeable batteries (section 13.1.1). An external charger is required to recharge the batteries

(Accessories).

For more detailed information on the use of batteries and rechargeable batteries, refer to section

13.1.1.

Note:

- Remove batteries or rechargeable batteries from the instrument if not in use for extended

periods.

- The battery symbol indicates 5 different battery states. l.

- When reaching the lowest battery state, the battery level symbol will start to flash. In this

state, voltage is insufficient for powering the display backlight and keypad illumination. The

symbol is no longer displayed.

Page 13

3. Description of the measuring system

© ElektroPhysik MiniTest 2500 - MiniTest 4500 13 of 73

- If batteries are completely discharged, the messages „E06“ and „Low Batt“ appear and the

gauge switches off.

- Insert fresh batteries within one minute immediately after removing the used ones. If you

wait for longer than one minute, time settings may be lost. However, readings and

calibration values will remain in memory.

- For field use, replacement batteries should always be at hand

- Erratic readings due to low battery do not occur as the gauge switches off automatically or

does not switch on at all if batteries are too low.

- Used or defective batteries or rechargeable batteries may contain hazardous substances

and must be disposed of according to the legal provisions of your country.

3.2 Sensors

Select a sensor suitable for your measuring task, plug to the gauge and screw on.

Important: Whenever a sensor is connected or removed, the gauge must be switched off.

All sensor systems (except sensor type CN02 and customized designs) are spring-mounted in the

handling sleeve. This construction ensures stable positioning of the sensor with a constant contact

pressure. The V-groove at the top of the handling sleeve allows reliable measurement on objects

of cylindrical shape.

Hold the sensor at the handling sleeve and place on the object to be measured.

Note: Sensors are equipped with a hard, wear-proof sensor pole. However, sliding sensors across

rough and hard surfaces, for example shot blasted surfaces, should be avoided.

3.2.1 Sensors of the MiniTest 1100 – 2100 - 3100 - 4100 series

All sensors of the predecessor series are compatible with coating thickness gauges MiniTest 2500

and MiniTest 4500. However, it is required to perform a one-time adaptation of the sensor to the

measurement electronics.

3.2.1.1 Adaptation of sensor types F05, F1.6, F3, F1.6/90, F2/90, F10, F20, N.08 Cr, N02, N1.6,

N1.6/90, N2/90, CN02 and FN1.6, FN1.6P, FN 1.6/90, FN2/90

Upon initial connection of the sensor to the gauge, the MiniTest 2500 or 4500 will display “INF”

flashing as well as “SET” and “SENSOR IN AIR” when switched on.

Hold the sensor in a sufficient distance to any metal and press the OK key.

‘INF’ and ‘WAIT’ will continue to flash on the display and a counter will count down from 30 to 0.

Keep the sensor away from any metal until the counter has reached ‘0’.

Once the ‘INF’ adaptation is completed, ‘ZERO”, ‘NFe” and ‘ALUMINIUM-PLATE’ will flash on the

display when an N-type or FN-type sensor is connected to the gauge.

Place the sensor on the aluminum zero standard.

‘ZERO’ and ‘ALUMINIUM-PLATE’ will continue to flash on the display and a counter will count

down from 30 to 0. Do not remove the sensor from the standard until the counter has counted

down to ‘0’.

Once the aforesaid adaptation is completed, ‘ZERO”, ‘Fe” and ‘STEEL-PLATE’ will flash on the

display when an F-type or FN-type sensor is connected to the.

Place the sensor on the steel zero standard.

Page 14

3. Description of the measuring system

© ElektroPhysik MiniTest 2500 - MiniTest 4500 14 of 73

‘ZERO’ and ‘STEEL-PLATE’ will continue to flash on the display and a counter will count down

from 30 to 0. Do not remove the sensor from the standard until the counter has counted down to

‘0’.

‘SAVE’ and ‘OK’ will flash on the display.

Press ‘OK’ in order to complete the adaptation of the sensor. Gauge and sensor are now ready to

measure.

Adaptation of a sensor to the series MiniTest 2500 / 4500 does not affect the use of the same

sensor with a gauge from the series MiniTest 1100 / 2100 / 3100 / 4100.

The adaptation procedure can be repeated at any time in point 20 of the initial settings.

Note: Sensor type F 20 requires a multi-point calibration according to section 7.4 in order to

adhere to the tolerances. Sensor type F 50 is only supported by the MiniTest 2500 / 4500 series

beginning from software version 1.1.

3.2.1.2 Adaptation of sensor types N10, N20 and N100.

To adapt the sensor to the gauge, the zero standard and the three precision standards from the

calibration set supplied with the sensor is required.

When a sensor from the MiniTest 1100-4100 series is connected to a MiniTest 2500 or 4500 for

the first time, the gauge will display ‘INF”, ‘SET’ and ‘ON COATING WITHOUT SUBSTRATE‘ after

being switched on.

Place the sensor on the three precision standards stacked on top of each other and hold the

sensor and the precision standards in the air keeping a sufficient distance to any metal objects or

place the three standards on a polystyrene plate. Press the OK key. This procedure eliminates

dielectric influences oft he coating material as described in section 7.7.3.

‘INF’ and ‘WAIT’ will continue to flash on the display and a counter will count down from 30 to 0.

Keep the sensor away from any metal until the counter has reached ‘0’.

Once the ‘INF’ adaptation is completed, ‘ZERO”, ‘NFe” and ‘ALUMINIUM-PLATE’ will flash on the

display when an N-type or FN-type sensor is connected to the gauge.

Place the sensor on the aluminum zero standard.

‘ZERO’ and ‘ALUMINIUM-PLATE’ will continue to flash on the display and a counter will count

down from 30 to 0. Do not remove the sensor from the standard until the counter has counted

down to ‘0’.

‘SAVE’ and ‘OK’ will flash on the display.

Press ‘OK’ in order to complete the adaptation of the sensor. Gauge and sensor are now ready to

measure.

Adaptation of a sensor to the series MiniTest 2500 / 4500 does not affect the use of the same

sensor with a gauge from the series MiniTest 1100 / 2100 / 3100 / 4100.

The adaptation procedure can be repeated at any time in point 20 of the initial settings.

Hold the sensor in a distance to any metal and press ‘OK’.

Precision standards

Polystyrene plate

Page 15

4. Measuring, Storage and Data Processing in DIRECT or APPL-BATCH mode

© ElektroPhysik MiniTest 2500 - MiniTest 4500 15 of 73

4. Measuring, Storage and Data Processing in DIRECT or

APPL-BATCH mode

The following section describes:

the DIRECT mode

the APPL-BATCH mode

the structure of APPL-BATCH memory system

How to change from DIRECTto APPL-BATCH mode

How to select a scertain memory in APPL-BATCH mode

How to enter calibration values and limits

Special features of the APPL-BATCH memory system.

APPL = Application memory

BATCH = Memory for series of measurement

4.1 Switch on / start-up screen

Being switched on the unit will display the measurement mode of the last active series of

measurements („Batch“).

The model MiniTest 4500 offers two different working modes: ‘DIRECT mode’ and ‘APPL-

BATCH mode’.

‘DIRECT mode’ is intended for quick occasional readings. Readings as well as the 6

statistical values (8 if limits have been set) can be shown on the display and printed by

pressing STATS’. The statistical analysis function can evaluate up to 9,999 readings.

In ‘APPL-BATCH mode’ a maximum of 10,000 single readings and approx. 500 separate

series of measurements can be stored in data memory individually. Single readings,

statistical values and the related histogram can be printed directly or at a later point.

Important note:

Working in APPL-BATCH mode (e. g. calibrating, measuring setting of limits etc.) is only possible,

when the display shows „APPL BATCH“. Otherwise, activate the APPL-BATCH memory using the

keys APPL and BATCH. Also refer to Section 3.4 and 3.5.

Status line

Display Illumination

Batterylevel

Active measuring

principle: Fe

Time

Number of

readings

Measuring

unit

Current

reading

Page 16

4. Measuring, Storage and Data Processing in DIRECT or APPL-BATCH mode

© ElektroPhysik MiniTest 2500 - MiniTest 4500 16 of 73

Status after Switch on

Press ON key while holding the probe in the air. The gauge automatically resumes the mode

selected previously (either ‘DIRECT-’ or ‘APPL-BATCH’).

If start-up proceeds in ‘APPL-BATCH mode’, the gauge will select the ‘APPL-BATCH’ memory

previously selected and the last ready (if available) will be displayed.

Calibration values and statistics are stored in memory.

Measurement can start directly in ‘DIRECT mode’ or be continued in ‘APPL-BATCH’ mode

provided the gauge works with a valid calibration.

If all data have been deleted, only the measuring unit, e.g. < µm > along with the measuring mode

FERROUS or NONFERROUS will be shown depending on the sensor connected to the gauge.

Note:

If you switch from ‘DIRECT’ mode to ‘APPL-BATCH’ mode, all statistical data will be kept in

memory.

The statistical data will not be stored if you change the probe.

When pressing the APPL-BATCH key, the pair of numbers of the last active APPL-BATCH

memory will be shown on the display.

The gauges switches off automatically according to the selected switch-off-time after the last

measurement (see also section 11.1 initial settings).

Page 17

4. Measuring, Storage and Data Processing in DIRECT or APPL-BATCH mode

© ElektroPhysik MiniTest 2500 - MiniTest 4500 17 of 73

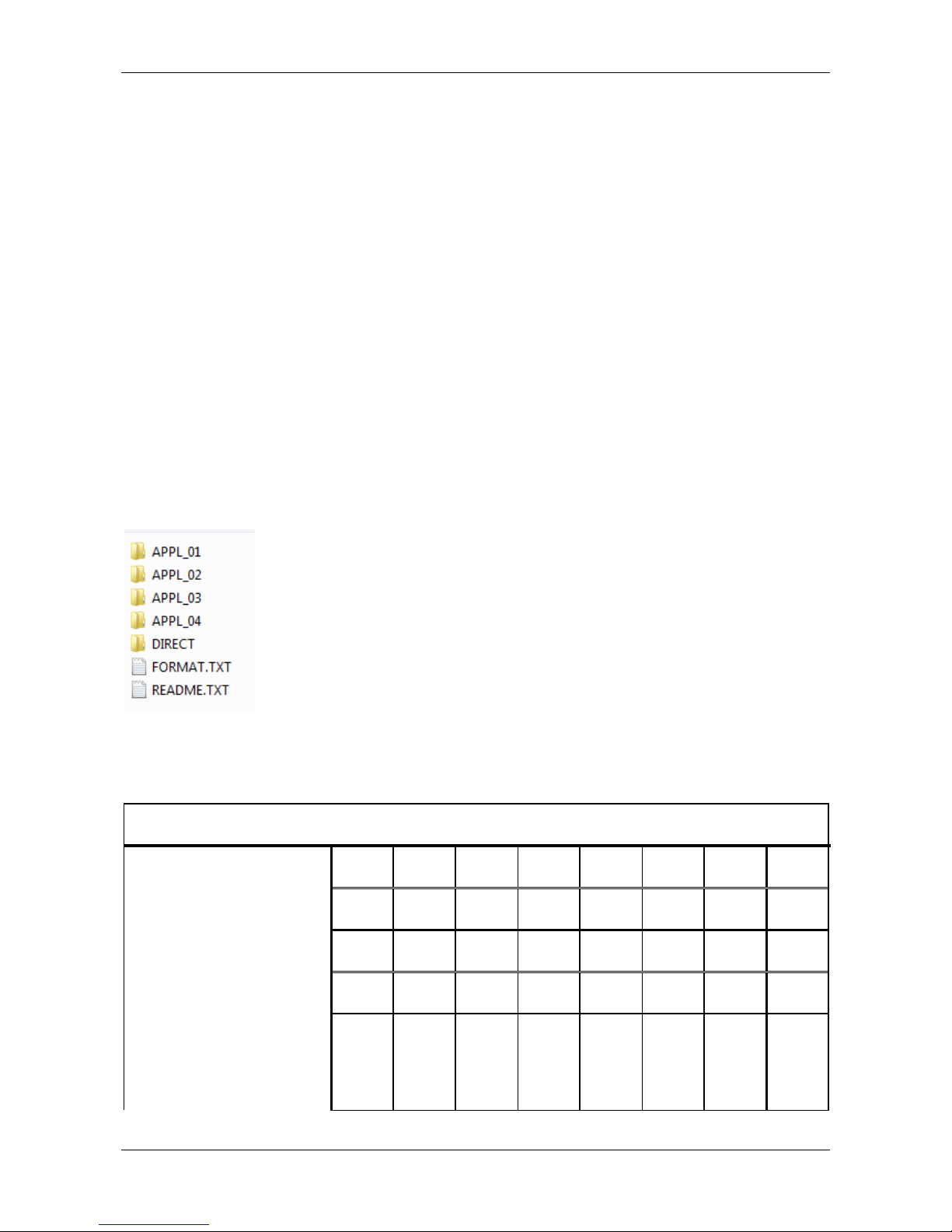

4.2 Structure of the APPL-BATCH system

MiniTest 2500 and MiniTest 4500 generally group reading in series of measurements in one

memory batch. MiniTest 2500 features one fixed memory (DIRECT) whereas MiniTest 4500

features one DIRECT memory and 99 application memories (APPL) combined with memories for

series of measurements (BATCH).

New readings are always added to the active memory and stored. The gauge will preserve the

active memory when switched off and automatically resume this memory when switched on again

not requiring any further settings. The following actions are possible:

- Continue to measure in active memory

- Set up a new series of measurement (BATCH) within an application memory (APPL)

- Set up of a new application memory (APPL) with corresponding series of measurement

(BATCH)

- Selection of an existing series of measurement (BATCH) within an application memory

(APPL)

- Selection of an existing application memory (APPL) with corresponding series of

measurement (BATCH))

Perform one of the above mentioned actions in order to specify the active series of measurement

(BATCH) for measurements hereinafter.

The application memories (APPL) with their corresponding batch memories (BATCH) allow to

store calibration settings for different applications in an application memory (APPL). The batch

memory (BATCH) stores single readings of a series of measurement along with their statistical

analysis (see illustration: APPL-BATCH memory).

BATCH memory columns

APPL

(application) memory

lines

1 2 3

...

97

98

99

1

1 2 3 97

98

99 2 1 2 3 97

98

3 1 2 3 97

98

.

.

.

Page 18

4. Measuring, Storage and Data Processing in DIRECT or APPL-BATCH mode

© ElektroPhysik MiniTest 2500 - MiniTest 4500 18 of 73

97

1 1 1 97

98

98

1 1 1 97

98

99

1 1 1 97

98

99

Illustration: APPL-BATCH memory

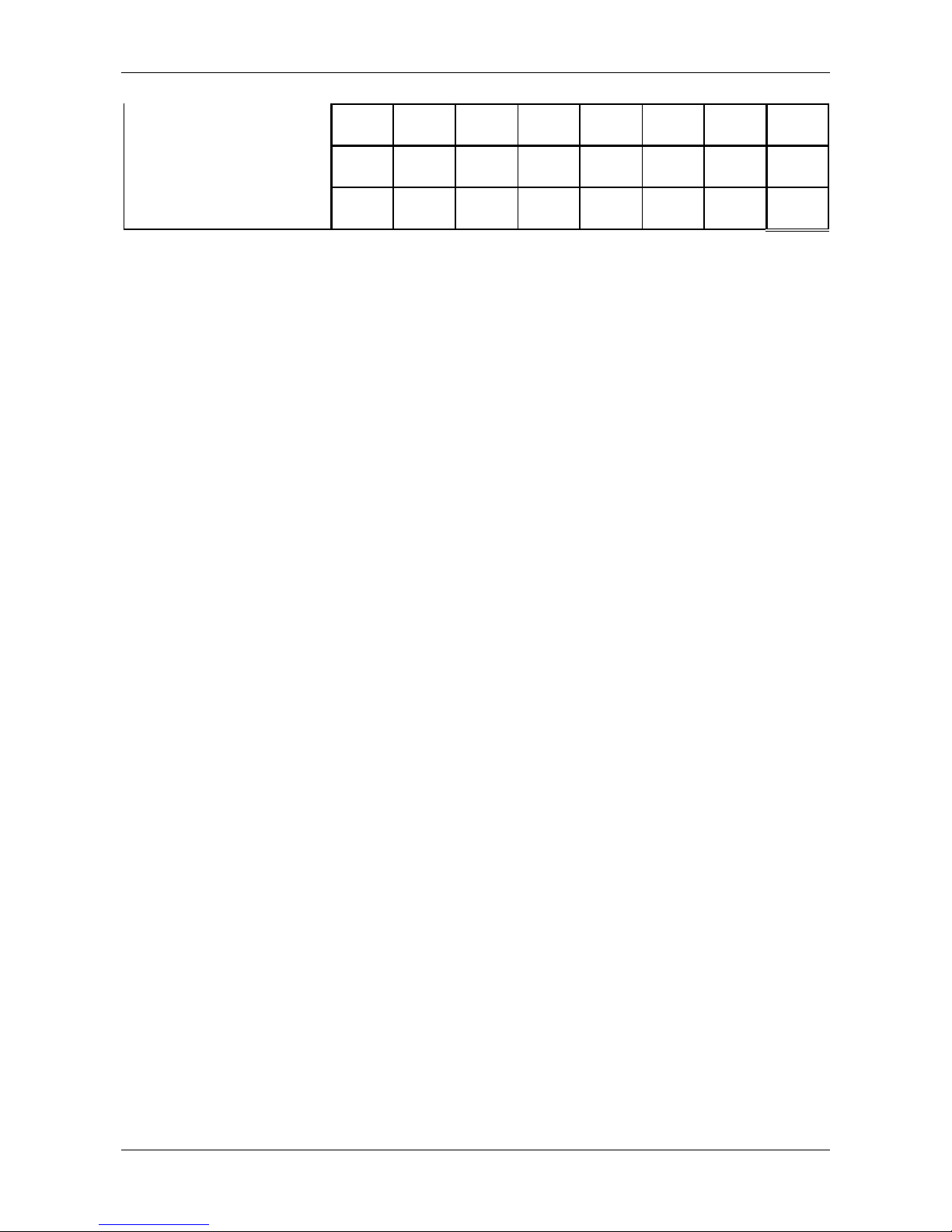

With MiniTest 4500 99 application memories (APPL-memory lines) – subdivided in 99 BATCH-

memory columns each, i.e. 9,801 memories in total, are available.

Several million readings can be logged to the memory.

APPL memory line

(for saving calibration values only)

Each of the 99 application memory lines can be allotted a calibration and an OFFSET setting for

one probe. A selection of calibrations are thus instantly available for different tasks, e.g. for

measuring coating thickness on flat or curved surfaces or for taking measurements using a range

of probe types. Once a calibration has been entered into an APPL memory line it remains there

and can be activated at any time simply by entering the corresponding APPL number. After this,

readings can start immediately within a selected group (BATCH) of particular application memory

BATCH-(Group) Memory

(for storing limits and readings)

Each of the application memories (APPL memory lines) is subdivided into BATCH memories. Each

BATCH memory can store a series of readings using one calibration and also evaluate them in

statistical form. In addition, a set of two tolerance limits (LO and HI) can be stored in each BATCH

memory. The BATCH subdivisions provide for individual assessment of the coatings of a number

of product samples measured with one probe and based on the same calibration.

4.3 Switching APPL-BATCH mode on / off

When the gauge is switched on it will resume the previously selected mode, i.e. either APPL-

BATCH or DIRECT mode.

In order to switch from DIRECT to APPL-BATCH mode, press ‘APPL’. The last APPL-BATCH

number will appear, e.g. < 2 : 1 >.

Either continue taking readings in this APPL-BATCH memory or select a different memory (see

section 4.5). Confirm your choice by pressing ‘APPL’ again. Readings can be taken as soon as

“APPL-BATCH” appears on display.

Page 19

4. Measuring, Storage and Data Processing in DIRECT or APPL-BATCH mode

© ElektroPhysik MiniTest 2500 - MiniTest 4500 19 of 73

To switch from APPL-BATCH mode to DIRECT mode, press and hold the APPL key while the

gauge is switched on. DIRECT mode is activated and the gauge is ready to measure.

4.4 Displaying the number of active APPL-BATCH

If the gauge is switched on and is already functioning in APPL-BATCH mode, a reading will

normally be displayed.

Press either APPL or BATCH to display the two-number memory in current use, e.g.<2 : 1>. Press

the same key again to confirm your choice. Readings can be taken as soon as APPL-BATCH

appears on the display.

4.5 Selection of an APPL memory

1. Press the APPL key in order to display the two-number designation of the active APPL-BATCH

memory. Use the arrow keys to select a new APPL memory.

2. If you hold down the key you can quickly scroll through the memory showing a running display

of numbers already occupied until a free APPL address is found. The number of this memory

will then appear on screen, e.g. < 5 : 1>. Free memories can be distinguished by a flashing

APPL number.

Note:

An APPL memory can be activated directly by connecting the sensor that served to create the

APPL memory originally. If another sensor even of the same sensor type is connected, the

message “LOC“ will be displayed along with sensor type and serial number.

This also happens if the probe which has been used for APPL-memory creation has been

repaired.

To delete or select APPL-memories please refer to section 9.6

3. The calibration valid for your selected APPLmemory is shown on display, e.g. one-point or

twopoint calibration. If the standard calibration is valid, there will be no indication on the

display.

Either maintain the currently valid calibration or recalibrate according to one of the methods

described in section 7.1 to 7.13.

4. All following readings will be stored in the selected APPL-BATCH memory.

4.6 Selection of a BATCH memory

1. Select an APPL memory line if this has not been done.

2. Press BATCH. The number of the previously selected number will now appear, e.g. <3 : 2>.

If, for example, APPL memory line number 3 has not yet been used, the gauge automatically

selects the first BATCH memory, e.g. <3 : 1 >. A free BATCH is indicated by flashing numbers

on the display.

3. If required, use the arrow keys to select a new BATCH no. Keep the key pressed down for

quickly scrolling through the memory until a free BATCH number is found. The number will

then be displayed, e.g. <3 : 8>. Press BATCH to confirm.

Page 20

5. Measuring

© ElektroPhysik MiniTest 2500 - MiniTest 4500 20 of 73

5. Measuring

5.1 Important Notes on Coating Thickness measurement

Make sure the operator has been properly instructed regarding the use of coating thickness

gauges and has basic knowledge of the specific requirements for measurement of the application.

The operator should have basic knowledge of the following:

Appropriate selection of a measuring device suitable for his application

Fundamentals on the electro-magnetic measuring principle

Influences through magnetic fields and the surrounding fields

Influence through the surface properties of the object to be tested (roughness, shape and

build-ups on the surface)

Statistical evaluation of measuring series

5.1.1 Interpretation of readings

The information obtained from the coating thickness measurement only refers to those parts of the

test object that have been covered by the sensor. For that reason, conclusions may not be drawn

on parts of the measuring object that have not been covered by the sensor during measurement.

In general, such conclusions are only admissible if comprehensive experience and approved

methods of statistical data acquisition are available.

5.2 Basic settings

Before taking readings, it is necessary to adjust a few settings:

Fix the data format for data storage before the first use of the gauge.

Either comma or point are available. This setting is important for later transfer of data to a

spreadsheet calculation for example Microsoft Excel (see section 10.2)

If required or necessary, the following settings can also be performed at initial set-up:

Definition of block statistics (see section 8.3)

Limit setting (see section 8.4)

Offset setting (see section 8.2)

All readings will be stored to the active APPL-BATCH memory.

Note:

Limits can still be set after readings have been taken.

Page 21

5. Measuring

© ElektroPhysik MiniTest 2500 - MiniTest 4500 21 of 73

5.3 Preparing measurement

5.3.1 Calibration

According to your setting of task, you may use different calibration methods. Measuring accuracy

depends on the selected calibration method. .

The following calibration methods are available. (see section 6.2):

- Factory presetting

- Zero point calibration

- Two-point calibration

- Multi-point calibration

- Calibration through a coating when the base material is not accessible (CTC)

5.4 Taking readings

5.4.1 Taking readings without using the sensor stand

All sensor systems are spring-mounted to ensure a safe contact pressure on the measuring object

without tilting. The V-groove of the sensor ensures correct positioning of the sensor on cylindrical

objects.

To take readings, place the external sensor onto the object to be measured. As soon as the sensor

has been placed onto the object, a reading will be displayed and will be registered for statistics

when working in “single value” mode. Lift the sensor briefly from the surface and take the next

reading.

In „continuous mode”, readings are displayed continuously as long as the sensor scans the

surface. To store the single reading being displayed into the statistics, press the „OK” key.

Note that grinding movements on the measuring object will affect the sensor pole (small pin in the

center of the sensor end surface touching the measuring object) and lead to abrasion which should

be prevented in order to maintain the high precision of the gauge.

Page 22

5. Measuring

© ElektroPhysik MiniTest 2500 - MiniTest 4500 22 of 73

5.4.2 High-precision stand

In order to take readings on small objects and small geometries, it is recommended to use the

external sensor in connection with the high-precision stand.

Measurement with standard sensor

5.4.3 Duplex coating systems

To add additional corrosion protection to a product or for design reasons, it is common practice to

apply a zinc coating to a steel product before painting. For measurement of zinced steel with

additional surface finish, please use the dual sensor FN 1.6. This sensor type allows to determine

the total coating thickness working in „Ferrous” mode and then the thickness of the paint coating on

the zinc substrate working in „Non-Ferrous”mode. The thickness of the zinc coating is calculated by

subtracting the paint thickness from the total thickness value.

Verify the zero value in non-ferrous setting with a zinc-coated but not yet painted sample. Starting

from a 50µm zinc thickness, the zero value is sufficiently good so that you can measure your duplex

coating as described aboven.

5.5 Errors during measurement

After the sensor has been calibrated, you can proceed on taking readings in the measuring mode.

Readings will be correct as long as the sensor specifications will be observed. Please refer also to

section 6.1 Calibration “General remarks“ and Section 13 “Technical specifications“.

5.6 Measurement on high temperatures using high-temp sensors

The measuring system MiniTest 2500 / MiniTest 4500 (gauge + sensor) is designed for a

maximum operating temperature of 50°C / 122°F for the gauge and 70°C / 158°F, at short periods

120 °C / 248°F for the sensor. Whilst the current operating temperature of the gauge depends on

the ambient temperature of the air, the current operating temperature of the sensor is also

influenced by the surface temperature of the object to be measured. This is due to the heat transfer

taking place when the sensors comes into contact with the object to be measured.

Measurements on objects with surface temperatures higher than the specified sensor operating

temperature are permissible with the special high-temperature sensors

80-0A1-1202 - F2 HT up to 250°C / 482°F and

80-0A1-1302 - F2 HT up to 350°C / 662°F

under the following conditions.

1. When taking readings, a measuring signal will sound approx. 1 second after placing the

sensor onto the object to be measured in order to confirm acquisition of the reading. Make

sure to lift the sensor immediately after the bleep sounds. This is to keep the heat transfer

from the object to the sensor as low as possible. Do not keep the senor in contact with the

measuring object for longer than one second.

2. Note that between two subsequent measurements on hot surfaces, a recovery time is

required to cool down the sensor. Please refer to the table below for the temperature

Page 23

5. Measuring

© ElektroPhysik MiniTest 2500 - MiniTest 4500 23 of 73

depending recovery times. If the below recovery times are respected, a virtually unlimited

number of subsequent measurements can be taken.

3. During a measurement pause, make sure not to place the sensor on hot surfaces to prevent

heating up. Keep the sensor away from hot measuring objects to prevent heating up through

heat radiation.

Sensor recovery times in high-temp operation

Temperature / °C

100

150

200

250

300

350

Temperature / °F

212

302

392

482

572

662

Recovery time / s

1

2.5 6 12

20

30

Page 24

6. Calibration

© ElektroPhysik MiniTest 2500 - MiniTest 4500 24 of 73

6. Calibration

6.1 General notes on calibration

The MiniTest 2500/4500 series offers a number of calibration methods to meet the individual

requirements of various applications, procedures and industrial standards.. When a batch is being

created you can select a suitable calibration method for this batch. The calibration can be carried

out immediately after you have created a batch or at a later time in measuring mode using the

„CAL” key. The calibration method can be changed as long as no readings are stored in the

currently active batch.

A calibration is made in the currently active batch and is directly related to this batch.

To ensure an optimum calibration, the following points should be observed:

Correct calibration is vital for accurate measurement. For calibration, a sample similar to the

later object to be measured should be used, i.e. both, calibration sample and the object to be

measured should be of the same shape and geometry. As a rule, you can say that the more

similar the calibration sample and the later object to be measured are, the more accurate

calibration and thus accuracy of readings will be.

Make sure the calibration sample and the later object to be measured have same

characteristics such as:

· identical curvature radius of surface

· identical substrate materials (such as magnetic permeability, electrical

· conductivity; in the ideal case, they should be made of the same material)

· identical substrate thickness

· identical size of measuring area

Before starting calibration, make sure the calibration spot, the sensor tip and the calibration

standard are clean. If necessary, remove any built-ups such as grease, metal chips, etc. Any

impurities might affect calibration and lead to erratic calibration.

Make sure the calibration position and the measuring position are always the same, this

applies especially for measurement on small parts and measurements at edges and

corners.

Keep away from strong magnetic fields during the calibration procedure.

For maximum accuracy of calibration and later measurements, choose the thickness of

calibration standard within the same thickness range as the later measuring sample.

For measuring thick non-ferrous metal coatings on steel or ferrous substrates according to

the magnetic induction method (using sensor type F 1.6, FN 1.6, F3, F10 or F20) a multipoint calibration must be carried out. The thickness standards must be of the same metal as

the later object to be measured.

If using calibration foils, make sure they are placed in plane position on the substrate material.

Any air gap below the foils must be avoided as this would lead to erratic readings. If the foils

are curved, make sure to place on them on the substrate as shown below (see illustration).

The precision thickness standards must be handled with care. Any wear-and tear of the

thickness standard will be reflected as erratic calibration value. Do not fold calibration foils.

Page 25

6. Calibration

© ElektroPhysik MiniTest 2500 - MiniTest 4500 25 of 73

Any buckling will cause air gaps below the foil and result in erratic readings. Keep thickness

standard clean, free from grease, oil, dust or other build-ups. Build-ups on the foils will be

considered as thickness and will lead to a measuring error of the same value as thickness of

build-up. To give you a rough idea: a build-up from a finger-print will be enough to add an

additional thickness of some microns.

Please note:

If the gauge switches off during the calibration procedure due to low battery, the calibration

procedure must be repeated after batteries inserting fresh batteries .

6.2 Calibration methods

According to your setting of task, you may use different calibration methods. Measuring accuracy

depends on the selected calibration method. For more details see sensor-specifications, section

14.2.

6.2.1 Factory pre-setting

The status line shows: „„.

The factory pre-setting is used for quick and easy measurement with a medium accuracy (for more

details please refer to section 14.2 Sensor Specifications). This calibration mode setting will be

valid as long as you do not choose and/or activate another calibration mode.

6.2.2.1 Zero Calibration

The status line shows: „ZERO „.

Calibration point: zero point (directly on the substrate material).

Calibration is to be made on an uncoated calibration sample of the same geometry and material as

the later measuring object. Only one calibration point is to be taken directly on the substrate to give

you the zero point

Zero calibration - is for quick calibration if a medium accuracy is sufficient.

6.2.2.2 Two-point Calibration

The status line shows: ”Z 1 „.

Calibration points: zero point (directly on the substrate material) and on the precision standard.

Calibration is to be made on an uncoated calibration sample of the same geometry and material as

the later measuring object. Two calibration points are to be taken: one directly on the substrate to

give you the zero point, the other one on a precision standard which is put on the substrate.

Compared to the zero calibration, this calibration method implies a higher accuracy. Accuracy will

increase if the thickness of the precision standard is close to the thickness of the later object to be

measured.

6.2.2.3 Multi-point Calibration

The status line shows: „Z 1“ „Z 2“ „Z 3“ „Z 3“

Calibration points: zero point (directly on the substrate material) and on two to four precision

standards.

Calibration is to be made on an uncoated calibration sample of the same geometry and material as

the later measuring object. Three calibration points are to be taken: one directly on the substrate to

give you the zero point, and two further ones on two precision standards to be put on the substrate.

It is recommended to choose a precision standard to cover the lower half of expected thickness

range, the other one should be in the higher half of expected thickness range.

Page 26

6. Calibration

© ElektroPhysik MiniTest 2500 - MiniTest 4500 26 of 73

This calibration method should be used if readings are to be taken over an extended thickness

range and if a high accuracy is required.

6.2.2.4 Two-point Calibration without zero

The status line shows: “12“.

Calibration points: two precision standards) (no zero point).

Calibration is to be made on an uncoated calibration sample of the same geometry and material as

the later measuring object. Two calibration points are to be taken on two precision standards which

are to be put on the substrate. The first precision standard should be thinner than the thickness to

be expected, the other one should be thicker than the thickness to be expected. There is no zero

point to be taken directly on the uncoated sample. There is no zero point to be taken directly on the

uncoated sample.

This specific calibration method should be used when taking readings on rough surfaces. Taking

zero point on rough surfaces would imply strong deviations due to the uneven surface. That’s why

zero point is omitted in this calibration method as this would lead to erratic calibration and thus

affect accuracy.

6.2.2.5 Calibration through a coating (CTC)

The status line shows: “CTC“.

Calibration using a calibration foil. Recommended if the test sample is coated and no uncoated

sample is available for comparison. This method is suitable for the following probes. F05, F1.6,

F1.6/90, F3 and FN1.6 (only F-part), F1.6/90, F10, F20 and F50.

6.4.3.1 Calibration of FN-type sensors

Calibration can be performed in direct mode or in an active batch for

the F-part as well as for the N-part of the system.

If “Auto FN“ is activated, pressing of the “Zero” or the “Cal” key will

display the message “Substrate”. Select Fe or NFe using the keys „

“or „ “ and confirm with the “OK” key. .

If no selection is made at all, the gauge will automatically display

FERROUS after about 5 secs. And select the magnetic induction

method.

Page 27

7. Calibration

© ElektroPhysik MiniTest 2500 - MiniTest 4500 27 of 73

7. Calibration

7.1 Activate factory settings

Applies to all sensor types (except CN02).

1. 2. 3.

Take a reading

Calibration using a calibration foil. Recommended if the test sample is coated and no uncoated

sample is available for comparison. This method is suitable for the following probes.

Note:

Verify on an uncoated sample if zero is read with sufficient accuracy. In case zero is not read

correctly, perform a zero or two-point calibration.

7.2 Zero Calibration

Applies to all sensors (except CN02 and continuous mode).

1. Press ZERO to initialise ZERO calibration. The display will show ‘Calibration ZERO’ (flashing).

2. Place the probe on uncoated sample (zero coating thickness) and raise it after the bleep.

Repeat this procedure several times. The display always shows the mean value of the previous

readings.

3. Press ZERO to complete Zero calibration. ‘ZERO’ is displayed steadily.

4. Now take readings by placing the probe on the object to be measured and raise the probe

after the bleep. The reading is shown on display.

Deleting a zero calibration: (for example necessary if an incorrect zero value has been entered.):

a) Press ZERO and then CLEAR for a longer time to delete the zero calibration and any existing

CAL calibration.

Note:

This will reactivate the default standard calibration for use on even surfaces.

b) or restart ZERO calibration by repeating steps 1 to 3 above. This automatically deletes the old

calibration and saves the new one.

Note:

ZERO calibration deletes any existing CAL calibration.

ZERO

flashes.

ZERO

steady

ZERO

flashes

n x

Press Clear for some

seconds

Page 28

7. Calibration

© ElektroPhysik MiniTest 2500 - MiniTest 4500 28 of 73

7.3 Two-point calibration (zero setting plus one calibration foil)

Applies to all sensors (except CN02 and continuous mode).

This method is recommended for high precision measurements, measurements on small parts and

on hardened and low-alloy.

1. Press ZERO to initialize ZERO calibration. ‘ZERO’ flashes

2. Place the probe on uncoated sample (zero coating thickness) and raise it after the bleep.

Repeat this procedure several times. The display always shows the mean value of the

previous readings.

3. Press the OK key to complete zero calibration. ‘ZERO’ is displayed steadily.

4. Press CAL to initialize foil calibration. ‘CAL’ flashes

5. Place the calibration foil on an uncoated sample, apply the probe and raise it after the

bleep. The thickness of the foil should be roughly equivalent to the estimated coating

thickness. Apply the probe to the test sample several times. The display always shows the

mean value of the previous readings. To discontinue calibration, press CLEAR.

6. Adjust to the thickness of the calibration foil using the ARROW keys.

7. Press the OK key to complete CAL calibration. ‘CAL’ is displayed steadily.

8. Now take readings by placing the probe on the coating and raise it after the bleep.

It may be necessary to delete CAL calibration, e.g. after entry of a faulty calibration value:

a) Press CAL key followed by CLEAR key. CAL calibration is now deleted.

ZERO calibration is now activated.

b) Restart CAL calibration by repeating steps 4 to 7 above.

Note:

Even while a series of measurements is being taken, foil calibration can be carried out as often as

necessary. The old calibration will be overwritten; the ZERO calibration remains in memory.

Special remark

When using F10, F20 or F50 probes for measuring on metal coatings, it is essential to carry out

two-point calibration. The calibration standards must be of the same metal as the actual coating.

Under certain circumstances, this may also apply to F probes with a low measuring range.

Folie

ZERO

steady

ZERO

flashes

ZERO

n x

CAL

steady

CAL

flashes

Adjust to value of

calibration foil

n x

Page 29

7. Calibration

© ElektroPhysik MiniTest 2500 - MiniTest 4500 29 of 73

7.3 Multi-point calibration (zero setting plus up to four calibration

foils)

Applies to all sensors (except CN02).

This calibration method is recommended for high precision measurement and measurements

taken over a larger scale of coating thickness values.

1. Press ZERO to initialise ZERO calibration. ‘ZERO’ flashes

2. Place the probe on uncoated sample (zero coating thickness) and raise it after the bleep.

Repeat this procedure several times. The display always shows the mean value of the

previous readings.

3. Press the OK key to complete zero calibration. ‘ZERO’ is displayed steadily..

4. Press CAL to initialize foil calibration. ‘CAL’ flashes.

5. Place the calibration foil on an uncoated sample, apply the probe and raise it after the

bleep. The thickness of the foil should be roughly equivalent to the estimated coating

thickness. Apply the probe to the test sample several times. The display always shows the

mean value of the previous readings. To discontinue calibration, press CLEAR.

Folie

ZERO

steady

ZERO

flashes

ZERO

n x

n x

CAL2 flashes

CAL1 flashes

Adjust to thickness value

of the calibration foil

4 steady

2 steady

3 steady

Or quit calibration

pressing

Or quit calibration

pressing

CAL3 flashes

Adjust to thickness value

of the calibration foil

Adjust to thickness value

of the calibration foil

CAL4 flashes

Adjust to thickness value

of the calibration foil

n x

n x

n x

n x

n x

Page 30

7. Calibration

© ElektroPhysik MiniTest 2500 - MiniTest 4500 30 of 73

6. Adjust to the thickness of the calibration foil using the ARROW keys.

7. Press the Cal key in order to initialize the following calibration point. ‘CAL2’ flashes.

8. Repeat steps 5 and 6.

9. Press the Cal key in order to initialize the following calibration point. ‘CAL3’ flashes. If the

OK key is pressed instead of the CAL key, the calibration procedure will be completed with

at the previous point. ‘Z 2’ is displayed.

10. Repeat steps 5 and 6.

11. Press the Cal key in order to initialize the following calibration point. ‘CAL4’ flashes. If the

OK key is pressed instead of the CAL key, the calibration procedure will be completed with

at the previous point. ‘Z 3’ is displayed.

12. Repeat steps 5 and 6.

13. Press the OK key in order to confirm that calibration is completed, ‘Z 4’ is displayed.

14. Now position the sensor on the coating to be measured and lift after the bleep.

It may be necessary to delete CAL calibration, e.g. after entry of a faulty calibration value:

c) Press CAL key followed by CLEAR key for some seconds. CAL calibration is now deleted.

ZERO calibration is now activated.

d) Restart CAL calibration by repeating steps 4 to 13 above.

Note:

Even while a series of measurements is being taken, foil calibration can be carried out as often as

necessary. The old calibration will be overwritten; the ZERO calibration remains in memory.

Note:

Measurement of metallic coatings using sensor types F10, F20 or F50 requires a two-point

calibration. This may also apply to F type probes for smaller measuring ranges. Calibration

standards must be made of the same metal as the coating to be measured.

7.5 Two-point calibration using two calibration foils without zero

calibration

Applicable to all sensors (except CN02)

Calibration is only possible in single measurement mode. If necessary switch to the mode as in

section 4.1. This method requires the use of two different foils. The thicker one should be, if

possible, twice as thick as the thin one. According to probe, the following foils should be used:

F05, F1.6, FN 1.6, N02, N1.6 (as of production date

26.08.04):

min. 10µm

F10, N10:

min. 100µm

F20, N20:

min. 400µm

F50:

min. 1000µm (1mm)

N100:

min. 5000µm (5mm)

All other sensors:

min. 25µm

For best results, the thickness to be expected should be somewhere between the two calibration

values.

Page 31

7. Calibration

© ElektroPhysik MiniTest 2500 - MiniTest 4500 31 of 73

This method is especially suitable for taking measurements on rough shot-blasted surfaces or for

high-precision readings. It is advisable to take a mean of CAL values. This considerably reduces

the effect of scattering which occurs during calibration of upper and lower values.

Note:

Before carrying out the two-foil calibration, the factory set standard calibration should be enabled

(see also 4.2.1).

Press ZERO key followed by ”Clear“ and “OK“. Proceed with step 1.

The calibration foils may be used in any order.

1. Press the CAL key to initialize the calibration procedure. ‘CAL I’ flashes.

2. Place the thinner of the two foils (e.g. approx. 30μm) on the uncoated test sample, apply the

probe and raise it after the bleep. Repeat this procedure several times. The display will show

the mean value of readings taken previously.

3. To discontinue calibration at any time, press CLEAR. All calibration values entered so far will

be deleted and the calibration procedure can be continued taking new readings. In order to

discontinue and quit the calibration procedure, press “OK/ “ for several seconds.

4. If necessary, adjust the value displayed to the thickness value of the calibration foil using the

arrow keys.

5. Press the CAL key in order to calibration with the second foil. ‘CAL2’ flashes on the display.

6. Place the thicker of the two foils (this should be at least twice as thick as the other foil) on the

uncoated sample, apply the probe and raise it after the bleep.

To discontinue calibration at any time, press CLEAR. All calibration values entered so far will

be deleted and the calibration procedure can be continued taking new readings. In order to

discontinue and quit the calibration procedure, press “OK/ “ for several seconds.

7. If necessary, adjust the value displayed to the thickness value of the calibration foil using the

arrow keys.

8. Press OK, Calibration ‘2’ is displayed steadily.

9. Now take readings placing the sensor on the coating to be measured, lift after the bleep and

read the measuring value on the display.

It may be necessary to delete CAL calibration, e.g. after entry of a faulty calibration value:

a) Press CAL and CLEAR key followed by OK key. The second calibration value is now deleted.

CAL

steady

n x

1. Foil

CAL

flashes

Adjust to thickness value

of the calibration foil

n x

2. Foil

CAL

flashes

CAL

steady

Adjust to thickness value

of the calibration foil

Page 32

7. Calibration

© ElektroPhysik MiniTest 2500 - MiniTest 4500 32 of 73

b) Pressing the CLEAR key for a longer time will delete both calibration values.

Note:

The default standard calibration for flat surfaces is now active.

c) For a new CAL calibration repeat steps 2 -7. The previous calibration is deleted and the new

calibration is active.

Page 33

7. Calibration

© ElektroPhysik MiniTest 2500 - MiniTest 4500 33 of 73

7.6. Calibration Through the Coating

(CAL-THROUGH-COATING: CTC: Procedure according license patent DE3404720C2)

This method is recommended when an uncoated test sample is not available. It can be employed

with the probe types F06, F1.6, F3, FN1.6 and FN2 (F-part), F1.6/ 90, F2/90, F10, F20 and F50.

The CTC method may, however, only be used when the coating is smooth at the calibration point

and measured values are reproducible. Do not use for textured coatings.

1. Press CAL/CTC key for some seconds to initialize CTC calibration. CTC1 flashes.

2. Place the probe on the calibration point of the test sample and raise it after the bleep. Repeat

this procedure several times. The display always shows the mean value of the previous

readings.

3. Press CAL key.

4. Place the calibration foil on the same point, apply the probe and raise it after the bleep.The

thickness of the foil should be roughly equivalent to the estimated coating thickness. Apply the

probe to the test sample several times. The display always shows the mean value of the

previous readings.

To discontinue calibration, press CLEAR.

All calibration values entered so far will be deleted and the calibration procedure can be

continued taking new readings. In order to discontinue and quit the calibration procedure,

press „OK/ “ for several seconds.

1. If necessary, adjust the value displayed to the thickness value of the calibration foil using the

arrow keys.

2. Press OK key shortly to confirm and complete CTC calibration. ‘CTC1’ is displayed steadily.

1.

3.

2.

5.

6.

7.

Calibraion

foil

CTC2 flashes

CTC1 flashes

CAL

steady

Adjust to value oft

he calibration foil

n x

n x

Page 34

7. Calibration

© ElektroPhysik MiniTest 2500 - MiniTest 4500 34 of 73