Page 1

Technical Manual /Operating Instructions

MiniTest 7200 FH / MiniTest 7400 FH

Thickness Gauges

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 2

Contents

Contents

1. INTRODUCTION..........................................................................................................................5

2. FIRST STEPS.................................................................................................................................6

NSERT BATTERIES AND CONNECT SENSOR.................................................................................6

2.1 I

WITCH ON AND TAKE READINGS..............................................................................................7

2.2 S

2.2.1 Setting language..................................................................................................................7

3. DESCRIPTION OF THE MEASURING SYSTEM...................................................................9

3.1 B

ASIC UNIT .................................................................................................................................9

3.1.1 General Remarks.................................................................................................................9

3.1.2 Operating keys ....................................................................................................................9

3.1.3 Sockets and interfaces.......................................................................................................10

3.1.4 Power supply.....................................................................................................................10

3.1.4.1 Batteries and storage batteries......................................................................................10

3.1.4.2 Power supply unit...........................................................................................................11

3.2 S

ENSORS FH 4 AND FH 10........................................................................................................11

3.2.1 General Remarks...............................................................................................................11

3.2.2 Sensor Models...................................................................................................................11

3.2.3 Sensor Stand......................................................................................................................12

HE USER MENU.........................................................................................................................13

4. T

4.1 G

ENERAL REMARKS

4.2 S

WITCH

-ON / S

EASURE SCREEN /STATISTICS SCREENS ..................................................................................13

4.3 M

....................................................................................................................13

TART SCREEN

......................................................................................................13

4.3.1 Measure Mode – Numerical Screen..................................................................................13

4.3.2 Measure Mode –Graphics Screen with MiniTest 7400 FH ..............................................14

4.3.3 Statistics Screens...............................................................................................................14

SER MENU..............................................................................................................................15

4.4 U

4.4.1 U

4.4.2 N

4.4.3 A

SER PREFERENCES...............................................................................................................15

UMERICAL ENTRIES .............................................................................................................16

LPHANUMERICAL ENTRIES (ON MINITEST 7400 FH)...........................................................16

5. MEASURE MODE......................................................................................................................17

MPORTANT NOTES ON THICKNESS MEASUREMENT..................................................................17

5.1 I

5.1.1 Limitations to magneto-static thickness measurement......................................................17

ATCH CONFIGURATION / NECESSARY SETTINGS.....................................................................17

5.2 B

5.2.1 Batch .................................................................................................................................17

5.2.2 Target Ball Size.................................................................................................................18

5.2.3 Data Logging Mode..........................................................................................................18

5.3 P

REPARING MEASUREMENT......................................................................................................18

5.3.1 Calibration........................................................................................................................18

5.3.2 Measurement without Sensor Stand..................................................................................19

5.3.3 Using the Sensor Stand.....................................................................................................19

AKE READINGS .......................................................................................................................19

5.4 T

5.4.1 Measurement without Sensor Stand..................................................................................19

5.4.2 Using the sensor stand......................................................................................................20

5.4.3 Delete Readings ................................................................................................................20

5.5 S

TORING READINGS INTO STATISTICS MEMORY .......................................................................20

5.5.1 Data Logging Mode..........................................................................................................20

5.5.2 Manual Data Storage........................................................................................................21

© ElektroPhysik MiniTest 7200 FH / MiniTest 7400 FH

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

2

Page 3

Contents

5.5.3 Automatic Data Storage (Auto).........................................................................................21

5.5.4 Storing Minimum Reading................................................................................................21

5.5.5 Storing Maximum Reading................................................................................................21

5.6.1 Correct Sensor Position....................................................................................................22

5.6.2. Incorrect Readings through tilting of the Sensor.............................................................22

5.6.3 Incorrect readings through Blocked Target Ball..............................................................23

5.6.4 Air gap...............................................................................................................................23

5.6.5 Measuring material with ferruginous particles................................................................23

6. CALIBRATION...........................................................................................................................24

ENERAL REMARKS ON CALIBRATION .....................................................................................24

6.1 G

ALIBRATION METHODS............................................................................................................25

6.2 C

OW TO CALIBRATE ..................................................................................................................26

6.3 H

6.3.1 Factory Calibration ..........................................................................................................26

6.3.2 Zero only...........................................................................................................................26

6.3.3 Multi-point calibration (Zero + 1 to 4 point(s) )..............................................................27

6.4. D

ELETE CALIBRATION PO INT ....................................................................................................28

ALIBRATION ERROR SOURCES ................................................................................................29

6.5 C

7. DATA STORAGE........................................................................................................................30

ATCHES...................................................................................................................................30

7.1 B

7.1.1 General..............................................................................................................................30

7.1.2 Batch Data ........................................................................................................................30

7.2 D

ATABASE OF THE MINITEST 7400 FH .....................................................................................31

7.2.1 General Remarks...............................................................................................................31

7.2.2 Tree structure....................................................................................................................31

7.2.3 Create a Directory............................................................................................................31

7.2.4 Create a New Batch ..........................................................................................................32

7.2.5 Select a Batch for Measurement .......................................................................................32

7.2.6 Delete a Batch / a Directory .............................................................................................33

7.2.7 Rename a Batch / Rename a Directory.............................................................................33

8. STATISTICS................................................................................................................................34

TATISTICAL PARAMETERS.......................................................................................................34

8.1 S

8.1.1 Upper and lower specifications limits (USL and LSL).....................................................34

8.1.2 Set Point (Differential Mode)............................................................................................35

8.2 R

EADINGS .................................................................................................................................35

8.2.1 View Readings...................................................................................................................35

8.2.2 Delete Single Readings .....................................................................................................35

8.2.3 Delete all Readings...........................................................................................................36

UMERICAL STATISTICS ...........................................................................................................36

8.3 N

ISTOGRAM ON MINITEST 7400 FH .........................................................................................37

8.4 H

8.5 T

REND DIAGRAM ON MINITEST 7400 FH.................................................................................37

9. DATA OUTPUT / DATA TRANSFER......................................................................................38

9.1 D

ATA PRINT-OUT

........................................................................................................................38

9.1.1 Screen Shot........................................................................................................................39

9.1.2 Print-out a Batch...............................................................................................................39

RANSFER DATA TO A PC.........................................................................................................40

9.2 T

10. MAIN MENU .............................................................................................................................41

10.1 D

© ElektroPhysik MiniTest 7200 FH / MiniTest 7400 FH

ATABASE ..............................................................................................................................41

3

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 4

Contents

TATISTICS..............................................................................................................................41

10.2 S

10.3 C

10.4 A

ALIBRATION..........................................................................................................................41

CTIVE BATCH .......................................................................................................................41

10.4.1 Batch Properties .............................................................................................................41

10.4.2 Readings..........................................................................................................................42

10.4.3 Configuration..................................................................................................................42

10.4.4 Calibration......................................................................................................................42

10.5 S

ETUP

.......................................................................................................................................43

10.5.1 General Remarks.............................................................................................................43

10.5.2 Display............................................................................................................................43

10.5.3 Date and Time.................................................................................................................43

10.5.4 Data Outputs...................................................................................................................44

10.5.5 User Preferences.............................................................................................................45

10.5.6 Gauge Specifications.......................................................................................................45

11. SPECIAL FUNCTIONS............................................................................................................46

11.1 I

NITIALIZING ...........................................................................................................................46

11.2 S

PECIAL FUNCTIONS

..................................................................................................................47

12. QUICK REFERENCE ..............................................................................................................48

13. CARE AND MAINTENANCE.................................................................................................49

13.1 C

ARE.......................................................................................................................................49

13.1.1 Using NiMH storage batteries........................................................................................49

13.2 M

AINTENANCE

.....................................................................................................................49

14. TECHNICAL SPECIFICATION.............................................................................................50

14.1 G

AUGE AND SENSORSPECIFICATION

14.2 D

ELIVERY SCHEDULE .............................................................................................................52

..........................................................................................50

14.2.1 Thickness gauge MiniTest 7200 FH / 7400 FH..............................................................52

14.2.2 Sensors............................................................................................................................52

14.3 A

CCESSORIES..........................................................................................................................53

15. APPENDIX.................................................................................................................................56

15.1 T

ROUBLESHOOTING

15.2 D

ETECTION OF ERROR SOURCES

TATISTICAL TERMS ...............................................................................................................60

15.3 S

AFETY NOTES........................................................................................................................62

15.4 S

15.5 D

ECLARATION OF CONFORMITY

15.6 A

FTER SALES SERVICE

...................................................................................................................56

(INF

FLAG

)

...............................................................................59

.................................................................................................64

..............................................................................................................65

INDEX...............................................................................................................................................66

© ElektroPhysik MiniTest 7200 FH / MiniTest 7400 FH

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

4

Page 5

1. Introduction

Designed for non-destructive thickness measurement, the portable MiniTest 7200 / 7400 FH

measuring systems are suitable for in the field or laborator y use. Working on the m agneto-static

principle, the gauges enable quick and easy measurement on non-ferromagnetic mat er ials.

The measuring system consists of a handy sensor, which is connected via a cable to the base and

display unit for visualization and processing of readings. For m easurement , specially treated targ et

balls made of a ferromag netic material are used as a r eference. For measurement , a target ball is

placed on the material to be measured so that the material thickness between target ball and

sensor will be measured. The measuring system comes with sensor st and (available as an option)

to add additional comfort of handling during measurement.

For documentation a portable data printer is available. The measuring system may also be

connected to a PC for data communication.

For taking reading s, the sensor is placed on the surf ace of t he measuring object, the target ball is

placed on the opposite side of sample. The sensor is placed on the opposite side of sample.

Equipped with a strong perm anent magnet, the sensor at tracts the target ball and holds it exactly

over its sensor tip. W hen moving the sensor, the t arget follows accordingly. The presence of t he

target ball will change the magnetic field near the sensor tip. The magnetic field changes according

to the distance between target ball and sensor tip. T he chang e of magnetic f ield increases with the

distance between target ball and sensor t ip getting smaller and can be taken as a ref er ence for the

material thickness of the sample to be measured. The sensor incorporates a Hall element to

capture the change of mag net ic field and to translate it into thickness.

For measuring hollow parts, a target ball is placed into the interior of sample and the sensor is

placed on the opposite side in order to attract t he target ball exactly over the sensor tip. For taking

readings, the sensor is moved over the surface of sample. For measuring sheets, the sensor is

placed on the surface of sheet and the target ball is placed near the sensor on the opposite side of

sheet. The target ball will automatically center on the correct measuring position and the

measuring processes can be started.

For measuring large-sized parts, the sensor can be guided manually over the sample to be

measured. For measuring small part s , it is recommended to use the sensor stand supplied with the

sensor.

Suitable for use in industrial production areas, the measuring systems MiniTest 7200 / 7400 FH

measure hollow parts, containers and sheet material of all kinds such as bottles, cans, inject ions

moldings, car bodies, glass, SMC components etc made of non-magnetic (non-ferr ite) materials.

© ElektroPhysik MiniTest 7200 FH / MiniTest 7400 FH

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

5

Page 6

2. First Steps

This section refer s to persons to use the gauge for the first tim e. This section explains the main

features of the g auge and how to take readings.

2.1 Insert Batteries and connect Sensor

a) Take gauge and batteries from the carrying case.

b) Push the battery compartment lid at the gauge bottom in arrow direction (as shown below)

c) Inser t bat teries into the battery compartment. Respect polar it ies ( as shown below).

d) Close lid.

b) c)

e) Take requested sensor (FH4 or FH10) form t he carrying case. Plug sensor into the sock et on

top of the base unit (as shown below). Make sure the nib of plug is correctly inserted into the

guide way of socket. The red mark ing at the probe plug must be positioned correctly to the red

marking at the sensor plug .

f) Fully engage the sensor plug into the sensor sock et t o the stop.

Sensor Socket

© ElektroPhysik MiniTest 7200 FH / MiniTest 7400 FH

6

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 7

2.2 Switch ON and Take Readings

2.2.1 Setting language

This setting can be made at initial use or as requested at any time (see section 11.1)

Press the red ON/OFF button on the left side of gauge and ESC simultaneously to switch on and to

go to initialization menu.

1. A banner appear s with a language option.

User arrow keys ↑↓ to go to your requested lang uage option.

Press OK to confirm or ESC to abor t.

2. On display appears “Total Reset”. A Total Reset restores factory settings. To abort Total

Reset, press Function key “No” (section 11.1)

a) Start Screen appears showing company logo, gauge version

and sensor type that is currently connected (see illustr. on the

left.

Flashing antenna symbol if sensor is

connected

b) After approx. 2 seconds, the gauge switches automatically into

measure mode and is ready to take readings. The Measure

Screen will appear without any reading being shown.

c) At initial switch-on the gauge is in “Direct Mode“ (see section

7.1.1). For this mode, the factory calibration is preset (for more

detailed information on “Calibr at ion” topics please refer to section

6). The Status Line provides inform ation on the active calibration

method and the active batch (MiniTest 7400 FH) Please check

whether the target ball size as adjusted mat ches your application

(for more details on targ et ball size pleaser refer to sect ion 5.2.2

“Target ball size”).

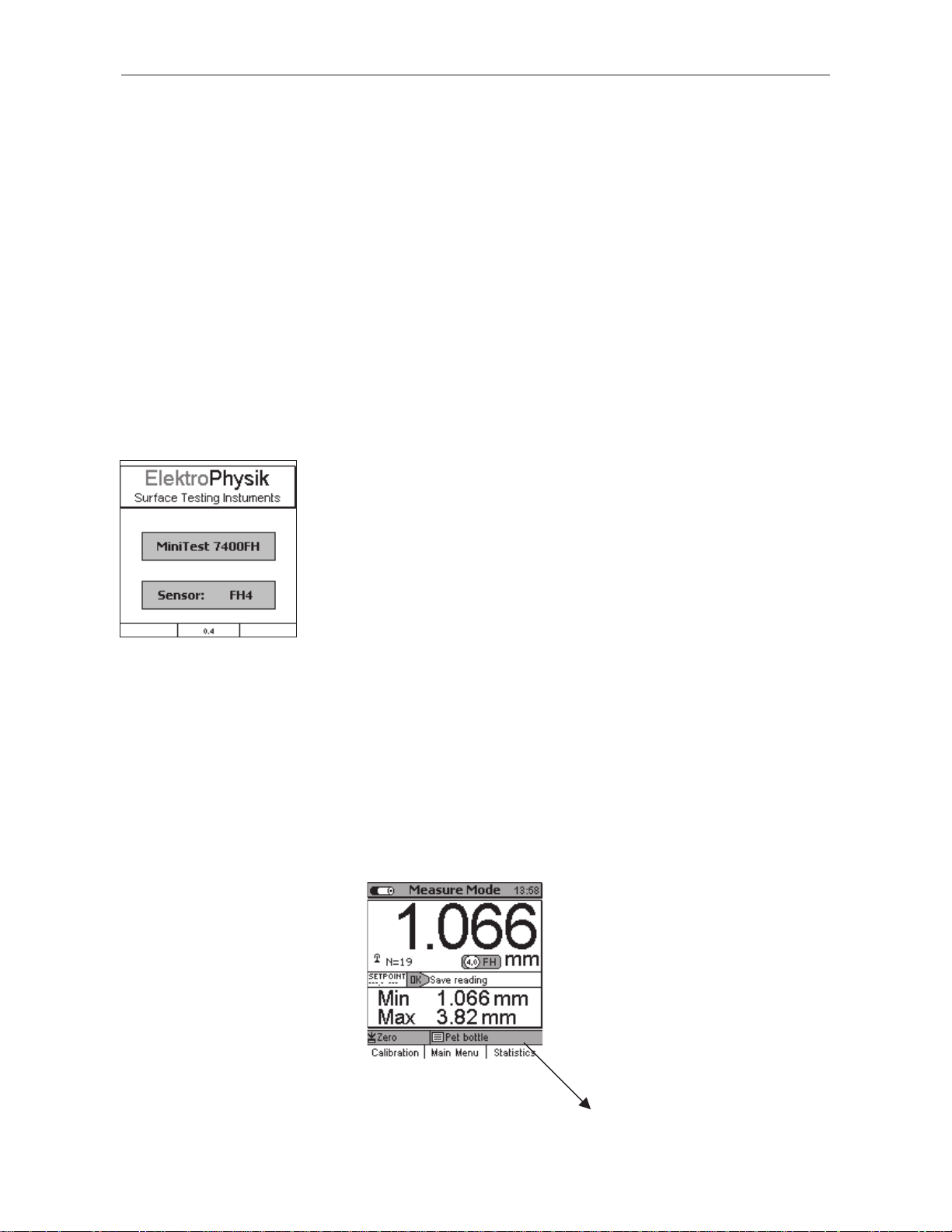

Target ball diameter, hiere: 4.0 mm.

Selected calibration mode, here:

© ElektroPhysik MiniTest 7200 FH / MiniTest 7400 FH

Find Quality Products Online at: sales@GlobalTestSupply.com

Zero calibration

www.GlobalTestSupply.com

Active batch, here: Pet bottle

(only with Minitest 7400 FH)

Status line

7

Page 8

d) The factory calibration is for quick and easy measurement when larger measuring errors are

acceptable. For other calibration methods please refer to section 6.2.

e) For measurement, please use the sensor stand supplied with the gauge. Place the measur ing

object on the sensor. Place the targ et ball on the opposite side. For measuring hollow parts,

place the ball inside the sample. Equipped with a strong permanent magnet, the sensor attracts

the target ball and holds it exactly over its sensor tip. Hold t he measuring obj ect in rectangular

position to the sensor and move it smoothly over the sensor. Press OK t o store the reading into

memory. Press Function key “Statistics” to view readings and the numerical statistics.

For measuring large-sized sheeting material or large hollow parts, place the senor on the

surface of sample. T he target ball is placed on the opposite side near the sensor. Keep the

sensor in rectangular position to the surface and move it across the surface of sample.

© ElektroPhysik MiniTest 7200 FH / MiniTest 7400 FH

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

8

Page 9

3. Description of the measuring system

f

3.1 Basic unit

3.1.1 General Remarks

Graphics display

160 x 160 Dots

3.1.2 Operating keys

ON/OFF button

Command and

navigation key

block

Large backlit display for easy reading o

measuring values, statistical data, histog ram and

trend diagram.

Robust scratch resistant plastics housing.

Function keys

Use the ON/OFF button to switch the gauge ON or OFF. If you press ON/OFF button and ESC

simultaneously, the initializing procedure will be perform ed (for more details please refer to section

11.1).

The Function keys may assume different functions according to the menu being active. Their

current properties are displayed in the line upper to the Function keys.

The command and navigation key block may also assume different functions:

-

Press OK to confirm setting s, st or e values or select m enu it ems.

-

Press ESC to abort actions or to quit subm enus.

-

Use ARROW k eys to navig at e t hrough the menu or change settings.

-

If the alphanumerical block has been activated, O K and ESC keys also assume navigation

functions.

The Function keys and the command and navigation k ey block may be backlit on request. This

adds additional comfort in poor light conditions (for more details please refer to section 10.5.2)

© ElektroPhysik MiniTest 7200 FH / MiniTest 7400 FH

9

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 10

Press the “Help” Function key for calling the context-or iented on-line “Help“.

3.1.3 Sockets and interfaces

Multi-purpose socket

The basic unit features a sensor sock et for connecting the FH 4 or the FH 10 sensor. The multipurpose socket is used for connecting the mains unit, the foot switch, the alarm device or the

RS232 interface cable.

3.1.4 Power supply

3.1.4.1 Batteries and storage batteries

Sensor socket

IR Interface

Both models, MiniTest 7400 FH and MiniTest 7200 FH, are powered by a set of four alkalinemanganese cells, 1.5V, AA LR6 size (Batteries included in the standar d supply schedule.) .

As an alternative, both models may be operated on rechargeable NiMH (type AA-HR6) storage

batteries or via a power supply unit (available as an option). Please use only products as

recommended by ElektroPhysik (See section 14.3, Accessories) .

If you wish to use the storage batteries, they must be recharge using the external charger unit

(available as an option). Please also refer to sect ion 13.1 “Care and maintenance” for more details.

Note:

• Remove batteries or storage batteries from the instrument if you are not going to use it for a

longer period of time.

• The battery symbol on display indicates the battery state.

• For field use, replacement batter ies should be m ade available.

• Erratic readings due to low battery voltage do not occur because the gauge switches off or

does not switch on if the battery is too low.

© ElektroPhysik MiniTest 7200 FH / MiniTest 7400 FH

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

10

Page 11

• Used or defective batteries or storage bat t er ies m ay contain hazardous substances and

must be disposed according to the legal provisions of your count r y.

3.1.4.2 Power supply unit

For mains operation, the power supply unit must be used. If operated via the power supply unit,

batteries should be inserted to supply the internal time clock , otherwise, after approx. 1 minute, the

settings of the real-t im e clock will go lost as soon as supply from the mains is cut.

The power supply unit comes with two different adapter plug versions ( Eur o and US plug). If the

power supply unit comes with an adapter plug connected that does not match your socket, simply

change the adapter plug accordingly.

Simply remove the adapter from the power supply unit and f ix the ot her one as r equired.

Note:

The adapter has not been designed for frequent change.

3.2 Sensors FH 4 and FH 10

3.2.1 General Remarks

In this new SIDSP (Sensor integrated digital signal processing) procedure, all necessary

measuring signals are created and complet ely processed in the sensor itself. Only the completely

processed digital readings are transferred to the base unit for display, statistical evaluation and

data storage. Unlike the comm only used analog procedures, the new SIDSP procedure excludes

any error influences on the measuring data during transfer over the pr obe cable. The result is a

measuring accuracy and constancy of readings that has been unmatched so far. The complete

sensor technique is integrated into a r obust st ainless- steel housing.

3.2.2 Sensor Models

Two sensor models are available:

-

FH 4 sensor to cover the 0 …4 mm range

-

FH 10 sensor to cover the 0…10 mm range.

Both sensors feature a wear-resistant sensor tip most suitable also for hard materials such as

glass, for instance.

© ElektroPhysik MiniTest 7200 FH / MiniTest 7400 FH

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

11

Page 12

3.2.3 Sensor Stand

Both sensor types come with a spring-loaded V-grooved sensor stand. The use of the sensor stand

ensures increased reproducibility of readings by adding stability of the sensor during measurement

so that even small parts can be measured without problems.

© ElektroPhysik MiniTest 7200 FH / MiniTest 7400 FH

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

12

Page 13

4. The User Menu

r

A

t

E

4.1 General Remarks

4.2 Switch-ON / Start Screen

At switch on, the company logo, gauge version and type of sensor being connected appear on

display.

After approx. 2 seconds the gauge switches to the m easur e screen of the last batch that was

active before the gauge was switched off.

4.3 Measure screen /Statistics screens

Readings can be displayed numerically only or numerically combined with a diagram (only with

MiniTest 7400 FH)

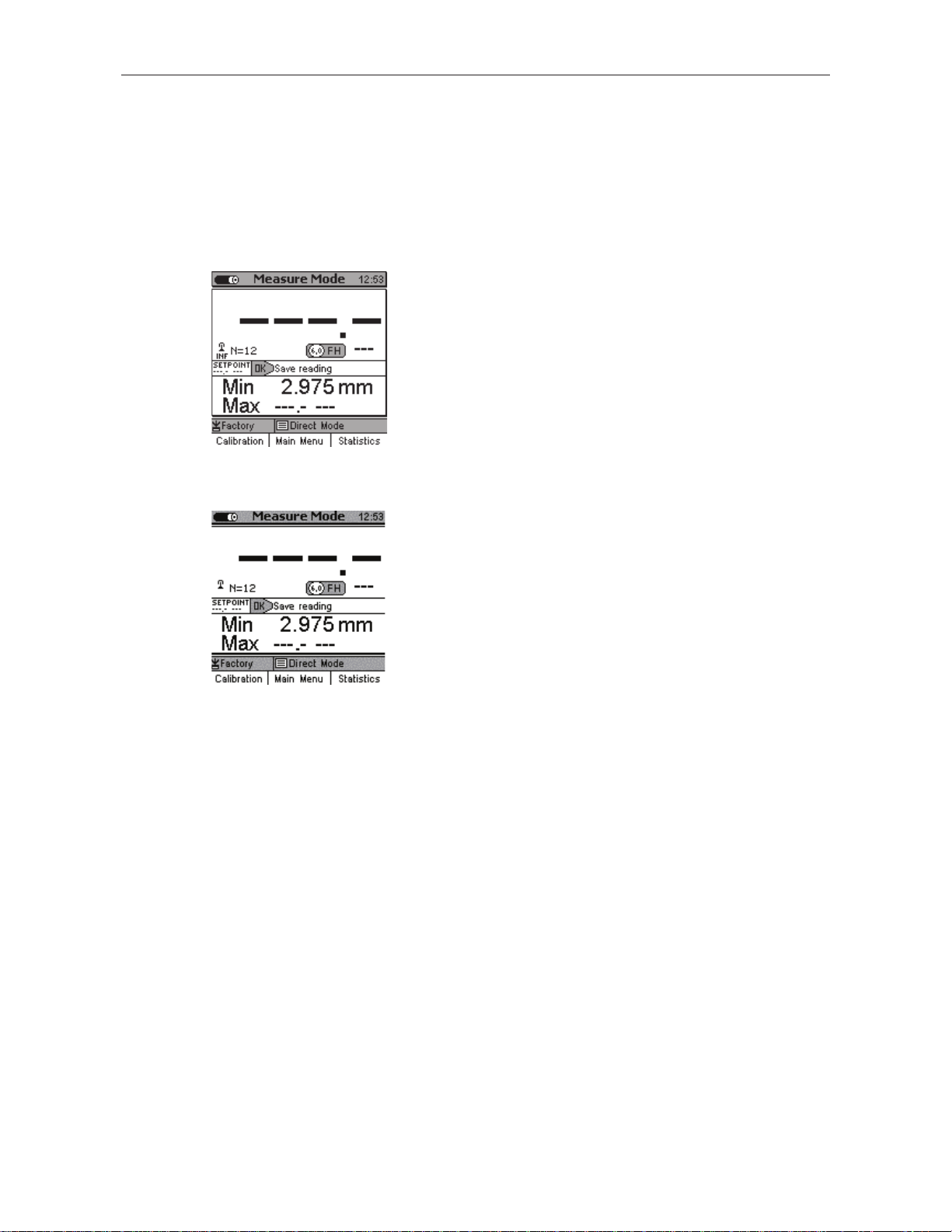

4.3.1 Measure Mode – Numerical Screen

Power supply indicato

Number of readings

djusted set poin

CALIBRATION MOD

The current function key proper-ties

are indicated in the line above the

function keys.

Time clock

Current reading

Target ball size and measuring unit

Minimum reading

Maximum reading

Active batch (MiniTest 7400FH only)

Status line

© ElektroPhysik MiniTest 7200 FH / MiniTest 7400 FH

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

13

Page 14

4.3.2 Measure Mode –Graphics Screen w i t h M iniTest 7400 FH

r

H

⇑

T

t

r

Power supply indicato

Reading

Set poin

REAL-TIME TREND

CALIBRATION METHOD

The current function key proper-ties

are indicated in the line above the

function keys.

Time clock

Target ball size, measuring unit

DATA LOGGING MODE

UPPER LIMI

MAX = MAXIMUM READING

N = NUMBER OF READINGS

MINIMUM READING

⇓

LOWER LIMIT

NAME OF ACTIVE BATC

STATUS LINE

For setting the Real-Time Trend display option, select “ Active Batch” form the Main Menu. Press

OK to confirm. Select “Configuration” from the Batch Menu and press OK to confirm. Use the arrow

keys to move to the “Graphics” option. O N or OFF is highlighted. Use arrow keys to make your

selection and press OK to confirm or t he “ ESC” navigation button to restore previous setting and to

go back to the previous menu level.

To take full advantage of the real-time trend it is necessary to toler ance lim its (see also section

8.11 „Upper specification limits (USL) and lower specification limits (LSL)“.

4.3.3 Statistics Screens

,

Power supply indicato

Process capability,

cp and cpk

Selected calibration mode

The current function key proper-ties

are indicated in the line above the

function keys.

Time clock

Active batch

(MiniTest 7400 FH only)

© ElektroPhysik MiniTest 7200 FH / MiniTest 7400 FH

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

14

Page 15

4.4 User Menu

The numerous MiniTest FH 7400 / 7200 features can be accessed via the dif ferent menus that are

divided into submenus.

Press the Function key “Main menu“ in order to get access to the main menu.

Select an item from the Main Menu (e.g. Database) and press OK to confirm. You will go to a

submenu. Use the arrow keys to select the request ed it em and press OK to confirm.

To go back to the previous menu level press ESC.

According selected submenu you can

-

View settings (e.g. Gauge specs = Gauge specifications in the Setup Menu)

-

Select preset parameters (e.g . 100% br ightness from the Display Menu)

-

Make numerical or alphanumerical entries (e.g. Ent er a directory name in the database / new

directory option).

4.4.1 User Preferences

Use the arrow keys to select your requested menu item, e.g. Language.

Press OK to confirm. T he current selection will be highlighted. Use the

arrows to select the requested parameter ( e. g. English) and press OK to

confirm. To undo your selection, pr ess ESC and you will return t o t he

previous menu level.

© ElektroPhysik MiniTest 7200 FH / MiniTest 7400 FH

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

15

Page 16

4.4.2 Numerical Entries

As soon as the alphanumeric block is activated, ESC and OK will

assume navigation functions to the lef t or right. Choose your character

by placing the cursor over the requested character. After a certain period

of time, the entry will be accepted automatically without the need to

confirm. This period of tim e can be specified under User Pref erences in

the “Entry accepted” option. See also section 10.5.5 for further

reference. Complete your entry by pressing Function key “Ready” and

then confirm “Save changes?” by pressing OK.

4.4.3 Alphanumerical Entries (on MiniTest 7400 FH)

For alphanumerical entries you can use as many as 15 characters for

entering a name. ESC and OK assume navigation f unctions to the left or

right. Choose your character via the alphanumerical block. Your

selection will be automatically accepted after the previously specified

period of time. This period of time can be set under User Pref erences in

the “Entry accepted” option. See also section 10.5.5 for further

reference. Complete your entry by pressing Function key “Ready”.

Complete your entry by pressing Function key “Ready” and then confirm

“Save changes?” by pressing OK.

© ElektroPhysik MiniTest 7200 FH / MiniTest 7400 FH

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

16

Page 17

5. Measure Mode

5.1 Important Notes on Thickness Measurement

Make sure that the operator has been properly instructed r egarding the use of thickness gauges

and has basic knowledge of the specific requirements for measurement of the application. The

operator should have basic knowledge of the following:

• Selection of a measuring device suitable f or his applicat ion

• Fundamentals on the magneto-static m easuring principle

• Influences on the magnetic f ields t hr ough the surrounding field

• Influence of the surf ace pr oper ties of the material to be tested (roug hness, build- up on t he

surface)

• Statistical evaluation of measuring ser ies

• Gravity influencing the ref e r ence ball

5.1.1 Limitations to magneto-stati c t hi ckness measurement

The information obtained f rom thickness measurements according to the magneto-static principle

only refer to t hose parts of the t est object that have been covered by the magnetic sensor. For that

reason, be careful to draw conclusion on other parts of the measuring object that have not been

covered by the sensor during measurement. I n general, such conclusions are only admissible if

comprehensive experience and approved methods of statistical data acquisition are available.

5.2 Batch Configuration / Necessary Settings

Before taking reading s, it is necessary to make a few settings in the Configuration menu. The

Configuration always refers to a certain measuring series (Batch).

5.2.1 Batch

-

You can continue to take readings in the active batch

-

You can create a new batch (only with MiniTest 7400 FH model)

-

You can choose an exiting batch from the database (please refer to section 7.2).

© ElektroPhysik MiniTest 7200 FH / MiniTest 7400 FH

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

17

Page 18

5.2.2 Target Ball Size

According to sensor type and the shape of measuring object, a

suitable target ball must be set. This can be m ade in the Configuration

menu, menu item “Targ e t ball” (also refer to section 6 “Calibration”.

Use arrow keys to move to “Target Ball” size and press OK. Use arrow

keys to adjust the requested t arg et ball size. Press O K to confir m your

setting or press ESC to undo your setting. If you undo, you will

automatically quit target ball setting option and go back to the previous

menu level.

5.2.3 Data Logging Mode

In the data logg ing mode you can specif y how you wish readings to be stored in memory. Several

modes are available:

-

manually or via footswitch (Current reading, MIN, MAX)

-

Automatic (Auto)

Note: For logging data into memory please always proceed as follows: Put the sensor into the

correct measuring position, press ESC. Then readings can be taken.

5.3 Preparing Measurement

Before measurement, the probe must be adapted to the ambient temperature. In case of high

variations in temperature, the targ et ball must be lifted f rom the probe tip at regular intervals (e.g.

every other minute). This is to compensate f or f r equency drif t due to variations in temperature. It is

recommended to switch on the gauge for warming up around 2 to 3 minutes in order to ensure

maximum measuring accuracy.

5.3.1 Calibration

According to your setting of task , you may use different calibration methods. Measuring accuracy

depends on the selected calibration method. Please refer to section 6 for more details on this

issue.

There are three calibration methods available:

-

Factory

-

Zero only

-

Multi-point calibration (Zero + 1 to 4 Point(s)

© ElektroPhysik MiniTest 7200 FH / MiniTest 7400 FH

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

18

Page 19

5.3.2 Measurement wit hout Sensor St and

For measuring large-sized parts, the sensor can be guided manually over the measuring sample.

For measuring thick samples (6 m m and thicker) make sure to k eep the sensor in vertical position

to the sample. When holding the sensor in horizontal position, due to the influence of gravity on the

steel ball, the readings will be higher than the actual thickness.

5.3.3 Using the Sensor Stand

For measuring small part s, bottles or other cylindrical bodies the sensor stand (supplied with the

sensor) and a footswitch (available as an option) should be used.

Put the sensor into the stand and secure with the red sensor stand

retaining ring.

5.4 Take Readings

5.4.1 Measurement wit hout Sensor St and

For measurements on large-sized sheeting m aterial or large hollow parts, place the sensor onto

the surface of the object to be measured. Place an appropriate tar get ball on the opposite side of

object near the sensor. The t arget ball will be attr acted by the strong permanent m agnet of sensor

and be positioned centrally just opposite of the sensor t ip. Keep the sensor in right-ang le position

to the object to be measur ed and scan continuously over the surface. For storing readings, please

refer to section 5.5.1.

© ElektroPhysik MiniTest 7200 FH / MiniTest 7400 FH

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

19

Page 20

5.4.2 Using the sensor stand

If you are using the sensor stand, position the sample on the sensor tip and keep it in right-angle

position to the sensor. Place the appropriate t arget ball on the opposite side of obj ect. Make sure

to keep the right -angle position while moving the object continuously over the sensor. For st oring

readings, please refer to sect ion 5. 5. 1.

When measuring small hollow parts such as bottles e.g., put the target ball inside the object and

place the object onto the v-grooved device of sensor stand. Turn the object unt il the target ball is

centered directly over the sensor tip. Then move the object continuously over the v-groove of

sensor stand. For storing readings, please r efer to section 5.5.1.

5.4.3 Delete Readings

Please refer to section 8.2.2 “Delet e Single Readings“.

5.5 Storing Readings into Statistics Memory

5.5.1 Data Logging Mode

During measurement, readings can be stored into memory manually or automatically. Data in

memory will be used for statistics.

The following storing options ar e available:

-

Storing the current reading manually or automatically

-

Storing the minimum reading (only manually)

-

Storing the maximum reading ( only manually).

The Data logging mode can be specif ied in t he “Conf ig uration” submenu. Use arrow keys to select

the Data logging mode option and pr ess OK to conf irm. You can chose f rom t he following setting

options:

-

Curr. reading (Current r eading)

-

Auto

-

Max

-

Min

Make your selection and press OK to confirm. If you wish to undo your setting (before OK has

been pressed) press ESC and the gauge will return to t he pr evious menu level.

© ElektroPhysik MiniTest 7200 FH / MiniTest 7400 FH

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

20

Page 21

5.5.2 Manual Data Storage

During the measuring procedure, current readings can be stored manually into the active batch by

pressing OK or by actuating a foot switch. For this option set Data logging mode to “ Cur r . r eading”.

5.5.3 Automatic Data Storage (Auto)

Auto option

In the auto mode, readings will be stored automatically during the measuring procedure as soon as

you press OK. To st op the automatic data storage pr ess OK again. If a footswitch is connected,

readings are stored as long as the f ootswitch is actuated.

Before starting the automatic data storage make sure the sensor is placed in the correct measuring

position. Make sure to st op the automatic data storage BEFORE the sensor has left the measuring

position. This is to avoid err atic readings to be stored into memory that m ight occur when putting

the sensor to or lifting it from the sample.

After setting the Data logging option to the Auto option, a Logging rate option will appear. The

logging rate defines t he time intervals at which data will be stored into memory (1, 2, 5, 10 or 20

readings per second). For slow measurement scans, a low logging rate should be set, for quick

scanning, the logging rat e should be set to a higher rate.

5.5.4 Storing Minimum Reading

In the Minimum option, minimum readings will be stored to t he active batch by pressing OK during

measurement or by activating a foot switch.

To set Data logging mode t o the MIN option, go to the Configuration submenu and select Data

logging mode. Use arrow keys to select MIN and press O K to confirm. Please note: The minimum

reading can also be stored even after the sensor has been lifted from the sample.

5.5.5 Storing Maximum Reading

In the Maximum option, maximum readings will be stored to the active batch by pressing OK during

measurement or by activating a footswitch.

To set Data logging mode t o the MAX option, go to the Configuration submenu and select Data

logging mode. Use arrow keys to select MAX and press OK t o confirm.

Important note:

-

Make sure to put the sensor into the correct measuring position and to press ESC before

storing the Maximum reading into memory.

-

© ElektroPhysik MiniTest 7200 FH / MiniTest 7400 FH

Find Quality Products Online at: sales@GlobalTestSupply.com

OK must be pressed BEFORE the sensor is moved from its measuring position.

21

www.GlobalTestSupply.com

Page 22

5.6 Error Sources during Measurement

After calibrating the gauge according to your application and appropriate target ball size, the gauge

is ready for measurement.

The readings will be correct as long as you measure within the range as specif ied for this target

ball. The target ball is placed on one side of the sample to be measured and will be attracted by

the sensor tip on the other side of the sample. The tar get ball serves as a reference to the sensor.

What is being m easur ed is t he distance between sensor and target ball.

Make sure to place both, the sensor tip and the targ et ball correctly onto the sample. Both must be

in good contact with the surface of sam ple. Otherwise erratic readings (higher readings) might

occur. Make sure to keep the sensor in perpendicular position while moving it over the sample. The

target ball on the other side must be freely movable.

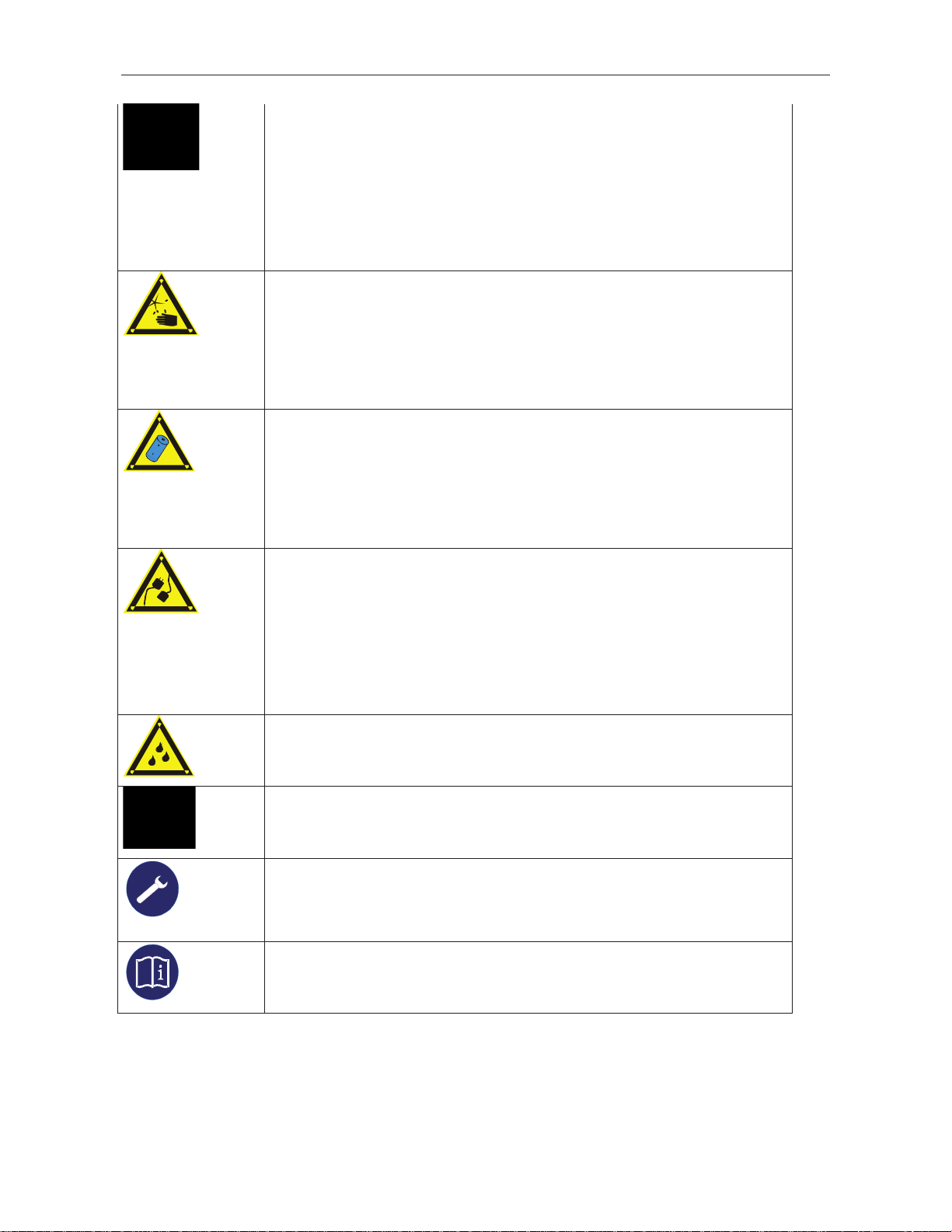

5.6.1 Correct Sensor Position

The picture illustrates the correct posit ion of sensor tip and steel

ball. Make sure to keep the sensor tip perpendicular t o t he

surface of sample.

5.6.2. Incorrect Readings through tilt i ng of t he Sensor

Error source:

The sensor tip is not positioned corr ectly in perpendicular position

to the sample. The reading will therefore be higher t han the actual

thickness.

Remedy:

Make sure to keep the sensor in perpendicular position to t he

sample. If necessary, use the sensor stand.

© ElektroPhysik MiniTest 7200 FH / MiniTest 7400 FH

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

22

Page 23

5.6.3 Incorrect readings through Blocked Target Ball

Error source:

The target ball has got stuck through a bulge, e.g. inside the

sample. It is out off t he correct measuring position.

Remedy:

Move the sample in order to release the target ball.

5.6.4 Air gap

Error source:

Due to the shape of sample, an air gap is between

target ball and measuring object. The reading will be

higher than the actual thickness.

Remedy:

If the tar get ball is too large, use a smaller one. If the

sensor is not in good contact, change measuring

position and use a smaller target ball, if necessary.

5.6.5 Measuring material with ferruginous parti cl es

Ferruginous particles in the material to be measur ed m ay lead to er r at ic readings because the

ferruginous particles may inf luence t he m easuring signal. This will lead to readings smaller than

the actual thickness.

© ElektroPhysik MiniTest 7200 FH / MiniTest 7400 FH

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

23

Page 24

6. Calibration

Calibration is made in the batch being active and will always refer to this batch, i. e. each batch has

its own calibration. Before calibration, an appr opr iat e target ball diameter must be set in the

Calibration menu. Please refer to section 5.2.2 “Targ et ball size”.

There are two options to go to the Calibrat ion menu:

-

from the Main menu choose Calibration

-

from the Measure Mode menu press Calibration function key.

For selecting an appropriate targ et ball, the following aspects should be taken into considerat ion:

-

minimum radius of sample to be measured

-

maximum thickness to be measured

-

required measuring accuracy

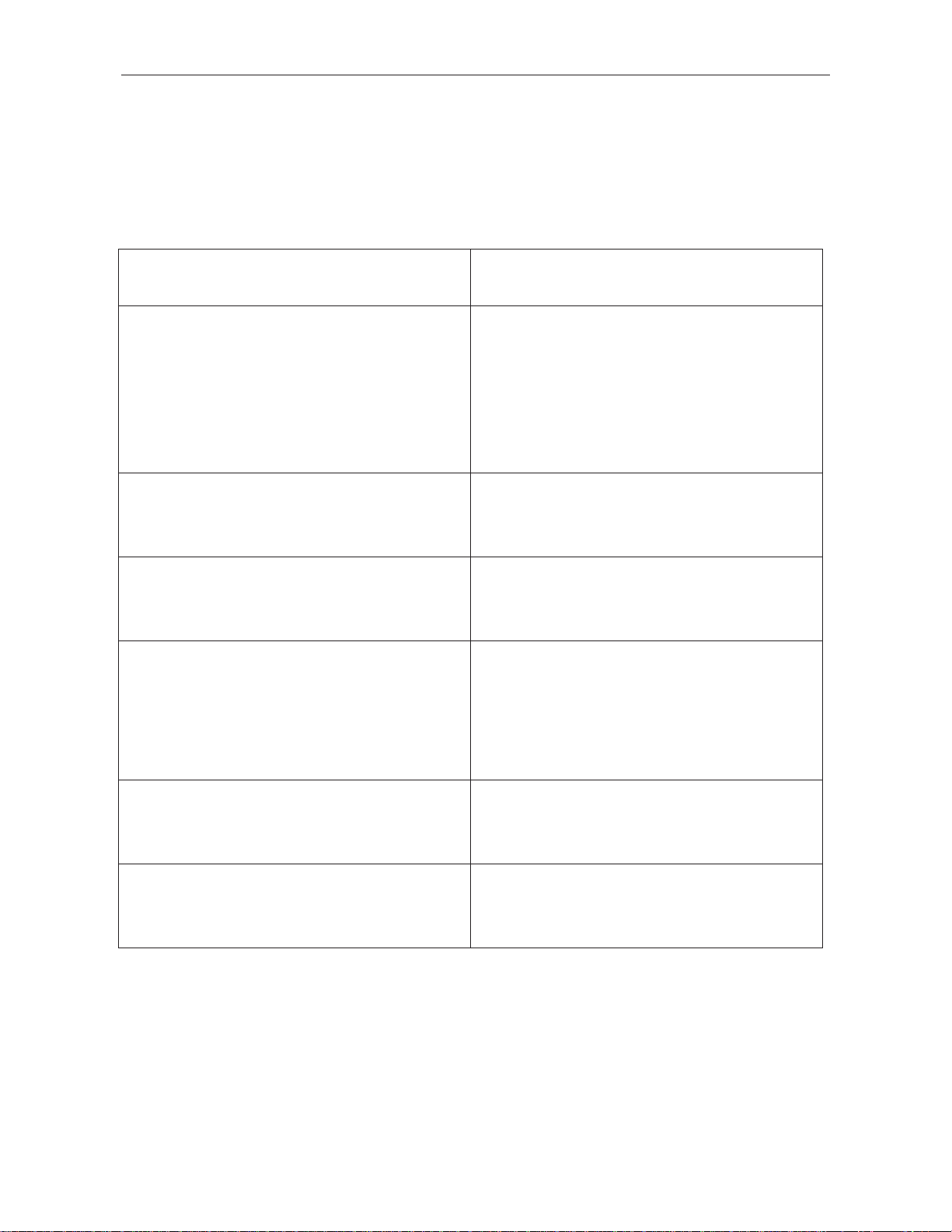

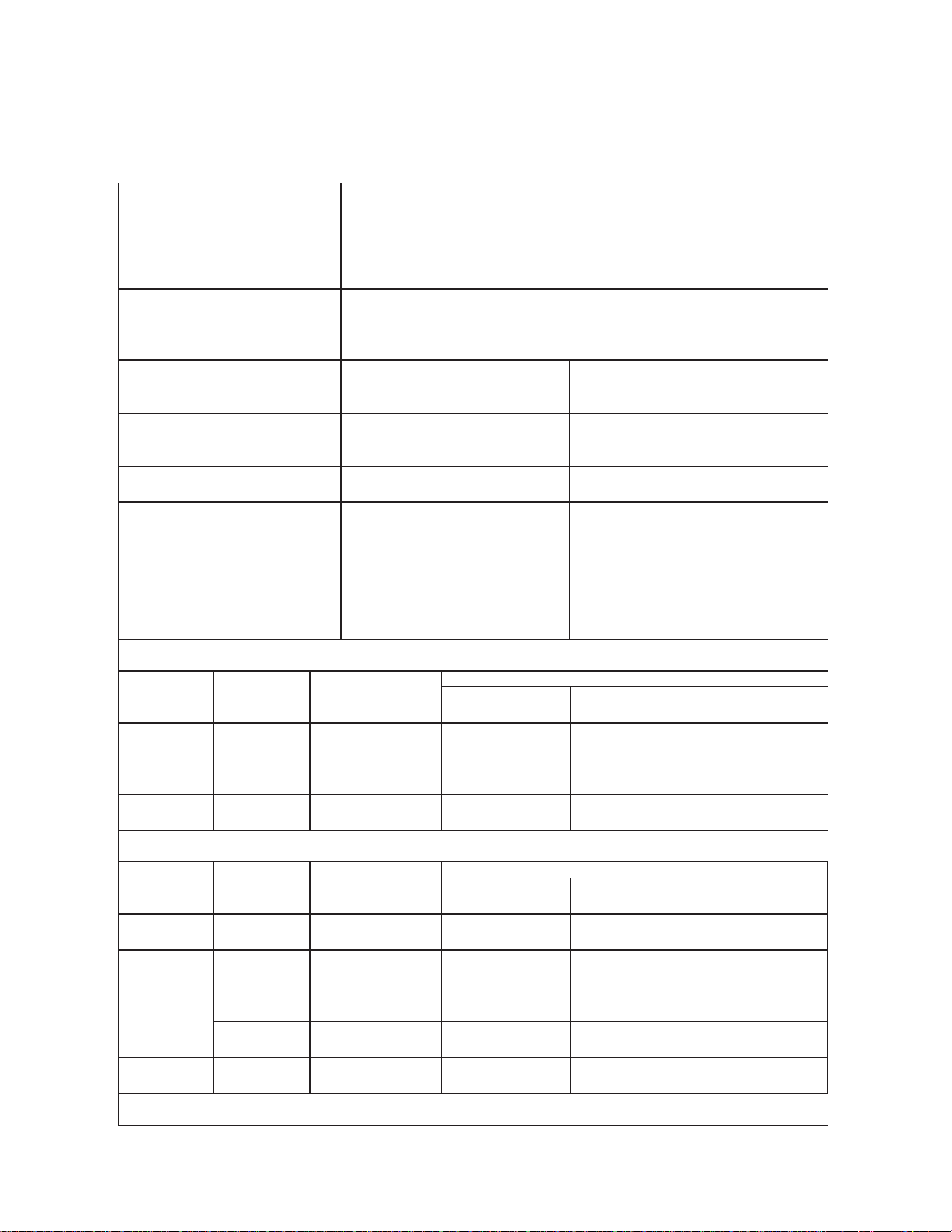

Sensor Target ball to

be used

Min. Internal

radius of sample

Measuring

range

Recommended

measuring range

FH 4 Ø 1.5 mm 0.75 mm 0 ... 1.5 mm 0... 1.5 mm

FH 4 / FH 10 Ø 2.5 mm 1.25 mm 0 ... 2.5 mm 1... 2.5 mm

FH 4 / FH 10 Ø 4.0 mm 2.0 mm 0 ... 4.0 mm 2... 4.0 mm

FH 10 Ø 6.0 mm 3.0 mm 0 ... 10 mm 3... 6 mm

FH 10 Ø 9.0 mm 4.5 mm 0 ... 10 mm 6... 10 mm

6.1 General Remarks on Calibration

For achieving maximum accuracy, please observe the following calibration instruct ions:

• Make sure to keep off str ong magnetic fields from t he sensor dur ing measurement.

• Keep away from any ferromagnetic metal par ts in a safety distance of at least 30 cm.

• It is recommended to switch on the gauge for warming up around 2 to 3 minutes before

starting calibration procedure.

• Make sure the sensor tip, target balls and calibration standards are clean. Any foreign

matter may lead to erratic readings.

• For maximum accuracy of calibration and later measurements, choose the thickness of

calibration standard within the same thickness range as the later measuring sample.

• In some cases it may become necessary to recalibrate if a new target ball is used (also if it

has the same diameter as the previously used one). To be sure, check calibration in

© ElektroPhysik MiniTest 7200 FH / MiniTest 7400 FH

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

24

Page 25

measuring mode by putting the matc hing precision standard with the appropriate target ball

on the sensor.

• Please note that large targ et balls will compress soft material more than small tar get balls.

Please note:

If the gaug e switches off during the calibration procedure due to low battery voltage, calibration

must be repeated after installing fresh batteries.

Please note:

Each time the target ball is removed f r om the sensor tip in a distance of more than 30 mm, t he

gauge will automatically be adjusted to the infinite range. Any possible drift influences ( e . g.

through variations in temperature) will be extensively compensated. The m or e often the target ball

is removed form the sample, the more often compensation will take place so as to increase

measuring accuracy.

For that reason it is recommended to lift the target ball fr om t he sensor tip at least every three

minutes. A message will appear on display accordingly to remind you to repeat infinite setting

(“Refresh infinite Value !!!).

To ensure measuring accuracy, check calibrat ion after one hour of use of the g auge and

recalibrate if necessary.

6.2 Calibration methods

According to your setting of task, you may use different calibration methods. Measuring accur acy

depends on the selected calibration method. The following calibration methods are available:

-

Factory calibration.

This calibration method is suitable for quick and simple measurement and if larger

measuring errors are admissible as compar ed t o zero calibr at ion.

-

Zero only (zero point calibration).

This method is for quick calibration with a medium measuring accuracy.

-

Multi -point calibration (Zero + 1 to 4) Calibration standard(s).

In most cases a Two-point calibration (Zero + one standard) will be sufficiently good as

far as calibration is made in the rang e of thickness to be expected. Further calibration

points are recommended if measurem ent will be over a larger thickness range and if

accuracy requirements are high.

© ElektroPhysik MiniTest 7200 FH / MiniTest 7400 FH

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

25

Page 26

6.3 How to calibrate

Using the sensor stand will add additional comfort during the calibration procedure. For more

details please refer to section 5.3.3.

For all calibration methods the following applies:

-

To call the Calibration menu from Measure mode m enu, pr ess t he Calibration function key.

-

Use the arrow keys to go to “Targ et Ball”. Press OK to confirm. Use arrow keys to adjust to

the requested target ball size. Pr ess O K t o confirm.

-

Use arrow key to go to “Calibration Mode”. Press OK to confirm and use arrow keys to

make your selection. Press OK to confirm.

-

6.3.1 Factory Calibration

Use arrow keys to select “Factory“. Press OK to confirm. The gauge is

ready for measurement.

6.3.2 Zero only

Use arrow keys to select “Zero only“. Press OK to conf ir m .

For zero point calibration, the zero standards supplied with the gauge

must be used together with the matching target balls. Make sure

always first to place the target ball into the zero standard. Then put

both together onto the sensor. Wait for the sound to bleep, remove the

precision standard and keep it in a distance of at least 30 mm.

For mean calculation it is recommended to repeat the procedure

several times. (To g et reasonable values it is always recommended to

take several readings and to have the mean calculated). Pr ess OK to

confirm.

A ticked box right to “Zero“ will confirm successful calibration.

Now the gauge is ready for measurement.

© ElektroPhysik MiniTest 7200 FH / MiniTest 7400 FH

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

26

Page 27

Zero calibration standard wit h t arget bal l put on it

6.3.3 Multi-point calibrat ion (Zero + 1 to 4 point(s) )

For multi-point calibration you must f irst carry out a zero point calibrat ion. The precision standards

must be used (1 to 4 as requested) to calibrate for the further calibration points. The precision

standards have different thick ness values.

1. In most cases a Two-point calibration ( Zero + one standard) will be sufficiently good as far

as calibration is made in the range of t hickness to be expected.

2. Further calibration points are only necessary if measurement will be made over a larger

thickness range and if accuracy req uir em ents are high.

Now use arrow keys to select “Zero + 1 point” calibration. Pr ess OK

to confirm. Carr y out zero calibration as described under 6. 3.2. Then

use arrow keys to select “Calibr. Point 1”, press OK to confirm.

Please always use one of the precision standards supplied with the

sensor. Make sure first to place the target ball on the precision

standard. Then place t he precision standard tog ether with the target

ball onto the sensor. W ait for the signal tone to sound and lift the

precision standard more than 30 mm from the sensor. For calculation

of average repeat several times.

In the “CAL = “ field, the calibration mean value will be shown

which has been calculated form the set of single readings you have

taken. If this value is the same as specified on the precision

standard, press OK to complete the calibration procedure. If not,

please use arrow keys to correct the value as requested.

© ElektroPhysik MiniTest 7200 FH / MiniTest 7400 FH

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

27

Page 28

In the alphanumerical input field, you can enter the t hickness of the

precision standard along with the unit. ESC and OK assume

navigation functions to the left or right. You can select the requested

character via the numerical block. Your selection will be

automatically accepted after the specif ied period of t ime. This period

of time can be specified in the Setup menu. Chose User Pref er ences

and select “Entry accepted” (see also section 10.5.5). Complete your

entry by pressing Function key “Ready”. To store your setting, press

OK. Then press OK again to quit .

For more calibration points repeat procedure as necessary. The current state of calibration is

indicated in the calibration check box in the calibration menu. Ticked boxes will mark successful

calibration points.

After successful calibration of the last calibration point, the gauge is r eady for measurement.

6.4. Delete calibration point

Use arrow keys to move to the calibration point to be deleted.

Press “Delete” Function key and press OK to conf ir m or ESC to abort. Pressing “Delete” Function

key a second time will remove the (X) from t he check box. If you press again “Delete” Function

key, the calibration value will also be deleted.

© ElektroPhysik MiniTest 7200 FH / MiniTest 7400 FH

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

28

Page 29

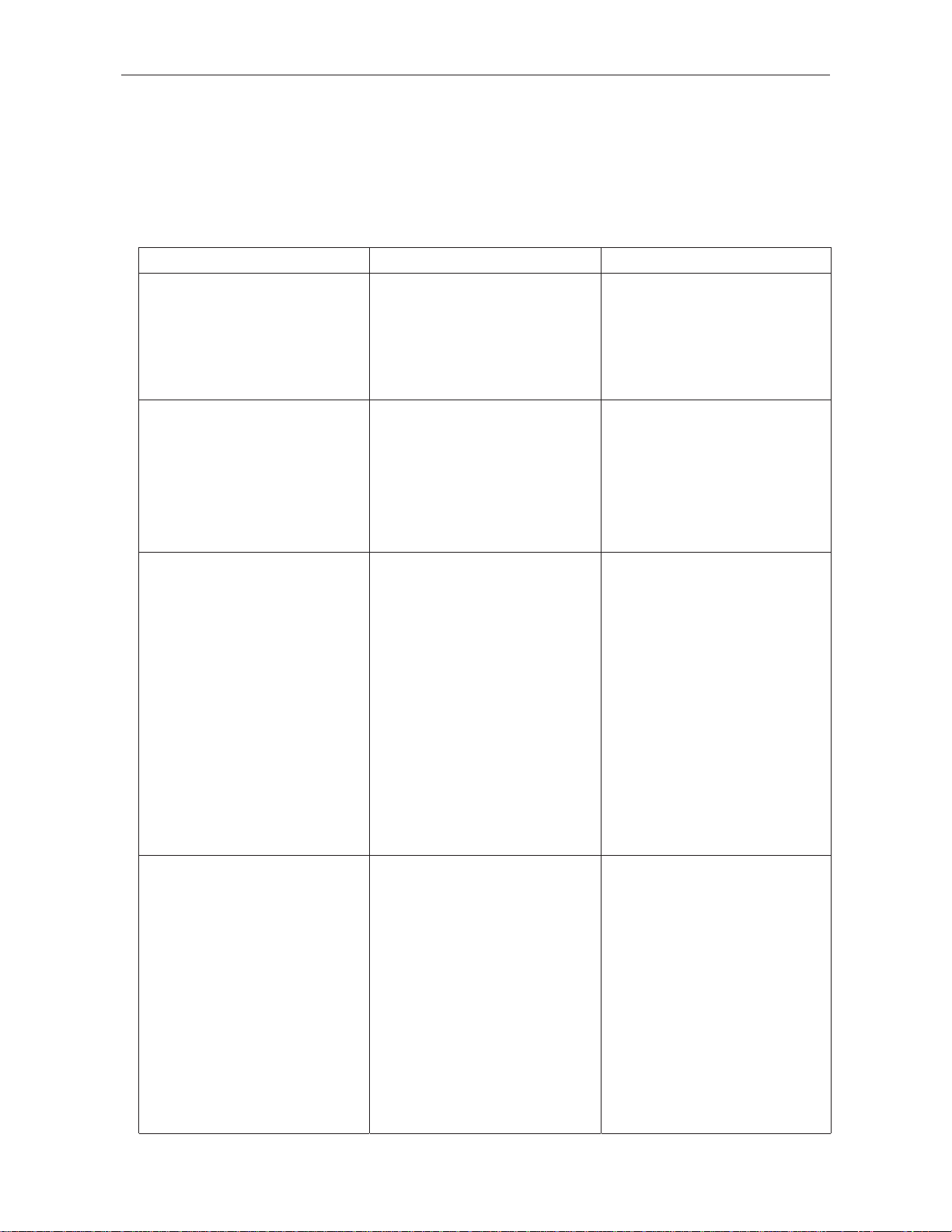

6.5 Calibration Error Sources

The following situations may lead to errat ic calibr at ion:

Error: Remedy:

Wrong target ball: Select an appropriate target ball suitable for

your measuring sample and the thickness to be

expected.

Adjust to the correct target ball size via the

menu.

Calibration range does not match to t he

thickness to be expected:

During calibration, the precision standard has

not been placed correctly on the sensor Tipp.

Calibration error due to changes in temper at ure Before calibr at ion, t he sensor m ust be adapted

Worn or dam aged precision standards: Please use new precision standards in

Build-up on the sensor tip. Clean sensor tip from metal parts, dirt particles

Calibrate within the thickness range to be

expected.

Make sure to fully engage the precision

standard on the sensor tip.

to the ambient temperature. Please wait 30

minutes after switch on before starting

measurement.

impeccable condition.

etc. by using a soft cloth.

© ElektroPhysik MiniTest 7200 FH / MiniTest 7400 FH

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

29

Page 30

7. Data Storage

7.1 Batches

7.1.1 General

Readings and their statistics will be stored in batches. Batches can be named alphanumerically

and stored in the database directly or under a certain direct or y. O ne bat ch is firmly installed under

the name “Direct Mode”. This batch cannot be deleted nor can it be renamed.

The model MiniTest 7200 FH does not include the database feat ure, but it offers one

measuring batch.

7.1.2 Batch Data

7.1.2.1 Readings

One batch may include as many as 100,000 single readings plus statistics. The model MiniTest

7400 FH offers a maximum of 240,000 values in total.

7.1.2.2 Calibration Values

Calibration always refers to a certain measuring batch. As soon as a measuring batch is called, the

corresponding calibration will become active. The calibration includes the following parameter

settings: diameter of t ar get ball, type of calibration and sensor.

7.1.2.3 Other Parameters

predefined

The parameters as set in the Conf iguration submenu such as Data logging mode, Logging rate,

Graphics (ON/OFF), Upper spec. lim it, Lower spec. limit, and Setpoint refer t o a cer tain batch and

will become valid as soon as this batch is called.

© ElektroPhysik MiniTest 7200 FH / MiniTest 7400 FH

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

30

Page 31

7.2 Database of the MiniTest 7400 FH

7.2.1 General Remarks

The database includes numerous features for data management. Measuring batches can be stored

in directories and subdirectories. In total, as many as 500 directories may be created in a

maximum of 5 levels. Directories and batches can be named alphanumer ically.

7.2.2 Tree structure

Example for a tree-structured database divided in directories and

batches. At first use of the MiniTest 7400 FH, the database only

includes one batch named “Direct Mode”. You can create other

directories or batches as required.

Note: For creating new directories or batches, make sure to place

7.2.3 Create a Directory

the cursor below

Press function key “ Main Menu”. Then select “Database” and press

OK to confirm.

Use arrow down key of the navigation block to place the cursor

below “Direct mode” or, if other directories have already been

created, to the request ed position where a new directory should be

created.

This may be below or between directories or batches. Now press

function key “Actions” and press OK to confirm “New Directory”

which is highlighted.

Enter a name in the alphanumerical input field. For more details,

please refer to section 4.4.3 “Alphanum er ical Entries”.

this Direct Mode directory.

© ElektroPhysik MiniTest 7200 FH / MiniTest 7400 FH

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

31

Page 32

7.2.4 Create a New Batch

From Measure Menu pr ess function key “Main Menu”. Then select

“Database” and press OK. Use arrow down key of the navigation

block to place the cursor below “Direct mode” or, if other directories

have already been created, to the req uested position where a new

directory should be created. This may be below or between

directories or batches. Now press function key “Actions” and move

cursor to “New Batch” which is highlighted. Press OK to confirm.

Enter a name in the alphanumerical input field. For more details,

please refer to section 4.4.3 “Alphanum er ical Entries”.

After you have entered the bat ch name, the alphanumerical screen

appears. Now you can enter a user name below the batch name

according to the procedure as described above.

After completion of user name input, the confirmation as shown on

the left appears. If you wish to accept the parameters (calibration

and configuration) as set f or t he active batch for t he new batch to be

created press OK. If you press ESC, preset parameters of the factory

calibration will become valid. Parameter settings can be made in the

“Configuration” submenu. Please refer to section 10.4.3 for more

details.

7.2.5 Select a Batch for Measurement

From Main Menu select “Database”. Use arrow keys to select the

requested batch. Press OK to confirm. The data stored under this

batch appear on display. Press OK to switch to Measure Menu.

© ElektroPhysik MiniTest 7200 FH / MiniTest 7400 FH

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

32

Page 33

7.2.6 Delete a Batch / a Directory

From Measure Menu press function key “Main Menu“ and select

„Database“. Press OK to confirm .

Use arrow keys to select the directory or batch to be deleted. Press

function key “Actions”. Select “Delete” from the “Actions” submenu. A

confirmation appears. Press OK t o confirm or ESC to abort.

If you have chosen a directory, the delete action will only delete

empty directories. If the directory includes subdirectories and

batches, these must be deleted previously.

Please note: The batch “Direct Mode” is a permanent part of the

database. It can neither be deleted nor r enam ed. Nor you can assign

a username to it. However, you can delete readings or statistical

values.

Once you have deleted data they cannot be restored.

7.2.7 Rename a Batch / Rename a Directory

From Measure Menu press function key “Main Menu“ and select

“Database“. Press OK to confirm .

Use arrow keys to select the directory or batch to be renamed. Your

selection will be highlighted. Press function key “Actions”.

Use arrow keys to go to “Rename”. Press OK t o confirm.

On the alphanumerical input field the name t o be changed appears.

This name can be changed (see section 4.4.3 “Alphanumerical

Entries”.) This action will not change the username.

© ElektroPhysik MiniTest 7200 FH / MiniTest 7400 FH

33

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 34

8. Statistics

From Measure Menu press function k ey “Statist ics“ .

From Main Menu use arrow keys to select “Statistics” and press OK to confirm .

8.1 Statistical Parameters

8.1.1 Upper and lower specifi cat i ons l imits (USL and LSL)

Tolerance limits can be set as requested and offer you the following features:

-

Readings beyond the specificat ion limits will be indicated by a signal tone and marked in

the statistics.

-

The process capability indices Cp and Cpk will be calculated according to the set

specification limits.

-

In the trend diagram and histog ram, readings lying within the set specification limits will be

highlighted. This range will determ ine the real- time tr end (only available with MiniTest 7400

FH).

The specification limits can be set in the “ Configuration” submenu. .

Use arrow keys to go to “Upper spec. limit ” and/or “Lower spec. limit”

Specify limits and measur ing system (metric/imperial) as requested

via the alphanumerical input field. See also section 4.4.2

“Alphanumerical Entries”.

Complete your setting by pressing Function k ey “Ready”. The gaug e

will check automatically whether your spec. limits are reasonable.

This is to prevent input er rors such as entering a wrong measuring

unit. Press OK to confirm your chang es.

Spec. limits can be deleted via the function key “Delete” .

Spec. limits can be set before or after readings have been taken.

© ElektroPhysik MiniTest 7200 FH / MiniTest 7400 FH

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

34

Page 35

8.1.2 Set Point (Differential Mode)

In quality control, it may be interesting to measure the difference between a set point and the

actual thickness. Once you have specified a set point, the dif ference between this set point and the

actual thickness will be displayed. A set point must be entered BEFO RE stor ing t he f irst reading . I f

you change a preset set point, the stored reading s must be deleted previously.

The set point can be set in the “Conf iguration” submenu. Use arrow keys to g o to “Set point” and

enter a value as requested along with the correct measuring system (metric/imperial) via the

alphanumerical input field. See also section 4.4.2 “ Alphanum er ical Entries”.

Complete your setting by pressing Function key “Ready”. Set point set tings can be deleted via the

function key “Delete”.

8.2 Readings

8.2.1 View Readings

From Main Menu go to “Statistics”. Press OK and select “Readings” subm enu.

From Measure Menu press function key “Statistics” . Then press function key “Batch” followed by

function key “Readings”.

Use arrow keys to scroll through the batch as requested. Readings will be indicated along with

their current reference number. If spec. limits have been set previously, information is included

whether the readings have been above (>>) or below (<<) the spec. limit.

8.2.2 Delete Single Readings

Erratic readings may be deleted from t he list .

Move the cursor to the reading to be deleted.

Press function key “Help/Extra”. Move cursor to “Delete Readings”

and press OK to confirm or press ESC to abort.

Readings that have been deleted are marked by (X) .

© ElektroPhysik MiniTest 7200 FH / MiniTest 7400 FH

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

35

Page 36

8.2.3 Delete all Readings

From Main Menu chose “Statistics“. Use arrow keys to move to

“Delete all readings“. Press OK to confirm.

From Measure Menu press function key “Statistics” followed by

function key “Help/Extras”. Use arrow keys to move to “Delete all

readings“. Press OK to confirm.

To abort, press ESC.

The delete action will delete all readings of the active batch. Batch

name, sensor config uration and calibration f or this batch will remain

in memory.

8.3 Numerical Statistics

From Main Menu chose “Statistics“. Use arrow keys to move to “Numerical Statistics”. Press OK to

confirm.

From Measure Menu press function k ey “Statist ics” .

Number of readings

Average (

Standard deviation (s)

Minimum

Maximum

Variation coefficient

Process capability indices Cp and Cpk (if spec. limits have been set).

For more detailed information on statistics please refer to section

15.3.

x

)

© ElektroPhysik MiniTest 7200 FH / MiniTest 7400 FH

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

36

Page 37

8.4 Histogram on MiniTest 7400 FH

From Main Menu chose “Statistics“. Use arrow keys to move to “Histogram“. Press OK to confirm.

From Measure Menu press function k ey “Statistics” followed by function key “Histogram”.

A histogram is a kind of plot that summarizes how data are

distributed. It gives you information on how the production process

might be changed in order to be optim ized.

The limit rang e is the gray-highlighted area. See also 8.1.1 “Upper

and lower spec. limits”.

Please note: For a histogram, a minimum number of 5 readings are

required.

8.5 Trend Diagram on MiniTest 7400 FH

From Main Menu chose “Statistics“. Use arrow keys to move to “Trend Diagram“. Press OK to

confirm.

From Measure Menu press function key “Statistics” followed by function key “Histogram”. Then

press function key “Trend”.

A trend illustrates the tendency of reading s so that deviations can be

quickly identified.

The limit range is the gray-highlighted-area.

For a trend-diagram, at least 5 readings are required.

© ElektroPhysik MiniTest 7200 FH / MiniTest 7400 FH

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

37

Page 38

9. Data Output / Data Transfer

Both models, MiniTest 7200 FH and MiniTest 7400 FH are equipped with a bi-directional RS232

interface and an infrared interface ( I rDA 1.9). Readings and statistics of a batch can be tr ansferred

to a PC or to the MiniPrint 7000 data printer (available as an option).

9.1 Data Print-Out

Data transfer of readings and statistics to the dat a printer MiniPrint 7000 is made via the infrared

interface (IrDA 1.0). Before printing out, go to the Main Menu and select “Setup”. Use arrow keys to

move to “Data Output” and press OK to conf irm. Use arrow keys to select “Infrared (IrDA)”. For

more details, please refer to sect ion 10.5.4.2.

Readings and statistics may be printed out from all statistical views

such as statistics, batch, histogram or trend (MiniTest 7400 FH).

Press “Help/Extra” Function key from your select ed statistical view.

The Help/Extra window opens (Fig. 1)

Fig. 1

Fig. 2

Select “Print” form t he list and confirm by “OK”.

A “Printing sequence” menu opens (Fig. 2) Move the cursor to the

first item on the list and press OK. Use arrow keys to make your

selection (Fig. 3). The following options are available:

-

Logo (Company logo or other customized logo in graphics

format (160x80 Pixel). For inserting such logo, MSoft 7000

software is required.

-

Name (of batch) / or name ( of batch) + date (MiniTest 7400

FH).

-

Operator (with MiniTest 7200 FH Notes-Field only)

-

Statistics (number of readings, Average (x) Standard

deviation (s), Min., Max. Variation Coefficient, Cp and Cpk ).

-

Measuring Values or Measuring Values + Deleted Values

(see also section 8.2.2).

-

Trend (MiniTest 7400 FH only)

-

Histogram (MiniTest 7400 FH only)

-

Fig. 3

© ElektroPhysik MiniTest 7200 FH / MiniTest 7400 FH

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Notes-Field (space for remarks with 5 lines)

-

----- (remains empty)

38

Page 39

Press OK to confirm your selection and go to the next position on the

printing list and proceed as described above.

The print-out list can also be limited to fewer items (e.g. statistics and

measuring values only, Fig. 4)

Fig. 4

Now align the infrared windows of the MiniTest and MiniPrint 7000.

Press function key “Print” to start the print-out.

To abort, press “ESC”.

9.1.1 Screen Shot

Please refer to section 11.2 “Special functions“.

9.1.2 Print-out a Batch

Please refer to section 9.1 “Data Pr int - out”

© ElektroPhysik MiniTest 7200 FH / MiniTest 7400 FH

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

39

Page 40

9.2 Transfer Data to a PC

Before transferring data, go to the Main Menu and select “Setup”. Use arrow keys to move to

“Data Output” and press OK to confirm. Use arrow keys to select “RS232 cable” or “Infrared (IrDA).

Press OK to conf irm. See also section 10.5.4. I f you adjust to RS232, please mak e sure to make

the correct settings for baud r at e and t r ansm ission protocol.

Readings and statistics may be transfer r ed to a PC from all statistical

views such as statistics, batch, histogram or trend (MiniTest 7400

FH). Press “Help/Extra” Function key from your selected statistical

view. The Help/Extra window opens (Fig. 1)

Select “Print” form t he list and confirm by “OK”.

A “Printing sequence” menu opens. Move the cursor to the first item

on the list and press OK. The following opt ions ar e available:

-

Name (of batch) / or name ( of batch) + date (MiniTest 7400

FH).

-

Statistics (number of reading s, Average (x) Standard

deviation (s), Min., Max. Variation Coefficient, Cp and Cpk ).

-

Measuring Values or Measuring Values + Deleted Values

(see also section 8.2.2).

-

Operator (with MiniTest 7200 FH Notes-Field only)

-

----- (remains empty)

Press OK to confirm you selection.

Connect the MiniTest FH via the RS232 cable to your computer or

align the infrared windows of your computer or of your IrDA adapter