Page 1

1

(OUTDOOR UNIT)

SCM60ZD-S

(INDOOR UNIT)

SKM22ZD-S STM25ZE-S SRRM25ZE-S

SKM25ZD-S STM35ZE-S SRRM35ZE-S

SKM28ZD-S STM50ZE-S SRRM50ZE-S

SKM35ZD-S STM60ZE-S SRRM60ZE-S

SKM50ZD-S

SCM-ZD (3room)

INVERTER MULTI-SPLIT SYSTEM

ROOM AIR-CONDITIONER[3room]

(Air to air heat pump type)

Page 2

2

CONTENTS

5.1 GENERAL INFORMATION ........................................................................ 377

5.1.1 Specific features ................................................................................. 377

5.1.2 How to read the model name ............................................................. 377

5.2 SELECTION DATA ..................................................................................... 378

5.2.1 Specifications ...................................................................................... 378

5.2.2 Range of usage & limitations ............................................................. 386

5.2.3 Exterior dimensions............................................................................ 387

5.2.4 Piping system ...................................................................................... 389

5.2.5 Selection chart .................................................................................... 390

5.3 ELECTRICAL DATA................................................................................... 391

5.3.1 Electrical wiring .................................................................................. 391

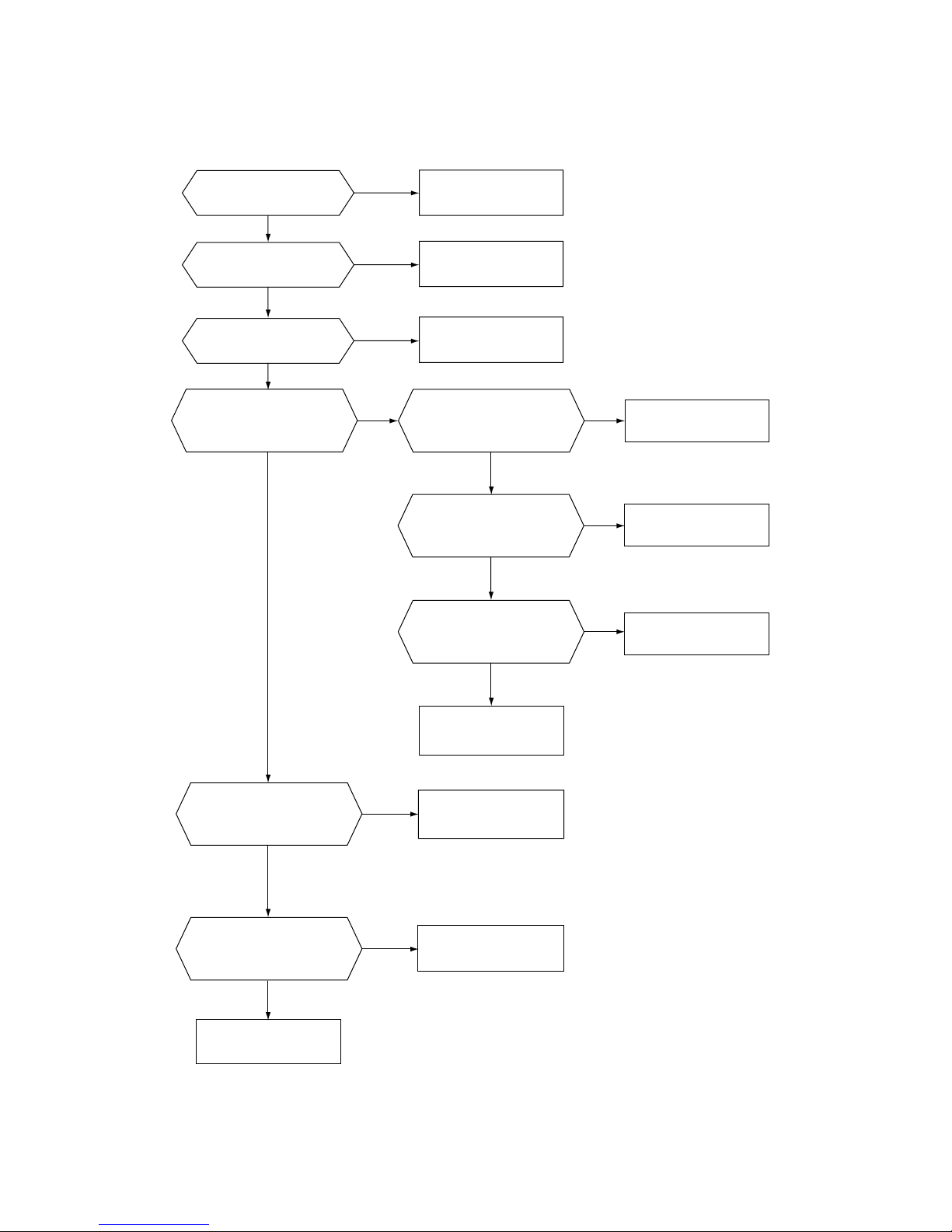

5.4 OUTLINE OF OPERATION CONTROL BY MICROCOMPUTER ............. 395

5.5 APPLICATION DATA ................................................................................. 419

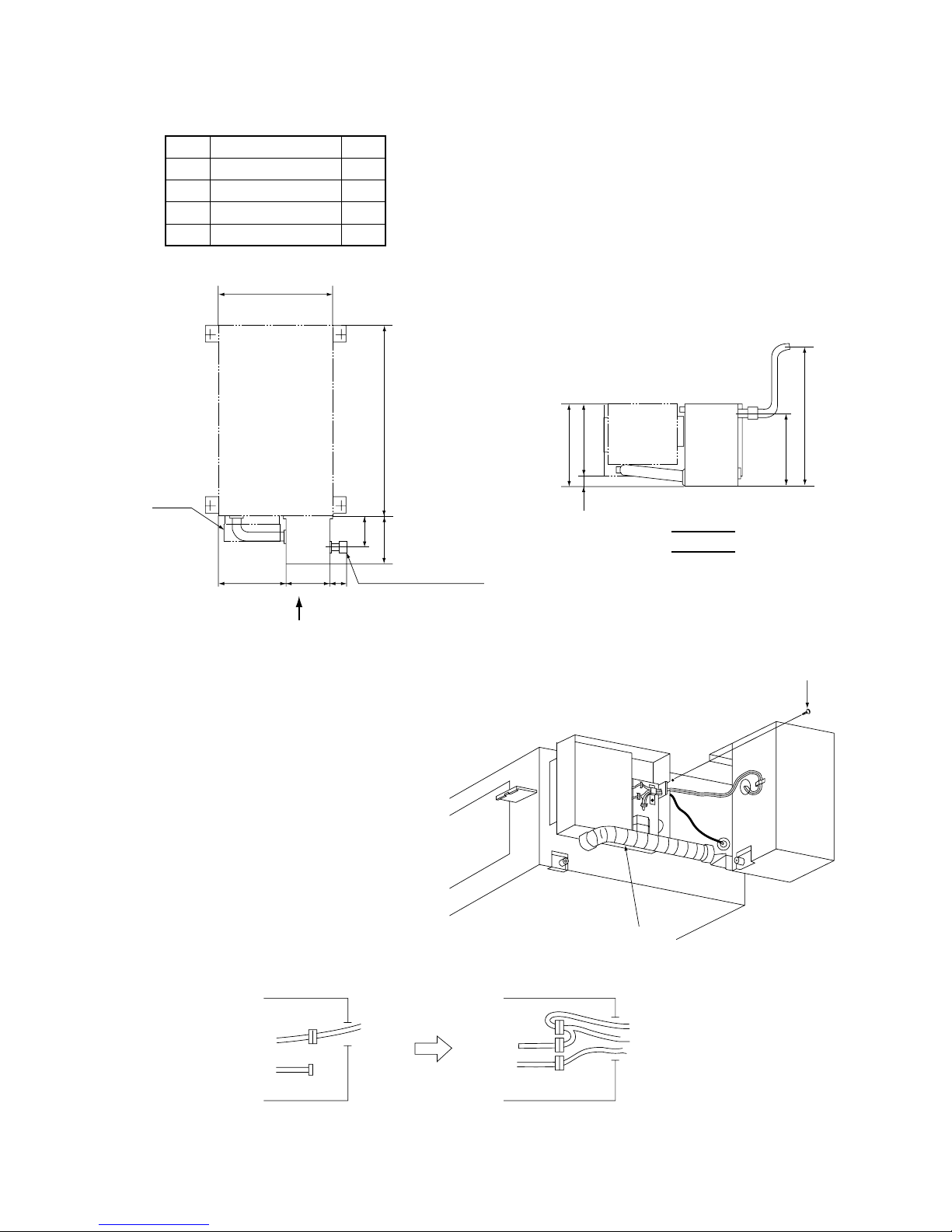

5.5.1 Installation of indoor unit ................................................................... 420

5.5.2 Installation of remote control............................................................. 429

5.5.3 Installation of outdoor unit................................................................. 430

5.5.4 Electrical wiring .................................................................................. 431

5.5.5 Refrigerant piping ............................................................................... 432

5.5.6 Test run and handling instruction ..................................................... 434

5.5.7 Installation of remote control and super link adapter

(SC-AD-E) (Optional parts) ................................................................ 435

5.5.8 Installation of optional parts (Ducted type) ...................................... 442

5.6 MAINTENANCE DATA ............................................................................... 447

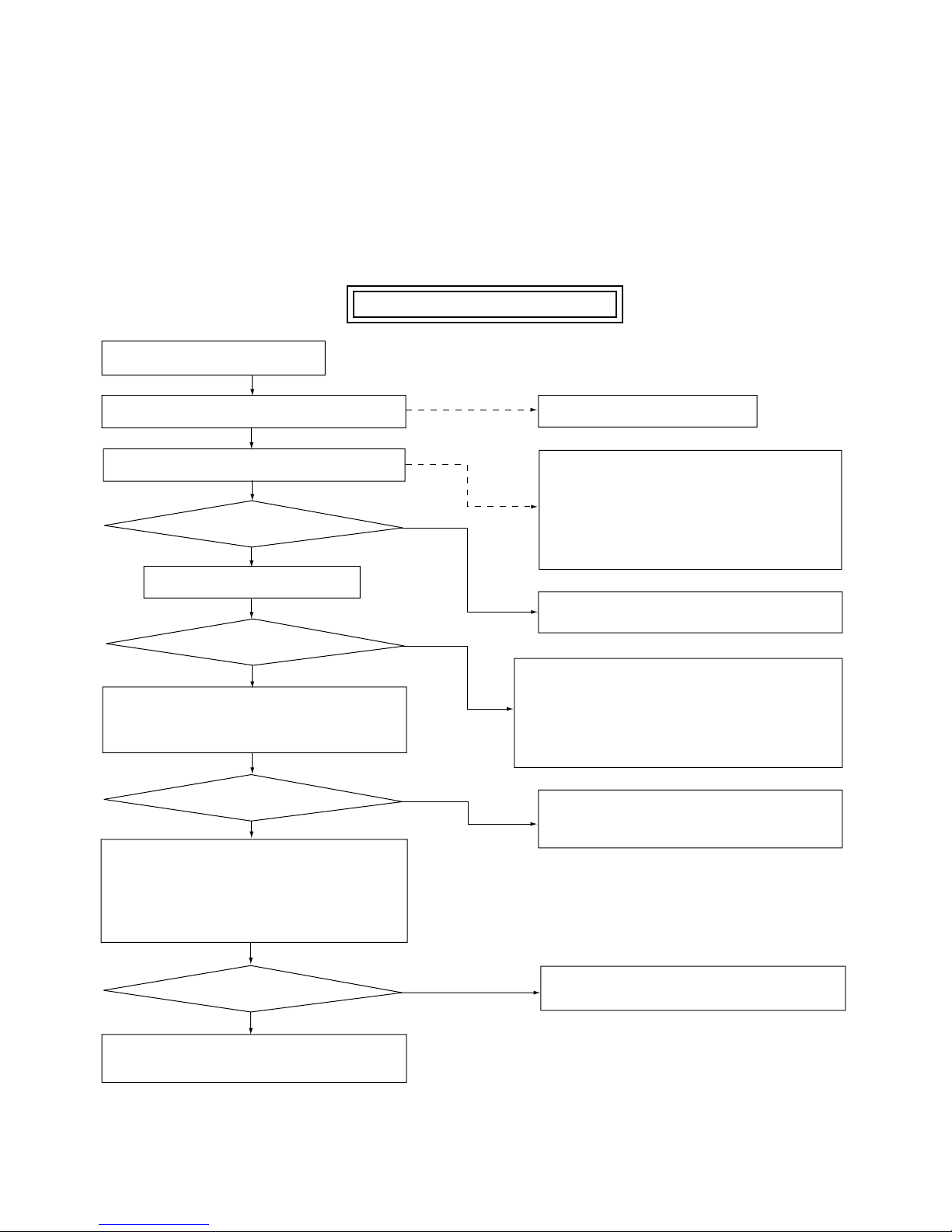

5.6.1 Trouble shooting ................................................................................. 447

5.6.2 Servicing .............................................................................................. 456

5.7 REFRIGERANT PIPING INSTALLATION/SERVICING MANUAL

FOR AIR CONDITIONERS USING R410A ................................................ 456

Page 3

3

5.1 GENERAL INFORMATION

5.1.1 Specific features

(1) The long piping makes the location of the inside and units flexible.

¡ No need for additional charge of refrigerant : 30m

¡ Maximum piping length : 40m

(2) Connectable indoor capacity

Number of connectable units : 3 units

Total of indoor units (class kW) : 11.0kW

(3) Indoor units are available with 5 capacities.

5 capacities ................ 22, 25, 28, 35, 50, 60

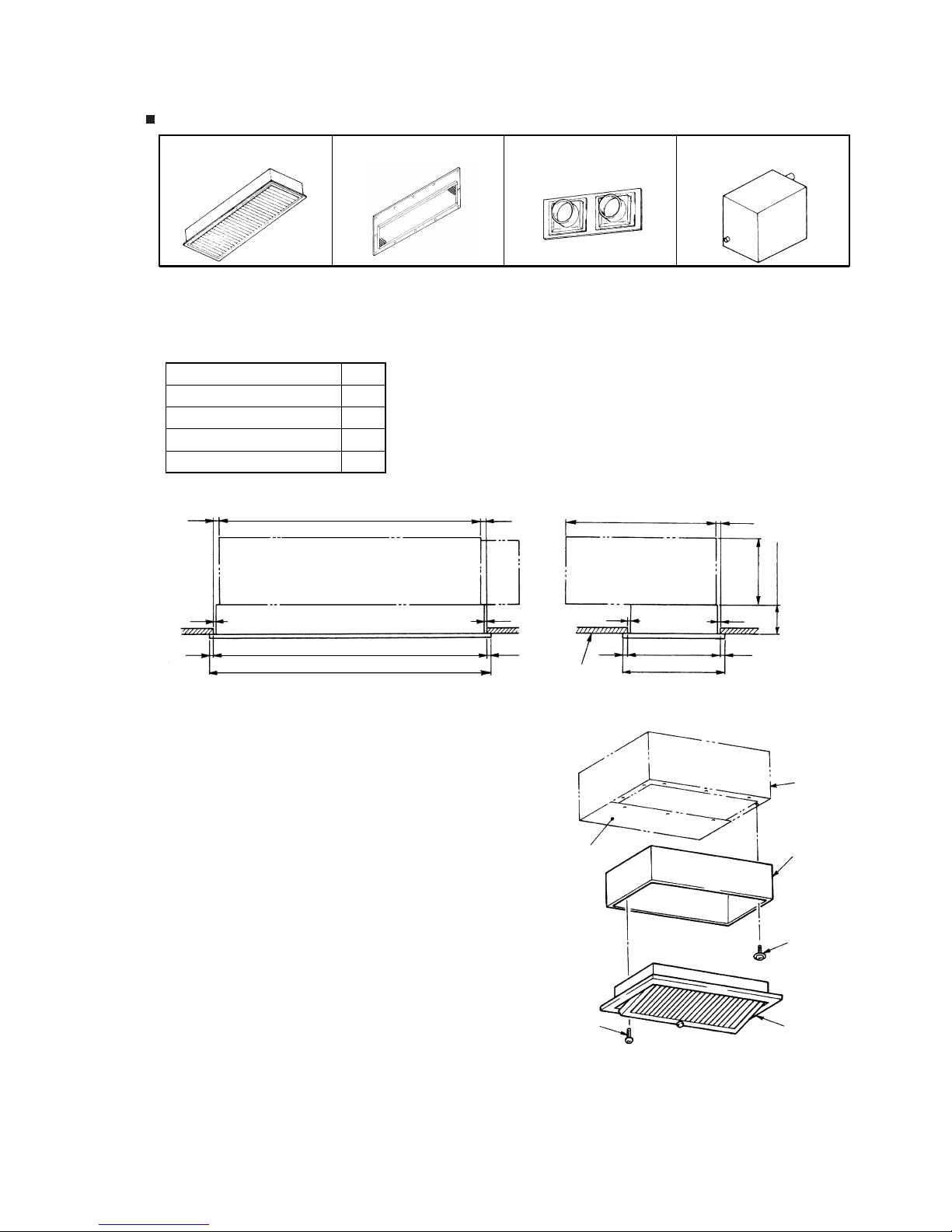

Types ......................... Wall mounted type (SKM).

4-way ceiling cassette type (STM).

Ducted type (SRRM).

(4) Inverter (Frequency converter) for multi-steps power control

¡ Heating / Cooling

The rotational speed of a compressor is changed in step in relation to varying load, to interlock with the indoor and outdoor unit

fans controlled to changes in frequency, thus controlling the power.

¡ Allowing quick heating/cooling operation during start-up period. Constant room temperature by fine-tuned control after the

unit has stabilized.

(5) Fuzzy control

Fuzzy control calculates the amount of variation in the difference between the suction air temperature and the setting temperature

in compliance with the fuzzy rules in order to control the air capacity and the inverter frequency.

(6) Self diagnosis function

We are constantly trying to do better service to our customers by installing such judges that show abnormality of operation as

follows. (See Page 74)

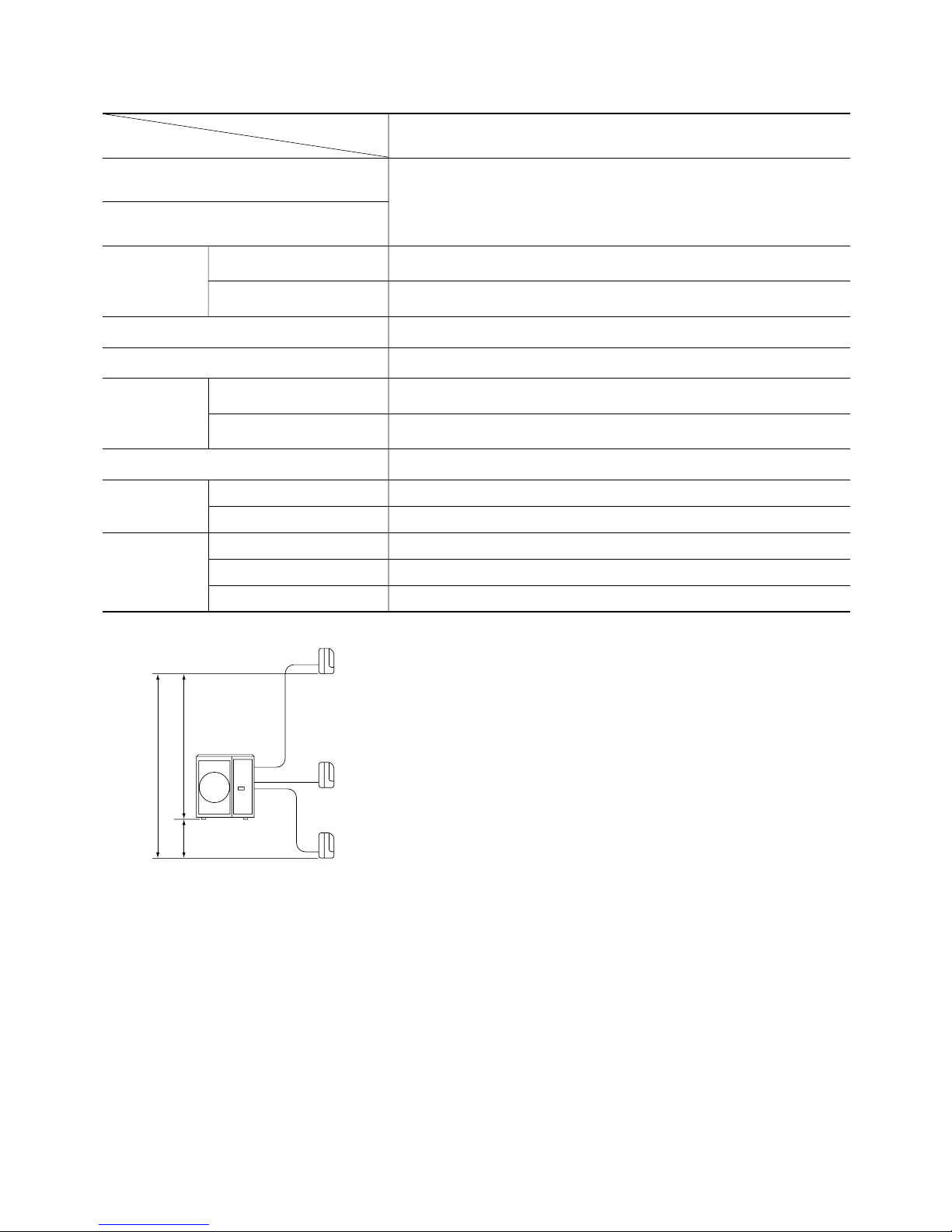

5.1.2 How to read the model name

Example : ST M 25 Z E - S

R410A models

Series No.

Inverter and Heat pump type

Product capacity

Multiple system

Model name

SK : Wall mounted type

ST : 4 way ceiling cassette type

SRR : Ducted type

SC : Outdoor unit

Page 4

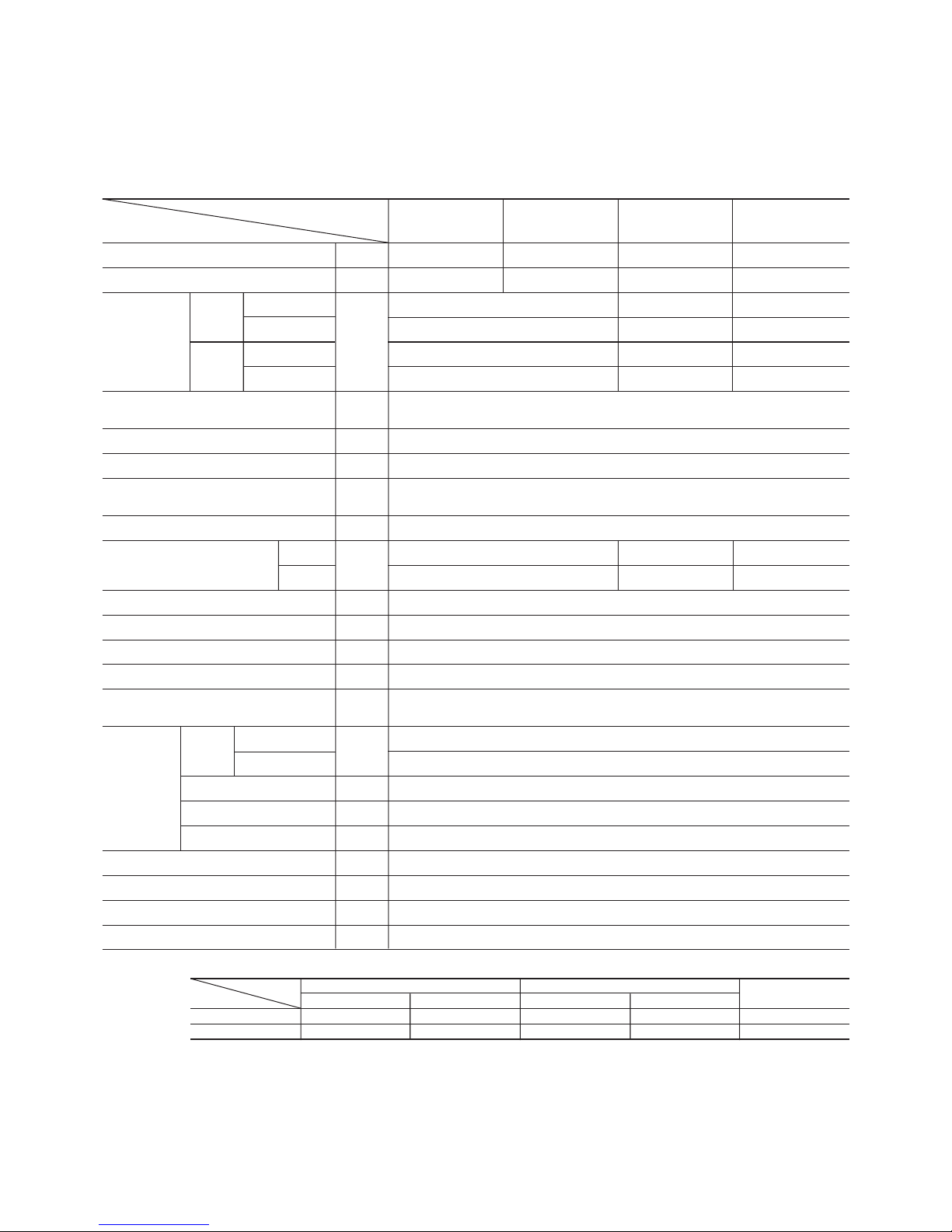

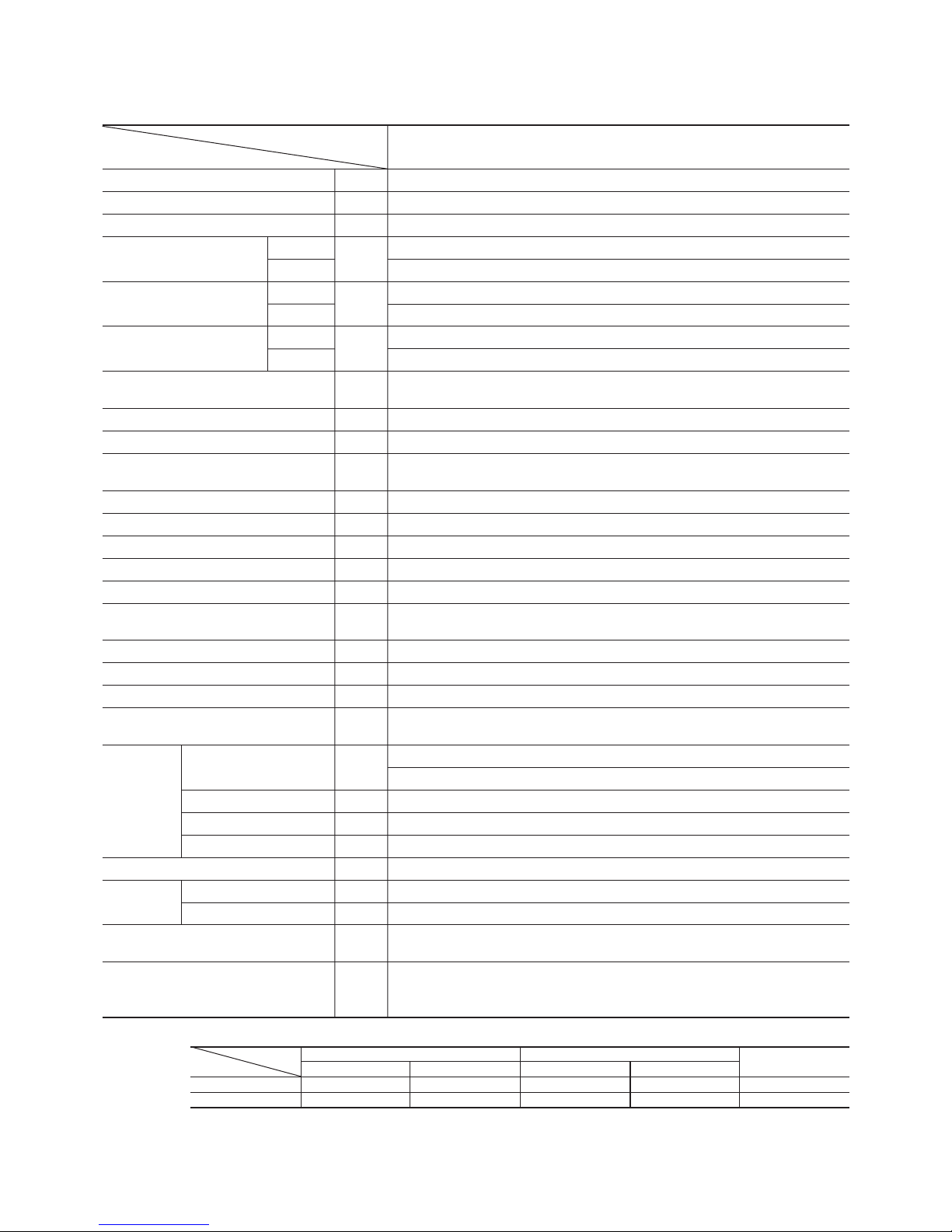

4

Item

Models

SKM22ZD-S SKM25ZD-S SKM28ZD-S SKM35ZD-S

Cooling capacity W 2200 2500 2800 3500

Heating capacity W 3200 3400 4000 4500

Noise level

Cooling

Hi : 37 Me : 30 Lo : 23

Hi : 38 Me : 31 Lo : 24 Hi : 39 Me : 32 Lo : 25

dB

Hi : 53 Hi : 54 Hi : 55

Heating

Hi : 39 Me : 33 Lo : 27

Hi : 40 Me : 34 Lo : 28 Hi : 41 Me : 35 Lo : 29

Hi : 55 Hi : 56 Hi : 57

Exterior dimensions

Height × Width × Depth

mm 250 × 815 × 249

Color Cool white

Net weight kg 9.0

Air handling equipment

Fan type & Q’ty

Tangential fan × 1

Motor W 16

Cooling 8.0 8.2 8.4

Air flow (at high)

Heating

CMM

8.7 9.0 9.2

Air filter, Q’ty

Polypropylene net × 2 (Washable)

Operation switch Wireless-Remote control

Room temperature control M.C thermostat

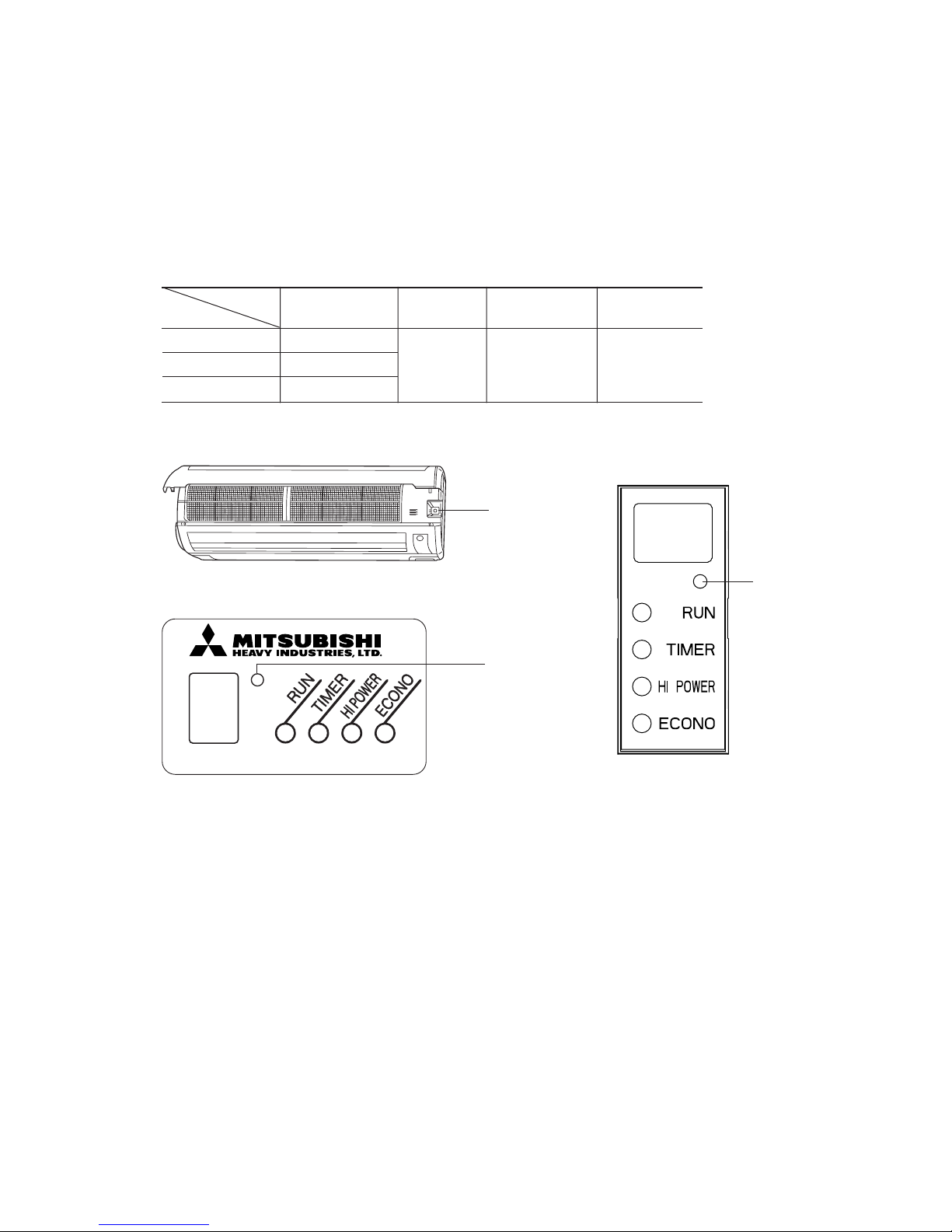

Pilot lamp RUN (Green), TIMER (Yellow), HI POWER (Green), ECONO (Orange)

Safety equipment

O.D mm (in)

φ 6.35 (1/4″)

φ 9.52 (3/8″)

Connecting method Flare connecting

Attached length of piping Liquid line : 0.4m Gas line : 0.33m

Insulation Necessary (Both Liquid & Gas lines)

Drain hose Connectable

Accessories (including)

Mounting kit, Clean filter (Natural enzyme filter × 1, Photocatalytic washable deodorizing filter × 1)

Optional parts —

Outdoor unit to be combined SCM60ZD-S

5.2 SELECTION DATA

5.2.1 Specifications

(1) Indoor unit

Models SKM22ZD-S, 25ZD-S, 28ZD-S, 35ZD-S

(2) Capacity indicated is the rated capacity with one unit operating under ISO-T1 standards conditions.

Refrigerant

piping

Liquid line

Gas line

Frost protection, Serial error protection

Fan motor error protection

Notes (1) The data are measured at the following conditions.

Item Indoor air temperature Outdoor air temperature

Standards

Operation DB WB DB WB

Cooling 27ºC 19ºC 35ºC 24ºC ISO-T1, JIS C9612

Heating 20ºC – 7ºC 6ºC ISO-T1, JIS C9612

Sound level

Power level

Sound level

Power level

Page 5

5

Item

Model

SKM50ZD-S

Cooling capacity W 5000

Heating capacity W 5800

Noise level

Cooling

Sound level

dB

Hi : 47 Me : 36 Lo : 23

Power level Hi : 62

Noise level

Heating

Sound level Hi : 48 Me : 37 Lo : 27

Power level Hi : 63

Exterior dimensions

Height × Width × Depth

mm 250 × 815 × 249

Color Cool white

Net weight kg 9.5

Air handling equipment

Fan type & Q’ty

Tangential fan × 1

Motor W 29

Cooling 11

Air flow (at high)

Heating

CMM

13.9

Air filter, Q’ty Polypropylene net × 2 (Washable)

Operation switch Wireless-Remote control

Room temperature control M.C thermostat

Pilot lamp RUN (Green), TIMER (Yellow), HI POWER (Green), ECONO (Orange)

Safety equipment

O.D mm (in)

φ 6.35 (1/4″)

φ 12.7 (1/2″)

Connecting method Flare connecting

Attached length of piping Liquid line : 0.4m Gas line : 0.33m

Insulation Necessary (Both Liquid & Gas lines)

Drain hose Connectable

Accessories (including)

Mounting kit, Clean filter (Natural enzyme filter × 1, Photocatalytic washable deodorizing filter × 1)

Optional parts —

Outdoor unit to be combined SCM60ZD-S

Item Indoor air temperature Outdoor air temperature

Standards

Operation DB WB DB WB

Cooling 27ºC19ºC35ºC24ºC ISO-T1, JIS C9612

Heating 20ºC – 7ºC6ºC ISO-T1, JIS C9612

(2) Capacity indicated is the rated capacity with one unit operating under ISO-T1 standards conditions.

Refrigerant

piping

Liquid line

Gas line

Frost protection, Serial error protection

Fan moter error protection

Notes (1) The data are measured at the following conditions.

Model SKM50ZD-S

Page 6

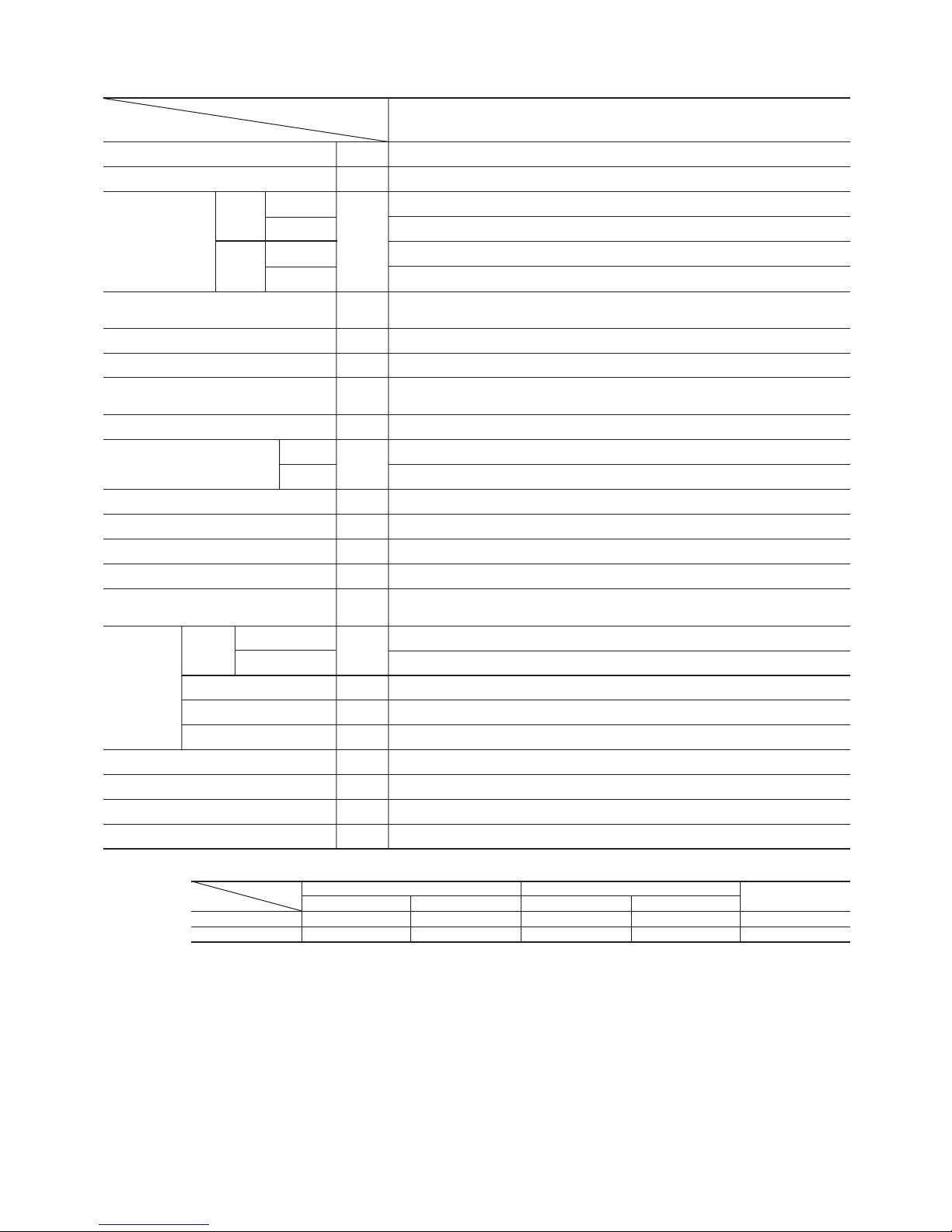

6

Sound level

Power level

Sound level

Power level

Item

Models

STM25ZE-S STM35ZE-S STM50ZE-S STM60ZE-S

Cooling capacity W 2500 3500 5000 6000

Heating capacity W 3400 4500 5800 6800

Noise level

Cooling

35 38 40 47

dB

51 54 56 63

Heating

35 38 40 47

51 54 56 63

Exterior dimensions

Main unit 248 × 570 × 570

Height × Width × Depth

Panel

mm

35 × 700 × 700

Color

–

Net weight

Main unit

kg

14 14.5

Panel 3.5

Air handling equipment

Fan type & Q’ty

Turbo fan × 1

Motor W 40

Cooling 8.0 9.0 10.0 13.0

Air flow (at high)

Heating

CMM

9.0 10.0 11.0 14.0

Air filter, Q’ty

Long life filter

× 1

(Washable)

Operation switch Wireless-Remote control

Room temperature control M.C thermostat

Pilot lamp RUN (Green), TIMER (Yellow), HI POWER (Green), ECONO (Orange)

Safety equipment

O.D mm (in)

φ 6.35 (1/4″)

φ 9.52 (3/8″) φ 12.7 (1/2″)

Connecting method Flare connecting

Attached length of piping —

Insulation Necessary (Both Liquid & Gas lines)

Drain hose Connectable

Accessories (including) Mounting kit

Optional parts Wired remote control

Outdoor unit to be combined SCM60ZD-S

Models STM25ZE-S, 35ZE-S, 50ZE-S, 60ZE-S

(2) Capacity indicated is the rated capacity with one unit operating under ISO-T1 standards conditions.

Refrigerant

piping

Liquid line

Gas line

Frost protection, Serial error protection

Fan motor error protection, Drain error protection

Notes (1) The data are measured at the following conditions.

Item Indoor air temperature Outdoor air temperature

Standards

Operation DB WB DB WB

Cooling 27ºC19ºC35ºC24ºC ISO-T1, JIS C9612

Heating 20ºC – 7ºC6ºC ISO-T1, JIS C9612

Page 7

7

Sound level

Power level

Sound level

Power level

Models SRRM25ZE-S, 35ZE-S, 50ZE-S, 60ZE-S

Item

Models

SRRM25ZE-S SRRM35ZE-S SRRM50ZE-S SRRM60ZE-S

Cooling capacity W 2500 3500 5000 6000

Heating capacity W 3400 4500 5800 6800

Noise level

Cooling

38 40 46 49

dB

53 55 60 63

Heating

39 41 46 49

54 56 60 63

Exterior dimensions

Height × Width × Depth

mm 230 × 740 × 455

Color —

Net weight kg 22.0 23.0

Air handling equipment

Fan type & Q’ty

Centrifugal fan × 2

Motor W 51

Cooling 8.5 9.0 10.5 12.5

Air flow (at high)

Heating

CMM

10.0 11.0 13.0 15.0

Air filter, Q’ty

Polypropylene net × 1

Operation switch Wireless-Remote control

Room temperature control M.C thermostat

Pilot lamp RUN (Green), TIMER (Yellow), HI POWER (Green), ECONO (Orange)

Safety equipment

O.D mm (in)

φ 6.35 (1/4″)

φ 9.52 (3/8″) φ 12.7 (1/2″)

Connecting method Flare connecting

Attached length of piping

–

Insulation Necessary (Both Liquid & Gas lines)

Drain hose Connectable

Accessories (including) Mounting kit

Optional parts Wired remote control

Outdoor unit to be combined SCM60ZD-S

(2) Capacity indicated is the rated capacity with one unit operating under ISO-T1 standards conditions.

Refrigerant

piping

Liquid line

Gas line

Frost protection, Serial error protection

Fan motor error protection, Drain error protection

Notes (1) The data are measured at the following conditions.

Item Indoor air temperature Outdoor air temperature

Standards

Operation DB WB DB WB

Cooling 27ºC19ºC35ºC24ºC ISO-T1, JIS C9612

Heating 20ºC – 7ºC6ºC ISO-T1, JIS C9612

Page 8

8

(2) Outdoor unit

Model SCM60ZD-S

Item

Model

SCM60ZD-S

Cooling capacity W 6000 (1400~6900)

Heating capacity W 7000 (750~7200)

Power source 1 Phase 220/230/240V 50Hz

Power consumption

Cooling

W

1860 (400~3000)

Heating 1740 (320~2700)

Running current

Cooling 8.5/8.2/7.8

Heating

A

8.0/7.6/7.3

Sound level Cooling : 48/48/50 Heating : 50/50/52

Noise level

Power level

dB

Cooling : 63/63/65 Heating : 65/65/67

Exterior dimensions

Height × Width × Depth

mm

640 × 850 × 290

Color Stucco white

Net weight kg 51

Refrigerant equipment

Compressor type & Q’ty

TNB220FLBM1 [Twin rotary type] × 1

Motor kW 1.3

Starting method Direct start

Refrigerant control Capillary tubes + Electronic expansion valve

Refrigerant kg R410A 2.2 (Pre-charged up to the piping length of 30m)

Refrigerant oil R 0.67 (MEL56)

Air handling equipment

Fan type & Q’ty

Propeller fan × 1

Motor W 45

Air flow (at high) CMM 42

Shock & vibration absorber Rubber (for compressor)

Safety equipment

Size × Core × Number mm (in)

Liquid line: φ 6.35 (1/4″) × 3

Gas line: φ 9.52 (3/8″) × 3

Connecting method Flare connecting

Attached length piping —

Insulation Necessary (Both Liquid & Gas lines)

Power source supply Terminal block (Screw fixing type)

Size × Core number 1.5 mm2 × 4 cores (Including earth cable) × 3

Connecting method Terminal block (Screw fixing type)

Accessories (included)

Union : (φ 9.52 / φ 12.7) × 2

Installation sheet, Manual instruction

SKM22, 25, 28, 35, 50 type

Indoor units to be combined STM25, 35, 50, 60 type

SRRM25, 35, 50, 60 type

Compressor overheat protection, Overcurrent protection

Serial signal error protection

Notes (1) The data are measured at the following conditions.

Refrigerant

piping

Connection

wiring

Item Indoor air temperature Outdoor air temperature

Standards

Operation DB WB DB WB

Cooling 27ºC19ºC35ºC24ºC ISO-T1, JIS C9612

Heating 20ºC – 7ºC6ºC ISO-T1, JIS C9612

(2) The values for capacity and power consumption shown in a range ( ) indicate the minimum and maximum of the range.

(3) If the piping length exceeds 30 m, additional charging is required. (20g/m)

Page 9

9

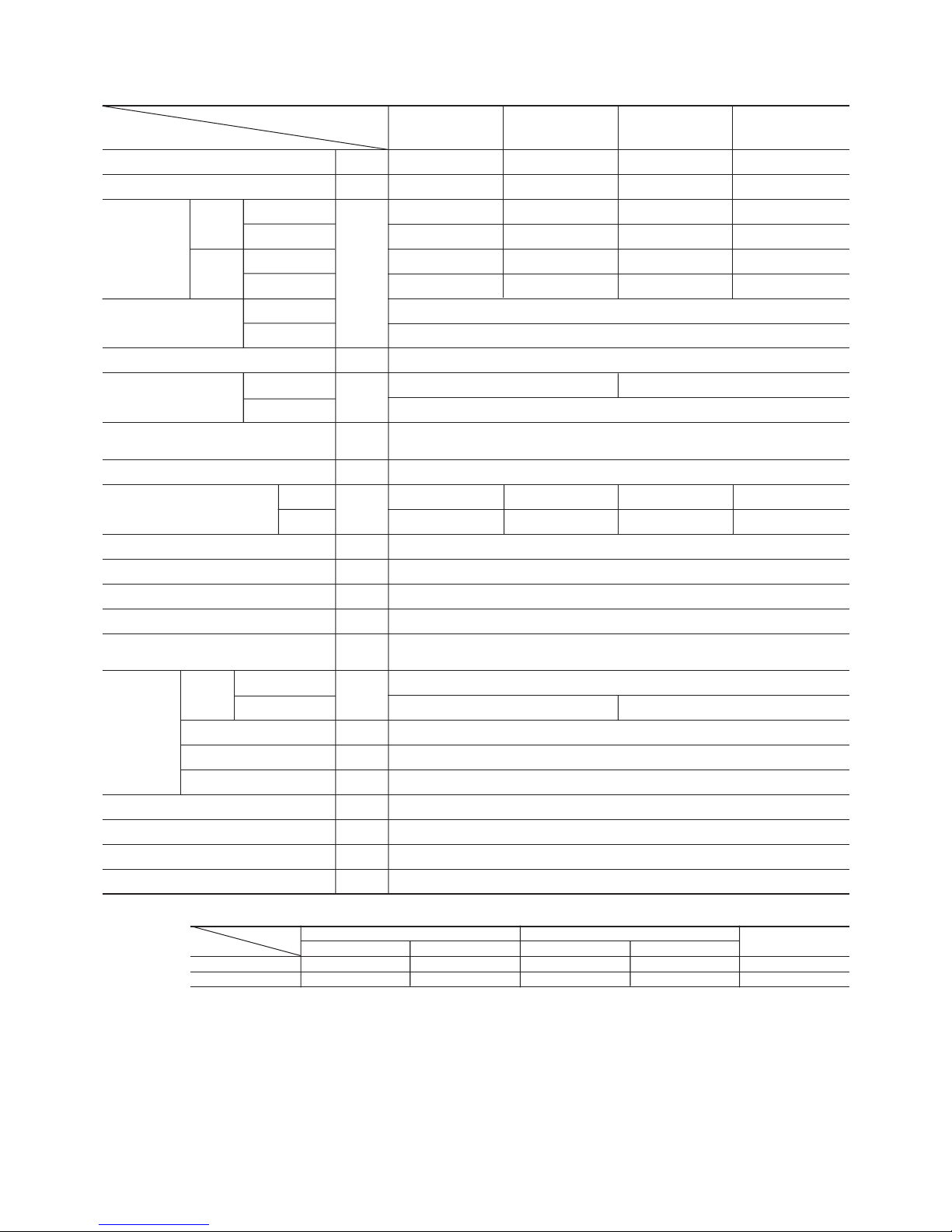

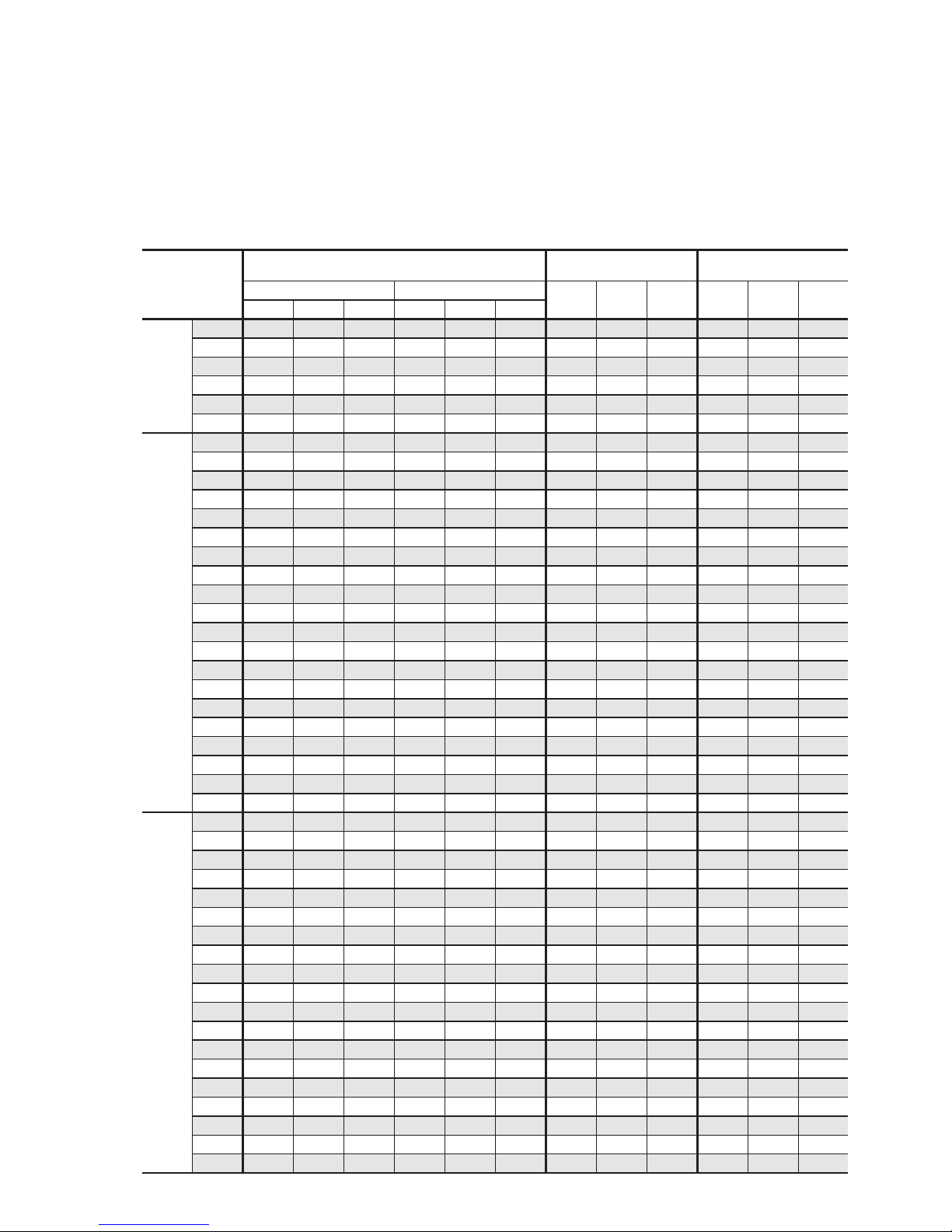

(3) Operation data

¡ The combinations of the indoor units is indicated by numbers. They are read as follows.

(Example) SKM22ZD-S / 22 SKM35ZD-S / 35

¡ The capacity of the indoor units is shown by rooms. If this exceeds the maximum capacity of the outdoor unit, the demand

capacity will be proportionally distributed.

¡ If units are to be combined, use the table below to make the proper selection.

Model SCM60ZD-S

(a) Heating

1

room

22 3.2 - - 0.75 3.2 3.4 320 1100 1200 5.1 4.8 4.6

25 3.4 - - 0.75 3.4 3.6 320 1200 1300 5.5 5.3 5.1

28 4.0 - - 0.75 4.0 4.2 320 1450 1550 6.7 6.4 6.1

35 4.5 - - 0.75 4.5 4.6 320 1750 1800 8.0 7.7 7.4

50 5.8 - - 0.75 5.8 6.2 320 2100 2400 9.6 9.2 8.8

11.9

10.3

11.4

10.1

10.9

60 6.8 - - 0.75 6.8 6.9 320 2600 2650

2

room

22+22 2.55 2.55 - 1.1 5.1 6.5 330 1450 2350 6.7 6.4 6.1

22+25 2.48 2.82 - 1.1 5.3 6.5 330 1500 2350 6.9 6.6 6.3

22+28 2.55 3.25 - 1.1 5.8 6.5 330 1700 2400 7.8 7.5 7.2

22+35 2.35 3.75 - 1.1 6.1 6.6 330 1900 2500 8.7 8.3 8.0

22+50 2.02 4.58 - 1.2 6.6 6.8 360 2150 2700 9.9 9.4 9.0

9.9 9.5

10.6 9.7

22+60 1.80 4.90 - 1.2 6.7 6.8 360 2250 2700

25+25 2.75 2.75 - 1.1 5.5 6.5 330 1600 2350 7.3 7.0 6.7

25+28 2.78 3.12 - 1.1 5.9 6.5 330 1800 2400 8.3 7.9 7.6

25+35 2.63 3.68 - 1.1 6.3 6.6 330 2000 2500 9.2 8.8 8.4

25+50 2.23 4.47 - 1.2 6.7 6.8 360 2250 2700 10.3 9.9 9.5

25+60 1.97 4.73 - 1.2 6.7 6.8 360 2300 2700

28+28 3.20 3.20 - 1.1 6.4 6.6 330 2050 2450 9.4 9.0 8.6

28+35 2.98 3.72 - 1.1 6.7 6.7 330 2200 2550 10.1 9.7 9.3

28+50 2.41 4.29 - 1.2 6.7 6.8 360 2400 2700 11.0 10.5 10.1

11.2 10.8 10.3

28+60 2.13 4.57 - 1.2 6.7 6.8 360 2450 2700

35+35 3.35 3.35 - 1.1 6.7 6.7 330 2350 2600 10.8 10.3 9.9

35+50 2.76 3.94 - 1.2 6.7 6.8 360 2550 2700 11.7 11.2 10.7

11.9 11.4 10.9

35+60 2.47 4.23 - 1.2 6.7 6.8 360 2600 2700

50+50 3.35 3.35 - 1.5 6.7 6.8 420 2600 2700 11.9 11.4 10.9

12.2 11.6 11.2

50+60 3.05 3.65 - 1.5 6.7 6.8 420 2650 2700

3

room

22+22+22

2.23 2.23 2.23 1.7 6.7 7.2 440 1650 2700 7.6 7.2 6.9

22+22+25

2.20 2.20 2.50 1.7 6.9 7.2 440 1750 2700 8.0 7.7 7.4

22+22+28

2.14 2.14 2.72 1.7 7.0 7.2 440 1800 2700 8.3 7.9 7.6

22+22+35

1.95 1.95 3.10 1.7 7.0 7.2 440 1850 2700 8.5 8.1 7.8

22+22+50

1.64 1.64 3.72 1.9 7.0 7.2 500 1740 2700 8.0 7.6 7.3

9.0 8.6 8.2

22+22+60

1.50 1.50 4.10 1.9 7.1 7.2 500 1950 2700

22+25+25

2.14 2.43 2.43 1.7 7.0 7.2 440 1750 2700 8.0 7.7 7.4

22+25+28

2.05 2.33 2.61 1.7 7.0 7.2 440 1850 2700 8.5 8.1 7.8

22+25+35

1.88 2.13 2.99 1.7 7.0 7.2 440 1950 2700 9.0 8.6 8.2

22+25+50

1.61 1.83 3.66 1.9 7.1 7.2 500 2050 2700 9.4 9.0 8.6

9.4 9.0 8.6

22+25+60

1.46 1.66 3.98 1.9 7.1 7.2 500 2050 2700

22+28+28

1.97 2.51 2.51 1.7 7.0 7.2 440 1950 2700 9.0 8.6 8.2

22+28+35

1.84 2.34 2.92 1.7 7.1 7.2 440 2050 2700 9.4 9.0 8.6

22+28+50

1.56 1.99 3.55 1.9 7.1 7.2 500 2100 2700 9.6 9.2 8.8

9.6 9.2 8.8

22+28+60

1.42 1.81 3.87 1.9 7.1 7.2 500 2100 2700

22+35+35

1.70 2.70 2.70 1.7 7.1 7.2 440 2150 2700 9.9 9.4 9.0

10.1 9.7 9.3

22+35+50

1.46 2.32 3.32 1.9 7.1 7.2 500 2200 2700

25+25+25

2.33 2.33 2.33 1.7 7.0 7.2 440 1800 2700 8.3 7.9 7.6

25+25+28

2.24 2.24 2.51 1.7 7.0 7.2 440 1900 2700 8.7 8.3 8.0

Indoor unit

combinaton

Cooling capacity (kW)

Power cosumption (W) Standard current (kW)

Roomcooling capacity (kW) Total capacity (kW)

Min. Standard Max. 220V 230V 240V

B room C room

Min. Standard Max.

A room

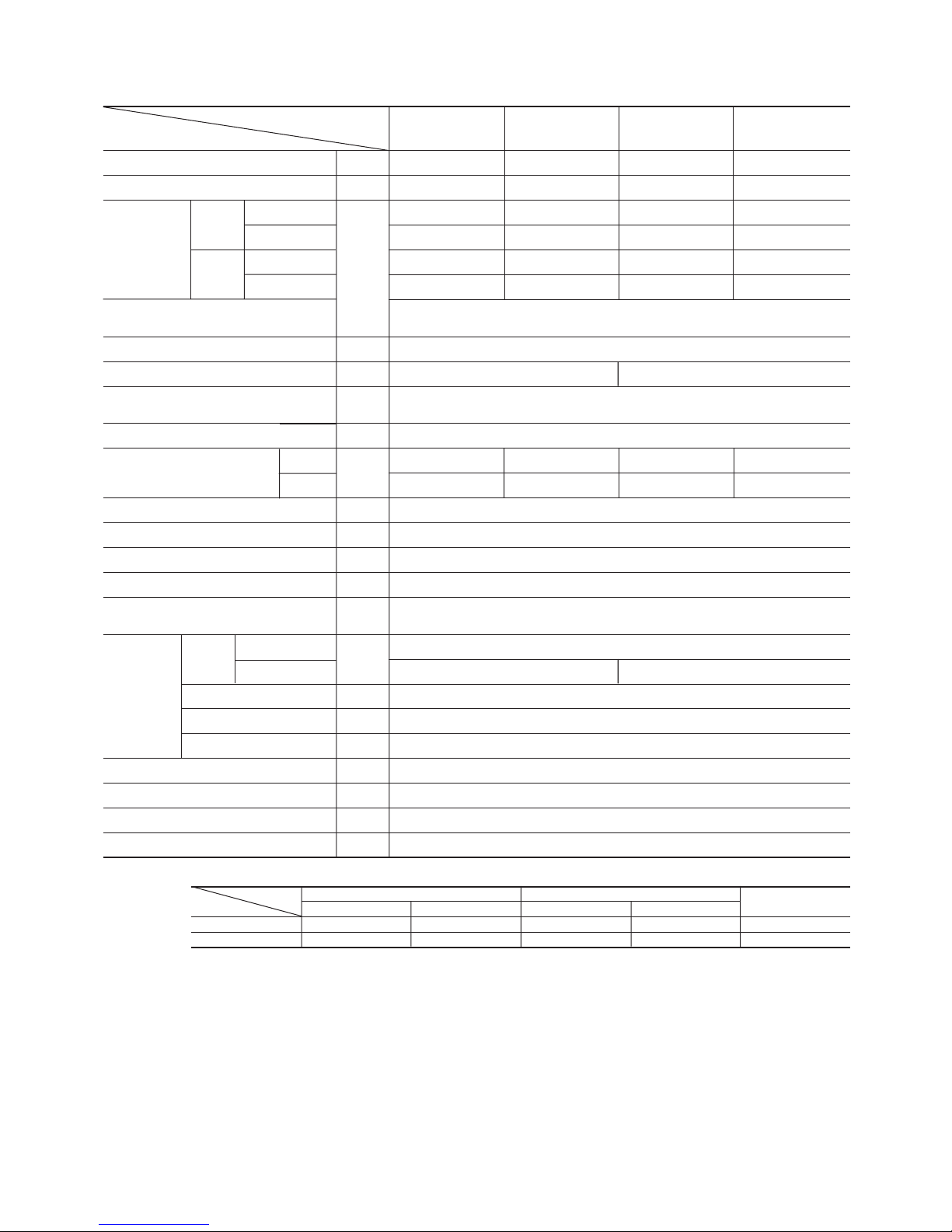

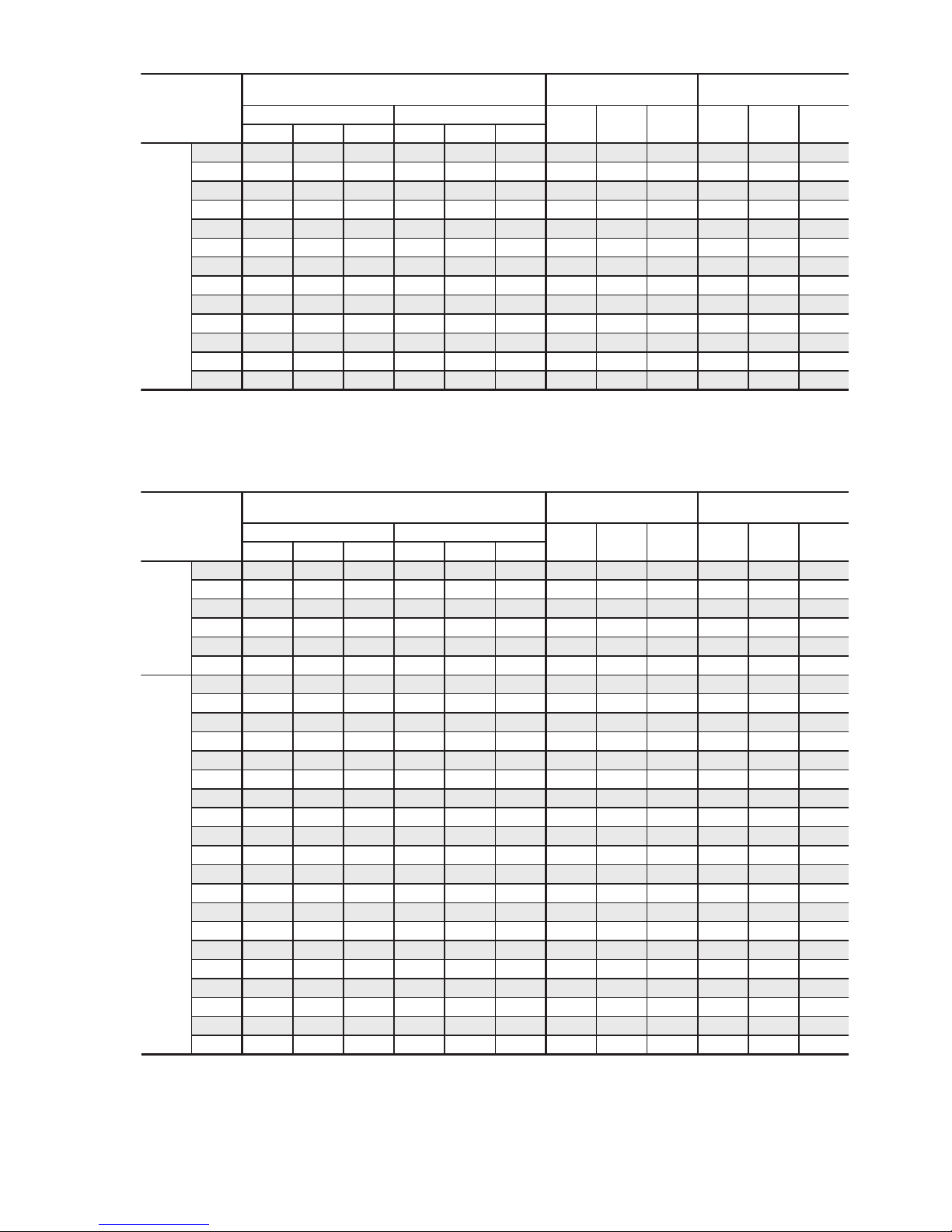

Page 10

10

25+25+35

2.06 2.06 2.88 1.7 7.0 7.2 440 2000 2700 9.2 8.8 8.4

25+25+50

1.78 1.78 3.55 1.9 7.1 7.2 500 2050 2700 9.4 9.0 8.6

9.4 9.0 8.6

25+25+60

1.61 1.61 3.87 1.9 7.1 7.2 500 2050 2700

25+28+28

2.19 2.45 2.45 1.7 7.1 7.2 440 2000 2700 9.2 8.8 8.4

25+28+35

2.02 2.26 2.82 1.7 7.1 7.2 440 2100 2700 9.6 9.2 8.8

25+28+50

1.72 1.93 3.45 1.9 7.1 7.2 500 2250 2700 10.3 9.9 9.5

25+35+35

1.87 2.62 2.62 1.7 7.1 7.2 440 2200 2700 10.1 9.7 9.3

10.3 9.9 9.5

25+35+50

1.61 2.26 3.23 1.9 7.1 7.2 500 2250 2700

28+28+28

2.37 2.37 2.37 1.7 7.1 7.2 440 2150 2700 9.9 9.4 9.0

28+28+35

2.18 2.18 2.73 1.7 7.1 7.2 440 2200 2700 10.1 9.7 9.3

28+28+50

1.88 1.88 3.35 1.9 7.1 7.2 500 2350 2700 10.8 10.3 9.9

28+35+35

2.03 2.54 2.54 1.7 7.1 7.2 440 2300 2700 10.6 10.1 9.7

35+35+35

2.37 2.37 2.37 1.7 7.1 7.2 440 2400 2700 11.0 10.5 10.1

3

room

Indoor unit

combinaton

Cooling capacity (kW)

Power cosumption (W) Standard current (kW)

Roomcooling capacity (kW) Total capacity (kW)

Min. Standard Max. 220V 230V 240V

B room C room

Min. Standard Max.

A room

(b) Cooling

1

room

22 2.2 - - 1.4 2.2 2.3 400 720 750 3.3 3.2 3.0

25 2.5 - - 1.4 2.5 2.6 400 800 830 3.7 3.5 3.4

28 2.8 - - 1.4 2.8 3.0 400 950 1050 4.4 4.2 4.0

35 3.5 - - 1.4 3.5 3.6 400 1300 1350 6.0 5.7 5.5

50 5.0 - - 1.4 5.0 5.1 400 2200 2250 10.1 9.7 9.3

60 6.0 - - 1.4 6.0 6.1 400 2700 2800

2

room

22+22 2.20 2.20 - 1.5 4.4 4.6 410 1450 1650 6.7 6.4 6.1

22+25 2.20 2.50 - 1.5 4.7 4.9 410 1600 1750 7.3 7.0 6.7

22+28 2.20 2.80 - 1.5 5.0 5.2 410 1720 1900 7.9 7.6 7.2

22+35 2.05 3.25 - 1.5 5.3 5.4 410 2100 2150 9.6 9.2 8.8

22+50 1.86 4.24 - 1.6 6.1 6.4 440 2550 2750 11.7 11.2 10.7

12.9 12.3 11.8

12.4 11.9 11.4

22+60 1.74 4.76 - 1.6 6.5 6.6 440 2800 2880

25+25 2.50 2.50 - 1.5 5.0 5.2 410 1720 1900 7.9 7.6 7.2

25+28 2.50 2.80 - 1.5 5.3 5.4 410 1850 1950 8.5 8.1 7.8

25+35 2.42 3.38 - 1.5 5.8 5.9 410 2200 2300 10.1 9.7 9.3

25+50 2.10 4.20 - 1.6 6.3 6.5 440 2720 2850 12.5 11.9 11.4

13.2 12.6 12.1

13.2 12.6 12.1

13.2 12.6 12.1

13.2 12.6 12.1

25+60 1.94 4.66 - 1.6 6.6 6.6 440 2880 2880

28+28 2.80 2.80 - 1.5 5.6 5.7 410 2000 2100 9.2 8.8 8.4

28+35 2.71 3.39 - 1.5 6.1 6.2 410 2420 2500 11.1 10.6 10.2

28+50 2.37 4.23 - 1.6 6.6 6.6 440 2880 2880 13.2 12.6 12.1

28+60 2.10 4.50 - 1.6 6.6 6.6 440 2880 2880

35+35 3.30 3.30 - 1.5 6.6 6.6 410 2880 2880 13.2 12.6 12.1

35+50 2.72 3.88 - 1.6 6.6 6.6 440 2880 2880 13.2 12.6 12.1

35+60 2.43 4.17 - 1.6 6.6 6.6 440 2880 2880

50+50 3.30 3.30 - 1.9 6.6 6.6 500 2880 2880 13.2 12.6 12.1

50+60 3.00 3.60 - 1.9 6.6 6.6 500 2880 2880

Cooling capacity(kW)

220V 230V 240V

Indoor unit

combinaton

Roomcooling capacity (kW) Total capacity (kW)

Power cosumption (W) Standard current (kW)

Min. Standard Max.

B room C room

Min. Standard Max.

A room

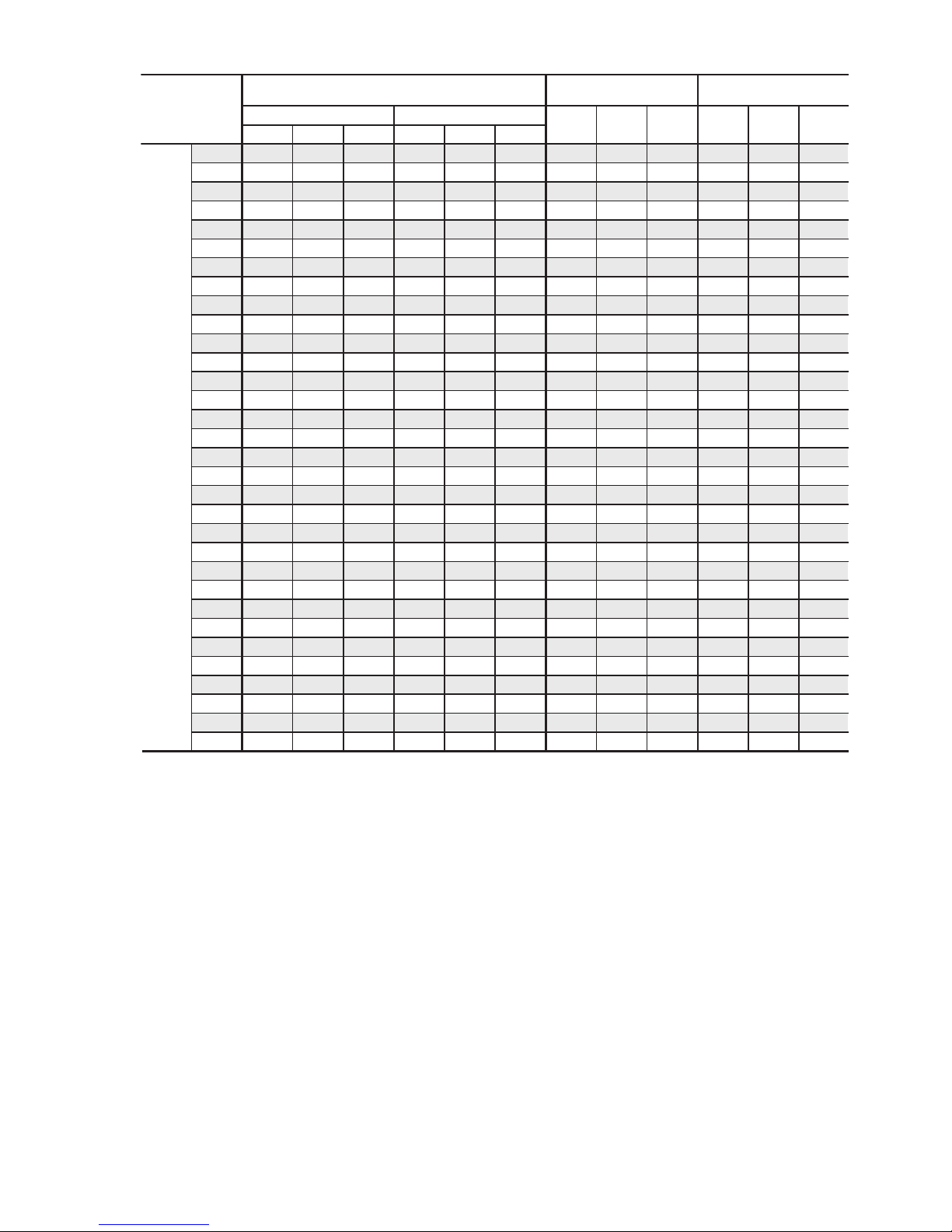

Page 11

11

3

room

22+22+22

1.70 1.70 1.70 1.9 5.1 6.8 620 1470 2950 6.7 6.5 6.2

22+22+25

1.66 1.66 1.88 1.9 5.2 6.8 620 1500 2950 6.9 6.6 6.3

22+22+28

1.59 1.59 2.02 1.9 5.2 6.9 620 1500 3000 6.9 6.6 6.3

22+22+35

1.50 1.50 2.39 1.9 5.4 6.9 620 1600 3000 7.3 7.0 6.7

22+22+50

1.40 1.40 3.19 2.1 6.0 6.9 680 1860 3000 8.5 8.2 7.8

9.2 8.8 8.4

9.2 8.8 8.4

9.2 8.8 8.4

22+22+60

1.29 1.29 3.52 2.1 6.1 6.9 680 2000 3000

22+25+25

1.59 1.81 1.81 1.9 5.2 6.9 620 1500 3000 6.9 6.6 6.3

22+25+28

1.55 1.77 1.98 1.9 5.3 6.9 620 1550 3000 7.1 6.8 6.5

22+25+35

1.48 1.68 2.35 1.9 5.5 6.9 620 1620 3000 7.4 7.1 6.8

22+25+50

1.36 1.55 3.09 2.1 6.0 6.9 680 1860 3000 8.5 8.2 7.8

22+25+60

1.27 1.45 3.48 2.1 6.2 6.9 680 2000 3000

22+28+28

1.52 1.94 1.94 1.9 5.4 6.9 620 1600 3000 7.3 7.0 6.7

22+28+35

1.45 1.84 2.31 1.9 5.6 6.9 620 1650 3000 7.6 7.2 6.9

22+28+50

1.32 1.68 3.00 2.1 6.0 6.9 680 1860 3000 8.5 8.2 7.8

9.4 9.0 8.6

22+28+60

1.26 1.60 3.44 2.1 6.3 6.9 680 2050 3000

22+35+35

1.39 2.21 2.21 1.9 5.8 6.9 620 1750 3000 8.0 7.7 7.4

22+35+50

1.27 2.03 2.90 2.1 6.2 6.9 680 2000 3000

25+25+25

1.77 1.77 1.77 1.9 5.3 6.9 620 1550 3000 7.1 6.8 6.5

25+25+28

1.73 1.73 1.94 1.9 5.4 6.9 620 1600 3000 7.3 7.0 6.7

25+25+35

1.65 1.65 2.31 1.9 5.6 6.9 620 1650 3000 7.6 7.2 6.9

25+25+50

1.50 1.50 3.00 2.1 6.0 6.9 680 1860 3000 8.5 8.2 7.8

9.4 9.0 8.6

25+25+60

1.43 1.43 3.44 2.1 6.3 6.9 680 2050 3000

25+28+28

1.70 1.90 1.90 1.9 5.5 6.9 620 1620 3000 7.4 7.1 6.8

25+28+35

1.62 1.81 2.27 1.9 5.7 6.9 620 1700 3000 7.8 7.5 7.2

25+28+50

1.48 1.66 2.96 2.1 6.1 6.9 680 2000 3000 9.2 8.8 8.4

25+35+35

1.55 2.17 2.17 1.9 5.9 6.9 620 1800 3000 8.3 7.9 7.6

9.4 9.0 8.6

25+35+50

1.43 2.00 2.86 2.1 6.3 6.9 680 2050 3000

28+28+28

1.87 1.87 1.87 1.9 5.6 6.9 620 1650 3000 7.6 7.2 6.9

28+28+35

1.78 1.78 2.23 1.9 5.8 6.9 620 1750 3000 8.0 7.7 7.4

28+28+50

1.64 1.64 2.92 2.1 6.2 6.9 680 2100 3000 9.6 9.2 8.8

28+35+35

1.69 2.11 2.11 1.9 5.9 6.9 620 1800 3000 8.3 7.9 7.6

35+35+35

2.07 2.07 2.07 1.9 6.2 6.9 620 2100 3000 9.6 9.2 8.8

Cooling capacity(kW)

220V 230V 240V

Indoor unit

combinaton

Roomcooling capacity (kW) Total capacity (kW)

Power cosumption (W) Standard current (kW)

Min. Standard Max.

B room C room

Min. Standard Max.

A room

Page 12

12

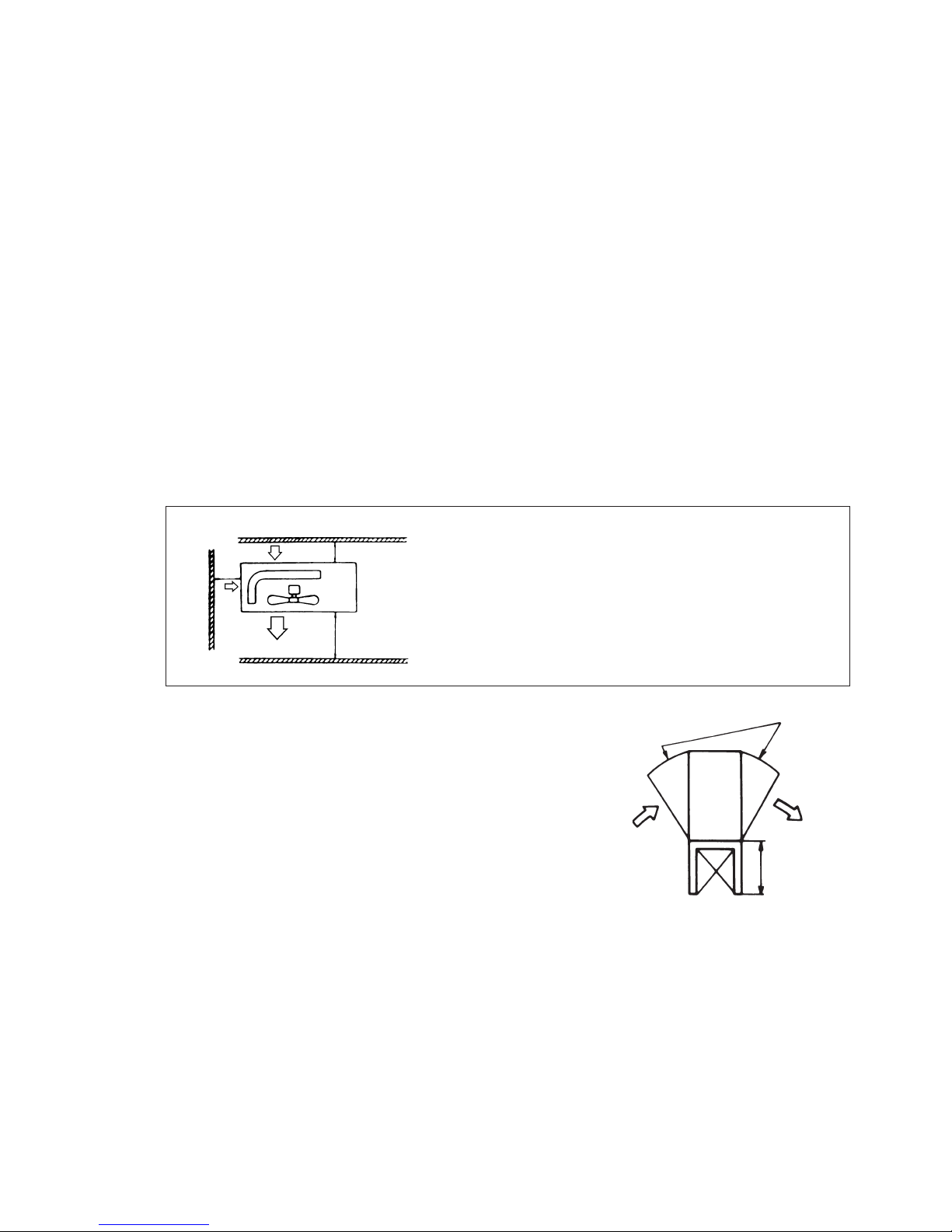

5.2.2 Range of usage & limitations

Indoor intake air temperature

(Upper, lower limits)

Indoor units

that can be

used in

combination

Length for one indoor unit

Total length for all rooms

Max. 25m

Max. 40m

11.0kW

2 to 3 units

SCM60ZD-S

Refer to the selection chart.

Compressor

stop/start

frequency

Power source

voltage

1 cycle time

Stop time

Voltage fluctuation

Voltage drop during start

Interval unbalance

Difference in height between indoor units (C)

Within ±3% of rated voltage

Within ±15% of rated voltage

Within ±10% of rated voltage

3 min or more

6 min or more (from stop to stop or from start to start)

Max. 25m

Max. 15m

Max. 10m

Outdoor air temperature

(Upper, lower limits)

Number of connected units

Total of indoor Units (class kW)

Difference in

height between

indoor and outdoor

units

When above outdoor unit (B)

When below outdoor unit (A)

Item

Model

A

B

C

Page 13

13

VIEW A

45

14.5

60

788

5

60

45

815

A

250

117.5

580 117.5

148.5

216.5216.5

8.2

44.5

236.1

5.7

450

450

67.5

42.7

47.2

175

44.5

216.5216.5

148.5

53.5

Piping for Gas

Drain hose 540 (ø16)

Piping for Liquid 465.1 (ø6.35)

Piping hole (ø65)

Piping hole (ø65)

( )

22,25,28,35: ø9.52

50: ø12.7

397.1

Piping hole right(left)

Terminal block

9

60

45

3

249

150

18

56

Remote controller

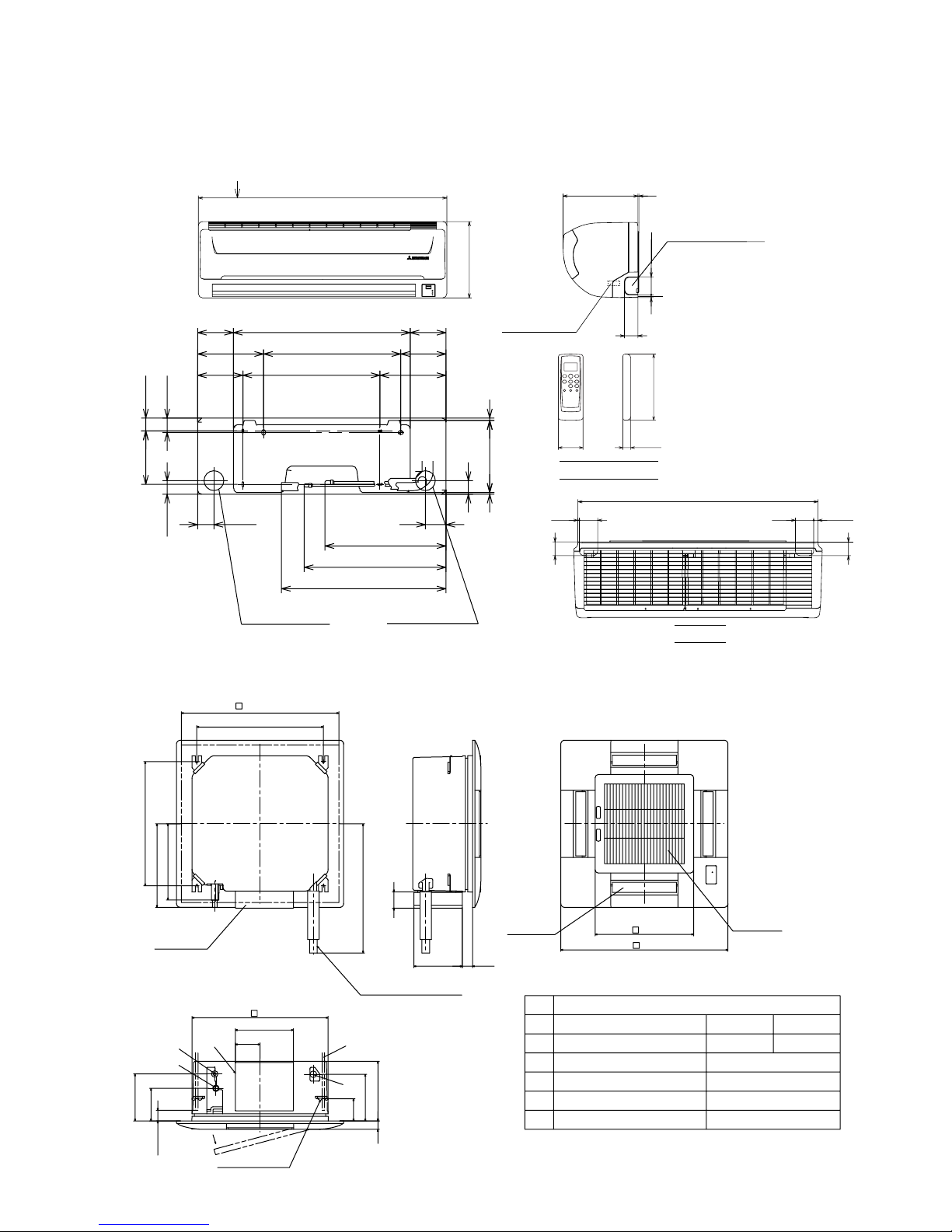

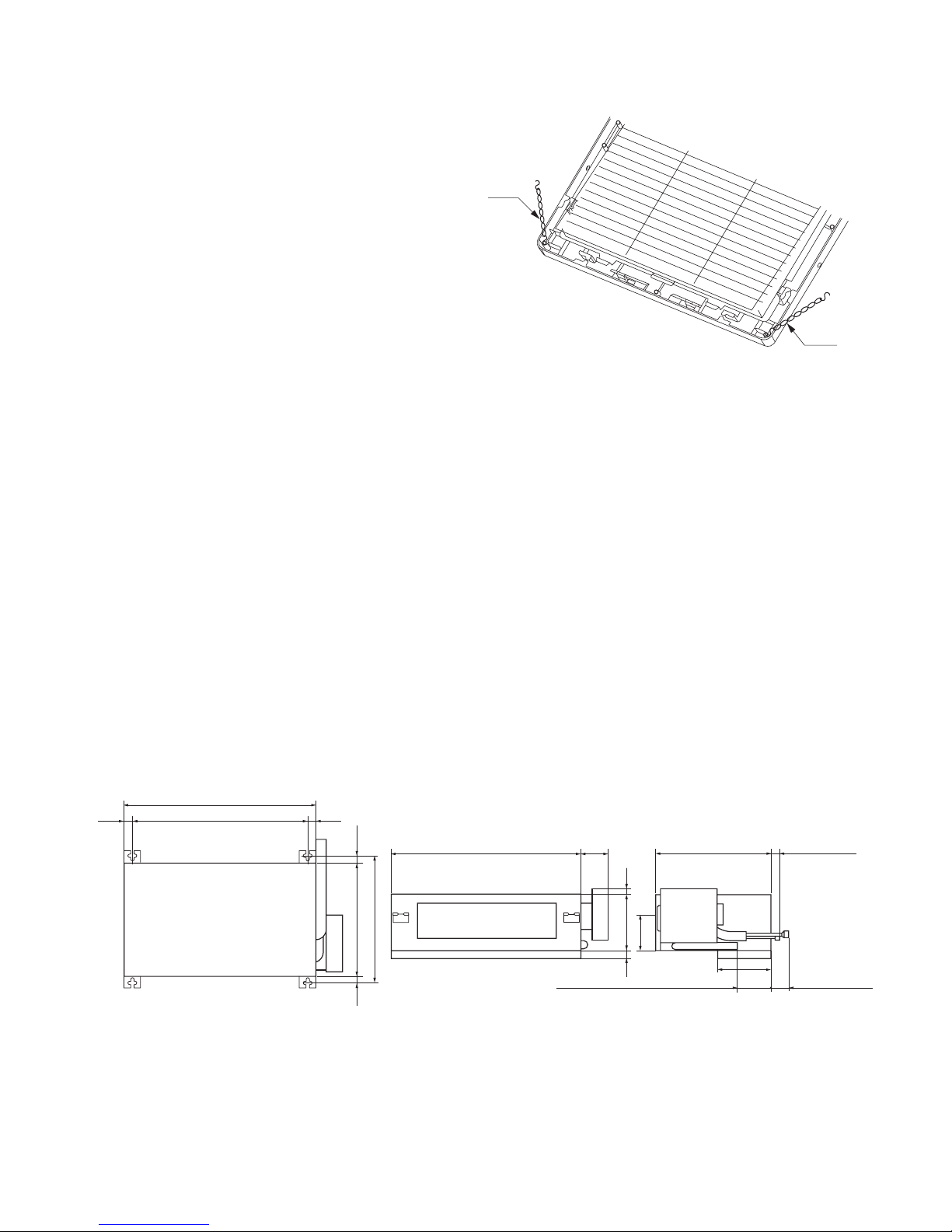

5.2.3 Exterior dimensions

(1) Indoor unit

Models SKM22ZD-S, 25ZD-S, 28ZD-S, 35ZD-S, 50ZD-S

Unit : mm

Models STM25ZE-S, 35ZE-S, 50ZE-S, 60ZE-S

Hanging bolt pitch 530

Celling opening 660 (For conventional celling)

Hanging fixture

C

B

A

D

Drain hose (accessory)

To be installed at site

Control box

Hanging bolt pitch 530

Air outlet

Air intake

PANEL

E

*Please arrange VP25 connector sockets on the installer's part.

350

319

104

more

45 or

541

700

413

43202

570

243

196

250

93

35

137

197

68

Mark Description

Model 25,35ZE-S 50,60ZE-S

A

Gas pipe connecting port ø 9.52(Flare) ø 12.7(Flare)

B

Liquid pipe connecting port ø 6.35(Flare)

C

Drain line tube connecting port VP25*

D

Power intake

E

Hanging bolt (M10 or M8)

Page 14

14

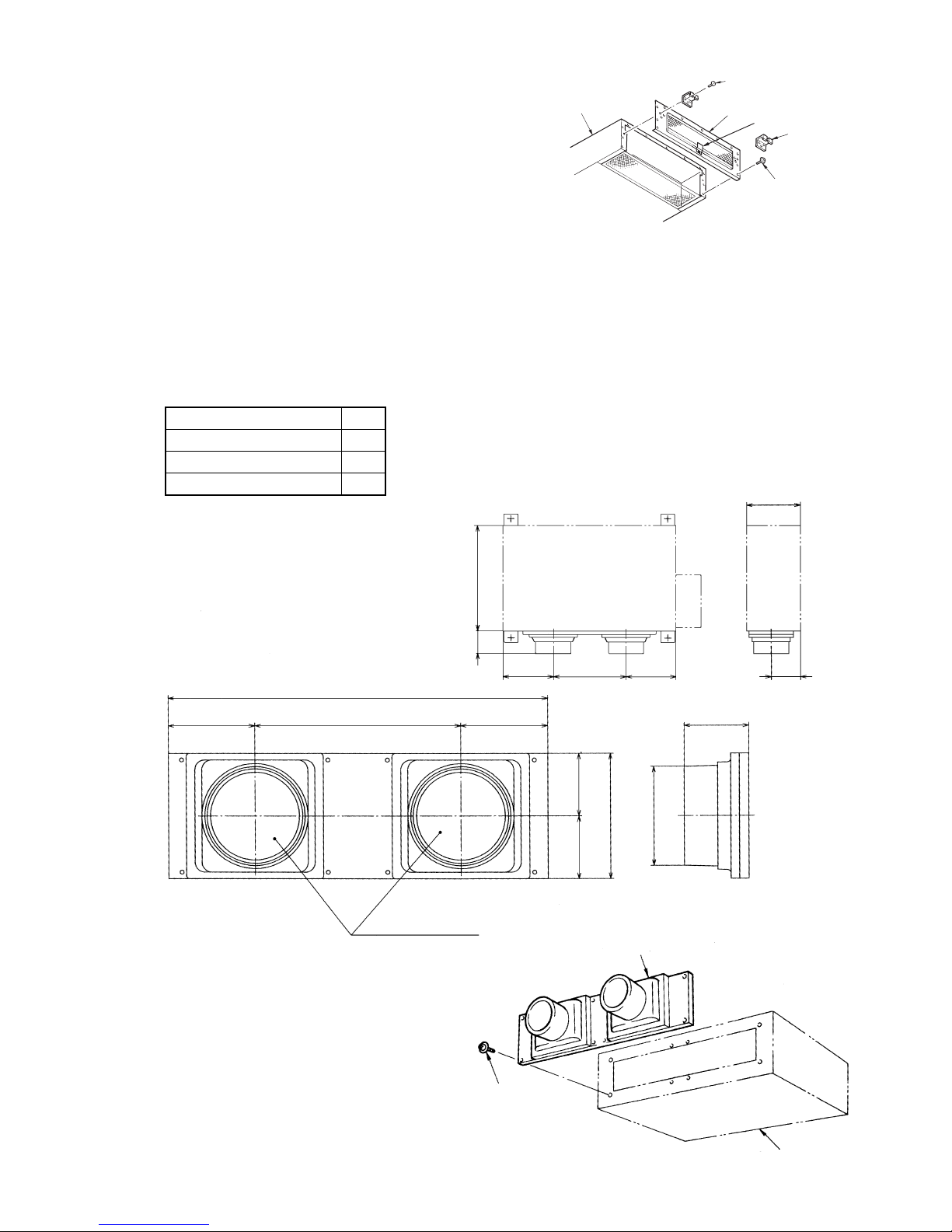

Models SRRM25ZE-S, 35ZE-S, 50ZE-S, 60ZE-S

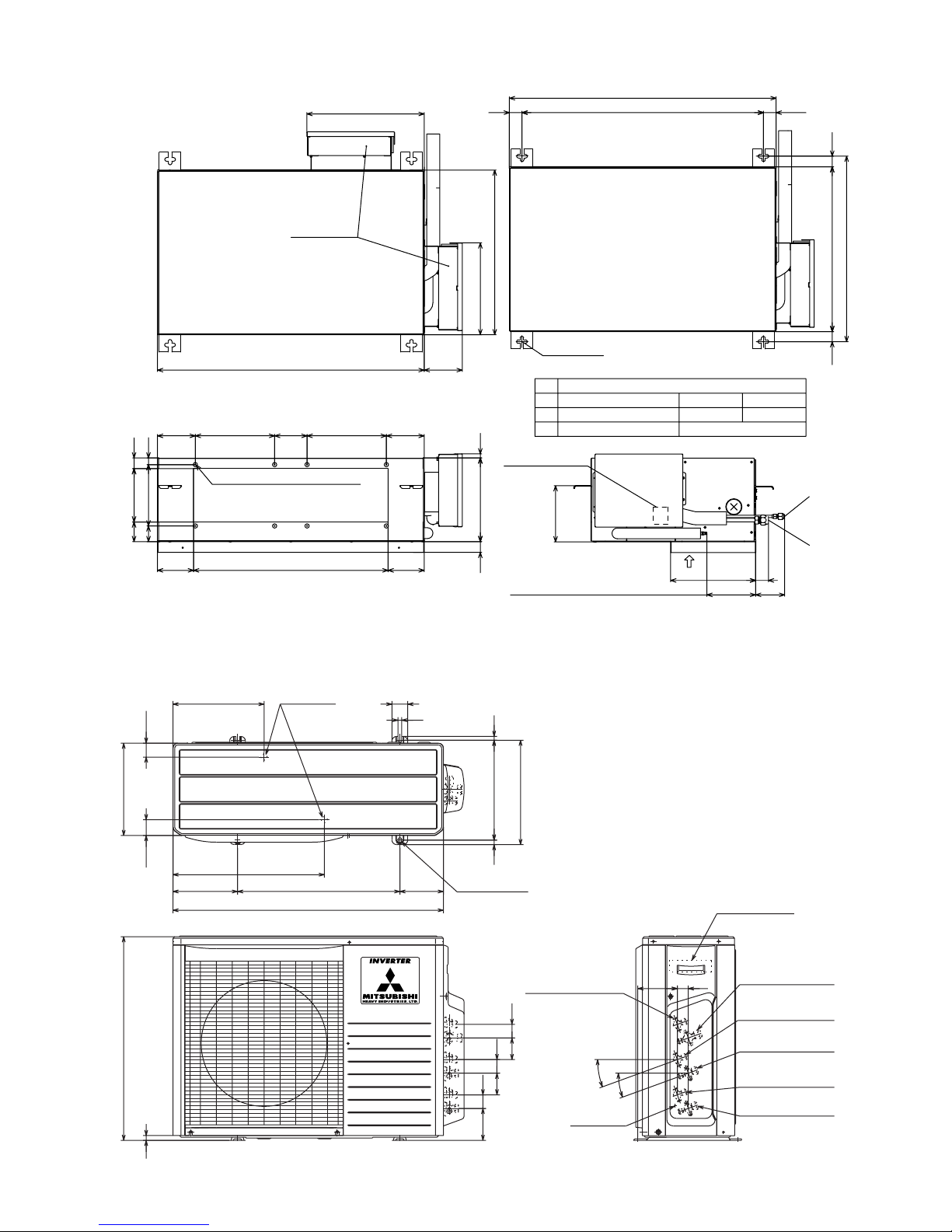

(2) Outdoor unit

Model SCM60ZD-S

42.7

42.7

42.7

Drain holes

Elogated hole

(2-12X16)

Terminal block

Gas line service

valve C Unit (ø9.52)

Liquid line service

valve C Unit (ø6.35)

Liquid line service

valve B Unit (ø6.35)

Gas line service

valve B Unit (ø9.52)

Liquid line service

valve A Unit (ø6.35)

Gas line service

valve A Unit (ø9.52)

Ground

terminal

314

14

12

850

203.1 510 136.9

476

286.4

12

50

290

49.6

43.5

328

100.3

67.9

67.9

15

640

124

34.6

20º

20º

Unit : mm

Controller

Terminal block

Air outlet

ø 4 × 8(Holes for tapping screws)

B

A

Air inlet

Hanging bolt

(M8 × 4)

35 670 (Suspension bolts pitch)

740

35

515 (Suspension bolts pitch)

455 3030

325

455

106740

150

38

78135

30 230 11 255

236

105

Drain hose

(Connection opening diameter ø16)

220 90 220 105

3014855

1917044

100 540 100

Mark

Description

Model 25,35ZE-S 50,60ZE-S

A

Gas pipe connecting port ø9.52(Flare) ø12.7(Flare)

B

Liquid pipe connecting port

ø6.35(Flare)

Page 15

15

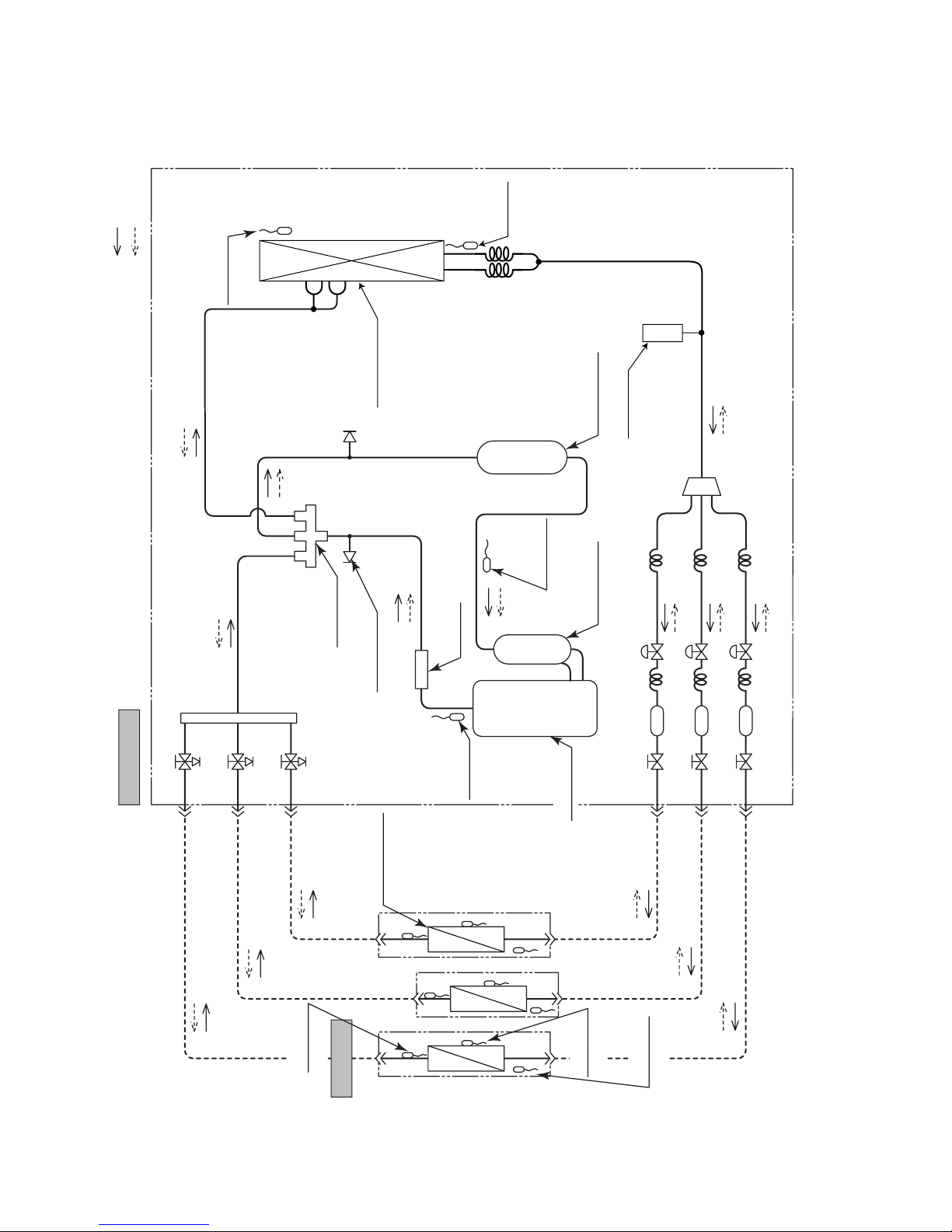

Gas line

Liquid line

(ø9.52 or ø12.7)

(ø9.52 or ø12.7)

(ø6.35)

(ø6.35)

(ø6.35)

EEVA

Strainer

EEVB

EEVC

(ø9.52 or ø12.7)

Service valve (Gas)

Outdoor Unit

Indoor Unit

Sensor

(Th

I-

R

2

)

Heat exchanger

Sensor

(Th

I-A

)

Sensor

(Th

I-R1

)

Sensor

(Th

O-D

)

Sensor

(Th

O-A

)

Accumlator

Accumlator

Muffler

Sensor

(Th

o-C

)

Service valve

(Liquid)

Electronic

expansion valve

Gas line 22, 25, 28, 35 type:

ø9.52

50, 60 type :

ø12.7

Capillary

tube

Compressor

Check joint

4way valve

Heating

Cooling

Discharge

Suction

Receiver

Sensor

(Th

O

-R)

Heat exchanger

5.2.4 Piping system

Model SCM60ZD-S

Page 16

16

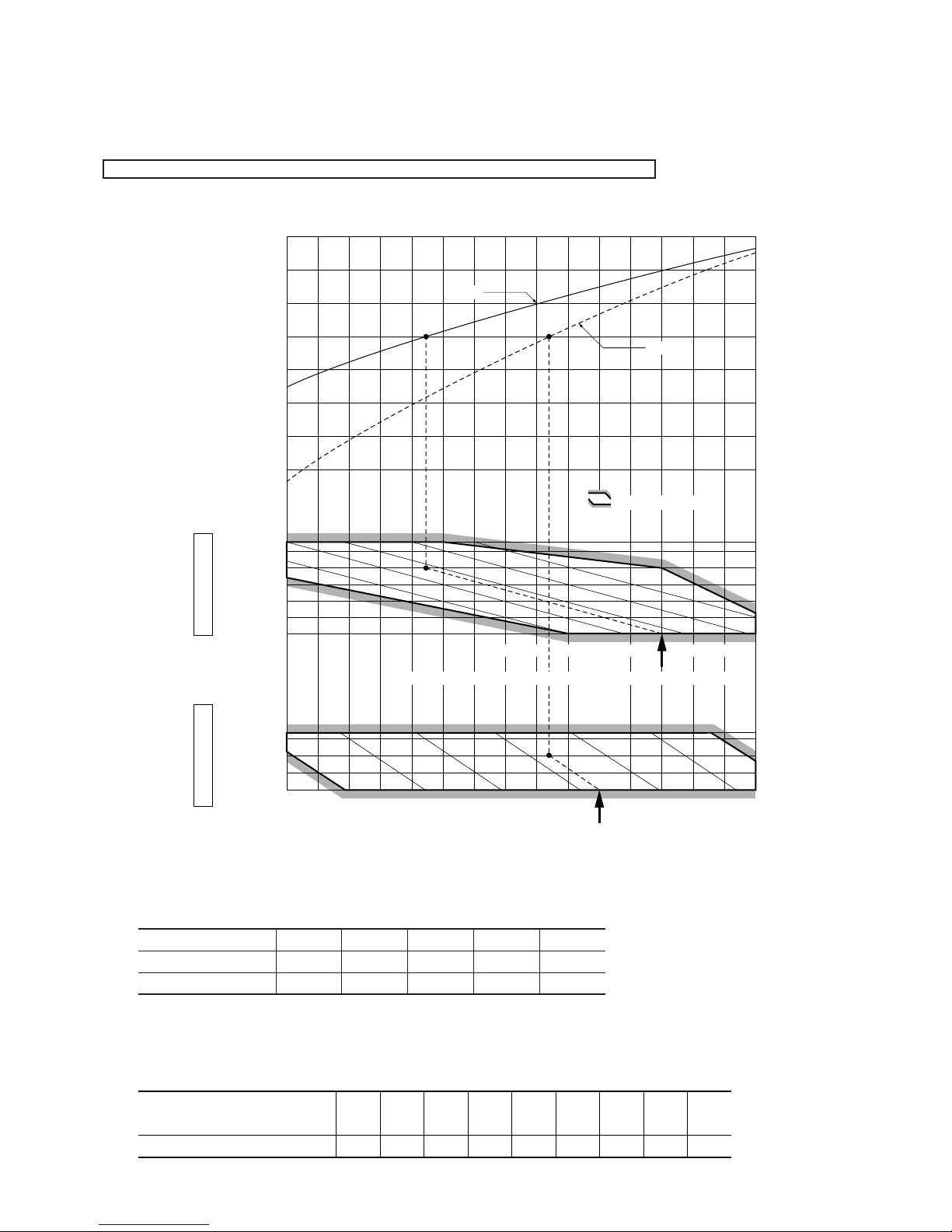

5.2.5 Selection chart

Correct the cooling and heating capacity in accordance with the conditions as follows. The net cooling and heating capacity can be

obtained in the following way.

Net capacity = Capacity shown on specification × Correction factors as follows.

(1) Coefficient of cooling and heating capacity in relation to temperatures

15

ISO-T1 Standard ConditionOutdoor air W.B. temperature °C W.B.

010-10 -5 5

14 16 18 20 22

15

10

27

25

20

15

20

25

30

35

40

0.6

0.7

0.8

0.9

1.0

1.1

1.2

1.3

43

24

20

ISO-T1 Standard ConditionIndoor air W.B. temperature °C W.B.

Heating

Cooling

Applicable range

Coefficient of cooling &

Heating capacity in

relation to temperature

Cooling operation

Outdoor air D.B.

temperature

°C D.B.

Heating operation

Indoor air D.B.

temperature

°C D.B.

Air inlet temperature of

outdoor unit in ºCWB

Adjustment coefficient

-10

0.95-90.94-70.93-50.91-30.88-10.8610.8730.9251.00

Piping length [m]

Cooling

Heating

7

1.0

1.0

10

0.99

1.0

15

0.975

1.0

20

0.965

1.0

25

0.95

1.0

(2) Correction of cooling and heating capacity in relation to one way length of refrigerant piping

It is necessary to correct the cooling and heating capacity in relation to the one way piping length between the indoor and outdoor

units.

(3) Correction relative to frosting on outdoor heat exchanger during heating

In additions to the foregoing corrections (1), (2) the heating capacity needs to be adjusted also with respect to the frosting on the

outdoor heat exchanger.

Page 17

17

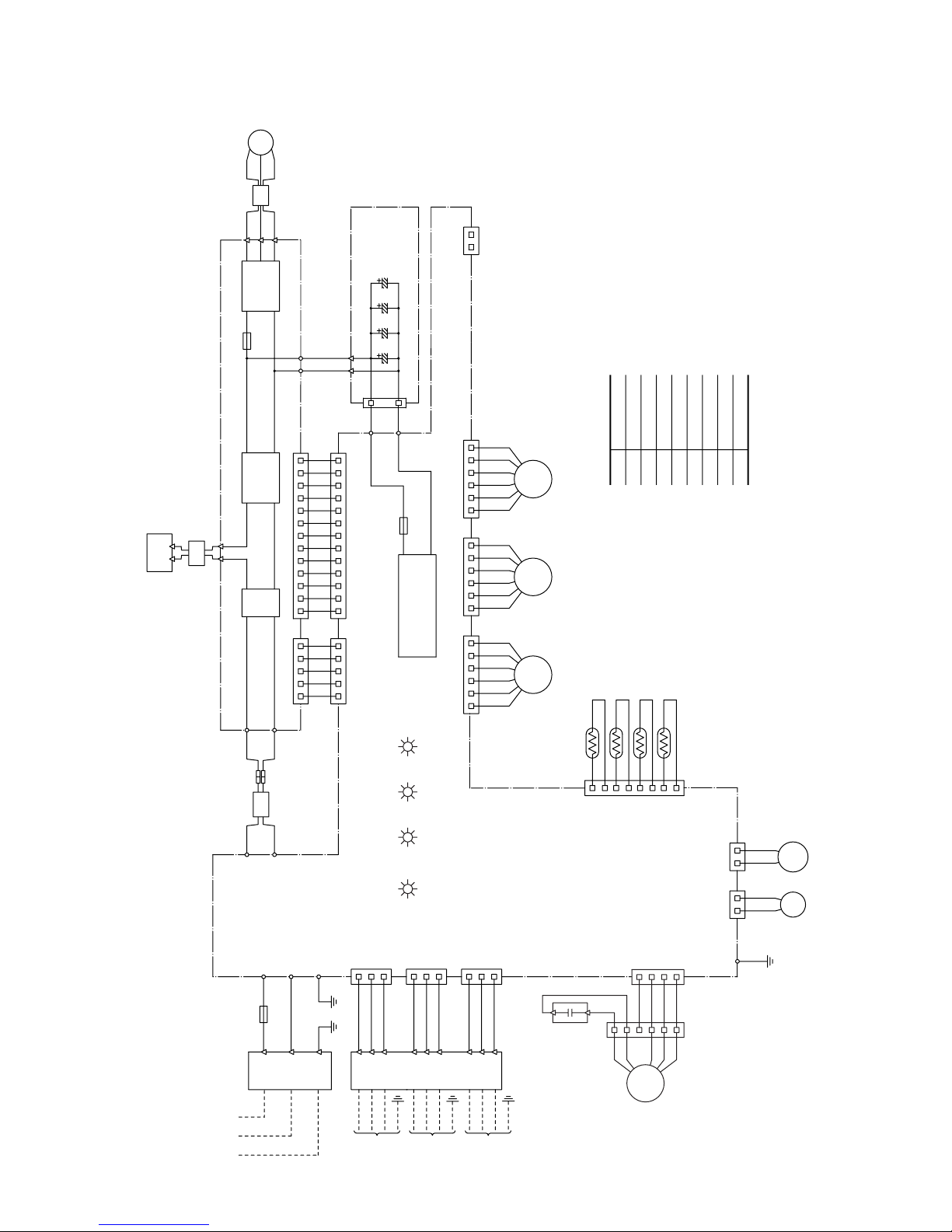

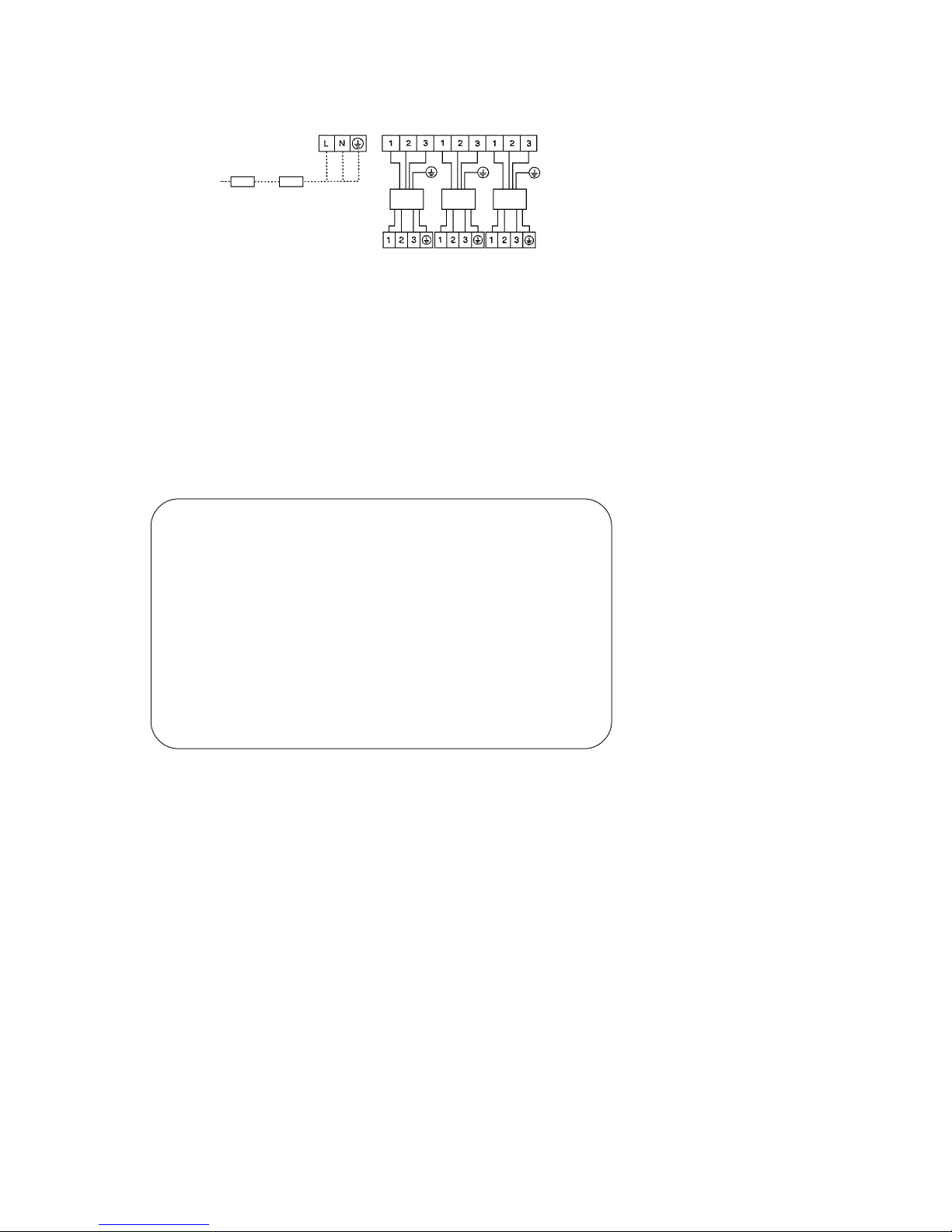

5.3 ELECTRICAL DATA

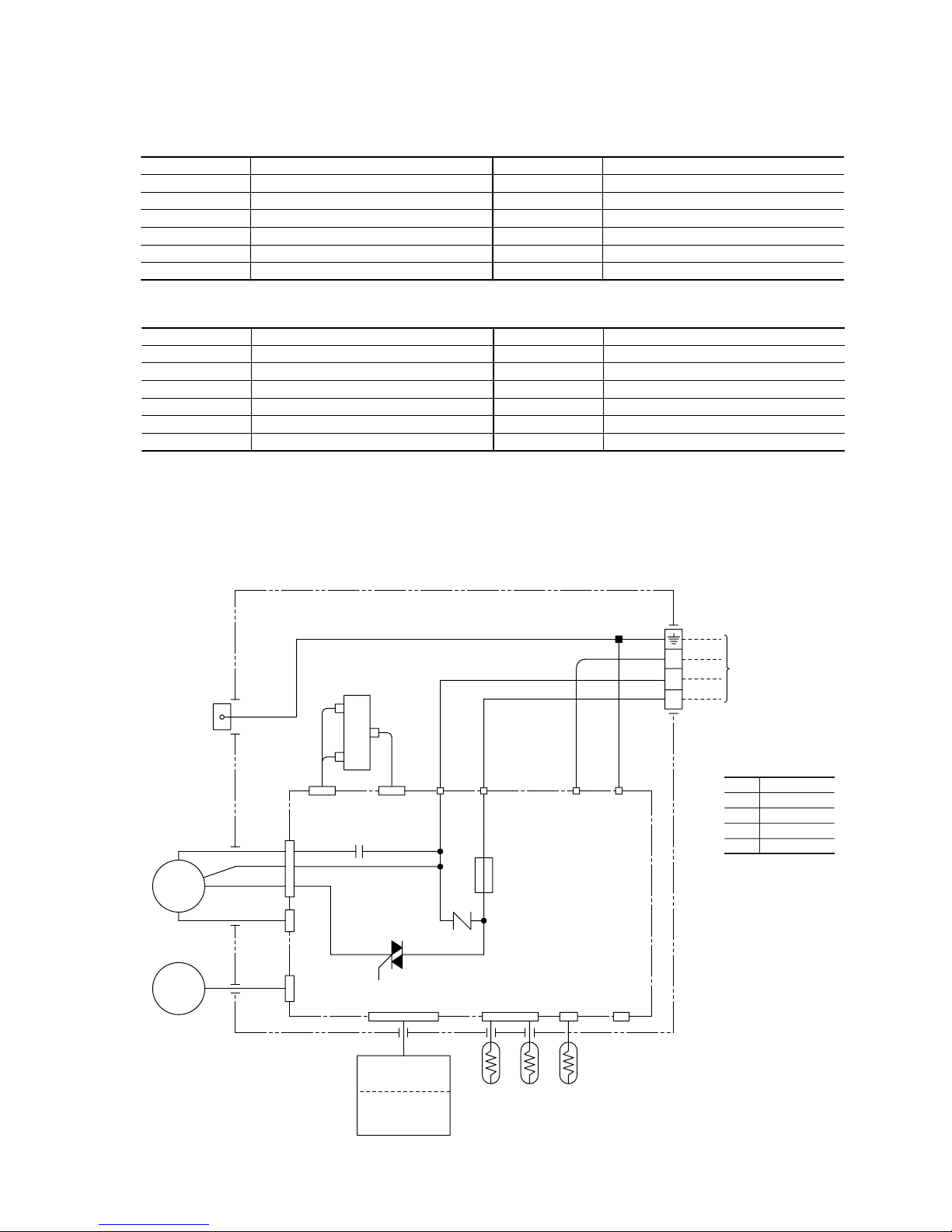

Meaning of marks

• Outdoor Unit

• Indoor Unit

FM

I

CF

I

SM

Tr

ZNR

F

Parts name

Fan motor

Capacitor (for FM

I

)

Flap motor

Transformer

Varistor

Fuse

Symbol

DM

FS

Th

I

-A

Th

I-R1

ThI-R

2

Parts name

Drain motor

Float switch

Sensor (room temp.)

Sensor (indoor H.X temp.)

Sensor (indoor H.X temp.)

Symbol

CM

FM

O

CFO

L

DS1

Q11

Parts name

Compressor motor

Fan motor

Capacitor (for FM

O)

Reactor

Diode stack

Power transistor

Symbol

EEVA ~ D

20S

Tho-A

Tho-R

Tho-D

Tho-C

Parts name

Electronic expansion valve

4 way valve (coil)

Sensor (outdoor air temp.)

Sensor (outdoor H.X temp.)

Sensor (discharge pipe temp.)

Sensor (suction pipe temp.)

Symbol

5.3.1 Electrical wiring

(1) Indoor unit

Models SKM22ZD-S, 25ZD-S, 28ZD-S, 35ZD-S

CNW

CF

I

HEAT

EXCHANGER

Power line

(Outdoor unit)

CNM

CNU

CNC

Tr

F

(250V 3.15A)

Printed circuit

board

1

52C-4

N

ZNR

IC8

3

5

1

WH

2/N

3

SM

FM

I

BK

RD

WH

Y/GN

RD

WH

BR

TB

RD

J

Y/GN

G

BK

CNB

CNE

CNG CNF

Back up

switch

ThI-A ThI-R

2

ThI-R

1

Display

Wireless

R-Amp

Black

Brown

Red

White

Yellow/Green

BK

BR

RD

WH

Y/GN

Color symbol

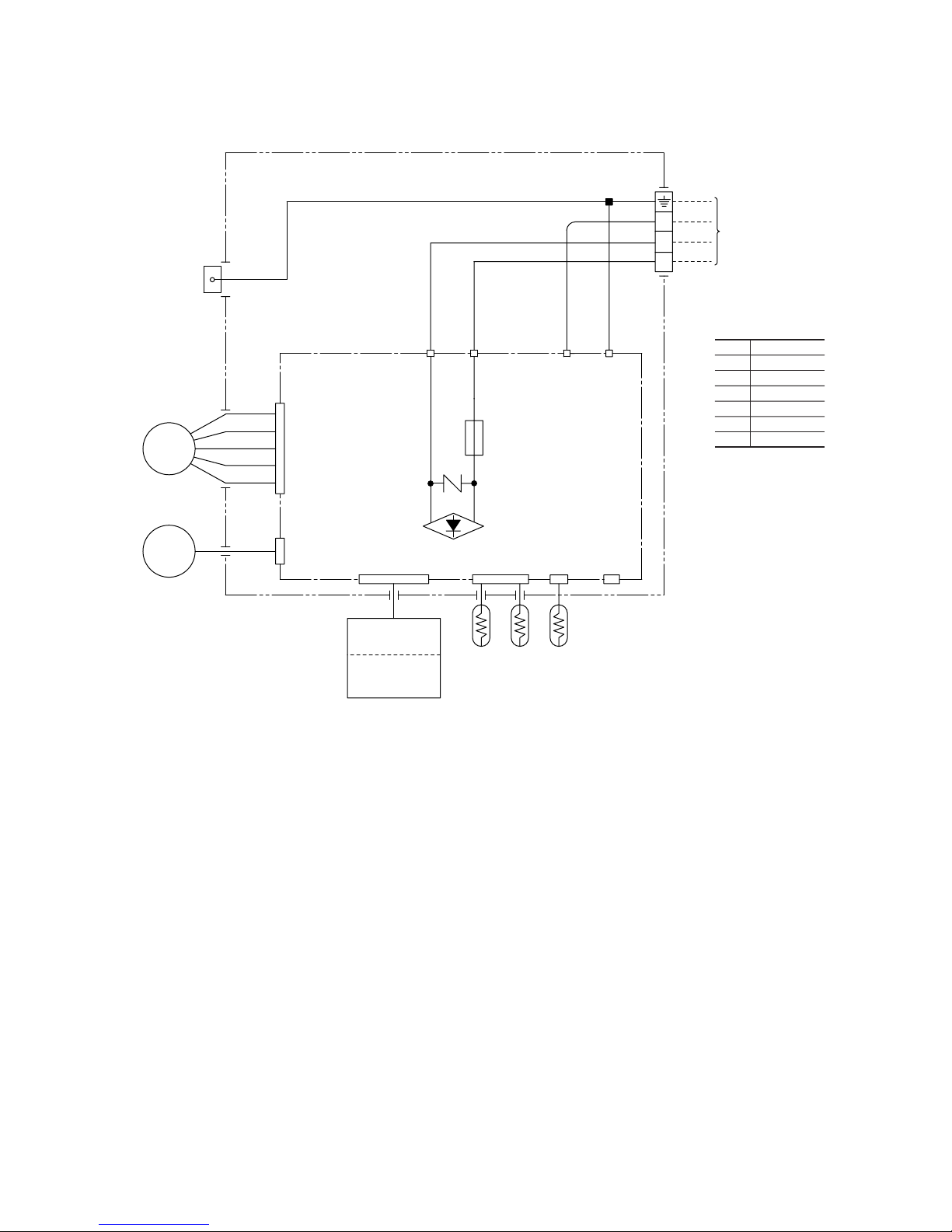

Page 18

18

HEAT

EXCHANGER

Power line

(Outdoor unit)

CNM

F

(250V 3.15A)

Printed circuit

board

1

52C-4

N

~~

ZNR

WH

2/N

3

SM

FM

I

BK

RD

WH

Y/GN

RD

1

3

4

5

6

WH

BL

CNU

Y

BK

TB

RD

J

Y/GN

G

BK

CNE

CNG CNF

Back up

switch

ThI-A ThI-R

2

ThI-R

1

Display

Wireless

R-Amp

Black

Brown

Red

White

Yellow/Green

BK

BR

RD

WH

Blue

Yellow

BL

Y

Y/GN

Color symbol

Model SKM50ZD-S

Page 19

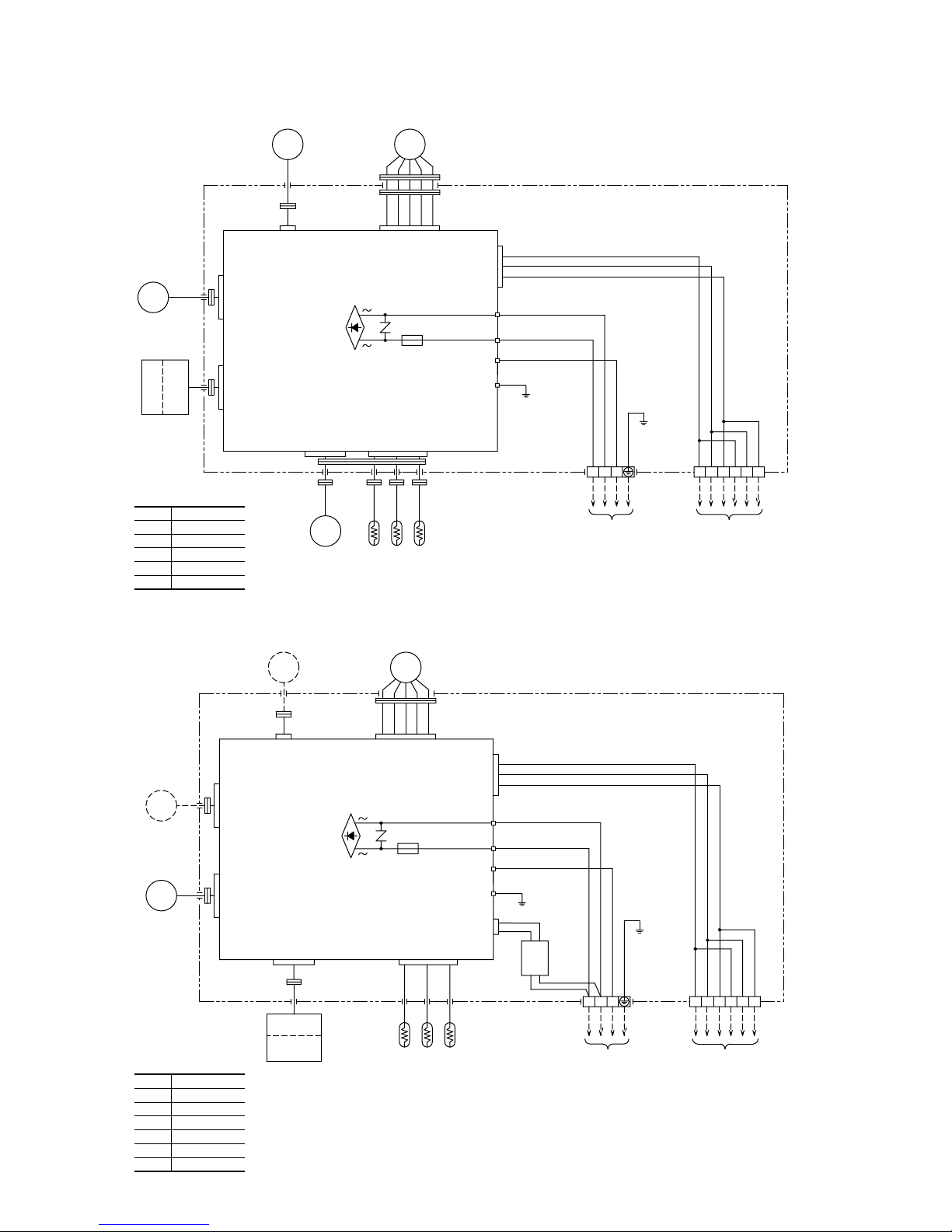

19

Models STM25ZE-S, 35ZE-S, 50ZE-S, 60ZE-S

Models SRRM25ZE-S, 35ZE-S, 50ZE-S, 60ZE-S

Display

Wireless

R-amp

Display

Wireless

R-amp

DM

DM

FS

FS

Tr

SM

SM

FM

I

FM

I

BK

BK

Printed circuit

board

F

(250V 3.15A)

ZNR

Printed circuit

board

(Optional parts)

(Optional

parts)

F

(250V 3.15A)

ZNR

13 546

G

2/N

Power line

(Outdoor unit)

13

J

R/L

S/N

Control

box

Control

box

YXZXYZ

BK

RD

T2

T1

Wired remote control

(Optional parts)

Power line

(Outdoor unit)

Wired remote control

(Optional parts)

T1

CNG

CNP

CNE

CNQ

CNM

CNU

13 546

G

CNC

1

2/N

3

S/N

J

R/L

CNB

YXZXYZ

T2

ThI-A ThI-R1ThI-R

2

ThI-A ThI-R1ThI-R

2

Y

BL

Y

BKRDWH

WH

BK

RD

Y/G

Y/G

RD

BK

WH

BK

WH

RD

RD

RD

BL

Y

BKRDWH

BK

BK

Y/G

OR

WH

BK

Y/G

RD

RD

BK

WH

WH

BK

RD

BK

Color symbol

BL

Y/G

Black

Blue

Yellow/Green

WH White

RD Red

Y Yellow

BK

Color symbol

BL

OR

Y/G

Black

Blue

Orange

Yellow/Green

WH White

RD Red

Y Yellow

CNP

CNE

CNG

CNQ

CNM

CNU

CNB

Page 20

20

SWITCHING

POWER CIRCUIT

EEV-C

P

L-1

N-1

L

N

BK

WH

1

2

3

RD

20S

G2

~

~

+

-

CNI

RAM DATA

URD

W

CM

V

PWB ASSY(POWER) PWB2

F1

250V 20A

F1

200V 2A

EEV-BEEV-A

Tho-D

Tho-A

Tho-R

Tho-C

1

2

3

4

5

6

7

8

HEATER

F

250V 20A

EARTH

1

2

3

BR

1

2

3

BL

BK

BK

BK

WH

WH

WH

1122

CNO

CNP

CNQ

CNB CNC

CND

CNJ CNK CNL

CNG

RD

BK

P_1N_1

P_1

123456 123456 123456

12

CNN CNH

1234567891011121312345

12345 12345678910111213

PWB ASSY(CAPACITOR) PWB3

PWB ASSY(CPU) PWB1

NW

V

U

DC-P

DC-N

N1

L

N2

P2

BK

C1 C2 C3 C4

2

1

IC12 Q11

RD

BK RD

BL

GR

BL

GR

L-OUT2

AC.L

AC.N

N-OUT2

CNG

CNH

T1

T2

DS1

AF-L2

N_3

G3

AF-L1

OR OR

L

OR OR

Y/G

Y/G Y/G

WH

BK

WH

BK

Power source

1 Phase

220/230/240V

Unit

A

Unit

B

Unit

C

Black

Red

White

Yellow/Green

BK

RD

WH

Blue

Yellow

BL

Brown

BR

Gray

GR

Orange

OR

Y

Y/GN

Color symbol

NF

NF

NF

LED4

Unit A

LED5

ERROR

LED2

Unit C

LED3

Unit B

FMo

CNS

1

3

7

5

CAP1

CAP2

Me

Lo

COM

CFO

OR

Y

BK

BL

RD

WH

(2) Outdoor unit

Model SCM60ZD-S

Page 21

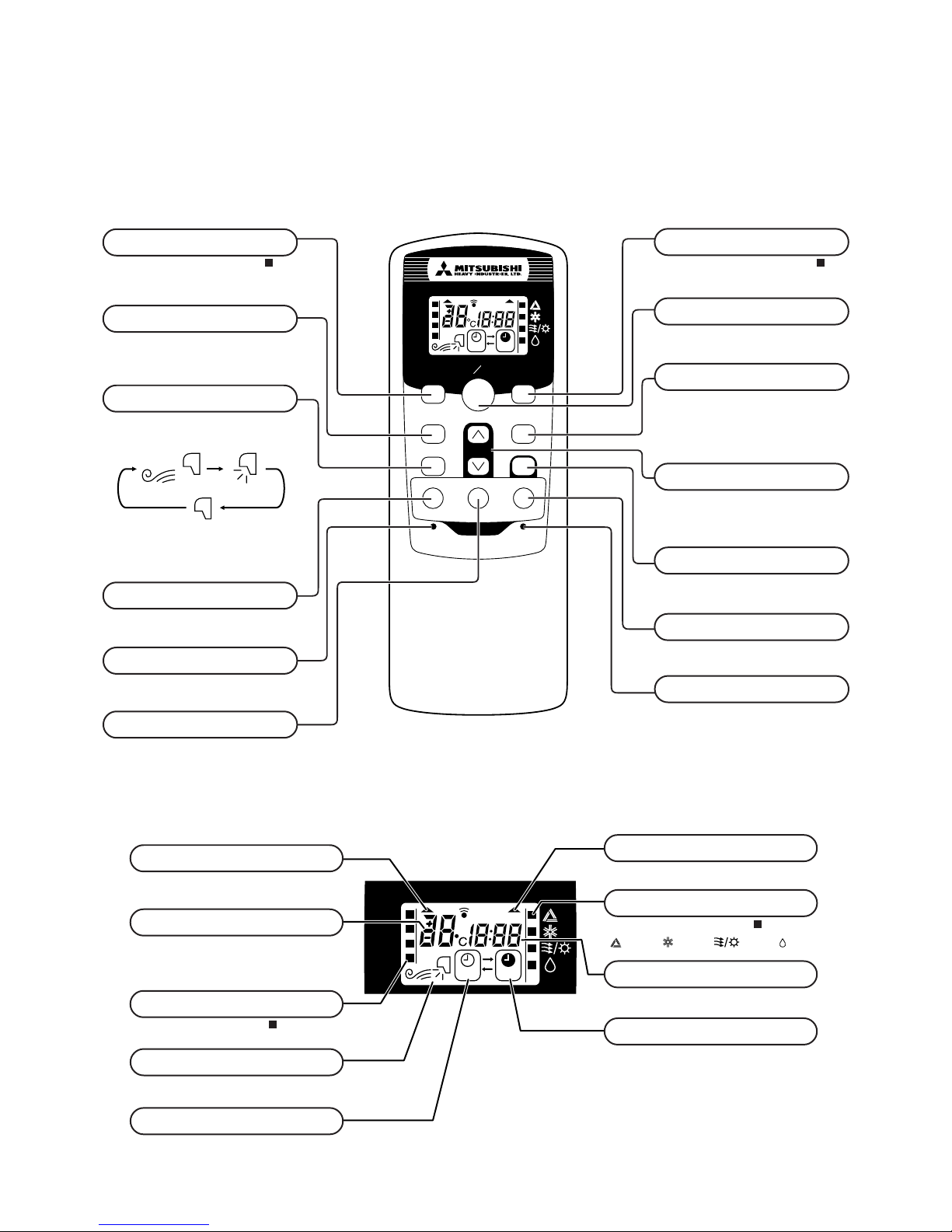

21

LO

MED

HI

AUTO

HI POWER

ECONO

ON OFF

AM PM

HI POWER

TEMP

ECONO

AIR FLOW

CANCEL

ON OFF

RESERVE

TIMER

TIME

ACL

FAN SPEED

ON

MODE

LO

MED

HI

AUTO

TIME

OFF

HI POWER

ECONO

ON OFF

AM PM

FAN SPEED button

Each time the button is pushed, the indicator is switched over in turn.

• The above illustration shows all controls, but in practice

only the relevant parts are shown.

OPERATION MODE select button

Each time the button is pushed, the indicator is switched over in turn.

AIR FLOW button

This button changes the flap mode. When

pressed, this button changes the mode in the

following order:

ON/OFF button

Press for starting operation, press again for

stopping.

HI POWER button

This button changes the HI POWER mode.

ECONOMY button

This button changes the ECONOMY mode.

RESET switch

Switch for resetting microcomputer.

ON TIMER button

This button selects ON TIMER operation.

Clock switch

This switch for setting the clock.

OFF TIMER button

This button selects OFF TIMER operation.

TEMPERATURE button

This button sets the room temperature.

(This button changes the present time and

TIMER time.)

CANCEL button

This button cancels the ON timer and OFF

timer.

RESERVE button

This button sets the present time and

TIMER time.

S Indication section

OPERATION MODE indicator

Indicates selected operation with lamp.

[

(Auto) • (Cool) • (Heat) • (Dry)]

TEMPERATURE indicator

Indicates set temperature.

(Does not indicate temperature when operation

mode is on AUTO)

FAN SPEED indicator

Indicates set air flow rate with lamp.

AIR FLOW indicator

Shows selected flap mode.

HI POWER MODE indicator

Indicates during Hi power mode operation.

ECONOMY MODE indicator

Indicates during economy mode operation.

ON TIMER indicator

Indicates during ON TIMER operation.

Clock indicator

Indicates present time or timer setting time.

OFF TIMER indicator

Indicates during OFF TIMER operation.

(a) Wireless remote control

Models All models

S Operation section

(Air scroll) (Swing)

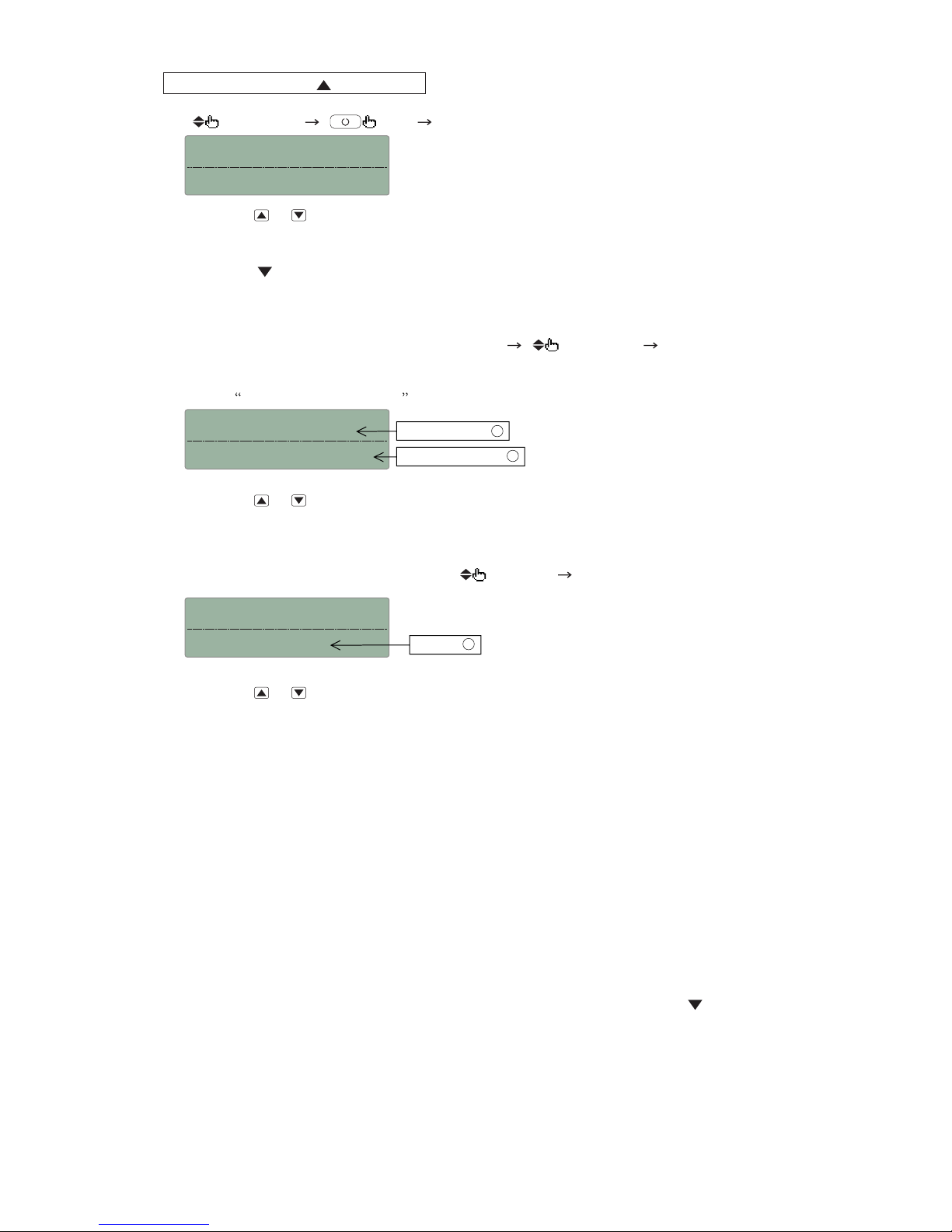

5.4 OUTLINE OF OPERATION CONTROL BY MICROCOMPUTER

(1) Operation control function by remote control switch

This button is not used for SRRM-ZE series.

(Air flow direction adjustment can not be

performed.)

(Flap stopped)

Page 22

22

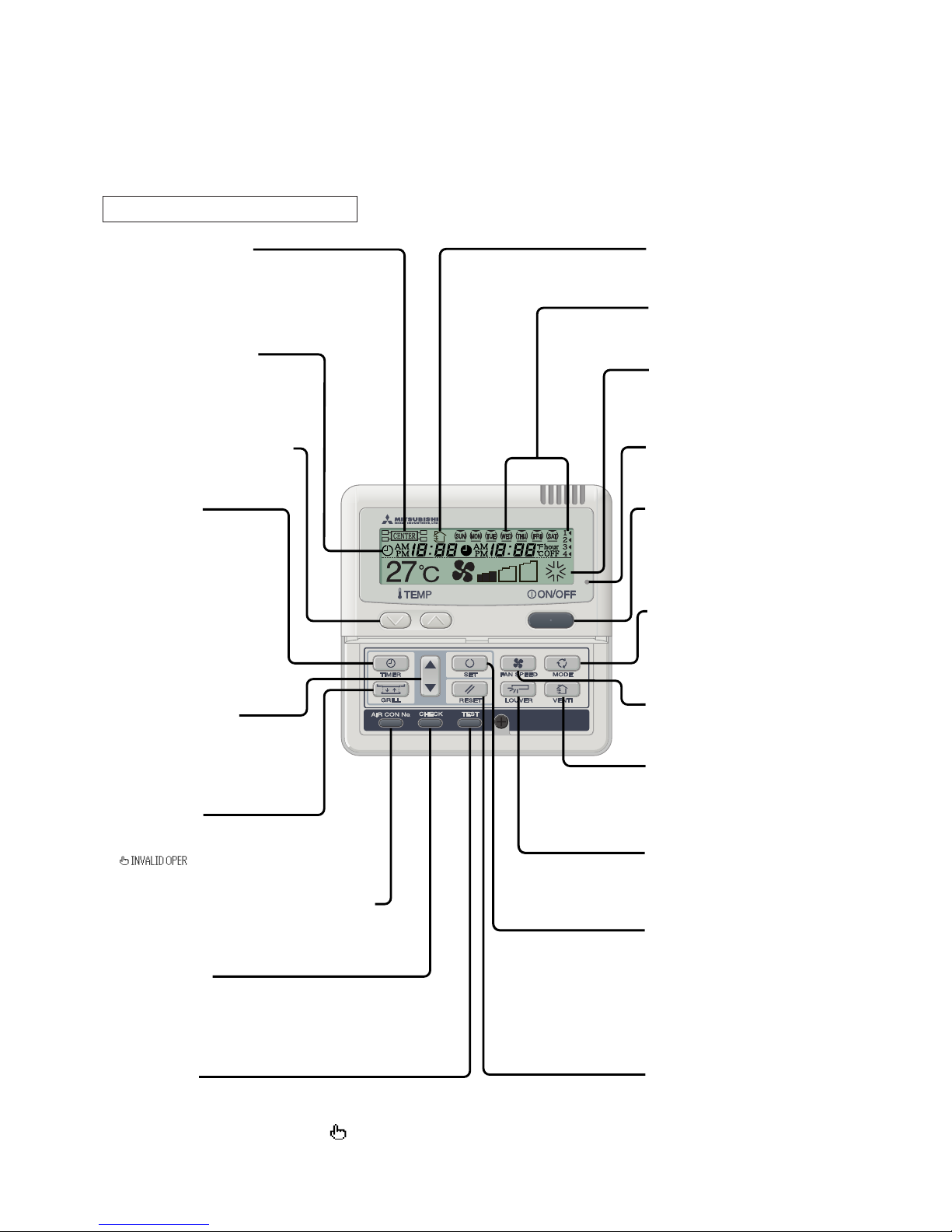

(b) Wired remote control (Optional parts)......STM, SRRM only

The figure below shows the remote controller with the cover opened. Note that all the items that may be displayed in the liquid crystal

display area are shown in the figure for the sake of explanation.

Characters displayed with dots in the liquid crystal display area are abbreviated.

Pull the cover downward to open it.

Weekly timer display

Displays the settings of

the weekly timer.

[Vent Indicator]

Indicates operation in the

Ventilation mode.

Operation/Stop switch

This switch is used to operate and

stop the air conditioning system.

Press the switch once to operate

the system and press it once again to

stop the system.

MODE switch

This switch is used to switch between

operation modes.

Operation setting display area

Displays setting temperature,

airflow volume, operation mode and

operation message.

Operation/Check indicator light

During operation: Lit in green

In case of error: Flashing in red

FAN SPEED switch

This switch is used to set the

airflow volume.

(AUTO, HI POWER or ECONO

cannot be selected.)

SET switch

This switch is used to apply the timer

operation setting.

This switch is also used to make silent

mode operation settings.

[RESET switch]

Press this switch while making settings

to go back to the previous operation.

This switch is also used to reset the

FILTER CLEANING message display.

(Press this switch after cleaning the air filter.)

Central control display

Displayed when the air conditioning

system is controlled by the option controller.

Timer operation display

Displays the settings related to

timer operation.

AIR CON No. (Air conditioning system No.) switch

Displays the number of the connected

air conditioning system.

[CHECK switch]

This switch is used at servicing.

[TEST switch]

This switch is used during test operation.

Temperature setting switches

These switches are used to set

the temperature of the room.

[VENT switch]

Switch that operates the

connected ventilator.

Timer setting switches

These switches are used to set

the timer mode and time.

TIMER switch

This switch is used to select

a timer mode.

(The comfortable timer cannot

be selected.)

[GRILL switch]

This switch has no function.

When this switch is pressed,

(Invalid Operation)

is displayed, but it does not mean a failure.

LOUVER switch

This switch is used to operate/stop

the swing louver.

This button is not used for SRRM-ZE

series.

(Air flow direction adjustment can not

be performed.)

* If you oress any of the switches above and INVALID OPER is display, the switch has no function.

But it does not mean a failure.

Note (1) The STM, SRRM models don't support the switches and functions displayed in [ ].

Page 23

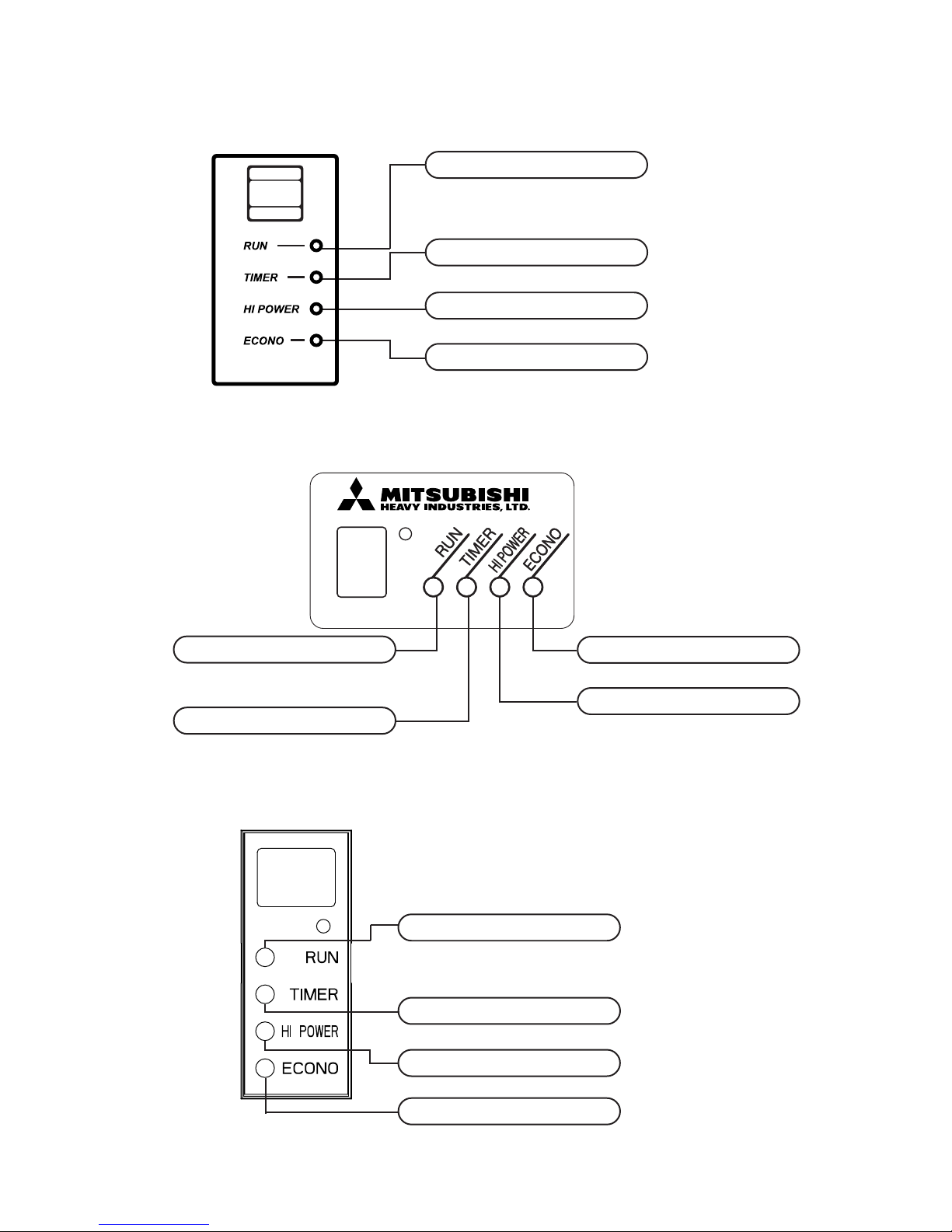

23

RUN (HOT KEEP) light (green)

• Illuminates during operation.

• Blinks at air flow stop due to the ‘HOT KEEP’.

ECONOMY light (orange)

Illuminates during ECONOMY operation.

TIMER light (yellow)

Illuminates during TIMER operation.

HI POWER light (green)

Illuminates during HI POWER operation.

Models STM25ZE-S, 35ZE-S, 50ZE-S, 60ZE-S

Models SRRM25ZE-S, 35ZE-S, 50ZE-S, 60ZE-S

RUN (HOT KEEP) light (green)

• Illuminates during operation.

• Blinks at air flow stop due to the ‘HOT KEEP’.

TIMER light (yellow)

Illuminates during TIMER operation.

RUN (HOT KEEP) light (green)

• Illuminates during operation.

• Blinks at air flow stop due to the ‘HOT KEEP’.

ECONOMY light (orange)

Illuminates during ECONOMY operation.

TIMER light (yellow)

Illuminates during TIMER operation.

HI POWER light (green)

Illuminates during HI POWER operation.

ECONOMY light (orange)

Illuminates during ECONOMY operation.

HI POWER light (green)

Illuminates during HI POWER operation.

(c) Unit indication section

Models SKM22ZD-S, 25ZD-S, 28ZD-S, 35ZD-S, 50ZD-S

Page 24

24

(2) Unit ON/OFF button

When the remote control batteries become weak, or if the remote control is lost or malfunctioning, this button may be used to turn

the unit on and off.

(a) Operation

Push the button once to place the unit in the automatic mode. Push it once more to turn the unit off.

(b) Details of operation

The unit will go into the automatic mode in which it automatically determines, from room temperature (as detected by

sensor), whether to go into the cooling, thermal dry or heating modes.

Function

Room temperature Flap

Operation mode

setting

Fan speed

(SKM, STM only)

Timer switch

Cooling About 25ºC

Thermal dry About 25ºC Auto Auto Continuous

Heating About 26ºC

Unit ON/OFF button

Unit ON/OFF button

Unit ON/OFF button

¡ SKM model

¡ STM model

(3) Drain motor forced operation functions (STM, SRRM only)

(a) Operation

• When the float switch detects drain water, please use the wireless remote control to set the operation mode to "heating",

set the temperature to 30°C, and set the timer to continuous operation.

• When the float switch detects drain water, press the TEST switch on wired remote control for 3 seconds.

(b) Detail of operation

Sets the decision speed to 0 rps, stops the indoor fan motor, and only lets the drain motor run for 5 minutes. After this

operation finishes, if the float switch detects drain water, it will display an error and stop operation.

(C) Reset condition

(i) When the drain motor has run for 5 minutes.

(ii) Use the remote control to set the operation mode to heating, set the temperature to 30°C, and set the timer to something

other than continuous operation.

¡ SRRM model

Page 25

25

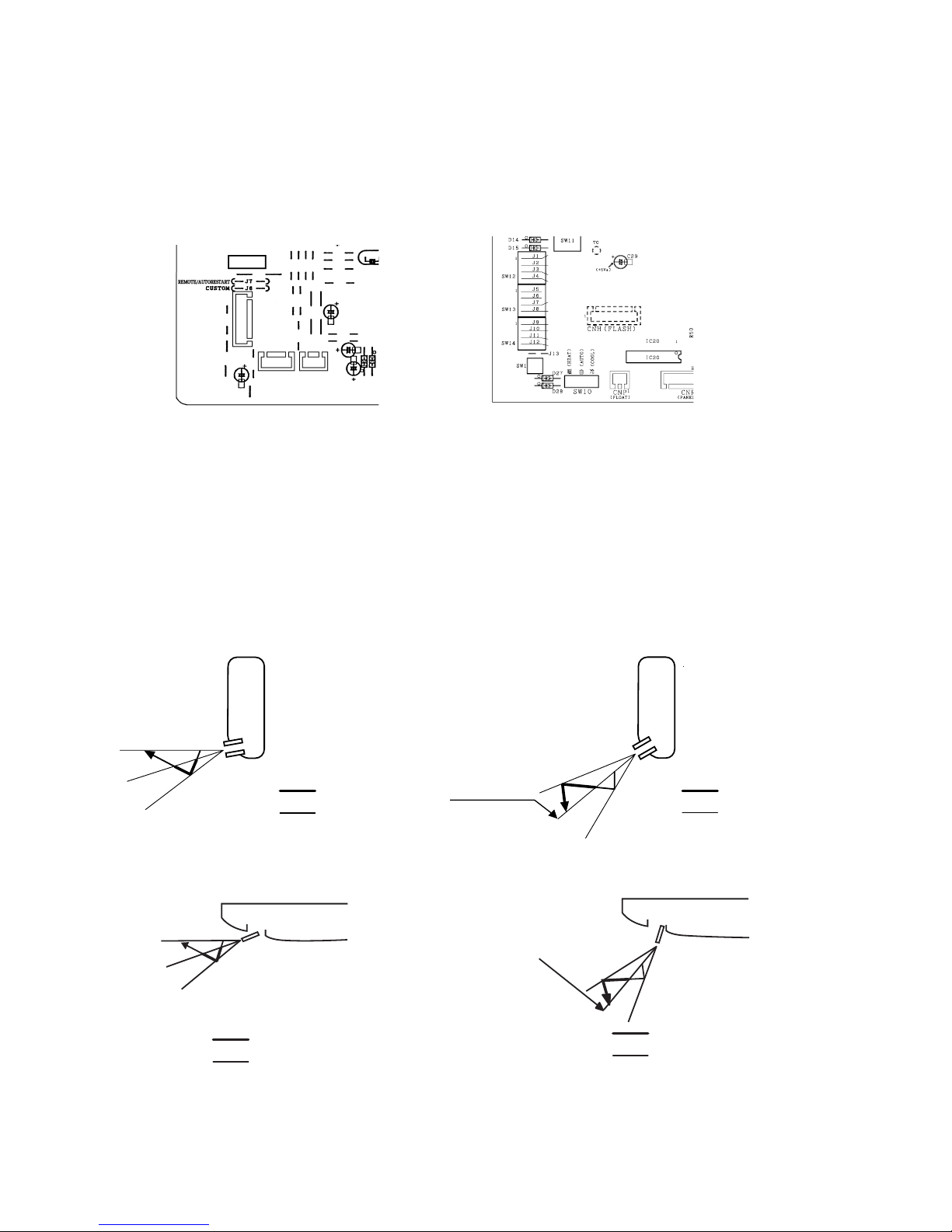

(4) Power blackout auto restart function

(a) Power blackout auto restart function is that records the operational status of the air-conditioner immediately prior to it being

switched off by a power cut, and then automatically resumes operations at that point after the power has been restored.

(b) The following settings will be cancelled:

(i) Timer settings

(ii) High-power operations

Notes (1) Power blackout auto restart function is set at on when the air-conditioner is shipped from the factory. Consult with your dealer if this function needs to

be switched off.

(2) When power failure ocurrs, the timer setting is cancelled. Once power is resumed, reset the timer.

(3) If the jumper wire (J7) “REMOTE/AUTORESTART (SKM), AUTORESTART (STM, SRRM) ” is cut, auto restart is disabled. (See the diagram at

above)

¡ SKM model

(5) Flap control (SKM, STM only)

Control the flap by AIRFLOW button on the wireless remote control.

(a) Air scroll

The flap will be automatically set to the angle of air flow best to operation.

(i) Starting time of operation

(ii) When not operating

The flap closes, when operation has stopped.

s

During cooling and

t

dry operation

Thick line : Rapid movement

Thin line : Slow movement

Stops for approximately

5 seconds in the

horizontal position.

s

During heating

t

operation

Stops for approximately

5 seconds in this

position.

Thick line : Rapid movement

Thin line : Slow movement

¡ STM, SRRM model

¡ SKM model

¡ STM model

Thick line : moves quickly

Thin line : moves slowly

Stops at this position

for 5 seconds.

Thick line : moves quickly

Thin line : moves slowly

Stops at this position

for 5 seconds.

s

During cooling and

t

dry operation

s

During heating

t

operation

EXTERNAL INPUT

WIRED REMOCON

OPE PERMISSION

CUSTOM

AUTO RESTART

LO TEMP

DIRT PREVENT

COOL ONLY

HI CEIL

PANEL

50/60

Page 26

26

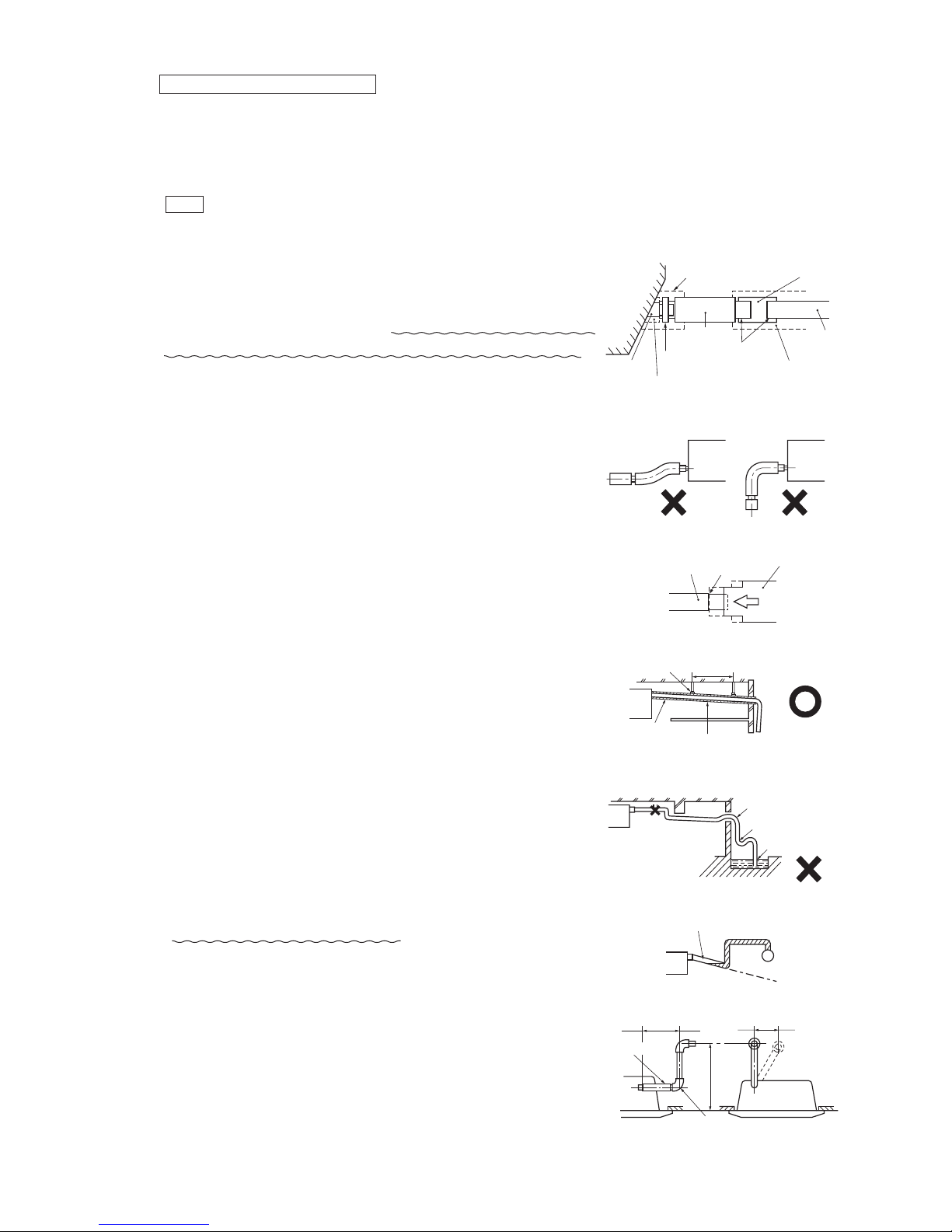

(b) Memory flap

While the flap is operating if the AIRFLOW button is pushed once, it stops swinging at an angle.

As this angle is memorized in the microcomputer, the flap will be automatically set to the angle when next operation is

started.

¡ Recommendable stopping angle of the flap

Horizontal

blowing

COOL•DRY

Slant forward

blowing

HEAT

¡ SKM model

(c) Swing flap

Flap moves in upward and downward directions continuously.

¡ STM model

Setting time

15 min. 10 min. 5 min.

earlier earlier earlier

Corrects the starting time of next operation by

calculating the temperature difference.

(Example) Heating

Setting temperature

Room temperature

Operation starting time

Time

¡ If the difference (= Setting temperature – Room tempera-

ture) is 4ºC, the correction value is found to be +5 minutes from the table shown above so that the starting time

of next operation is determined as follows:

15 min. earlier + 5 min. = 20 min. earlier

↑↑

Current operation Correction value

start time

(6) Comfortable timer setting

If the timer is set at ON when the operation select switch is set at the cooling or heating, or the cooling or heating in auto mode

operation is selected, the comfortable timer starts and determines the starting time of next operation based on the initial value of 15

minutes and the relationship between the room temperature at the setting time (temperature of room temperature sensor) and the

setting temperature. (Max. 60 minutes)

Operation mode Operation start time correction value (Min.)

3 < Room temp. – Setting temp. 1 < Room temp. – Setting temp.

<

=

3 Room temp. – Setting temp.

<

=

1

At cooling

+5 No change –5

3 < Setting temp. – Room temp. 2 < Setting temp. – Room temp.

<

=

3 Setting temp. – Room temp.

<

=

2

At heating

+5 No change –5

Notes (1) At 5 minutes before the timer ON time, operation starts regardless of the temperature of the room temperature sensor (Th

I-A).

(2) This function does not operate when in the Dry or Auto Dry mode. However, the operation in item (1) does operate in the Auto Dry mode.

(3) During the comfortable timer operation, both the RUN light and TIMER light illuminate and the TIMER light goes off after expiration of the timer, ON setting

time.

COOL•DRY

HEAT

Horizontal

blowing

Slant forward

blowing

Page 27

27

Capacity control is within the range shown above. If demand capacity of the indoor units exceeds the maximum capacity

of the outdoor unit, the demand capacity will be proportionally distributed.

(ii) Outdoor unit speed control (10 ~ 95 rps)

(7) Cooling operation

(a) Summary

(i) Capacity control

Model

Capacity

SCM60ZD-S

1.4 ~ 6.9 kW

10 rps or less

More than 10 rps, but 95 rps or less

More than 95 rps

Decision speed

10 rps

10 to 95 rps

95 rps

Indoor unit command total speed value

Note (1) The indoor unit command total speed value is the total of the values from each unit in item (b).

(b) Mode switching

Within the selected mode, the unit operates using the values shown below which were obtained by multiplying a conversion

coefficient to the indoor unit command speed.

◆SKM model

Model (Indoor)

Operation Mode

Automatic

High

Medium

Low

Hi power

Econo

5 ~ 21

5 ~ 21

5 ~ 16

5 ~ 11

21

5 ~ 16

5 ~ 21

5 ~ 21

5 ~ 18

5 ~ 11

21

5 ~ 18

5 ~ 25

5 ~ 25

5 ~ 19

5 ~ 12

22

5 ~ 19

5 ~ 30

5 ~ 30

5 ~ 20

5 ~ 13

24

5 ~ 20

7 ~ 46

7 ~ 46

7 ~ 24

7 ~ 13

46

7 ~ 24

22 25 28 35 50

(rps)

(c) Operation of major functional components in cooling mode

Functional

components

Operation

Command speed

Indoor

unit fan

Compressor

Outdoor unit fan

Electronic

expansion valve

See preceding table

ON

According to command speed

According to outdoor unit speed

According to decision

speed

0

(All indoor units)

OFF

According to stop mode

According to mode switching

OFF

0

(Thermostat off units)

ON

All closed

(Thermostat off units)

According to outdoor unit speed

According to mode switching

All closed

(Fan, stop, abnormal stop units)

0

(Fan, stop, abnormal stop units)0 (All units)

ON

According to command speed

OFF

OFF

According to stop mode

Cooling

Thermostat OFF

(All indoor units)

Thermostat OFF

(Some of indoor units)

Fan, stop, abnormal stop

(Some of indoor units)

Failure

(Outdoor unit)

Fixed

Automatic

◆STM, SRRM models

Model (Indoor)

Operation Mode

Automatic

High

Medium

Low

Hi power

Econo

5 ~ 25

5 ~ 25

5 ~ 18

5 ~ 12

25

5 ~ 18

5 ~ 46 (5 ~ 42)

5 ~ 46 (5 ~ 42)

5 ~ 32

5 ~ 19

42

5 ~ 32

7 ~ 59

7 ~ 59

7 ~ 42

7 ~ 24

59

7 ~ 42

7 ~ 64

7 ~ 64

7 ~ 47

7 ~ 27

64

7 ~ 47

25 35 50 60

(rps)

Note (1) Values in ( ) are for type SRRM.

Page 28

28

(b) Mode switching

Within the selected mode, the unit operates using the values shown below which were obtained by multiplying a conversion

coefficient to the indoor unit command speed.

◆SKM model

(c) Operation of major functional components in heating mode

Model (Indoor)

Operation Mode

Automatic

High

Medium

Low

Hi power

Econo

5 ~ 35

5 ~ 35

5 ~ 24

5 ~ 14

35

5 ~ 24

5 ~ 35

5 ~ 35

5 ~ 23

5 ~ 14

35

5 ~ 23

5 ~ 36

5 ~ 36

5 ~ 25

5 ~ 15

36

5 ~ 25

5 ~ 39

5 ~ 39

5 ~ 26

5 ~ 16

38

5 ~ 26

7 ~ 64

7 ~ 64

7 ~ 28

7 ~ 17

64

7 ~ 28

22 25 28 35 50

(rps)

Functional

components

Operation

Command speed

Indoor

unit fan

Compressor

Outdoor unit fan

Electronic

expansion valve

See preceding table

ON

According to mode switching

According to command speed

According to outdoor unit speed

According to decision

speed

0

(All indoor units)

OFF

According to stop mode

Hot Keep

Hot Keep

OFF

0

(Thermostat off units)

ON

According to heating stop unit control

(Thermostat off units)

According to mode switching

According to command speed

According to outdoor unit speed

According to heating stop unit control

(Fan, stop, abnormal stop units)

0

(Fan, stop, abnormal stop units)

0

(All units)

ON OFF

Hot Keep

Hot Keep

OFF

According to stop mode

Heating

Thermostat OFF

(All indoor units)

Thermostat OFF

(Some of indoor units)

Fan, stop, abnormal stop

(Some of indoor units)

Failure

(Outdoor unit)

Fixed

Automatic

10 rps or less

More than 10 rps, but 95 rps or less

More than 95 rps

Decision speed

10 rps

10 to 95 rps

95 rps

Indoor unit command total speed value

Note (1) The indoor unit command total speed value is the total of the values from each unit in item (b).

(8) Heating operation

(a) Summary

(i) Capacity control

Model

Capacity

SCM60ZD-S

0.75 ~ 7.2 kW

Capacity control is within the range shown above. If demand capacity of the indoor units exceeds the maximum capacity

of the outdoor unit, the demand capacity will be proportionally distributed.

(ii) Outdoor unit speed control (10 ~ 95 rps)

◆STM, SRRM models

Model (Indoor)

Operation Mode

Automatic

High

Medium

Low

Hi power

Econo

5 ~ 40

5 ~ 40

5 ~ 29

5 ~ 17

40

5 ~ 29

5 ~ 49

5 ~ 49

5 ~ 36

5 ~ 21

49

5 ~ 36

7 ~ 59

7 ~ 59

7 ~ 42

7 ~ 24

59

7 ~ 42

7 ~ 64

7 ~ 64

7 ~ 47

7 ~ 27

64

7 ~ 47

25 35 50 60

(rps)

Page 29

29

1st speed

Indoor heat exchanger temp. (˚C)

Note (1) Refer to the table shown above right for the values A and B.

¡ Hot keep T mode (During heating thermostat operation or fuzzy auto; operation except when the deci-

sion speed is 0 rps.)

Indoor heat exchanger temp. (˚C)

30 35 40

2nd speed

(1st speed)

3rd speed

(2nd speed)

4th speed

(3rd speed)

5th speed

(4th speed)

6th speed

(5th speed)

45 50

(d) Hot keep operation

◆22, 25, 28, 35 models

If the hot keep operation is selected during the heating operation, the indoor fan is controlled based on the temperature of the

indoor unit heat exchanger (detected with Th

I-R1) to prevent blowing of cool wind.

¡ Normal mode (Normal heating operation, operation after HI POWER completion)

1st speed

¡ Values of A, B

AB

At 0 rps command 22 25

Other than 0 rps

17 19

command

Note (1) Refer to the table shown above right for the values A and B.

¡ Hot keep M mode [During HI POWER operation (for 15 min.)]

Indoor fan

Indoor heat exchanger temp. (˚C)

2nd speed

3rd speed

5th speed

6th speed

7th speed

8th speed

2nd speed

3rd speed

5th speed

6th speed

7th speed

9th speed

Indoor fan

10th speed

Indoor fan

Note (1) Values in ( ) are for type STM, SRRM.

Page 30

30

¡ Hot keep M mode [During HI POWER operation (for 15 min.)]

1st speed

Indoor heat exchanger temp. (˚C)

2nd speed

3rd speed

5th speed

6th speed

7th speed

8th speed

(9th speed)

Indoor fan

¡ Hot keep T mode (During heating thermostat operation or fuzzy auto; operation except when the deci-

sion speed is 0 rps.)

Indoor heat exchanger temp. (˚C)

30 35 40

1st speed

2nd speed

3rd speed

4th speed

5th speed

45 50

◆50, 60 models

¡Normal mode (Normal heating operation, operation after HI POWER completion)

1st speed

¡ Values of A, B

AB

At 0 rps command 22 25

Other than 0 rps

17 19

command

Notes (1) Refer to the table shown above right for the values A and B.

(2) Values in ( ) are for type STM, SRRM.

Indoor heat exchanger temp. (˚C)

2nd speed

3rd speed

5th speed

6th speed

7th speed

8th speed

9th speed

(10th speed)

OFF

A B 27.5 28 29.5 31.5 34 36 37.5 39 40

Indoor fan

Notes (1) Refer to the table shown above right for the values A and B.

(2) Values in ( ) are for type STM, SRRM.

Indoor fan

Page 31

31

F1

F1

R2rps

Decision rps

300 pulse

EEV control

Opening in relation to conditions

R1rps

Decision rps

0rpsOutdoor unit speed

After compressor software

has started

According to rpsOutdoor unit fan

OFF

ON4-way valve

OFF

470 pulse

fully opened

250 pulseElectronic expansion

valve EEV

(Operating unit)

EEV control

50 sec.

Opening in

relation to

conditions

Electronic expansion

valve EEV

(Stopped unit)

0 pulse

X1 pulse

X2 pulse

Start of defrost operation Defrost end operationDefrost operation

Defrost end condition

100 sec. 120 sec.

Indoor unit fan is

in response to Hot

Keep.

Notes (1)

(e) Defrosting

(i) When the following conditions are met, the defrosting operation will start.

1) During normal operation

a) When 40 minutes has passed since the start of heating or 40 minutes after the last defrosting (based on cumulative

operation time of compressor).

b) When the outdoor heat exchanger sensor (Tho-R) temperature is –2 °C or less for 3 continuous minutes after 37

minutes have passed.

c) Outdoor temperature sensor (Tho-A) – outdoor heat exchanger sensor (Tho-R) temperature

>

=

0.44 × outdoor

temperature sensor (Tho-A) temperature + A °C or more.

A = Outdoor temperature

>

=

– 2 °C: 4, outdoor temperature < – 2 °C: 6.

d) When the compressor is operating.

u Or, during heating, defrosting will start when the decision speed counts zero (0) rps for 10 times or more and

all conditions in a), b) and d) have been satisfied.

2) During defrosting acceleration

a) When 40 minutes has passed since the last defrosting (based on cumulative operation time of compressor).

b) When the compressor is operating.

u Or, during heating, defrosting will start when the decision speed counts zero (0) rps for 10 times or more and

all conditions in a) and b) have been satisfied.

Note (1) Defrosting acceleration is when the finishing of the previous defrosting is according to the defrosting conditions of the 10 minutes

that have passed.

3) Operation of function component in defrosting

Page 32

32

4) Conditions for finishing defrosting

When any of the following conditions is met, the defrosting finishing operation will start.

1 When the temperature of the outdoor heat exchanger sensor (Tho-R) is 20 °C or more.

2 When 10 minutes has passed after the start of defrosting.

(9) Outline of automatic operation

(a) Determination of operation mode

The unit checks the room temperature and the outdoor air temperature after operating the indoor and outdoor blowers for 20

seconds, determines the operation mode and the room temperature setting correction value, and then enters in the automatic

operation.

Heating

Dehumidifying

Cooling

Room temperature (˚C)

Outdoor temperature (˚C)

27.5

25.5

19.5

18

30

(b) The unit checks the temperature every hour after the start of operation and, if the result of check is not same as the previous

operation mode, changes the operation mode.

(c) When the unit is started again within one hour after the stop of automatic operation or when the automatic operation is

selected during heating, cooling or dehumidifying operation, the unit is operated in the previous operation mode.

(d) Setting temperature can be adjusted within the following range. There is the relationship as shown below between the signals

of the wireless remote control and the setting temperature.

Signals of wireless remote control (Display)

–6 –5 –4 –3 –2 –1 ±0+1+2+3+4+5+6

Setting

Cooling 19 20 21 22 23 24 25 26 27 28 29 30 31

temperature

Dehumidifying 19 20 21 22 23 24 25 26 27 28 29 30 31

Heating 20 21 22 23 24 25 26 27 28 29 30 31 32

◆SCM60ZD-S

Outdoor unit speed Outdoor unit fan

R1 (rps) R2 (rps) F1

1-room 2-room 3-room 1-room 2-room 3-room

Me

20 35 50 15 25 35

X1 pluse X2 pluse

1-room 2-room 3-room 1-room 2-room 3-room

Currently heating unit

180 160 150 140 115 110

Page 33

33

(10) Determining the operating mode

The cooling and heating operating modes are the remote control switch mode that have been previously determined.

If a mode differing from these is selected after this, the selected mode will appear in the display of the remote control, but only the

fan will operate.

A unit

B unit

Cooling

Cooling

Fan Heating

HeatingFan

Cooling

switch

ON

Heating

switch

ON

Heating

switch

ON

Cooling

switch

ON

Heating

switch

ON

Operation Operation

Operation Operation

Operation

Example of operating pattern

Note (1) [ ] indicates currect operation.

First operation Second operation

Notes

Selected Mode

Cooling

Heating

Example

1

2

Remote Control Display

Cooling

Heating

Operation

Cooling

Heating

Selected Mode

Heating

Cooling

Remote Control Display

Heating

Cooling

• Different mode is

only fan operation.

Operation

Fan

(1)

Fan

Note (1) If the display shows

heating and the operation is fan, Hot Keep

will operate.

CnT Input

A Unit

B Unit

OFF

OFF

*ON

ON

ON

ON

OFF

OFF

OFF

ON

ON

ON

OFF

OFF

OFF

Note (1) The ON with the * mark indicates

an ON operation using the remote

control unit switch, etc.

(ii) When Jumper wire J1 on the PCB of indoor unit is cut at the field or “PULSE INPUT” is selected in the wired remote

control’s indoor unit settings.

Input signal to CnT becomes valid at OFF → ON only and the motion of air conditioner [ON/OFF] is inverted.

CnT Input

A Unit

B Unit

OFF

OFF

OFF

ON

OFF

ON

OFF

ON

ON

OFF

OFF

*ON

(11) External control (remote display)/control of input signal

Make sure to connect the standard remote control unit. Control of input signal is not available without the standard remote control unit.

(a) External control (remote display) output

Following output connectors (CNT) are provided on the printed circuit board of indoor unit.

(i) Operation output: Power to engage DC 12V relay (provided by the customer) is outputted during operation.

(ii) Heating output: Power to engage DC 12V relay (provided by the customer) is outputted during the heating operation.

(iii) Compressor ON output: Power to engage DC 12V relay (provided by the customer) is outputted while the compres

sor is operating.

(iv) Error output: When any error occurs, the power to engage DC 12V relay (provided by the customer) is outputted.

(b) Control of input signal

Control of input signal (switch input, timer input) connectors (CNT) are provided on the control circuit board of the indoor

unit. However, when the operation of air conditioner is under the Center Mode, the remote control by CnT is invalid.

(i) If the factory settings (Jumper wire J1 EXTERNAL INPUT on the PCB) are set, or “LEVEL INPUT” is selected in the

wired remote control’s indoor unit settings.

1) Input signal to CnT OFF → ON Air conditioner ON

2) Input signal to CnT ON → OFF Air conditioner OFF

Page 34

34

(12) Operation permission/prohibition control

The air conditioner operation is controlled by releasing the jumper wire (J3) on the indoor control board and inputting the external

signal into the CnT.

(a) The operation mode is switched over between Permission and Prohibition by releasing the jumper wire

(1)

on the indoor control board.

(b) When the CnT input is set to ON (Operation permission)

(i) The air conditioner can be operated or stopped by the signal from the remote control signal line.

(When the "CENTER" mode is set, the operation can be controlled only by the center input.

(ii) When the CnT input is changed from OFF to ON, the air conditioner operation mode is changed depending on the status

of the jumper wire (J1) on the indoor control board.

(c) When the CnT input is set to OFF (Prohibition)

(i) The air conditioner cannot be operated or stopped by the signal from the remote control signal line.

(ii) The air conditioner operation is stopped when the CnT input is changed from ON to OFF.

(d) When the operation permission / prohibition mode is set to effective by the indoor function setting selected

by the remote control, the operation depends on (a) above.

When the jumper wire (J3) is short circuited

Normal operation is enable (when shipping)

When CnT input is set to ON, the operation starts and

if the input is set to OFF, the operation stops.

For the CnT and remote control inputs, the input which

is activated later has priority and can start and stop the

operation.

When the jumper wire (J3) is released

Permission / Prohibition mode

When Cnt input is set to ON, the operation mode is

changed to permission and if input is set to OFF the

operation is prohibited.

When the jumper wire (J1) is short circuited

The signal (i) above starts the air conditioner.

(Shipping status)

When the jumper wire (J1) is released

When the CnT input is set to ON, the air conditioner

starts operation. After that, the operation of the air

conditioner depends on (i) above. (Local status)

Page 35

35

¡ Temperature list

ABC

ThI-A

<

=

24 48.5 56 62

24 < ThI-A

<

=

27 47.5 53 61

27 < ThI-A 46.5 50 60

(Example) Fuzzy

Indoor unit heat exchanger temperature (˚C)

Lower limit (4)

After lapse of 20 Sec. or over

(2)

After lapse of 20 Sec. or over

(2)

After lapse of 20 Sec. or over

(2)

B

C

8 rps

(1)

8 rps

0 rps

A

Unit : ºC

(13) Control and protection functions

(a) Frost prevention for indoor heat exchanger (During cooling or dehumidifying)

(i) Operating conditions

1) Indoor heat exchanger temperature (detected with Th

I-R1) is lower than 5ºC.

2) 10 minutes elapsed after the start of operation.

(ii) Detail of anti-frost operation

• SKM model • STM, SRRM models

(iii)Reset conditions: Indoor heat exchanger temperature (Th

I-R1) is higher than 8ºC (7ºC).

Note (1) Values in ( ) are for type STM, SRRM.

(b) High pressure control

(i) Purpose: Prevents abnormally high pressure operation during heating.

(ii) Detector: Indoor unit heat exchanger sensor (Th

I-R1)

(iii)Detail of operation:

Notes (1) When the indoor unit heat exchanger temperature is in the range of B~C ºC, the indoor command speed is reduced by 8 rps at each 20 seconds.

When the temperature is C ºC or over for 1 minute continuously, the compressor is stopped.

(2) When the indoor unit heat exchanger temperature is in the range of A~B ºC, if the indoor command speed is been maintained and the operation has

continued for more than 20 seconds at the same speed, it returns to the normal heating operation.

(3) Indoor blower retains the fan tap when it enters in the high pressure control. Outdoor blower is operated in accordance with the speed.

(4) 22~35 type: 20 rps. 50~60 type: 35 rps

Indoor heat exchanger temp. (°C)

2.5 5 8

0 rps

minimum rps

decision rps

Indoor heat exchanger temp. (°C)

3257

0 rps

minimum rps

(

decision+min

) rps

2

decision rps

Page 36

36

(c) Freezing cycle system protective control

(i) Operating conditions: When both of following conditions have continued for more than 5 minutes later than 5

minutes after the start of operation.

1) Indoor command speed is higher than 0 rps

2) During cooling, dehumidifying: Indoor heat exchanger temperature - Room temperature > – 4ºC

(ii) Detail of operation

1) Indoor unit

The command speed is forced to operate at 16 rps.

2) Outdoor unit

For 5 minutes after the main controller starts, the outdoor unit speed is 10 rps. After 5 minutes, the outdoor unit speed

is 30 rps, up until 8 minutes of operation. After 8 minutes, the outdoor unit speed is 10 rps, up until 13 minutes of

operation. After 13 minutes, the outdoor unit speed is 30 rps, up until 16 minutes of operation.

(iii)Restoration conditions: When the condition becomes either conditions shown below

During cooling, dehumidifying: Th

I-R1 (8) – ThI-R1(5)

<

=

-2 ºC, ThI-R1 (16) – ThI-R1(13)

<

=

-2 ºC

Notes (1) ThI-R1(X): After this control starts, the indoor heat exchanger temperature after X minutes.

(2) This control is valid when the room air temperature is in the range of 10 to 40ºC at cooling and dehumidification operation.

(d) Crankcase heater

(i) Operating conditions (When all the conditions below are satisfied)

1 After the operation mode is changed to stop and the decision speed becomes 0 rps continuously for 30 minutes.

2 When the temperature detected by the outdoor temperature sensor is 10 ºC or lower after the compressor stops.

(ii) Detail of operation

The crankcase heater operates, warming up the compressor, then refrigerant begins circulating smoothly when the cooler

starts its heating operation, and heating begins.

(iii)Restoration conditions

When the temperature detected by the outdoor temperature sensor reaches 12ºC or higher, or the operation mode changes

from stop to cooling or heating.

(e) Inching prevention

When the compressor becomes to the thermo operation within 3 minutes since operation start or becomes dehumidifying

operation, the operation is continued with the indoor command speed of 16 rps forcibly.

(f) Inching protection control

(i) In order to prevent the refrigerant from dissolving in the refrigerant oil and diluting it due to frequent starts and stops of

the compressor under thermostat operation, the unit is controlled so that the temperature detected by the sensor is continued

for 1 minute during cooling: at 21ºC or lower, during heating: at 0ºC or lower.

(ii) It recovers if the temperature sensed by the outdoor temperature sensor is 23ºC or higher during cooling, 2ºC or higher

during heating.

1 min. 55 sec.

Stop mode

Outdoor unit

speed

Crankcase

heater

Decision

rps

0 rps

ON

OFF

1 min.

Page 37

37

(g) Start of protection for compressor

Compressor protection starts when the operation mode changes from stop to cooling or heating and the decision speed is

other than 0 rps.

(i) Start of protection I (Operation mode: cooling; Decision speed: other than 0 rps)