en

Electrical operating instructions

Door control panel TS 981

Software 2.6 (Design and functions subject to change)

51171314 -

l 02.2013

OPERATING INSTRUCTIONS

Page

SAFETY DIRECTIONS................................................................................................. 4

INST ALLATION ADVICE ..............................................................................................6

INSTALLATION OVERVIEW ........................................................................................7

ENCLOSURE INSTALLATION .................................................................................... 8

CONNECTING THE CONTROL AND THE ELEKTROMATEN

®

..........................................................

8

MAINS SUPPLY............................................................................................................9

PHASE ROTATION .......................................................................................................1 0

MOTOR CONNECTION (internal wiring) ....................................................................10

RAPID ADJUSTMENT OF THE LIMITS.......................................................................11

HARDWARE OVERVIEW .............................................................................................12

WIRING DIAGRAM .......................................................................................................14

CONTROL PROGRAMMING........................................................................................18

Operating mode.............................................................................................................19

Door position .................................................................................................................19

Functions .......................................................................................................................20

Safety functions..............................................................................................................21

Settings only for ELEKTROMA TEN® with direct / frequency inverter DU/FI ......................23

Extended door functions.................................................................................................24

Maintenance cycle counter .............................................................................................25

MEMORY CHECK ........................................................................................................25

RESET..........................................................................................................................26

SOFTWARE..................................................................................................................26

SAFETY DEVICES ....................................................................................................... 27

Door safety switch X2 ....................................................................................................27

Safety edge system with optional connection for shutter pass - door or slack wire switch contact. X2 ...27

T yp 1: Resistance evaluation 1K2 with normally closed safety edge contact...................27

Typ 2: Resist ance evaluation 8K2 with normally open safety edge contact .....................28

Typ 3: Optical safety edge (V itector) ..............................................................................28

Mounting the spiral cable................................................................................................28

Function of the safety edge system.................................................................................29

Page 2

Page

Pass door / slack rope switch input X2 ...........................................................................30

Emergency stop X3.......................................................................................................30

FUNCTION DESCRIPTION .......................................................................................... 31

Internal push button / Three push button / Key switch X5 / X15.......................................31

Automatic closing...........................................................................................................31

Automatic closing interruption.........................................................................................31

Through / Reflective photo cell X6 / X16 or Light curtain X6 ............................................32

Ceiling pull switch / Radio control X7 / X17....................................................................34

Key switch – intermediate stop X8 ................................................................................34

Key switch (latching) interrupt automatic closing X1 1 ......................................................35

Smoke draining - Function (RWA) X12..........................................................................35

Light indicator for traffic control X13 ...............................................................................35

Safety against entrampment X18 ...................................................................................37

Potential free changeover contact X20 / X21 .................................................................37

Overrun correction..........................................................................................................37

Door overload monitor ...................................................................................................38

AIR look SLF..................................................................................................................39

Status monitoring function SMF......................................................................................39

Main tenanc e cycl e count er .............................................................................................39

Software Update ............................................................................................................40

Short circuit / overload monitor .......................................................................................40

OPERATING STATUS DISPLAY ..................................................................................41

TECHNICAL DATA.......................................................................................................46

LIFETIME / DOORCYKLES..........................................................................................47

DECLARATION OF INCORPORATION .......................................................................48

FUNCTION OVERVIEW ............................................................................................... 49

Page 3

SAFETY DIRECTIONS

Basic Directions

This control has been built in accordance with EN 12453 Industrial, commercial and garage

doors and gates - Safety in use of power operated doors - Requirements and EN

12978 Industrial, commercial and garage doors and gates - Safety devices for power

operated doors - Requirements and T est methods; and left the factory in perfect condition

from the point of view of safety . T o maintain this condition and to ensure safe operation, the user

must observe all the directions and warnings contained in these operating instructions.

In principle, only trained electrical craftsmen should work on electrical equipment. They must assess

the work which has been assigned to them, identify potential danger sources and take suitable

safety precautions.

Reconstruction of or changes to TS 981 are only permissible with the approval of the manufacturer .

Original replacement parts and accessories authorised by the manufacturer guarantee safety.

Liability ceases to apply if other parts are used.

The operational safety of an T S 981 is only guaranteed if it is used in accordance with the

regulations. The limiting values stated in the technical data should not be exceeded under any

circumstances (see corresponding sections of the operating instructions).

Safety Regulations

During the installation, initial operation, maintenance and testing of the Control Panel, it is

necessary to observe the safety and accident-prevention regulations valid for the specific

application.

In particular, you should observe the following regulations (this list is not exhaustive):

European normative

- EN 12445

Safety in use of power operated doors - Test methods

- EN 12453

Safety in use of power operated doors - Requirements

- EN 12978

Industrial, commercial and garage doors and gates -

Safety devices for power operated doors - Requirements and Test methods

Please check normative´s bellow.

VDE-regulations

- EN 418

Safety machinery

Emergency stop equipment functional aspects

Principles for design

- EN 60204-1 / VDE 0113-1

Safety of machinery - Electrical equipment of machines - Part 1:

Prescriptions générales

- EN 60335-1 / VDE 0700-1

Safety of household and similar electrical appliances - Part 1:

General requirements

Regulations

- Please ensure that the local regulations relating to the Safety of Operations of Doors are followed

Page 4

SAFETY DIRECTIONS

Explanation of warnings

These operating instructions contain directions which are important for using the ELEKTRO-

®

MATEN

The individual directions have the following meaning:

General warnings and safety precautions

appropriately and safely.

DANGER

This indicates danger to the life and health of the user if the appropriate

precautions are not taken.

CAUTION

This warns that the ELEKTROMATEN® or other materials may be damaged if

the appropriate precautions are not taken.

The following warnings are to be understood as a general guideline for working with the

ELEKTROMATEN® in conjunction with other devices. These directions must be observed

strictly during installation and operation.

Check that all screw connections are secure before operating the control

and adjusting the limit switches.

Please observe the safety and accident prevention regulations valid for

the specific application.

The ELEKTROMATEN® must be installed with the authorised coverings

and protective devices. Care should be taken that any seals are fitted

correctly and screw couplings are tightened correctly.

In the case of ELEKTROMA TEN® with a permanent mains connection, an

all-pole main switch with appropriate back-up fuse must be provided.

Check live cables and conductors regularly for insulation faults or

breakages. When a fault is detected in the cabling, the defective cabling

should be replaced after immediately switching off the mains supply.

Before starting operation, check whether the permissible mains voltage

range of the devices corresponds to the local mains voltage.

With three – phase motor connection it must have right phase rotation

Page 5

INST ALLA TION ADVICE

After the ELEKTROMA TEN® is fitted we recommend the following procedure to rapidly reach

a fully functioning door.

• Installation Enclosure installation page 8

• Installation Wiring the Drive to the Control page 8

• Check Mains supply page 9

• Check Phase rotation page 1 0

• Programming Rapid limit adjustment page 11

The door is ready to work in Dead man mode.

• Installation Safety devices page 14, 27

• Programming Door functions page 1 8

The door is ready to work in automatic mode.

Check connection of external devices e.g. push button etc.

Overview to connect external devices see diagram (page 14-17).

After the devices are connected the programming of the control panel must be finalised.

(page 18).

Page 6

INSTALLATION OVERVIEW

Important!

Using the connection cable out side the building is not permitted.

Connection cable ELEKTROMAT® for

Motor and DES ( electronic limit)

11

Spiral cable for

Safety edge system

Mains supply

Photo-beam

Pull switch

Three push button

Key switch (latching) interrupt

automatic closing

4

Emergency stop

Key switch (latching) intermediate stop

5

5

3

5

3

3

3

( )

Number of cores in the cable

Red / Green Traffic- Light

Page 7

2x4

ENCLOSURE INSTALLATION

Before mounting the enclosure, the surface has to be checked for flatness, slope and freedom

from vibrations. Mounting must be vertical. It is important that the door can be clearly seen

from the position of the control through-out its travel.

CONNECTING THE CONTROL AND THE ELEKTROMATEN

After the drive and control are fitted they can be connected with a plug-in cable. The cable

has plugs on each end and for easy fitting. The plugs for motor and control panel are different

and cannot be interchanged.

Control panel TS 981 ELEKTROMAT

Motorconnection (MOT)

Motor plug-in

Connection cable for

1

2

PE

3

4

PIN

2 -

5 6 -

digital limit (DES)

3

2

1

4

PE

PIN

- 14 -

- 2

- 3

®

- 6

- 5

- 4

®

Cable identification

Motor plug to control unit

PIN - Wire-No. Excution:

1 - 3 Phase W

2 - 2 Phase V

3 - 1 Phase U

4 - 4 Neutral (N) (not used)

5 - PE Earth

Limit plug-in to control panel TS 981 (DES)

PIN - Wire-No. Excution:

1 - 5 Safety chain 24V DC

2 - 6 RS485 B

3 - 7 GND

4 - 8 RS485 A

5 - 9 Safety chain

6 - 10 8V DC

Page 8

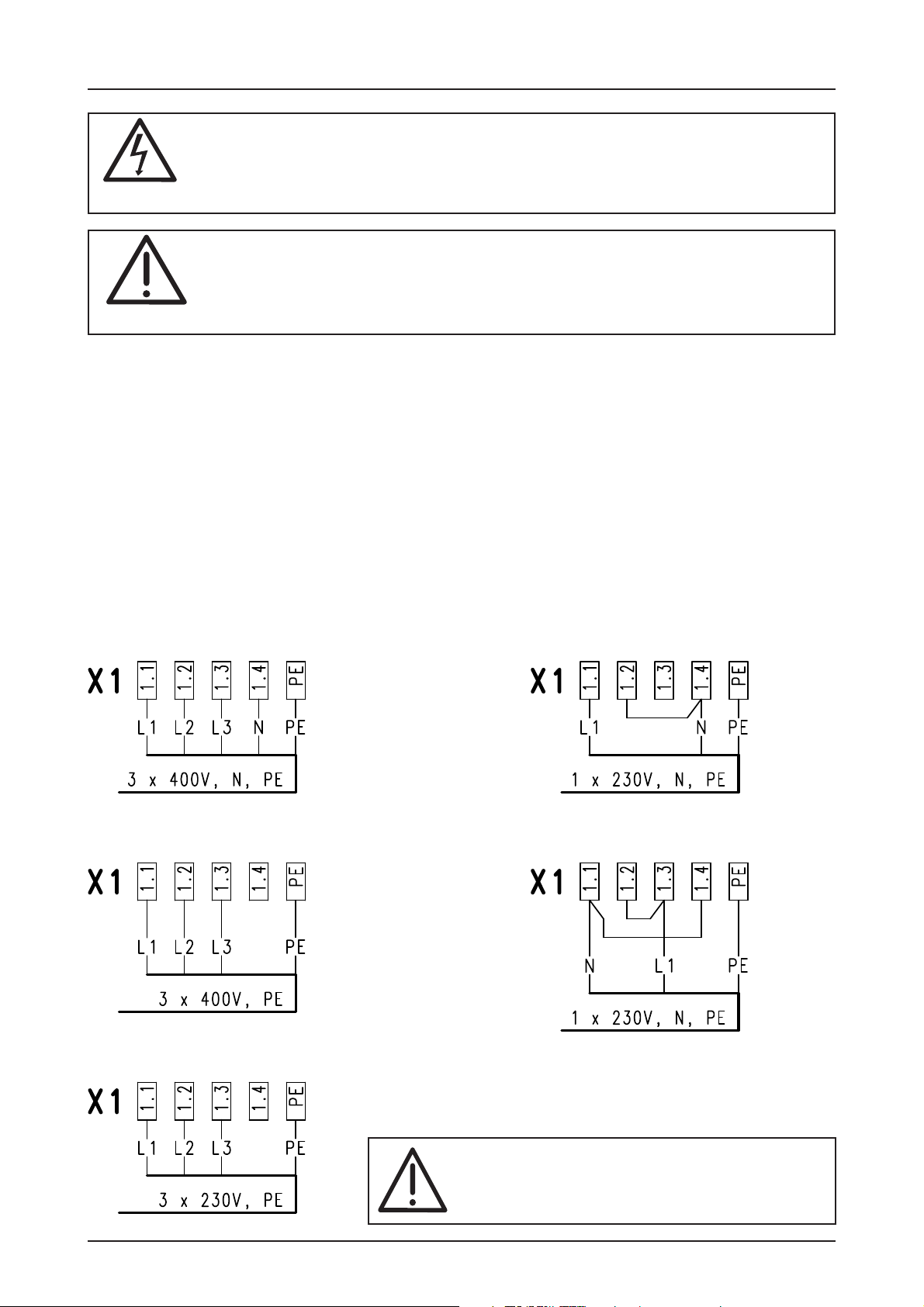

MAINS SUPPLY

DANGER! T o the life and health through electric shock.

If a GfA frequency drive FI is installed, it must be used a class B earth-leakage

circuit breaker in the mains supply . Other switches can fail and switching

unintentionally .

External fuse!

Control must be saved against short circuit and overload by an external fuse,

max. 10A delayed, in the mains supply . An automatic cut off switch is required,

regarding the supply for three-phase or single-phase.

When connecting control to mains supply a mains isolator switch or (16A CEE – plug) according

EN 12453 is required. The control panel has an integrated auto controlled power unit for

voltages from 230V up to 400V +/- 10%.

The supply disconnect device (Main switch or CEE plug) must be installed between 0,6m

and 1,7m above floor level.

The Control panel TS 981 has a universal electric supply and works with the following supplies.

(See diagram Fig.1-5)

Mains supply terminal

Fig.: 1

Fig.: 2

Fig.: 4

symmetric winding

Fig.: 5

Fig.: 3

asymmetric winding

DU = 3x400V

FI 1,5KW = 1x230V/N/PE or 3x400V/N/PE

FI 4,5 kW = 3x400V/PE or 3x400V/N/PE

Page 9

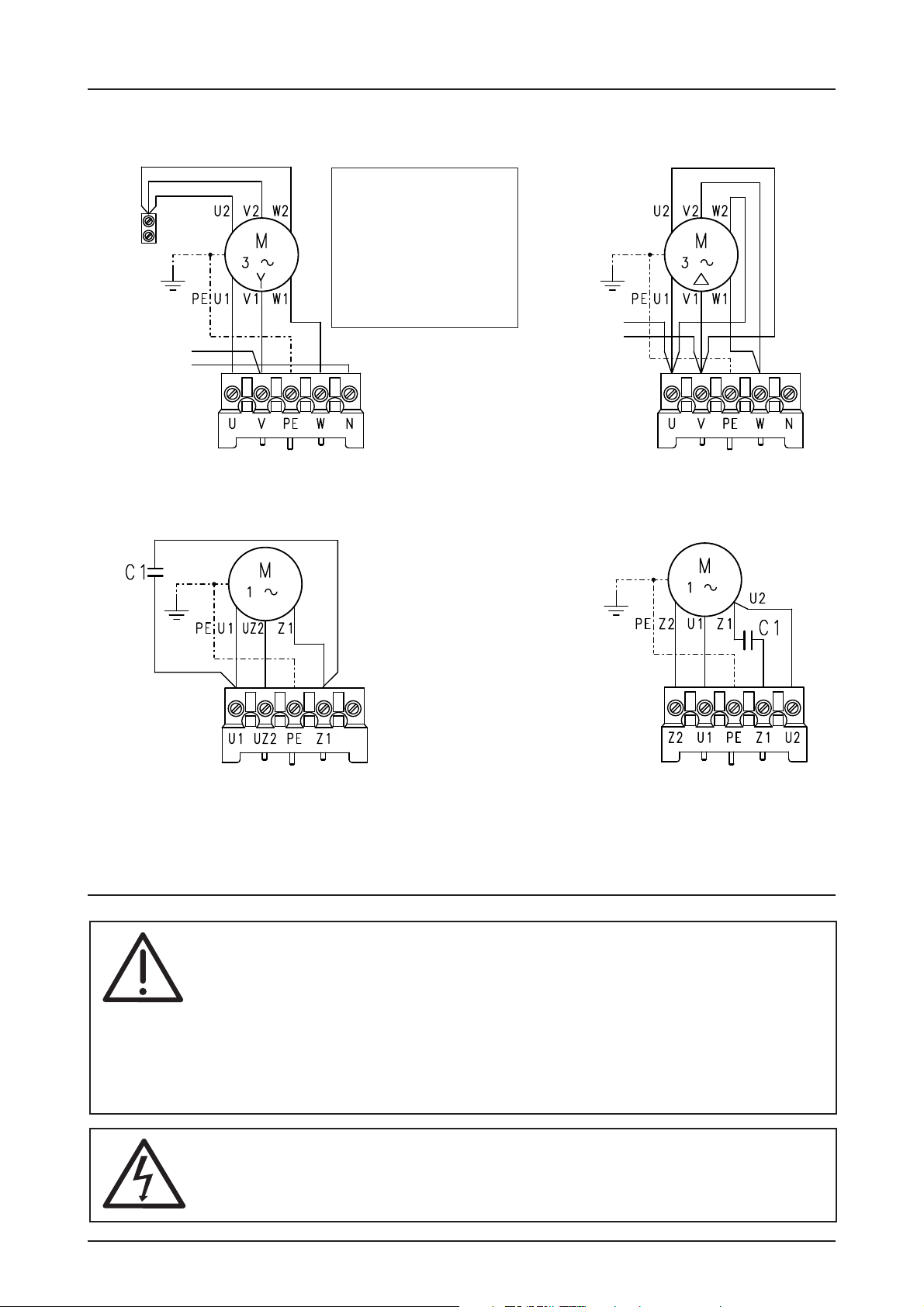

MOTOR CONNECTION (internal wiring)

Three-phase 3 x 400V AC, N, PE

Star connection

Important note!

For 3x400V AC PE no

neutral, the brake

rectifier must be

connected between

terminal V and starpoint terminal.

brown

blue

supply for

brake

rectifier

Single-phase 1 x 230V AC, N, PE

symmetrical winding

Three-phase 3 x 230V AC, PE

Delta connection

brown

blue

supply for

brake

rectifier

Single-phase 1 x 230V AC, N, PE

asymmetrical winding

On several ELEKTROMATEN® the connection U1 und V1 on the motor-plug are

interchanged.

PHASE ROTATION

Important Notice!

After the mains supply has been connected: to confirm that the phase rotation of

the electrical motor is correct the door shall move UPWARDS if the OPEN push

button is operated. If the door does not OPEN change first phase rotation.

For all three phase ELEKTROMA TEN® even DU: Change wiring at terminal X1: 1.1 – 1.2.

For inverter drives FI-ELEKTROMA TEN® see page 13.

For all single phase ELEKTROMA TEN® :Change wiring at the connection cable plug,

change core no. 1+3 reciprocal.

DANGER! To the life and health through electric shock.

Before changing phase rotation the mains supply must be switched OFF.

Page 10

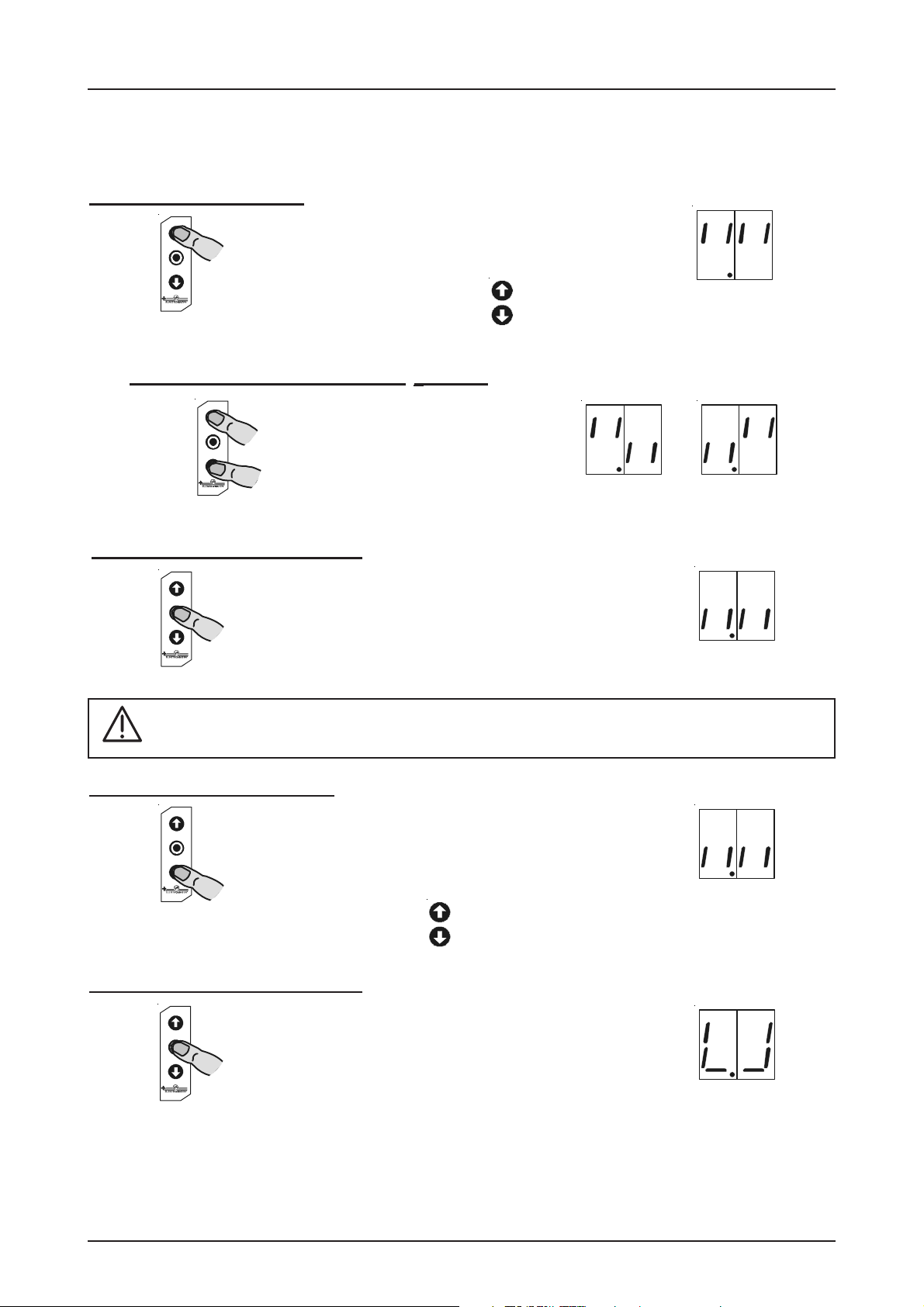

RAPID ADJUSTMENT OF THE LIMITS

When the phase rotation has been checked the Rapid limit adjustment can be made.

The final setting can be made with the fine adjustment (Control Programming page 19).

Safety limits and pre-limits are automatically adjusted.

1. Setting final limit open

Door open

press button to reach upper limit

1a. Reversing FI-ELEKTROMAT® rotation

T o reverse the motor rotation

keep both buttons pressed for

three seconds until the display

changes

2. Memorise the final limit open

Press stop-button for 3 sec. until

the display changes

The final limit OPEN is memorised when the door moves for at least one second from

close into the upper limit position.

Display

blinking

Display

blinking

Display

changes

Display

changes

3.Setting the final limit close

Door close

press button to reach lower limit

4. Memorise the final limit close

Press stop-button for 3 sec. until

the display changes

The Rapid adjustment is finished

The door could be moved in DEADMAN mode UP/DOWN

Further adjustments see programming mode

Display

blinking

Display

changes

Page 11

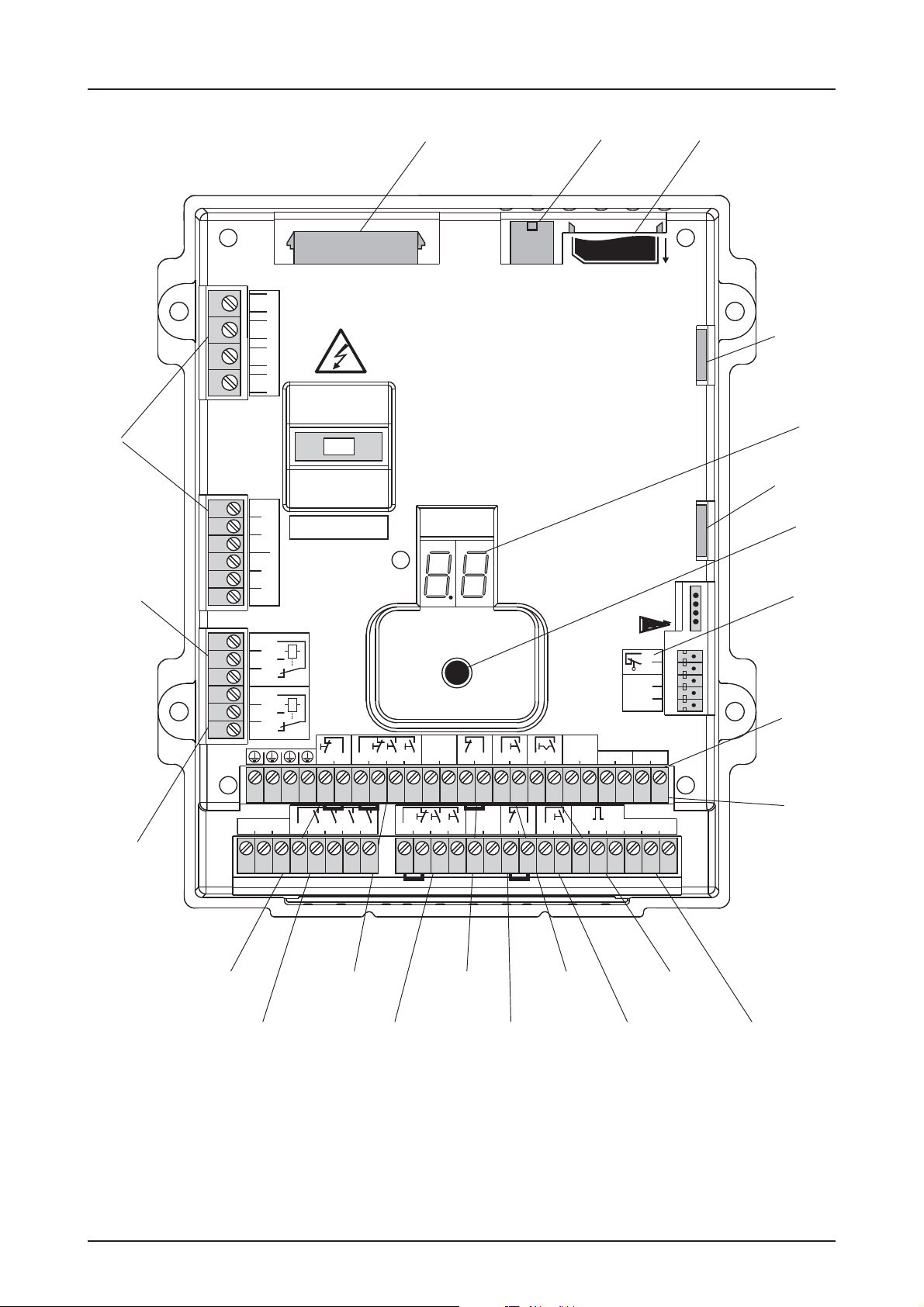

HARDWARE OVERVIEW

MOT DES MMC/SD

X1

X20

1.1

1.2

1.3

1.4

1.8

1.8

1.8

1.9

1.9

1.9

20.1

20.2

20.3

21.1

21.2

21.3

MOT

F1 = 1,6A t

3.1

3.2

5.1

5.2

5.3

5.4

24V

GND

TS 981

6.1

6.2

7.1

7.2

DES

8.1

8.2

24V

GND

MMC / SD

RWA

11.1

11.2

12.1

2.1

2.2

2.3

2.4

2.5

12.2

SLF

SMF

SLF

V1

SMF

S1

X2

X11

40014900

X21

13.1

13.1

13.1

13.2

13.3

13.4

13.5

13.6

15.1

15.2

15.3

15.4

X3

X13 X16

X5

X15

X6 X7

24V

GND

16.1

16.2

17.1

17.2

12V24V24V

18.1

X17

18.2

X8

X12

GND

X18

Page 12

HARDW ARE OVER VIEW

Description Print:

X1 Mains supply

external supply 230V

1.9 = L1 L1 fused with F1 = 1,6A

1.8 = N

(only with 3 x 400V , N, PE und 1 x 230V

X2 Safety edge system and pass-door plug

X3 Emergency push button

X8 Key switch for intermediate stop

X11 Key switch ON / OFF for automatic closing

X12 Smoke draining

X13 Traffic lights 2x Red / Green

X18 Entrapment safety evaluation

X20 Potential free relay contact 1

X21 Potential free relay contact 2

DES Limit connection

MOT Motor connection

MMC/SD Slot for memory cards

SLF Slot for Air-lock control function

SMF Slot for Status / Information function

S1 Selector switch

, N, PE symmetric winding)

V1 7-segment display

Internal push button

Command from inside Command from outside

X5 Three push button / Key switch

X6 Reflective photo-beam / photo-beam

X7 Ceiling pull switch / Radio control

X15 Three push button / Key switch

X16 Reflective photo-beam / photo-beam

X17 Ceiling pull switch / Radio control

Page 13

WIRING DIAGRAM

L1 fused

N L1

via F1 = 1,6At

Normallyclosed contact 1K2

spiral

plug-in bridge

cable

Normallyopen contact 8K2

spiral

cable

plug-in bridge

Optical safety edge system

spiral

cable

plug-in bridge

Terminal box

Bridge

Terminal box

Bridge

Terminal box

Bridge

end-of-line

resistor 1K2

end-of-line

resistor 8K2

br

gr

wh

Transmitter Receiver

pass or /

slack wire

switch contact

or crash

detector

pass or /

slack wire

switch contact

or crash

detector

pass or /

slack wire

switch contact

or crash

detector

Emergency

stop button

inside

outside

inside

OPEN

STOP

CLOSE

Three push

button station

inside or outside

or

OPEN/

CLOSE

STOP

Key switch with

stop button

inside or outside

Page 14

or

OPEN/

CLOSE

Key switch

inside or outside

WIRING DIAGRAM

or

outside

inside

Reflective photo-beam

inside or outside

for closing direction

Ceiling pull switch /

Radio control

inside or outside

Transmitter- Receiver

photo-beam

inside or outside

Key switch ON / OFF

Intermediate stop

Transmitter- Receiver

light curtain

inside

Key switch ON / OFF

automatic closing

Smoke draining

contact RWA

external

or

X1 1.8/1.9

Page 15

Red - Green

light

inside

Red - Green

light

outside

WIRING DIAGRAM

or

Input for external entrapment

safety device 1K2

single

Input for safety edge 8K2

against entrapment

single

Input for external entrapment

safety device 1K2

double

or

Input for safety edge 8K2

against entrapment

double

br

gr

wh

Transmitter - Receiver

br

gr

wh

Raytector photo-beam or

Optical safety edge

against entrapment

single

br

gr

wh

or

br

wh

gr 1

gr 2

Transmitter - Receiver

br

gr 1

wh

Receiver - Transmitter

br

gr 2

wh

Raytector photo-beam or

Optical safety edge

against entrapment

double (inside - outside)

br

gr 1

wh

br

gr 2

wh

Page 16

WIRING DIAGRAM

or

Transmitter - Receiver

photo-beam

single,

against entrapment

comply EN 12978

Transmitter - Receiver

Receiver - Transmitter

photo-beam

double,

against entrapment

comply EN 12978

Potential free

relay contact

Potential free

relay contact

Page 17

CONTROL PROGRAMMING

1. Enter programming Mode

Press selector switch for 3 sec. until display = 00

2. Chose program and confirm

and

Turn selector Press selector

3. Adjustment

Functionen Door position

Turn selector Press foil buttons

4. Memorise

Functionen Door position

Press selector Press stop-button

further adjustments

or

or

5. Exit programming

and

Turn selector until display = 00 Press selector

Page 18

CONTROL PROGRAMMING

2. Choose program and

confirm

Operating mode

Door function

Door position

Final limit open

coarse adjustment

Final limit close

coarse adjustment

Dead man OPEN

Dead man CLOSE

Self-hold OPEN

Dead man CLOSE

Self-hold OPEN

Self-hold CLOSE

Self-hold OPEN, CLOSE

(X5/X15) release for external

pushbutton function only dead man

close

Move door

upwards or downwards

Move door

upwards or downwards

4. Memorise 3. Adjustment

Press

selector

Press stop

Button

Press stop

Button

Final limit open

fine adjustment

Final limit close

fine adjustment

Pre-limit safety edge

fine adjustment

Switching position Relay 1

Switching position Relay 2

Final limit open can change

without door movement using +/-

Final limit close can change

without door movement using +/-

Pre-limit safety edge can

change using +/-

Move to intermediate stopIntermediate stop

Move to switching position relay 1

Move to switching position relay 2

Press

selector

Press

selector

Press

selector

Press stop

Button

Press stop

Button

Press stop

Button

Page 19

CONTROL PROGRAMMING

2. Choose program and

confirm

Functions

Safety edge function in

Pre - limit area

Overrun correction

Automatic closing

feature

Automatic closing after

photo-beam is interrupted

and re-made

Safety edge is activated

Safety edge is deactivated

Safety edge is activated

+ automatic ground adjustment

Active safety edge

+ re-open

OFF

ON

time can be set between 1 - 240 sec.

0 = OFF

OFF

ON

4. Memorise 3. Adjustment

Press

selector

Press

selector

Press

selector

Press

selector

Step by Step function

(X7 / X17): only Ceiling

pull switch / Radio

remote control

Vehicle recognition, closes when the

contact is more than 1,5 sec.

triggered

X7 / X17 = Command 1

X7 = Command 1, X17 = Command 2

X7 = Command 2, X17 = Command 1

X7 / X17 = Command 2

X7 / X17 = Command 3

Press

selector

Page 20

CONTROL PROGRAMMING

2. Choose program and

confirm

Functions

4.

Memorise 3. Adjustment

Function Relay 1

only available with

menu 1.7

Function Relay 2

only available with

menu 1.8

Functions Intermediate

Position

OFF

Switch contact impulse: 1sec.

Switch contact continuous

Switch contact impulse: 1sec.

by open - commands

Extended switch contact similar NES cam

Light curtain testing at final Open position

before closing

External brake supply

Intermediate position terminal input via

X7 / X17 and Three Push Button X5 /X15

Intermediate position terminal input via

X7 / X17; and fully open via Three Push

Button X5 / X15

Press

selector

Press

selector

Safety functions

Door overload monitor

Intermediate position terminal input via

X7 / X17; and fully open via Three Push

Button X5 / X15

OFF

sensitive

insensitive

Press

selector

Page 21

CONTROL PROGRAMMING

2. Chose program and

confirm

Safety functions

Photo beam interrupt

function

Function: Door safety

switch

RWA smoke draining – position

Selection of external

safety against entrapment devices

3. Adjustment

OFF

ON

Slake rope / Pass door

Crash detector via NC Contact

Crash detector via NO Contact

Move to RWA position, up to a minimum height of 2,5m

OFF

NC contact evaluation 1 K2 without

testing single

4. Memorise

Press

selector

Press

selector

Press stop

Button

Press

selector

This is the reaction time

actuation of the safety

edge up to the moment

that the door re-opens

NC contact evaluation 1 K2 without

testing double

NO contact evaluation 8K2 single

NO contact evaluation 8K2 double

Impulse-evaluation 1 kHz (Raytector

or OSE) single

Impulse-evaluation 1 kHz (Raytector

or OSE) double

Impulse-evaluation testing signal

(Transmitter – Receiver photo-beam)

single

Impulse-evaluation testing signal

(Transmitter – Receiver photo-beam)

double

Normal re - open time

Re - open time reduction

Press

selector

Re – open time extension

Three adjustment levels available

Page 22

CONTROL PROGRAMMING

2. Choose program and

4. Memorise 3. Adjustment

confirm

Settings only for ELEKTROMATEN® with direct / frequency converter DU/FI

OPENING speed

CLOSING speed

HIGHER CLOSING

speed

CLOSING speed

UPWARD

acceleration

DOWNWARD

acceleration

UPWARD

deceleration

DOWNWARD

deceleration

Creep-speed

Output speed rpm

Output speed rpm

Increased output speed down to door

height of 2.5 m 0 = OFF

Changeover position higher/lower speedChangeover position

Setting for

DU in 1.0 s steps

FI in 0.1 s steps

Setting for

DU in 1.0 s steps

FI in 0.1 s steps

Setting for

DU in 1.0 s steps

FI in 0.1 s steps

Setting for

DU in 1.0 s steps

FI in 0.1 s steps

Output speed rpm

Press

selector

Press

selector

Press

selector

Press stop

Button

Press

selector

Press

selector

Press

selector

Press

selector

Press

selector

The appeared numbers for output speed OPEN and CLOSE corresponding to

the real RPM of the drive unit. The speed has a direct influence into operating

forces of the door. The maximum and minimum speed will be delivered by the

drive unit in use and can not be raised or reduced.

Check again the adjustment and drive unit’s speed.

The adjustment of acceleration and deceleration is given by the control panel and can be

adjusted as follows:

At DU from 1,0 – 3,0 seconds in steps of 1 seconds.

At FI from 0,5 – 3,0 seconds in steps of 0,1 seconds.

Page 23

CONTROL PROGRAMMING

2. Choose program and

confirm

Extended door functions

Traffic light management

selection

Extended green light

period

Fore-warning period

Gateway evacuation

period

3. Adjustment

OFF

One-way traffic

Two-way traffic - priority OFF

Two-way traffic - priority inside

Two-way traffic - priority outside

Adjustment 0 - 90 seconds

Adjustment 0 - 10 second

Adjustment 0 - 90 seconds

4. Memorise

Press

selector

Press

selector

Press

selector

Press

selector

Red light function if the

door is CLOSED

Air-lock function OFF

Door OPEN command

transmission if the Air-lock

function is ON

Status message function

SMF ON / OFF

Red lights OFF

Red light inside ON

Red light outside ON

Red light inside/outside ON

ON

Time adjustment between 0 – 10 seconds. Delayed opening door 2

starts if door 1 is closed

SMF OFF

SMF for message module

Press

selector

Press

selector

Press

selector

Press

selector

SMF for unidirectional RS 232 interface

module

Page 24

CONTROL PROGRAMMING

2. Chose program and

confirm

Maintenance cycle counter

Counter adjustment

Reaction when

reaching 0

3. Adjustment

01-99 correspond from 1.000 up to 99.000

Count down cycles

Display appears „CS“ and adjusted number of cycles

Changing to DEADMAN display appears

„CS“ and adjusted number of cycles

Changing to DEADMAN same as 0.2 reset

to about 500 cycles possible, press 3 sec.

Stop – Button

Display appears „CS“ and adjusted number

of cycles and Relay contact is activated

4. Memorise

Press

selector

Press

selector

MEMORY CHECK

2. Chose program and

confirm

Info Cycle counter

7- digit

Info last 2 faults

Info Program changes

7- digit

Displayed

Press

selector

M HT ZT T H Z E

The cycles would be displayed as follow.

M = 1.000.000 H = 100

HT = 100.000 Z = 10

ZT = 10.000 E = 1

T = 1.000

Press

selector

Press

selector

Last 2 faults would be alternately displayed.

M HT ZT T H Z E

The Number of program changes would be displayed as follow.

M = 1.000.000 H = 100

HT = 100.000 Z = 10

ZT = 10.000 E = 1

T = 1.000

Info Program version

Press

selector

Program version will be displayed

Page 25

RESET

2. Chose program and

confirm

RESET except cycleand Program change

counter

SOFTWARE

2. Chose program and

confirm

3. Adjustment

Reset

3. Adjustment

4. Memorise

Press stop

button

3 sec.

4. Loading

Software loading

2. Chose program and

confirm

Software saving

Select required software version from S-D card

Press

selector

Press stop

button

3 sec.

Page 26

SAFETY DEVICES

Door safety switch X2

This switch could be fitted on to the surface of the door and will be connected with the spiral

cable into the control panel. This door safety switch can used and programmed in two functions.

Menu 3.4 a change of function can be realised.

Function Reaction following the activation

Slake rope / Contact interrupted: No reaction door stops

Pass door

Crash detector Contact interrupted: Door will stop immediately out of the movement.

Contact closed: Door ready to run.

Contact closed: Switches the door function into Dead Man Mode.

(If a GfA frequency inverter drive would be in use,

the function changes to very slow speed). A reset

is available and made when pushing the built-in

stop button for a minimum of three seconds.

Safety edge system with optional connection for shutter pass - door or slack wire

switch contact.

The control recognizes and works with 3 different safety edges.

Each one needs a special 4 core spiral cable and includes an optional shutter pass - door or

slack wire switch contact.

The spiral cable connection must be made on the print with the plug provided. The opposite

side of the cable is connected to a terminal box or a signal (pressure switch) emitter.

X2

T yp 1: Resistance evaluation 1K2 with normally closed safety edge contact

This evaluation system is made for pressure-wave switches (N/C) within an end-of-line resistor

of 1K2 +/- 5% 0,25W .

A pressure wave is generated by compressing the rubber profile, which is conducted to the

pressure-wave switch through the plastic hose. The system should be tested in the CLOSE

position. The pre-limit would be set automatically and activate the "Testing function".

When the shutter runs over the pre-limit door position, a timer of two seconds starts to

countdown at once. If a pressure wave activates the pressure switch in this time the TS

970 recognizes the function of the safety edge. If the pressure switch has not been activated,

the control goes into fault mode and the system works only in DEAD MAN function in

downwards direction. Fault information F 2.8 would be displayed.

Page 27

SAFETY DEVICES

Pressure-wave switch - function

The contact between the contact screw and diaphragm is opened (opening contact). The pressure-wave switch is set to a release pressure of

approx. 1,5 mbar .

The valve screws are set to a throughput of 1 10

ml/min with a static admission pressure of 5 mbar .

This warrants that a maximum temperature increase of 30° is compensated for in 20 minutes.

The setting of the valve screws may not be altered. Should the release pressure be insufficient

(pressure wave too insensitive), the contact screw

may be turned counterclockwise to the left by 1-2

graduation marks. The switch's sensitivity is thus increased.

In case of excessive sensitivity , the contact screw is set clockwise by 1-2 graduation marks

(decreased sensitivity).

Pressure-wave switch

Hose contact for: pressure opens

contact screw

valve screws (may

not be altered)

T yp 2: Resistance evaluation 8K2 with normally open safety edge contact

This evaluation system is made for electrical safety edges within an end-of-line resistor of 8K2

+/- 5% 0,25W. The resistor must be connected p arallel with the switch in the safety edge.

T yp 3: Optical safety edge (Vitector)

The principle of operation is as a one way light barrier . By activating the safety edge, the photobeam will be interrupted.

Important note!

When connecting a safety edge, take account of EN 12978 for Industrial,

commercial and garage doors and gates - Safety devices for power

operated doors - Requirements and Test methods.

Mounting the spiral cable

A bush is provided on both sides of the control box for mounting the spiral cable.

Push the plugs through into the enclosure until there is sufficient cable to allow the (2 and 3

pole) plugs to be connected to the board. The plug with two cores must be connected to the

passdoor or slack wire switch terminals. The three core plug must be connected to the safety

edge terminal.

The control panel TS 981 recognizes on first installation the safety edge system being used.

If passdoor / slack wire switch contact exists, remove bridge at terminal ST and ST+ in

the terminal box. The plug at terminal X2 must be removed.

Important note!

When using a safety edge system the automatic pre-limit adjustment (5cm)

must be checked. When the safety edge is activated the door should stop

and reverse to the open position.

Page 28

SAFETY DEVICES

Function of the safety edge system

With Menu 2.1 the function of the safety edge system can be chosen.

Function Reaction following the activation

Active safety edge stop

De-activated safety edge no reaction, door moves until final limit close only for

folding doors

Active safety edge+ stops and automatically re-adjusts the final limit with the

downward automatic next movement

floor adjustment

Active safety edge + Re-opens the door up to the half way of the overrun way

re-open

The function 'Auto ground adjustment' is used for doors with a cable e.g. Sectional doors or

vertical lift-gate. An automatic correction of slackness or change of ground height up to 2-5 cm is

possible. The slack wire switch is be still recognised.

Important note!

T o use the automatic floor adjustment, the safety edge must be operated in

the door closed position by an auxiliary puffer switch.

Important !

The automatic ground adjustment works only when the following safety edge

systems are connected:

T yp 2: electrical system resistance evaluation 8K2 or T yp 3: optical safety

edge (Vitector)

The active safety edge function with re-open function shall be used only if the overrun way of the

door will be more than 5cm.

Important note!

When the safety edge has been operated twice the automatic closing feature

will be interrupted and fault F2.2 will be displayed.

T o reset the fault press the internal push button so that the door travels down

until the final limit is reached.

Page 29

SAFETY DEVICES

Pass door / slack rope switch input X2

The pass door switch Entrysense features a protective function complying with safety

category 2 under EN 954-1. The electrical contact is monitored by the control panel that outputs

fault F1.7 when it malfunctions.

The electronic pass door switch Entrysense: function and test

The pass door switch Entrysense is fitted with two reed contacts that are switched by a permanent magnet. The control panel evaluates the switching states and the contact resistance

independently of each other.

At the lower limit position F1.2 is displayed when an OPEN command is given and at the same

time the pass door / slack rope switch circuit is open. The door can be moved only after the pass

door has closed or when the pass door / slack rope switch circuit signals OK. If the circuit will be

opened when the door is moving the door is stopped immediately .

F1.7 is displayed when an OPEN command is given after the door controller has detected

beforehand asymmetrical pass door switch positions (see below for reasons). This fault can be

reset when the door is reopened. This ensures that contact misalignments caused by vibrations

from the moving door do not trigger door shutdown.

Possible reasons for fault F1 .7

Decription

Door was not fully closed for longer than

2 s so that only one reed contact was

switched during this time.

The control voltage was less than 21,6V

for longer than 2 s (by 10%).

Contact resistances too high in the pass

door / slack rope switch circuit

Electronic pass door switch is not

installed correctly:

• distance between switch and magnet

too large

• switch and magnet not attached at

the same height

• switch installed at wrong position

Measures to solve the problem

Reopen and close the door.

Measure the control voltage at the terminals 24V -GND.

After troubleshooting reopen and close the door.

With the pass door closed: Measure resistance and

if necessary replace the contact resistances in the

pass door / slack rope switch circuit.

Check that the shutter pass door switch is

installed correctly .

After troubleshooting reopen and close the door.

Emergency stop X3

These terminals are to connect an emergency stop button according to DIN EN 418. Alternatively

the terminals can be used to connect a safety device against entrapment (e.g. self-testing light

barrier).

Page 30

FUNCTION DESCRIPTION

Internal push button / Three push button / Key switch X5 / X15

Internal and external push button

Internal and external push button working seperately from each other. Pushing at the same

time, the internal push button has priority.

Important note!

Dead man mode UP and DOWN with internal push button.

Dead man mode DOWN with external push button. (Menu 0.1 Adjustment .4)

In Dead man mode the user shall be in full view of the door throughout its travel.

Automatic closing

Menu 2.3 the timer works between 1 - 240 sec. If the automatic closing is active, the shutter

will close, from each limit position after the pre-adjusted time.

Important note!

The timer can be interrupted by pressing the internal pushbutton stop when

the shutter has reached a limit position. With a new command UP / DOWN

the timer is re-set.

Automatic closing interruption

Menu 2.4 can be used if the timer operation is required after interrupting and re-making the

photo-beam. The door closes after 3 seconds.

Page 31

FUNCTION DESCRIPTION

Through / Reflective photo cell X6 / X16 or Light curtain X6

Photo cell X6 / X16

A photo cell is used for presence detection. It is only active in door operating mode „3“ and „4“,

in the OPEN limit position or during the closing operation.

If the photo cell is interrupted, fault indication „F2.1“ appears.

Light curtain X6

The light curtain must be self-testing and correspond at least to safety category 2. If the light

curtain corresponds to these requirements, the door can close into self-hold without safety edge

system.

Important note!

- Operation without safety edge system, connect 8K2 resistor via

terminals X2/3 and X2/3

- Photo cells must not be used via the UBS system

- Do not use menu „3.2“ for the light curtain

T o test the light curtain, activate relay contact X20 or X21. Description of the relay functions see

menu „2.7“ or „2.8“.

If the photo cell is interrupted, fault indication „F4.6“ appears.

T esting is carried out at each CLOSE command, the contact of the light curt ain must switch off

within 100 ms. If the test is positive, the contact must switch back on within 300 ms. If the test

fails, fault indication „F4.7“ appears.

Reset fault indication „F4.7“: Switch control off and on.

Important note!

Only photo cells or light curtains with „Light switching“ mode

Effect of obstructing the photo cell

Door position Effect of obstructing photo cell

CLOSE limit position No function

Upwards travel No function

OPEN limit position No function

Without automatic closing

OPEN limit position Reset automatic closing

With automatic closing delay timer 2.3

OPEN limit position The door close 3 seconds after the photo cell is re-made

With automatic closing delay timer 2.3

and photo cell interrupt function 2.4

Downwards travel The door stops and re-opens

Page 32

FUNCTION DESCRIPTION

Advanced photo cell interrupt function Menu 2.4:

Function Photo cell interrupt functions

„0“ No function

„1“ automatic closing The door closes 3 seconds after the photo cell is re-made

„2“ vehicle recognition As above „1“ but the photo cell must be obstructed for more than

1.5 seconds.No function if the photo cell is obstructed for less than

1.5 seconds

Photo cell ignore function: Menu 3.2:

Function Photo cell function disabled

„0“ Off

„1“ On

Set parameter „3.2“ = 1 and then exit programming to activate the „photo cell ignore“ teach-in mode.

Warning!

Presence detection „stop and re-open“ is disabled in the T each-in mode

In the T each-in mode, the door must be fully opened and closed twice. The photo cell must be

interrupted twice at the same door position. The Teach-in mode then terminates. The photo cell

does not function below this stored door position.

Teach-in mode display

Upon exiting the programming

When the light beam is interrupted for the first time (1st open / close cycle)

After the second interruption of the light beam, 2nd open / close cycle and

must be at the same door position as the interruption in the 1st cycle, at the

final limit CLOSE position

Important note!

If the teaching-in is not successful, open and close the door again until the

photo cell has been interrupted at the same door position twice.

Page 33

FUNCTION DESCRIPTION

Ceiling pull switch / Radio control X7 / X17

It is possible to connect a ceiling pull switch or a radio receiver.

The radio receiver's switching contact must be potential free. Menu 2.6: Several types of

commands can be adjusted. With each command (impulse) the shutter operates in the

following sequences.

With each command (contact) the shutter operates in the following sequence:

Command 1: Without stop

Shutter position Shutter operation

Shutter closed Shutter travels to fully OPEN*-position

Shutter moving upwards No reaction

Shutter open Shutter moves to fully closed position

Shutter intermediate position open Shutter moves to fully closed position

Shutter moving downwards Shutter will STOP and moves BACK UP to final open Position*)

*) or to the intermediate stop position when the key switch is in the ON position

Command 2: With stop

Shutter position Shutter operation

Shutter closed Shutter moves to fully open* or intermediate position

Shutter moving upwards Door closed

Shutter open Shutter moves to fully closed position

Shutter intermediate position open Shutter moves to fully closed position

Shutter somewhere in between Shutter moves in opposite direction

position

Shutter moving downwards Door closed

*) or to the intermediate stop position when the key switch is in the ON position

Command 3: Open

With each impulse the door travels to the final open position

Key switch – intermediate stop X8

Intermediate stop can be activated / de-activated by connecting a key switch (latching ONOFF). The intermediate shutter position „ P ART OPEN“ is only in ef fect in the upwards direction

and is the new open position.

In Menu 1.6 the position can be adjusted. This is the new final position.

By turning the key switch to the OFF position, the shutter works in standard mode.

Menu 2.9 Adjustment of these several functions.

T o get adjusted function working the terminals X8.1 / X8.2 need to be bypassed.

Important note!

T o ensure error free function of the panel, the terminal X8 must not be used

without intermediate stop adjustment.

Page 34

FUNCTION DESCRIPTION

Key switch (latching) interrupt automatic closing X11

The automatic closing time can be interrupted with a normally open switch (latching)

Smoke draining - Function (RWA) X12

With this special function the door may be used for smoke and heat draining (RWA) according

to an industrial buildings directive for buildings up to 1600sqm.

Menu 3.5 here the height may be adjusted, to where the shutter shall move when Alarm is

given.

Attention!

The adjusted height fort his RWA- requirement must be a minimum height of

2,5m and works only if (RWA-function) adjusted.

If the contact which is related to X12.1 / 12.2 will be triggered (closed) by a signal supplied by

the central fire detector (BMA) the shutter will travel up to the adjusted height (RWA

position).The contact must be kept continuously close at all the time when the shutter travels.

When the door travels in RWA function the control sets all safety devices (safety edge,

photo-beam, etc.) and pushbutton signals (OPEN-STOP-CLOSE) out of order . External safety

switches as emergency stop, pass-door or slack cable switch are further in function. If the

contact related to X12.1 / 12.2 would be interrupted (opened) all shutter and control functions

going back in work.

Attention!

If Display appears indication as follows , RWA-function activated.

Light indicator for traffic control X13

TS 981 control have a complete one-way and two-way traffic light management integrated.

Two p airs of red/green light indicators may be connected on terminal X13. Supply voltage for

these light indicators is selectable and could be provided from external or directly from internal

terminals X1 1.8 / 1.9. A neutral is always required.

Attention !

Light indicators with 230V LED-bulbs are recommended. They have a big

luminosity, low requirement of energy, and they are maintenance free.

If conventional bulbs in use the maximum power for each indicator light

shall not exceed 40W.

Page 35

FUNCTION DESCRIPTION

Menu 6.1 Traffic light management

The integrated traffic light management of TS 981 supplies two traffic modes

One-Way

Two-Way

One-Way mode: This could be selected if the shutter width delivers enough space for two

cars driving through the door. The lights indicating only when the shutter is fully OPEN.

Additionally the lights supplying fore - warning signal when the shutter travels downwards.

Two-way mode: This could be selected if the shutter gateway does not deliver enough

space for two cars and sequence must be controlled. Priority for inside or outside could be

adjusted.

Menu 6.2 Extended green light period

Timer could be selected from 3 seconds up to 90 seconds. This works only if the shutter is

OPEN and the green light is illuminated. Timer counts down after a CLOSE command or if

two-way traffic mode is selected, and a command from opposite side is given. The indicator

keeps green light during the whole time. This function could be used for green light activation

only, and without automatic closing function.

Menu 6.3 Fore – warning period

Fore - warning supplies an additional signal before the shutter closes; red lights flushing

hereby with a frequency of 1 Hz. Selectable time is 10 seconds and the function starts when

green light period has finished.

Menu 6.4 Doorway evacuation period

The selected mode supplies the possibility to keep the gateway free from present car , before

a new car drives into the doorway.

Timer counts down if green period has finished, respectively af ter adjuster pre-warning time;

during this time the red light is indicated.

Menu 6.7 Red light function if door closed

On requirement continuous red light function ON or OFF may be selected.

Attention:

Traffic light management works independent of automatic closing or

continuously Open command.

Page 36

FUNCTION DESCRIPTION

Safety against entrampment X18

At terminals X18/ 18.1 and 18.2 two of safety devices against entrapment could be connected.

This function works only when the shutter moves upwards. If safety devices would be activated

the shutter stops and reverses to downwards direction for 2 seconds. With Menu 3.7 can be

selected whether one ore two entrees shall be activated.

The TS 981 works with four several evaluating principles.

Principle To be used

NC contact 1 k2 with out testing NC contact for one external evaluator

NO contact 8k2 Electrical safety edge with 8k2 resistor

Impulse evaluation1 kHz Raytector optical safety edge impulse signal

1 kHz12 / 24 V supply

NC contact with testing Photo beams, with a separate testing before each

Upwards movement.

Attention!

All safety devices in use respectively their directly connected sensors must

comply with EN 12978 safety devices entrapment protective.

Potential free changeover contact X20 / X21

In Menu 2.7 / 2.8 this contact is able to work for several functions.

Important note!

It is only possible to work with one adjusted function.

When activating the switching point the shutter must be moved to the point. Menu 1.7 / 1.8 must

be activated.

Overrun correction

The stopping position of the door can be influenced by various factors e.g. temperature,

cable extension etc.

To always have the same door stopping position the overrun correction can be activated.

Using Menu 2.2 the overrun correction can be switched ON or OFF

Important!

Great variations of temperature during a time when the door is not in

use, could cause a position variation of about 1cm. This will be reset

automatically after reaching the final close limit.

Page 37

FUNCTION DESCRIPTION

Door overload monitor

The door overload monitor recognises that a person is being lifted by the door (hanging on a

handle, etc.) and could be adjusted within Menu 3.1 with a possibility of two steps of sensitivity .

Adjustment 0.1 sensitive reaction and adjustment 0.2 insensitive reaction

Important!

After programming the force monitoring the door must perform a

complete opening and closing cycle in automatic mode, during which

the system reads the increments to calculate the way .

Important Note!

To have a trouble-free service the following points must be checked:

- The door must be correctly balanced

- The cable drum diameter should not be less then 160mm

Environmental influences e.g. temperature or wind load can cause the

overload monitor to be activated.

The overload monitor is a self-learning system, and checks the system from 5 cm up to ca.

2,0 m, slow-occurring changes e.g. spring tension will be automatically recognised and

equalized.

Important Note!

The overload monitor does not take place against other safety devices e.g.

(safety against entrapment)

When an overload is detected the door works only Dead man Mode in the UP and DOWN

direction.

The control unit automatically resets to impulse control when a final limit position has been

reached.

Page 38

FUNCTION DESCRIPTION

AIR look SLF

Air-lock management could be realised by means an easy electrical cable connection between

two shutters with TS 981.

The required module with cable should be connected into SLF plug-in. This module would be

delivered complete within a manual.

When cable connection is finalized select AIR-LOCK ON in Menu 7.1 in both control p anels.

Automatic OPEN - Transmission

To realise Air-lock operation a push button is not required. An automatic open impulse about

timer adjustment could be selected in Menu 7.2, thereafter the present closed shutter OPENS

when acting shutter has CLOSED.

Status monitoring function SMF

When in use a port supplies status or error information’s to a central monitoring unit. To

realise a lot of different uses the control has a socket to be used with external modules that

supplies relay contacts or BUS-gateway.

Users manual would be delivered with the module.

Maintenance cycle counter

Free adjustable maintenance cycle counter Menu 8.5 makes it possible to pre-adjust a max.

No of cycles until a maintenance is agreed.

The no of cycles can be adjusted from 1.000 up to 99.000; the adjustment is possible in

steps of 1.000 cycles.

Three different reactions can be chosen if the point of pre- adjusted maintenance cycles has

been reached, see Menu 8.6

Whenever the final open limit has been contacted the pre-adjusted number will be reduced

with 1 until 0 is reached.

When maintenance was done the cycle counter could be re-adjusted to a new maintenance

period and count down starts again.

Page 39

FUNCTION DESCRIPTION

Software Update

For software updates TS 981 have a MMC/SD card slot available. With this function the

software can be updated respectively in external places saved. For that purpose the new

program can be taken from a PC with special card reader function for GFA cards, following

the card could be guided into the control panel existing slot.

Attention!

Before loading the new program check the existing program is saved.

Menu 9.7 MMC/SD card program can be uploaded. If this function is selected the display

appears 0.

When pushing the integrated open and close button the display appears all existing software

versions on MMC/SD card. To start the uploading mode the stop-button shall be pushed for

three seconds. As long the loading has not started the mode may be interrupted if pushing

the selector switch.

With Menu 9.8 present up to date programs could be saved onto MMC/SD card.

Down load initialising: Insert MMC/CD card, select menu 9.8 and push selector switch.

Short circuit / overload monitor

The TS 981control panel delivers 2 supplies for external devices.

230V AC; max. 1,6 A

24V DC; max. 1000mA

At a short circuit or overload at the 24V DC supply , the display is off.

Page 40

OPERATING STATUS DISPLAY

The control TS981 can display up to three different status conditions one after another. Each

status is displayed with a letter and a number . The letter and the number are flashing alternately ,

thereby the control differentiates between a FAULT = F and a command = E.

Report Description Measure to solve the problem

Door safety switch

Pass door contact open

X 2.1- X 2.2

Emergency operator or

motor-winding thermal

protection operated

Emergency stop activated

Error AIR-LOCK function

Failure pass door contact

X 2.1- X 2.2 or control voltage

circuit less than 24V

Failure input pass door

X 2.1- X 2.2

Safety edge not recognised Check the safety edge is connected correctly or the

Check the proper operation of pass door contact, or

whether the supply cable is broken

Check emergency operator or whether the drive unit is

overloaded.

Check the emergency stop is activated, or whether

the supply cable is broken

Check, whether opposite control panel is ON and Air-lock

function is adjusted or possibly the cable connection is

interrupted

Check pass door circuit’s transition resistance and

weather pass door switch works; verify the voltage is OK

at 24V terminal to GND. Fault acknowledgement: open

and close the pass door switch or switch OFF and ON the

main switch or disconnect and reconnect the mains plug.

Fault acknowledgement: switch OFF and ON the main

switch or disconnect and reconnect the mains plug.

If necessary replace the control panel.

wrong type has been selected in the program

Light barrier activated Check the light barrier has been fitted properly, or

whether the connecting cable is broken

Safety edge operated in

two consecutive cycles

Safety edge 8K2 activated

Check if there is an obstacle in the shutter area, or

the connecting cable is broken or there is a short

circuit in the cable

Check the safety edge is activated or there is a short

circuit in the connecting cable

Page 41

OPERATING STATUS DISPLAY

Report Description Measure to solve the problem

Safety edge 8k2 defect

Safety edge 1K2 activated

Safety edge 1k2 defect Check safety edge and connecting cable do not have

Safety edge 1k2 pneumatic

system TESTING negative

Optical safety edge activated

or defect

Limits not adjusted

Safety open limit operated

Safety close limit operated

Check safety edge and connecting cable are not

broken

Check safety edge and connecting cable are not

broken

a short circuit

Check the proper safety edge function and that testing

in the lower door position is correct

Check the proper safety edge function or whether the

supply cable is interrupted

Adjust limits

Turn mains supply OFF and move the shutter

downwards - with the manual operator- until the

safety limit is free or the open limit should be readjusted.

T urn mains supply OFF and move the shutter upwards

- with the manual operator- until the safety limit is

free or the close limit should be re-adjusted.

Door load monitor has activated

Entrapment safety device

actuated

Entrapment safety device

defective

Door safety switch: function

Crash detector interrupted.

X2.1-X2.2

Terminals X6.1 – X6.2 open.

Light curtain obstructed.

Light curtain defective.

Check the door mechanism for tightness

Check all connected sensors (e.g. re-adjust photo –

beam)

Check all connected sensors

Check the switch is proper fitted or activated. After

fault repair: Press Stop button for a minimum of 3 sec.

Check light curtain.

Check the connection cable is in order.

Read the light curtain manufacturer specification instructions. Check connection cable.

Page 42

OPERATING STATUS DISPLAY

Report Description Measure to solve the problem

ROM - Fault

Internal fault report

RAM - Fault

Internal control fault

DES – no response

Drive unit does not work

Phase rotation failure

Inadmissible door movement when

stopped, e.g. owing to worn brake

or by a failure delivered from the

inverter.

The drive does not follow the given

command e.g. torque overload or a

failure at the frequency inverter.

Fault acknowledgement: open and close the pass door

switch or switch OFF and ON the main switch or

disconnect and reconnect the mains plug.

Fault acknowledgement: open and close the pass door

switch or switch OFF and ON the main switch or

disconnect and reconnect the mains plug.

Fault acknowledgement: open and close the pass door

switch or switch OFF and ON the main switch or

disconnect and reconnect the mains plug.

Fault acknowledgement: open and close the pass door

switch or switch OFF and ON the main switch or

disconnect and reconnect the mains plug.

Check electronic limit DES connection. To acknowledge the

fault switch off and on the main switch or disconnect and

reconnect the mains plug.

If necessary replace the control panel or digital limit DES).

Check the shutter mechanics. Check the limit shaft

for function (turning) Check phase rotation.

Check main supply phase rotation turns right

Fault acknowledgement: with next command being given.

Check function of the brake and replace if necessary. If the

brake works correct and if the fault reappears replace the

frequency inverter.

Fault acknowledgement: with next command being given.

Check drives load and mains voltage. If this is correct and

if the fault reappears replace the frequency inverter.

Page 43

OPERATING STATUS DISPLAY

Report Description Measure to solve the problem

Closing rpm over speeded at

DU / FI

Internal FI communication fault

at FI.

Insufficient mains supply or

by a fault delivered from FI.

Intermediate circuit overload,

e.g. braking time too short

Exceeding of the admissible

temperature of the FI e.g.

delivered by exceeded no

cycles, heat accumulation,

heat transmission etc.

Exceeded motor current by

overload of the drive unit or

failure at the frequency

inverter.

Fault acknowledgement: switch OFF/ON on the mains

or disconnect and reconnect the mains plug and if the

fault reappears replace the frequency inverter.

Fault acknowledgement: switch OFF/ON on the mains

or disconnect and reconnect the mains plug and if the

fault reappears replace the frequency inverter.

Fault acknowledgement: with next command being

given. Braking time must be increased, see menu.

Fault acknowledgement: with next command being

given. Braking time must be increased, see menu.

Fault acknowledgement: with next command being

given.

Check the door mechanism and weight.

Fault acknowledgement: with next command being

given and if the fault reappears replace the

frequency inverter.

Fault brake / FI

FI Group status

Check brake, replace if required. If the fault reappears

replace frequency inverter.

Fault acknowledgement: with next command being

given and if the fault reappears replace the

frequency inverter.

Page 44

OPERATING STATUS DISPLAY

Report Command description

open command being given

stop command being given

close command being given

adjusted cycles for maintenance reached

Display off = short circuit or overload at the 24V DC supply

Report Status

opening

flashing

closing

flashing

door stopped between set limits

door stopped at upper limit

door stopped at lower limit

Page 45

TECHNICAL DA TA

Housing Dimensions 190mm x 300mm x 1 15mm (W x H x D)

Mounting vertical

ELEKTROMATEN® Supply Three-phase 3 x 230 / 400V AC ± 5%, 50...60Hz

Single-phase 1 x 230V ± 5%, 50...60Hz

Power max. at 3 x 400V AC, max. 3kW

Control supply via L1,L2 400V AC or 230V AC + - 10%, 50-...60Hz,

voltage changing with bridge to 3- pole terminal,

safety fuse F1 (1,6A t)

External supply fuse 10A delayed

Permitted Load ca. 40 VA (without motor and ext. 230V)

External supply 1 230V via L1 and N, safety fuse F1 (1,6A t)

External supply 2 24V DC uncontrolled, max. Load 150mA,

Protected via electronic fase

Inputs 24V DC / typ. 10mA

signal length must be more than 100ms

Relay output If inductive loads are to be switched (e.g. other relays)

those have to be protected with free-wheeling Diodes

contact load at 230V max. 1A

Traffic light cont acts LED - bulb 230V

or

Normal bulb 230V shock resistant max. 40W

Temperature Working: -5.... +40°C

Storage: +0....+50°C

Humidity: To 93% not condensing

Vibration: Vibration free mounting, e.g. on flat built wall

Protection class IP54 (CEE Plug), IP65 available

www.gfa-elektromaten.de

Page 46

LIFETIME / DOORCYKLES

The GfA control panels working with electro mechanical contactor boards.

Contactor boards having generally a limited life time; this depends on the switched power of

ELEKTROMATEN® in use and the amount of switching cycles. Therefore we recommend a

replacement for control boards in use after doors having reached their confirmed lifetime

cycles. Coherence between power and amount of cycles for ELEKTROMATEN® describes

diagram bellow.

Cycles according

Torzyklen

to EN 12433-2

nach DIN EN 12433-2

1000.000

900.000

800.000

700.000

600.000

500.000

400.000

300.000

200.000

3~ 230/400V, 50Hz

1~230V, 50Hz

100.000

0,25 0,50 0,75 1,00 1,25 1,50 1,75 2,00 2,25

Page 47

2,50 2,75 3,00

Leistung in kW

Power in KW

DECLARA TION OF INCORPORA TION

in the terms of Machinery Directive 2006/42/EC

for partly completed machinery , Appendix II Part B

Declaration of conformance

in terms of EMC Directive 2004/108/EC

We, the

GfA - Gesellschaft für Antriebstechnik

Wiesenstr. 81, 40549 Duesseldorf (Heerdt), Germany

hereby declare that the following products are conform with the

above EC Guidelines and are only intended for installation in door equipment.

Door control panel TS 981

Standards applied

GfA-Gesellschaft für Antriebstechnik

Dr.-Ing. Hammann GmbH & Co. KG

Wiesenstraße 81

40549 Düsseldorf

Telefon: +49 (0) 211-500 90 0

Telefax: +49 (0) 211-500 90 90

www.gfa-elektromaten.de

DIN EN 12453 Doors - safety in use of power operated doors

DIN EN 12978 Industrial, commercial and garage doors and gates -

Safety devices for power operated doors - Requirements and Test methods

DIN EN 60335-1 Safety of household and similar electrical appliances

Purposes - Part 1 : General requirements

DIN EN 61000-6-2 Electromagnetic compatibility (EMC) Part 6-2

Generic standard – Emission standard for industrial environments

DIN EN 61000-6-3 Electromagnetic compatibility (EMC) Part 6-3

Generic standard – Emission standard for residential,

commercial and light-industrial environments

We undertake to transmit in response to a reasoned request by the appropriate regulatory

authorities the special documents

on the partly completed machinery.

Authorised representative for the compilation of the relevant technical documents

(internal EU address)

Dipl. Ing. Bernd Synowsky

Documentation representative

Incomplete machines within the meaning of the EC Directive 2006/42/EC shall only be intended

to be integrated into other machines (or into other incomplete machines/systems) or to be

assembled with them to form a complete machine within the sense of the Directive. Therefore,

this product cannot be commissioned before it is determined that the entire machine/system to

which it was integrated shall comply with the provisions of the Machinery Directive indicated

above.

Düsseldorf, . . 20 Stephan Kleine

CEO Signature

Erstelldatum: 1.1.200 Zeichnungs-Nr.: 52397057 Revisionsstand: b

Page 48

FUNCTION OVERVIEW

Control panel for ELEKTROMATEN® up to. 3 kW at 400V / 3~ with electronic limit DES

•

designed for only low-level adjustment

7- Segment led display showing

•

- Programming the control panel

- Displays Command - / Info- / Fault

Software release loading and saving

•

Mains supply

•

- 400V / 3~ with and without Neutral

- 230V / 3~

- 230V / 1~ (for single-phase motors)

Door operating modes

•

- Dead-man open- and close

- Self-hold open- and dead-man mode close (without safety edge)

- Automatic open- and close (with safety edge connected)

Integrated safety edge systems

•

- 8K2 normally open contact

- 1K2 normally close contact

- optical safety edge system (System Vitector)

Automatic close feature

•

- Free programmable from 1 up to max. 240 Sec.

- On interrupting and re-making light barrier closing after 3 sec..

- Can be interrupted by a separate switch

Supply for external devices

•

- 230V (at 400V / 3~ with N), up to 1,6A load

- 24V DC, up to 1000mA load

Plug for 5 pole motor connector 6 pole for electronic limit DES

•

Plug for spiral cable (safety edge and pass-door contact)

•

Integrated internal pushbutton OPEN / STOP / CLOSE

•

Additional terminals for different control equipment

•

- Emergency stop ( LATCHING)

- Additional safety stop s

- External three push button OPEN / STOP / CLOSE

- Light barrier activated Stop and Reverse function, time reset, time interruption 3 sec.

- One channel - impulse functions e. g. Ceiling pull switch for OPEN / CLOSE / STOP

– sequencing or radio control

- Key switch ( latching) for intermediate Stop

- 2x potential free relay output (NC / NO), output signal from aux. limit

If a signal lamp is in use, the potential free limit is not available

Integrated traffic light management

•

- One-way

- T wo-way

Page 49

Loading...

Loading...