Elektrolux 18cc, 21cc, 24cc User Manual

For Discount Poulan Poulan Pro Parts Call 606-678-9623 or 606-561-4983

SERVICE MANUAL FOR WEED EATER/POULAN/POULAN PRO

18cc,21cc AND 24cc ENGINES

LT7000;LT7500;FEATHERLITE SERIES;WT21;PP110;PT112;PP113;PT115;PT165;

LT17; PROLITE; TWIST-N-EDGE(TE) UNITS; ULTRATRIM

www.mymowerparts.com

For Discount Poulan Poulan Pro Parts Call 606-678-9623 or 606-561-4983

1. SCREW SPECIFICATIONS

TORQUE

PART NO. LOCATION (QTY) SIZE (IN-LBS)

CRANKCASE & CYLINDER

530015953 CYLINDER/CRANKCASE (2) 1/4 – 20 90-100

952030201 SPARK PLUG (1) 14mm 11-15(FT LBS)

530015810 FAN HSG/CRANKCASE (4) 10 - 24 40 - 50

530016014 CARB ADAPTER/CYL (2) 12 - 24 50 - 60

530015887 CARB/CARB ADAPTER(2) 9 - 15 60 - 70

530015966 AIR BOX COVER/BOX (2) 10 - 14 10 - 15

IGNITION SYSTEM

530038604 DRIVE COUPLING (1) 5/16 - 24 10 – 12(FT LBS)

530015954 MODULE/CRANKCASE (2) 8 – 32 30 - 40

STARTING SYSTEM, FAN HOUSING & CLUTCH HOUSING

530015882 STARTER DOG/FLYWHEEL (2) 6 - 19 8 - 12

530016080 PULLEY/ROPE (1) 6 - 19 10 - 12

530015886 CLUTCH HSG/FAN HSG (3) 10 - 14 30 - 40

530015882 SPRING/HSG RET. (1) 6 - 19 8 - 12

530015875 NOSE CLAMP 10 - 24 25 - 35

SHROUD & TANK

530015810 SHROUD/CRANKCASE (4) 10 - 24 40 - 50

530015934 SHROUD/FAN HSG (10 10 - 14 30 - 40

53015886 TANK/SHROUD (2) 10 - 14 40 - 50

LOWER END

530047905 HUB/DRIVESHAFT (1) 5/16-24 70 - 90

530016273 THROTTLE/HSG 8-16 10-15

USE LOCTITE 242 ( MEDIUM STRENGTH) OR PERMA-LOK MM 115.

www.mymowerparts.com

For Discount Poulan Poulan Pro Parts Call 606-678-9623 or 606-561-4983

2. SUMMARY OF ENGINE SPECIFICATIONS

A. COMPRESSION (COLD ENGINE AFTER MOTOR TEST) 110 - 130 PSIG

B. CRANKSHAFT RUN-OUT .004 MAX

(CIRCULAR RUN -OUT @ .400 GAGE DIA)

C. IDLE SPEED 3400 - 4200 RPM

D. WIDE OPEN THROTTLE INTERMITTENT 2/4 TO (AFTER 3 MINUTES

WARM-UP AND MOTOR TEST). JUST CLEAN

2-CYCLE (2/4 MUST BE MAX 1/8 TURN

RICHER THAN POINT WHERE ENGINE JUST

BREAKS INTO A CLEAN 2-CYCLE).

E. IGNITION TIMING (FIXED) 18° - 22° BTDC @ 3000 RPM

F. MIXTURE SCREW SETTING 1 1/2 - 2 1/2 TURNS OUT

G. COIL AIR GAP .010" - .014"

H. SPARK PLUG GAP (RCJ8Y) .023" - .028"

I. CHOKE SHUTTER STAND OFF .004" MAXIMUM

www.mymowerparts.com

For Discount Poulan Poulan Pro Parts Call 606-678-9623 or 606-561-4983

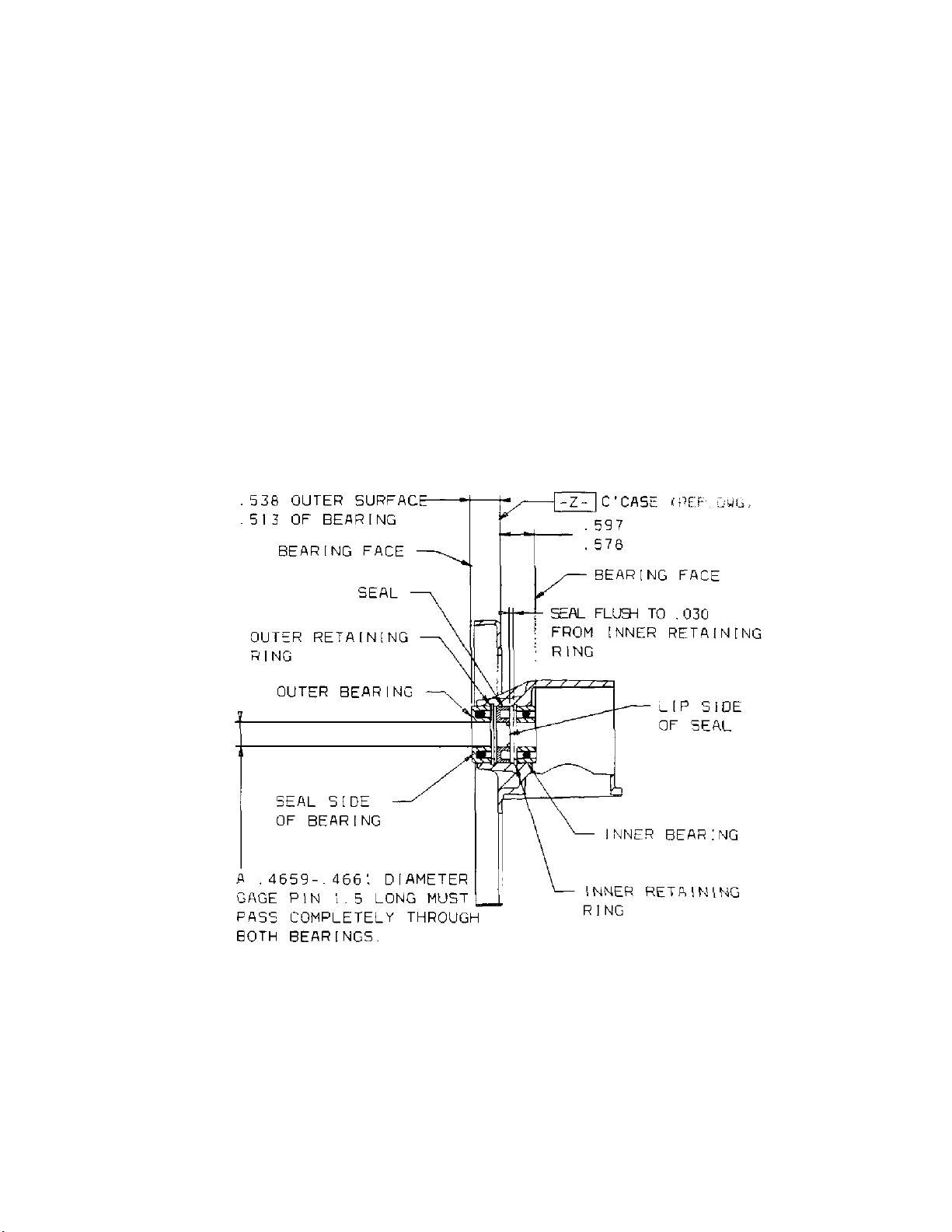

3. CRANKCASE ASSEMBLY SPECIFICATIONS

A. INSTALL INNER RETAINING RING IN CRANKCASE.

B. PRESS SEAL INTO CRANKCASE WITH SEAL “LIP: ORIENTED TOWARDS

CYLINDER END OF CRANKCASE.

C. INSTALL OUTER RETAINING RING INTO CRANKCASE.

D. PRESS OUTER BEARING (WITH SEAL) UNTIL IT STOPS AGAINST OUTER

RETAINING RING. SEE FIGURE 1.

NOTE: MAKE SURE SEAL SIDE OF BEARING FACES AWAY FROM RETAINING

RING.

E. PRESS INNER BEARING (NO SEAL) UNTIL IT STOPS AGAINST INNER

RETAINING RING ON OPPOSITE SIDE OF RING FROM SEAL.

FIGURE 1

www.mymowerparts.com

For Discount Poulan Poulan Pro Parts Call 606-678-9623 or 606-561-4983

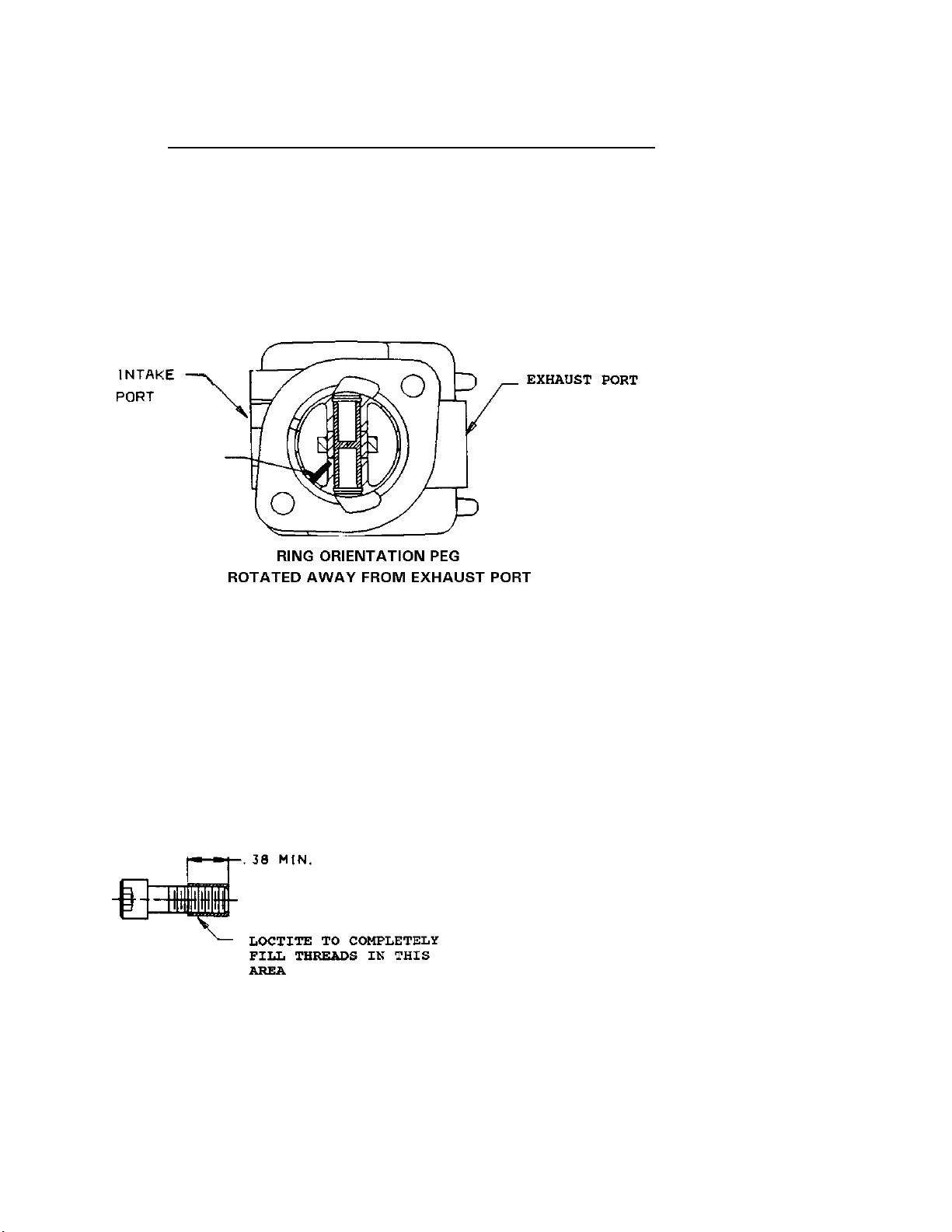

4. PISTON, CRANKSHAFT, CYLINDER ASSEMBLY SPECIFICATIONS

A. SPECIAL CAUTION NOTES:

1) CARE MUST BE TAKEN TO PROTECT PISTON FROM SCRAPES AND NICKS.

2) ASSEMBLY FIXTURES MUST BE KEPT CLEAN TO AVOID DAMAGE TO THE

PISTON.

3) DO NOT HAMMER OR TAP PISTON PIN INTO PISTON.

4) CRANKCASE MUST BE KEPT FREE OF CHIPS, DIRT, AND DEBRIS

BEFORE AND DURING ENGINE ASSEMBLY.

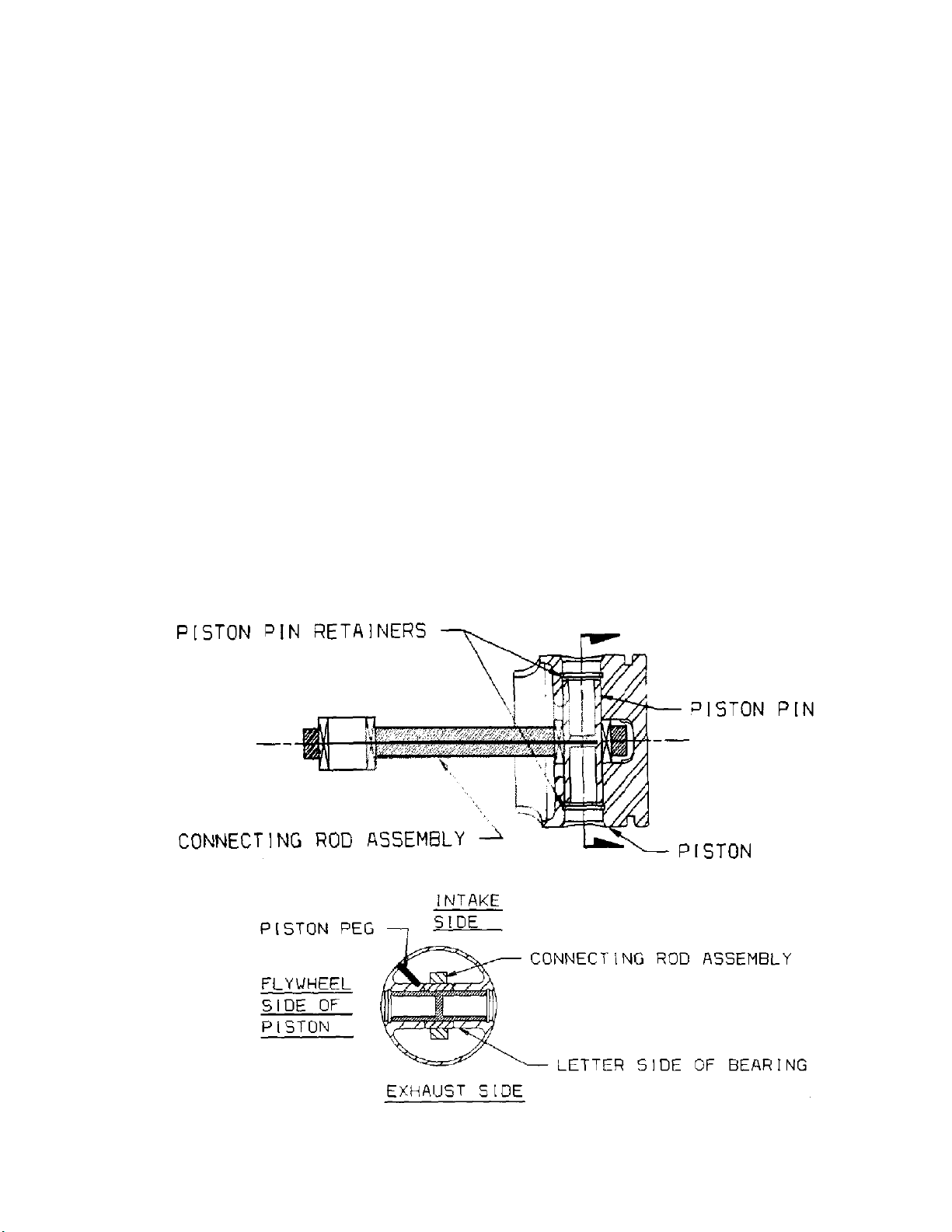

B. PISTON AND CONNECTING ROD ASSEMBLY

1) INSTALL PISTON PIN RETAINER IN ONE SIDE OF PISTON.

2) ASSEMBLE CONNECTING ROD TO PISTON (SEE FIGURE 2 FOR

ORIENTATION OF CONNECTING ROD ASSEMBLY).

3) PRESS PISTON PIN (NO SPECIAL ORIENTATION) TO PISTON AND

CONNECTING ROD.

4) INSTALL PISTON PIN RETAINER TO OTHER SIDE.

www.mymowerparts.com

FIGURE 2

For Discount Poulan Poulan Pro Parts Call 606-678-9623 or 606-561-4983

4. PISTON, CRANKSHAFT, CYLINDER ASSEMBLY SPECIFICATIONS - CON TINUED

C. CRANKSHAFT ASSEMBLY

1) PRESS CRANKSHAFT ASSEMBLY INTO BEARINGS UNTIL SHOULDER OF

COUNTERWEIGHT BOTTOMS OUT ON INNER BEARING. IMPORTANT:

CHECK TO SEE IF RETAINING RING GROOVE IS CLEAR TO ASSEMBLE

RETAINING RING AND CRANKSHAFT TURNS FREELY (FIGURE 3) WHILE

SUPPORTING THE OUTER BEARING COMPLETELY AND ORIENTING

PROPERLY THE COUNTERWEIGHT.

2) ASSEMBLE RETAINING RING INTO CRANKSHAFT GROOVE.

NOTE: CARE MUST BE TAKEN TO DETERMINE WHEN THE SHOULDER OF

THE CRANKSHAFT WILL CONTACT THE INNER RACE OF THE

INSIDE BEARING SO NO EXCESSIVE FORCE WILL BE APPLIED

OVER THE BEARING.

FIGURE 3

www.mymowerparts.com

ASSEMBLE TWO (2) SCREWS TO CYLINDER AND CRANKCASE USING LOCTITE ON THE

For Discount Poulan Poulan Pro Parts Call 606-678-9623 or 606-561-4983

4. PISTON, CRANKSHAFT, CYLINDER ASSEMBLY SPECIFICATIONS - CONTINUED

D. CYLINDER ASSEMBLY

1) COAT CYLINDER WALLS, PISTON, AND PISTON RING WITH 30 OR 40

WEIGHT OIL PRIOR TO ASSEMBLY.

2) ASSEMBLE CYLINDER GASKET TO CYLINDER

3) ASSEMBLE PISTON TO CYLINDER USING A RING PROTECTOR

4) TURN CRANKSHAFT TO TOP-DEAD-CENTER. ASSEMBLE CONNECTING ROD

TO CRANKSHAFT ASSEMBLY.

5) FIT CYLINDER TO CRANKCASE.

6)

THREADS.

www.mymowerparts.com

For Discount Poulan Poulan Pro Parts Call 606-678-9623 or 606-561-4983

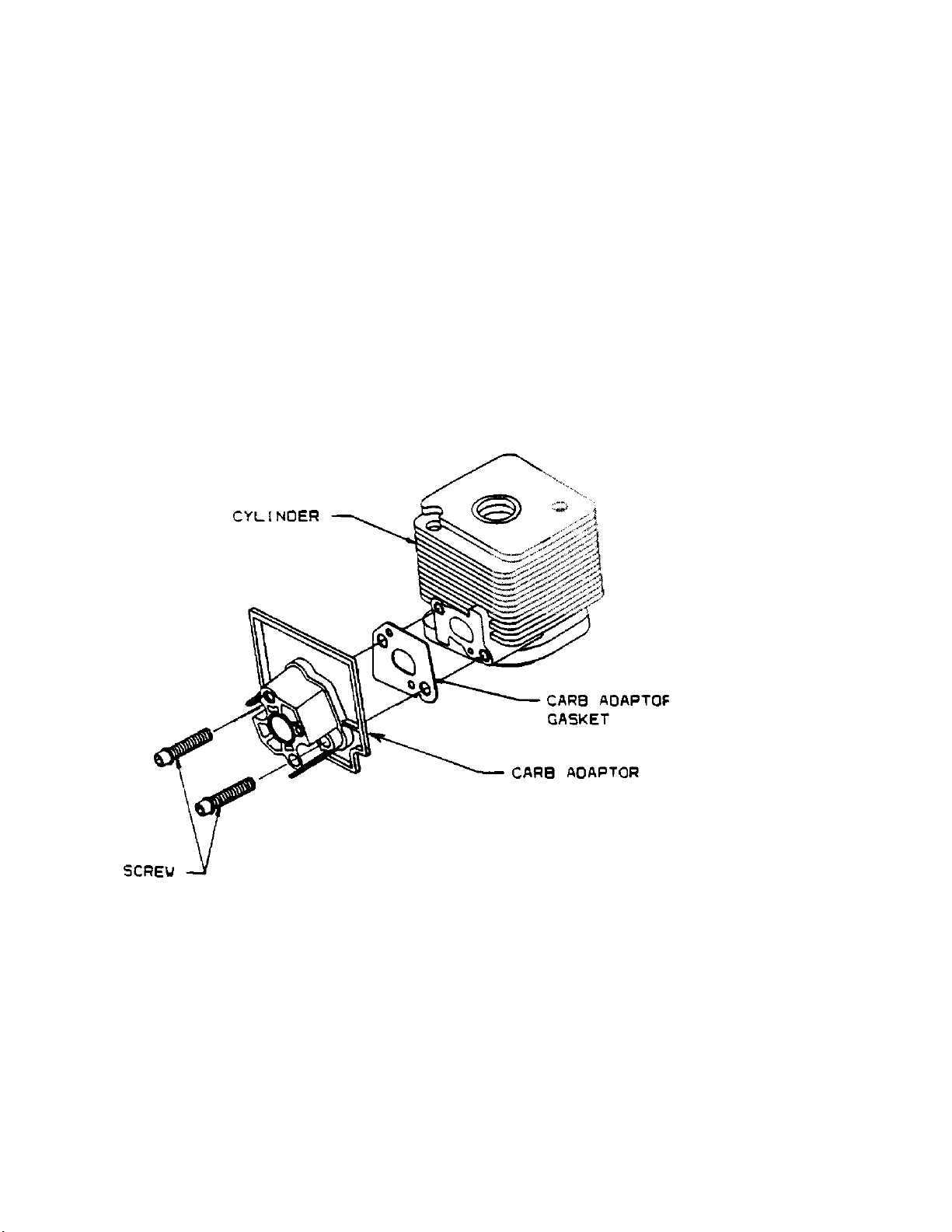

5. CARBURETOR, AIR BOX ASSEMBLY SPECIFICATIONS(18cc FEATHERLITE SERIES)

A. ASSEMBLE CARBURETOR ADAPTER GASKET TO CARB ADAPTER (FIGURE 4)

(NOTE GASKET RETENTION POSTS).

B. ASSEMBLE CARB ADAPTER TO CYLINDER WITH TWO (2) SCREWS. TORQUE TO

SPECIFICATION.

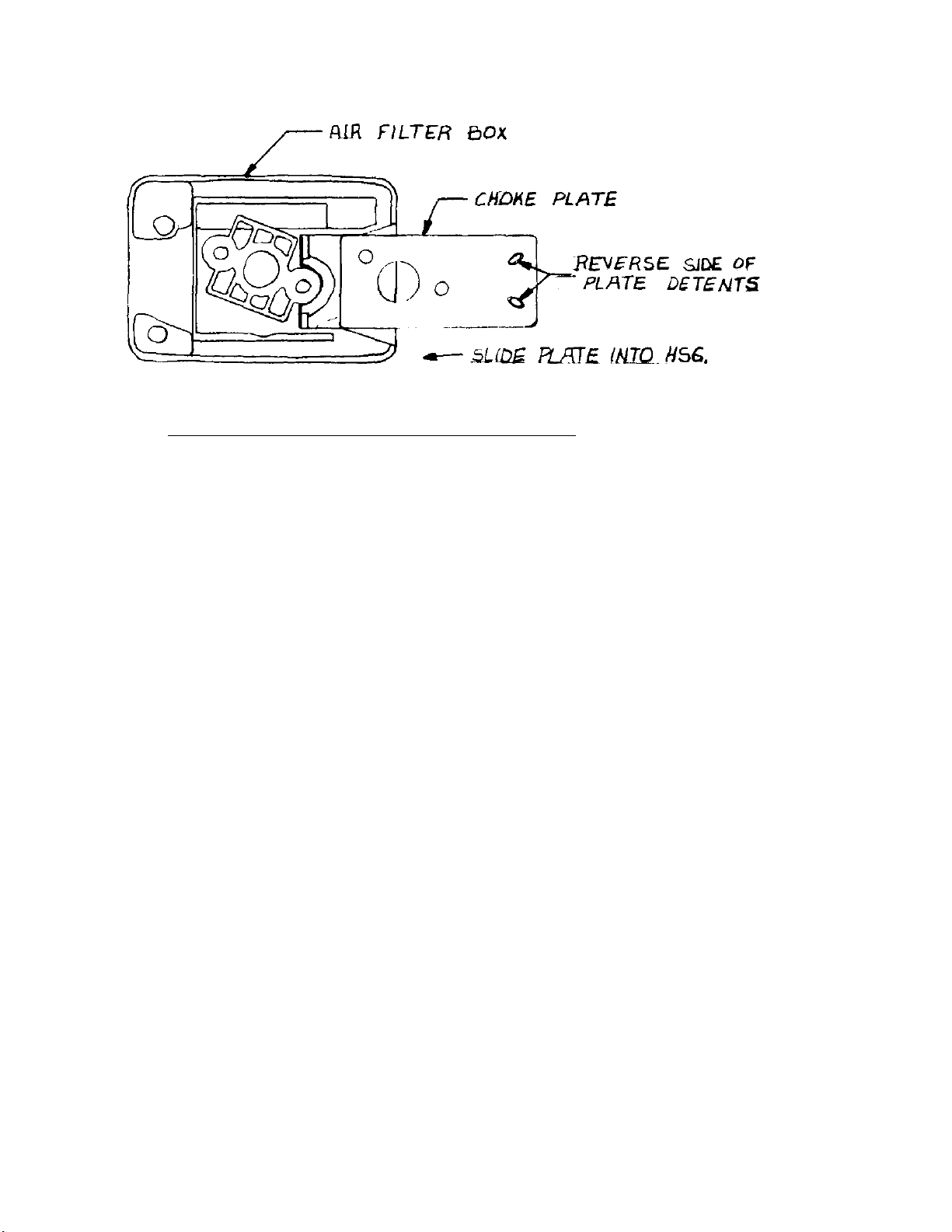

C. SLIDE CHOKE PLATE (SIDE WITH THREE DETENTS TO BE FACING AIR FILTER

BOX) INTO AIR FILTER BOX UNTIL ALL THREE HOLES LINE UP WITH THE

HOLES IN AIR FILTER BOX.

D. PLACE CHOKE SHUTTER INTO FILTER BOX MAKING SURE THAT DETENT ON THE

SHUTTER WILL ENGAGE THE THREE DETENTS IN THE CHOKE PLATE (FIG. 5).

FIGURE 4

www.mymowerparts.com

For Discount Poulan Poulan Pro Parts Call 606-678-9623 or 606-561-4983

FIGURE 5

5. CARBURETOR, AIR BOX ASSEMBLY SPECIFICATIONS - CONTINUED

E. PLACE CARB GASKET TO CARB ADAPTER, MAKING SURE SLOTS IN GASKET

ALIGN WITH PINS ON ADAPTER (FIGURE 6).

F. ATTACH LARGE DIA. PURGE RETURN LINE FROM FUEL TANK TO LOWER ANGLED

FITTING ON CARB (AS VIEWED FROM REAR OF POWERHEAD).

G. ATTACH SMALL DIA. FUEL LINE FROM FUEL TANK TO FUEL INLET FITTING

ON THE CARBURETOR (THE FUEL INLET FITTING IS THE UPPER STRAIGHT

FITTING AS VIEWED FROM THE REAR OF THE POWERHEAD).

H. INSTALL SCREW THROUGH THE CHOKE SPACER (WITH THE FLANGE AGAINST

THE SCREW HEAD), THROUGH WAVE WASHER AND THEN THROUGH THE CHOKE

SHUTTER INTO AIR FILTER BOX. INSTALL OTHER SCREW THROUGH THE

OTHER HOLE IN THE AIR BOX.

I. ALIGN SCREWS IN AIR FILTER BOX THROUGH CARBURETOR INTO CARB

ADAPTER AND TORQUE SCREWS TO SPECIFICATION.

J. IMPORTANT: CHECK CHOKE LEVER MOVEMENT. CHOKE LEVER MUST HAVE

POSITIVE STOP AT ALL DETENTS AND CYCLE THROUGH ALL THREE POSITIONS

OF CHOKE FREELY.

K. POSITION FILTER SUPPORT PLATE INTO AIR FILTER BOX, RAISED CENTER

AREA UP.

L. FIT AIR FILTER FOAM INTO AIR FILTER BOX. THERE ARE TO BE NO GAPS

OR PINCH AREAS AROUND EDGES.

M. INSTALL AIR BOX COVER TO AIR FILTER BOX WITH VERBIAGE TO TOP OF

UNIT. TORQUE (2) SCREWS TO SPECIFICATION.

www.mymowerparts.com

Loading...

Loading...