MY 150 USER’S MANUAL

(V1.12)

Elektralite is a division of Group One. 70, Sea Lane, Farmingdale, NY 11735, USA.

Tel: +1 (516)-249-3662. Fax: +1 (516)-249-8870

WWW.MYELEKTRALITE.COM

INTRODUCTION:

Thank you for choosing Elektralite’s MY150 fixture.

Please read the User Manual carefully and keep it in a safe place after reading it.

MY150 is very easy to install and use once you have read the manual. Failure to do so could result in damage

to the fixture, which will not be covered under warranty so please take the time to read it.

When you unpack MY 150 you should find inside the box: the fixture, a 120 volt power cable, a 3 pin DMX

signal cable, a safety cable and of course this CD. Please check carefully that there is no damage caused by

transportation. Should there be any, consult your dealer immediately and don’t install it.

Features

Pan 360° / Tilt 265°

9 colors plus white & rainbow effect

7 rotating gobos

Strobe : with a frequency of 0~10 flashes per second.

Automatic program

Display : digital address and function setting (also the display can be inverted if

fixture is hung upside down).

High speed pan & tilt movements

Local or remote resetting

Lamp switch ON/OFF locally

Auto test for all functions

Value of each DMX-channel can be displayed

Saved Program : You can edit and save a program internally in the fixture by using either the

display panel of the fixture or using an external controller (your

can save a maximum of 48 scenes. You can then run this saved program by using the “run” feature

from the menu on the display panel

Elektralite CP10xt or CP20xt).

You

SAFETY INSTRUCTIONS

A Word of Caution.

Please remember you will be working with 120 volts and you can suffer electric shock from any exposed lives

wires. So please be careful at all times and behave wisely.

Now you’re MY 150

ensure a safe operation, it is absolutely essential that the installer and user follow the safety instructions and

warning notes written in this user manual. Remember any damage caused by disregarding the manual or not

reading it, will not be covered by warranty and Elektralite (or any of its dealers) will not accept responsibility for

any resulting damage or problems.

If MY 150 has been exposed to large environmental temperature changes in transit please do not switch it on

immediately it is unpacked. There maybe internal condensation. So leave MY 150 off until it has reached the

running temperature of the venue.

Elektralite’s MY 150 needs to be grounded. Do NOT cut the ground pin or try to use two-core cable to connect

it to a 120-volt receptacle. To be safe and to work properly you must have this fixture grounded.

A qualified electrician must do any electrical work.

Make sure that the power is only 120 volts. This unit will be damaged if you chose to install it at any other

voltage. In an installation it is always best to check the voltage before connecting. And remember never try to

left

Elektralite’s

factory in perfect condition. In order to maintain this condition and to

1

connect your MY150 live.

Make sure that the power cable is not damaged and never break off the ground pin.

Always disconnect the power, when the device is not in use or before cleaning it. If you don’t then you are

wasting the lamp life. Merely closing the shutter just stops the light output, it does NOT TURN OFF THE LAMP.

Never try to disconnect your MY150 by pulling out the plug by tugging the cord.

Never touch MY 150 when powered up. The lamp produces a considerable amount of heat and as a result the

housing does get hot. You can be burnt if you touch it.

Never look directly into the lamp source. Sensitive person could suffer an epileptic shock.

Never open MY 150 and look at the lamp when the lamp is still on or when it is turned off but still hot or even

warm. MY 150 uses a discharge lamp, which is volatile. The lamp can explode at anytime. Use extreme

caution and do not expose yourself to it. When replacing the lamp do not touch any glass part of the lamp. Only

handle by the silver terminal ends. Do not over tighten when installing a new lamp. Hand tight is more than

enough. PLEASE make sure that power to the fixture is disconnected

room temperature before installing a new lamp.

and allow the fixture to cool down to

Please keep out of reach of the general public, children and animals.

2

GENERAL GUIDELINES

MY 150 is a lighting effect for professional use on stages, in clubs, theatres, and so on.

This fixture should only be operated at the voltage, which stated in the technical specifications in the last page

of this manual.

MY 150 is designed for indoor use only.

MY 150 is not designed for permanent operation. Consistent operation breaks may ensure that the device will

serve you for a long time without defects.

Do not shake MY 150.

Do not use physical force when installing or operating MY 150.

While choosing the installation position, please make sure that MY 150 is not exposed to extreme heat,

moisture or dust.

The minimum distance from MY 150 front lens to any illuminated surface must be more than 3 feet.

Please be careful what surface you shine the light onto; light also has heat and this can effect the illuminated

surface. Elektralite will not be responsible for fading, color distortion or heat distortion caused by the light

beam.

When you hang MY 150 please use an appropriate safety cable. Please make sure that any hanging

equipment, like threaded rod or C clamp is appropriate for the job. Remember, with a moving yoke fixture, that

the momentum of moving this large mass will cause extra “stress” on any mounting materials. When mounting

MY 150 in the air you need to use M10 bolts. The M10 bolts should be no less

type should be 1.5mm.

Metric explanation:- If you go to a good hardware store (like Home Depot or Lowes) you will be purchasing

bolts that have written on the packaging 10mm x 1.5mm x 25mm. [The last figure of 25mm can be a higher

value read on].

10mm is the diameter of the bolt itself. 10mm is roughly 0.4 of an inch. In engineering drawings 10mm is also

written or described as M10.

1.5mm is the distance between each thread or turn of the screw. Engineering drawings refer to this as the pitch

of the screw. Now in places like Home Depot they stock 10mm bolts with 1.0mm, 1.25mm and 1.5mm pitch. So

be careful you buy the right pitch: 1.5mm.

25mm is the minimum

30mm, 35mm and so on. Choose the bolt that best fits the length you will need to hold the C clamp or whatever

clamping device you will be using.

Finally, just FYI 25.4mm is 1 inch.

Only operate MY 150 after you know its functions. Do not permit operation by persons not qualified.

Please use the original packaging if the device is to be transported. [Beware the majority of shipping

companies will not accept any liability for damage if the fixture is not shipped in the manufacturer’s original box

and insert packaging material].

If this fixture is operated in any other way different to that described in this manual, the fixture could be

damaged and any warranty would be void.

length of bolt you should use. Bolts are available in 5mm steps. So you can get 25mm,

than 25mm long and the thread

3

INSTALLATION INSTRUCTIONS

A). Installing or replacing the lamp

1. Install the lamp with the fixture unplugged from the electric source.

Never try to replace a lamp with the fixture still turned on and still hooked up to the electric.

2. If you are replacing the lamp, before opening the housing to replace it,

let it cool down to room temperature. The lamp burns at very high

temperatures and it is a discharge lamp. If the lamp has been running then

expect anything up to half an hour before the housing is cool enough to

consider even opening up.

3. When installing a new lamp do not touch any glass part of the lamp.

Always use a clean cloth to handle lamps. The sweat from your fingers will cause the lamp to

burn incorrectly and will shorten lamp life. If you do touch the glass, then check in the lamp box

for a special wipe to clean the lamp.

4. Only install HTI 150 GY 9.5 lamps. Any other lamp is not acceptable.

Procedure :

1) Unscrew the 2 screws on the back of the housing that hold the lamp housing plate in position.

2) Gently pull the plate out using the knob in the middle of the plate.

3) Carefully insert the lamp into the socket. The socket is polarized so there is only one way to insert the lamp.

Gently slide the lamp into the socket making sure the spring clips secure the lamp socket correctly. Then insert

the plate back into the fixture and fasten the 2 screws back in place.

4) On the plate there are 3 small screws marked 1, 2 and 3. These are used to adjust the lamp. You can adjust

the 3 screws to fine-tune the position of the lamp. In this way you can achieve the maximum output from the

lamp.

Please remember the lamp is not a hot-restrike type, you must wait for approximately 10

minutes after turning the lamp off before turning it back on again.

Warning:- Never ever operate the lamp when it is not inside the fixture. HTI lamps are volatile and could

possibly explode. Only turn on the fixture with the lamp securely inside the fixture and the cover plate screwed

on.

4

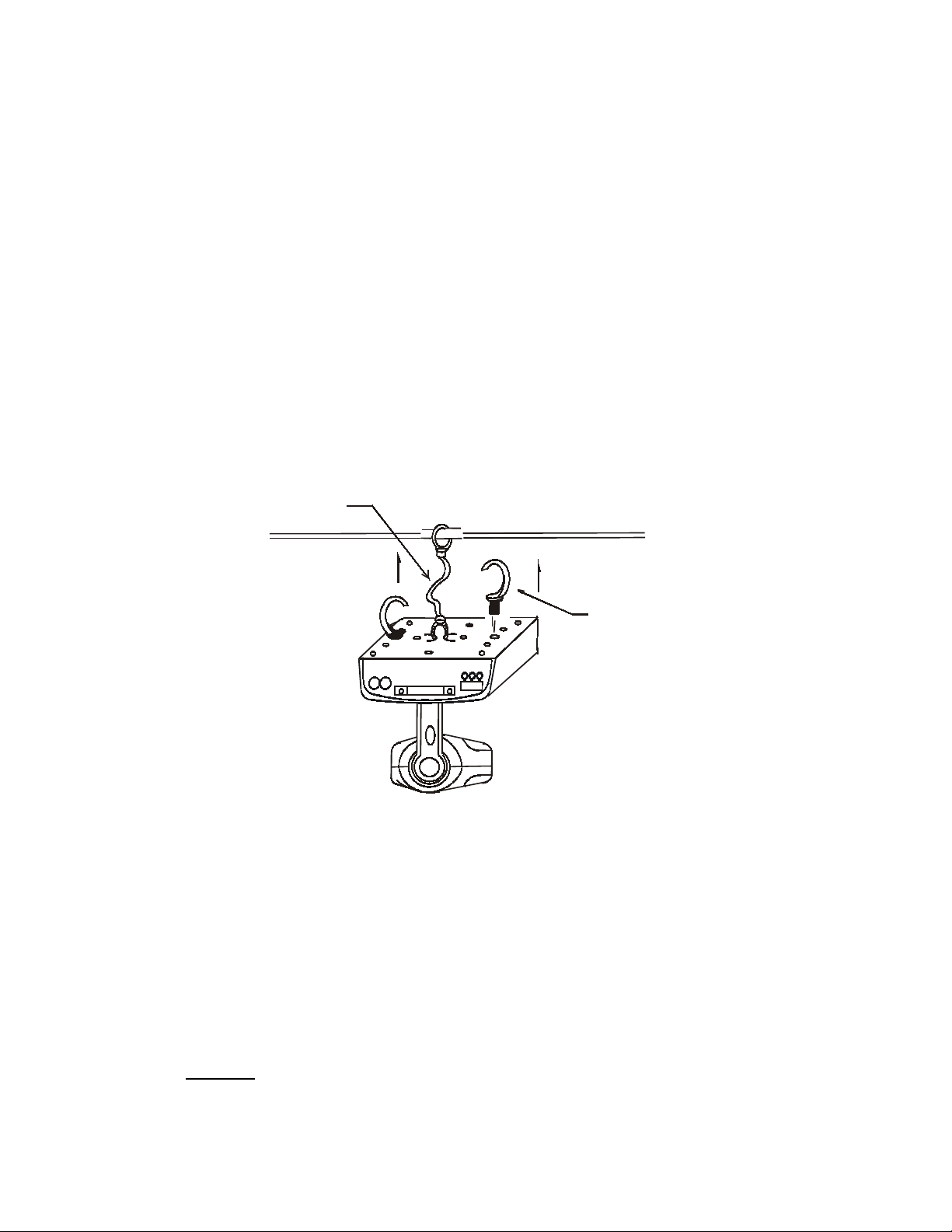

B). Mounting MY 150

Method 1: Installation Using a C Clamp.

The installation must always be secured with a backup safety attachment: namely an appropriate sized safety

cable. Don’t clamp the safety to the C clamp. That defeats the reason for a safety cable….namely a

SEPARATE backup to the primary hanging mechanism.

Never stand directly below the device when mounting, removing or servicing the MY 150.

Please make sure MY 150 has been installed correctly both from a mechanical and electrical aspect before

powering up and operating for the first time. Spending a few extra minutes double-checking everything, is

better than rushing to turn the fixture on.

Care should be taken to mount MY 150. Make sure that MY 150 is mounted in such a way that no one can

touch it directly. For example, when hanging MY 150 make sure it is high enough up not to hit anyone’s head or

run into any obstruction in its movement. Always keep MY 150 away from any inflammable material.

Mounting MY 150 is a job that requires qualified personnel with experience. If the personnel doing the

installation lack these qualifications do not use them to do the installation.

.

Installation via ordinary clamp

Safety-chain

M10 X 25m m

Using M10 (10mm) bolts screw the C clamps onto the base of MY150 make sure that the bolts are firmly

tightened but take care not to over tighten. Fit a suitable safety chain to MY 150 center hole and attach to the

truss or whatever MY 150 is attached to.

Metric explanation:- If you go to a good hardware store (like Home Depot or Lowes) you will be purchasing

bolts that have written on the packaging 10mm x 1.5mm x 25mm. [The last figure of 25mm can be a higher

value read on].

10mm is the diameter of the bolt itself. 10mm is roughly 0.4 of an inch. In engineering drawings 10mm is also

written or described as M10.

1.5mm is the distance between each thread or turn of the screw. Engineering drawings refer to this as the pitch

of the screw. Now in places like Home Depot they stock 10mm bolts with 1.0mm, 1.25mm and 1.5mm pitch. So

be careful you buy the right pitch: 1.5mm. If you try to force a bolt with the wrong thread into the hole then the

threads in the holes will be ruined and render these mounting points useless as a load bearing point. Then

you’ll have to replace the base of the fixture.

25mm is the minimum

30mm, 35mm and so on. Choose the bolt that best fits the length you will need to hold the C clamp or whatever

clamping device you will be using.

length of bolt you should use. Bolts are available in 5mm steps. So you can get 25mm,

5

Finally, just FYI 25.4mm is 1 inch.

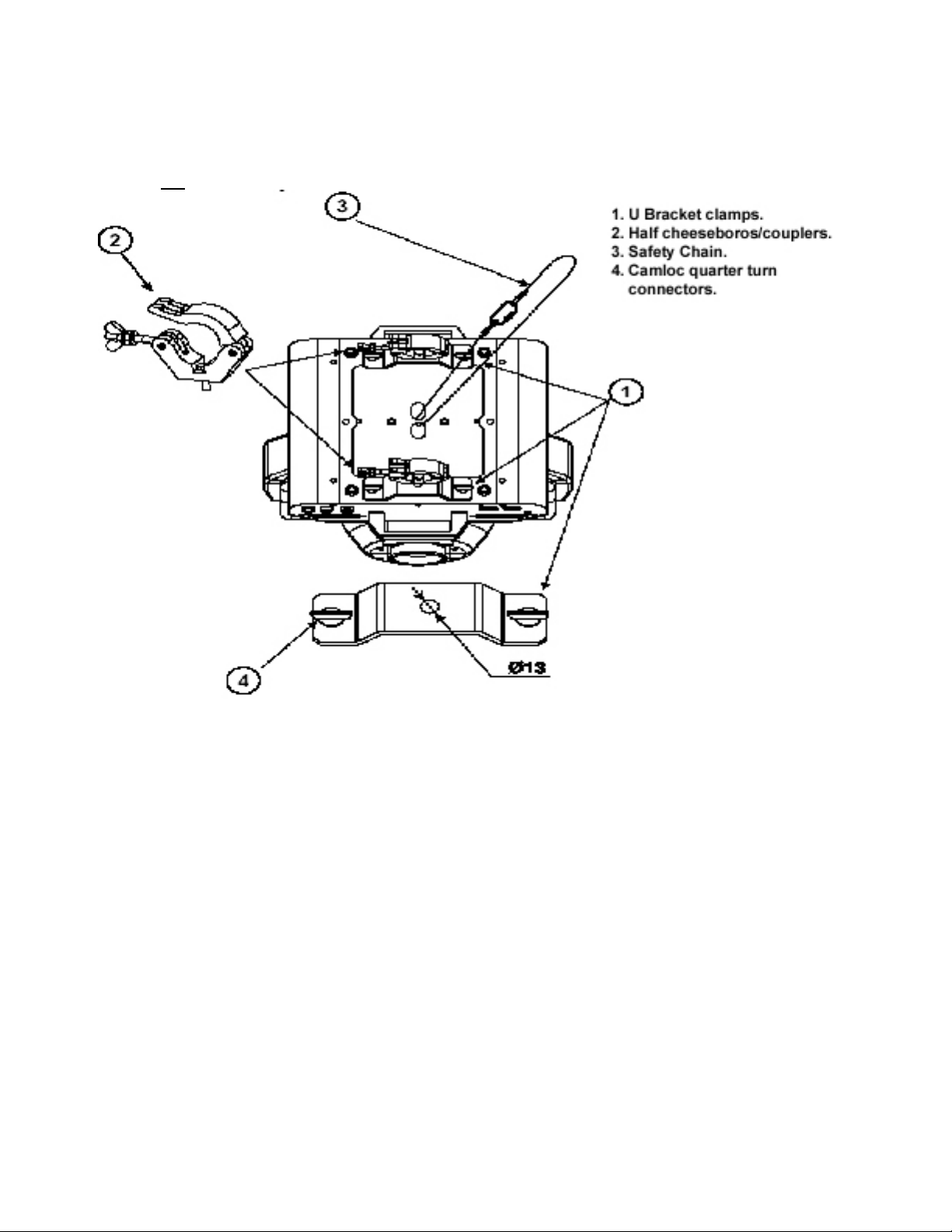

Method 2 : Installation using U Bracket Claps with half Cheeseboros/couplers.

[The U brackets and the appropriate base for the mounting these brackets are an after sales accessory.

They do not come as standard when the fixture is purchased].

U brackets can be used as an alternative installation method. They can have either half cheeseboros or C

clamps fitted to them.

Fit the half cheeseboros or C clamps to the U brackets. Then fit the U brackets to the MY150 using the

camlocs.

Finally, fit a safety chain to MY 150. Don’t clamp the safety to the half cheeseboros or C clamp. That defeats

the reason for a safety cable….namely a SEPARATE backup to the primary hanging mechanism.

DMX-512 control connection.

Connect the 3 pin XLR cable to the DMX controller and then to the first MY150 in the daisy chain. Doing this

way round avoids the pain of rewiring, if you get the wrong end of the cable back at the controller.

Continue wiring from one MY 150 to another in a daisy chain manner. Never try to Y split cables. Never try to

“star wire” a DMX cable run. It will not work.

If additional cable needs to be made up then two-core cable with a screen needs to be purchased. For wiring

please see the diagram below.

6

Loading...

Loading...