Page 1

A0327IVZ.fm

KGS 303

Operating Instructions. . . . . . . . .. . . . . . . . .5

Instructions d'utilisation . . . . . . . . . . . . . . .23

Manual de uso . . . . . . . . . . . . . . . . . . . . . .43

115 170 8400 / 0105 - 1.2

Page 2

Warranty Terms and Conditions

Dear Customer:

Thank you very much for selecting a product from METABO, the leading name in power tools. The name METABO

has been known for decades for proven quality and first class service. We offer our customers a wide array of high

performance products for the professional user as well as the hobbyist. Our quality control, constant innovation and extensive

measures to assure quality at every step of the design and manufacturing processes, lead to the high quality and state of th

art products that METABO is known for in many countries around the world.

We hope you will enjoy using this new product and will have much success with it.

e

Important! Please enter the model number and date of manufacture here

Model number: ______________________

Date of manufacture: _________________

You will need this data and will have it immediately available in the future in the event you have any questions

regarding your new METABO product or in case

technical data of your new METABO product can be found on the label affixed to the product. For details please refer to

chapter 3.4 of th

this warranty. Please keep your receipt in a safe place.

high quality materials. They are subject to strict quality control guidelines and the corresponding inspections in accordance

with the applicable international quality standards. Nevertheless, if your METABO product

METABO’s

FOLLOWING CAREFULLY. ALL RIGHTS NOT EXPRESSLY GRANTED ARE RESERVED BY THE MANUFACTURER.

workmanship from the date of original purchase from an authorized dealer in the United States

This warranty is not transferable and only covers the initial original purchaser. Proof of purchase (ledgible copy of, or original

sales receipt) is required for any warranty claim or any service under this warranty.

is manual.

Proof of purchase (legible copy of, or original sales receipt) is required for any warranty claim or any service under

All METABO products are state of the art. They are

NOTICE: THIS ONE (1) YEAR LIMITED WARRANTY GIVES YOU CERTAIN RIGHTS. PLEASE READ THE

The manufacturer provides a limited warranty and warrants its products to be free

of a warranty claim. Model number and date of manufacture as well as other

designed and manufactured using the latest technologies and

One (1) Year Limited Warranty

Warranty Terms and Conditions

right away.

ever fails, it is covered by

from defects in material and

for a period of one (1) year.

No warranty coverage can be provided without proof of purchase.

In the event of a defect in material or workmanship during this one (1) year period from the date of the original

purchase, the manufacturer will, at the manufacturer’s sole discretion, repair or replace the product on the terms and

conditions and with the limitations and exclusions as set forth below or refund the purchase price. The manufacturer’s

decision in this respect is final.

This limited warranty does not cover any on-site repair. To obtain warranty service, defective products and/or

defective parts

using a traceable method of shipping, to one of the manufacturer’s authorized service and repair facilities. For service

locations please visit www.metabousa.com.

www.metabousa.com or the number below for detailed return merchandise instructions and a RMA (Return Machine

Authorization) number.

must be shipped, properly packaged to protect against damage in shipping, and shipping or postage pre-paid,

Before shipping any defective products or parts please call your nearest service center, found at

Metabo Corporation

P.O. Box 2287

1231 Wilson Drive

West Chester, PA 19380

Phone: 800-638-2264

Fax: 800-638-2261

2

Page 3

Any repairs performed or payments made under this limited warranty do not extend the warranty period beyond the

date of one (1) year from the original purchase.

This limited warranty shall be null and void in case of abuse

mispackaging for shipping, improper operation, unauthorized repair or modification, use of non-proprietary, after market or

non-OEM spare parts, or failure to follow the manufacturer’s instructions w

service and maintenance of the product as outlined in this manual.

This limited warranty is limited to replacement of the product or defective parts or a refund of the purchase price.

NY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OF THIS

A

PRODUCT IS LIMITED TO THE ONE (1) YEAR DURATION OF THIS WRITTEN WARRANTY. ALL WARRANTIES SET

FORTH IN THIS WARRANTY ARE LIMITED TO ONE (1) YEAR FROM THE DATE OF THE ORIGINAL PURCHASE. NO

WARRANTIES WHA

HOWEVER, SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY LASTS,

SO IN SUCH STATES THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

IF THIS PRODUCT IS DEFECTIVE, YOUR ONLY REMEDY IS REPAIR OR REPLACEMENT OR A REFUND OF

THE PURCHASE PRICE, AS DESCRIBED ABOVE. TO THE MAXIMU

IN NO EVENT AND UNDER NO CIRCUMSTANCES WILL THE MANUFACTURER, ITS DISTRIBUTORS, DEALERS OR

AGENTS BE LIABLE FOR ANY SPECIAL, INCIDENTAL, INDIRECT, PUNITIVE OR CONSEQUENTIAL DAMAGES,

INCLUDING BUT NOT LIMITED TO ANY LOST PROFITS, LOST COMPENSATION OF ANY KIND, BUSINESS

INTERRUPTION, OR ANY OTHER DAMAGES CAUSED BY THE USE OF THIS PRODUCT OR INA

EVEN IF THE MANUFACTURER, ITS DISTRIBUTORS, DEALERS OR AGENTS HAVE BEEN ADVISED OF SUCH

LIABILITY CLAIMS OR OTHER CLAIMS OR THE POSSIBILITY OF SUCH CLAIMS OR OTHER CLAIMS.

SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL

DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

TSOEVER WILL COVER THE PRODUCT BEYOND THE ONE (1) YEAR PERIOD. *

, neglect, accident, disaster, misuse, mishandling,

ith respect to the proper handling, operation,

M EXTENT PERMITTED UNDER APPLICABLE LAW,

BILITY TO USE IT,

THIS W

FROM STATE TO STATE.

In the event of a claim which is or may be covered by this one (1) year limited warranty, please contact your nearest

service center, found at www.metabousa.com

(Return Machine Aut horization) number.

ARRANTY GIVES YOU SPECIFIC RIGHTS, AND YOU MAY HAV E OTHER RIGHTS WHICH MAY VARY

or the number below for detailed return merchandise instructions and a RMA

Metabo Corporation

P.O. Box 2287

1231 Wilson Drive

West Chester, PA 19380

Phone: 800-638-2264

Fax: 800-638-2261

METABO Authorized Customer Service

All METABO products are state of the art, designed and manufactured using the latest technologies and they are

subject to strict quality control guidelines. Nevertheless, if your METABO product ever fails, or you have problems w

operation, before calling METABO directly at 800-638-2264 or your nearest authorized Customer Service Center, try to

identify and solve the problem with help contained in chapter 14 of this manual, entitled “Trouble Shooting Guide” by

reviewing other chapters of this manual which cover the area of the problem.

ith its

the machine still does not function trouble free, Customer Service will be glad to help you. When you call

If

Customer Service, please have the following information from the label on the machine handy:

x The model number

x The date of manufacture of the defective machine

x The purchase date of the defective machine and

x A description of the malfunction, defect or problem

of the defective machine

Thank you for buying a METABO product.

3

Page 4

4

Page 5

XA0053E3.fm Betriebsanleitung

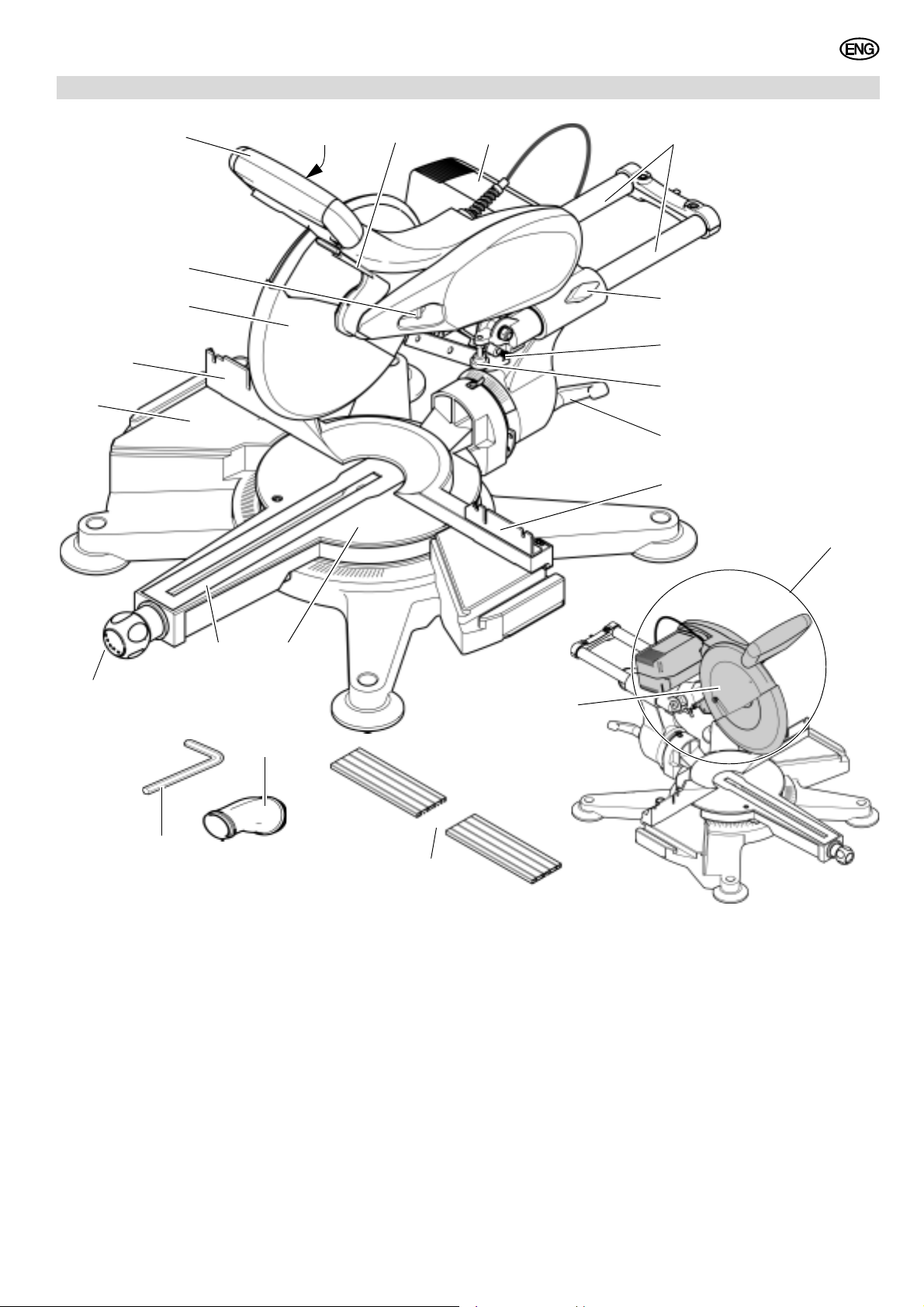

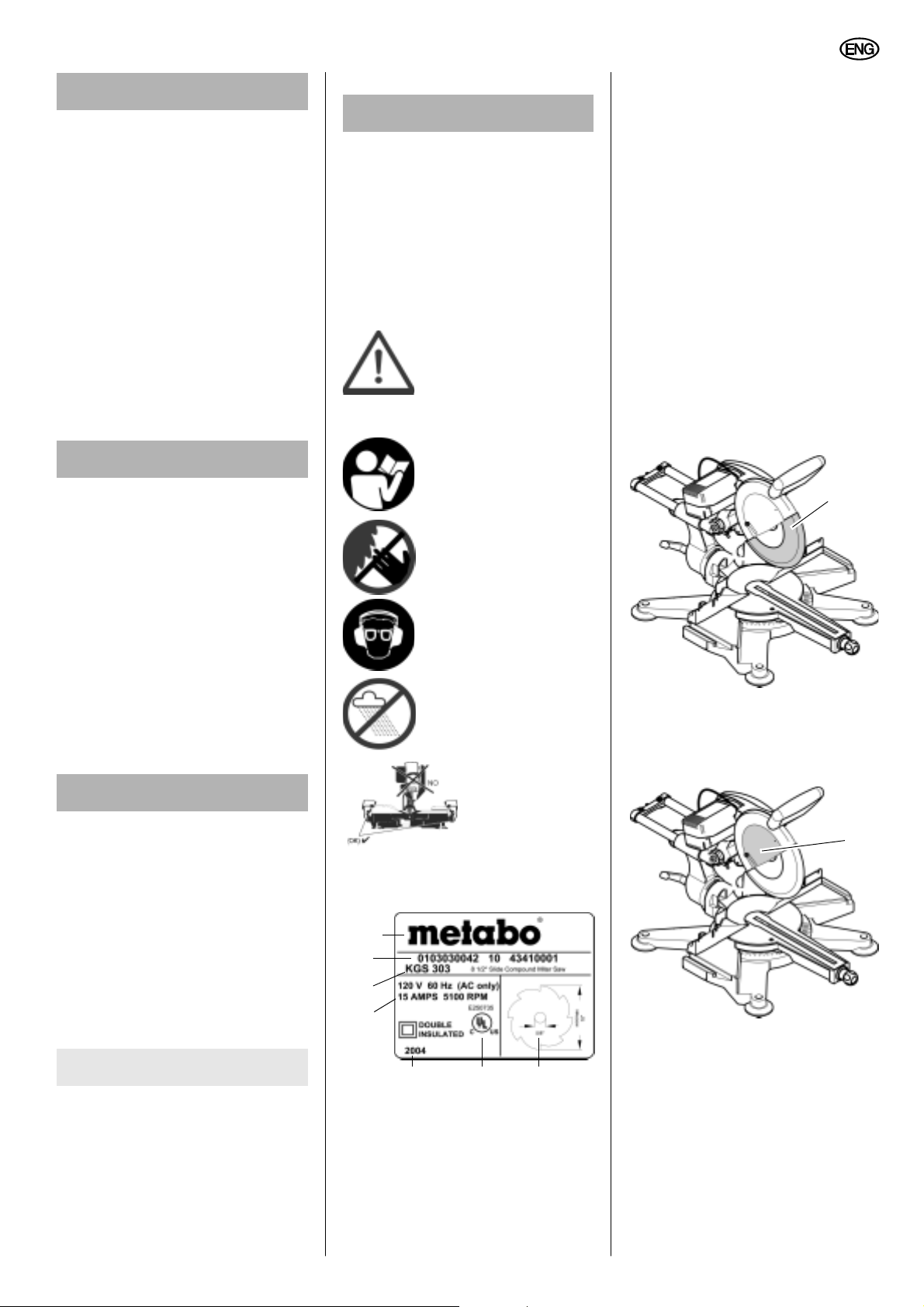

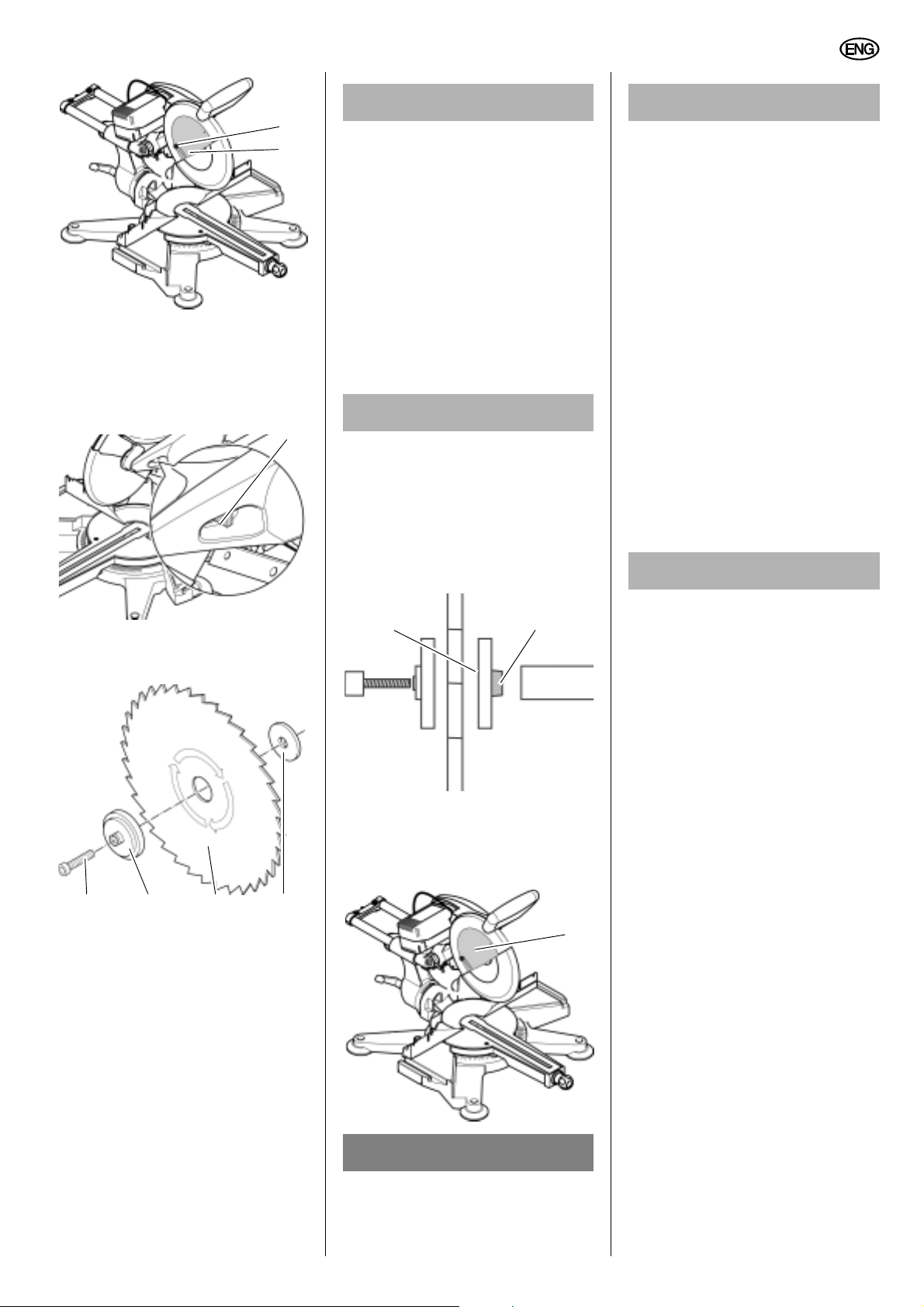

1. Components and Parts (base model; optional equipment not shown)

ENGLISH

14

15

12 4 5

17

16

3

6

7

8

9

10

18

13

20

22

1 Handle

2 ON/OFF switch

3 Holder for Allen wrench 6 mm

4 Motor

5 Track arm guide bars

6 Track arm lock screw

7 Transport lock

8 Cutting depth limiter

9 Sawhead tilt lock lever

10 Hinged fence

11 Rotating table

1112

19

21

12 Table insert

13 Rotating table lock screw

14 Saw base

15 Fence

16 Retractable blade guard

17 Saw blade lock

18 Sawhead assembly

19 Flange guard

20 Dust spout adapter

(for connection of dust collector)

21 auxiliary fence

Tools

22 Allen wrench 6 mm;

use metric tools

adjusting, repairing or maintaining this machine

Machine documents

– Operating Instructions (with War-

ranty Terms and Conditions)

– Spare parts list

only when

5

Page 6

ENGLISH

Table of Contents

1. Components and Parts (base

model; optional equipment not

shown)..........................................5

2. Please Read First! .......................6

2.1 Symbols Used ...............................6

3. Safety ...........................................6

3.1 Specified Conditions of Use ..........6

3.2 General Safety Instructions...........7

3.3 Specific Safety Instructions ...........9

3.4 Labeling.......................................11

3.5 Safety Devices ............................11

4. Installation and transport .........12

5. Special Product Features .........12

6. Machine Details .........................12

7. Initial Operation.........................14

7.1 Connection of a Dust Collector ...14

7.2 Mains Connection .......................14

8. Operation ...................................14

8.1 Standard Crosscuts.....................15

8.2 Miter Cuts....................................15

8.3 Bevel cuts....................................16

8.4 Compound Miter Cuts .................1

8.5 Making Grooves ..........................17

8.6 Auxiliary Fence............................18

9. Care and Maintenance ..............18

9.1 Changing the Saw Blade.............18

9.2 Drive Belt Tensioning..................19

9.3 Kerf Plate Replacement ..............20

9.4 Adjustments ................................20

9.5 Cleaning ......................................21

9.6Storage........................................21

9.7 Maintenance................................21

10. Tips and Tricks..........................21

11. Available Accessories ..............21

12. Repairs.......................................21

13. Environmental Protection ........21

14. Trouble Shooting ......................21

15. Technical Specifications ..........22

electrical power tools. Inexperienced persons are strongly advised

to seek competent ad

ance from an experienced person

before operating this machine.

Keep all documents supplied with

this machine for future reference.

Retain proof of purchase in case of

warranty claims. For details on war-

ranty terms and conditions, refer to

chapter "Warranty Terms and

the

Conditions" at the beginning of this

manual.

This machine must not be sold or

lent to someone else without being

accompanied by these operating

instructions.

The manufacturer, its agents and

distributors assume no liability for

any personal injury to operating personnel or bystanders, damage to

property or damage to the machine

itself caused entirely or in part by

operational malfunction of the

machine resulting from the nonobservance of any operating or

instructions given in this man-

safety

6

ual.

2.1 Symbols Used

A DANGER

THE DESIGNATION DANGER, THE

GENERAL DANGER SIGN (SEE SIGN

ABOVE) AND THE OTHER TRIANGULAR DANGER SIGNS USED IN THIS

MANUAL INDICATE AN IMMINENTLY

HAZARDOUS SITUATION. FAILURE

TO ADHERE TO THE WARNING AND

THE INSTRUCTIONS GIVEN MAY

RESULT IN SEVERE PERSONAL

INJURY OR DEATH OF OPERATING

PERSONNEL.

OBSER

ALL TIMES AND BE EXTREMELY

CAREFUL!

VE THESE INSTRUCTIONS AT

vice and guid-

LAR WARNING SIGNS USED IN THIS

MANUAL INDICATE A HAZARDOUS

SITUATION. FAILURE TO

THE WARNING AND THE INSTRUCTIONS GIVEN MAY RESULT IN PERSONAL INJURY AND/OR PROPERTY

DAMAGE.

OBSERVE THESE INSTRUCTIONS AT

ALL TIMES.

ADHERE TO

A CAUTION

THE DESIGNATION CAUTION INDI-

CATES A HAZARDOUS SITUATION

AND ALERTS THAT FAILURE TO

ADHERE TO THE WARNING AND THE

INSTRUCTIONS GIVEN MAY RESULT

IN PROPERTY DAMAGE AND/OR

DAMAGE TO THE MACHINE.

OBSERVE THESE INSTRUCTIONS AT

ALL TIMES.

Note:

This symbol indicates additional and useful information for the efficient and

safe operation of the

machine.

At times numbers are used in illus-

trations (1, 2, 3, ...)

denote component parts;

are consecutively numbered;

relate to the corresponding

number(s) in brackets (1), (2), (3) ...

in the neighboring text.

Numbered steps must be carried out

in sequence.

Instructions

out in any order are indicated by a

bullet point (•).

Lists are indicated by a dash (–).

. These numbers:

which can be carried

2. Please Read First!

These operating instructions have been

written to

user, to learn how to operate this

machine and do so safely. These

instructions should be used as follows:

Read these instructions before use.

These operating instructions are

6

make it easier for you, the

When reading these instructions,

pay special attention to and always

follow all safety instructions.

intended for people with basic technical knowledge regarding the operation of a machine like this or similar

IN ADDITION, PAY ATTENTION TO

ALL OTHER APPLICABLE SAFETY

RULES AND REGULATIONS, REGULATIONS FOR ACCIDENT PREVENTION, OCCUPATIONAL SAFETY AND

HEALTH ADMINISTRATION (OSHA)

RULES AND REGULATIONS, ENVI-

ENTAL AND ALL OTHER FED-

RONM

ERAL, STATE AND LOCAL LAWS IN

EFFECT AT THE OPERATION SITE.

A WARNING

THE DESIGNATION WARNING, THE

GENERAL WARNING SIGN (SEE SIGN

ABOVE) AND THE OTHER TRIANGU-

3. Safety

3.1 Specified Conditions of

Use

This saw is intended for cross cuts,

bevel cuts, miter cuts, and compound

miter cuts of strips, framing lumber, profiles, moldings, etc. It is also possible to

make grooves. Please refer to chapter

15, "Technical Specifications", for the

per saw blade(s) for the materials

pro

you want to cut!

Do not cut materials and work pieces

unless they conform to the permissible

dimensions. See chapter 15, "Technical

Specifications", for more information

Page 7

regarding the permissible dimensions of

work pieces.

Do not cut pieces having an irregular

cross section, such as firewood,

because such pieces cannot be held

securely during cutting and pose serious

danger to the operator.

A suitable auxiliary fence must be

for firm support when cutting thin work

pieces in an upright position, such as

moldings.

Any use other than the use specified

above, any alteration, modification, use

of used spare parts, use of non-OEM

spare or replacement p

parts and components not specifically

approved by the manufacturer, may

cause unforeseeable danger, may result

in damage and/or personal injury. Any of

the above will void the machine warranty.

The manufacturer,

ies, distributors or dealers shall have no

liability whatsoever for injuries or damage caused entirely or in part through

use other than the use specified above,

any alteration, modification, use of used

pare parts, use of non-OEM spare or

s

replacement parts, use of other parts

and components not specifically

approved by the manufacturer.

arts, use of other

its agents, subsidiar-

used

3.2 General Safety Instructions

A DANGER

x All power tools carry with them

some degree of danger. Observe

the following safety instructions to

minimize this danger and to assure

the safe and efficient operation of

this machine.

x Do net let convenience or famili-

arity with this machine (resulting

from repeated use) lead to nonobservance of any safety rules.

If you are careless or use this

machine incorrectly you can suffer serious personal injuries.

General Danger

A DANGER

x Keep bystanders, particularly chil-

dren, at least 6 feet away from the

machine at all times.

x Children must never be allowed in

the work area. Do not let children

handle the machine, any tools or

the extension cord.

A WARNING

x Keep your work area clean at all

times. Always remove small wood

chips and small pieces from the

machine. A messy work area tends

to lead to accidents.

YOU CAN PREVENT ACCIDENTS!

x Be alert. Know what you are doing.

Set out to work with reason.

x DO NOT OPERATE THE

MACHINE WHILE UNDER THE

INFLUENCE OF ALCOHOL OR

DRUGS, INCLUDING PRESCRIPTION DRUGS AND OVER-THECOUNTER MEDICATION. SOME

PRESCRIBED DRUGS AND

SOME OVER-THE-COUNTER

MEDICATION MAY IMPAIR YOUR

ABILITY TO SAFELY OPERATE

THIS MACHINE. CONSULT YOUR

PHYSICIAN IF YOU TAKE

PRESCRIPTION DRUGS OR

YOUR PHARMACIST IF YOU

TAKE ANY OVER-THE-COUNTER

MEDICATION.

x Always choose a body position with

secure footing and proper balance

which allows you to operate the

machine without straining or reach-

too far.

ing

x Do not operate the machine near

inflammable liquids or gases.

x Do not permit other persons to

touch the machine or power cable

while it is running.

x Do not step on the machine.

x For ev

x Use this machine only in accord-

x After use

x Never store the machine outdoors,

ery job there are power tools

to do the job right and others that

are not really appropriate.

ance with the Specified Conditions

of Use. Please refer to chapter 3.1

for details.

, store the machine in a

dry and safe place where it cannot

be used or tampered with by any

unauthorized person or by children.

in unprotected areas or in damp

locations.

ANY

A CAUTION

x Make your work place safe. Only

operate the machine in well lit

places.

ENGLISH

A CAUTION

x Do not overload the machine. For

more information on the performance range and limitations of this

machine, see chapter 15, "Technical Specifications".

x Protect bystanders in your work

area from injury by flying sparks or

chips by keeping them at least 6

feet away from the machine.

x Remove the transport locking pin

before initial operation of the

machine.

Electricity

A DANGER

x Do not expose machine to rain.

Do not operate machine in damp or

wet environment.

x Position power supply cable so it

does not interfere with the work

and is not damaged.

x Do not operate machine with dam-

ged power cord.

a

x Make sure of sufficient lighting at

the work place.

A WARNING

x Do not use the power cable for pur-

poses it is not intended for.

x Use only suitable U.L. or CSA

approved extension cords. Minimum gauge:

cord length up to 50 ft:

AWG #12

cord length up to 100 ft:

AWG #10

x To reduce the risk of electric shock,

this equipment has a polarized plug

(one blade is wider than the other).

This plug will fit in a polarized outlet

only one way. If the plu

fit fully in the outlet, reverse the

plug. If it still does not fit, contact a

qualified electrician to install the

proper outlet. Do not change the

plug in any way.

g does not

7

Page 8

ENGLISH

A WARNING

x Before plugging the machine in,

check the voltage and cycle rating

(120 V, 60 Hz) on the nameplate of

the machine and make sure you

have a proper power source with

the same

qualified electrician for assistance.

x Be careful not to kink, squeeze or

pull the power cord and/or any

extension cord, and make sure that

you protect the cord(s) from dam-

age caused by rolling over

aggressive substances like acid, or

other potential damage arising at

the work site.

x If the power cord or an extension

cord is damaged, never try to repair

it, but have a qualified electrician or

other auth

replace the damaged cord.

rating. If not, consult a

, heat,

orized repair personnel

A CAUTION

x To avoid electrical shock, ensure

there is no contact with grounded

objects such as radiators, pipes,

ovens, refrigerators, etc. when

operating this machine.

x Ensure nobody can trip over or

inadvertently pull on the power

cord.

ver pull on the power cord to

x Ne

unplug the machine as this can

damage the cord and lead to a

hazard.

Risk of injury by moving parts

A DANGER

x Do not operate the machine with-

out installed guards.

x Make sure the power cord is

unplugged before servicing, troubleshooting or changing parts.

x Remove all tools and loose parts

from the machine before plugg

in and operating the machine after

service or troubleshooting.

x After completing a cut, do not let go

of the handle of the machine or

your work piece until all moving

parts of the machine have

a full stop.

come to

A WARNING

x When the machine is not in use,

switch it to OFF and unplug it.

ing

A WARNING

x Make sure your work pieces are

secured in place during cutting so

that they cannot move.

x Work stock only in the direction

intended for the machine.

x Do not exert exessive force on the

machine with the work piece.

x Never have the machine running

unattended. Turn power OFF.

Don't leave the machine until it

comes to a full stop.

Entanglement with the machine

A DANGER

Be careful that no part of your body or

your clothing can be caught by and

pulled into the machine.

x Do not wear any loose clothing.

x Do not wear any gloves.

x Long hair has to be covered (for

example by

then tucking the hair in under a cap

or hat).

x Dangling jewelry, rings, bracelets,

necklaces and other personal items

which might get caught in the

machine have to be removed

efore starting to work with this

b

machine.

Insufficient personal protection gear

making a pony tail and

A WARNING

x Use eye protection. Always wear

ANSI approved impact safety goggles. If you are producing metal filings or wood chips, wear a full face

shield.

x Use ear protection. Always wear

ANSI approved ear

as ear plugs or ear muffs.

x Use respiratory protection when

working around metal, wood, espe-

cially treated wood, chemical dusts

or mists. Always wear an ANSI

approved dust mask or respirator

or other respiratory protection in

accordance

MSHA and NIOSH regulations.

x Wear head protection if required by

your type of work or by regulations

applying to the job site.

x Wear protective, electrically non-

conductive clothes and non-skid

foot wear.

with current OSHA,

protection such

A CAUTION

x Wear suitable work clothes.

x When working outdoors wearing

of non-slip shoes is recommended.

x Ensure a fire extinguisher is within

reach.

Dust

A DANGER

x DO NOT CUT ANY HAZARDOUS

MATERIALS OR MATERIALS

THAT CONTAIN HAZARDOUS

SUBSTANCES OR HAVE BEEN

TREATED WITH HAZARDOUS

SUBSTANCES.

A WARNING

x Some types of wood dust (e.g.

maple, oak, cedar) may cause

allergic reactions and other health

problems such as skin rashes, etc.

If possible, work with a suitable

dust collector connected to the

saw. The dust collector must com-

y with the data stated in chapter

pl

15, entitled "Technical Specifications".

x Dust generated by sawing, sand-

ing, drilling and similar work may

contain substances that are known

or suspected to cause cancer,

damage to reproductive organs

and/or the

or may cause damage to fetuses

and unborn children. Lead, lead

paint, arsenic or chromium treated

wood (often referred to as "green

wood" or pressure-treated lumber)

and quartz dust or silica from concrete are just some, but in no case

an e

stances. The actual health risk

depends on the length of exposure

to these substances, the circumstances as well as the degree of

respiratory and other protection

used.

ability to procreate, and/

xclusive list of such sub-

8

Page 9

A WARNING

x Minimize the amount of wood dust

escaping from the machine and the

job site:

Remove dust deposits from the

work area. DO NOT BLOW THE

DUST AWAY WITH COM-

PRESSED AIR BECAUSE THIS

WILL ONLY SPREAD THE

DUST RATHER THAN REMOV-

ING IT.

Make sure the dust collector is

leak free and repair any leaks

immediately.

Keep your work area well venti-

lated at all times.

Modification of the machine and use

of non-OEM parts or parts not tested

nor approved by the manufacturer

A DANGER

x Unauthorized changes and/or mod-

ifications affect machine safety and

are not allowed. The manufacturer

disclaims any liability for any damage or injuries resulting from

changes or modifications or from

the use of non-OEM parts. The use

of any parts

approved by the manufacturer

voids the warranty of the machine.

not supplied or

A WARNING

x Follow all instructions given in this

manual strictly when you assemble and start up the machine.

Defects and malfunctions

A DANGER

x Keep the machine and all accesso-

ries in good, clean and safe working condition. Strictly observe all

maintenance instructions contained

in this manual.

x Before every use of this machine

check for possible damage. Every

time you want to

make sure that all safety devices

and protective guards are undamaged and fully operational.

x Check that all moving parts operate

smoothly and without jamming.

x Make sure that all parts and acces-

are properly installed and

sories

safely secured to ensure the safe

and trouble-free operation of the

machine.

use the machine

A DANGER

x Any damaged parts or protection

devices must be replaced by fully

qualified and factory authorized

personnel only.

x Damaged switches may only be

replaced at a factory authorized

service center. For information on

the service center nearest you

refer to the information contained in

"Warranty Terms and Conditions"

at the beginning of this manual.

x NEVER OPERATE THE MACHINE

IF THE ON/OFF SWITCH IS DAMAGED!

x If the machine is not working prop-

erly, mark or tag it accordingly and

en move it to a safe place where

th

it cannot be used inadvertently, or

by unauthorized persons or any

children.

Noise

A WARNING

x Prevent hearing loss! Use ear pro-

tection. Always wear ANSI

approved ear protection such as

ear plugs or ear muffs.

Contamination upon contact

A WARNING

x The insulation of power cords may

contain substances that are known

or suspected to cause cancer,

damage to reproductive organs

and/or the ability to procreate, and/

or may cause damage to fetuses

and unborn children.

Wash your hands

soap and water every time after

touching the power cord.

Grounding and insulation

thoroughly with

A DANGER

x Fully insulated machines have a

special plug. Consult an electrician

if you do not have a matching outlet.

x Do not tamper with the plug or the

outlet yourself. Consult a qualified

electrician for assistance.

ENGLISH

3.3Specific Safety Instruc-

tions

A DANGER

x When using this machine, observe

the following safety instructions to

avoid the risk of personal injury or

property damage.

,

Lack of experience and expertise with

compound miter saws

A WARNING

x PAY ATTENTION TO AND FOL-

LOW, WHERE APPLICABLE, ALL

SAFETY RULES AND REGULA-

TIONS, REGULATIONS FOR

ACCIDENT PREVENTION,

OCCUPATIONAL SAFETY AND

HEALTH ADMINISTRATION

(OSHA) RULES AND REGULA-

TIONS, ENVIRONMENTAL AND

ALL OTHER FEDERAL, STATE

AND LOCAL LAWS IN EFFECT

AT THE OPERATI

THEY APPLY TO MITER SAWS.

x This machine shall only be oper-

ated by persons familiar with miter

saws, their operation and the specific risks associated with the operation of miter saws.

x Contact your supervisor,

or any other qualified individual in

case you lack substantial experience and expertise regarding the

operation of miter saws.

Personal injury inflicted by track arm

holder and sawhead assembly

ON SITE, AS

A WARNING

x Hold the handle firmly when you

start the cutting operation. The risk

of the sawhead being kicked up is

particularly high at the moment

when the saw blade makes its first

contact with the work piece.

x If you tilt th

the side, hold it at the handle and

keep your fingers away from the

track arm holder and out of its tilting range.

x Avoid lateral pressure on the saw-

head when making grooves. Use

clamps to firmly position your work

piece and secure it against acci-

dental movement.

e sawhead assembly to

instructor

9

Page 10

ENGLISH

A CAUTION

x Hold the handle of the sawhead

firmly because the momentum

generated by the motor may

cause the sawhead to move

slightly up or down at start-up.

x Transport the machine only if it is

locked securely in

tion. To lock the machine for

transport, lower the sawhead and

push in the transport locking pin.

x Do not carry the machine by the

handle; the handle is not designed

to bear the weigh

When carrying the machine, hold

it on both sides of the base.

x Be careful to avoid the risk of con-

tusion. Fingers may be squeezed

and in extreme cases crushed

between the

lever and the track arm holder.

Always position the tilt lock lever

(by pulling it out and turning) so

that there is sufficient space

between the lock lever and the

track arm holder.

Accessories and consumables

transport posi-

t of the machine.

sawhead tilt lock

A DANGER

x Use only parts approved by the

manufacturer. This applies in particular to saw blades and safety

devices listed in chapter 15, "Technical Specifications".

A WARNING

x Never use grinding or cut-off

wheels instead of saw blades.

Insufficient care

A WARNING

x Keep the machine clean and in

good working condition at all times.

In particular, keep all handles and

adjustment knobs, etc., free of

grease and oil.

Hot saw blade

A WARNING

x Cutting causes friction and gener-

ates heat. Immediately after cutting, the saw blade may be very hot

and pose a fire hazard.

x Always let the saw blade cool

down, especially before touching it.

x Do not clean a hot saw blade with

bustible liquids.

com

Personal injury by damaged saw

blades

A DANGER

x Do not use blunt, damaged or

warped saw blades.

x Never attempt to cut any work

pieces which contain

ropes,

strings,

cords,

cables,

wires, or work pieces to which

any of the above are attached.

x Wh

ere applicable or when in doubt,

always check the work piece for

screws, nails or any other matter

which may be embedded.

A WARNING

x Do not use any cleaning agents

that contain acids or caustic or corrosive substances which would

tend to corrode the light metal components of the machine. The stability and safety of the machine could

be compromised if

stances were used for removing

resin residue.

x If resin residue is to be removed,

use a clean cloth.

Work piece kickback

such sub-

A WARNING

x Make sure the saw blade is suita-

ble for the material of the work

piece you are cutting.

x Cut thin or thin-walled work pieces

only with fine-toothed saw blades.

x Make sure thin or thin-walled work

ieces are supported over their

p

entire length.

x Ensure proper feeding of work

pieces:

Place work piece on turntable

only when the sawhead assembly is fully raised.

Always hold the work piece

against the fence wh

x Always use sharp saw blades.

Replace blunt saw blades immediately. When a blunt, dull or otherwise damaged saw blade it used,

the risk that a blunt tooth is caught

by the work piece’s surface, rath

than cutting through it, increases,

and so does the risk of work piece

kickback, which poses a great dan-

ger of injury to the operator of the

machine.

en cutting.

A WARNING

x Cut only work pieces that have

dimensions which allow them

safely and securely held (or

clamped) during cutting.

x Long work pieces require support.

x Do not cut bundles or more than

one work piece at a time. When

bundles or more than one work

piece are cut at the same time, t

individual pieces cannot be properly secured and controlled and

once they then come in contact

with the saw blade serious personal injury may occur.

x Do not jam work pieces.

x Release the ON/OFF switch imme-

diately if the saw blade

Unplug the machine. Carefully

remove the jam. Plug the machine

in again. Continue sawing.

x Make sure that when starting up

the machine the saw blade does

not have any contact with the wor

piece because otherwise dangerous kickback may result.

x Never try to slow the saw blade

down or stop it by pushing the work

piece against the saw blade from

the side.

Cuts and cut-off limbs

to be

he

jams.

k

A DANGER

x Be very careful at all times.

x Always keep sufficient distance to

the saw blade.

x Always keep sufficient distance to

all moving or driven components.

A WARNING

x Make sure that the saw blade has

come to a complete standstill

before changing any settings or

moving the work piece.

x Always remove small wood chips

and small pieces from the machine.

Messy work areas can

dents. To remove small wood chips

and small pieces, wait until the saw

blade has come to a complete

standstill. Unplug the machine.

x Carefully remove the small pieces.

er

Plug the machine in again. Con-

with the work.

tinue

x Never fix the ON/OFF switch in the

pressed in (= ON) position. The

switch is supposed to snap back

into the OFF position after being

released.

lead to acci-

10

Page 11

ENGLISH

A WARNING

x Make sure all adjustment and set-

ting devices are securely tightened

before starting the machine.

x Make sure that the machine is on a

level and solid surface to prev

tipping over. All four feet must be

securely on the surface before you

can use the machine.

x If something goes wrong, e.g. a

jam occurs, make sure that all

safety devices are put in place

again after the problem

or the jam is elimated, etc., and

that all safety devices are fully

operational again before you start

up the machine.

Incorrectly installed saw blade

is resolved

ent

A WARNING

x Make sure the inner blade flange is

correctly fitted. Otherwise the saw

may jam or the saw blade may

work itself loose!

x Do not use loose-fitting reducing

rings; the saw blade could work

loose.

x Make sure the sa

installed correctly. Saw blades

must be installed so that they do

not wobble, that they run balanced

and that they do not work themselves loose.

Cuts and scratches from non-moving

saw bladel

w blade is

A WARNING

Even when standing still, the saw blade

is a source of potential injury, especially

when the blade needs to be changed.

To avoid injury:

Do not use excessive force

when tightening the arbor nut.

Do not extend your wrench to

get more leverage.

Do not hit your wrench with a

hammer to tighten the arbor bolt.

Electricity

A WARNING

x Make sure the power cord does not

come in contact with the running

saw blade.

3.4 Labeling

All warning labels affixed to the machine

are listed at the end of these instructions. Contact the manufacturer if labels

are missing or illegible.

Symbols on the machine

Danger!

Non-observance of the

following warnings may

cause serious personal

injury or property damage.

Read instructions.

Do not reach into the run-

ning saw blade.

safety goggles and

Wear

ear protection.

Do not operate the machine

in a damp or wet environment.

Do not carry the

machine by the handle; the handle is not

designed to bear the

weight of the

machine.

Information on the nameplate:

23

24

25

26

(28) UL Mark with UL - number–

machines cfarrying this symbol

meet the safety requirements of

Underwriters’ Laboratories, Inc.

UL number of this machine:

E250735

(29) Dimensions of permissible saw

blades

3.5 Safety Devices

Retractable blade guard

The retractable blade guard (30) protects against accidental contact with the

saw blade and from chips flying about.

The retractable blade guard must always

return automatically into its starting position when the sawhead is lifted. The

saw blade must be covered.

entire

NEVER DISABLE THE AUTOMATIC

RETRACTING MECHANISM!

30

Flange guard

The flange guard (31) protects against

accidental contact with the outer blade

flange.

31

A CAUTION

x Alwa ys wear protective gloves

when you change the saw blade.

x Store the saw blade(s) in a safe

place and in such a manner that

nobody can get hurt, e.g. put the

saw blade(s) in protective

board sleeves.

card-

27

(23) Manufacturer

(24) Serial number

(25) Model number

(26) Motor specifications (see also

"Technical specifications")

(27) Date of manufacture

28

29

Padlock hole

A hole (32) in the ON/OFF switch enables the

lock.

blocking of the switch by a pad-

11

Page 12

ENGLISH

32

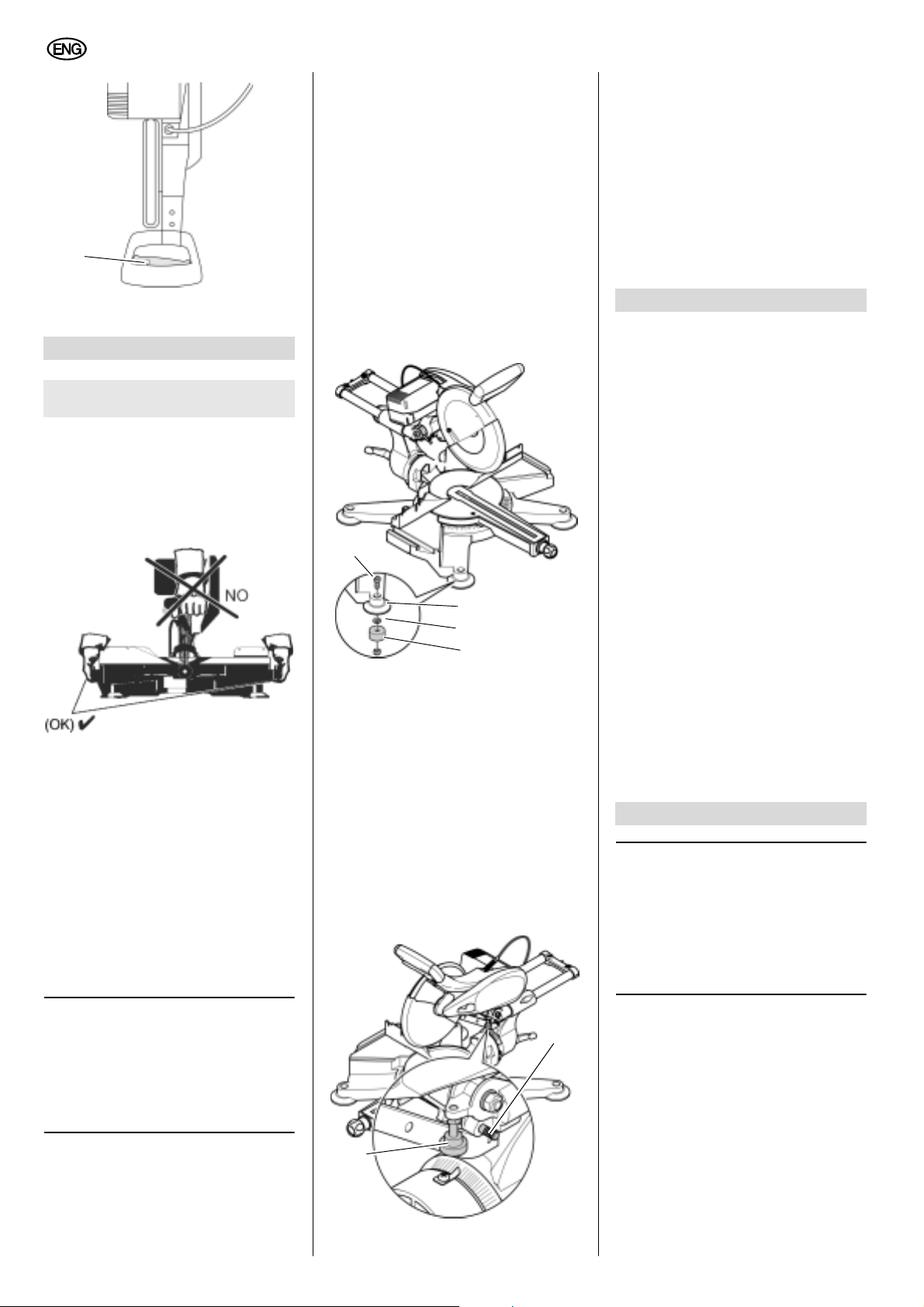

4. Installation and transport

A CAUTION

Do not carry the machine by the

handle; the handle is not designed

to bear the weight of the entire

machine. When carrying the

machine, hold it on both sides of

the base.

Installation

1. The machine is heavy. Carefully lift

it out of its shipping carton with the

help of another person.

(The manufacturer recommends

that you keep the shipping carton

and all packing materials in case the

machine needs to be

service or repair. If you discard the

packing materials, do so in observance of and in compliance with all

environmental laws, rules and regulations regarding disposal and recycling that apply at y

shipped for

our site.)

Before proceeding, be sure that

the machine is standing firmly in

place even while ti

3. Fit the nut (36) into the hole on the

bottom of the rubber foot.

4. Insert the Allen head screw (33) into

the machine’s foot from the top. Fit

the washer (34) on the screw (33)

and attach the rubber foot (35) with

the previously inserted nut (36) to

the screw (33) by hand and start to

tighten.

5. To do so hold the screw (33) with

the 6mm Allen wrench.

6. Hand tighten only!

33

7. Place the machine on a flat and

sturdy surface, large enough to

allow for all necessary movements

and adjustments.

All four feet must firmly rest on

the base.

The ideal height for the base is

32 inches.

The machine must remain stable,

in particular when cutting work

pieces which could cause it to tip.

8. Push the sawhead assembly slightly

down and pull the transport locking

pin (37) out.

pped over.

34

35

36

Transport

1. The transport lock

be inserted for transport.

2. Depending on what kinds of cuts

were made previosuly, it may be

necessary to adjust the limit screw

(38) for the adjustment of the cutting

depth. This allows th

be fully lowered, after which the

transport locking pin (37) can then

be inserted.

ing pin (37) must

e saw head to

5. Special Product Features

96q cutting angle range for bevel

cuts (48q left through 48q right) with

five preset stops.

110q cuttin

cuts (50q left through 60q right) with

ten preset stops.

Soft start.

Cutting depth adjustment for making

grooves with integrated limit screw.

Easy mobility due to lightweight

struction.

Precise and sturdy die-cast alumin-

ium construction.

TCT saw blade.

Easy saw blade change. The saw

blade can be held with the saw

blade lock. No disassembly of the

protective devices required.

Maximum cutting depth

Maximum cutting width 11 1/4".

Ergonomic and easy for both left-

handed and right-handed operation.

Installation of auxiliary fence possi-

ble.

g angle range for miter

con-

3 3/16".

6. Machine Details

Note:

3

In this chapter the essential operating elements of the machine are introduced.

The proper use of the machine is

described in chapter 8, "Operation".

Read this chapter in its entirety before

using the saw for the first time.

Note:

3

Do not install rubber feet if the

machine is going to be mounted on the

optional machine stand. The machine

stand is not included in standard delivery, but can be purchased separately.

For more information, see chapter 11.

2. Turn the machine over to install the

rubber feet:

The feet must be accessible from

all directions.

12

38

37

ON/OFF switch

x To turn the motor on, press and hold

the ON/OFF switch (39) in the handle. To stop the motor, release the

ON/OFF switch.

Page 13

A WARNING

Ensure all setting devices are fully

tightened before making a cut.

ENGLISH

Hinged fence

The hinged fence (44) permits the saw-

head assembly to tilt up to 48° to the

right for bevel cuts.

39

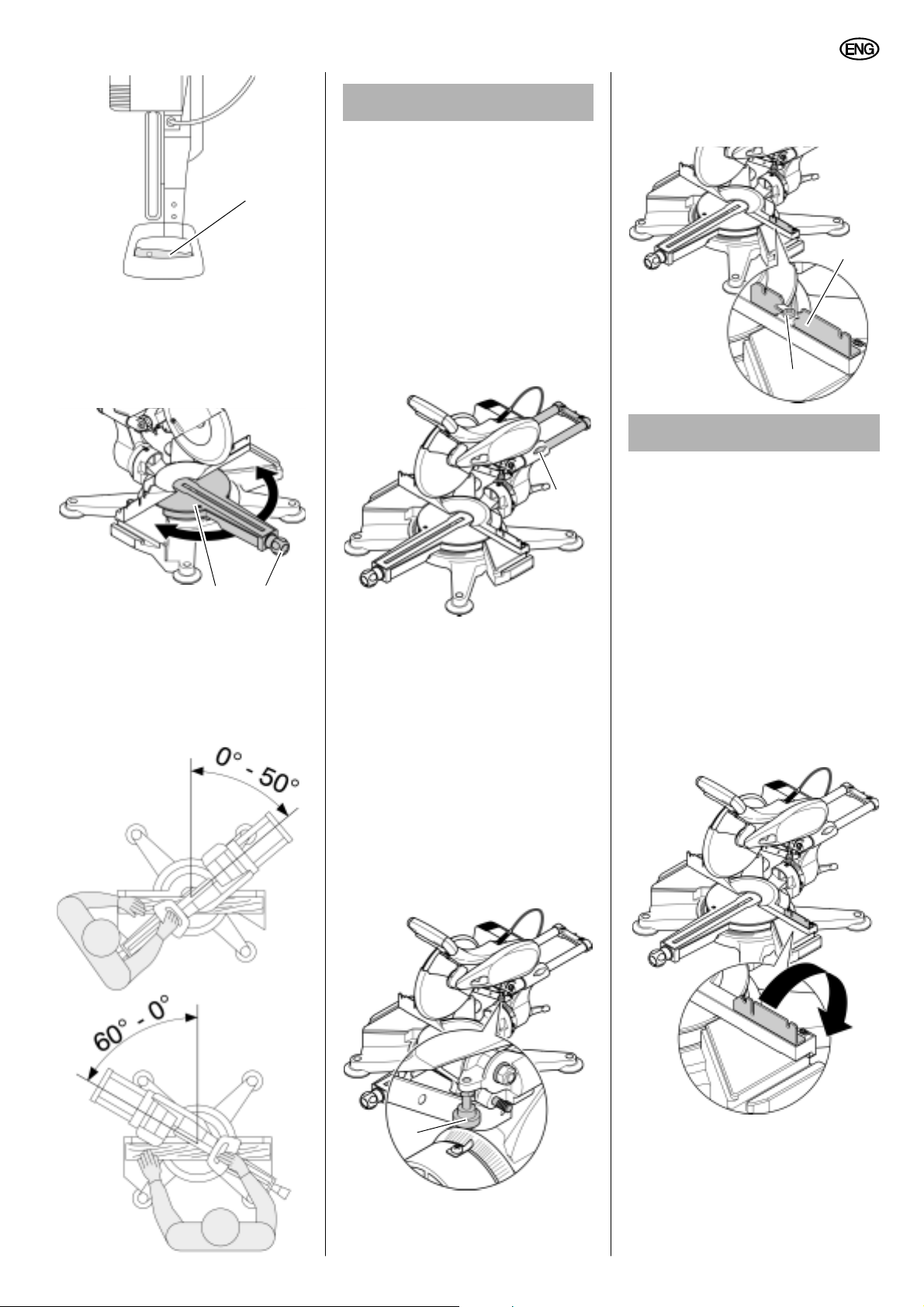

Rotating table

To make miter cuts, loosen the rotating

table lock screw (41) and turn the rotating table (40) to the desired position.

The turning range is 50° to the left and

60° to the right.

40 41

The rotating table en

stops and engages at the 0°, 15°, 22.5°,

30°, 45°, and 60° positions.

After selecting the desired angle,

TIGHTEN THE ROTATING TABLE

LOCK SCREW (41) before you start to

cut.

gages at preset

To prevent the miter angle from chang-

ing while cutting, the rotating table lock

screw must be securely tightened even if

you are using one of the preset stops

( 0°, 15°, 22.5°, 30°, 45°, or 60°).

Push/pull action

The track arm permits the cutting of work

pieces having a larger cross section.

The track

(standard cross cuts, miter cuts, bevel

cuts, compound miter cuts).

When making smaller cuts not requiring

the track am, lock the track arm in position with the track arm lock screw (42).

Adjusting the cutting depth

The cutting depth can be adjusted at the

limit screw (43).

After adjusting the cutting

sure that the limit screw is securely fastened before you proceed with your

work.

If you want to make grooves, adjust the

cutting depth at the limit screw (43),

secure the limit screw adjustment,

loosen

make your grooves as desired.

can be used for all type of cuts

42

depth, make

the track arm lock screw and

44

45

A WARNING

Secure the work piece against slip-

ping off while being worked.

To provide firm support for the wor

piece (as much supporting area as pos-

sible), the hinged fence is to be used as

follows:

x Whenever possible, for example for

straight cuts, it should be up and be

firmly secured in place with the Phil-

ead screw (45).

lips h

x If the sawhead assembly is tilted

between 22.5° and 48° to the right,

the hinged fence might be in the

way. In this case, loosen the Phillips

head screw (45) and swing the

hinged fence to the rear.

k

43

x If the sawhead assembly is tilted

between 0° and 22.5° to the right

OR between 0° and 48° to the left,

the hinged fence does not interfere

with operation: loosen the Philli

head screw (45), swing the hinged

fence up and then tighten the Phillips head screw (45).

ps

13

Page 14

ENGLISH

Bevel tilt setting

After loosening the tilt lock lever (46) at

the rear, the sawhead assembly can be

tilted continuously to any setting

between vertical (0°) up to 48° from vertical, both to the left and the right sides.

46

A CAUTION

There is a risk of crushing your fingers between the tilt lock lever and

the track arm holder. Always position the tilt lock lever (by pulling it

out and turning) so that there is sufficient space between the lock lever

and the track arm holder.

A WARNING

Ensure all setting devices are fully

tightened before making a cut.

Once you have found your desired tilt

angle, TIGHTEN THE TILT LOCK

LEVER (46) before starting to cut, so

that the angle setting does not change,

even if you are using one of the preset stops at 0°, 22.5 °, or 45°.

7. Initial Operation

7.1 Connection of a Dust Collector

A WARNING

Some types of wood dust (e.g.

maple, oak, cedar) may cause allergic reactions and other health problems, including but not limited to

skin rashes and other skin problems. If possible, work with a suitable dust collector connected to the

saw. The dust collector must comply

with the data stated in chapter 15,

entitled "Technical Specifications".

Dust spout adapter installation

x Before a dust collector can be con-

nected, the dust spout adapter (47),

which comes with the machine,

must be installed on the machine by

pushing it into its holder as illustrated.

7.2 Mains Connection

A DANGER

x Do not expose machine to rain.

Do not operate the machine in a

damp or wet environment.

x Make sure that the power cord is

out of the way, so that it does

not interfere with the work and

does not pose a tripping hazard.

A WARNING

x Before plugging the machine in,

check the voltage and cycle rating (120 V, 60 Hz) on the nameplate of the machine and make

sure you have a proper power

source with the same rating.

Only operate the machine if you

have the correct power source!

x Connect to properly installed

und grounded outlets only.

x Be careful not to kink, squeeze

or pull the power cord and/or

any extension cord.

Protect the cord(s) from damage

caused by objects rolling over

them, heat, aggressive substances

such as acid, or other potential

damage arising at the work site.

x Use only suitable U.L. or CSA

approved extension cords. Minimum gauge:

cord length up to 50 ft:

AWG #12

cord length up to 100 ft:

G #10

AW

x Do not pull on the power cord to

unplug the machine. This can

damage the cord and lead to a

hazard.

The track arm holder

and engages at the 0°, 22.5°, and 45°

positions.

has preset stops

14

47

8. Operation

A DANGER

x Before using the machine

always check for possible damage. Every time you want to use

the machine make sure that all

safety devices and protective

guards are undamaged and fully

operational.

x Any damaged parts or protection

devices must be replaced by

fully qualified and factory

authorized personnel BEFORE

THE MACHINE CAN BE USED.

Page 15

A WARNING

x Use eye protection. Always wear

ANSI approved impact safety

goggles. If you are producing

metal filings or wood chips, wear

a full face shield.

x Use ear protection. Always wear

ANSI approved ear protection

such as ear plugs or ear muffs.

x Use respiratory protection when

working around metal, wood,

especially treated wood, chemical dusts or mists. Always wear

an ANSI approved dust mask or

respirator or other respiratory

protection in accordance with

current OSHA, MSHA and NIOSH

regulations.

x Wear head protection if required

by your type of work or by regulations applying to the job site.

x Wear protective, electrically non-

conductive clothes and non-skid

foot wear.

x Safeguard your work piece and

secure it against unintended

movement and slipping during

cutting. Use support for long

work pieces which would otherwise fall off the machine’s rotating table after the cut. Use the

auxiliary fence for cutting small

pieces.

x If possible, work with a suitable

dust collector connected to the

saw. The dust collector must

comply with the data stated in

chapter 15, entitled "Technical

Specifications".

x Cut only work pieces that have

dimensions which allow them to

be safely and securely held (or

clamped) during cutting.

x Do not jam work pieces.

x Never try to slow the saw blade

down or stop it by pushing the

work piece against the saw

blade from the side.

x Avoid strained body positions

and over-reaching. Assume

proper operating position:

in front of the machine with

body positioned for normal

operation;

directly in front of the saw;

to the side of the machine.

A WARNING

x When tilting the sawhead assem-

bly to the side, hold the sawhead

by the handle and keep your fingers away from the track arm

holder and out of its tilting

range.

x Do not reach under the rotating

table when adjusting the miter

angle.

x After each cutting operation

return the track arm to its rear

starting position.

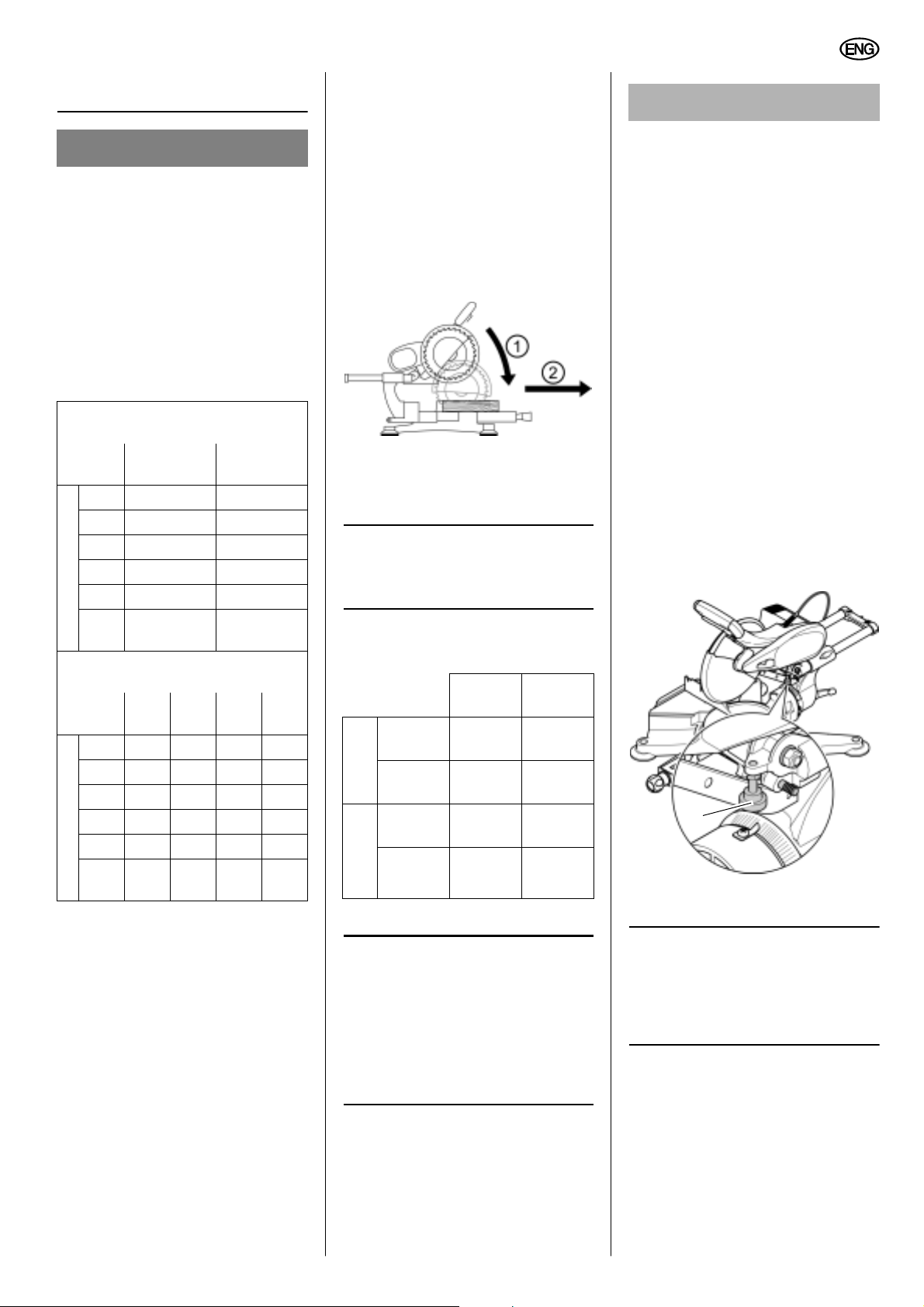

8.1 Standard Crosscuts

For standard crosscuts the maximum

dimension (inches) of the work pieces

are:

Width approx.11 7/32

eight approx.3 3/16

H

Starting position:

Transport locking pin pulled out.

Sawhead assembly fully raised.

Cutting depth limit screw set to max-

imum depth. Limit screw is securely

tightened.

Rotating table in 0° position, the lock

screw of the rotating table is

securely tightened.

Sawhead assembly is in vertical (0°)

position, bevel tilt lock lever tight-

ened.

Hinged fence on top of the fence

and secured.

Track arm not extended.

Lock screw of the track arm loos-

ened (only if required, such as when

cutting a wide work piece).

Cutting the work piece:

1. Hold the work piece against the

fence.

2. Press and hold the ON/OFF switch .

3. Slowly swing the sawhead assembly

all the way down, holding the handle

firmly. When sawing exert only moderate pressure. This keeps the

motor speed from dropping.

4. For wider work pieces pull sawhead

assembly forward (towards the

operator).

5. Cut work piece in a single pass.

ENGLISH

6. Release the ON/OFF switch and let

the sawhead slowly return to its

upper starting position.

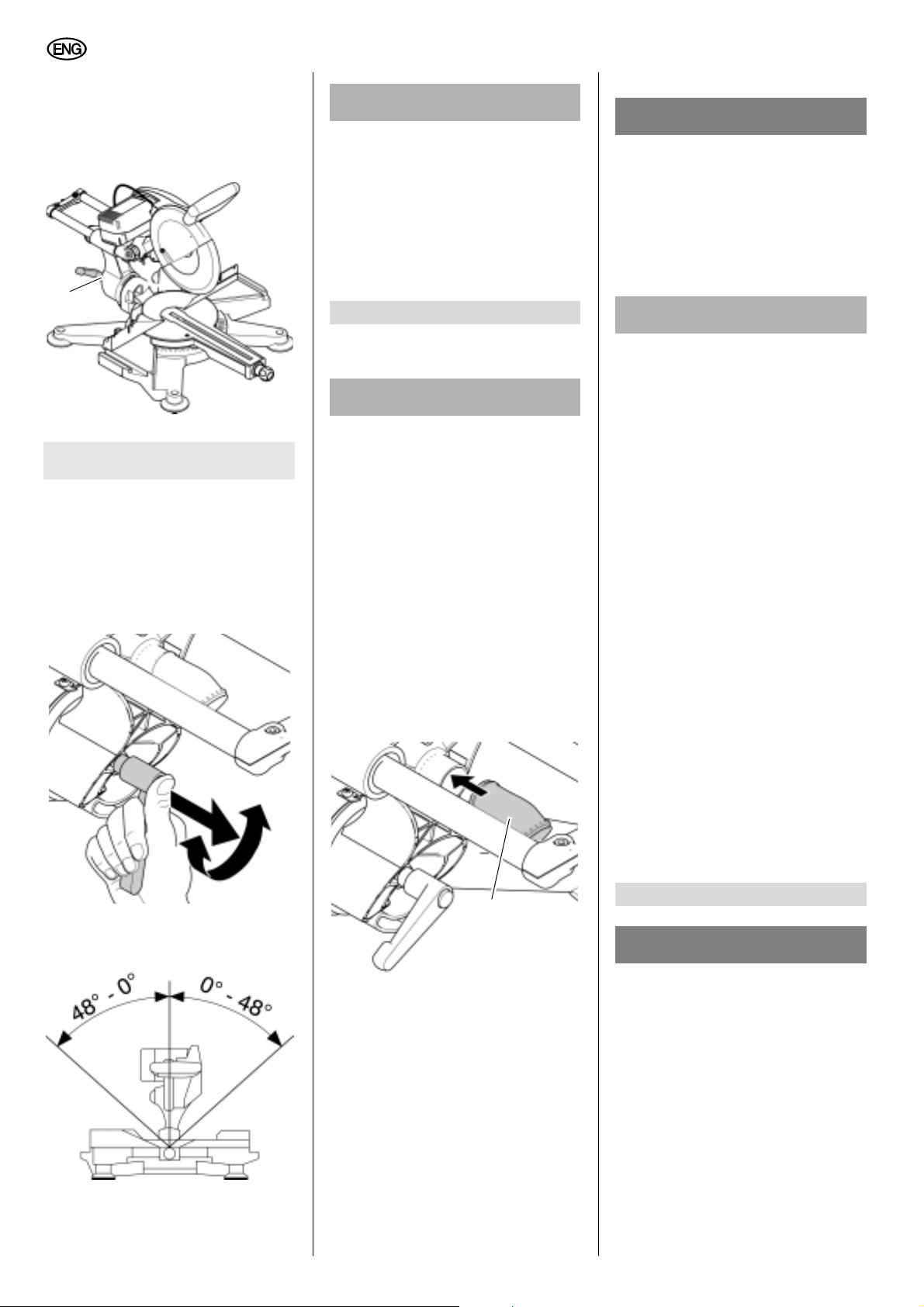

8.2 Miter Cuts

Note:

3

A miter cut cuts the work piece at

an angle to the fence.

The maximum work piece dimensions

for miter cut angles are shown in inches

in the table below:

Width

approx.

15° 10 13/16 3 3/16

22.5° 10 1/4 3 3/16

30° 9 5/8 3 3/16

45° 7 7/8 3 3/16

50° 7 1/16 3 3/16

60 °

right

Rotating table position

Starting position:

Sawhead assembly fully raised.

Cutting depth limit screw set to max-

imum depth. Limit screw is securely

tightened.

Sawhead assembly is in vertical (0°)

position, bevel tilt lock lever tight-

ened.

Hinged fence on top of the fence

and secured.

Track arm not extended.

5 1/2 3 3/16

Height

approx.

15

Page 16

ENGLISH

Lock screw of the track arm loos-

ened.

Cutting the work piece:

1. Loosen the lock screw (49) of the

rotating table (48).

48 49

2. Turn the rotating table (48) to either

the right or left to desired angle.

Note:

3

The rotating table has preset

stops and engages at the 0°, 15°, 22.5°,

30°, 45°, and 60° positions.

3. Once you have found your desired

angle, TIGHTEN THE ROTATING

TABLE LOCK SCREW (49), before

starting to cut, even if you are

using one of the preset stops (0°,

15°, 22.5°, 30°, 45°, or 60°).

4. Hold the work piece against the

fence.

5. Press and hold the ON/OFF switch .

6. Slowly swing the sawhead assembly

all the way down, holding the handle

firmly. When sawing exert only moderate pressure. This keeps the

motor speed from dropping.

7. For wider work pieces pull sawhead

assembly forward

operator).

8. Cut work piece in a single pass.

9. Release the ON/OFF switch and let

the sawhead slowly return to its

upper starting position.

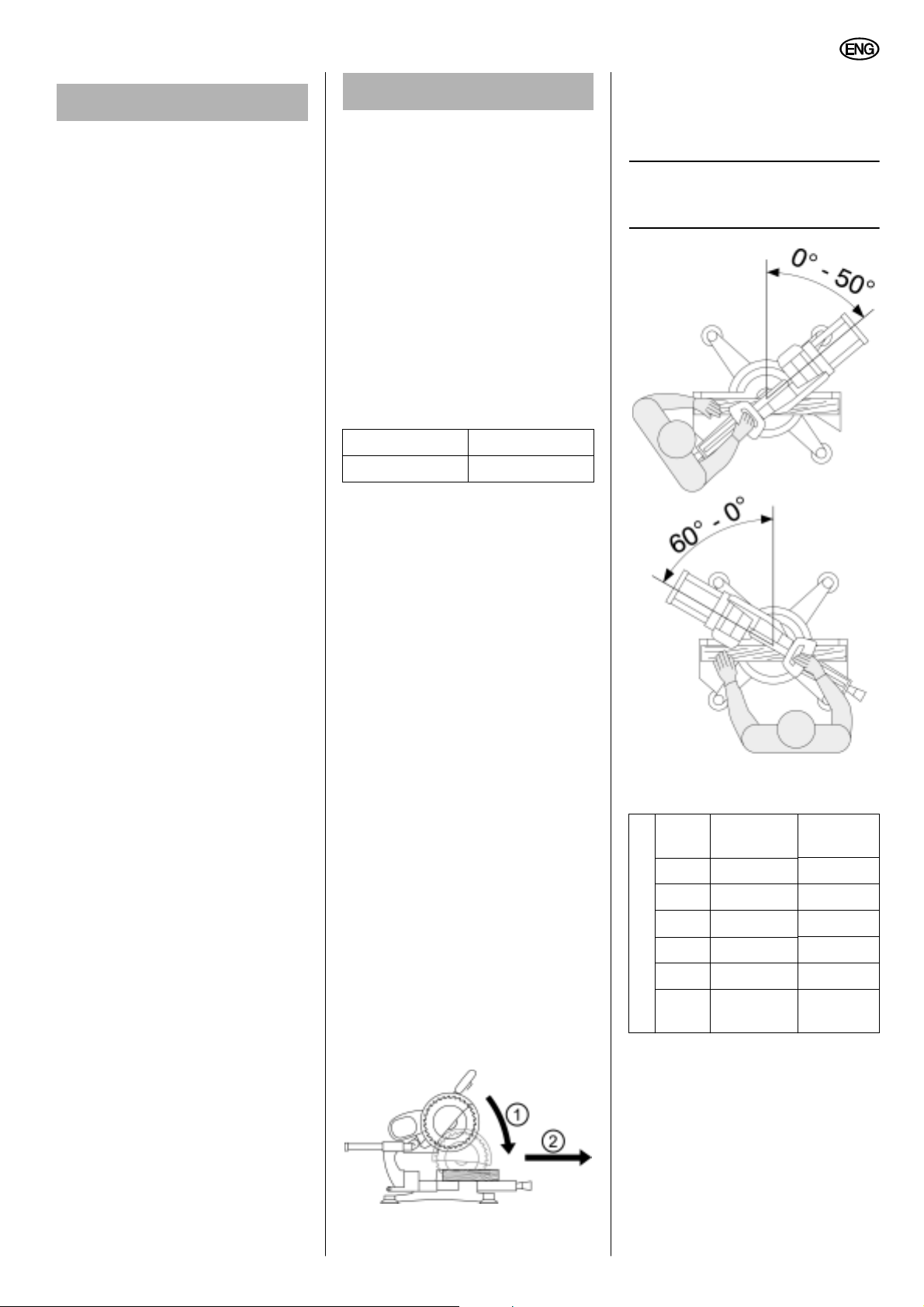

8.3 Bevel cuts

Note:

3

A bevel cut cuts the work piece at

an angle other than 90°.

(towards the

Maximum work piece cross section

(dimensions in inches):

Width

approx.

22.5°

left

22.5°

right

45 °

left

45 °

right

48 °

left

48 °

right

Angle of sawhead assembly

Starting position:

Sawhead assembly fully raised.

Cutting depth limit screw set to max-

imum depth. Limit screw is securely

tightened.

Rotating table in

screw of the rotating table is

securely tightened.

Track arm not extended.

Lock screw of the track arm loos-

ened.

Cutting the work piece:

1. If the sawhead assembly is tilted

between 22.5° and 48° to the right:

loosen the Ph

swing the hinged fence to the rear.

2. Loosen the sawhead assembly tilt

lock lever (50) at the rear of the

machine so that the sawhead

assembly can be tilted to the

11 7/32 2 3/4

11 7/32 2 9/16

11 7/32 2 1/8

11 7/32 1

11 7/32 1 3/4

11 7/32 13/16

0° position, the lock

illips head screw and

Height

approx.

side.

50

3. Grip the handle and slowly tilt the

sawhead assembly to the desired

position.

Note:

3

The track arm holder has preset

stops and engages at the 0°, 22.5°, and

45° positions.

4. Once you have found your desired

angle, TIGHTEN THE SAWHEAD

TILT LOCK LEVER (50)before starting to cut, even if you are using

one of the preset stops (0°, 22.5°

or 45°).

5. Hold the work piece against the

fence.

6. Press and hold the ON/OFF switch .

7. Slowly swing the sawhead assembly

all the way down, holding the handle

firmly. When sawing exert only moderate pressure. This keeps the

motor speed from dropping.

8. For wider work pieces pull sawhead

assembly forward (towards

operator).

9. Cut work piece in a single pass.

10. Release the ON/OFF switch and let

the sawhead slowly return to its

upper starting position.

the

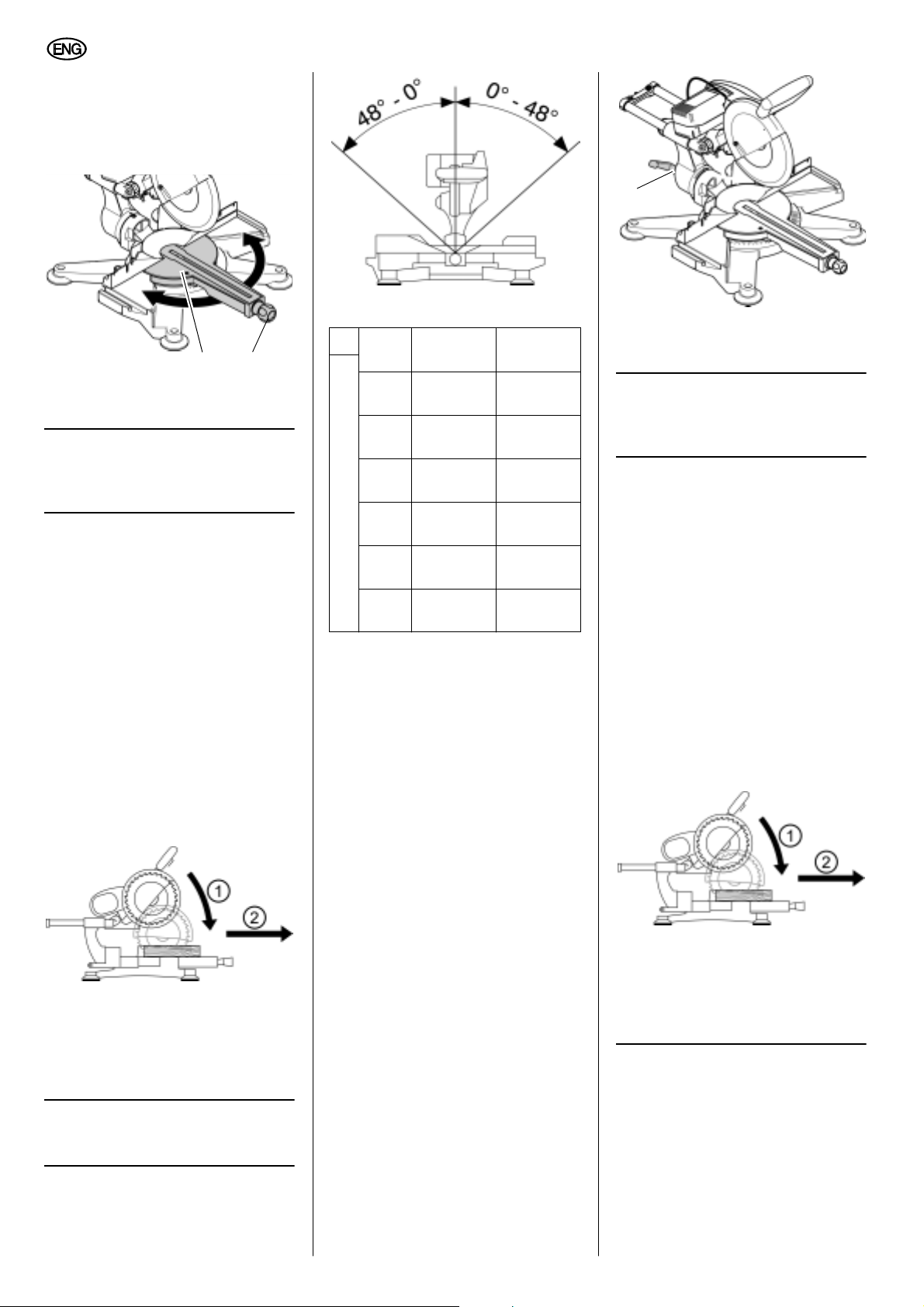

8.4 Compound Miter Cuts

3

Note:

A compound miter cut is a combination of the miter and bevel cuts. This

means that in a single pass the work

16

Page 17

ENGLISH

piece is cut at an angle other than 90° to

the fence and material surface.

A DANGER

When making compound miter cuts

the saw blade is much more exposed

than during normal cuts and so the

risk of injury increases. Always stay

a sufficiently safe distance away

from the saw blade.

For compound miter cuts the maximum

dimensions of the work pieces depends

on both cutting angles - the angle of the

rotating table and the tilt angle of the

sawhead. These are s

below.

Work piece width (in.) with sawhead

assembly tilted approximately

left and right

15° 10 13/16 10 13/16

22.5° 10 1/4 10 1/4

30° 9 5/8 9 5/8

45° 7 7/8 7 7/8

50° 7 1/16 7 1/16

60 °

right

Rotating table position

Work piece width (in.) with sawhead

assembly tilted approximately

22.5°

left

15° 2 3/4 2 9/16 1 3/4 13/16

22.5° 2 3/4 2 9/16 1 3/4 13/16

30° 2 3/4 2 9/16 1 3/4 13/16

45° 2 3/4 2 9/16 1 3/4 13/16

50° 2 3/4 2 9/16 1 3/4 13/16

60 °

2 3/4 2 9/16 1 3/4 13/16

right

Rotating table position

Starting position:

Sawhead assembly fully raised.

Cutting depth limit screw set to max-

imum depth. Limit screw is securely

tightened.

Rotating table locked in desired

position.

Sawhead tilted to desired angle

against the work piece's surface and

locked.

If the sawhead assembly is tilted

between 22.5° and 48° to the right:

loosen the Phillips head screw and

swing the hinged fence to the rear.

Lock screw of t

ened.

Track arm not extended.

hown in the table

22.5°

5 1/2 5 1/2

22.5°

right

he track arm loos-

48 °

left and right

48 °

left

48 °

right

Cutting the work piece:

1. Hold the work piece against the

fence.

2. Press and hold the ON/OFF switch .

3. Slowly swing the sawhead assembly

all the way down, holding t

firmly. When sawing exert only moderate pressure. This keeps the

motor speed from dropping.

4. For wider work pieces pull sawhead

assembly forward (towards the

operator).

5. Cut work piece in a single pass.

6. Release the ON/OFF switch and let

the sawhead slowly return to its

upper starting position.

Note:

3

Crown moulding can be cut with

the back on the saw table and the top

edge against the fence.

For cutting crown moulding the following

settings apply:

Sawhead

tilt

Inside corner

Outside corner

Left

side

Right

side

Left

side

Right

side

33.9°

left

33.9°

right

33.9°

right

33.9°

left

he handle

Miter angle

31.6°

right

31.6°

left

31.6°

left

31.6°

right

8.5 Making Grooves

Note:

3

During groove cutting only a partial cut, up to a certain depth, is made in

the work piece. This operation is made

possible by use of the track arm, which

allows the sawhead assembly to move

horizontally over

limit screw, which allows for adjustment

of a given cutting depth.

the work piece and the

A WARNING

During the groove cutting operation

it is especially important no lateral

pressure is applied to the saw blade.

Otherwise the sawhead may be

kicked up abruptly! Always use a

clamp to hold the work piece in

place when making grooves. Avoid

lateral pressure on the sawhead.

Make sure that the work piece lies

flat and does not jam.

Starting position:

Sawhead assembly fully raised.

Sawhead tilted to desired angle

against the work piece's surface and

locked.

Rotating table locked in desired

position.

Lock screw of the track arm loos-

ened.

Track arm not extended.

Cutting the work piece:

1. Adjust the cutting depth limit screw

(51) to the desired depth for the

groove and then tighten it securely.

51

2. Hold the work piece against the

fence.

Note:

3

For the groove to be cut at the

desired depth across the whole work

piece width, a suitable spacer strip

needs to be placed between the work

piece and the fence.

3. Press and hold the ON/OFF switch .

4. Slowly swing the sawhead assembly

fully down, holding the handle firmly.

When sawing exert only moderate

pressure, to prevent the motor

to drop too much.

speed

5. When sawing, pull sawhead assem-

bly forward (towards the operator).

17

Page 18

ENGLISH

9. Care and Maintenance

A DANGER

Make sure the machine is unplugged

before you do any servicing, maintenance, repair or troubleshooting.

6. Cut the groove in a single pass.

7. Release the ON/OFF switch and let

the sawhead slowly return to its

upper starting position.

8.6 Auxiliary Fence

Note:

3

Use the auxiliary fence for vertical cuts of work pieces which are higher

than the fence of the machine. Bevel

cuts are only possible without the auxiliary fence in place.

Installing the auxiliary fence:

1. Fit the washers (52) on the carriage

bolts.

2. Slide the carriage bolts (52) into

fence extrusions.

53

4. Set the fence extrusions against the

fence and guide t

from the top into the slots (54) in the

fence for proper positioning.

he carriage bolts

56

55

54

Any repair and maintenance work

not described in this section must

be performed only by trained and

factory authorized personnel.

All defective or worn parts, espe-

cially all defective safety devices,

must only be replaced with OEM

parts! Non-OEM p

not specifically approved by the

manufacturer may lead to unforeseen damage and possibly result in

personal injuries.

Check that all safety devices are

operational again after each service.

arts and/or parts

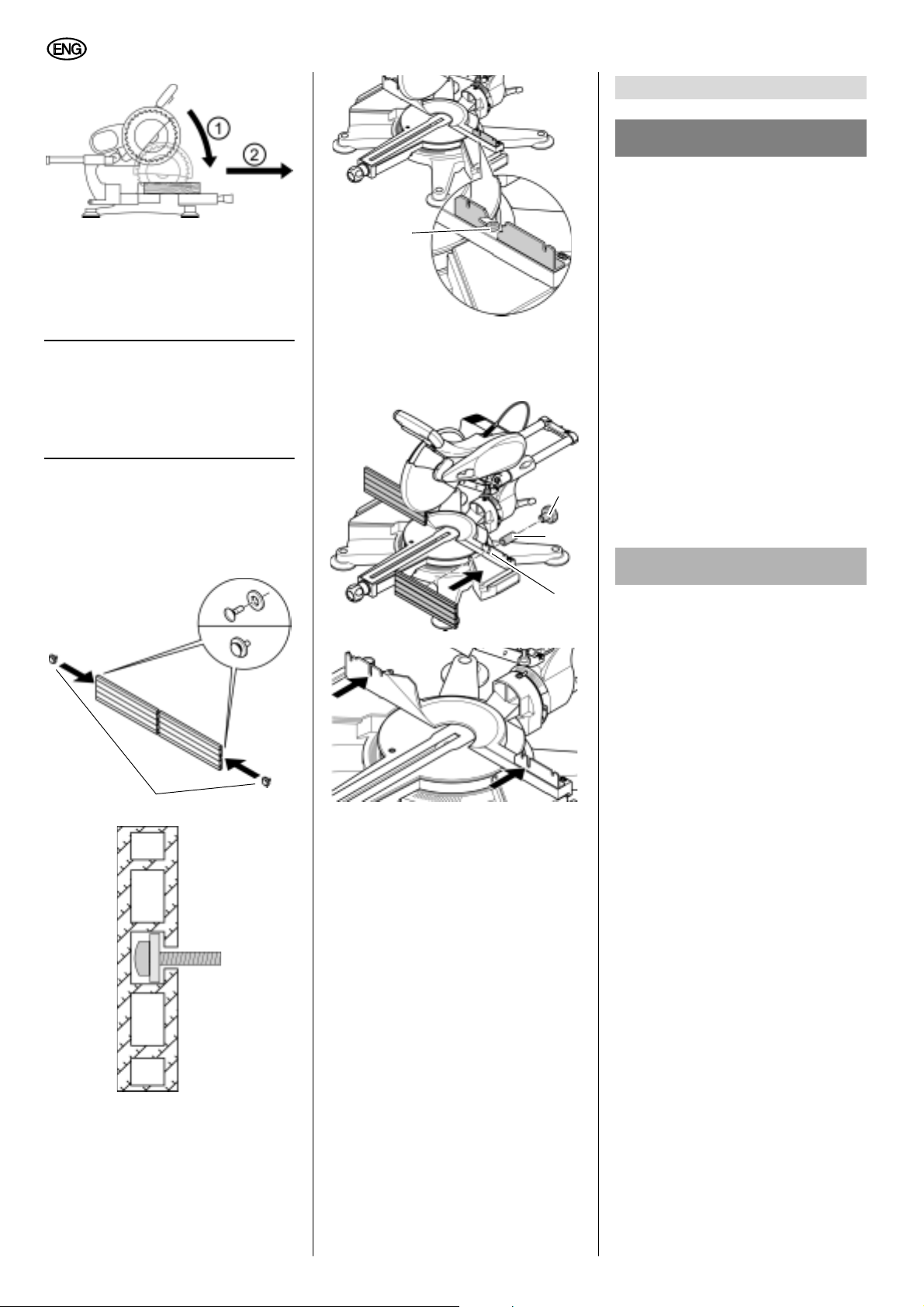

9.1 Changing the Saw Blade

A WARNING

Cutting creates friction, which in

turn generates heat. Right after cutting, the saw blade may be very hot.

Be extremely careful. Burning hazard!

52

3. Loosen Phillips head screw (53) one

turn.

5. Fit the sleeves (55) on the carriage

bolts.

6. Going clockwise, screw the star

knobs (56) on the carriage bolts and

hand tighten while still allowing the

fence extrusions to be shifted for

adjustment.

7. Move the auxiliary fence halves

against the kerf plate.

8. Tighten the star knobs.

9. Press the auxiliary fence against

fence and tighten Phillips head

screw (53) again.

the

Wear protective gloves when changing the saw blade, whether the saw

blade is hot or not. Let a hot saw

blade cool down. Do not clean a hot

saw blade with combustible liquids.

Even after coming to a complete

standstill, the saw blade is dangerous and a potential source of serious injury.

Never handle the saw blade without

protective gloves. When loosening

or tightening the arbor bolt the

retractable blade guard must be

pushed back and the flange guard

swung up in order to expose the saw

blade. It is NOT necessary to remove

the retractable blade guard!

1. Loosen screw (57) and swing flange

guard (58) up.

18

Page 19

ENGLISH

57

58

2. To keep the saw blade from turning,

pull the saw blade lock (59) forward,

towards the front of the machine. At

the same time slowly turn the saw

blade by hand, until the saw blade

lock engages.

59

3. Remove the arbor bolt (60) from the

saw spindle (left-handed thread –

turn clockwise to remove).

A WARNING

If resin residue is to be removed or

for any other cleaning, do NOT use

any cleaning agents that contain

acids or caustic or corrosive substances which would tend to corrode

the light metal components of the

machine if splashing occurs. The

stability and safety of the machine

could be compromised if such substances were used for cleaning and

are inadvertently splashed onto the

machine.

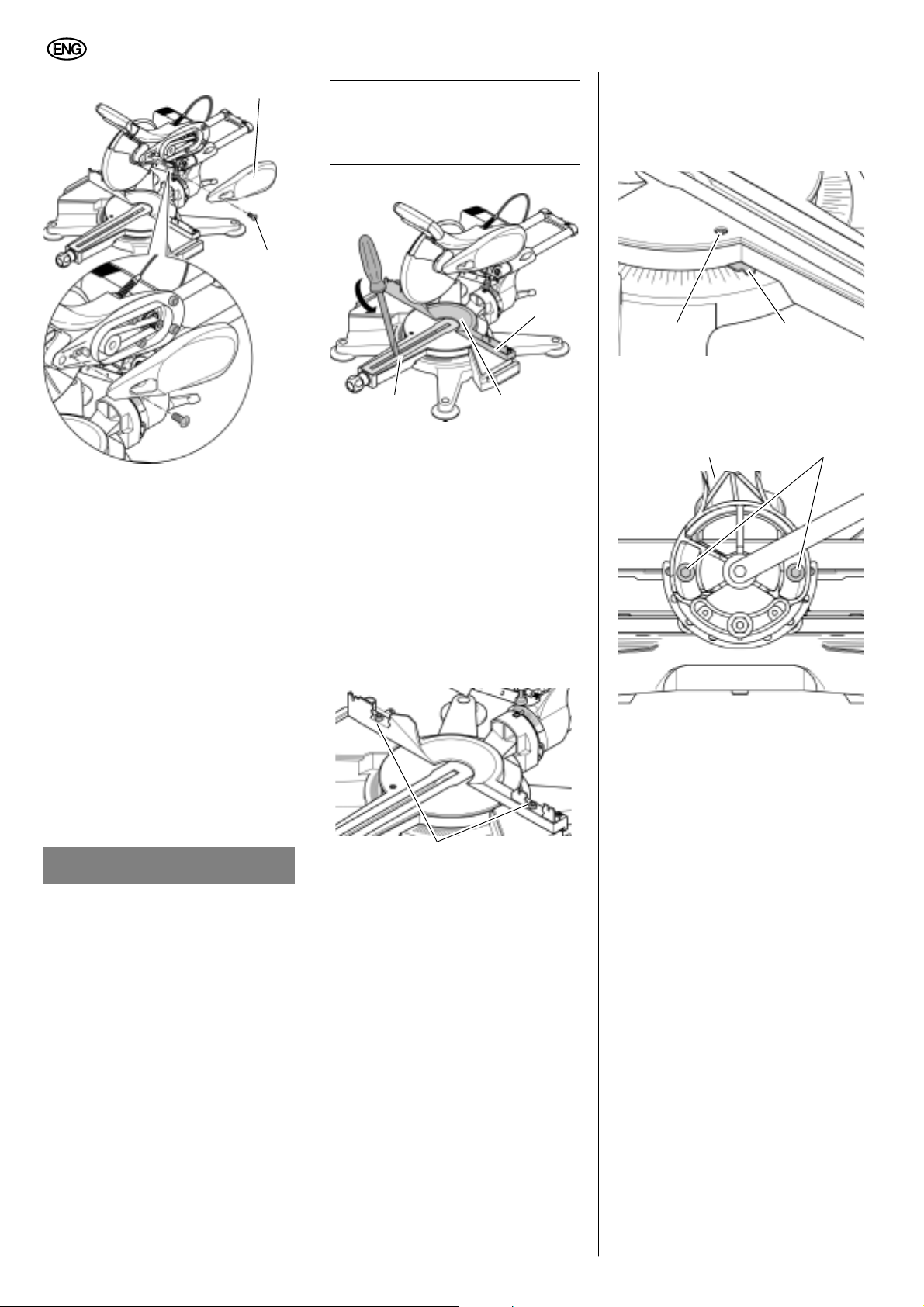

7. Put the inner blade flange

the saw spindle.

(63) on

A WARNING

Make sure the inner blade flange is

correctly fitted. Otherwise the saw

may jam or the saw blade may work

itself loose! The inner blade flange

(63) is correctly installed when the

bevelled collar (65) points to the

right and the groove for the safety

ring (64) points to the left.

64 65

A WARNING

x Never use grinding or cut-off

wheels instead of saw blades.

x Use only saw blades approved

by the manufacturer. Do not use

super-speed steel (HSS) saw

blades.

x Do not use loose-fitting reduc-

tion rings; the saw blade could

work itself loose.

x Be sure that the saw blade is

properly fitted. Make sure the

blade it is firmly secured, does

not wobble, runs balanced and

cannot work itself loose.

9. Install the outer

and be sure that the flat surfaces

are properly aligned and match.

10. Insert the arbor bolt (60), turn it

counterclockwise (left-hand thread)

and hand tighten with a metric Allen

wrench while keeping saw blade in

with the saw blade lock (59).

place

blade flange (61)

A WARNING

x Do not use excessive force when

tightening the arbor bolt:

Do not extend your wrench to

get more leverage.

Do not hit your wrench with a

hammer to tighten the arbor

bolt.

x When tilting the sawhead assem-

bly, keep your hands out of the

track arm holder's tilting range!

60 61 6362

4. Swing the retractable blade guard

up.

5. Remove the following parts from the

saw spindle:

arbor bolt (60),

outer blade flange (61),

saw blade (62),

inner blade flange (63).

6. Clean clamping surfaces of:

saw spindle,

inner blade flange,

saw blade,

outer blade flange,

arbor nut.

8. Mount the new saw blade (62) and

pay attention to the direction. The

arrow on the saw blade must point

in the same direction as the arrow

on the blade cover (66).

66

A DANGER

Do not use blunt, damaged or

warped saw blades.

11. Swing flange guard (58) down and

tighten screw (57).

12. Check function. To do so, lower the

sawhead assembly:

The retractable blade guard must

open without touching the saw

lade or any other parts.

b

When returning the sawhead

assembly to its starting position

the retractable blade guard must

return automatically so that the

entire saw blade is covered.

Check the saw blade lock – the

saw blade must turn freely.

9.2 Drive Belt Tensioning

The drive belt, running on the right-hand

side of the sawhead assembly behind a

plastic cover, needs to be tightened if it

has more than a 1/8" of play if pressed in

the middle between the tw

To check, tighten and/or change the

drive belt:

1. Loosen and remove the Phillips

head screw (68), unhook the cover

(hook at the rear) and remove it.

o pulleys.

19

Page 20

ENGLISH

67

68

2. Check the drive belt with your

thumb. If the drive belt needs to be

tightened (more than 1/8" play) or if

it needs to be replaced because of

visible wear, tear or cracking:

Loosen the four metric Allen head

screws by turning each screw

about one turn counterclockwise.

Replace the belt if necessary or

just tighten it by sliding the motor

to the rear until the belt is tight.

Hold the motor in its position and

tighten all four screws by turning

them clockwise until they are

securely tightened.

3. Replace the plastic cover (67) and

secure with the Phillips head screw

(68).

9.3 Kerf Plate Replacement

A DANGER

If the kerf plate is damaged, small

parts may become stuck between

kerf plate and the saw blade and

cause the saw blade to jam. Check

the machine for possible damage

before every use. Replace a damaged kerf plate immediately! Use

only OEM parts! Non-OEM parts and/

or parts not specifically approved by

the manufacturer may lead to unforeseen damage and possibly result in

personal injuries.

To replace the kerf plate:

1. Swing the hinged fence down (69).

2. Take the fence (70) off.

3. Loosen the kerf plate (71) by prying

it loose with a screwdriver and then

remove it.

Note:

3

This will destroy the kerf plate

(71). Once removed from the machine, a

kerf plate must never be re-used.

69

71

4. Insert the new kerf plate, making

sure it snaps into place.

5. Install the fence (70) and adjust it.

6. Swing the hinged fence (69) up and

secure it.

70

9.4 Adjustments

Fence adjustment

1. Swing the hinged fence down.

2. Loosen the fastening screws (72) of

the fence.

72

3. Adjust the fence position with a contractor's square or another appropriate right angle until it is exactly per-

pendicular (90

with the rotating table locked in the

0° position.

4. Tighten the metric Allen head set

screws on the the fence and then

use the square to check your adjustment. If necessary, re

adjustment procedure.

5. Swing the hinged fence up and

secure it.

Miter angle indicator adjustment

1. Turn the rotating table to one of the

preset stops at the °0, 15°, 22.5°,

30°, 45°, or 60°positions.

2. Loosen the metric Allen head scre

(73).

°) to the saw blade

peat the

3. Adjust the position of the indicator

(74) until it points exactly to the cor-

responding angle value.

4. Tighten the metric Allen head screw

(73).

73 74

Bevel tilt positive stop adjustment

1. Lock the track arm holder (75) in the

0° position.

75 76

Loosen the two metric Allen head

2.

screws (76) at the back of the

machine by turning them about one

turn counterclockwise.

3. Use a contractor’s square or

another appropriate right angle and

adjust the track arm

saw blade is exactly perpendicular

(90°) to the the rotating table.

4. Tighten the two metric Allen head

screws (76) at the back of the

machine by turning the screws (76)

clockwise until the

secured. Check your adjustment

with the square. If necessary, repeat

the adjustment procedure.

Miter angle indicator adjustment

1. Loosen the Phillips head screw (78).

2. Adjust the position of the indicator

(77) until it points exactly to the cor-

ponding angle value, e.g. 0°.

res

3. Tighten the Phillips head screw (78).

w

angle setting is

holder until the

20

Page 21

ENGLISH

77

78

Note:

3

The track arm holder engages at

preset stops at the 0°, 22.5°, and 45°

position.

9.5 Cleaning

Using a brush and dust pan or vacuum

cleaner, remove all small wood chips

and saw dust from these parts of the

machine:

setting devices;

operating elements;

the motor ventilation slots;

the space below the kerf plate.

9.6 Storage

A WARNING

x Store the machine in a dry and

safe place where it cannot be

used or tampered with by unauthorized persons or by children.

x Safeguard the machine with a

padlock.

x Never store the machine out-

doors, in unprotected areas or in

damp or wet locations. Please

refer to chapter 15, "Technical

Specifications," for permissible

ambient conditions.

x Store the saw blade(s) in a safe

place and in such a manner that

nobody can get hurt, e.g. put the

saw blade(s) in protective cardboard sleeves.

9.7 Maintenance

Prior to every use

x Remove all small wood chips and

saw dust from the machine with a

brush and dust pan or a vacuum

cleaner.

x Check the power cord and plug for

damage and if damaged, have the

cord and/or plug replaced by a

ified electrician.

x Check all moving parts and make

sure that they can move freely and

smoothly across their entire ranges.

qual-

Periodically, depending on operating

conditions

x Check the drive belt for wear, tear,

cracking or other damage, as well

roper tension and tension

as for p

(1/8" maximum play in the middle

between the pulleys).

x Check all nuts, bolts and screws for

proper fit and tightness and tighten

where necessary.

x Check if the sawhead assembly

returns to its starting or home position after being released. If necessary, have the springs replaced by

fully qualified and factory authorized personnel.

10. Tips and Tricks

For long work pieces use suitable

supports on both sides of the

machine so that

not bend.

Use an auxiliary fence when cutting

small work pieces.

When cutting warped or bent work

pieces, make sure that you place

the work piece so that the convex

side (i.e. the outer side of the bow)

is against the fence.

Do not cut any work piece while it is

standing on edge; always place it

flat on the rotating table.