Elektra Beckum hobbymaster MIG/MAG 140, hobbymaster MIG/MAG 160 Operating Instructions Manual

Page 1

G

F

N

J

S

Operating Instruction

Welding machine

Instructions d'utilisation

L’appareil de soudage sous

gaz protecteur

Bruksanvisning

Dekkgass-sveiseapparatet

Käyttökäsikirja

Parhaat onnittelumme tämän

korkealaatuisen

Bruksanvisning

skyddsgassvets

MIG/MAG 140

MIG/MAG 160

Page 2

G

F

N

Please return the enclosed warranty card to us.

Retain proof of purchase! You are only entitled to claim warranty against

Great Britain 1.

France 2.

Norge 3.

proof of purchase.

Please see back cover for manufacturer representative´s address nearest you.

SVP, retournez-nous la carte de garantie jointe.

Conservez le reçu d'achat! La garantie ne peut être accordée que sur

présentation de ce reçu.

Vous trouverez l'adresse de votre représentant le plus proche à la dernière page de couverture.

Send vedlagte garantikort tilbake til oss.

Oppbevar kvitteringen!

Garantiytelser skjer kun på grunnlag av forelagt kvittering.

Adressen til ditt nærmeste serviceverksted finner du bak på siste

omslagside.

J

S

Ole hyvä ja palauta oheinen takuukortti meille.

Suomi/ Finland 4.

Sverige 5.

Säilytä ostokuitti!

Takuu on voimassa vain kuittia vastaan.

Lähimmän edustajan osoite löytyy takakannesta.

Återsänd medföljande garantisedel till oss.

Förvara kvittot!

Garantianspråk erkännes endast mot uppvisande av kvitto.

Adressen till närmaste representant finns på bakre uppslagets insid.

Redaktion: Zindel • Technische Dokumentation und Multimedia • D-22417 Hamburg

Page 3

1

2

3

4

5

XS0006E.fm

1Great Britain

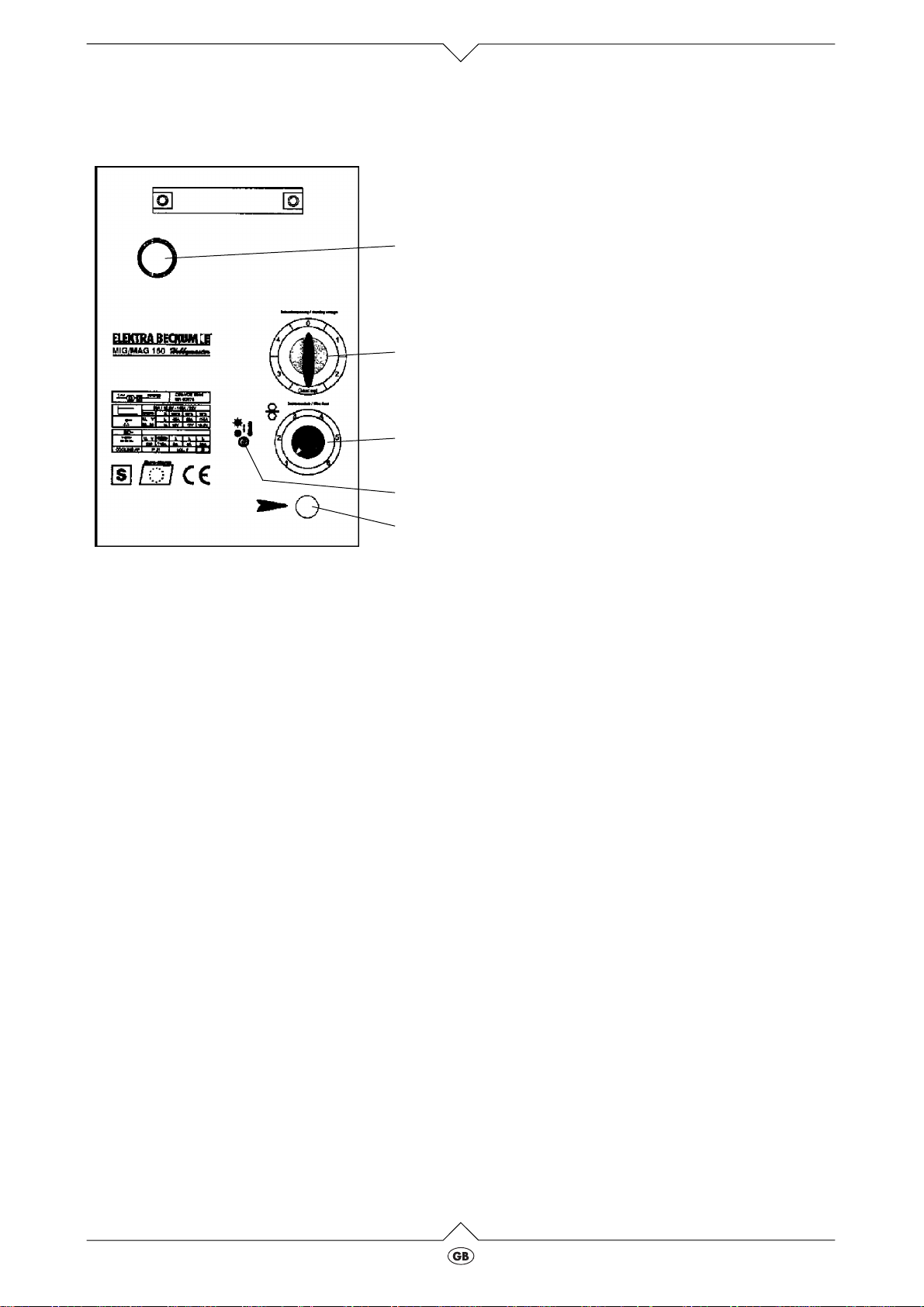

Operation elements

1

2

3

4

5

Connection for torch

Switch on/off and welding currant

Wire feed regulator

Overload control light

Connection for earth clamp

Dear customer,

Congratulations to your purchase of this high-quality

MIG/MAG welding machine.

To ensure your personal safety and for reasons of

appliance safety we ask you to read the instructions

completely before operating this machine and to

observe all points.

cause disturbances to other consumers in the distribution system. Check with your power utility before

connecting to power.

Keep the welding machine out of the reach of children.

Please note the hazards associated with the welding process and observe any work and fire prevention regulations.

The welding machine is not suitable for outdoor use

in rain. Store in a dry place.

Danger!

A

person with a heart condition wearing a pace

maker must contact their doctor before operating this welding machine.

Safety Information and Accident

Prevention Measures

·

Keep the welding machine out of the reach of

children.

·

Observe all applicable work and fire prevention

regulations when operating this welding

machine. Observe all applicable accident prevention regulations.

·

With welding a number of different hazards are

associated, which can pose a danger to health

under certain circumstances.

·

When welding always wear a close fitting, dry

overall (preferably fire retardant welders

apparel) unsoiled by combustible substances,

sturdy, insulating boots, headgear and leather

welders gloves.

·

Clothing made of synthetic fabrics and shoes

are not suitable.

Dry, insulating gloves worn on both hands protect against electric shock (open-circuit voltage

of the welding current circuit), hazardous rays

(heat and ultra-violet rays) as well as against

glowing metals and slag spatters. The ultra-violet radiation causes sunburn-like effects on

unprotected parts of the body.

Basic Information for the Operator

The MIG/MAG welding machine is a DC welding

power source with integrated wire feed, designed

and manufactured exclusively for MIG and MAG

electric arc welding.

Any other use of this machine involves dangers and

is not permitted.

The welding machine must only be operated on the

mains voltage stated on the machine's rating plate.

Connection to the supply circuit must be made via

an earthed outlet, installed by a qualified electrician.

The supply circuit must be protected by a fuse or

miniature circuit breaker.

Depending on the mains connection conditions at

the point of connection, welding power sources can

MIG/MAG 140/160

1.1

Page 4

Fumes – Vapours – Smoke

·

During welding hazardous smoke and metal

dust develops. We strongly recommend the

wearing of welding fume respirators, and to weld

only in sufficiently vented rooms, to ensure the

necessary operator protection.

·

For enclosed spaces forced ventilation, installed

below the welding area, must be used.

·

The material to be welded must be free from halogen solvents or degreasing agents, to prevent

the generation of toxic vapours.

·

Metals coated with lead, graphite, cadmium,

zinc, mercury or beryllium, or containing any of

these materials, can generate much smoke during welding.

·

Welding releases ozone, which is a type of oxygen that can lead to irritation or disorder of the

respiratory organs.

·

Degreasing agents such as trichlorethylene, tetrachloroethylene etc. vaporise during welding

and are chemically converted into phosgene.

Phosgene is poisonous!

UV-Rays

·

The arc radiation can cause eye damage and

skin burns.

·

For protection against sparks, heat, visible and

invisible rays suitable eye protection gear (welding visor or helmet with standardised filter

lenses to class 10 – 15 of DIN 4647, depending

on welding current) must be worn.

·

Do not look into the arc with unprotected eyes

(risk of blinding and burns). The invisible ultraviolet radiation causes, with insufficient eye protection, a very painful conjunctivitis, which

appears only hours later.

·

Weld only within the range of visibility of other

persons, who can assist you in an emergency.

·

Other persons or helpers near the arc must be

made aware of the hazards, and equipped with

the necessary protective gear.

·

Neighbouring workplaces are to be screened off

to provide protection against radiation.

·

When welding inside rooms and buildings sufficient ventilation must be ensured.

Fire

Danger!

A

The arc temperature is approx. 2400 ˚C.

Before starting to weld observe the following information:

·

Remove all combustible materials and objects

within a radius of 5 m from the welding point.

·

Materials that can not be removed within a 5 m

radius must be protected by covering with sheet

metal, wet cloths etc.

·

Any wall openings, cracks and the like must be

covered or sealed respectively, to prevent

uncontrolled flying of sparks.

·

Keep fire extinguishing equipment such as fire

extinguisher, water pale etc. at hand.

·

Keep in mind that by heat dissipation from the

welding point a fire may be started on covered

parts or in other rooms respectively.

·

After completion of the welding work check the

vicinity of the welding point several times within

a period of 6 – 8 hours for heat conduction,

glowing combustion spots, hidden seats of fire

etc.

Handling of Shielding Gas Cylinders

·

Observe all applicable regulations pertaining to

the handling of gas cylinders. Because of the

dangerously high internal pressure (up to 200

bar) shielding gas cylinders are to be specially

protected against mechanical damage, falling

over or falling down, heating up (max. 50˚C),

prolonged radiation by sunlight and heavy frost.

·

When the welding machine is equipped with a

gas cylinder too large in size this can cause, on

uneven ground, the welding machine to fall

over. To prevent subsequent damage to the

welding machine or the gas cylinder, use only

proper size gas cylinders (10l / 20l cylinders).

·

Have cylinders refilled only by authorised filling

stations.

1.2

MIG/MAG 140/160

Page 5

Electrical Hazards

·

The connection to power mains and servicing of

the welding machine is to be done in accordance with VDE regulations or other standards

applicable in your area.

·

Ensure proper protective bonding of the supply

circuit.

·

Ensure proper protective bonding of the workbench.

·

Any service or maintenance work must only be

carried out by qualified personnel.

·

Replace defective or damaged parts of torch or

torch leads without delay.

·

The unit must only be connected to an earthed

outlet as a matter of principle. Only connections,

including outlets and extension cables with an

earthed plug, having an earth conductor and

installed by a qualified electrician, are permitted.

·

The fuse protection of the supply circuit must be

in accordance with local regulations. According

to these regulations fuses or miniature circuit

breakers respectively, suitable for the conductor

cross section, must be installed. Installation of a

fuse with to high an ampere rating may cause

line fire and subsequent fire damage to the

building.

·

Replace damaged torch insulation and welding

cables without delay.

·

Replacement of a damaged power cable, plug

etc. and repairs to the electrical components of

the welding machine must be left to a qualified

electrician.

·

Welding torches must not be held in an armlock,

or in such way that electricity can run through

the body.

·

Switch the unit off for longer work breaks.

Unplug when work is completed and before relocating the unit. In case of accidents separate the

welding power source at once from the power

supply.

General Machine Description

The MIG/MAG welding machine consists of a transformer, a series-connected silicon rectifier, a welding circuit choke, and a wire feed unit.

The welding machine is suitable for the welding of

different electrode wires (e.g. steel, see "Technical

Specifications") under a shielding gas cover (CO2,

mixed gas and argon).

The machine is fan cooled and has an overload protection.

Commissioning

Taking out of enclosed parts

All enclosed parts are inside the wire feed compartment and can be taken out after the wire feed compartment cover is removed..

Installation Conditions

The MIG/MAG welding machine is to be set up in

dry surroundings with enough space to ensure sufficient cooling. The welding machine is designed for

indoor use. It must not be use outdoors in rain.

Mains connection

·

Check to see that mains voltage matches the

voltage shown on the machine's rating plate.

·

Set welding step switch to "0" before plugging

in.

Shielding gas cylinder connection

·

Place gas cylinder onto the welding machine's

cylinder rack and secure with the chain to the

cylinder holder at the rear of the unit. Take off

the cylinder cap and open cylinder valve briefly,

facing away from your body.

·

Screw pressure reducer to the gas cylinder

valve. Run gas hose from pressure reducer to

gas inlet port of the unit.

·

Recommended gas flow rate in draft-free

rooms: 5-10 l/min.

·

When using adjustable pressure reducers set

flow rate according to litre scale in the clock with

the T-screw. Turning the T-screw in increases

the gas flow rate, turning it out reduces the gas

flow rate.

·

While setting the gas flow rate, the unit must be

switched on and the torch's trigger switch held

down, so the solenoid gas valve is open. To prevent wasting electrode wire swing the wire feed

unit's leaf spring to the side.

Modifications and repairs to pressure reducers are

strictly prohibited due to the hazards involved. Send

faulty pressure reducers to a service centre.

MIG/MAG 140/160

1.3

Page 6

Earth lead connection

Connect earth clamp of the unit's earth cable as

close as possible to the welding point. Ensure good

metal to metal contact.

Preparation of the welds

The joint section of the workpieces to be welded

must be free of colour, metall covering, dirt, rust,

grease and humidity.

The preparation of the welds is to be done under

observation of all welding techniques regulations.

Hints for Setting and Welding Techniques

Switching the unit on

The unit is switched on with the combination ON/

OFF – welding step switch. With the switch in the

"0"- position the unit is electrically separated from

the power supply.

The unit is fitted with an embedded temperature

detector, which shuts the unit down in case of an

thermal overload.

The tripping of the thermal overload protector is indicated by the front panel control light. Welding power

source and wire feed are temporarily disabled.

After cooling down the welding power source is

automatically activated again, the control light extinguishes.

Setting the welding parameters

After preparation of the welding machine the welding can begin.

To do so, welding voltage and wire feed have to be

matched to suit the welding task. If the wire feed

speed is increased the welding current increases

accordingly.

For every electrode wire diameter and every welding task optimal parameters can be found. They are

recognisable at the typical humming sound of the

arc, amongst other.

If there is too much deviation from the optimal

parameters, a satisfactory welding is not possible.

The right joint

The list gives hints for the shaping of the joints.

I-joint onesided

I-joint on both

sides

V-joint

K-joint

Double-K-joint

Cornerjoint

Form of joint Execution

s

b

25

s

b

s

s

Platethick-

ness

s (mm)

< 1,5

> 1,5

2 – 4 < 2

3 – 6 < 1

3 – 6 < 1

> 0,6 –

0,6 – 1,5 –

> 0,6 –

> 1 –

Gapwidth

b (mm)

0

< 2

1.4

MIG/MAG 140/160

Page 7

Care and Maintenance

The unit is nearly maintenance-free.

Danger – Voltage!

B

Disconnect from power before servicing!

· Check feed roller, pressure roller and wire leadin nozzle at regular intervals for dirt build-up,

clean if necessary.

· At appropriate intervals the complete torch

including torch leads should be cleaned, as

rubbed-off parts and dust build-up inside.

· The torch's contact tip is a wearing part. If its orifice has enlarged the contact tip must be

replaced.

· On the inside of the plug-on gas shroud spatters

build up. These have to be removed when necessary. An anti-spatter spray eases this job and

keeps spatters from sticking to the shroud.

· Replace damaged cables without delay.

Trouble Shooting

Mechanical faults are mostly indicated by an irregular or completely blocked wire feed. Electrical faults

cause a malfunction of the unit, in part or complete.

Danger - Voltage!

B

Electrical fault finding must be left to a qualified electrician.

Further fault finding can proceed according to the

wiring diagram supplied.

Fault find should first start with the unit de-energized, and in the following order:

1. Check of the power supply cable connection

and all other connections on switches, transformer and choke, as well as all plug-and-socket

connections and soldered connections for tightness.

2. Check of fuse for continuity and contact.

3. Visual check for possible shorts or overloads of

windings (discoloring).

Fault, Likely causes Remedy

• Noisy or unstable arc?

Incorrect welding voltage

Too much/too little wire

feed

Earth clamp loose or

high contact resistance

(rust, paint)

Contact tip worn or

incorrect diameter

Incorrect gas flow rate

setting

Workpiece not clean in

seam area

Power unit faulty Have machine checked by

Spiral liner dirty Clean or replace

Wire feed faulty See below

Correct with welding step

switch

Correct with wire feed pot

Ensure good contact

between earth clamp and

workpiece

Replace

Correct

Remove paint, rust, grease

etc.

service centre

• Excessive spattering

Wire feed rate too high Correct with wire feed pot

Welding voltage too

high

Workpiece not clean Clean

Correct with welding step

switch

• Wire feed motor does not run

No power Check power supply

Welding step switch in

"0" position

Torch trigger switch not

activated

Fuse blown Have replaced by a qualified

Motor faulty Have repaired by service

• No wire feed

Pressure roller loose Increase pressure of leaf

Wire kinked at wire

feed

Groove in feed roller

worn

Electrode wire stuck to

contact tip

Set to a welding step

Activate torch trigger switch

electrician

centre

spring with knurled thumb

screw

Adjust wire lead-in nozzle

Replace

Replace contact tip, if wire is

deformed, reduce pressure

of pressure roller

MIG/MAG 140/160

• Machine shuts down, overload control light

comes on

Duty cycle exceeded Let machine cool down,

observe duty cycle stated on

nameplate

Power unit faulty Have repaired by service

centre.

1.5

Page 8

Technical Specification

MIG/MAG 140 MIG/MAG 160

Power supply 1 x 230 V, 50/60 Hz 1 x 230 V, 50/60 Hz

Power input max. 4,4 kVA 4,4 kVA

Current draw max. 21 A 20 A

Mains fuse, time-lag 16 A 16 A

Open-circuit voltage 17,5 – 28 V 19 – 30 V

Welding current range 30 – 140 A 30 – 160 A

max. Duty cycle at 145 A 7 % 15 %

Welding steps 4 4

Wire feed rate 1,0 – 12 m/min 1,0 – 12 m/min

Electrode wire diameter 0,6 – 0,8 mm 0,6 – 0,8 mm

Insulation class N N

Protection class IP 21 IP 21

Length x Width x Height 590 x 260 x 420 mm 590 x 260 x 420 mm

Weight 26 kg 28 kg

Circuit diagram

max

Ø

min

L1

N

1

2

1B

1A

2B

2A

H1

M2

1

2

T1

S2S1

1A

1

1B43A2

2

1

TH

L1

N1

N

B

13

C

U1

VAR-03

M1

3254

TV

L1

S3

P1

1

L1

N

MIG/MAG 140

S1

1

2

6

43

6

10

1211

T1

1

2A

3

4

H1

M2

MIG/MAG 160

U1

B

M1

TH

L1

N1

N

3254

TV

VAR-03

L1

S2

P1

1

1.6

MIG/MAG 140/160

Page 9

B

Belgium

Elektra Beckum Belgium N.V.S.A.

Industriezone

Hofte te Bollebeeklaan

B-1730 Asse-Mollem

Tel.: 0032-24540454

Fax: 0032-24540450

G

Great Britain

Elektra Beckum Machinery Ltd.

6 The Quadrangle

Premier Way

GB-SO51 9AQ Romsey

Tel.: 0044-1794-834900

Fax: 0044-1794830083

D

K

E

Deutschland

Elektra Beckum AG

Daimlerstraße 1

D-49716 Meppen

Tel.: 01803-333 456

Fax: 01803-333 457

Danmark

Elektra Beckum Danmark

Lundeborgvej 9

Postbox 8113

DK-9220 Aalborg OE

Tel.: 0045-98-151300

Fax: 0045-98-151451

España

Elektra Beckum Import S.A.

Calle Alejandro Coicoechea 6

E-08960 Sant Just Desvern

Tel.: 0034-9-34739009

Fax: 0034-9-34739755

I

N

H

Italia

Elektra Beckum AG Germania

Daimlerstraße 1

D-49716 Meppen

Tel.: 0049-1803-333456

Fax: 0049-1803-333457

Norge

Profilma-Import A/S

Postboks 536 Nanset

Sophus Buggesvei 48

N-3252 Larvik

Tel.: 0047-33114777

Fax: 0047-33114108

Nederland

Elektra Beckum Nederland

Einsteinstraat 15

NL-1704 RT Heerhugowaard

Tel.: 0031-7257-44660

Fax: 0031-7257-44250

F

J. Muller

1.Place de Lábattoir

F-67190 Mutzig

Tel.: 00333-88479971

Fax: 00333-88479970

J

Nofa OY

P.O.Box 28

Hannuksentie 1

FIN-02270 Espoo

Tel.: 00358-9804-861

Fax: 00358-9803-9485

MIG/MAG 140/160 115 164 4534 GB/F/N/SF/S 3298 1.0

France

Suomi/ Finland

P

Costa & Garcia S. A.

Vilar do Paraíso, Ap. 23

P-4408 Valadares

Tel.: 00351-2-7121279

Fax: 00351-2-7124670

S

HDF-Paulsson AB

Box 525

Svaravaregatan 5

S-30180 Halmstad

Tel.: 0046-35-154400

Fax: 0046-35-121780

Portugal

Sverige

Loading...

Loading...