Page 1

ELEKTRA

BECKUM

Operating

Instructions

Planer/Thicknesser

HC 260

.

-

-

Serial-No.

11.004 M )

_

•

.

;

Attention!

Before

taking

your

machine into operation

please

read

the

operating instructions carefully

and

adhere

to

strictly.

Elektra

Beckum reserves

the

right

to

discontinue models, accessories

or

options

at any

time

or

change specifications

and

materials, equipment

and

design without notice

and

without incurring obligation

of any

kind. Equipment referred

to as

02/95

- GB

available

or

optional

may be at

extra cost.

Art.-Nr.

115 104 71

'

Page 2

U.K.

Supplement

to

Operating

Instructions

for

Eiektra Beckum

HC 260 M

Combination

Surfacing

and

Thicknessing

Machine

Please

note

the

following supplementary information associated with this machine:

U.K.

Legislation

and

Codes

of

Practice

When

used industrially within

the

U.K. this machine falls under

the

scope

of

Woodworking Machines Regulations

1974

and

Use and

Provision

of

Work Equipment Regulations

1992.

We

strongly advise

you to

study

and

follows theses regulations.

Section

4.0

Connection

to

Power Mains

230 V

motor. Although

the

motors supplied with

this

machine will

run

safely

on a 13A

domestic ring main.

On

starting

the

machine

a

high current

of

very short duration

is

drawn, which will blow your

13A

fuse. Thismachine

can

only

be

connected

to a

16A

separate

radial circuit using

BS

4343 (CEE

17)

plug

and

socket. Ensure

the

installation

is

protected

by a

suitably sized fuse

or

miniature circuit

braker.

This work should

be

undertaken only

by a

qualified electrician!

DUST COLLECTION

We

strongly recommend

the use of a

Dust Collector with this machine.

Our

Sales Department

will

be

happy

to

offer

you

advice

on the

correct

collector.

Contents

1.0

Technical Data

2.0

Final Assembly

3.0

Setting

of

Fence

4.0

Connections

to

Power Mains

5.0

Switch

6.0

Motor

Protection

7.0

Chip Removal

8.0

Chip Removal when Planing

9.0

Chip Removal when Thicknessing

10.0

Setting

of

VARIO

Guard

11.0 Planing

12.0 Thicknessing

13.0 Replacing/Setting

of

Disposable Blades

14.0

Fitting/Setting

of

Resharpenable Blades

15.0 Belt Tension

16.0 Care

and

Maintenance

17.0 Safety Instructions

18.0

User Responsibility

19.0 Wiring Diagrams

20.0 Spare Part List

1.0

Technical

Data

Over

length planing tables

Length thicknessing

bed

Max. working width

Max. thicknessing capacity

Max.

depth

of cut

planing

Cutter block

HSS

steel

Cutter

block speed

Thicknesser

feed rate

Motor

speed 50/60

Hz

Motors

1000

mm - 40"

400mm-

153/4"

260

mm-10

3/16"

160

mm-6

1/8"

3 mm

-1/8"

0 63

mm - 2.480"

6500

Upm

5

m/min

- 16

ft/min

2800/3360

rpm

Fence

tilt

Might

of

planing beds from floor

Weight

max.

45°

860 mm - 34"

ca. 60 kg - 132

Ibs

Work

place related noiseemmission according

to

DIN

45635

no-load

75.7

dB (A)

under

load

90.3

dB (A)

Sound power according

to DIN

45635

no-load 92.2

dB (A)

under load 95.4

dB (A)

1

.8

kW/2.45

hp

2.2

kW/3.00

hp

2.2

kW/3.00

hp

3.1

kW/4.20

hp

2.8

kW/3.80

hp

4.2

kW/5.70

hp

4.2

kW/5.70

hp

230V

220-240

V

110V

220-240

V

380/41

5V

380/415

V

220V

50 Hz

50/60

Hz

50/60

Hz

50/60

Hz

50/60

Hz

50/60

Hz

50/60

Hz

single phase

single phase

single phase

single

phase

three

phase

three phase

three phase

Page 3

Optional Accessories

Drilling/Morticing Attachment

Cam-lock Clamp

Workstand

HC -

E/ES

Rollerstand

RS 300

Lock

Bar

Conversion

Kit

HSS

Planer Blade

Flexible

Shaft

0-8 mm

chuck

Waxilit

anti-seizing paste

70 gr tin

Drill Chuck

0-10

mm UNF

1/2-20

Rustic

Planer Blade

HSS

Wheel

Set/Workstand

HCK

Carrying Handle

HC

Wheel

Set HCM

Stock-No.

091

1003791

091

1009811

091

1003775

091 101

2367

091

1001020

091

1001047

091

100

1004

091

100

1071

091

1003805

091

1005603

091

1007100

091

1009048

091

1003783

2.0

Final Assembly

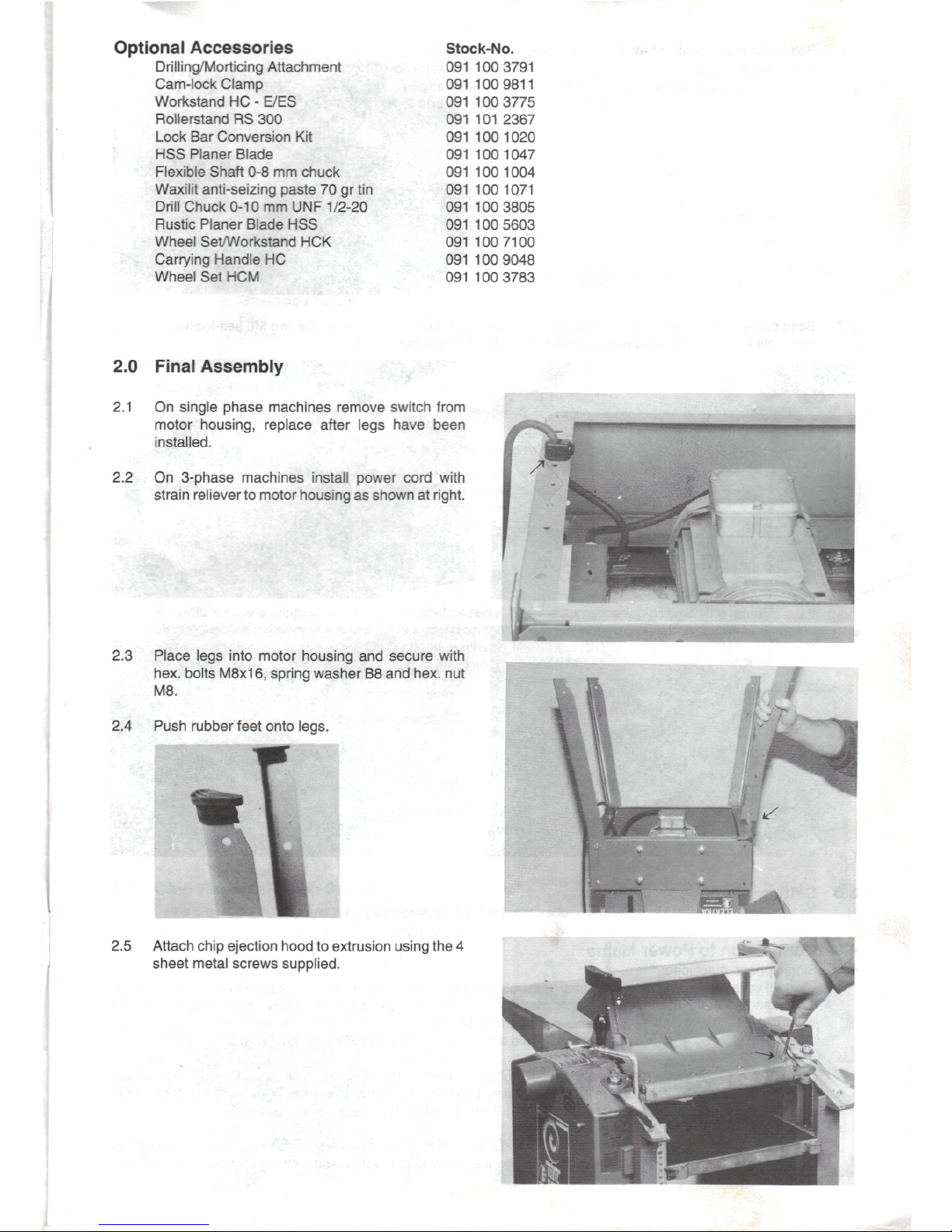

2.1 On

single phase machines remove switch from

motor housing, replace after legs have been

installed.

2.2 On

3-phase machines install power cord with

strain reliever

to

motor housing

as

shown

at

right.

2.3

Place legs into motor

housing

and

secure with

hex.

bolts

M8x16,

spring washer

B8 and

hex.

nut

M8.

2.4

Push rubber feet onto legs.

2.5

Attach chip ejection hood

to

extrusion using

the 4

sheet metal screws

supplied.

Page 4

2.6

Bolt

fence carrier with 2 hex. bolts

M8 to the

infeed

table.

Pull, then

lever

swings freely

2.7

Slide carriage bolts into

the

fence extrusion

and

bolt

to

fence

segment,

using

the two M6

self-locking nuts.

Fix

cover plate

to

fence bracket with

two

cyl.

bolts M4x8

and

washers

A4.2.

3.0

4.0

4.1

4.2

4.3

Setting

of

Fence

By

turning fence setting screws

in or out as

required, adjust fence segment stops

to

true

90° and

45

C

Connection

to

Power

Mains

Single phase machines:

Check

if

voltage

of

power mains matches with voltage stated

on the

machine's type plate.

Fit

plug matching your

local standard outlet

to

power cord.

This

machine must

be

safety earthed.

The

yellow/green lead

is the

earth

conductor. A 220/240 V circuit must have a 13

amp

fuse, fitted

on a

110 V circuit a min.

20 amp

time-lag circuit

breaker

is

required. Extension cords must have a min. cross section

of 2.5

mm2/12

AWG.

3-phase

machines:

Check

if

voltage

of

power mains matches with voltage

stated

on the

machine's type plate.

Fit

plug

of

your local

standard

to

power cord. This machine must

be

safety earthed.

The

yellow/green lead

is the

earth conductor. Min.

lead cross section required

is

1.5

mm2/16

AWG. Protect circuit with

16 amp

time-lag fuses.

Direction

of

rotation

on

3-phase machines:

Switch

machine

on

briefly

to

check

cutterblock

direction

of

rotation.

If

necessary correct

by

interchanging

two

phase leads (black

or

brown).

Do not

interchange

the

yellow/green earth lead with

the

blue neutral

lead.

If in

doubt leave

job to a

qualified electrician.

Page 5

5.0

Switch

All

switches

are

equipped with a no-volt release solenoid (magnetic switch). This feature prevents

the

machine

from

starting

up

after a power

failure. A light humming from

the

switch when machine

is

switched off,

but

connected

to

power mains,

is

normal

and

does

not

represent a fault.

5.1

-IMPORTANT - WIRING

INSTRUCTIONS

Warning:

This

appliance

must

be

earthed!

For

machines with a single phase motor (220-240 volt

or

110

volt)

the

mains lead

is to be

connected

in

accordance

with

the

following

colour

code.

Green

and

Yellow - Earth

^

Blue

-

Neutral

Brown

-

Live

3-Phase

Motors

Machines

fitted

with

3-phase

motors

are

connected

to the

mains using a 5-pin

industrial

appliance-inlet/connector

to

BS

4343

(IEC 309)

Ensure

it is

wired

and

connected only

by a

qualified electrician.

c

IF IN

DOUBT - CONSULT A QUALIFIED

ELECTRICIAN!

6.0

Motor

Protection

All

switches

are

equipped with a motor protection relay, which automatically trips when

the

motor

is

overloaded.

On

single-phase machine a small

pin is

located

on the

switch housing, which simply needs

to be

pushed

in to

reset

the

motor protection relay.

On

3-phase machines

the

switch needs

to be

switched off.

After

the

motor protection relay

has

tripped

let

motor cool down

for at

least

10

minutes.

7.0

Chip

Removal

Standard delivery with this machine

is a

suction connector

of

100

mm/4" diameter.

We

recommend

to use the

Elektra Beckum Dust

Collector

SPA

1000, which

has

been

designed

specifically

for use

with

this

planer/

thicknesser.

8.0

Chip

Removal

when

Planing

Set

thicknessing

bed to

approx.

2/3

capacity

and

place suction connector onto

it.

Raise thicknessing

bed to

lock

suction connector

in

position. Make sure that

the

notch

on top of the

connector locks

on the

spacer shaft.

Page 6

9.0

Chip Removal when Thicknessing:

9.1

Thicknessing without dust collector:

Take

off

outfeed table, slide guard extrusion clear

of

table

and set

guard

to

highest position. Swing

chip ejection hood over

the

cutterblock

and

secure

in

place with

the

lock levers

as

well

as

lowering

the

guard onto

it.

I

9.2

Thicknessing with dust collector:

Bring chip ejection hood into position

as in

9.1,

then place

the

suction connector onto

it.

Secure

with

lock levers

and

guard.

Caution!

The

chip ejection hood

is the

cutterblock guard

when

the

machine

is set up for

thicknessing.

Never operate machine without chip ejection

hood

in

place

and

properly secured.

10.0 Setting

of

VARIO

Guard (Standard

on

HC-M/K/ES,

optional

on

HC-E models)

Height adjustment

is

made with

the

lever mounted

on the

left side

of the

machine.

After

lifting

the

lock lever

the

blade

cover

can be

slid sideways

to set the

required stock width

for

jointing. Push lock lever down

to

lock guard

extrusion

in

position.

.

Page 7

11.0

Planing

Place stock flush onto infeed table, with your

left

hand

set the

cutter guard

to the

required

hight

(stock should just

run

clear

of the

guard. Start machine

and

push stock slowly

and

steady against

the

cutterblock.

Hands slide over

the

blade cover.

11.1

Jointing

For

planing

the

narrow sides

of a

workpiece release

the

blade cover's lock lever

and set

blade cover

to

width

of

stock.

The

plastic spring

on the end of the

blade

cover should

exert a slight pressure against

the

stock. Lock blade

cover

in

place

and

start machine. Push stock slowly

and

steady

against

the

cutter block.

Be

sure that fence

is set at

true

90° (or ony

other angle required)

and

stock

is

kept flush against fence.

.

12.0

Thicknessing

Prepare machine

for

thicknessing

as

described

under para. 9.0.

Set

thicknessing

bed to

required

thickness

of

stock (but max.

5 mm

more than

actual thickness

of

stock). Start machine

and

place stock with planed side facing down onto

thicknessing

bed and

slowly

push

forward

until

feed

roller engages. With wedge-shaped stock

feed

thicker side

first.

Wet

stock

can be

slightly

coated with kerosene

to

improve sliding

capabilities.

For

working long stock

use of the

Elektra Beckum

roller

stand

(stock-no.

091 101

2367)

is re-

commended.

Page 8

13.0 Replacing/Setting

of

Disposable

Blades

Disconnect machine from power before

servicing!

Remove

fence.

Loosen hex.

bolts

of

lock

bar

with

tool set's spanner

SW

10

mm by

turning

the

bolts

clockwise

(into

the

lock bar). Remove lockbar

complete with blade from cutterblock. Clean lock

bar, lock

bar

seat

and

blade from chips

and

dust

with oily rag. Reverse blade

or fit

fresh

one

onto

lock bar. Place assembly into cutterblock

and

secure

in

place

by

turning hex. bolts-counter-

clockwise,

at

this stage only tighten bolts lightly.

Check projection

of

blade against outfeed table

with dial indicator

or

straight edge placed onto

outfeed

table. Max. blade projection over

outfeed table

0.1

mm/0.004 inch.

Use the

tool set's Allen

key SW 3 mm to

correct projection

by

turning

the

three setting screws

of the

lock

bar in

or

out,

as

required. When correct setting

is

reached

fully

tighten

the

hex. bolts. Start with

the

centre bolts, then

the

outer

ones.

Caution!

Do

not use

spanner

SW 10

with longer handle than supplied with machine

to

prevent excessive torque

and

possible stripping

of

threads.

For

your

own

safety replace lock bars

or

bolts with damaged thread

at

once.

Use

only genuine Elektra Beckum replacements.

i--~

Allen

key SW 3 mm

Dial indicator

14.0

Fitting/Setting

of

Resharpenable Blades

For

certain

markets

this machine

may

be

fitted with resharpenable

HSS

planer

blades

as

standard.

If

this machine

is

fitted with disposable planer blades

it can

easily

be

modified

to

accept

HSS or TCT

resharpenable blades.

14.1

To

fit

resharpenable blades, either

HSS or

TCT, a Lock

Bar

Conversion

Kit

(stock-no.

091

100

1020)

is

needed

in

addition

to the

blades. Remove standard disposable blades

as

descriped under para

13.0.

14.2

Place resharpennable blade onto lock

bar of

lock lock

bar

conversion

kit and

place assembly into cutterblock.

Tighten

hex.

bolts

lightly.

14.3

Check projection

of

blade against outfeed table with dial indicator

or

straight edge placed onto outfeed table. Max.

blade projection over outfeed table

0.1

mm/0.004 inch.

Use

Allen

key SW 3 mm to set

setting screws

of

lock bar.

14.4

When correct setting

is

achieved

fully

tighten

the

hex. bolts Start with centre bolts, then outer ones.

Caution!

Do not use

spanner

with

longer

handle

than

that

supplied

with

the

machine.

14.5

Replace lock

bar or

bolts

with

stripped thread

at

once

for

your

own

safety.

Use

only genuine Elektra Beckum

replacements.

Page 9

15.0 Belt Tension

After

the

first

5 hrs of

operation check belt tension.

Take

off cap nut

holding

the

drive belt cover

(215).

Check

tension

by

pushing against belt, play should

be

approx.

15-20

mm/5/8-2/4 inch).

16.0 Care

and

Maintenance

Regularly

clean

the

thicknesser drive gear from

dust with brush

or

compressed air. Lubricate

all

bearing

points

and

chains

regularly with

a few

drops

of

motor oil. Keep

flat

belt

free

of oil and

grease.

16.1 Regularly clean

the

thicknessing

bed

spindles

from

chips

and

dust

and

lubricate with spray

oil

(e.g.

WD 40) Do not use

regular

oil.

16.2

Keep infeed/outfeed tables

and

thicknessing

bed

free

of

resin. Clean regularly with kerosene

or

petrol, then coat

with a light

film

of

WAXILIT

antiseizing paste

to

enhance gliding

of

stock

on

tables.

17.0 Safety Instructions

-

Regularly check that blades

and

lock bars

are

locked tight

in

cutterblock

-

Max. allowable blade projection over cutterblock

1.0

mm/0.004 inch

+ 10

%.

-

Never remove

any of the

machine's safety guards other than

for

servicing

and

repair work. Keep guards

operational

at all

times.

-

Set and

secure safety guards

in

position before operating machine.

-

When operating machine

in

enclosed spaces connect

to a

dust collector.

-

This

machine

must

be

safety earthed.

The

yellow/green

lead

is the

earth

conductor.

-

Regularly check anti-kickback fingers

for

proper operation.

-

Always wear

eye

protection.

-

Rebating,

tenoning, moulding

and

recessing

may not be

undertaken

without

the use of

special

guards.

-

Never make jointing

or

planing

cut

deeper than 3 mm/1/2".

Page 10

18.0

User

Responsibility

This machine will perform

in

conformity with

the

description contained

in

this manual when

installed,

operated,

maintained

and

repaired

in

accordance with

the

instructions provided.

This machine must

be

checked periodically. Defective equipment (including power cable) should

not be

used.

Parts

that

are

broken, missing, plainly worn, distorted

or

contaminated, should

be

replaced immediately. Should

such repair

or

replacement become necessary,

it is

recommended that such repairs

be

carried

out by

qualified

persons

approved

by

Elektra Beckum

or its

representatives.

This machine

or any of its

parts should

not be

altered

or

changed from standard specifications.

The

user

of

this

machine shall have

the

sole responsibility

for any

malfunction which results from improper

use or

unauthorized

modification from standard

specification,

faulty maintenance, damage

or

improper repair

by

anyone other than

qualified

persons

approved

by

Elektra

Beckum

or its

representatives.

19.0 Wiring

Diagrams

19.1

Wiring diagram

for

motor 220-240 V 50/60

Hz

with

switch-plug-combinations

and NVR

220-240

V

19.2

Circuit diagram

for

motor

380/415 V 50/60

Hz and

220 V

50/60

Hz

switch-plug-combination

with

motor protection relay

and NVR

(solenoid

400/

230V)

3-400V

3-220V

50/60

Hz

Li

-

L2-

L3-

N

-

PE-

Page 11

20.0

Spare

Part List

HC 260

Pos.

Description

Dimension

DIN

Stock-no.

100

100

101

102

103

104

105

106

107

108

109

110

111

112

114

116

117

118

119

120

121

122

123

125

126

127

128

129

130

131

132

133

134

135

136

137

138

139

140

141

142

143

144

145

146

147

148

149

150

151

152

153

154

Planing

bed

w

Planing bed, hardened

Lock

bar

screw

Lockbar

for

disposable blades

Lockbar

for

resharpenable blades

Clamping

sleeve

for

lock

bar

Set

screw disposable blade

Set

screw resharpenable blade

Disposable planer blade

Resharpenable

planer blade

HSS

Cutter block HCM/K

Side panel

no. 3

Blind

rivet

Square

washer

Hexagon

nut

Hex.

socket head

cap

screw

Switch

HCM

Switch

HCK

Switch

HCK -

B/NL

Switch

HCM

- AUS

Switch

HCK

Switch

HCM -

GB/NZ/DK/CH

Switch

HCM - CDN

Clamping sleeve

Star

knob

Disk spring

Set

collar

Threaded

rod

Hex

socket head

cap

screw

Spacer

strip

Hex. socket head

cap

screw

Hex.

socket head

cap

screw

Cover

rail

Disk spring

Slotted cheese head screw

PVC

crank handle

Hexagon

nut

Thicknesser

bed

adjusting spindle

Thicknesser

bed

spindle

Grooved dowel

pin

Hexagon head screw

Glide

piece

HC

Washer

Feed roller, smooth

Spacer shaft w/tapped hole

Feed roller, coarse

Shim ring

Set

screw

Check

nut

Thicknesser

bed

w/pointer

Spread insert

Shim with hole

8.1

Pressure spring

Washer

Hexagon head screw

Slotted

set

screw

Pan

head tapping screw

Thicknesser

bed

scale

Shim ring

Spindle

bush

Shim

with hole 12.1

Chain

sprocket

Z=1 5 T=6

286.6x525

286.6x525

M6x11

5x10

M6x8

M6

18.6x1x260

260x20x3

RD

62.5x439

5x1

6F

M8

M6x25

2.8 DN 5 A

4.2

DN-M7A

4.2 DN

3-ph

220 V

2.2 WN 11 A

3.1 WN 15 A

1

.8/2.2

WN

2.2 WN

4x16

23.0x10.2x0.9

011

M10

060x470

M6x16

4x20x193

M6x12

M8x16

4x25x179

16.0x8.2x0.6

M6x60

M6

TR

14x3x365

TR

14x3x229.5

3x16

M6x80

A13

14x20x1.0

M5.5

TR14x3

M8x13

22x22

A

8.4

M8x80

M8x16

St

4.8x9.5

0.6x16x170

8x14x1.0

RD

16x10

22x22

32.4x15

1481

916

934

912

1481

2093

705

6912

6912

912

2093

84

934

1473

933

125

988

913

2076

125

931

7981

988

1390206760

139011

9468

148521

0365

1492020300

1492020326

650

302

9250

6164029245

6143043477

091 100

1012

091

100

1039

138521

2913

1390080260

662101

0415

1492020296

620

000

2235

612

1000766

101

1000904

101

101

1680

101

1136873

8133144243

8133144235

101 101

1426

101 101

8536

6503001681

700 706

9620

705301

0100

641

0147244

1395206555

6127059193

149201

9700

612715

1537

612 115

1101

149201

9697

705

301

6795

612001

7193

700 401

7433

6200002219

149201

9302

139501

6578

6501007275

6103008717

1391006039

630

001

6705

149501

9256

149501

9280

149501

9248

630 600

9832

616 115

1139

139501

6616

1390067107

633

001

7420

1390008895

7051005770

630 001

6322

6102001093

6160000358

617201

6683

1141073024

630 601

7266

1391029268

1390008887

724

601

7276

Page 12

Pos.

Description

Dimensions

DIN

Stock-no.

155

156

157

158

159

160

161

162

163

164

165

166

167

168

169

170

171

172

173

174

175

176

177

178

200

201

202

203

204

205

206

207

208

209

210

211

212

213

214

215

216

217

218

219

220

221

222

223

224

225

226

227

228

229

230

231

232

233

234

235

236

237

238

239

Roller

chain

pitch 8 210

links

Drive chain protection

plate

Washer

Setting bracket,

le

+ ri

Guide

rail,

left

Grub screw

Guide

rail,

right

Chip ejection hood extrusion

Pan

head tapping screw

Recoil lock segment

Recoil lock

bar

Recoil

lock

bar

Hexagon head screw

Chip

guide

plate

Spacer shaft

Chain

tension sprocket

Z-15

T=6

Nyloc

hexagon

nut

Threaded bolt

Chain

tension

plate

Chip ejection hood

Hex. socket

head

cap

screw

Pan

head tapping

screw

Hex.

socket head

cap

screw

Chip ejector hood

Fence extrusion

end

cap, right

Fence

segment

Glide segment

Hexagon

head screw

Fence extrusion

Carriage bolt

Fence extrusion

end

cap,

left

Guard extrusion

Guard

extrusion

clamping

lever

Cap nut

Guard support

Guard extrusion

end cap

Countersunk head tapping screw

Side

panel

lid

Countersunk head tapping screw

Drive

belt

cover

HCM/K

Washer

Ratched lever

Plastic washer

Fence carrier

HC

Guide

segment

Nyloc

hexagon head screw

Washer

Raised cheese head screw

Fence cover plate

PVC

pressure spring

Guard setting lever

Hex.

socket

head

cap

screw

Pressure plate

Setting

rod, cogged,

hexagonal

Gear

cover

Raised countersunk

head

screw

Shim ring

Lock lever, right

Lock

lever,

left

J-belt

pulley 5Jx42

Bearing

cup

O-ring

Grooved

ball

bearing 6203

LLU

Guide

bar

2x259x415

A

6.4

2x53x43

4x20x193

M6x8

258

St

4.8x1

3

RD

6x286

RD

10.72x286

M8x80

2x48x313

20x295

RD

32.4x9.5

M6

M6

8h9 1 3x20

2.5x25x76

M8x25

4.8x16

M8x25

ABS

M8x50

600

M6x20

M8

St

3.5x1

3

2x30x153

St

4.2x1

3

B8,4

M8

0

20x08x6

M6x10

A

4.3

4x8

1.5x190x190

M10x16

SW

14x285

M6x20

10x16x1.0

42x1

7

M

14x1

0

40x2.5

42x1

7

M1

4x1

010x75

125

916

933

985

668

7981

912

931

603

1587

7982

7982

9021

933

125

Ahl.

7985

6912

966

1093

723601

1873

139201

7620

630 001

6365

139201

7573

149201

9794

6164029245

149201

9719

1393086226

617201

5687

239

007

3596

139501

7396

139501

7388

6103030259

139201

7506

149501

9272

724

601

7365

620 200

2291

139501

7418

1392028591

139

1085141

612

1000820

617200

1830

612

1000820

139

1085133

139

1028644

1390028497

1391030606

6102008306

1393006850

611

0000608

1391028636

1393067280

1391067240

6201002131

1390067239

1391067666

6174001900

1392086508

617400

1942

1392065900

630

500

2486

700 602

8653

139

1040946

139001

5980

1390028500

6103041013

630

001

6330

6143025088

139201

7603

139

1082861

1391067259

6127151120

1492020245

149501

9264

1391067267

6134070321

6306002170

149201

9425

149201

9433

724

021

2921

1390028470

763 202

8622

710001

7703

139501

7884

Page 13

Pos.

Description

Dimension

DIN

Stock-no.

240

241

242

243

244

245

246

247

248

249

250

251

252

253

254

255

256

257

258

259

260

261

262

300

301

302

303

304

305

306

307

308

309

310

311

312

313

314

315

316

317

318

319

320

321

322

323

324

325

326

327

328

329

330

331

332

333

Fence

carrier support bracket

Hexagon

head screw

Carriage

bolt

Drive

chain

sprocket Z=25

T=38

Clamping sleeve

Bolt,

chain tensioner

Torsion spring

Chain tensioner

Roller chain pitch

6 74

links

Chain sprocket

Z=10

T=8

Threaded bolt

Bolt, short

Bolt,

long

Star

lock

w/o cap

Circlip

Shim ring

Flat belt

Flat belt pulley

Cam

wheel Z=25

T=38

Disk

spring

Hexagon

nut

Drill chuck cover

Thicknesser

drive gear cover

Spacer bush

Washer

Carrying handle

Hexagon head bolt

Side

panel, neutral

Hexagon

head bolt

Spring washer

Blind

rivet

Front

panel, CONDOR switch

Poly-V-belt

Hexagon

head screw

J-belt

pulley,

50 Hz

J-belt

pulley,

60 Hz

Feather

key

Hex.

socket head

cap

screw

Motor carrier

HCM/K

Carriage bolt

Capacitor

Capacitor

Capacitor clamp

Pan

head

tapping

screw

Motor

HCM

Motor

HCK

Motor

HCK

Motor

HCM

Motor

HCM

Motor

HCK

Rear

panel

Axle

bracket, right

Hexagon head screw

Washer

Spring washer

Axle

Hexagonal thin

nut

Wheel

Star

lock with

cap

Axle

bracket, left

Steel tube,

handle

Handle

PVC

LegHC

Rubber

foot

75

shore

M6x20

933

M8x40

603

69x16

4x20

1481

016x60.5

4x20x90

30.5x6.5

014x20

0

20x64.5

0

20x89

08

16x1.0

471

16x22x1.0

988

168x3.2x1.8

69x16

34.0x12.3x1.0 2093

1/2"

06/0

15x18

B 6.4

9021

M8x16

933

M

6x40

933

A

8.4

6798

6x8

F

5

PJ 864

7867

M

12x1.5Li.x25

961

5Jx94

A

6x4x30 6885

M6x16

912

M8x16

603

37.5^F/400

V

30.0^F/400

V

045

3.9x9.5 7981

2.8kW

380/41

5V

4.2

kW

380/41

5V

4.2 kW 230 V

3-ph

1

.8

kW/220-240

V

2.2 kW

220-240V

3.1 kW

220-240

V

6x16

958/933

B 6.4

9021

A

6.4

6798

0

20x526

M

16

936/439

100/35.5

012

2390008913

6103001135

611

001

5990

724 601

7284

650300

1665

139501

6586

705

1005753

1492020237

723601

1865

724

601

7292

1395028584

139501

6608

139501

6594

701

6056183

640 000

9900

630

600

9760

091

1008556

724

201

7301

724 701

7342

705 301

0096

620 901

7227

1391007027

1391005997

644

202

5779

630 500

2087

101 121

0127

6103001178

1392065829

610300

1151

630400

1745

662

1009530

1392067007

091

1007240

610300

1267

724 006

6690

724

020

7677

672

1059322

612

1023081

1392065837

611

0000632

805001

1829

805001

1810

1332025186

6172001791

801

304

6892

801 308

7769

801

302

6638

801 201

9603

801

202

7460

801

208

7757

1392065799

1392077215

610301

5675

630 500

2087

630

408

4047

149501

9345

620 503

2396

727 002

8750

701 602

5628

1392077207

201

1000625

700 802

2431

1392026530

705

701

9365

Page 14

If!

LQ

Page 15

Page 16

ELEKTRA

BECKUM

Aktiengesellschaft

Postfach

13 52,

D-49703

Meppen

cc

EG-Konformitatserklarung

- EC

conformity

declaration - Declaration

de

conformite

GEE

EG-verklaring

van

overeenstemming - EF-overensstemmelsesattest - EG-konformitetsdeklaration

EF-konformitetserklasring - Selvitys

ey-standardinmukaisuudesta - Dichiarazione

di

conformita

CE

Declaracion

de

conformidad-UE - Declaragao

de

conformidade

CE

Wir

erklaren,

daB

die

Bauart

der

Maschine/des

Cerates

- We

declare that

the

design

of the

machine/appliance

Nous

certifions

que

le

type

de la

machine/de

I'appareil - Wij

verklaren

dat de

constructie

van de

machine/het

apparaat

Vi

erklaerer,

at

konstruktionen

af

maskinen/apparatet - Harmed

forsakrar

vi

aft

maskin/apparat

- Vi

erklaerer

at

konstruksjonsmaten

til

maskin/apparat

Taten

selvitamme,

etta

alia

mainittu

kone/laite - Dichiariamo

che

il

modello

della

macchina/dell'apparecchio

Declaramos,

que el

modelo

de la

maquina/aparato - Declaramos

que o

tipo

de

construgao

da

maquina/do

aparelho

Abricht-

und

Dickenhobelmaschine

HC

260

M/2200

WNB - HC 260

K/3100

WNB - HC 260

M/2800

DNB - HC 260

K/4200

DNB

Art.-Nr. - Stock-no. - N°

d'

article - art.-nr. - art.-nr. - Art.-nr. - Art.-Nr. - tuotenumero - N°

Art. - Art.N* - artigo

n°:

011

3026081

- 011

2026053

- 011

3026090

- 011

2026061

folgenden

einschlagigen

Bestimmungen entspricht - corresponds with

the

following relevant regulations

est

conforme

aux

reglements

applicables suivants

- aan de

volgende

terzake

geldende

voorschriften

voldoet - opfylder

falgende

gaeldende

bestemmelser

enligt

sin

byggsatt

motsvarar

foljande

gal/ande

foreskrifter - oppfyller

de

folgende

gjeldende bestemmelser

vastaa

seuraavia asiaa koskevia

maarayksia - corrisponde

alle

seguenti

norme

in

materia

se

a/usta

a las

siguientes

directrices correspondientes

- se

enquadra

com as

seguintes

disposicoes

pertinentes:

EG-Maschinenrichtlinie

- EC

machine directive - directive

GEE

pour

les

machines - EG-machinerichtliln

- EF

maskindirektiv - EG-maskindirektiv

EF

maskindirektiv - Koneita

koskeva EY-direktiivi - Direttiva

CE per

macchinari - Directriz

de

maquinas-UE - Directiva

CE

para

maquinas

89/392/EWG

EG-Richtlinie

Elektromagnetische

Vertraglichkeit - EC-directive electro-magnetic compatibility - directive

GEE

sur la

conformite

electromagnetique

EG-richtlijn

elektromagnetische

compatibiliteit - EF-direktiv vedr. elektromagmetisk fordragelighed - EG-direktiv

for

elektromagnetisk

tolerans

EF-direktiv

om

elektromagnetisk kompatibilitet - Sahkomagneettista

toleranssitasoa koskeva EY-direktiivi - Direttiva

CE

compatibility

elettromagnetica

Directriz-UE

Compatibilidad electromagnetica - Directiva

CE

sobre compatibilidade electromagnetica

89/336/EWG

Angewendete

harmonisierte

Normen - Applied harmonized standards - normes

harmonisees

appliquees - Toegepaste

geharmoniseerde

normen

Anvendte harmoniserede standarder - Tillampade

harmoniserande

direktiv - Anvendte tilpassede normer - Sovelletut

harmonisoidut

normit

Norme

armonizzate

applicate - Normas

armonizantes

aplicadas - Normas

harmonizadas

aplicadas:

DIN-EN 294;

EN

60204-1

Angewendete

nationale

Normen - Applied national standards - normes

Rationales

apppliquees - Toegepaste

nationals

normen

Anvendte

tyske

standarder - Tillampade nationella direktiv - Anvendte nasjonale normer - Sovelletut kansalliset normit - Norme

nazionali

applicate

Normas

nacionales

aplicadas - Normas

nacionais

aplicadas

VBG

7j; ZH

1/3.8;

DIN

45635

Teil

1650

Die

Baumusterprufung

wurde

von

folgender gemeldeter Stelle

durchgefuhrt

- The

type

test

was

carried

out by the

following registered location

L'homologation a ete

effectuee

par

I'office suivant

- De

constructiemodel-keuring

werd

door

de

volgende

officiele

instantie uitgevoerd

Typem0nsterpr0ven

er

gennemfart

af

folgende

registrerede institut - Monsterprovet

utfordes

pa

fo/jande

auktoriserad

institution

Prototypen

ble

testet

av

felgende

registrerte

institusjon - Mallikappaleen

tarkastuksen

on

suorittanut

seuraava

rekisteroity

laitos

L'omologazione e stata

effettuata

dal

seguente

ufficio

- El

ensayo

de la

muestra constructiva

ha

sido realizada

por la

siguiente institution autorizada

A

inspeccao

do

modelo

de

construcao

foi

realizada

pela

seguinte autoridade:

TUV-Rheinland,

Postfach

910351,

D-51101

Koln

Nummer

der

EG-Baumusterprufbescheinigung - Number

of the EC

type

test certificate - Nummero

d'homogolation

GEE

Nummer

van

het

EG-constructiemodel-certificaat - EF-typem0nsterpr0veattestens

nummer - EG-provintygets

nummer

Nummeret

pa

EF-prototyptestsertifikatet - EY-mallikappaletarkastustodistuksen

numero - Numero

del

certificate

di

omologazione

CE

Numero

de la

Certificacion-UE

de la

muestra constructiva - Numero

do

certificado

de

inspeccao

CE

para o modelo:

9311212

Technischer

Leiter - Technical

Manager

- Le

responsable

technique - Cheftechniek - Teknisk

leder - Produktledare

Teknisk

leder - Tekninen

johtaja - Direttore

tecnico - Director

tecnico

- 0

director

tecnico

1000615

D/GB/F/NL/DK/S/N/SF/I/E/P

Loading...

Loading...