Page 1

Operating Instruction

Compressed Air-Dryer

Cool 201

Cool 401

I14 5003 EGB

03.03

Page 2

Type Code

Serie

Version

Cool 201 405AP

Cool 401 407AP

Types equipped with electromagnetic

drainvalve according 2.6.1 and 3.8.1.

(Types equipped with sensor operated

drainvalve according 2.6.1, 3.8.2 and 5.1.6 are

not available.)

03.03

2

Page 3

T ab le of contents

Page

Type Code

Part 1 Important user infor-

mation

All safety notes in this operating instruction which may cause harm to personnel

or equipment, when ignored, are marked by the following symbols:

1.1 General Notes 4

1.2 Safety regulations 5

1.3 Handling with refrigerant 6

2

!

General danger symbol Electrical danger symbol

1.4 First aid 7

1.5 Disposal 7

Part 2 Installation

Part 3 Description

Part 4 Operation

2.1 Transportation 8

2.2 Requirements on the place

of installation 8

2.3 Installation (Mounting) 8

2.4 Compressed air connection 9

2.5 Electric Connection 9

2.6 Connection condensate drain 10

3.1 Designation 12

3.2 Purpose 12

3.3 Unit layout 12

3.4 Electronic regulator 14

3.5 Nominal power of CA-dryer 15

3.6 Principle of operation 15

3.7 Mode of operation 15

3.8 Condensate draining 16

4.1 Commissioning 17

4.2 Starting 17

4.3 Operation 17

4.4 Stopping 17

4.5 Electronic regulator - operation 18

4.6 Changing the factory setting 18

Part 5 Maintenance

Appendix

11.02

5.1 Maintenance 20

5.2 Trouble shooting 22

Technical data

Wiring diagrams

Spare parts lists

Declaration EC-conformity

Additional sheets for options

3

Page 4

Part 1 Important User Information

1.1 General notes • This compressed air-dryer is called CA-dryer in the

following.

• The Company does not accept responsibility if safety

regulations are not met during handling, operation,

maintenance and repair, even though these are not

strictly stated in these operating instructions.

• We recommend the notice of these operating instructions verified by the operating personnel in writing (personnel file).

• We recommend translation of these operating instruction into native language of foreign workers.

• The usability and the life cycle of the compressed airdryer as well as the avoidance of premature repairs

depends on proper operation, maintenance, care and

competent repair under consideration of these operating instructions.

• Hints to figures and locations are in brackets, e.g.

(Fig. 5/2)

• Due to our position as suppliers of components we

do not always know the final usage and total range of

products' applications. We constantly improve our

products to the latest state of science and technology

and therefore, we assume that our products are free

from defects in the sense of product liability . Ho we ver ,

it cannot be excluded that during faulty operation in

critical areas of application especially at danger to life

and limb of persons involv ed, additionally safety measures may be necessary. Therefore, we request the

user of our components / units, to ensure in his own

interest, to inform us about the application of our products in order to initiate additional safety measures, if

necessary.

4

11.02

Page 5

Part 1 Important user Information

1.2 Safety regulations

Attention!

The operator has to observe the national working-, operating- and safety regulations . Also e xisting internal factory regulations must be met.

!

Maintenance and repair work must only be carried out

by specially trained personnel and, if necessary, under

supervision of a person qualified for this work.

• Protective or safety devices must not be removed,

modified or readjusted.

• During operation of the CA-dryer none of the protective of safety devices must be removed, modified or

readjusted temporarily or permanently.

• Use proper tools for maintenance and repair work only .

!

• Use original spare parts only.

Attention!

All maintenance and repair works must only be executed

at stopped machine, disconnected power supply and

pulled mains plug. Ensure that the CA-dr yer cannot be

switched on by mistake.

• Prior to dismounting a part under pressure disconnect the CA-dryer from all pressure sources and depressurize the CA-dryer.

• Do not use inflammable solvents for cleaning.

• Keep the environment absolutely clean during maintenance and repair works. Keep free of dirt by covering the parts and free openings with clean cloth, paper or adhesive tape.

• Never weld at the pressure vessel or modify it in any

way.

11.02

• Ensure that no tools, loose par ts or similar are left in

the system.

5

Page 6

Part 1 Important user Information

1.3 Handling with

refrigerant

• Wear eye protection and protective gloves

• Avoid contact of liquid refrigerants with your skin (frostbite).

• Do not inhale refr igerant vapours.

• To avoid higher concentrations, all work rooms must

be ventilated very well. The opening of windows and

doors may not be sufficient, so an exhausting system

must be used directly at the supply point or near the

floor.

• Do not smoke, because fire might decompose the

refrigerant. The resulting substances are toxic and

must not be inhaled.

• Do not have refrigerants escaped during filling or repair work. Cover with tape.

• Leave the room immediately and only enter after the

room has been sufficiently ventilated when refrigerant concentrations (e.g. pipe line leakages) appear

suddenly.

• Execute welding and soldering works on refrigerating

systems in well ventilated rooms only. Refrigerants

will be decomposed in flames as well as in electrical

arcs.

• The resulting decomposition products are toxic.

• Before welding and soldering at refrigerating systems,

the refrigerant must be removed.

• A stinking smell points to decomposition of refr igerant due to overheating:

- leave room immediately

- ventilate room ver y well.

6

11.02

Page 7

Part 1 Important user Information

1.4 First aid

1.5 Disposal

• Take victim immediately into the fresh air or into a

very well ventilated room.

• Splashes of refrigerant in the ey es must be blo wn out

with the mouth. Then rinse eyes with plenty of water.

Do not wipe with cloth!

• If the victim does not breathe, perform a mouth-tomouth resuscitation or use a respirator until the doctors arrival.

• Call the doctor and inform him that accident has

been caused by refrigerants, for refrigerant type

see identification plate!

• Never leave the victim unattended!

• When disposing of used devices, pay attention to oil

and refrigerant in the hermetical sealed refr igerating

circuit of the CA-dryers. Therefore, before dismounting, these operation media must be disposed by a

special company.

!

• The used mater ials are listed on the recycling label

inside the CA-dryer.

Attention!

Do not dispose waste oil into the environment. Do not

mix with household rubbish and do not burn in unauthorized plants.

• The escape of refrigerant into the atmosphere must

be prevented by appropriate measures.

11.02

7

Page 8

Part 2 Installation

2.1 Transportation

2.2 Requirements on

the place of installation

!

Transportation has to be carried out in the normal operating position of the CA-dryer.

For a short time an inclined position of 45 ° is allowed.

At the site of installation, the CA-dryer can be installed

without anchorage or special foundation at the location

desired.

The CA-dryer is provided for an ambient temperature of

25 °C.

Attention!

To avoid corrosion at components of the CA-dr yer the

compressed and ambient air must be free of aggressive

parts.

The CA-dryers are provided for inside mounting.

Deviating conditions require the consultation of the manufacturer.

To prevent the condensate from freezing the room temperature must not drop below +2 °C.

!

2.3 Installation

(mounting)

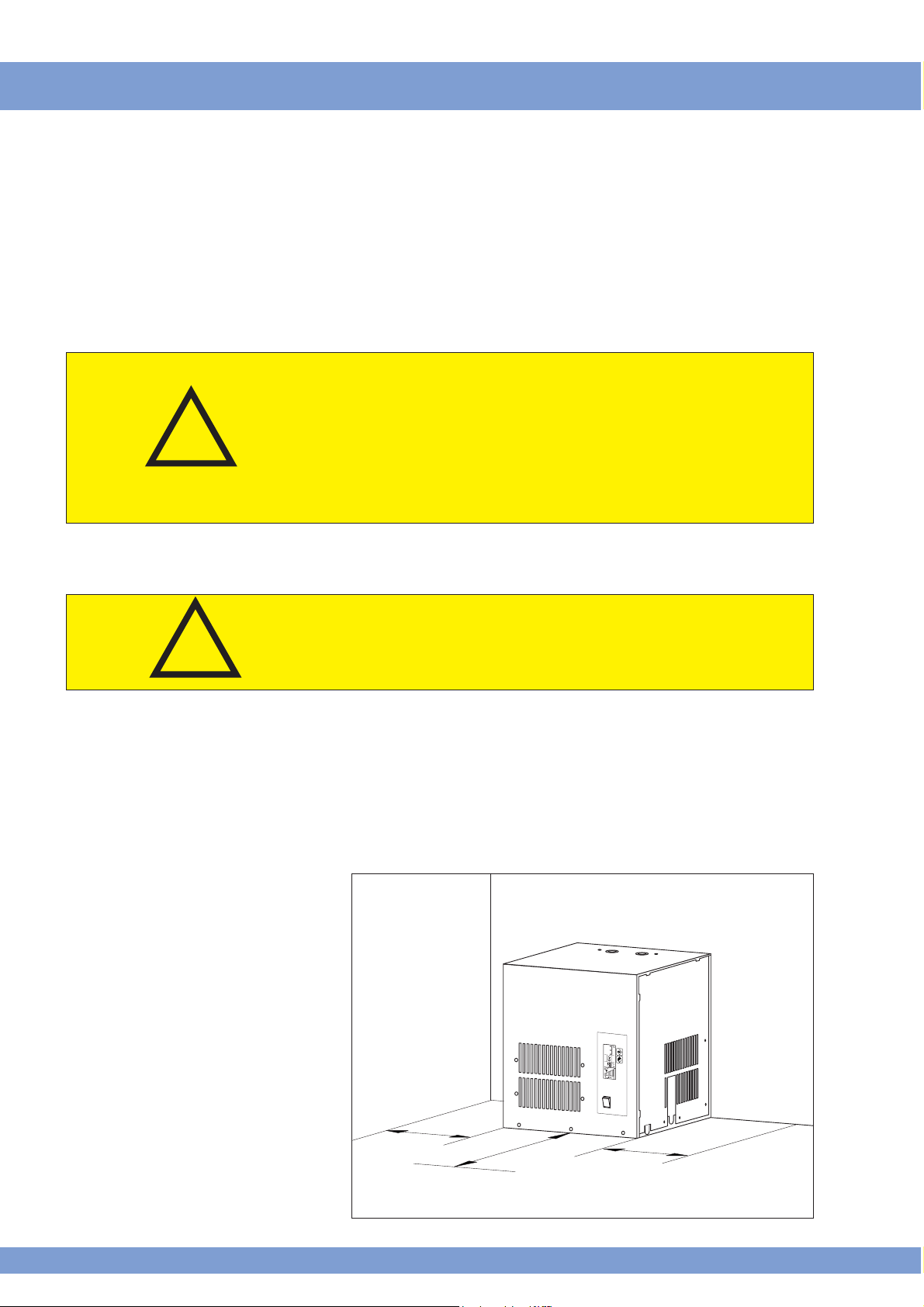

Fig. 1: Installation of

CA-dryer

Attention!

At different ambient conditions pay attention to the layout data!

The CA-dryer must be installed that accessibility to the

front panel is ensured. Furthermore leave space f or service purpose on both sides of the CA-dryer (fig. 1).

Wall mounting is possible with all types.

8

11.02

Page 9

Part 2 Installation

2.3.1 Version air cooled

2.4 Compressed air connection

!

The cooling air for the refrigerant condenser will be

sucked in at the front panel (fig. 5/3). This area must be

kept free and not be obstructed.

If necessary, sufficient cooling air supply must be provided by additional wall openings .

The cooling air outlet is positioned at the top of the unit

(fig. 5/8). Ensure a free air outlet and do not obstruct the

outlet of the cooling air.

If the CA-dryer is connected to an exhaust trunk, an additional fan must be installed to compensate the pressure drop. The controlling of the fan must be provided

through the CA-dryer.

The connection must be ex ecuted acc. to marking at the

CA-dryer (fig. 5/1+2).

For service purposes the installation of a bypass line is

recommended (additional equipment).

Attention!

Before mounting the CA-dryer, welding residual, rust or

other pollution must be removed from the pipelines to

be connected. If pollution cannot be excluded, proper

filter system must be installed

The compressed air pipes must be installed stress-free.

Expansion joints are recommended in case of vibrations

and pulsations.

2.5 Electric connection

The CA-dryers are completely equipped and wired. They

merely have to be connected to a power supply. The

CA-dryers are to be protected by slow-blow fuses as

defined in the wiring diagram.

Operation voltage: acc. to name plate or wiring diagram resp.

Attention!

Due to transportation reasons the power connection

cable with installed cable gland is located inside the casing of the CA-dryer.

After removal of the side wall (fig. 5/9) the cable gland

is mounted and fastened in the corresponding passage (fig. 5/6) of the casing.

11.02

9

Page 10

Part 2 Installation

2.6 Connection condensate drain

Attention!

A hose must be fixed at the condensate drain and led

out of the casing.

An opening (Fig. 5/7) can be used for leading out the

!

!

hose.

For safety reasons the side wall must be closed again.

The CA-dryer separates water as well as oil from the

compressed air. The water/oil mixture must not be led

into the sewage. Water and oil must be separated by

suitable separators (additional equipment).

Attention!

Route outflow so that persons or objects will not be struck

by condensate (condensate outlet with operating pressure)!

2.6.1 Version with solenoid valve

Fig. 2: Solenoid valve

2.6.2 Version with sensor

controlled drain

(option)

Fig. 3: Sensor controlled

drain

with electronic

regulated condensate drain

A minimum operation pressure of 2

bar is required for

safe oper ation.

10

11.02

Page 11

Part 2 Installation

2.6.3 Connection condensate draining

Fig. 4: Connection conden-

sate draining

The condensate drain pipe (fig. 2.1) may be fixed to the

wall with a rising slope of maximum 5 m. Thereby the

minimum operation pressure increases for 0,1 bar per

meter . The collecting pipe (fig. 2/2) should be laid throughout its whole length at least as the cross-section of the

condensate outlet.

2

1

from condensate drain

to treatment

11.02

11

Page 12

Part 3 Description

3.1 Designation

3.2 Purpose

3.3 Unit Layout

Fig. 5: Complete system

Refrigerating compressed air-dryer (CA-dryer).

Version see type code (page 2)

Compressed air will be dehumidified by the CA-dryer.

Following components of the CA-dryer are accessible

from outside (fig. 3).

12

9

8

Fig. 6: Electronic regulator

- operating panel

45 6 7

3

1 Compressed-air inlet

2 Compressed-air outlet

3 Cooling air inlet

4 Electronic regulator operating panel (Fig. 6)

5 Operation switch

6 Electric connection

7 Condensate drain

8 Cooling air outlet

9 Access for service

Data input key

Condensate draining key for

electronic regulated drain

Display electronic regulator

Operation switch

12

11.02

Page 13

Part 3 Description

3.3.1 Symbols

Fig. 7: Symbols

general

Operation switch “off”.

Compressed air inlet or outlet.

Before executing maintenance

work at the CA-dryer, the unit must

be disconnected from the power

supply.

If the CA-dryer is not disconnected

the risk of injuries is given, due to

free rotating fan wings.

The refrigerant compressor heats

up during operation so that there

is a danger of burns .

3.3.2 electronic regulator

symbols

Fig. 8: Symbols

electronic regulator

11

6

7

8

6

Condensate drain

1

1 Temperature in °C

2

2 Temperature in °F

3

3 Nor mal- or summer opera 4

5

9

tion

4 Percentage running time of

CA-dryer

5 Time to next condensate

draining

6 Failure indication

7 Condensate drain

8 Condensate tank

10

9 Maintenance interval ex-

ceeded

10 Counter working hours

12

11 Operation indication refriger

ant compressor

12 Actual energy consumption

Fig. 9: electronic regulator

operation

11.02

1 Data input key

2 Condensate drain key for

12

13

electronic regulated drain

Page 14

Part 3 Description

3.4 electronic regulator

Fig. 10: Normal display

electronic regulator,

example

The electronic regulator is a controller specially designed

for CA-dryers. It operates on the basis of micro

processors. Data as cooling temperature, pressure within

cooling circuit, ambient temperature as well as CA-dryer

specific parameter are processed by the electronic and

therewith the actual operational state of the unit is

determined.

If it is allowed due to the measuring data, the cooling

compressor is stopped for a predetermined time. The

pulsating measuring of the temperatures (multiple per

second) and the function of the aluminium-heat exchanger as cold store enables the quic k reaction on load

changes without allowing dew point peaks to e xceed the

max. adjusted nominal value.

Depending on loads the electronic regulator additionally

regulates the condensate drain to avoid compressed air

losses.

1

1 Pressure dew point

(shown Celsius)

3.4.1 Normal operation

(factory setting)

3.4.2 Summer operation

3.4.3 Automatic operation

2 Condensate level

4 lines = condensate

2

3

4

The electronic regulator sets the pressure dew point on

max. 3°C.

The electronic regulator sets the pressure dew point on

max. 7 °C.

The electronic regulator sets the pressure dew point in

dependence to the ambient temperature at the location,

to keep a relative humidity below 40% at the CA-dryer

outlet.

5

will be drained shortly

3 682 working hours

4 Refrigeration compressor

working

5 Actual energy consumption

is 50%

!

Attention!

To enab le this, it is necessary that the ambient temperature of the whole CA-network are not below the temperatures at the location of the CA-dryer.

14

11.02

Page 15

Part 3 Description

3.5 Nominal power of

CA-dryer

3.6 Principle of operation

The nominal power of the CA-dryer mentioned in the

technical data is related to a working pressure of 7 bar,

a compressed air inlet temperature of 35 °C as well as

an ambient temperature of 25 °C acc. to DIN ISO 7183.

Lower working pressure, higher compressed air inlet temperature and/or higher ambient temperatures overload

the compressor which causes to an increased pressure

dew point and the compressor can be stopped by internal safety devices.

At essentially deviating operation conditions , contact the

deliverer of the CA-dryer for support.

The CA-dryer includes a refrigerant system cooling the

compressed air flow. The steam saturation limit is lowered causing condensate to fall out, which is removed

by the condensate drain.

The higher the cooling temperature difference of the air,

the higher the amount of condensate.

The lower the cooling temperature of air, the lower the

moisture content.

The lower limit of air cooling results from the operating

principle of the CA-dryer based on the moisture separation in liquid form.

So the freezing point of water (0 °C) must not be undergone.

3.7 Mode of operation

3.7.1 Compressed air side

The compressed air precooled in the aftercooler and

saturated with moisture enters into the CA-dryer and is

precooled in the first cooling stage, the air-to-air heat

exchanger without additional energy. Cooling is carried

out in counterflow to the already cooled air heated during this process.

The cooling to the pressure dew point is perfor med in

the second cooling stage, the refrigerant-to-air heat exchanger cooled by the refrigerant system installed. Subsequently, the cooled compressed air is reheated in the

air-to-air heat exchanger as already described.

The pressure dew point is indicated at the electronic

regulator panel.

11.02

15

Page 16

Part 3 Description

3.7.2 Refrigerant side

3.8 Condensate draining

3.8.1 Condensate drain

electromagnetic

The refrigerant is injected into the refrigerant-to-air heat

exchanger where it ev aporates, thereby the compressed

air is cooled. The electronic regulator regulates the cooling temperature and keeps the pressure dew point constant in nearly all capacity stages.

The refrigerant compressed by the motor compressor is

condensed within the condenser and is availab le for the

evaporation again.

The condensate drain is used for draining the condensate.

Depending on the ambient- and cooling temperature of

the CA-dryer, the solenoid valve is opened by the

electronic regulator. This ensures a compressed air condensate draining with nearly no loss of compressed air.

If the condensate volume deviates from the set values

(see 4.6.1.6) the adaptation to the specific characteristics

of compressed air system is possible (see 4.6.1.6)

3.8.2 Condensate drain

sensor-controlled

(option)

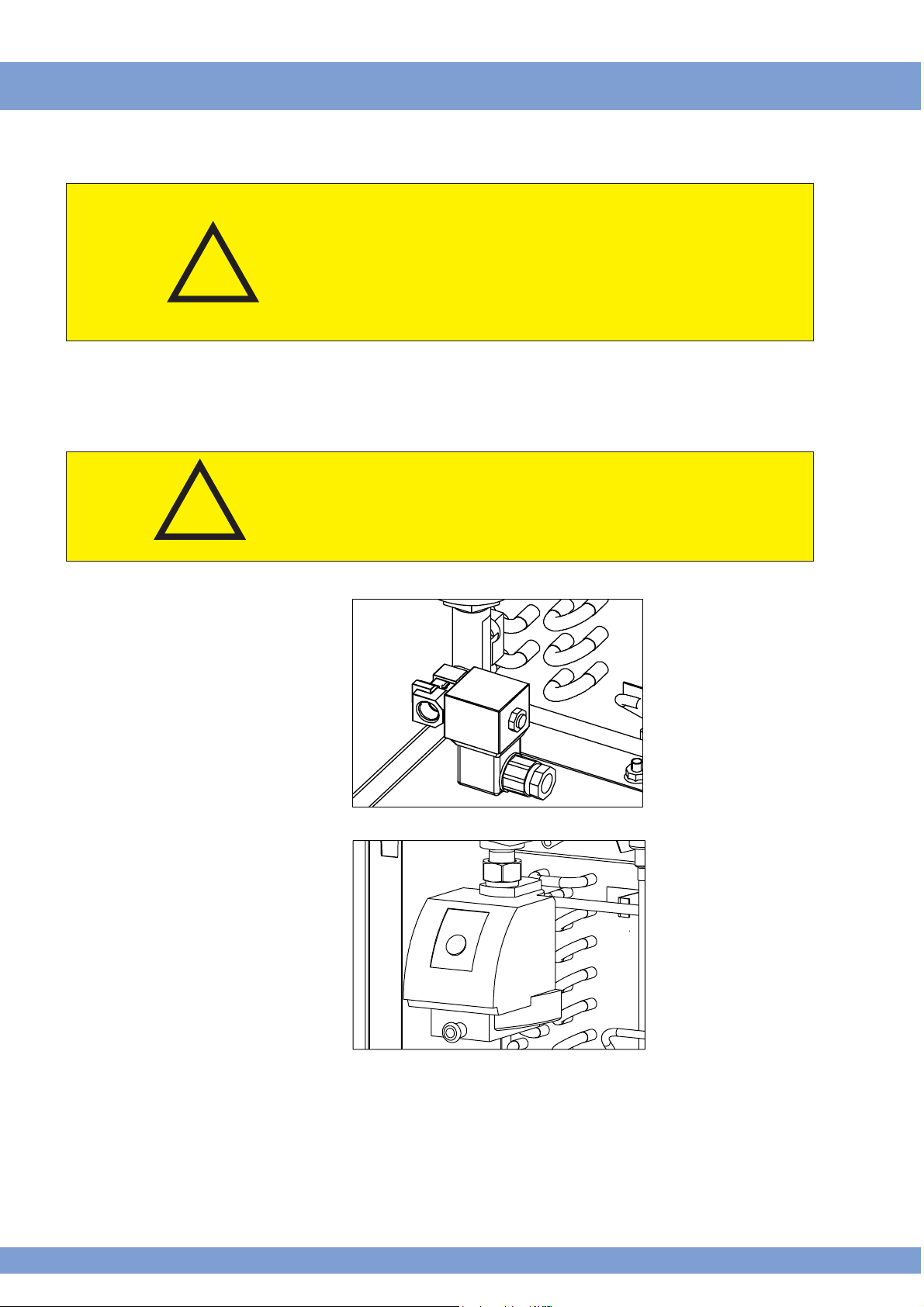

Fig. 11: Condensate drain

reports

Once the container has filled with condensate, so that

the capacitive level sensor emits a signal, the internal

solenoid valve opens and the condensate is forced by

the working pressure into the discharge pipe.

The condensate drain electronic system ensures the

closing of the outlet opening before any compressed air

can escape. For functional safety a minimum pressure

of 2 bar is necessary.

Power

Alarm

Test

Power

Alarm

Test

Power

Alarm

Test

123

At faulty condensate discharge (bloc ked discharge pipe,

pressure below minimum operating pressure), the unit

changes to the alarm control after 60 seconds. The green

LED flashes and a potential-free contact is activated.

While in alarm control mode, the solenoid valve will open

ever y 4 minutes for a period of 7,5 seconds, in order to

remove any possible obstructions in the discharge pipe

automatically.

A unit filled during a pressureless state will additionally

be emptied automatically , as soon as the minimum pressure within the condensate drain has been reached.

16

11.02

Page 17

Part 4 Operation

4.1 Commissioning

4.2 Starting

4.3 Operation

After installation the CA-dryer is supplied with power via

the power cab le (fig. 5/1) or by operating the main s witch

(fig. 5/13).

Before operating the operation switch (fig. 3/14), a waiting period of at least 6 hours is absolutely necessary.

The CA-dryer is switched on via the operation switch

(fig. 5/14). After approx. 5 minutes the compressed air

admission is possible by connecting the compressed air

compressor.

The CA-dryer is designed for continuous operation and

may remain switched on during periods of no load, as it

adapts to the required performance automatically.

Operation is indicated by the luminous operation s witch

(fig. 5/14).

The electronic regulator shows the pressure dew point

reached by the CA-dryer.

4.4 Stopping

At standstill periods, the CA-dryer is switched off with

operation switch (fig. 5/5).

For service works, the CA-dryer is switched off by pulling the power cable (Fig 5/6).

At restarting proceed acc. to item 4.1.

11.02

17

Page 18

Part 4 Operation

4.5 electronic regulator

- operation

Fig. 12: Pressure dew point

Fig. 13: Percentage running

time of CA-dryer

Fig. 14: Condensate drain

Following operation data can be

recalled by operating the data

selector key ( ):

- Pressure dew point

- Summer operation

- Percentage running time of

CA-dryer in relation to total

running time of the system

- Next condensate drain in 3

minutes

4.6 Changing the factory

setting

Fig. 15: Changing factory

setting

1. Press data selector key ( )

for 5 seconds to change from

display- into change mode.

2. If necessary press data selector ke y ( ) sev eral times until

requested change mode

appears.

3. Adjusting by condensate drain

key ( )

4. Press data selector k ey ( )

for 5 seconds to sav e changes

and returning into display

mode.

18

11.02

Page 19

Part 4 Operation

4.6.1 Change modes

4.6.1.1 P01

4.6.1.2 P02

4.6.1.3 P03

4.6.1.4 P04

4.6.1.5 P05

4.6.1.6 P06

Activation pressure dew point-summer set value (factory setting: pressure dew point 7 °C).

Acknowledgement of failures (see 5.1)

Acknowledgement maintenance interval (see 5.1)

Change of pressure dew point-normal set value by serv-

ice.

Change of pressure dew point-summer set value by serv-

ice.

Change of station time of condensate draining time

(optimization of condensate draining)

At normal operation conditions the condensate volume

per condensate draining time corresponds to the values

mentioned below.

Type of CA-dryer Condensate volume

405 AP, 406AP: 40cm³ - 60cm³

407 AP: 12cm³ - 18cm³

!

4.6.1.7 P07

4.6.1.8 P08

4.6.1.9 P09

4.6.1.10 P10

Attention!

- at greater amount of condensate per condensate

draining time the factor P06 must be lowered.

- at smaller amount of condensate per condensate

draining time the factor P06 must be raised.

P06 Minimum: Factor 1

P06 factory setting: Factor 16

P06 Maximum: Factor 33

Setting possibility of the pressure dew point failure limit

value (factory setting 18 °C).

Change °C / °F.

Activation solenoid valve condensate draining.

Activation automatic operation.

11.02

19

Page 20

Part 5 Maintenance

5.1 electronic regulator

maintenance display

Fig. 16: Maintenance display

5.1.1 Acknowledgement

maintenance interval

Fig. 17: Acknowledgement

maintenance interval

Flashing maintenance symbol:

- maintenance interval exceeded

1. For acknowledgement press

data selector key ( ) within 5

minutes after restart the CADryer for 5

seconds.

2. Press data selector key ( )

seve ral times until change mode

P03 appears.

3. Acknowledging the maintenance

interval key with condensate

drain key ( ) - the maintenance symbol disappears ( ).

4. For returning into display mode

press data selector key ( )

for 5 seconds

5.1.2 Maintenance

!

5.1.3 Daily checks

(without maintenance symbol)

Attention!

Prior to any maintenance works all safety regulations for

electrical systems and units must be observed.

Maintenance intervals highly depend on the mode of

operation and the ambient conditions on site, the intervals belo w are only to be understood as general recommendations.

Monitoring of all temperatures.

Check function of condensate drain.

a) electronic regulated condensate drain :

Operating condensate drain key ( )

check, if water is drained.

b) Sensor controlled condensate drain:

Operating key “Test ”.

check, if water is drained.

When operated, the condensate drain pulses all

2-3 seconds.

20

11.02

Page 21

Part 5 Maintenance

5.1.4 Weekly maintenance

!

5.1.5 Cleaning of filter before condensate

drain with solenoid

valve

5.1.5.1 Dismounting of

filters

Inspection and cleaning of condensate draining system

if necessary.

Attention!

Maintenance work must be performed at the depressurized condensate trap only. For this purpose, the installation of a bypass line is recommended (additional

equipment).

a) disconnect CA-dr yer from compressed air system

b) remove side wall (Fig. 5/9)

c) shut ball valve

d) depressurize by operating the condensate drain

key (Fig. 9/2).

e) remove cap

f) remove filter and clean with neutral cleaning agent,

replace if necessary.

Fig. 17: Solenoid valve, ball

valve with filter

1

5

2

3

4

1 Ball valve with filter insert

2 Filter

3 O-ring

4 Cap

5 Solenoid valve

5.1.5.2 Mounting of Filters

5.1.6 Sensor controlled

condensate drain

(option)

11.02

Mounting is done in reverse order.

Replace working parts yearly (see spare par ts list)

21

Page 22

Part 5 Maintenance

5.2 Trouble shooting

Fig. 19: Failure indication

general

5.2.1 electronic regulator

failure indication

Fig. 20: electronic regulator

Failure indication

Failure indication: CA-dryer

stopped.

CA-dryer stopped

Display changes be-

tween set value and

failure indication

(refrigerant overpressure)

Cause

5.2.1.1 F1 sensor pressure

dewpoint defective

5.2.1.2 F2 sensor ambient

temperature defective

5.2.1.3 EH EEPROM:

electronic regulator

5.2.1.4 EL electronic regulator

defective

5.2.1.5 FH refrigerantoverpressure

5.2.1.6 EU low voltage

5.2.1.7 H1 dew point too high

Remedy

Check sensor connection, replace sensor

Replace regulator

Restart CA-dr yer, if not possible:

Replace regulator

Restart CA-dr yer, if not possible:

Replace regulator

See 5.2.5

Ensure electric power supply acc. to technical data.

See 5.2.4

5.2.1.8 L1 dew point too low

See 5.2.6.3

22

11.02

Page 23

Part 5 Maintenance

5.2.2 Acknowledgement of

failures

Fig. 21: Acknowledgement of

failures

5.2.3 Function:

Cause

No function

1. For acknowledgement operate

data selector key ( ) for 5

seconds.

2. Operate data selector key ( )

once more until P02 appears .

3. Acknowledgement of failure

through condensate drain

key ( )

4. For returning into display mode

press data selector key ( )

for 5 seconds.

Remedy

- Check and establish power supply if necessary

- If the pow er supply is ok, call for service or send CAdryer to the manufacturer.

5.2.4 Water in compressed

air system

Cause

5.2.4.1 Condensate is not

drained properly

5.2.4.2 electronic regulated

condensate drain

5.2.4.2.1 Faulty condensate

draining

5.2.4.2.2 Solenoid valve de-

fective

Remedy

- check condensate separator behind the compressor.

- possibly install automatic drain

- no sufficient drainage of the condensate separator

behind the compressor, extend condensate draining

time.

Clean solenoid valve

Replace solenoid valve

11.02

23

Page 24

Part 5 Maintenance

5.2.4.3 Sensor-controlled

condensate drain

5.2.4.3.1 Blocked discharge

pipe

5.2.4.3.2 Operation pressure

below required minimum

Cause

5.2.4.4 Temporary overload of

the CA-dryer due to

non-uniform compressed air consumption

5.2.4.5 Overload due to high

volume flo w, or too high

compressed air inlet

temperature

Clean condensate drain with neutral cleaning agent.

Increase working pressure

Remedy

Reduce load, check whether CA-dryer´s capacity is properly selected

Reduce CA-consumption or increase CA-dryer´s capacity

(with installed bypass line)

5.2.4.6 Bypass valv e of bypass

line opened

5.2.4.7 Bypass valv e of bypass

line leaky

Close bypass valve in the bypass line

Seal or replace bypass valve in the bypass line,

24

11.02

Page 25

Part 5 Maintenance

5.2.5 Stopping CA-dryer

during operation:

Cause

Remedy

- Stopping of CA-dryer by

installed electric star t and

protection device (Klixon) at

the refrigerant compressor

due to overload

5.2.5.1 CA-volume flow too

high

5.2.5.2 CA-inlet temperature

too high

5.2.5.3 Room temperature too

high

5.2.5.4 Defectiv e fan or cooling

water regulator (watercooled version)

- eliminate cause of trouble, see 3.5 or call for service

- the CA-dryer will return to operation mode automatically after protection device has cooled down.

Note: The immediate restarting of the unit is not possible because the protection device requires a minimum time to cool down to an admissible operating

temperature.

Reduce volume flow

Check whether CA-dryer´s capacity is properly selected,

increase CA-dryer´s capacity

Check aftercooler with separator and drain behind the

compressed air compressor, install if not present

Ensure proper ventilation of CA-dryer´s location

Replace fan or cooling w ater regulator resp., call for service

5.2.5.5 Condenser polluted

5.2.5.6 Operating pressure too

low

Clean condenser

Increase operating pressure, chec k whether CA-dryer´s

capacity is properly selected

11.02

25

Page 26

Part 5 Maintenance

5.2.6 High differential

pressure at CA-side:

Cause

5.2.6.1 Compressed air volume

flow too high

5.2.6.2 Working pressure too

low

5.2.6.3 Icing of CA-dryer

Remedy

Check whether CA-dryer´s capacity is properly selected,

increase CA-dryer´s capacity

Increase operating pressure , check whether CA-dryer´s

capacity is properly selected

Characteristics: - differential pressure at com-

pressed air side increases

- volume flow decreases

Disconnect unit and maintain compressed air flow . After

approx. half an hour, the differential pressure will return

to normal value. Restar t the unit. If the heat exchanger

ices up again call for service.

26

11.02

Page 27

7 bar

2002-11-29 1

+35°C

3

m³/h 50 65 80

m³/min 0,83 1,08 1,33

450

0,036

2 / 16

16 / 50

bar

500

450

450

0,33

< 70

20

1/4"

+3°C

+25°C

max. +60°C

min. + 2°C

max. +50°C

405AP - 407AP

Type-No.: Date: Page 1 of

Size of Housing

low pressure side,

high pressure side

height

width

depth

at compressed air inlet temperature

operating pressure

ambient temperature

pressure dew point at CA-dryer outlet

Power consumption at ambient temperature

Compressed air inlet temperature

Volume flow reffered to the suction status of the air compressor

Pos.1 : +20°C 1 bar

Pos. 3, 4: +25°C

Allowed ambient temperature:

Technical modifications are subject to change without notice!

Refrigerated Compressed Air Dryer I1T 5003 0GB

Designation: Technical Data Sheet:

GB Technical Data

Pos. Type-No. 405 AP 406 AP 407 AP

1 Volume flow

3 Power consumption (total) kW 0,25 0,27 0,33

Power supply 230V 1N~

4 Power consumption (fan) kW

5 50 Hz

6 Allowable pressure (compressed air) min./ max. bar

Cooling air required

2 m³/h

Allowable pressure

(refrigerant)

Compressed air connections 3/4

Weight

7

8 G

9 kg 40 41 44

10 Dimensions mm

11 Refrigerant quantity R 134a kg 0,37

Condensate drain

Sound pressure level

Type of protection

12 dB (A)

13 IP

14 G

Specification:

Page 28

/2.1*

L1.1

A

/2.1*

N1.1

B

C

D

E

F

1

/2* Bl.

1

Blatt

von

+

=

only for options

*: nur fuer Optionen

13

15

R1

Regler Kälte-Drucklufttrockner

NTC-resistor

NTC-Widerstand

A1

Y1

A2PE

(A100)

Kondensatablass

condensate drain

E2A0405000

Zeichn.Nr./drawing no.

405AP-406AP

Typ:

2

A1

11

M

M2

K1

10

(V100)

Kälteverdichter

fridge compressor

1

fan

(M200)

Ventilator

L1L1 PEN PEN

X0

max.

10A

13.01.03

Datum

supply by plug

220-230V1N~/50Hz

Einspeisung durch Netzstecker

a0405000

Urspr. Ers. f.

Kälte-Drucklufttrockner

refrigerated dryer

RAH

DIN 40719

JN

Bearb.

Gepr.

NormNameÄnderungZustand Datum

1 2 3 4 5 6 7 8

1213 PE

M

1

C1

4

1

P>

A2

1 3 4 5 6 7 8 9 10 11 12

14

M1

L

N

S4

4

1

S1

(PS)

manostat

Pressostat

2 3 4 5 6 7 8

5

2

1

Betr.-schalter

operation switch

A

B

C

D

E

F

Page 29

/2.1*

L1.1

A

/2.1*

N1.1

B

C

D

E

F

1

/2* Bl.

1

Blatt

von

+

=

only for options

*: nur fuer Optionen

13

15

R1

Regler Kälte-Drucklufttrockner

NTC-resistor

NTC-Widerstand

A1

Y1

A2PE

(A100)

Kondensatablass

condensate drain

E2A0407000

Zeichn.Nr./drawing no.

407AP-409AP

Typ:

2

K1

RS PE

M

1

A1

4

1

P>

A2

C

1 3 4 5 6 7 8 9 10 11 12

1 N

3

1

M1

L

N

L

XM

S4

4

1

S1

(PS)

manostat

Pressostat

2 3 4 5 6 7 8

5

2

1

N

1 2

C1

M

1

(V100)

Kälteverdichter

fridge compressor

fan

(M200)

Ventilator

a0407000

Urspr. Ers. f.

Kälte-Drucklufttrockner

refrigerated dryer

13.01.03

RAH

DIN 40719

JN

M2

Datum

Bearb.

Gepr.

NormNameÄnderungZustand Datum

L1L1 PEN PEN

X0

max.

10A

supply by plug

220-230V1N~/50Hz

Einspeisung durch Netzstecker

1 2 3 4 5 6 7 8

Betr.-schalter

operation switch

A

B

C

D

E

F

Page 30

Remarks Order quantityDenomination Dryer type Short description IdentnumberP&I diagram

405 AP-407 AP I17 5003 0GB 2002-12-02 1

Type-No.: Sheet No.: Date: Page 1 of

Details by the manufacturer Details by the user

Wiring diagram Qty. Unit

GB Spare Parts List DIN 24 420

S1 1 Pcs. Operation switch 405AP-407AP 0108673000

A100 Y1 1 Pcs. Condensate Drain Solenoid Valve 405AP-407AP 0101775000

A102 1 Pcs. Drain Valve with Filter 405AP-407AP 0111713000

EICA A2 1 Pcs. Elektronic regulator 405AP-407AP 0111822405 - ...407 Type No. Coded

PS00 S2 1 Pcs. Fan pressostat 405AP-407AP 0103087000

M200 M2 1 Pcs. Fan motor 405AP-407AP 0102404000

Refrigerated Compressed Air Dryer

Denomination:

Page 31

D DEUTSCH ENG ENGLISH

Ñ

Ê

ÖRSÄ

A

KONFORMITÄTSERKLÄRUNG DECLARATION OF CONFORMITY

Wir erklären in alleiniger Verantwortlichkeit, dass dieses Produkt mit

den folgenden Normen übereinstimmt* gemäß den Bestimmungen der

Richtlinien**

F FRANÇAIS NL NEDERLANDS

DECLARATION DE CONFORMITE CONFORMITEITSVERKLARING

Nous déclarons, sous notre seule responsabilité, que ce produit est en

conformité avec les normes ou documents normatifs suivants* en vertu

des dispositions des directives **

We herewith declare in our sole repsonsibility that this product complies

with the following standards* in accordance with the regulations of the

undermentioned Directives**

Wij verklaren als enige verantwoordelijke, dat dit product in

overeenstemming is met de volgende normen*

conform de bepalingen van de richtlijnen**

IT ITALIANO ES ESPA

DICHIARAZIONE DI CONFORMITÀ DECLARACION DE CONFORMIDAD

Noi dichiariamo sotto la nostra esclusiva responsabilità che il presente

prodotto è conforme alle seguenti norme* in conformità con le

disposizioni delle normative **

PT PORTUGU

DECLARAÇÃO DE CONFORMIDADE

Declaramos sob nossa responsabilidade que este produto está de

acordo com as seguintes normas* de acordo com as directrizes dos

regulamentos **

FIN SUOMI NO NORGE

VAATIMUKSENMUKAISUUSVAKUUTUS SAMSVARSERKLÆRING

Vakuutamme, että tämä tuote vastaa seuraavia normeja* on direktiivien

määräysten mukainen**

DA DANSK POL POLSKI

OVERENSSTEMMELSESATTEST OŚWIADCZENIE O ZGODNOŚCI

Hermed erklærer vi på eget ansvar, at dette produkt stemmer overens

ed følgende standarder* iht bestemmelserne i direktiverne**

EL ΕΛΛHNIK

∆ΗΛΩΣΗ ΑΝΤΙΣΤΟΙΧΕΙΑΣ MEGEGYEZŐSÉGI NYILATKOZAT

∆ηλώνουµε µε ιδία ευθύνη ότι το προϊόν αυτό αντιστοιχεί στις

ακόλουθες προδιαγραφές*

σύµφωνα µε τις διατάξεις των οδηγιών**

S SV SVENSKA

Declaramos bajo nuestra exclusiva responsabilidad, que el presente

producto cumple con las siguientes normas* de acuerdo a lo dispuesto

en las directrices**

F

Vi försäkrar på eget ansvar att denna produkt överensstämmer med

följande standarder* enligt bestämmelserna i direktiven**

Vi erklærer under eget ansvar at dette produkt samsvarer med følgende

normer* henhold til bestemmelsene i direktiv**

Oświadczamy z pełną odpowiedzialnością, że niniejszy produkt

odpowiada wymogom następujących norm* według ustaleń wytycznych

**

HU MAGYAR

Kizárólagos felelősségünk tudatában ezennel igazoljuk, hogy ez a

termék kielégíti az alábbi szabványokban lefektetett követelményeket*

megfelel az alábbi irányelvek előírásainak**

OL

KRAN OM ÖVERENSSTÄMMELSE

Druckluftkältetrockner

Cool 201 - Cool 401

EN 292, EN 294, EN 378-1, prEN 387 -2, EN 60204-1, EN 60335-2-40, EN 50081, EN 50082

** 98/37/EG, 73/23/EWG, 89/336/EWG

Ing. grad. H. J. Schaller

Entwicklungsleiter

Metabowerke GmbH

Business Unit Elektra Beckum

Daimlerstr. 1

D - 49716 Meppen

Meppen, 12.06.2003 1001117

Loading...

Loading...