Page 1

U1A0168.fm

091 001 8442

3

5

2

5

1

5

0

5

9

4

8

4

7

4

6

4

5

4

4

4

3

4

2

4

1

4

Tischverbreiterung . . . . . . . . . . . . . . . . . . .3

Table Extension . . . . . . . . . . . . . . . . . . . . . .5

Rallonge latérale de table . . . . . . . . . . . . . .7

Tafelverbreding . . . . . . . . . . . . . . . . . . . . . .9

Allargamento del tavolo . . . . . . . . . . . . . . .11

Extensión de la mesa . . . . . . . . . . . . . . . .13

Alargador da bancada . . . . . . . . . . . . . . . .15

115 161 1687 / 1001 - 5.0

Bordforbredelse . . . . . . . . . . . . . . . . . . . . .17

Bordforlengelse . . . . . . . . . . . . . . . . . . . . .19

Tillsatsbord - bredd . . . . . . . . . . . . . . . . . .21

Pöydän levennys . . . . . . . . . . . . . . . . . . . .23

Asztalszélesítő . . . . . . . . . . . . . . . . . . . . . .25

Poszerzenie stołu. . . . . . . . . . . . . . . . . . . .27

Πεπλτυνση του πγκου . . . . . . . . . . . .29

Page 2

U

ELEKTRA BECKUM

XA0028E1.fm Operating Instruction ENGLISH

ENGLISH

1. Please Read First!

• Read these instructions before use.

Also observe the instructions for the

circular saw, the safety instructions

in particular.

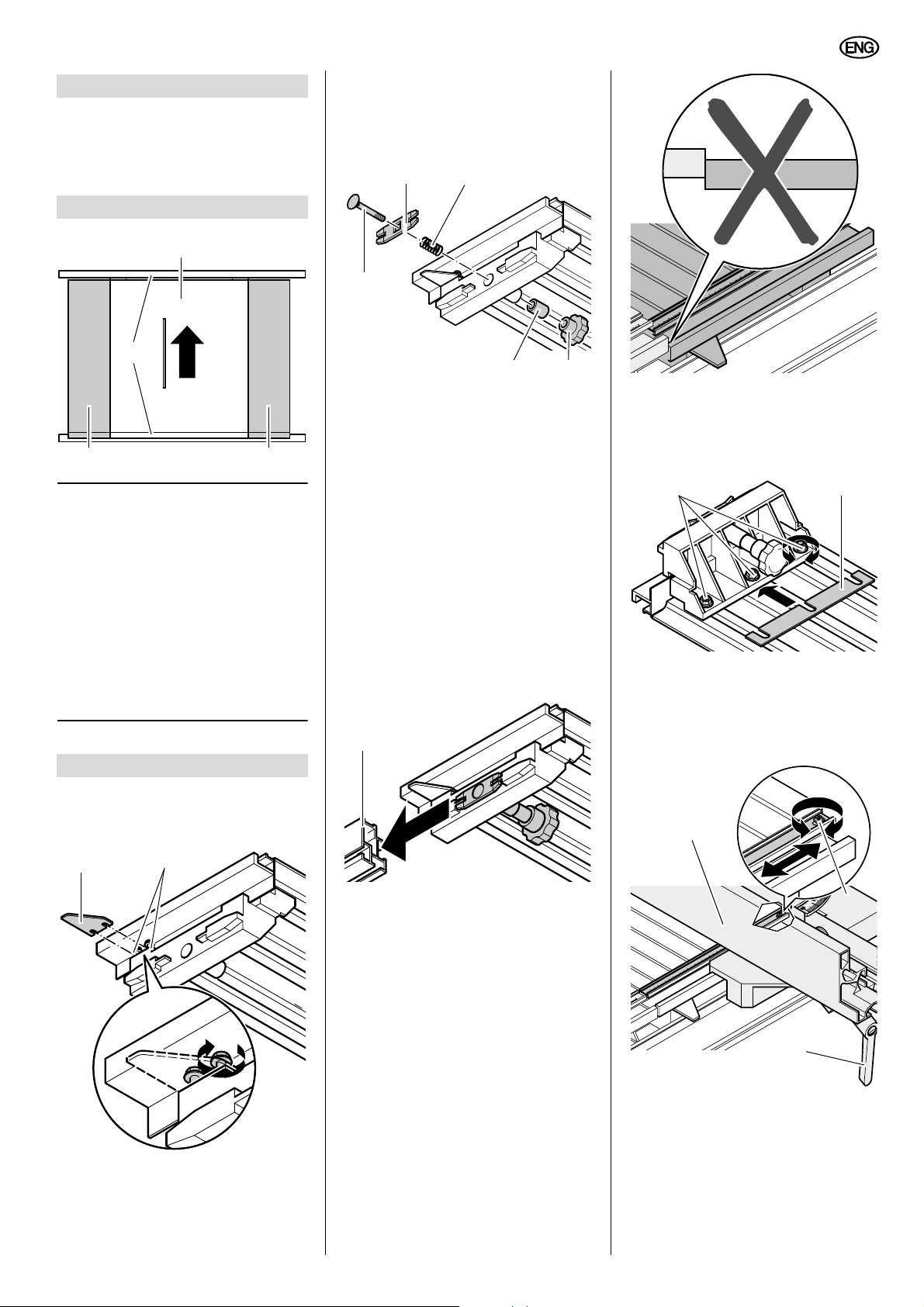

2. Mounting Locations

1

2

34

Note:

3

This table side extension is

intended for laterally extending the support area of the circular saw table (1). In

order to be able to install the table side

extension, the Base System Rails (2) fitting the saw must be installed.

The table side extension can be fitted

either to the left (4) or right (3) hand side

of the saw table. The scale supplied are

intended for installation on the right hand

side, as the sliding carriage can be

intalled on the left hand side.

3. Assembly

1. Slide pointer (5) under the two

screws (6) as illustrated and tighten

both screws.

2. Put both clamping plate (7) and coil

spring (8) on the carriage bolt (9) as

ilustrated: The offset ends of the

clamping plate must point towards

the carriage bolt's head.

78

9

10 11

3. Insert carriage bolt (with fitted

clamping plate and coil spring) from

the outside into the hole of the side

extension's mounting rail.

4. Put distance sleeve (10) from inside

on the carriage bolt and screw on

knurled thumb nut (11), but do not

yet tighten it.

5. Repeat steps 2. though 4. on the

other end of the table side extension.

6. Slide table side extension into the

two extrusions (12) of the base system rails: The table side extension

must be pushed at both ends fully

against the saw table.

12

ELEKTRA BECK

53

52

51

50

49

48

47

46

45

44

43

42

41

39

39

If the table side extension is too low:

Loosen screws (13) on the underside

and slide one or more shim plates (14)

below the table extension's mounting

rails. Tighten screws (13).

13 14

Scale alignment

1. Position rip fence (15) at the approximate centre of the table side extension and lock with ratchet lock lever

(16).

15

56

7. Tighten knurled thumb nuts (11).

Caution!

A

The table side extension must

be exactly level with the saw table,

otherwise workpiece and rip fence

may get caught by the step or rock.

17

ELEKTRA BECKUM

34

33

32

31

30

29

28

27

26

25

24

23

22

20

16

2. Make trial cut: Place workpiece

against rip fence and make a cut.

3. Measure the width of the workpiece

(from edge of cut to rip fence).

4. Loosen fixing screw (17) of the table

side extension's scale.

5

Page 3

ENGLISH

3

75

76

74

73

72

71

6

5. Move scale, until the value indicated

by the left-hand edge of the rip

fence corresponds with the value

measured at the workpiece.

6. Tighten scale fixing screw (17)

again.

7. Set rip fence exactly to 320 mm (for

UK 220 and PK 200) or 520 mm (for

PKF 255) and lock it in position.

8. Loosen scale fixing screw (18) of the

base system rail.

18

76

75

74

73

72

71

52

51

50

4

40

39

ELEKTRA BECKUM

43

42

41

49

48

47

46

45

44

A

B

A = B

1. Set rip fence exactly to 320 mm (for

UK 220 and PK 200) or 520 mm (for

PKF 255) and lock it in position.

2. Loosen knurled nuts on underside of

the table side extension and set

table extension (with the rip fence)

to desired width. The cutting width is

indicated by the base system rail's

scale.

3. Tighten knurled nuts on underside

of table extension again.

4. Place workpiece against rip fence

and perform the cut.

9. Move the base system rail's scale

(19), until the value indicated by the

table extension's pointer (20) corresponds exactly with the rip fence

distance (320 mm or 520 mm

respectively).

33

32

31

30

29

28

27

26

25

24

23

22

20

32

37

36

35

34

33

20

10. Tighten scale fixing screw (18)

again.

4. Operation

Risk of Kickback!

A

The rip fence's fence extrusion must always be exactly parallel

with the saw blade. Otherwise there is

a risk of the workpiece jamming between saw blade and rip fence, causing it to be kicked back against the

operator.

6

34

19

41

40

39

38

4

45

44

43

42

Loading...

Loading...