ELEKTRA TuffTec 30, TuffTec 30/400 V Installation Manual

www.elektra.eu

• Tuff Tec™ 30

• Tuff Tec™ 30/400 V

TuffTec™

Instrukcja instalacji

PL

Installation manual

UK

ELEKTRA

Инструкция по монтажу

RU

HEATING CABLES

Applications

ELEKTRA TuffTec™ heating cables are intended

for effective prevention of snow and ice deposition on:

• driveways, roads, footbridges, loading ramps

and parking spaces with asphalt or concrete

surface,

• roofs covered with bituminous materials,

• gutters and downpipes requiring the output of

60 W/m.

Characteristics

ELEKTRA TuffTec™ heating cables feature the

following characteristics:

• high mechanical strength

- cables intended for installations characterised by increased risk of mechanical damages

• high thermal properties

- max. operating temperature: +110°C

- max. exposure temperature (10 min): +240°C

- min. installation temperature: -25°C

• UV-Resistant

• resistance against chemical agents, including

bituminous substances.

3

Heating Cables

ELEKTRA

ELEKTRA TuffTec™ cables are intended for

installation in the conditions of increased risk

of mechanical damages, e.g. in case when

concrete consolidation machinery is utilized for

surface works.

Due to their exceptionally high thermal properties,

as well as resistance against bituminous

substances, the TuffTec™ cables can be safely laid

in asphalt.

Also, the cables can be laid on the roofs with

bituminous coverings.

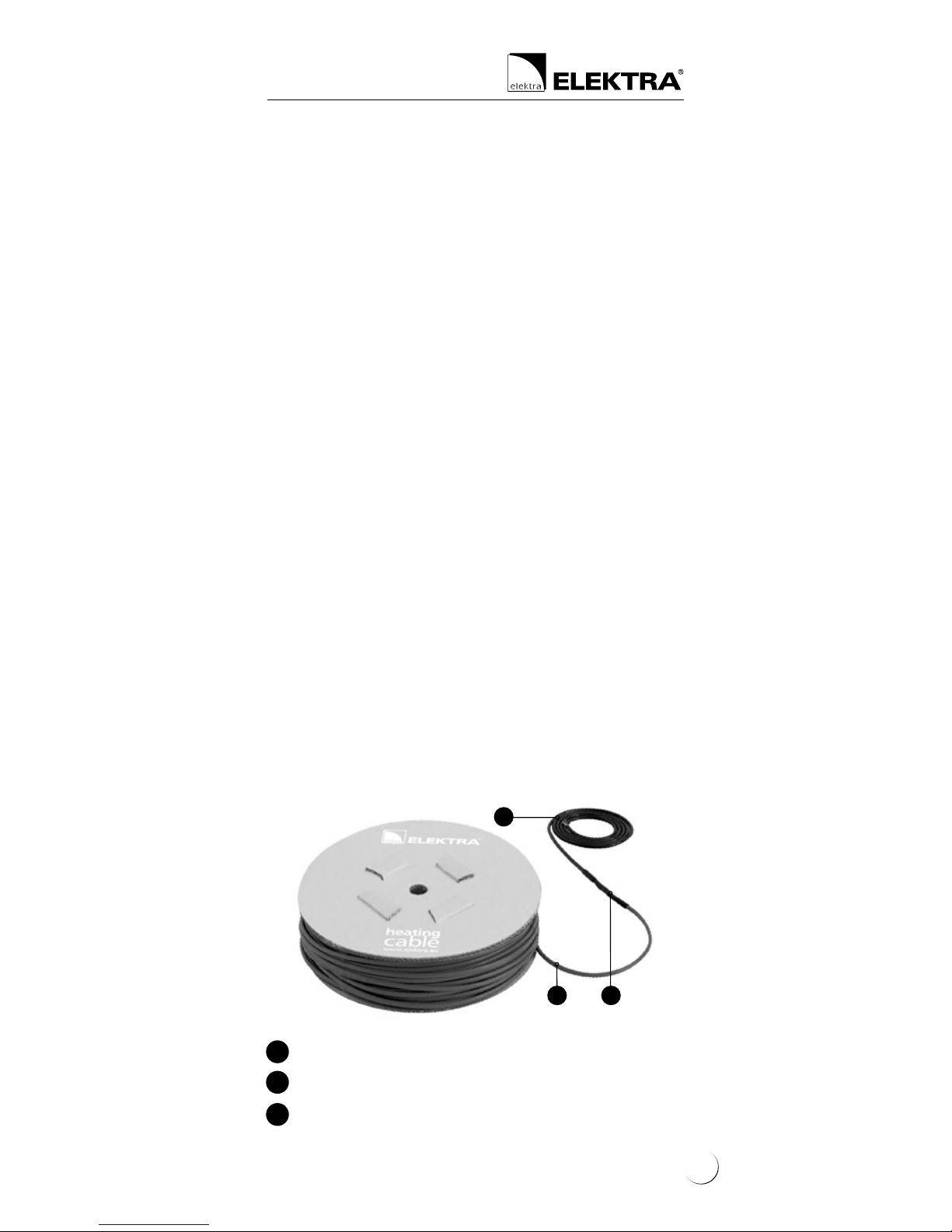

FEP (Teflon)

first insulation layer

Multi-wire

heating core

HDPE second

insulation layer

Tinned

copper braiding

UV resistant

HFFR outer sheath

Construction of the ELEKTRA TuffTec™ heating cable

4

• “cold” power supply conductor

• ELEKTRA TuffTec™ heating cable

• connecting joint between the power supply

conductor and the heating cable

1

2

3

1

2 3

Technical properties

The ELEKTRA TuffTec™ heating cables are produced in ready-made units, manufactured in

compliance with the EN 60335-1 standard.

The ready-made units include heating cables

terminated with a power supply conductor.

Power output 30 W/m

Power supply voltage 230 V, 400 V ~ 50/60 Hz

Cable diameter ~ 6.8 mm

Min. installation temperature -25°C

Max. operating temperature +110 ° C

Max. exposure temperature (10 min.) +24 0 ° C

Power supply conductors 1 x 4 m; 3 x 1.5 mm²

or 3 x 2.5 mm² rubber

insulation and outer

jacket

Heating cables double-core, screened,

single-side powered

Insulation double layer, FEP + HDPE

Outer sheath UV-resistant HFFR

Rated power output tolerance +5%, -10%

Min. cable bending radius 3.5 D

IP rating IPX7

System certication according to ISO 9001

IQNET, PCBC

Markings CE

5

Heating Cables

ELEKTRA

Single-side powered

heating cables

Self-adhesive label

Note:

ELEKTRA TuffTec™ 30 heating cables are designed

for the rated voltage 230 V/50 Hz, and TuffTec™

30/400 heating cables – for the rated voltage

400 V/50 Hz.

Heating cables’ heating output may vary with

+5% and -10% from the nameplate values.

!

The label features the following pictograph:

Note:

Never cut the heating cable.

Never trim the heating cable, only the power

supply conductor may be trimmed if required.

Never squash the “cold tail”.

Do not ever undertake on your own any attempts

to repair the heating cables, and in case any

damage is detected, report the damage to an

ELEKTRA authorized installer.

Never stretch or strain the cable excessively, nor

hit it with sharp tools.

Do not install the heating cables when ambient

temperature drops below -25°C.

!

6

General information

Surface protection against snow

and ice deposition

When protecting external areas from snow and ice

deposition, it is required to assess the required heat

output value per m

2

of the surface. Recommended

heat output depends on the regional climate conditions, i.e. minimum ambient temperature, snowfall

intensity and wind strength.

Higher output is required if the heated area is:

• exposed to wind from below:

- bridges, stairs, loading ramps, overpasses

• located in a regions of intense snowfall

Ambient

temperature

Heat output

[W/ m

2

]

> -5°C

-5°C ÷ -20°C

-20°C ÷ -30°C

< -30°C

200

300

400

500

Note:

Never lead the end joint and the connecting

joint between the heating cable and the power

supply conductor out of the surface. Both joints

must be placed – depending on the type of surface – within the layer of sand, dry concrete or

directly in concrete.

Never bend the joint and end seal.

Heating cables must be installed according to

the Instructions.

Mains connection of the heating cables should

be performed by an authorized electrician.

Power supply conductors (”cold tails”) in asphalt

should be positioned in the protective metal

installation conduit. Alternatively, power supply conductors can be led out of the area where

asphalt will be poured out.

!

7

Heating Cables

ELEKTRA

Applying insulation layer to the surfaces exposed

to wind from below can improve effectiveness.

Depending on the cable spacing, it is possible

to obtain required output per m

2

of the heated

area.

Cable spacing cannot drop below 5 cm.

To protect large areas against snow and ice deposition, one option is application of 400 V voltage

heating cables, which would evenly load the electric circuit. Application of such cables would also

reduce installation works, limiting the required

number of heating cables.

Heat output 30 W/m

[W/m

2

] [cm]

300

375

430

500

600

10

8

7

6

5

Protection of bituminous roofs,

gutters and downpipes against snow

and ice deposition

Thanks to their exceptionally high resistance

against damaging inuence of any bituminous

substances, ELEKTRA TuffTec™ heating cables are

ideally suited for the purposes of heating roofs

covered with tar paper, roof tiles or bituminous

shingles.

Selection of the required heat output depends on

the regional climate conditions of the zone where

the installation is to be positioned.

8

It is recommended to heat gutters and roof edges

adjoining them on the width of approximately 50

cm, as well as roof channels. Effective heating

of these elements will facilitate roof outow of

melted snow, and will prevent icicles.

Tar paper-covered roofs are usually at (up to

15°) and require higher heat output. Especially

roof valleys and channels are exposed to snow

deposition.

Heat output for the moderate climate zone

ELEKTRA TuffTec™ heating cables can be installed

in gutters or downpipes of buildings located

in cold climate zones, where it is also necessary

to execute high heat output, i.e. 60 W/m by

double-laying the cables in gutters.

Application Heat output

[W/ m

2

]

Roof channels 200-300

Roof edges approx. 200

Roof stretches

excessing the building’s facade

approx. 300

9

Heating Cables

ELEKTRA

Anti-snow and anti-ice controls

• for the protection of surfaces

ELEKTRA ETOG2 controller – max. load up to 3x16 A.

For applications in extended heating systems.

ELEKTRA ETR2 controller – max. load up to 16 A,

total output of installed heating cables must not

exceed 3600 W. As standard, equipped with one

temperature and moisture sensor with installation

tube.

Controls

Properly selected control system will ensure adequate operation of the heating system only during

snow and freezing rainfall. A temperature controller with a temperature and moisture sensor will

automatically recognize the weather conditions.

The heating system will be then kept on standby

and only switched on when actually necessary. For

this purpose, DIN-bus installed controllers ELEKTRA

ETR2 and ETO2 can be utilised.

10

• for the protection of roofs,

gutters and downpipes

ELEKTRA ETR2R controller – as standard,

equipped with one air temperature sensor and

moisture sensor.

ELEKTRA ETOR2 controller – as standard, equipped

with one air temperature sensor and moisture sensor. Additional moisture sensor can be connected

to this controller, which will enable protection of

two independent roof areas.

Additionally, it is possible to control two independent areas, e.g. a garage driveway and gutters,

with one controller only.

As standard, equipped with one temperature and

moisture sensor and an installation tube. Additional temperature and moisture sensor can be connected to this controller, which will enable protection of two outdoor areas.

11

Heating Cables

ELEKTRA

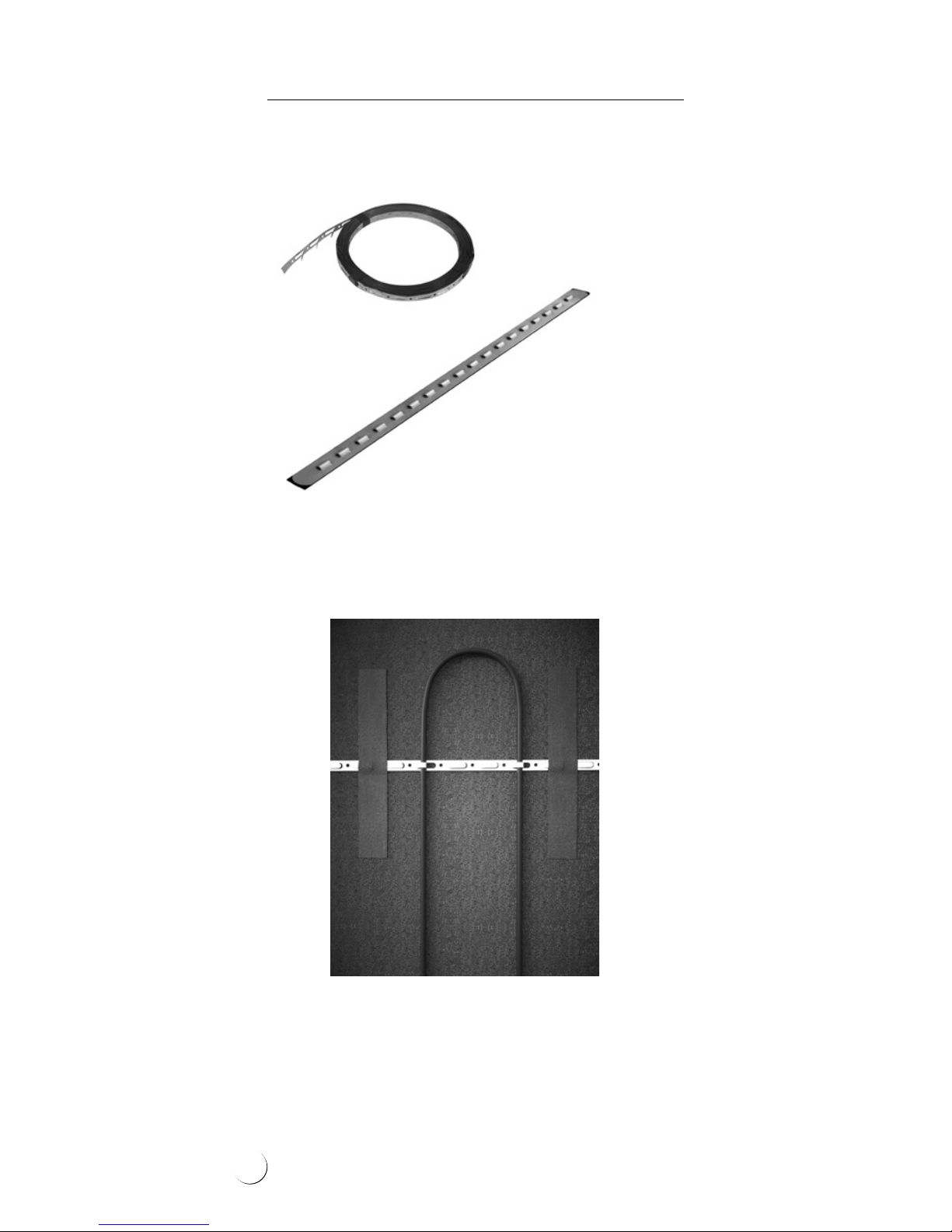

To maintain xed positioning of the cable and

steady spacing conforming to the calculated

values, the cables need to be attached with the

ELEKTRA TMS installation tape (the tape should be

positioned with the distances of 40 cm) or installation mesh of 5 cm x 5 cm grid, made of Ø 2 mm

wire.

The heating cable layout should be commenced

from the side of the power supply conductor,

in such a way to enable easy reach to the switchboard.

If the cold tail needs to be extended, a heat

shrink joint must be used. Ensuring that the connection is safely sealed.

TMS installation tape

Installation

Stage 1: Heating cable’s

installation

1) in the surface

Before commencing the installation of the system, it is required to assess the necessary heat

output per m

2

, as well as calculate the required

spacing of the heating cable.

In order to calculate the required heating cable’s

spacing, apply the following formula:

a-a = S/L

where:

a-a: distances between cables,

S: surface area, for the surface heated with

the heating cable,

L: heating cable’s length.

12

The heating cable layout will depend from

the surface type.

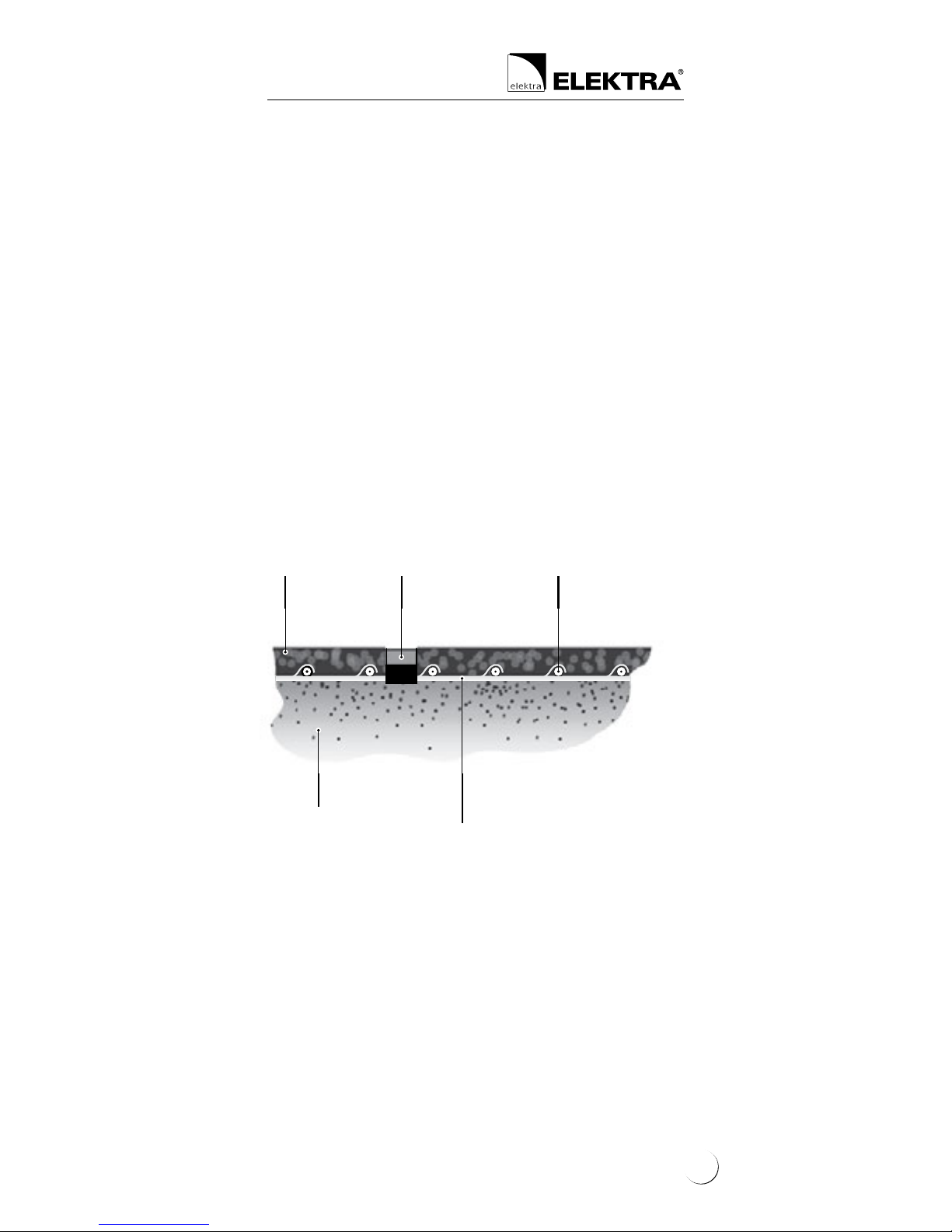

Asphalt surfaces

Stages of works:

• Metal installation tape or mesh is placed on the

compacted (hard core) base, with the heating

cable attached to it – installation tape’s tongues

should be folded so that they would not

straighten up during asphalt rolling

• Power supply conductors (”cold tails”) in

asphalt should be positioned in the protective

metal installation conduit. Alternatively, power

supply conductors can be led out of the area

where asphalt will be poured out

• The 40-50 mm-thick layer of asphalt is laid out

manually – Stage 4

• The asphalt surface is rolled – Stage 4

Cross section of a driveway or road with asphalt surface

40-50 mm-thick

layer of asphalt

Temperature

and moisture sensor

in installation tube

Compacted

base

TM

ELEKTRA TuffTec

heating cable

Metal installation mesh

or ELEKTRA TMS

steel installation tape

Concrete surfaces

Concrete surfaces require epansion joints. Unreinforced

concrete slabs should be divided into expanded areas

of the surface no larger than 9 m

2

, reinforced concrete

agstones – into areas no larger than 35 m

2

. The length

of the heating cables should be selected so that they

would not cross the expansion joints. Only the power

supply conduits (“cold tails”) can cross the expansion

joints. They are to be placed in a metal protective conduit of the length of approx. 500 mm.

13

Heating Cables

ELEKTRA

ELEKTRA TuffTec

TM

heating cable

Temperature

and moisture sensor

in installation tube

Expansion joint

Compacted

base

Concrete slab

min. 50 mm thick

Cross section of a pavement or driveway

made of concrete slab

Reinforced concrete agstones

Heating cables can be fastened to the reinforcement of the ferroconcrete agstones. Alternatively, the installation mesh of 100 mm x 100 mm

grid made of Ø 4 mm wire can be applied, which

would facilitate maintaining steady spacing of the

cable, conforming to the calculated values.

ELEKTRA TuffTec

TM

heating cable

Roadway layer

(e.g. resin, quartz)

Reinforcement

of the f

erroconcrete

flagstone

Metal

mesh

Layer of plaster,

e.g. acrylic,

on plastering mesh

Thermal

insulation

Cross section of a suspended loading ramp

Unreinforced concrete surfaces

Stages of works:

• The compacted base is levelled

• ELEKTRA TMS installation tape or installation

mesh are laid on the compacted base, the

heating cable is fastened to them

• The concrete slab works follow – Stage 4

14

Applying thermal insulation layer to ferroconcrete

agstone surfaces exposed to wind operation

from below (ramps, bridges, overpasses) can improve the system’s effectiveness.

2) on roofs covered with tar-paper,

roof tiles or bituminous shingles

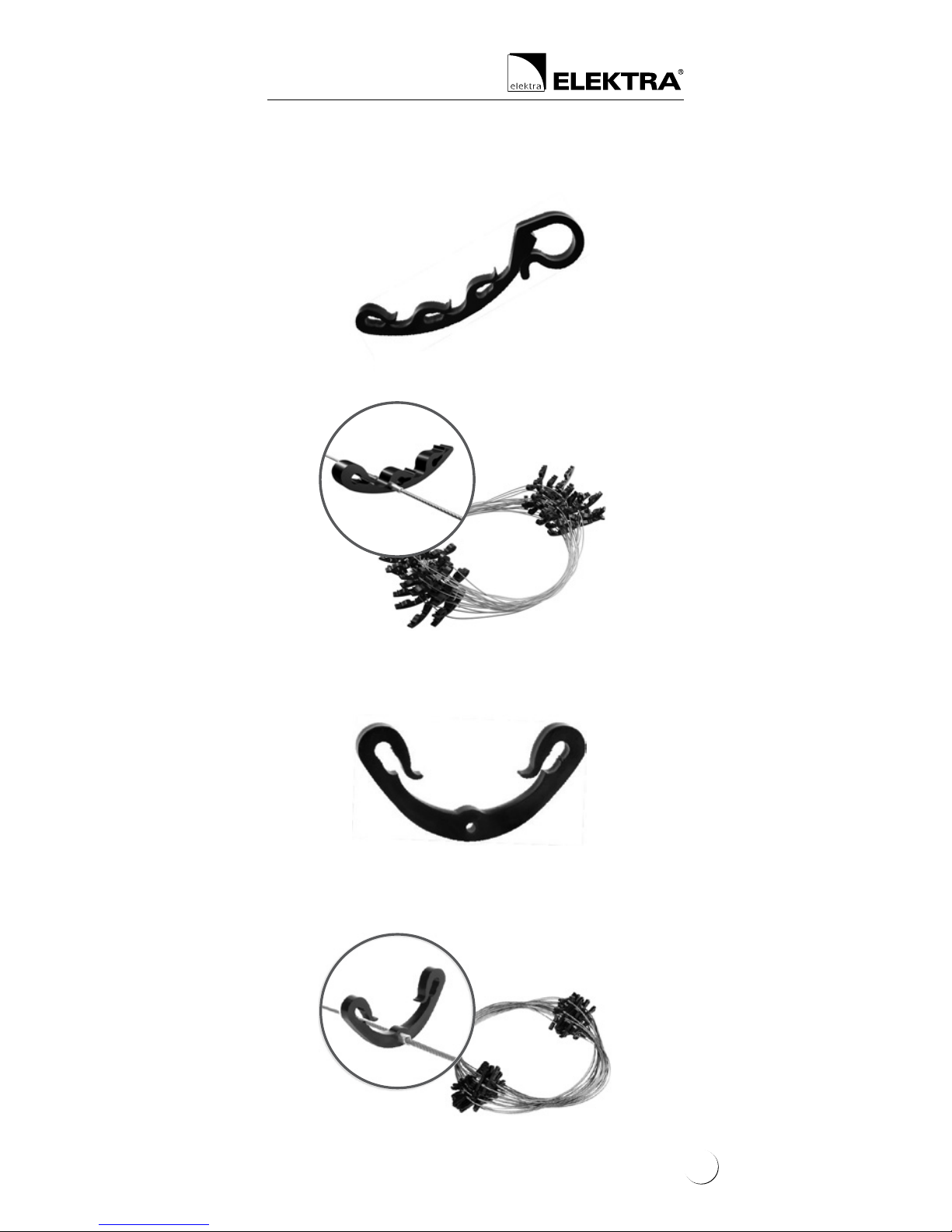

Fastening cables to roofs’ edges

The grips are attached to the roof’s stretches with

pieces of heat-sealing tar paper glued across the

grips.

Titanium-zinc or copper holders

15

Heating Cables

ELEKTRA

Fastening cables

in roof valleys

ELEKTRA TMS steel installation tape or installation

strips are attached to the roof’s stretches with

pieces of heat-sealing tar paper glued across

the tape or strips.

Downpipes receiving water from roof valleys

require heating:

• internal downpipes at the length of approx. 1 m

• external downpipes at their entire length

ELEKTRA TMS

steel installation tape

Installation strip

16

Gutter holder

Gutter spacing wire

(this method of installation will greatly facilitate cleaning)

Downpipe spacing clip

Downpipe spacing wire

Basic accessories for installation of heating cables

in gutters and downpipes:

17

Heating Cables

ELEKTRA

Stage 2: After the heating

cable has been laid

At this stage, it is necessary to undertake

the following steps:

• Stick into the Warranty Card the self-adhesive

label, positioned on the power supply conductor of the heating cable

• In the Warranty Card, prepare a sketch of the

heating cable’s layout positioning

• Feed the power supply conductor of the he-

ating cable into the switchboard

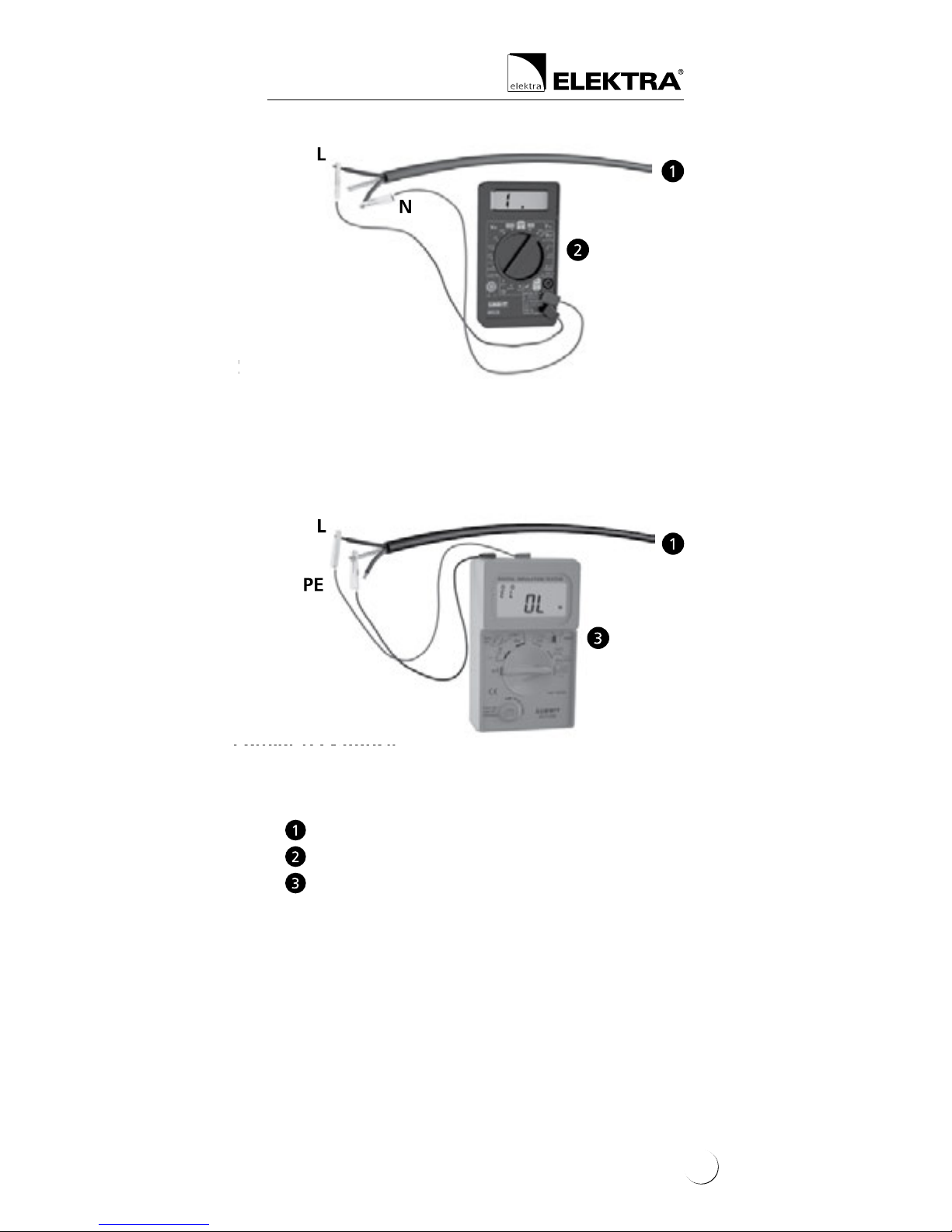

• Perform the measurements of:

– heating wire resistance

– insulation resistance

The measurement results of the heating

core’s resistance should not vary from the

one given on the label value with more than

- 5 % , +1 0 % .

The heating cable insulation’s resistance,

as measured with an appliance of the rated

voltage 1000 V (megaohmmeter), should not

drop below 50 MΩ. Enter the results into the

Warranty Card.

After the surface has been completed, repeat

the measurements to check whether the

heating cable has not been damaged while

conducting works.

18

(brown

or black)

(yellow-green)

Power supply conductor

Ohmmeter

Megaohmmeter

(brown

or black)

(blue)

Heating wire’s resistance measurement

Insulation’s resistance measurement

19

Heating Cables

ELEKTRA

Stage 3: Temperature and

moisture sensor’s

installation:

preparation to

in-surface installation

• Establish the optimal positioning for the tem-

perature and moisture sensor – a place which

would be especially vulnerable to prolonged

low temperatures and increased moisture

deposition (e.g. in a shade or exposed to

wind).

• Feed the protective conduit with the so called

“draw wire” from the planned sensor’s positioning to the switchboard (after the surface

has been completed, the protective conduit

will enable feeding the temperature and

moisture sensor’s wire).

Note:

Fill the spot selected for the sensor’s installation with material to be removed after concrete or asphalt has been cured (e.g. a wooden

block of 100 x 100 mm and the height equal to

the planned thickness of the nished surface).

!

Note:

The protective conduit should be run in such

a way to enable the future exchange of the temperature and moisture sensor, if required.

!

20

In case of a signicant sensor’s distance from

the switchboard, or bending of the protective

conduit, it is necessary to:

• install an additional sealed electric box “on

the way” to the board, or

• install the protective conduit with a twisted

pair screened control cable, min. 3-pair (e.g.

LIYCY-P 3x2x1.5)

– the sensor’s wire with the control cable is

to be connected with a heat shrink connecting joint

Stage 4: Finishing surface

works

During execution of the asphalt surface, rst

select the positioning place for the installation

tube, then – after the asphalt has been rolled and

it has cooled down – mount the tube. The space

between the tube and asphalt should be lled

with either concrete or asphalt poured cold, and

the tube should be levelled so that it will be positioned 5 mm below the level of the surface.

For the time of pouring and rolling the asphalt,

the place selected for the positioning of the sen-

sor should be lled with material which – after

the asphalt has cooled down – will be removed

(e.g. a wooden block 10x10x10 cm in size).

Note:

The section of the protective conduit to be laid

in asphalt should be made of a metal pipe, due

to high temperatures present while asphalting.

!

21

Heating Cables

ELEKTRA

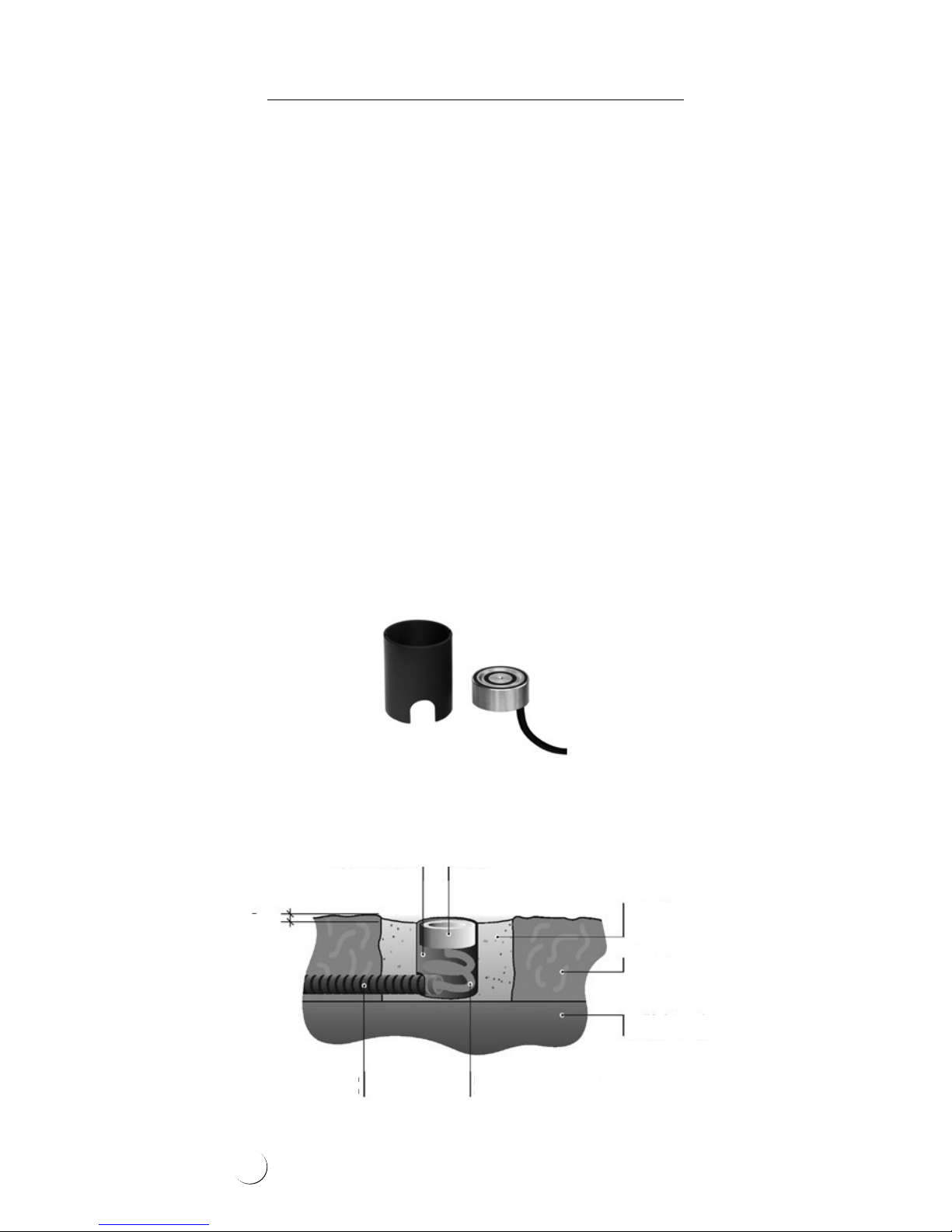

Stage 5: Sensor’s installation

1) in-surface temperature

and moisture sensor

The sensor should be installed on the previously

selected and prepared spot. Remove the wooden

block and feed the sensor’s wire with the so

called “draw wire” into the protective conduit

installed before nishing works on the surface.

Under the sensor, the wire excess should be deposited (min. 300 mm) for the future sensor replacement, if required.

The sensor should be positioned approx. 5 mm

below the surface level to enable water deposition on the sensor. After the sensor has been le-

velled, ll the vacant space e.g. with concrete.

Ground temperature and moisture sensor ETOG-56T with

installation tube (for soil, concrete agstones, paving

cobbles etc.) can be used for heating control of drive-

ways, trafc routes, etc.

Example of temperature and moisture sensor’s installation

in the surface

installation tube

protective

conduit

5 mm

sensor’s wire laid with

approx. 30 см excess

sensor

ller

e.g. concrete

surface

compacted base

under the surface

22

Stage 6: Temperature

controller’s

installation

The heating cable connection to the domestic

electric circuit should be performed by an authorised

electrician.

The in-controller connection of the:

1. mains,

2. power supply conductors (“cold” cables) of

the heating cable,

3. temperature and moisture sensor

should be executed according to the diagram

included in the temperature controller’s Instructions.

2) on-roof air temperature sensor

and moisture sensor

Position the ETF-744/00 temperature sensor on

the building’s northern wall, in shade.

Position the ETOR-55 moisture sensor between

the cables in the roof’s channel, optimally in the

vicinity of the downpipe.

While selecting the sensors’ positioning,

take into account the necessity of feeding the

wires of both sensors to the controller.

23

Heating Cables

ELEKTRA

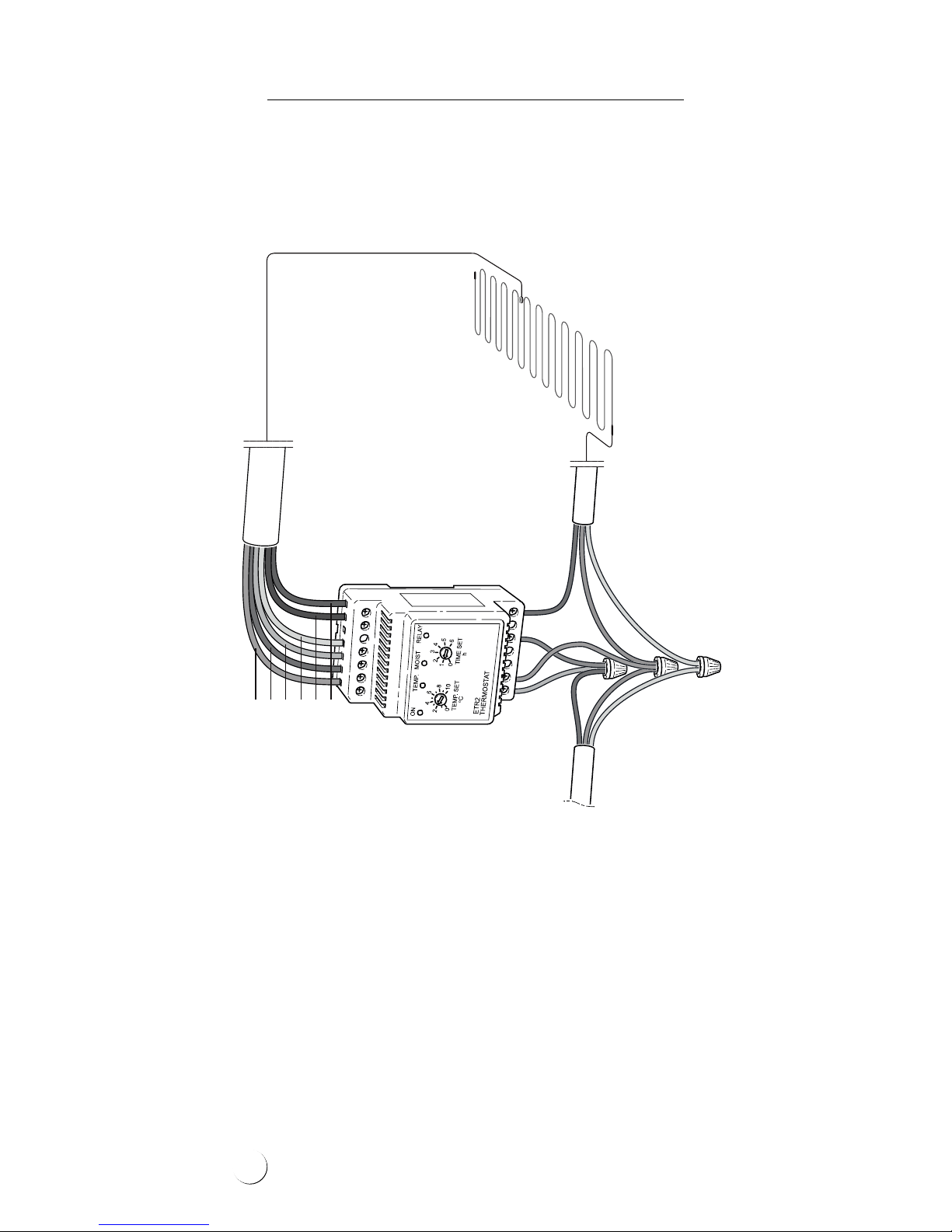

Single-phase electric circuit

Connection diagram of ELEKTRA TuffTec™ 30/230V heating cable

with temperature and moisture sensor

and ELEKTRA ETR2G temperature controller

ETR2G

230V

sensor’s wire

heating cable

grey

pink

yellow

white

brown

green

N

NL

PE

L

L

PE

L

N

24

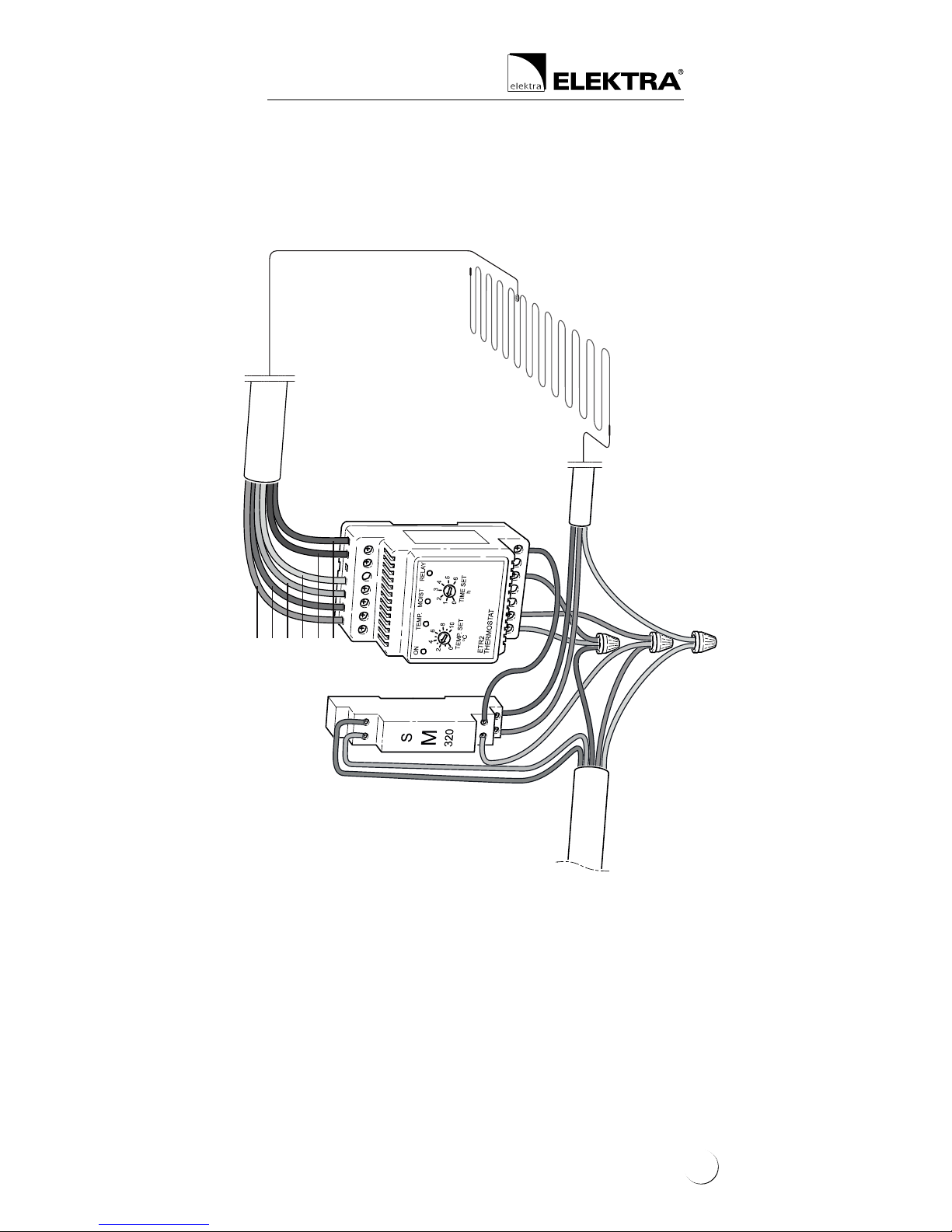

ETR2G

three-phase

electric circuit

heating cable

Three-phase electric circuit

Connection diagram of ELEKTRA TuffTec™ 30/400V heating cable

with temperature and moisture sensor and ELEKTRA ETR2G controller

L3

L2

L1

L3

L2

N

NL

PE

L

L

sensor’s wire

grey

pink

yellow

white

brown

green

25

Heating Cables

ELEKTRA

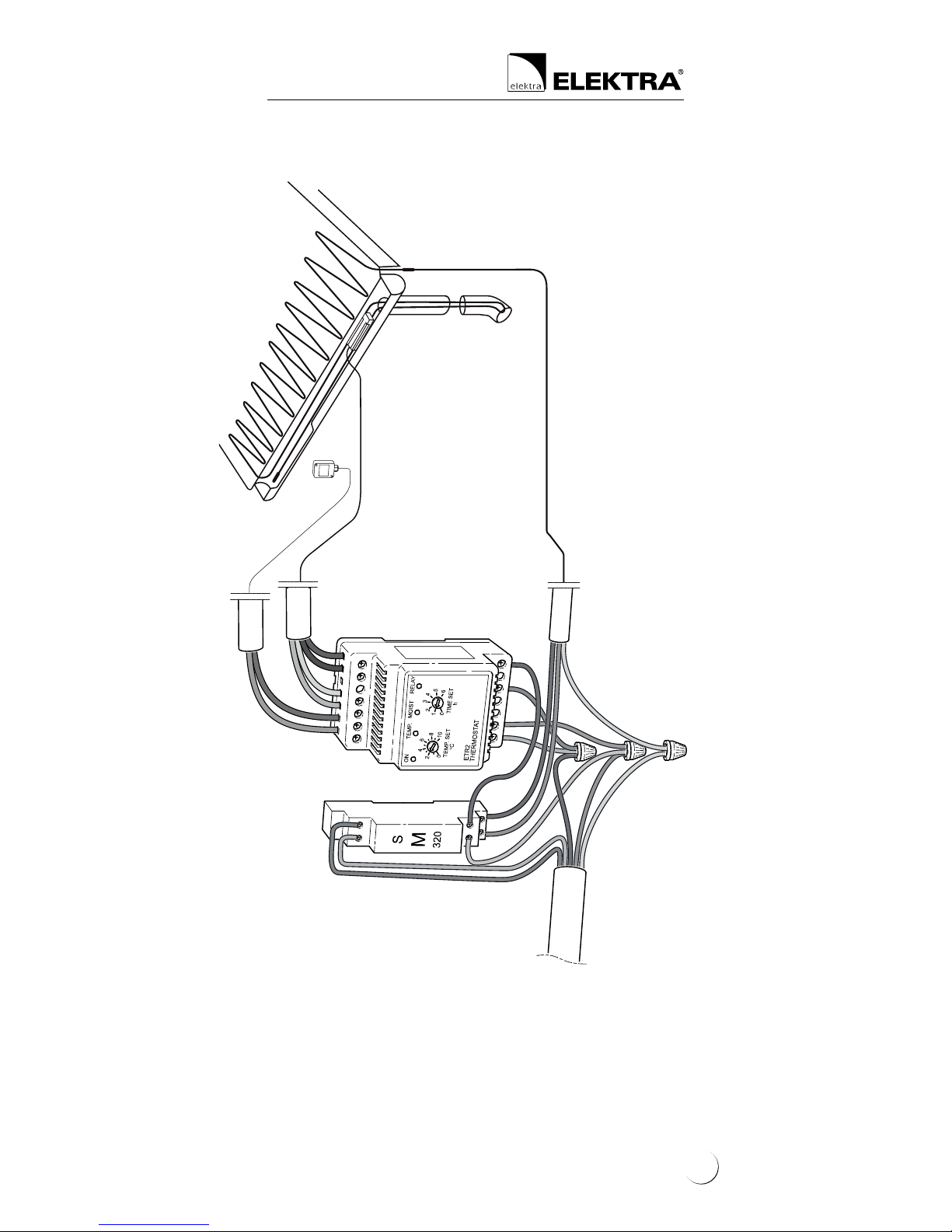

Single-phase electric circuit

Connection diagram of the heating cable

and temperature and moisture sensor

and ELEKTRA ETR2R controller

ETR2R

230V

heating cable

N

NL

PE

L

L

PE

L

N

yellow

white

brown

green

ETOR-55

ETF-744/99

26

ETR2R

Three-phase electric circuit

Connection diagram of the heating cable

and temperature and moisture sensor

and ELEKTRA ETR2R controller

L3

L2

L1

L3

L2

N

NL

PE

L

L

heating cable

ETOR-55

ETF-744/99

three-phase

electric circuit

27

Heating Cables

ELEKTRA

Anti-shock protection

The electric circuit of the heating cable should be

equipped with a residual current device of the

sensitivity level ∆ ≤ 30 mA.

Warranty

ELEKTRA company grants a 10 year-long

warranty (from the date of purchase) for the

ELEKTRA TuffTec™ heating cables.

28

Warranty Conditions

1. Warranty claims requires:

a. that the heating system has been executed

in full accordance with the Installation In-

structions herein, by a certied electrician,

b. presentation of the properly completed War-

ranty Card,

c. presentation of the proof of purchase of the

heating cable under complaint.

2. The Warranty loses validity if any attempt at

repair has been undertaken by an unauthorised

installer.

3. The Warranty does not cover the damages in-

icted as a result of:

a. mechanical fault,

b. incompatible power supply,

c. lack of adequate overload and differential

protection measures,

d. discord of the domestic heating circuit with

the current regulations in force.

4. Within the Warranty herein, ELEKTRA com-

pany undertakes to bear exclusively the costs

required to cover the necessary repairs to the

heating cable itself, or to exchange the cable.

5. The Warranty covering the purchased commer-

cial goods does not exclude, limit or suspend

other Buyer’s rights resulting from the incompatibility of the goods purchased with the

agreement of purchase.

Note:

The Warranty claims must be registered with the

Warranty Card and proof of purchase, in the place

of purchase or the ofces of ELEKTRA company.

!

29

ELEKTRA

Heating cables

The Warranty Card must be retained by the Client for the entire warranty period of 10 years.

The Warranty period starts on the date of purchase

PLACE OF INSTALLATION

Address

Zip code City/town

TO BE COMPLETED BY AN INSTALLER

Name and

surname

Electrical authorisation

certicate №

Address E-mail

Zip code City/town

Phone №

Fax

The Warranty claims must be

registered with the Warranty

Card and proof of purchase,

in the place of purchase

or the ofces of ELEKTRA

company

Loading...

Loading...