Page 1

MH660C

SPECIFICATIONS

Typical

Axial Frequency Response (swept

one-third-octave plnk noise, anecholc

envlronment, 4 volts at 10 feet, normalized

for 1 watt, 1 meter into mld-bass driver;

see Figure 1):

150-20,000

Low-Frequency 3-dB-Down Point:

150 Hz

Usable Low-Frequency Limit

point):

140 Hz

Recommended Crossover Frequencies:

160 Hz, 1,600

Crossover Slopes per Octave, Suggested:

24

Recommended Signal Delay,

Mid Bass: 0.00

High

Long-Term Average Power-Handling

Capacity (see Power Handling section),

Mid Bass

(per

High Frequency

(per

Sensitivity (SPL at 1 meter, 1 watt input,

anechoic environment, band-limlted pink-

noise signal),

Mid Bass: 107

High Frequency: 111

Impedance,

Nominal (mid bass/high frequency):

Minimum (mid bass/high frequency):

Average Efficiency,

Mid Bass:

High Frequency:

Hz

(10-dB-down

Hz

dB

Frequency: 0.60

ANSl/ElA RS-426-A):

300 watts

AES2-1984/ANSI S4.26-1984):

60 watts

16

ohms/8

11 ohms/6 ohms

25%

25%

msec

msec

dB

dB

ohms

Maximum Long-Term Average Mid-Band

Acoustic Output:

75 watts

Beamwidth (angle Included by

points on polar responses, Indicated

third-octave bands of pink noise; see

Figure

2),

Vertical:

Directivity Factor

Median (see Figure 3):

Directivity Index D,,

Median (see Figure 3):

Distortion (120 dB SPL at 1 meter from

mid-bass horn uslng typlcal

spectrum; see Figure

Transducer Complement,

Polarity (all drivers):

1.

600 to 20,000 Hz Horizontal or

60 degrees +/- 25

18.2

12.6 dB

Second Harmonic,

1,000 Hz: less than 1%

10,000 Hz: less than 1%

Third Harmonic,

1,000 Hz: less than 1%

10,000 Hz: less than 1%

Mid Bass:

DL10X-SH

Kevlar

rotatable MH660 60 x 60 degree horn

High Frequency:

DH2As2 compression driver on HP66

60

x 60 degree horn coaxially mounted

to a mid-bass horn

A positive voltage applied to the positively

marked input terminal produces a positive

acoustic pressure at the front of the system

Kevlar is a registered trademark of DuPont.

R, (a), 500- to

500-

(+3.8 dB, -4.0 dB)

4),

25.4-cm

epoxy composite cone on

(10-in.) driver with

6-dB-down

one-

20,000-Hz

to 20,000-Hz

music

Coaxial

Constant-

Directivity Horn System

.

High-output high-quality music

speech for stadiums and performing-arts

venues

.

Large, correctly sized horn mouths

provide uniform

directivity

500 Hz, for Increased

difficult acoustic conditions

High

“Q”

for increased intelligibility

Suspension system for safe and easy

installation

DH2As2 2-inch

compression driver for

extended high-frequency performance

Short throw/fill-in when used with the

very-large-format MH stadium

systems

.

60

degree vertical coverage angle

Input Connectlons,

Mid Bass/High

Screw

each driver can be individually accessed;

high-frequency driver has blocking

capacitor for protection

Construction,

Main Horn Bell:

One-piece

fiberglass laminate

reinforcement

Frequency:

terminals (#10)

black polyester and

on

Hanging Hardware:

4-point,

black , 10-gauge polyester-

powder-coated steel

Dimensions,

Height:

68.6

cm (27.0 in.)

Wldth:

68.6

cm (27.0 in.)

Depth:

71

.1

Net Weight:

Shipping Weight:

DESCRIPTION

The Electro-Voice

loaded speaker system for permanent installation. Because the mouth dimensions of both

the mid-bass and high-frequency horns were

correctly chosen and are large enough with

respect

MH660C

down to 500Hz.

increases speech intelligibility and musical clarity in difficult acoustic environments.

horn systems wlth smaller radlatlng areas

simply cannot provlde the hlgh degree of

directional control associated with the

MH660C.

cm (28.0 in.)

27.2 kg (60 lb)

33.6 kg (74 lb)

MH660C is a two-way horn-

to the wavelengths reproduced, the

provides unifon directivity control

This super directivity control

and

control to

intelligibility

under

horn

barrier strip;

with composite

Other

Page 2

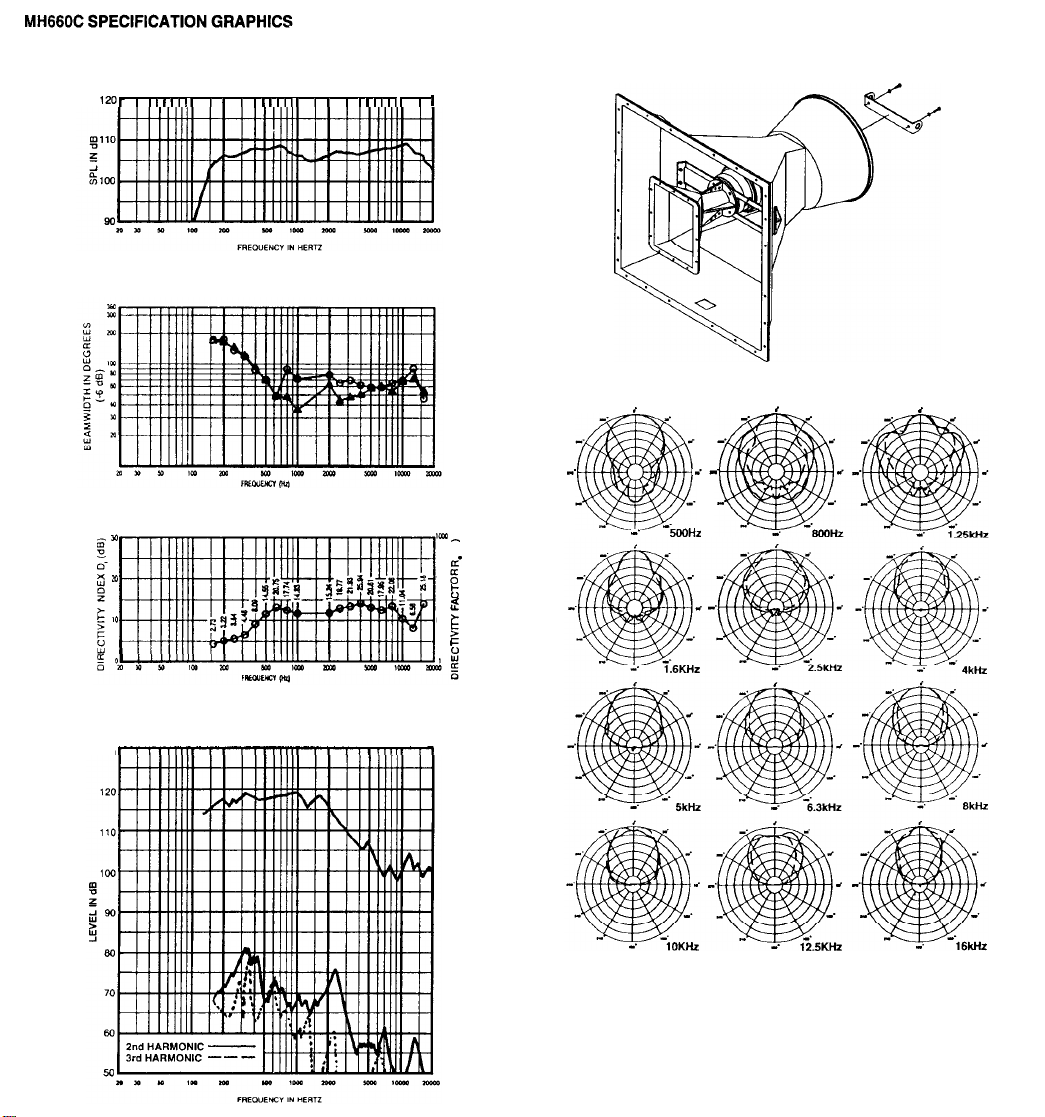

FIGURE

1

-

Typical Axial Frequency Response (anechoic

environment, 1 watt/1 meter into mid-bass section)

, , , , , , ,,,,,, , , , , ,,

FIGURE 2 - Beamwidth vs. Frequency

,,,, , , , , ,,,

FIGURE 6 -

Hanging Points

,

FIGURE 3

FIGURE 4 -

-

Directivity

*

1

Harmonic

bass horn using typical

130

Factor and Directivity Index vs. Frequency

Distortion (120 dB SPL at one meter from

music

spectrum)

‘W_

I(D g

I0 i

a

d

t,

0

mid-

FIGURE 6 - Polar Response

“.

,

_’

5OOHZ

HORIZONTAL

,

-

VERTICAL - -

,

-

Page 3

The

MH660C

is a 60 x 60 deg. two-way system

with mid-bass and high-frequency horns that

are coaxially mounted. The common acoustic

axes of these horns ensures smooth response

and coverage in the crossover region when the

appropriate signal delay is applied to the

high-

frequency driver.

Delivering smooth and extended performance,

the high-frequency section operates from 1,600

to 20,000 Hz and consists of a specially

developed, low-profile

driver coupled to an HP64 60 x 60

DH2As2

compression

constantdirectivity horn. The HP66 horn features integral fiberglass-and-zinc construction for exceptional strength and performance.

Beamwidthcontrol vanes in the horn throat correct all

coverage anomalies in the

10-

to

20-kHz

octave. This horn and driver combination is securely mounted to the mid-bass horn by a

heavy-duty steel bracket.

The mid-bass system is composed of a

DL1

0X-SH 24.5-cm (10-in.) reproducer

mounted on a MH660 60 x 60 deg. mid-bass

horn. The

Kevlar epoxy

DL10X-SH

reproducer contains a

cone, which is twice as strong as

the conventional paper cone. The mid-bass

section operates between 140 and 1,600 Hz,

and features a proprietary phase plug (U.S.

patent no.

4,718,517)

which extends the

highend output to blend seamlessly into the coaxial

high-frequency section.

If the MH660C is used in a full-range application, additional low-frequency reinforcement,

such as the PI1 15L or a TL-series enclosure

will be required.

APPLICATIONS

The

MH660C

has been designed specifically

with the permanent installation market in mind.

Sports arenas, performing arts centers, auditoriums and large gymnasiums are all candidates

for the

MH660C.

control, the

used in almost any situation. The

sound pedigree of the

With its superior directivity

MH660C

is a system that can be

MH660C

is evident by

concert-

the ease of installation and by the use of professional-grade components throughout the line.

SUSPENDING

MH660C ENCLOSURES

Suspending any object is potentially dangerous and should only be attempted by individuals who have a thorough knowledge of the

techniques and regulations of rigging objects

overhead.

that the

Electro-

Voice strongly recommends

MH66OC

be suspended taking into

account a// current national, federal, state and

local regulations. It is the responsibility of the

installer to ensure the

MH660C

is safely installed in accordance with all such regulations.

If

the

MH660C

is suspended,

Electro-Voice

strong/y recommends that the system be inspected af

least

once a year. If any sign of

weakness or damage is detected, remedial

action should be taken immediate/y.

A manual entitled installing the MH Series is

available from Electro-Voice. It is included with

every MH system and should be followed carefully. A general overview is included here to

help the system designer. This overview does

not replace

the installing the

MHSeries manual,

which includes additional information on suspending, configuring and equalizing the MH

series.

1.

Kevlar is a

registered

trademark of

Dupont.

The

MH660C

front brackets and the rear

can be suspended using the two

“U”

bracket (see

Figure 5). Therear "U” bracket must be screwed

to the rear cover with the bolts provided. Each

of the mounting brackets contains a %-in.-

diameter hole through which a shackle or chain

link could pass. The

MH660C can be oriented

in any direction. Electro-Voice strongly recommends that each

MH660C be suspended independently using at least three of the four suspension points provided.

If the

MH660C

is

suspended, it is recommended

that the unit be inspected at least once a year.

If any sign of weakness is detected, remedial

action should be taken immediately.

CAUTION: The

should be suspended overhead

cordance with the procedures and

MH660C

speaker systems

only In ac-

Iimitatfons specified in the installation manual

Included wlth the systems.

CONNECTIONS

Each frequency section can be individually

connected via #10 screw terminals. All drivers

are connected with the same polarity. A posi-

tive voltage applied to the positively marked

terminal produces a positive acoustic pressure

at the front of the system.

CROSSOVER, EQ AND SIGNAL DELAY

The

MH660C

is a two-way system which must

be biamped with a separate active crossover.

24-dB-per-octave crossover slopes are assumed for maximum performance and reliabil-

ity. For optimum performance, EQ and signal

delay are required. (Note: the delays noted

below are for fourth-order

(24-dB-per-octave)

Linkwitz-Riley crossover filter characteristics.)

The mid-bass section should be crossed over

to match the low-frequency section and at

1,600 Hz at the high end. No signal delay or

overall broadband EQ is required. The

frequency section requires a

1,600-Hz

high-

cross-

over and the typical constant-directivity-horn

high-frequency boost EQ. A

0.6-msec

signal

delay provides the smoothest response in the

crossover region. A low-frequency blocking

capacitor with a

3-dB-down

point of 800 Hz is

included.

An Electro-Voice XEQ-3 electronic crossover/

equalizer/time delay unit with EQW plug-in

module provides all of the necessary signal

processing. The

XEQ-3

is a three-way electronic crossover with adjustable crossover frequencies utilizing Linkwitz-Riley 24-dB-per-octave filters and signal delay equalization to

achieve zero lobbing error.

FREQUENCY RESPONSE

The

MH660C

measured in Electro-Voice’s large

axial frequency response was

anechoic

chamber at a distance of 3 meters (10 feet) with

a swept sine-wave input (see Figure 1). It has

been normalized for 1 watt/l meter into the

midbass section. Minimal level adjustment and

equalization have been used.

DIRECTIVITY

The directional characteristics of the MH660C

were measured in Electro-Voice’s large

anechoic

chamber, with a test signal of

onethird-octave filtered pink noise at the frequencies indicated. A full spherical measurement

system, which is fully compatible with ElectroVoice’s

AcoustaCADD

computer-aided design program, was used. All directional information was measured at 6.1 meters (20 feet).

Figure 6 illustrates the nominal horizontal and

vertical polar responses, with the long system

axis vertical. If the mid-bass/high-frequency

module is rotated, then the horizontal and vertical polars should be interchanged.

Figure 2 illustrates the horizontal and vertical

beamwidths. Beamwidth is

the

angle at which

the horizontal and vertical polar responses

have decreased in level by 6

dB

when com-

pared to the on-axis frequency response.

Figure 3 represents the total directivity of the

MH660C

The directivity factor R, (Q) is the

relative value, at a point, when compared to an

ideal spherical response. The directivity index

(D,) is calculated by D, =

10log,,,Re

SERVICE

In the unlikely event the

MH660C

requires

service, each driver can be replaced or repaired. A service data sheet is available from

Electro-Voice.

POWER-HANDLING TEST

Electro-Voice components and systems are

manufactured to exacting standards, ensuring

they will hold up, not only through the most

rigorous of powertests, but also through continued use in arduous, real-life conditions. Two

main test specifications are used: the AES

Recommended Practice for Specification of

Loudspeaker Components Used in Professional

Audio and Sound Reinforcement (AES2-1984/

ANSI

S4.26-1984)

Power Rating Full Range

and the EIA Loudspeaker

(ANSI/EIA

RS-426-A

1980). Both of these specifications use random-noise spectrums which mimic typical music and test the thermal and mechanical capabilities of the components. Electro-Voice will

support relevant additional standards as and

when they become available. Extreme, in-house

power tests,

which push

the performance boundaries of the components, are also performed

and passed to ensure years of trouble-free

service.

Specifically, the MH660C high-frequency section passes AES2-1984/ANSI S4.26-1984 with

the following values:

Z,,,

= 6.0 ohms at 7,000 Hz

P

= 60 watts

Test Voltage

Selected decade =

The

MH660C

= 19.0 volts rms,

38.0 volts peak

1,500-15,000

(+6 dB)

Hz

mid-bass section passes ANSI/

EIA RS-426-A 1980 with the following values:

R,, =

6.9 ohms (1.15 x RJ

P

= 300 watts

Test Voltage =

45.5 volts rms.

91 .0 volts peak

(+6 dB)

ARCHITECTS’ AND ENGINEERS’

SPECIFICATIONS

The loudspeaker system shall be a two-way,

active, horn-loaded type. The mid-bass

frequencies shall be reproduced by a single DL10X-

SH

25.4-cm

(10-in.) driver coupled to a

MH660

60 x 60 deg. constant-directivity horn. High

frequencies shall be reproduced by a

DH2As2 2-inch

compression driver coupled to

60-watt

an HP66 60x60 deg. constant-directivity horn.

The mid-bass and high-frequency devices shall

be coaxially mounted. The system will reproduce frequencies from 140 to 20,000 Hz and

have a nominal coverage pattern of

60 x 60 deg.

The directivity control shall be maintained down

to 500 Hz. The crossover frequency shall be

1,600 Hz. The module shall be capable of

producing average sound levels in excess of

Page 4

128 dB (1 watt/l meter) in the long term, with

short-term peaks of 134

made to provide four safe suspension points,

made from 10-gauge steel.

The dimensions shall be 68.6 cm (27.0 in.) tall,

68.6 cm (27.0 in.) wide, and 71.1 cm (28.0 in.)

deep. Weight shall be 33.6 kg (74 lb).

The loudspeaker system shall be the

Electro-Voice MH660C.

UNIFORM LIMITED WARRANTY

Electro-Voice products are guaranteed against

malfunction due to defects in materials or workmanship for a specified period, as noted in the

individual product-line statement(s) below, or in

the individual product data sheet or owner’s

manual, beginning with the date of original

purchase. If such malfunction occurs during the

specified period, the product will be repaired or

replaced (at our option) without charge. The

product will be returned to the customer prepaid. Exclusions and Llmltations: The Limited Warranty does not apply to: (a) exterior

finish or appearance; (b) certain specific items

described in the individual product-line

statement(s) below, or in the individual product

data sheet or owner’s manual; (c) malfunction

resulting from use or operation of the product

other than as specified in the product data

sheet or owners manual; (d) malfunction re-

dB.

Provision shall be

sulting from misuse or abuse of the product; or

(e) malfunction occurring at any time after repairs have been made to the product by anyone

other than Electro-Voice or any of its authorized

service representatives. Obtaining

Service:

tomer must deliver the product, prepaid, to

Electro-Voice or any of its authorized service

representatives togetherwith proof of purchase

of the product in the form of a bill of sale or

receipted invoice. A list of authorized service

representatives is available from Electro-Voice

at 600 Cecil Street, Buchanan, MI 49107 (616/

6956831 or

Consequential Damages Excluded:

repair or replacement and return to the customer are the only remedies provided to the

customer. Electro-Voice shall not be liable for

any incidental or consequential damages including, without limitation, injury to persons or

property or loss of use. Some states do not

allow the exclusion or limitation of incidental or

consequential damages so the above limitation

orexclusion may not apply to you. Other Rights:

This warranty gives you specific legal rights,

and you may also have other rights which vary

from state to state.

Electro-Voice Speakers and Speaker Systems are guaranteed against malfunction due

to defects in materials or workmanship for a

period of five (5) years from the date of original

To obtain warranty service, a cus-

800/234-6831). lncidental

Warranty

and

Product

purchase. The Limited

to burned voice coils or malfunctions such as

cone and/or coil damage resulting from improperly designed enclosures. Electro-Voice active

electronics associated with the speaker systems are guaranteed for three (3) years from

the date of original purchase. Additional details

are included in the Uniform Limited Warranty

statement.

Electro-Voice

closure-mounted hardware and

sories) is guaranteed against malfunction due

to defects in materials or workmanship for a

period of one (1) year from the date of original

purchase. Additional details are included in the

Uniform Limited Warranty statement.

Electro-Voice Accessories are guaranteed

against malfunction due to defects in materials

or workmanship for a period of one (1) year from

the date of original purchase. Additional details

are included in the Uniform Limited Warranty

statement.

Service and repair address for this product:

Electro-Voice, Inc.,

Michigan 49107

6831).

Specifications subject to change without no-

tice.

Warranty

Flying Hardware(including en-

600 Cecil

(616/695-6831

does not apply

rigging acces-

Street, Buchanan,

or

800/234-

Loading...

Loading...