Electro-Voice MB200 Datasheet

Mb200

And Mb200W

Installation Kit

• Mounting kit for SystemTM 200

speakers

• May be used in conjuction with

OmniMount

system

• Versatile design allows the

speaker to be aimed at any angle

from wall or ceiling

• Provides a rigid frame for flying

one or two speakers

• Creates arrays of two to six speakers when used with the M

Horizontal Array Kit

®

Series 100 support

1

300

b

in a rigid frame which has structurally sound

locations for attaching rigging hardware.

Description

The M

200 installation kit consists of a

b

U-bracket, two M8 x 1.25 hex-head bolts,

four lock washers, two friction pads, and two

3

/8-24 hex-head bolts (see Chart 1). The kit

is designed to accommodate the System

TM

200

installation in a variety of ways.

Wall or Ceiling Mounting:

The robust design of the M

bracket allows the System 200

200 installation

b

TM

speakers

to be mounted in almost any position to obtain the desired sound coverage (see Figure

3).

Flying Installations

The M

200 bracket “captures” the speaker

b

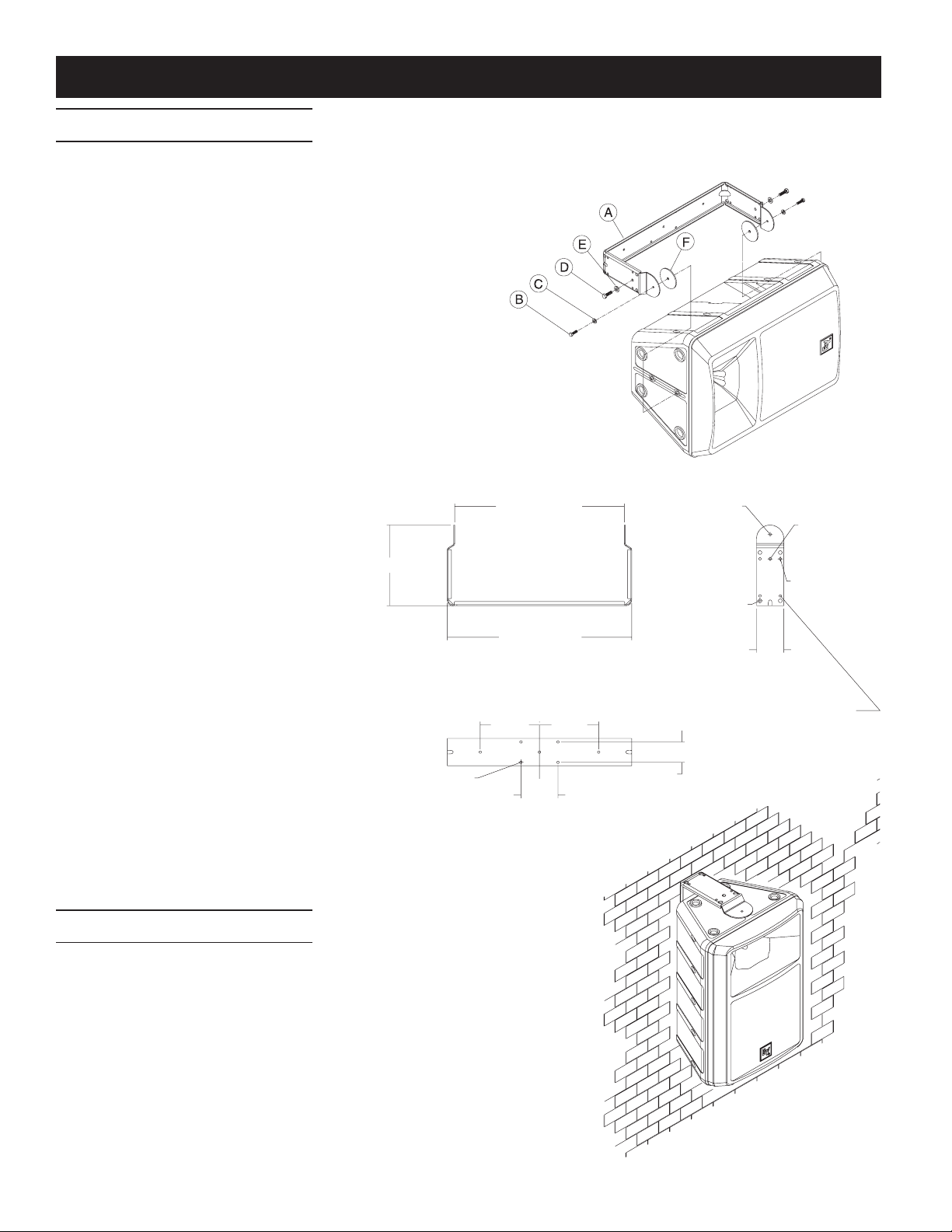

CHART 1: Mb200 Installation Kit Parts List

Item Description Quanity Part Number

A Bracket 1 71914

B M8 x 1.25 hex head bolt 2 63310

C 5/16 split ring lock washer 2 38144

D 3/8-24 hex head bolt 2 63311

E 3/8 split ring lock washer 2 38834

F Friction washer 2 38829

These attachment points are four 12.7-mm

1

(

/2-in.) diameter holes located on the ends

of the bracket. A

3

/8-in. “quick link” (or similar hardware) can be readily connected to

each attachment point.

System 200

TM

speakers can be flown individually in either a horizontal or vertical position, or two speakers can be flown together

in a vertical position (see Figures 4 and 5).

System 200

TM

Horizontal Arrays

Arrays of two to six speakers are securely

supported in a frame comprised of M

and M

300 brackets. T o create a horizontal

b

array, two M

200 brackets are simply locked

b

into the correct alignment position using the

brackets from the M

300 Horizontal Array

b

200

b

Kit (see Figure 6). The array is extended by

using one additional M

M

300 kit for each additional speaker. To

b

200 bracket and one

b

complete the circle for a six speaker array,

one additional M

300 kit is required. Please

b

refer to Chart 2 to select the exact number of

each kit needed, based on desired array size.

(Note: refer to M

300 Horizontal Array Kit

b

engineering data sheet for detailed instructions on System 200

struction using M

M

300 Horizontal Array Kits.)

b

CHART 2: Kit Requirements for

# of Enclosures # of Kits Req’d

in Array: Mb200 Mb300

System 200TM Horizontal

Array Construction

TM

horizontal array con-

200 Installation and

b

221

332

443

554

6 (complete circle) 6 6

Mb200/Mb200W Installation Kit

Wall Mounting Instructions

CAUTION: Due to the weight of System

TM

200

speakers, it is imperative that the

M

200 bracket be properly secured to the

b

wall or ceiling. The choice of fastener (not

provided with this kit) will be determined

by the material and construction of the

mounting surface.

1. Refer to Figure 1 for the following steps.

2. Remove the paper backing from one of

the friction pads (F) and, making sure the

holes are aligned, attach to the U-bracket (A)

as shown. Attach the second friction pad in

a similar manner.

3. Attach the U-bracket to the wall or ceil-

Mb200/Mb200W Installation Kit

ing using fasteners (not supplied) that are

suitable for the construction material.

4. Remove the hole plugs from the ends of

the System 200

TM

speaker by gently prying

with a small screwdriver.

5. Place one of the smaller lock washers

(C) on each of the two M8 bolts (B).

6. Place the speaker into the U-bracket and

finger tighten the M8 bolts.

7. Rotate the speaker so that the input

panel is accessible and attach the wires to

the input panel.

8. Position the speaker for the desired coverage and gently tighten the M8 bolts until

the speaker will no longer rotate. DO NOT

OVERTIGHTEN.

Note: The

3

/8-24 bolts (D) are used to

lock the speaker parallel to the bracket and

prevent it from being rotated. This is needed

when arraying the speaker for proper alignment and when flying in the vertical position.

Mb200 SPECIFICATION GRAPHICS

FIGURE 1 —Attaching Mb200 Bracket

to System 200TM Speaker (exploded view)

FIGURE 2 — Mb200 Installation Kit Dimensions

22.90 in.(582 mm)

10.87 in.(276 mm)

24.90 in.(632 mm)

8.0 in.

(203 mm)

0.33 in.(8 mm)

FIGURE 3 — Wall-Mounting a System 200

Using the Mb200 Installation Kit

8.0 in.

(203 mm)

5.0 in.(127 mm)

TM

Speaker

1

2.75 in.(70 mm)

0.33 in.(8 mm)

0.33 in.(8 mm)

0.5 in.(13 mm)

3.69 in.(94 mm)

HOLE PATTERN FOR OmniMount

LOCATED ON BOTH SIDES AND BACK

3/8–24

®

Flying Instructions

NOTE: A maximum of two speakers can

be suspended together vertically using the

M

200 installation bracket.

b

1. Refer to Figure 1 for the following steps.

2. Remove the paper backing from one of

the friction pads (F) and, making sure the

holes are aligned, attach to the U-bracket (A)

as shown. Attach the second friction pad in

a similar manner.

3. Remove the hole plugs from the ends of

2

1. OmniMount is a registered trademark of OmniMount

Systems, Inc.

Loading...

Loading...