Page 1

ID60D-8

ID60DT

General Product Description

The ID60D-8 and ID60DT are heavy-duty compression

drivers for use in high-power public address installations.

The drivers employ rugged phenolic diaphragms, 2-inch

diameter voice coils and “rim centered” ferrite magnet

structures for long life and reliability under extreme operating

conditions.

A hinged cycolac rear housing for easy access and

connection to a sound system, via a BX conduit connector,

is provided together with a plug-in, field replaceable

diaphragm assembly.

The transformer model (ID60DT) includes connections for

25-V and 70-V distributed systems and a screwdriver

operated power-tap select switch.

The exterior is finished in durable, weatherproof paint, and

all metal parts have been tropicalized for resistance to high

humidity and fungus.

Ideal for both indoor and outdoor applications, these drivers

are well suited for any installation requiring rugged,

high-power performance.

Architects’ and Engineers’ Specifications

The loudspeaker(s) shall be of the compression-driver type

utilizing a rugged phenolic diaphragm and a

high-temperature rated, 2-in. diameter voice coil.

The loudspeaker(s) shall exhibit essentially flat power

response from 300 to 4,000 Hz with a smoothly rolled-off

response beyond. Their sensitivity, when mounted on a PH

horn, will be 108 dB (1 W/1 m) with a 500- to 5,000-Hz

pink-noise signal applied.

Heavy-Duty

Compression Drivers

The loudspeaker(s) shall be capable of handling a 60-watt,

500- to 5,000-Hz pink-noise signal with a 6-dB crest factor

for a period of 8 hours.

The loudspeaker(s) shall have a diameter of 14.3 cm (5.6

in.) and a depth of 16.2 cm (6.4 in.) They shall have a 2.41

cm (0.95 in.) throat opening with a 1 3/8-18 thread for

mounting.

The loudspeaker shall be the ID60DT, which includes a 70-V/

25-V line-matching transformer and weighs no more than 3

4 kg (7.4 lb), and the ID60D-8, which has a nominal

impedance of 8 ohms and weighs no more than 2.7 kg (5.9

lb).

COMMERCIAL

Specifications:

Frequency Response:

............................................. 300 - 4,000 Hz ±5 dB (see Figure 2)

Power Handling, 8 Hours, 6-dB Crest Factor:

............................................... 60 watts (500-5,000 Hz pink noise)

Impedance, Nominal: ...................................................... 8 ohms

Minimum:7.5 ohms (Cobraflex Horns above 500 Hz)

Sound Pressure Level at 1 Meter, 1 Watt Input Averaged, Pink

Noise Band-Limited from 300-3,000 Hz:

..................................................................................... See Table I

Voice Coil Diameter: .......................................... 5.08 cm (2.0 in.)

Magnet Weight: ................................................... 0.48 kg (1.06 lb)

Magnet Material: ................................................ Strontium ferrite

Flux Density: ............................................................... 1.17 Tesla

Construction:

Rugged diecast housing with weatherproof finish for outdoor

use

Mechanical Construction of Driver:

1 3/8"-18 thread, 1/2 long allows the ID60 to be mounted on

any University Sound horn.

Dimensions:

Diameter: ..................................................... 14.3 cm (5.6 in.)

Height: .......................................................... 16.2 cm (6.4 in.)

Net Weight:

ID60D-8: .................................................. 2.7 kg (5.9 lb)

ID60DT: .................................................. 3.4 kg (7.4 lb)

Shipping Weight:

D60D-8:: .................................................. 2.9 kg (6.3 lb)

ID60DT: .................................................. 3.6 kg (7.9 lb)

Recommended Horns:

Cobreflex IIB, Cobreflex III, PH, 2WP, SMH, SH

Page 2

Installation

Remove the plastic cap from the threaded throat of the driver and screw

the driver into the horn until firmly seated.

Install the horn/driver assembly in intended location, referring to the

instructions provided with the horn.

Loosen the captive screw in the center of the plastic cover at the rear of the

driver, and open the hinged cover to expose wiring. Note the O-ring in the

annular housing groove.

Loosen the gland nut in the side of the driver housing enough to admit the

loudspeaker wire/cable. Alternately, a 1/2-inch conduit fitting can be

substituted for the gland nut. However, the sealing washer must be retained.

For the ID60DT, connect the loudspeaker wires to the “com” terminal and

the appropriate line terminal (25 V or 70 V). For the ID60D-8, connect to the

“com” and “8-ohm” terminals.

Tighten the gland nut securely and check that the O-ring is positioned

correctly before closing the clear plastic cover.

Low-Frequency Driver Protection

When frequencies below the low-frequency cutoff for the horn assembly

are fed to the driver, excessive current may be drawn by the driver. For

protection of driver, amplifier, and transformer (if driver with built-in

transformer is used), capacitor(s) in series with driver, or transformer primary

are recommended. Table I indicates recommended values. The values

shown are for 200 Hz. Values for other frequencies can be determined by

using the formula:

Values shown in the following table

C =

C

x 200

200

[

C

200

]

f f = New Frequency

For drivers without transformers: 8-ohm driver, 25 V - 100 mf 150 Vdc or

150 V non-polarized electrolytic, or two 150 Vdc electrolytics of two times

required value in series, back to back, for 70 volt lines.

nroHM1@W1rofLPS

BIIxelferboCBd701

IIIxelferboCBd701

Table I. Sound Pressure Level for ID60 with Various Horns

seniLtloV-07seniLtloV-52

rewoPecnadepmIecnaticapaCecnadepmIecnaticapaC

W06smho3801

fm

W03smho6615fmsmho1204

W51smho3332fmsmho2402

W5.7smho7661fmsmho3801

W57.3smho003,15.0

W88.1smho007,22.0

fm

fm

smho0108

fm

fm

fm

fm

smho6615

smho3332

fm

fm

Table II. Series Protection Capacitors for 200 Hz and Below

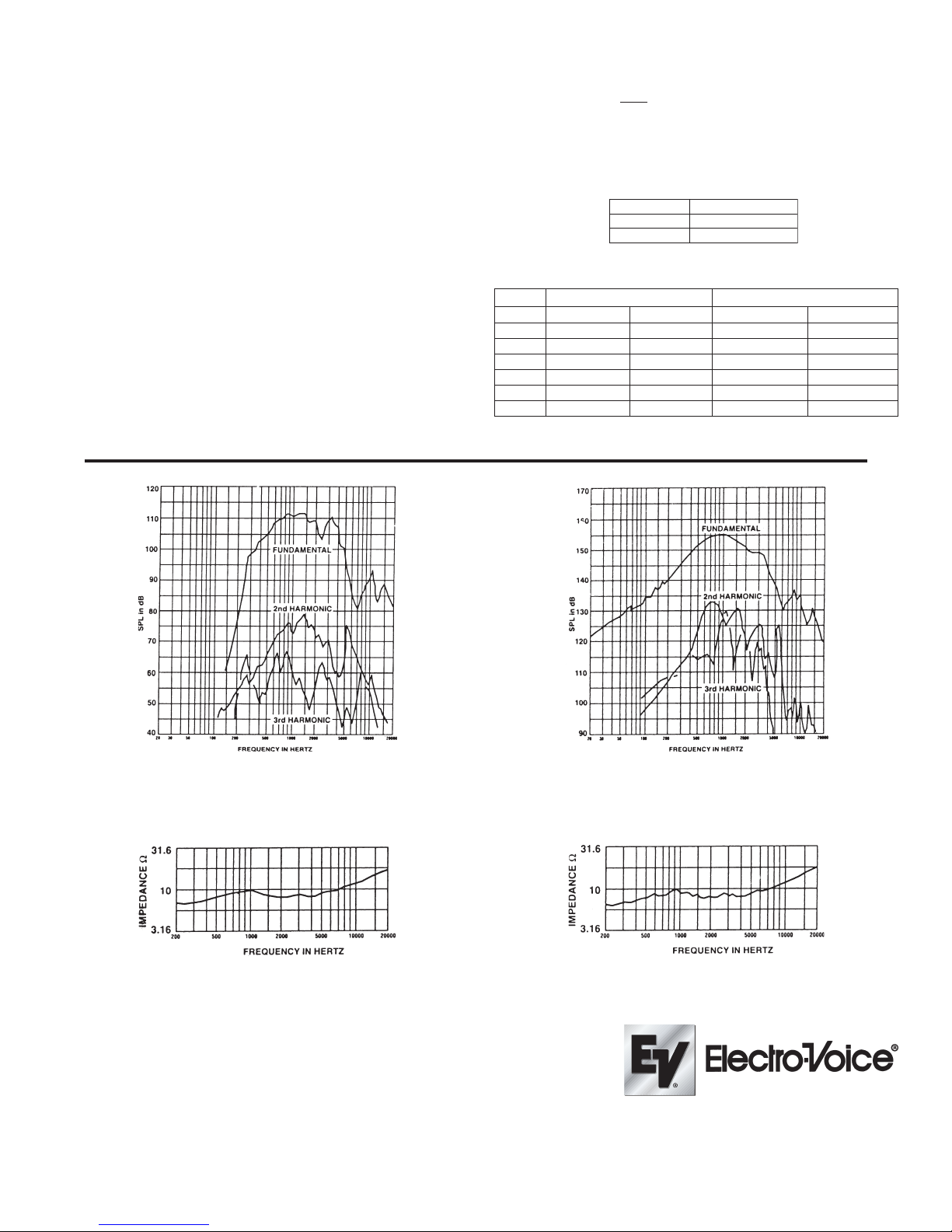

Disortion Response - Plane Wave Tube (1 inch)

Figure 1.

(6 watt input)

Figure 3.

Impedance Response - Plane Wave Tube (1 inch)

USA 12000 Portland Ave South, Burnsville, MN 55337, Phone: 952-884-4051, FAX: 952-884-0043

Canada 705 Progress Avenue, Unit 46,Scarborough, Ontario, Canada, M1H2X1,Phone: 416-431-4975, 800-881-1685, FAX: 416-431-4588

Switzerland Keltenstrasse 11, CH-2563 IPSACH, Switzerland, Phone: 41/32-331-6833. FAX: 41/32-331-1221

Germany Hirschberger Ring 45, D94315, Straubing, Germany, Phone: 49 9421-706 392, FAX: 49 9421-706 287

France Parc de Courcerin, Alle Lech Walesa, Lognes, 77185 Marne La Vallee, France, Phone: 33/1-6480-0090, FAX: 33/1-6480-4538

Australia Unit 23, Block C, Slough Business Park, Slough Avenue, Silverwater, N.S.W. 2128, Australia, Phone: 61/2-9648-3455, FAX: 61/2-96 48-5585

Hong Kong Unit E & F, 21/F, Luk Hop Industrial Bldg., 8 Luk Hop St., San PO Kong, Kowloon, Hong Kong, Phone: 852-2351-3628, FAX: 852-2351-3329

Japan 2-5-60 Izumi, Suginami-ku,Tokyo, Japan 168, Phone: 81-3-3325-7900, FAX:81-3-3325-7789

Singapore 3015A Ubi Rd 1, 05-10, Kampong Ubi Industrial Estate, Singapore 408705, Phone: 65-746-8760, FAX: 65-746-1206

Mexico Av. Parque Chapultepec #66-201, Col. EI. Parque Edo. Mex. 53390, Phone: (52) 5358-5434, FAX: (52) 5358-5588

UK 4, The Willows Centre, Willow Lane, Mitcham, Surrey CR4 4NX, UK, Phone: 44 181 640 9600, FAX: 44 181 646 7084

Africa, Mid-East 12000 Portland Ave South, Burnsville, MN 55337, Phone: 952-887-7424, FAX: 952-887-9212

Latin America 12000 Portland Ave South, Burnsville, MN 55337, Phone: 952-887-7491, FAX: 952-887-9212

www.electrovoice.com • Telex Communications, Inc. • www.telex.com

© Telex Communications, Inc. 02/2001

Part Number 38109-855 Rev A

Disortion Response - FC100 Horn

Figure 2.

Figure 4.

Impedance Response - FC100 Horn

For customer orders, contact the Customer Service department at

For warranty repair or service information, contact the Service

For technical assistance, contact Technical Support at 866/78 AUDIO

Please refer to the Engineering Data Sheet for warranty information.

800/392-3497 Fax: 800/955-6831

Repair department at 800/685-2606

Specifications subject to change without notice.

U.S.A. and Canada only.

Loading...

Loading...